CITROEN RELAY 2015 Handbook (in English)

Manufacturer: CITROEN, Model Year: 2015, Model line: RELAY, Model: CITROEN RELAY 2015Pages: 248, PDF Size: 8.86 MB

Page 141 of 248

139

QUICK HELP

8

Failed bulb or lamp

1 - Main beam headlamps

Type D , H7 - 55 W

- Remove the cover by pulling on the rubber tongue.

- Disconnect the electrical connector.

- Release the retaining spring by pressing on the central clip.

- Change the bulb taking care to align the metal part with the groove on the lamp. 2 - Dipped beam headlamps

Type D

, H7 - 55 W

- Remove the cover by pulling on the rubber tongue.

- Disconnect the electrical connector.

- Release the retaining spring by pressing on the central clip.

- Change the bulb taking care to align the metal part with the grooves on the lamp. Front lamps

Open the bonnet.

To access the bulbs, reach behind the

headlamp unit. If necessary you can remove

the headlamp:

- Disconnect the electrical connector by removing its locking ring.

- Remove the two headlamp fixing screws.

- Move the headlamp towards the centre of the vehicle to extract it from its

sliders.

On the left hand side, take care not to dislodge the bonnet stay. 3 - Direction indicators

Type A

, WY 21 W - 21 W

- Remove the cover by pulling on the rubber tongue.

- Turn the bulb holder a quarter turn anticlockwise.

- Change the bulb.

Page 142 of 248

140

Failed bulb or lamp

Halogen bulbs must be changed after

the headlamp has been off for several

minutes (risk of serious burns). Do not touch

the bulb directly with your fingers, use lint-

free cloths.

When each operation has been completed,

check the operation of the lamps.

5 - Foglamps

Type E , H1 - 55 W

- Turn the steering fully to the left.

- Remove the screw located in the wheel arch then open the flap.

- Remove the cover.

- Disconnect the electrical connector.

- Release the retaining spring by pressing on the two clips.

- Change the bulb taking care to align the metal part with the grooves on the lamp.

LED daytime running lamps

These light-emitting diode (LED) lamps

serve as both daytime running lamps and

sidelamps.

If your vehicle is fitted with LED daytime

running lamps, contact a CITROËN dealer. 4 - Sidelamps / daytime running lamps

Type A , W21/5W - 21W and 5W

- Remove the cover by pulling on the rubber tongue.

- Turn the bulb holder a quarter of a turn anti-clockwise.

- Change the bulb.

Page 143 of 248

141

QUICK HELP

8

Failed bulb or lamp

Courtesy lamps

Type C , 12 V 10 W - 10 W

- Press the points, indicated by the arrows, then remove the courtesy lamp.

- Open the protective flap.

- Change the bulb moving aside the two contacts.

- Ensure that the new bulbs are secured correctly between the two contacts.

- Close the protective flap.

- Fix the courtesy lamp in its housing and ensure that it is secured correctly.

Side marker lamps

Type A, W5W - 5W

- If your vehicle is fitted with these lamps (van type L4), remove the two fixing

screws.

- Pull the bulb holder to release it from the lugs.

- Pull the bulb out and change it.

Direction indicator side repeaters

Type A , W 16 W F - 16 W

- Move the mirror glass to access the screws.

- Remove the two fixing screws.

- Pull the bulb holder to release it from the dog points.

- Pull the bulb out and change it. Front / Rear

Page 144 of 248

142

Failed bulb or lamp

Rear lamps

For more information on the bulbs, refer to

the table "Types of bulb or lamp".

Carry out these operations in reverse order

to fit the new bulb.

1. Brake lamps

Type B, P21W - 21W

2. Brake/sidelamps

Type B, P 21/5W - 21W and 5W

3. Direction indicators

Type B, PY 21W - 21W

4. Reversing lamps

Type A, W16W - 16W

5. Foglamp

Type A, W16W - 16W - Identify the failed bulb then open the

rear doors.

- Remove the corresponding access cover by removing the seven fixing screws

(van)

or

Remove the corresponding access cover by pulling on its grip to unclip it (combi). - Disconnect the electrical connector by

pressing on its central tongue.

- Remove the two fixing nuts of the lens.

- Pull the lens from the outside.

- Remove the six bulb holder fixing screws.

- Spread the three retaining tongues and remove the bulb holder from its housing.

- Change the bulb.

Page 145 of 248

143

QUICK HELP

8

Failed bulb or lamp

Third brake lamp

Type B , P21W - 21W

- Unscrew the two screws.

- Remove the lamp.

- Remove the bulb holder moving aside the two tabs.

- Remove the faulty bulb by pressing it lightly while turning it anticlockwise.

- Change the bulb.

Number plate lamps

Type C, C5W - 5W

- Press the point, indicated by the arrow, then remove the plastic lens.

- Remove the failed bulb by moving aside the two contacts.

- With the new bulb in place, ensure that it is secured correctly between the two

contacts.

- Replace the plastic lens and press on it to lock it in place.

Page 146 of 248

144

Worn wiper blade

CHANGING A WIPER BLADE

The steps, located in the front bumper,

enable you to access the blades and the

screenwash nozzles. Changing a front wiper blade

Lift the wiper arm.

Unclip the blade by pressing the button and

remove it by pulling it outwards.

Fit the new blade and ensure that it is

secured correctly.

Push back the wiper arm.

Changing the rear wiper blade

Lift the wiper arm, then unclip the blade and

remove it.

Fit the new blade and push back the wiper arm.

To return the windscreen wipers to their

normal position, switch on the ignition

and operate the wiper control stalk. Check that the screenwash or headlamp

wash nozzles are not blocked.

Page 147 of 248

145

QUICK HELP

8

Puncture

Parking the vehicle

As far as possible, park the vehicle on level,

stable and non-slippery ground.

Apply the parking brake, switch off the

ignition and engage first gear.

Put on a high visibility vest and position the

warning triangle on the road.

Tools

These are located in a box under the front

passenger seat cushion.

- Turn the button a quarter of a turn then pull the box.

- After use, press the button then turn it a quarter of a turn to secure the box.

A. Long socket.

B. Ratchet wrench.

C. Jack.

D. Removable towing eye.

E. Wheelbrace.

F. Screwdriver.

CHANGING A WHEEL

You must ensure that the occupants get out

of the vehicle and wait in a safe location.

If possible, place a chock under the

wheel diagonally opposite the wheel to be

changed. The jack and the tool kit are specific to

your vehicle. Do not use them for other

purposes.

Never go underneath a vehicle supported

only by a jack (use an axle stand).

Page 148 of 248

146

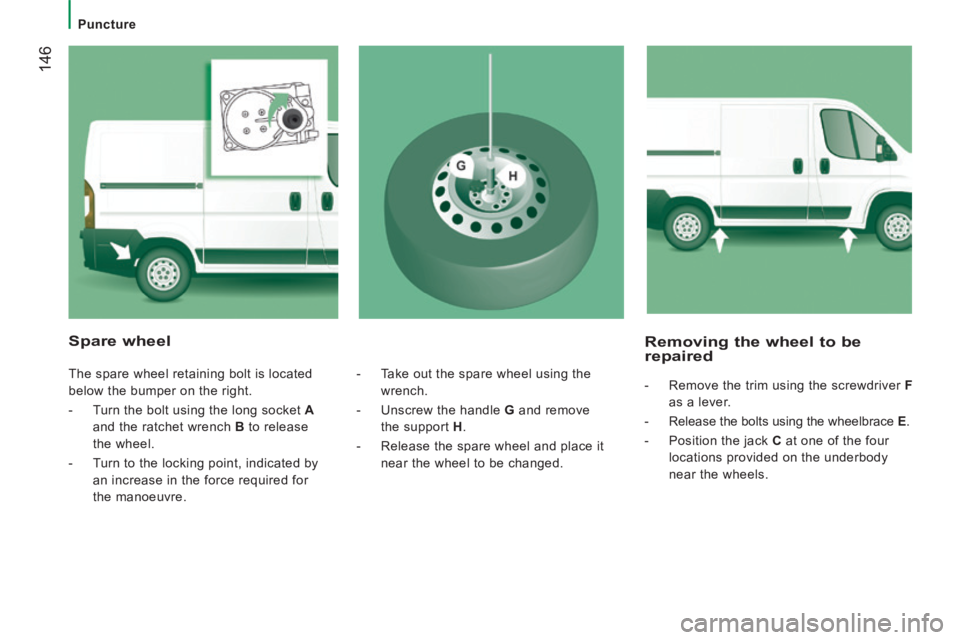

Puncture

Removing the wheel to be repaired

- Remove the trim using the screwdriver F

as a lever.

- Release the bolts using the wheelbrace E .

- Position the jack C at one of the four

locations provided on the underbody

near the wheels.

Spare wheel

The spare wheel retaining bolt is located

below the bumper on the right.

- Turn the bolt using the long socket A

and the ratchet wrench B to release

the wheel.

- Turn to the locking point, indicated by an increase in the force required for

the manoeuvre. - Take out the spare wheel using the

wrench.

- Unscrew the handle G and remove

the support H .

- Release the spare wheel and place it near the wheel to be changed.

Page 149 of 248

147

QUICK HELP

8

Puncture

Refitting the repaired wheel

Refitting the repaired wheel is the same as

fitting the spare wheel; don't forget to refit

the wheel trim. Refer to the "Technical data -

Identification markings" section for the

location of the tyre pressure label.

The spare wheel is not designed to be used

over long distances. Have the tightening of

the bolts and pressure of the spare wheel

checked by a CITROËN dealer or a qualified

workshop without delay.

Also, have the original wheel repaired and

refitted by a CITROËN dealer or a qualified

workshop as soon as possible.

Fitting the spare wheel

- Put the spare wheel in place on the hub and start screwing in the bolts by hand.

- Carry out an initial tightening of the bolts using the wheelbrace E .

- Lower the vehicle completely by folding the jack, then remove the jack.

- Tighten the bolts again using the wheelbrace E , tighten them fully without

forcing them.

- Stow the wheel to be repaired at the rear of the vehicle. - Hook the support H

and screw in the

handle G .

- Insert the long socket A in the hole then

wind the bolt fully, using the ratchet

wrench B , to raise the wheel.

- Stow the tools and the trim.

If you have a retractable foot board, the jack

must be positioned at 45°.

- Extend the jack using the ratchet wrench B until the wheel is a

few centimetres off the ground.

- Unscrew the bolts fully and remove the wheel to be repaired.

Page 150 of 248

148

Puncture

PUNCTURE REPAIR KIT Repairing the tyre

- Apply the parking brake. Unscrew the tyre valve cap, remove the filling hose B

and screw the ring E onto the valve, - start the engine,

- insert the connector G

into the nearest

power socket on the vehicle,

- switch on the compressor by placing the switch F in position I (on),

- inflate the tyre to a pressure of 4 bars.

To obtain a more accurate reading, you are

advised to check the pressure value on the

pressure gauge H , with the compressor off.

- check that the switch F on the

compressor is in position 0 (off),

This temporary puncture repair kit is located

at the front of the passenger compartment.

It consists of:

- a cartridge A

, containing the sealant

fluid, equipped with:

● a filling hose B ,

● a sticker C indicating "max. 80 km/h",

which the driver must affix in full view

(on the dashboard) after repairing

the tyre,

- a quick guide to use of the repair kit,

- a compressor D equipped with a

pressure gauge and unions,

- adaptors, for the inflation of various items.