check engine DATSUN 210 1979 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 250 of 548

Manual

Transmission

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Difficult

to

intermesh

gears

Causes

for

difficult

gear

shifting

are

classi

fie

t

o

ro

lb

c

QncerlJing

coJltr

1

syste

and

transmission

When

gear

shift

lever

is

heavy

and

it

is

difficult

to

shift

gears

clutch

disengagement

may

also

be

unsmooth

First

make

sure

that

clutch

operates

correctly

and

inspect

transmjssion

Gear

slips

out

of

mesh

In

most

cases

this

troubk

occurs

when

check

baD

and

or

spring

is

waIn

or

weaken

ed

or

when

control

system

is

faulty

In

this

case

the

troubk

cannot

be

correct

by

replacing

gears

and

therefore

trouble

shoot

ing

must

be

carried

out

carefuDy

It

should

also

be

noted

that

gear

slips

out

of

mesh

due

to

vibration

generated

by

weakened

front

and

rear

enigne

mounts

Noise

When

noise

occurs

with

engine

idling

and

ceases

when

clutch

is

disengaged

or

when

noise

occurs

while

shifting

gears

it

is

an

indication

that

the

noise

is

from

trans

mission

Transmission

may

rallk

during

engine

idling

Check

air

fuel

mixture

and

ignition

timing

After

above

procedure

readjust

engine

idling

Probable

cause

Worn

gears

shaft

and

or

bearing

Insufficient

operating

stroke

due

to

worn

or

loose

sliding

part

Worn

or

damaged

syncluonizer

Worn

check

baD

and

or

weakened

or

broken

spring

Worn

fork

rod

baU

groove

Worn

or

damaged

bearing

Worn

or

damaged

gear

Insufficient

or

improper

lubricant

Oil

leaking

due

to

damaged

oil

seal

or

sealant

clogged

breather

etc

Worn

bearing

High

humming

occurs

at

a

high

speed

Damaged

bearing

Cyclic

knocking

sound

occurs

also

at

a

low

speed

Worn

spline

Worn

bushing

MT34

Corrective

action

Replace

Repair

ClI

replace

Replace

Replace

Replace

Replace

Replace

Add

oil

or

replace

with

designated

oil

Clean

or

replace

Replace

Replace

Replace

Replace

as

a

rear

ex

tension

assembly

Page 264 of 548

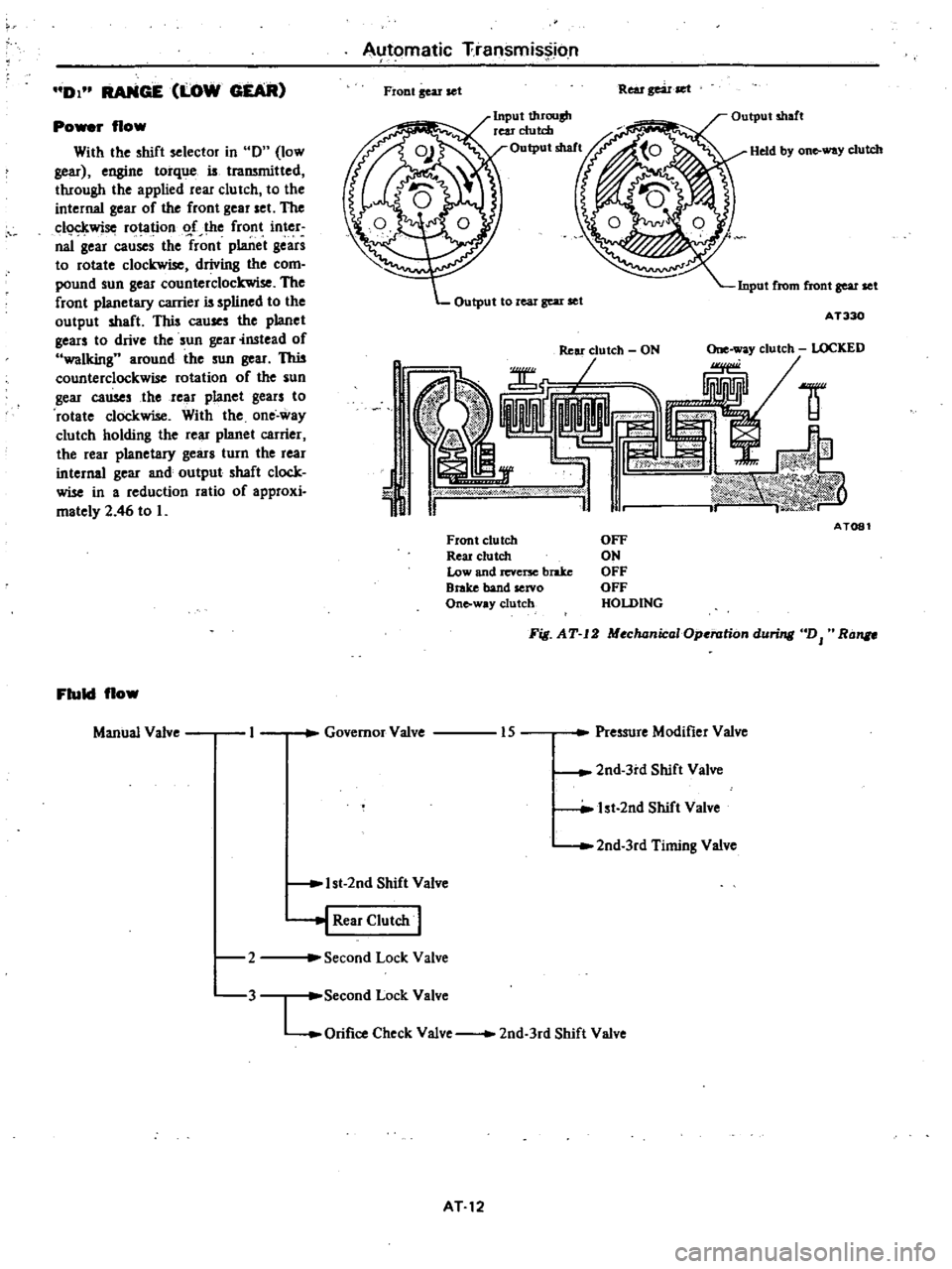

DI

RANGE

LOW

GEAR

Po

r

flow

With

the

shift

selector

in

0

low

gear

engine

torque

is

traJWnitted

through

the

applied

rear

clu

tch

to

the

internal

gear

of

the

front

gear

set

The

c1o

kwise

rotation

o

f

the

front

inter

naI

gear

causes

the

front

planet

gears

to

rotate

clockwise

driving

the

com

pound

sun

gear

counterclockwise

The

front

planetary

carrier

is

splined

to

the

output

shaft

This

cau

the

planet

gears

to

drive

the

sun

gear

instead

of

walking

around

the

sun

gear

This

counterclockwise

rotation

of

the

sun

gear

causes

the

rear

planet

gears

to

rotate

clockwise

With

the

one

way

clutch

holding

the

rear

planet

carrier

the

rear

planetary

gears

turn

the

rear

internal

gear

and

output

shaft

clock

wise

in

a

reduction

ratio

of

approxi

mately

2

46

to

L

Fluid

flow

Manual

Valve

2

3

Automatic

Transmission

Fiont

gear

set

Rear

gear

set

Input

t1uOllsh

rear

clutch

Output

shaft

Held

by

on

way

clutch

Input

from

front

gear

set

Output

to

real

gear

set

AT330

1

J

ld

AT081

Front

clutch

Reu

clutch

Low

and

revcrx

brake

Brake

band

servo

Onto

way

clutch

OFF

ON

OFF

OFF

HOLDING

Fig

AT

12

MochanicaIOp

rationduri

DJ

Ra

Governor

Valve

Pressure

Modifier

Valve

15

2nd

3rd

Shift

Valve

lst

2nd

Shift

Valve

2nd

3rd

Timing

Valve

1st

2nd

Shift

Valve

j

Rear

Clutch

I

Second

Lock

Valve

Second

Lock

Valve

LOrifice

Check

Valve

2nd

3rd

Shift

Valve

AT12

Page 266 of 548

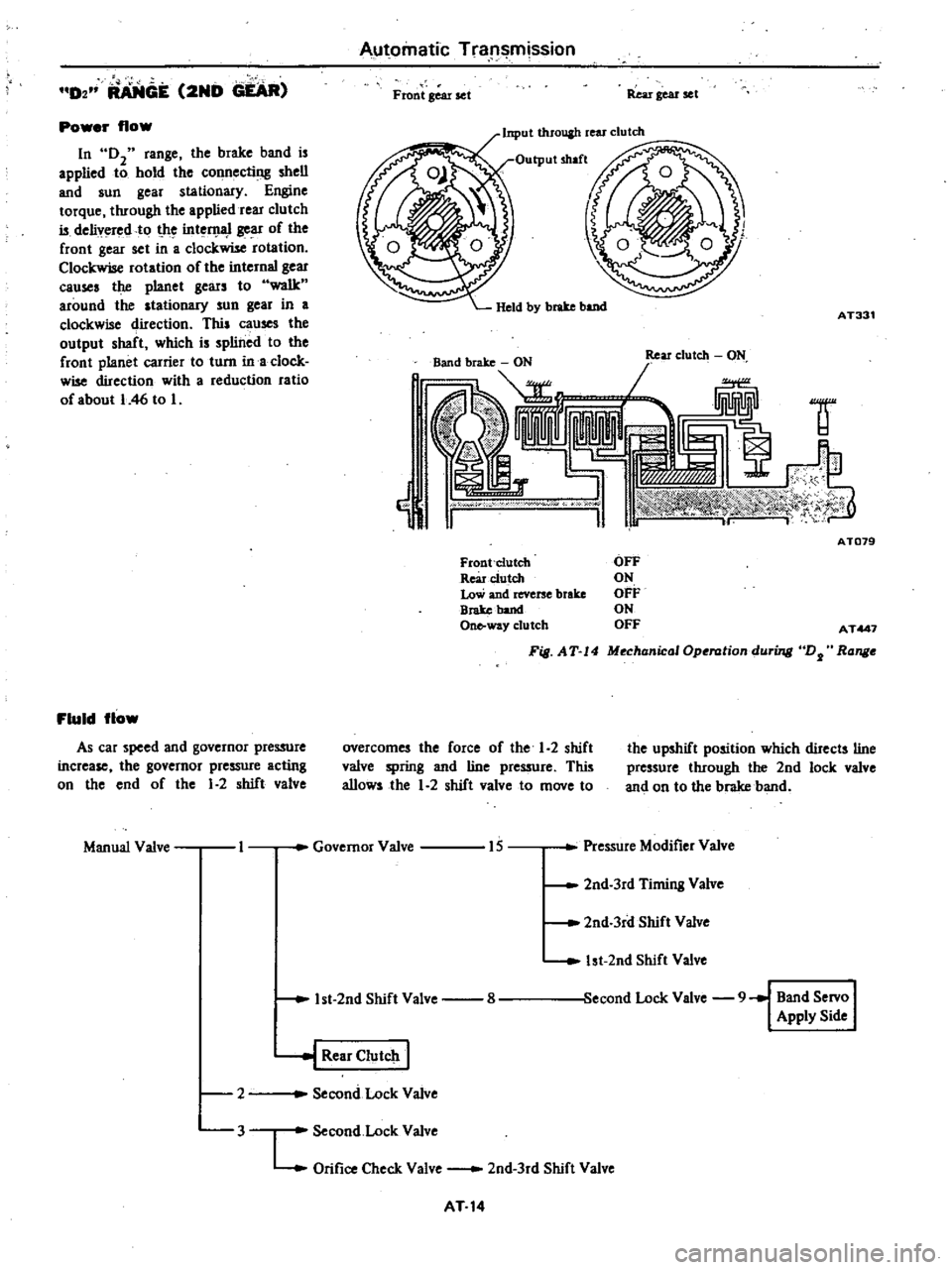

D2

RA

NGE

2ND

GEAR

Power

flow

In

02

range

the

brake

band

is

applied

to

hold

the

connecting

shell

and

sun

gear

stationary

Engine

torque

through

the

applied

rear

clutch

is

delivered

to

t

he

int

D

1l

1

gear

of

the

front

gear

set

in

a

clockwise

rotation

Clockwise

rotation

of

the

internal

gear

causes

the

planet

gears

to

walk

around

the

stationary

sun

gear

in

a

clockwise

direction

This

causes

the

output

shaft

which

is

splined

to

the

front

planet

carrier

to

turn

ina

clock

wise

direction

with

a

reduction

ratio

of

about

I

46

to

I

Fluid

flow

As

car

speed

and

governor

pressure

increase

the

governor

pressure

acting

on

the

end

of

the

1

2

shift

valve

Manual

Valve

I

Automatic

Tra

l

mission

Front

Bear

set

Rear

gear

set

Input

throuah

rear

clutch

AT331

1f

j

cW

oo

w

I

ATD79

Front

Clutch

Rearc1utch

Low

and

reverse

brake

Broke

band

One

way

clutch

OFF

ON

OFF

ON

OFF

AT447

F

S

AT

14

MechanicalOperation

during

DJ

Range

overcomes

the

force

of

the

1

2

shift

valve

spring

and

line

pressure

This

allows

the

1

2

shift

valve

to

move

to

the

upshift

position

which

directs

line

pressure

through

the

2nd

lock

valve

and

on

to

the

brake

band

Governor

Valve

15

Pressure

Modifier

Valve

2nd

3rd

Timing

Valve

2nd

3rd

Shift

Valve

1st

2nd

Shift

Valve

econd

Lock

Valve

9

Band

Servo

I

Apply

Side

1st

2nd

Shift

Valve

8

l

Rear

CIutclt

I

Second

Lock

Valve

2

3

Second

Lock

Valve

L

Orifice

Check

Valve

2nd

3rd

Shift

Valve

AT

14

Page 268 of 548

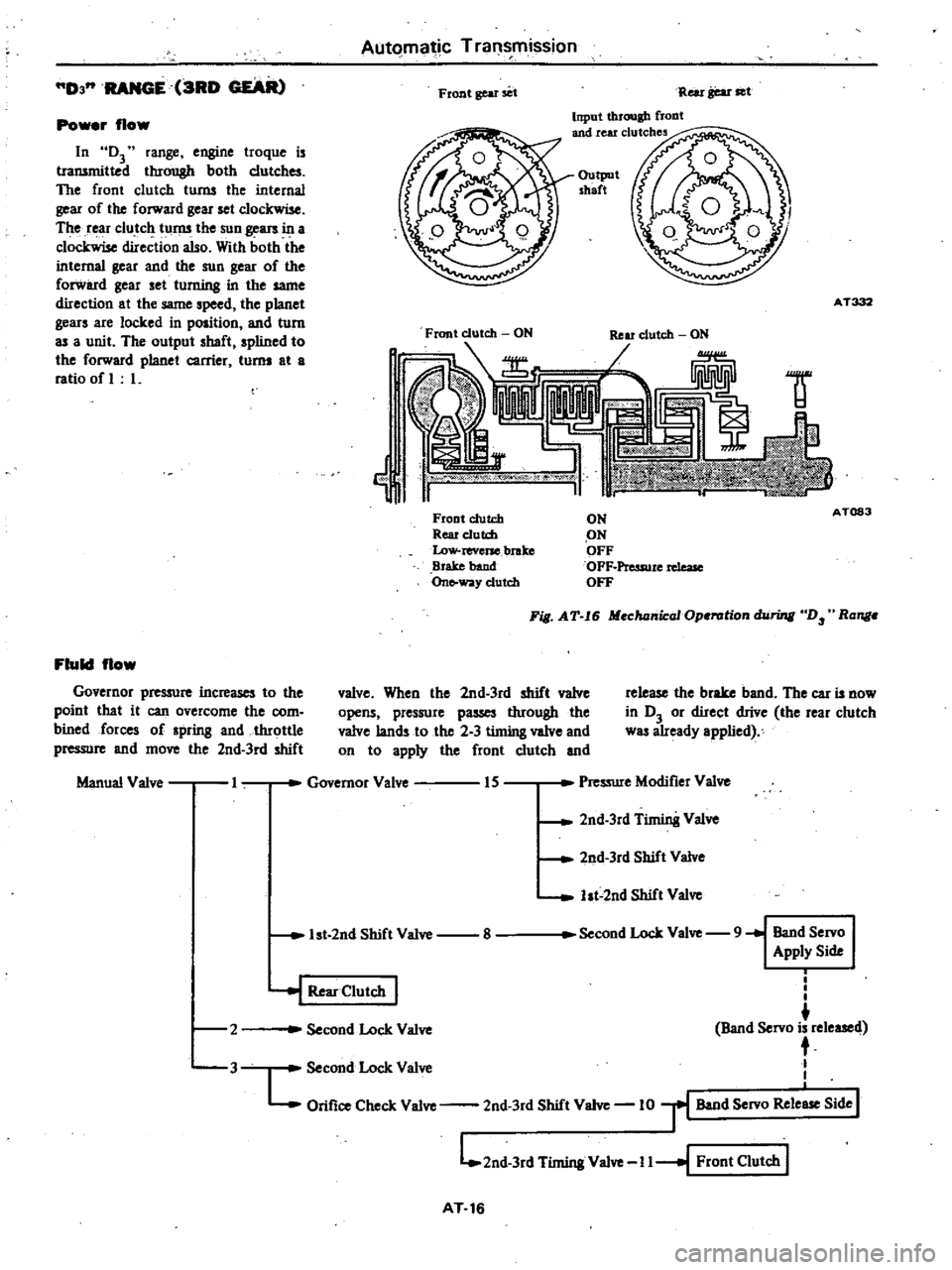

Automatic

Transmission

D3

RANGE

3RD

GEAR

Front

gear

set

Rei

r

gear

set

Input

through

flODt

and

rear

clutches

Power

flow

In

D3

range

engine

troque

is

transmitted

through

both

clutches

The

front

clutch

turns

the

internal

gear

of

the

forward

gear

set

clockwise

The

rear

clutch

turns

the

sun

gears

in

a

clockwise

direction

also

With

both

the

internal

gear

and

the

sun

gear

of

the

forward

gear

set

turning

in

the

same

direction

at

the

same

speed

the

planet

gears

are

locked

in

position

and

turn

as

a

unit

The

output

shaft

spIined

to

the

forward

planet

carrier

turns

at

a

ratio

of

L

Output

shaft

AT332

Front

clutch

ON

Ij

1f

Front

clutch

Rear

e1utd

Low

reverse

brake

Brake

band

On

way

clutch

ON

ON

OFF

OFF

Pressure

rdeaJe

OFF

A

T083

Fill

AT

I6

Mechanical

Operation

hiring

D

Ronge

Fluid

flow

Governor

pre

ure

increases

to

the

poinl

that

it

can

overcome

the

com

bined

forces

of

spring

and

throttle

pressure

and

move

the

2nd

3rd

shift

valve

When

the

2nd

3rd

shift

valve

opens

pressure

passes

through

the

valve

lands

to

the

2

3

timing

valve

and

on

to

apply

the

front

clutch

and

release

the

brake

band

The

car

is

now

in

D3

or

direct

drive

the

rear

clutch

was

already

applied

Manual

Valve

I

Governor

Valve

IS

Pressure

Modifier

Valve

2nd

3rd

Timin8

Valve

2nd

3rd

Shift

Valve

ht

2nd

Shift

Valve

1st

2nd

Shift

Valve

8

Second

Lock

Valve

9

Band

Servo

Apply

Side

2

i

I

I

Band

Servo

is

released

t

Second

Lock

Valve

L

Orifice

Check

Valve

2nd

3rd

Shift

Valve

10

r

Band

Servo

Rele

Side

I

L

2nd

3rd

Timing

Valve

I

I

I

Front

Clutch

I

J

Second

Lock

Valve

I

Rear

Clutch

I

3

AT

16

Page 278 of 548

4

Bolt

converter

to

drive

plate

Note

Align

chalk

mark

painted

a

cro5S

both

parts

during

disas

sembling

p

S

After

converter

is

installed

rotat

r

nkshait

veral

turns

and

check

to

be

sure

that

transmission

rotates

freely

without

binding

6

Pour

recommended

automatic

transmission

fluid

up

to

correct

level

through

oil

charge

pipe

7

Connect

manual

lever

to

shift

rod

Operation

should

be

carried

out

with

m

mual

and

selector

levers

in

N

8

Connect

inhibitor

switch

wires

Automatic

Transmission

NOte

a

Refer

to

page

AT40

for

Checking

and

Adjusting

Inhibitor

Switch

b

Inspect

end

edjust

switch

as

abo

whe

ever

it

has

to

be

removed

for

servi

e

9

Check

inhibitor

switch

for

op

eration

Starter

should

be

brought

into

op

eration

only

when

selector

lever

is

in

P

and

N

positions

it

should

not

be

started

when

lever

is

in

D

n

and

Ru

positions

Back

up

lamp

should

Iso

light

when

selector

lever

is

placed

in

R

position

10

Check

level

of

oil

in

transm

sion

For

detailed

procedure

see

page

AT39

AT

26

II

Move

selector

leve

through

all

positions

to

be

sure

that

transmission

operates

correctly

With

hand

brake

applied

rotate

engine

at

idling

Without

disturbing

the

above

seUlng

move

selector

lever

through

N

to

D

to

2

to

I

and

to

R

A

slight

shock

should

be

reU

by

handgripping

selector

each

time

transmission

is

shifted

Note

See

page

AT40

for

Checking

Engine

Idling

Revolution

12

Check

to

be

sure

that

line

pres

sure

is

correct

To

do

this

refer

to

page

AT

43

for

Line

Pressure

Test

13

Perform

stan

test

as

described

in

page

AT41

Page 279 of 548

Automatic

Transmission

MAJOR

REPAIR

OPERATION

SERVICE

NOTICE

FOR

DISASSEMBLY

AND

ASSEMBLY

I

It

is

advisable

that

repair

opera

tions

be

carried

out

in

a

dust

proof

room

2

Due

to

the

differences

of

the

engine

capacities

the

specifications

of

component

parts

for

each

model

s

transmission

may

be

different

They

do

however

have

common

adjust

ment

and

repair

procedures

as

well

as

cleaning

and

inspection

procedures

outlined

hereinafter

3

During

repair

operations

refer

to

Service

Data

and

Specific3ti

H1s

see

tion

for

the

correct

parts

for

each

model

4

Before

removing

any

of

subas

semblies

thoroughly

clean

the

outside

of

the

transmission

to

prevent

dirt

from

entering

the

mechanical

parts

5

Do

not

use

a

waste

rag

Use

a

nylon

or

paper

cloth

6

After

disassembling

wash

all

dis

assembled

parts

and

examine

them

to

see

if

there

3re

any

worn

damaged

or

defective

parts

and

how

they

are

affected

Refer

to

Service

Data

for

the

extent

of

damage

that

justifies

replacement

7

As

a

rule

packings

seals

and

similar

parts

once

disassembled

should

be

replaced

with

new

ones

TORQUE

CONVERTER

The

torque

converter

is

a

welded

construction

and

can

not

be

disas

sembled

INSPECTION

I

Check

torque

convert

for

any

sign

of

damage

bending

oil

leak

or

deformation

If

necessary

replace

2

Remove

rust

from

pilots

and

bosses

completely

If

torque

converter

oil

is

fouled

or

contaminated

due

to

burnt

clutch

flush

the

torque

converter

as

follows

I

Drain

oil

in

torque

converter

2

Pour

non

lead

gasoline

or

kero

sene

into

torque

converter

approxi

mately

0

5

liter

I

J

V

S

pt

U

Imp

pt

3

Blow

air

into

torque

converter

and

flush

and

drain

out

gasoline

4

Fill

torque

converter

with

torque

converter

oil

approximately

0

5

liter

I

J

V

S

pt

U

Imp

pt

5

Again

blow

air

into

torque

con

verter

and

drain

torque

converter

oil

TRANSMISSION

DISASSEM

LY

I

Drain

oil

from

the

end

of

rear

extension

Mount

transmission

on

Transmission

Case

Stand

ST07g70000

or

ST07860000

Remove

oil

pan

AT118

Fig

A

T

26

R

movin

g

Oil

Pan

2

Remove

bolts

securing

converter

housing

to

transmission

case

Remove

torque

converter

housing

3

Remove

speedometer

pinion

sleeve

bolt

Withdraw

pinion

4

Remove

downshift

solenoid

and

vacuum

diaphragm

Do

not

leave

dia

phragm

rod

at

this

stage

of

dis

assembly

Rod

is

assembled

in

top

of

vacuum

diaphragm

Fig

A

T

27

Dowmhift

Solenoid

and

Vacuum

Diaphragm

AT

27

5

Remove

bolts

which

hold

valve

body

to

transmission

case

Fig

AT

28

Removing

Valve

Body

6

Loosen

lock

nut

CV

on

piston

stem

CD

Then

tighten

piston

stem

in

order

to

prevent

front

clutch

drum

from

falling

when

oil

pump

is

withdrawn

AT121

Fig

AT

29

Loosening

Band

Se11

Jo

7

Pull

out

input

shaft

8

Withdraw

oil

pump

using

Sliding

Hammer

ST25850000

Do

not

allow

front

clutch

to

come

out

of

position

and

drop

onto

floor

AT122

Fig

AT

30

Removing

Oil

Pump

Page 291 of 548

Automatic

Transmission

TROUBLE

DIAGNOSIS

AND

ADJUSTMENT

Since

mo

automatic

transmission

troubles

can

be

repaired

by

simple

adjustment

do

not

disassemble

im

media

tely

Firstly

inspect

and

adjust

the

auto

D1

3tic

transmission

in

place

utilizing

the

Trouble

Shooting

Chart

If

the

trouble

can

not

be

solved

by

this

procedure

remove

and

disas

semble

the

automatic

tlllnsmission

It

is

advisable

to

check

overhaul

and

repair

each

part

in

the

order

listed

in

the

Trouble

Shooting

Chart

In

the

Trouble

Shooting

Chart

the

diagnosis

items

are

arranged

ac

cording

to

difficulty

from

easy

to

difficult

therefore

please

follow

these

items

The

tlllnsmission

should

riot

be

removed

unless

necessary

2

Tests

and

adjustments

should

be

inade

on

the

basil

of

standard

values

and

the

data

Should

be

recorded

INSPECTION

AND

ADJUSTMENT

BEFORE

TROUBLE

DIAGNOSIS

TESTING

INSTRUMENT

FOR

INSPECTION

I

Engine

t

chometer

2

Vacuum

gauge

3

Oil

pressure

gauge

It

is

convenieni

to

install

these

instruments

in

a

way

that

allows

meas

urements

to

be

made

from

the

driver

s

seat

CHECKING

OIL

LEVEL

In

checkIng

the

automatic

transmis

sion

the

oil

level

and

the

condition

of

oil

around

the

oil

level

gauge

should

be

examined

every

S

ooo

Ion

3

000

miles

This

is

an

easy

and

effective

trouble

shooting

procedure

since

some

changes

in

oil

condition

are

often

linked

with

developed

troubles

For

instance

Lack

of

oil

causes

defective

opera

tion

by

making

the

clutches

and

brakes

slip

resulting

in

severe

wear

This

is

because

the

oil

pump

sucks

air

causing

oil

foaming

thus

rapidly

deteriorating

the

oil

quality

and

pro

ducing

sludge

and

varnish

Excessive

oil

is

also

bad

because

of

oil

foaming

caused

by

the

gears

stirring

up

the

oil

During

high

speed

driving

excessive

oil

in

the

transmission

often

hlows

out

from

the

brealher

Me

urlns

011

level

To

check

the

nuid

leyel

sian

Ihe

engine

and

run

it

until

normal

operat

ing

temperatures

oil

temperature

SO

to

800C

122

to

1160F

Approxi

mately

ten

minute

of

operation

will

raise

the

temperature

to

this

range

and

engine

idling

conditions

are

stabi

lized

Then

apply

the

brakes

and

move

the

transmission

shift

lever

through

aU

drive

positions

and

place

it

in

park

P

position

In

his

inspec

tion

the

car

must

be

placc

d

on

a

level

surface

The

amount

of

the

oil

varies

with

the

temperature

As

a

rule

the

oil

level

must

be

measured

after

its

tempera

ture

becomes

sufficiently

high

I

Fill

the

oil

to

the

line

H

The

difference

of

capacities

between

both

H

and

L

is

approximately

0

4

liter

J

U

S

pt

Y

Imp

pt

and

therefore

do

not

fill

beyond

the

line

H

2

When

topping

up

and

changing

oil

care

should

be

taken

to

prevent

mixing

the

oil

with

dusl

and

water

In

pectlns

oU

condition

The

condition

of

oil

sticking

to

the

level

gauge

indicates

whether

to

OVOl

haul

and

repair

the

transmission

or

luok

for

Ihe

defective

part

If

the

oil

has

deteriorated

to

a

varnish

ike

quality

it

causes

the

con

trol

valve

to

stick

Blackened

oil

indi

cates

a

burned

clutch

brake

band

etc

AT

39

In

these

cases

the

transmission

must

be

repaired

CAUTION

I

In

checking

oil

IlVal

use

special

piper

Cloth

tohandla

the

18V81

llIugi

Ind

be

careful

not

to

let

the

scraps

of

paper

end

cloth

stick

to

the

IlIUp

b

U

lutomatic

transmission

fluid

having

OEXRON

ida

ons

only

in

the

3N71

B

eutomatic

trans

mission

c

Pay

IttBntion

blcau

the

oil

to

be

used

differs

from

that

used

in

the

Nissen

Full

Autometic

TllInsmis

sion

3N71A

N8V8r

mill

thl

oils

Note

Insert

the

gauge

fully

and

take

it

out

quickly

before

splesbing

oil

edheres

to

the

gauge

Then

observe

the

level

INSPECTION

AND

REPAIR

OF

OIL

LEAKAGE

When

oil

leakage

takes

place

the

portion

near

the

leakage

is

covered

with

oil

presenting

difficulty

in

detecting

the

spot

Therefore

the

places

where

oil

seals

and

gaskets

are

equipped

are

enumerated

below

Converter

housing

Rubber

ring

of

oil

pump

housing

Oil

seal

of

oil

pump

housing

Oil

seal

of

engine

crankshaft

Bolts

of

converter

housing

to

case

2

Transmission

and

rear

extension

Junction

of

transmission

and

rear

extension

Oil

cooler

tube

connectors

Oil

pan

Oil

pressure

inspection

holes

See

Fig

AT

81

Mounting

portion

of

vacuum

dia

phragm

and

downshift

solenoid

Breather

and

oil

charging

pipe

Speedometer

pinion

sleeve

Oil

seal

of

rear

extension

To

exactly

locate

Ihe

place

of

oil

leakage

proceed

as

follows

Page 292 of 548

Place

the

vehicle

in

a

pit

and

by

sampling

the

lealeed

oil

deiermine

if

it

is

the

torque

converter

oil

The

torque

converter

oil

has

a

color

like

red

wine

so

it

is

easily

distinguished

from

engine

oil

or

gear

oil

Wipe

off

the

lealeing

oil

and

dust

and

detect

the

spot

of

ill

lell8e

nonflammable

organic

solvent

such

as

carbon

tetrachloride

for

wiping

Raise

the

oil

tcmperature

by

op

erating

the

engine

and

shift

the

lever

to

D

to

increase

the

oil

pressure

The

sp

Q

of

o

1

1I8

u

J1en

be

found

more

easily

Note

As

oil

leakage

from

the

breath

er

does

not

talee

place

except

when

running

at

high

peed

it

iSimpos

sible

to

ate

this

lealcage

with

vehicle

stationary

CHECKING

ENGINE

IDLING

REVOLunON

The

engine

idling

revolution

should

be

properly

adjusted

If

the

engine

revolution

is

too

low

the

e

gine

does

not

operate

smoothly

and

if

too

high

a

strong

shocle

or

creep

develops

when

changing

over

from

ON

to

Dn

or

R

CHECKING

AND

ADJUSTING

KICK

WN

SWITCH

AND

DOWNSH

FT

SOLENOID

When

the

Ieickdown

operation

is

not

made

properly

or

the

speed

chang

ingpoint

is

too

high

check

the

kick

down

switch

downshift

solenoid

and

wiring

between

them

When

the

igni

tion

Ieey

is

po

iti

ned

at

the

1st

stage

and

the

accelerator

pedal

is

depressed

deeply

the

switch

contact

hould

be

closed

and

the

solenoid

should

clicle

If

it

does

not

click

it

indicates

a

defect

Then

check

each

part

with

the

testing

inatrumen15

Auto

lT1atic

Transmissiqn

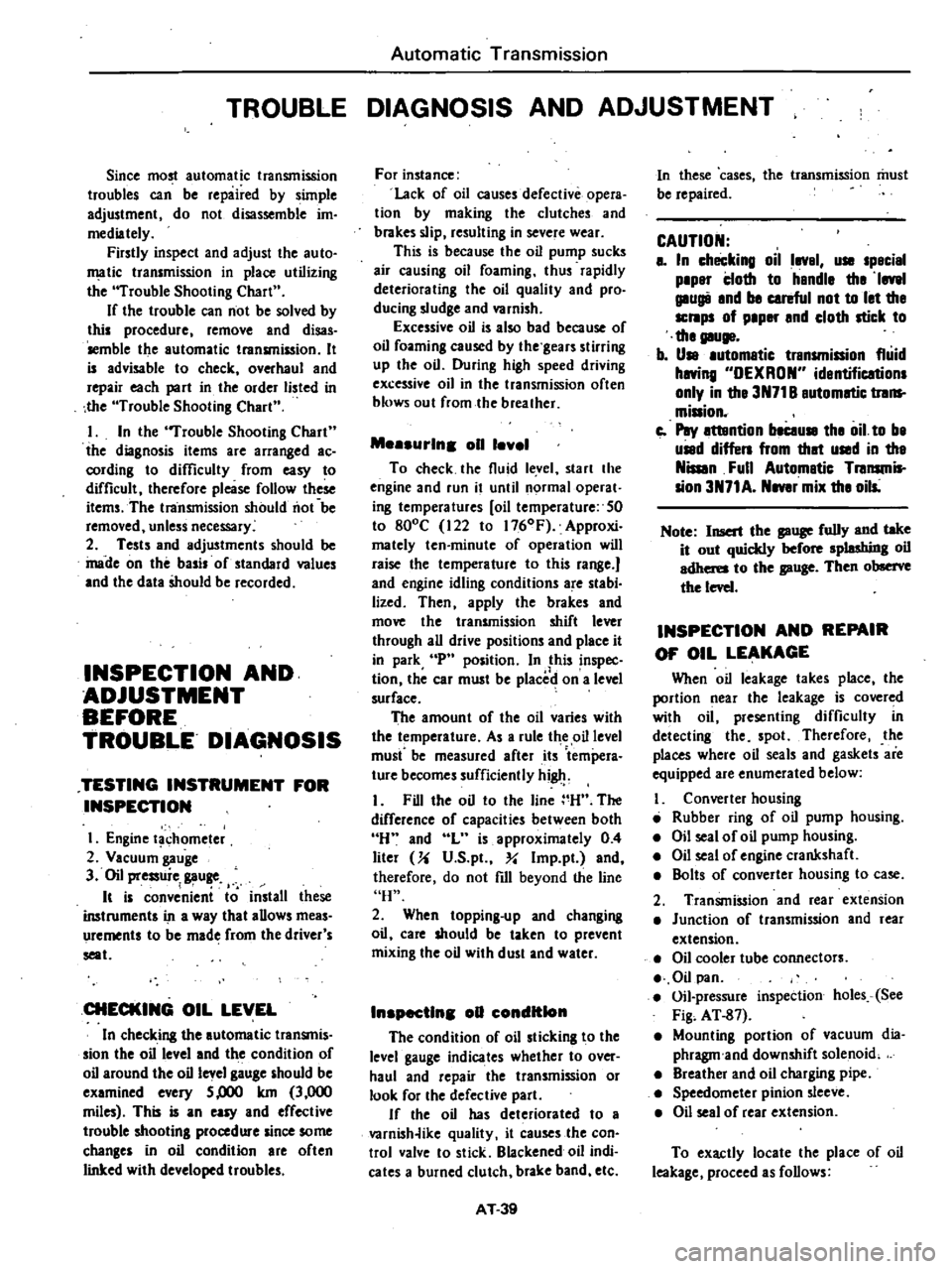

Fi

J

A

T

84

Down

ltift

Sole

id

Note

Watch

for

oil

leekage

from

tnnsmission

case

INSPECTION

AND

ADJUSTMENT

OF

MANUAL

LINKAGE

The

adjustmcnt

of

manual

linkage

i

equany

important

as

Inspection

of

Oil

Level

for

the

automatic

transmis

sion

Therefore

great

care

should

be

cxercised

oecause

incorrect

adjustment

will

result

in

the

breakdown

of

the

transmission

Inspection

pun

the

selector

lever

toward

you

and

turn

it

as

far

as

p

to

range

where

clicks

will

be

ell

by

the

hand

This

is

the

detent

of

manual

valve

in

the

valve

body

and

indicates

the

corrett

position

of

the

lever

Inspect

whether

the

pointer

of

selector

dial

corresponds

to

this

point

and

also

whether

the

lever

comes

in

alignment

with

the

stepping

of

posi

iion

plate

when

itis

released

CHECKING

AND

ADJUSTING

INHIBITOR

SWITCH

The

inhibitor

switch

lights

the

re

verse

lamp

in

the

range

R

of

the

transmission

operation

and

also

rotates

the

starter

motor

in

the

ranges

N

and

P

AT

40

i

j

tI

IlV

@

@

AT

I

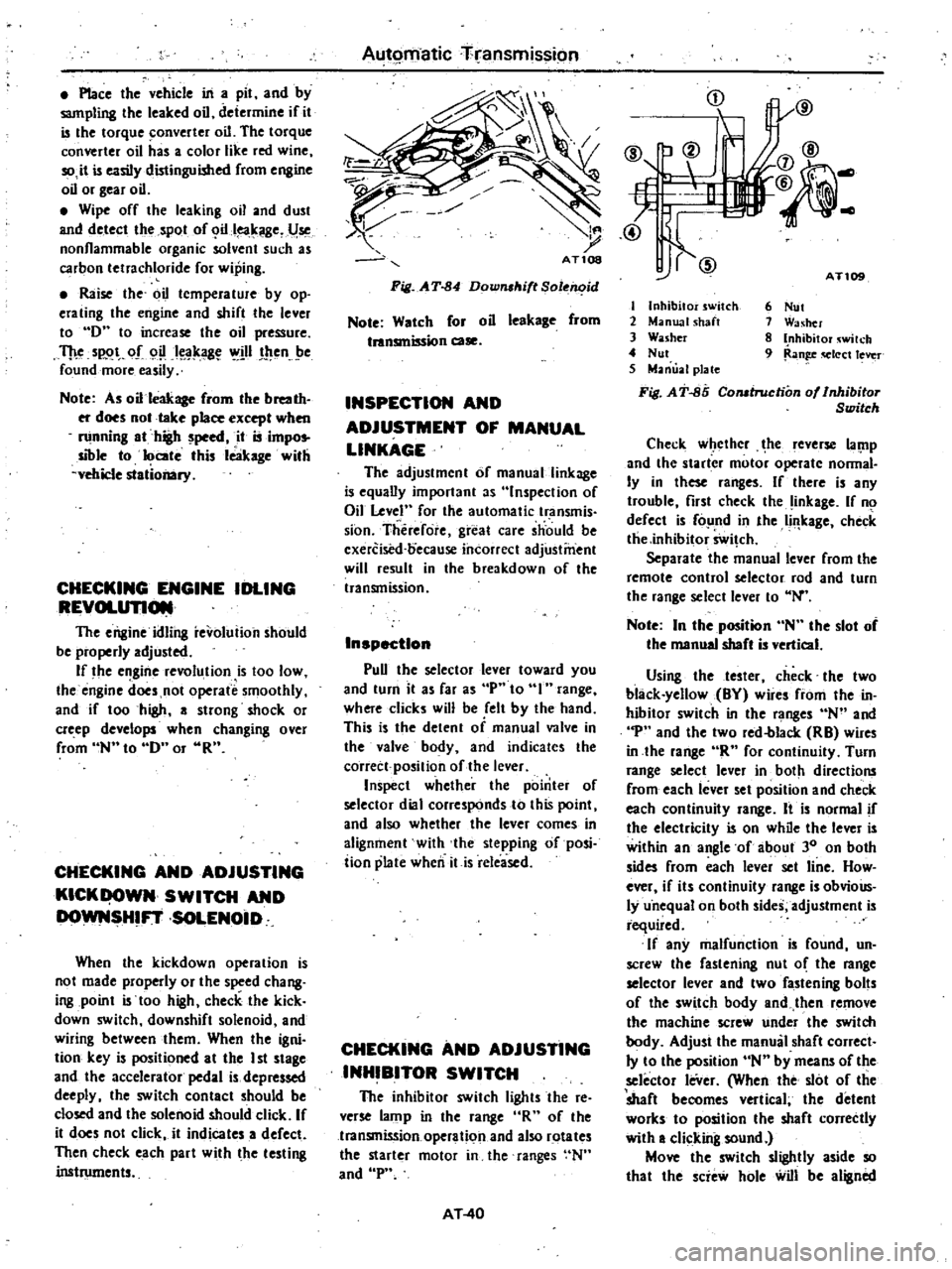

Inhibitor

switch

2

Manual

shaft

3

Washer

4

Nut

5

Manual

plate

Fi

J

AT

85

Comtruction

of

Inhibitor

Switch

6

Nut

1

Washer

8

Inhibitor

wilch

9

Ran

q

Iect

lever

Check

w

ethcr

he

leverse

lal

1p

and

the

starter

motor

operate

nonnal

Iy

in

these

ranges

If

there

is

any

trouble

first

check

the

inkage

If

no

defect

is

fo

nd

in

the

Ii

leage

check

tlie

inhibitor

Swi

ch

Separate

the

manual

lever

from

the

remote

control

selector

rod

and

turn

the

range

select

lever

to

N

Note

In

the

position

N

the

slot

of

the

manual

shaft

is

vertical

Using

the

tester

check

the

two

black

yellow

BY

wire

from

the

in

hibitor

switch

in

the

ranges

N

and

p

and

the

two

red

blacle

RB

wires

in

the

lange

R

for

continuity

Turn

range

select

lever

in

both

directions

from

each

lever

set

position

and

check

each

continuity

range

It

is

normal

if

the

electricity

is

on

while

the

lever

is

within

an

angle

of

about

30

on

both

sides

from

each

lever

set

line

How

ever

if

its

continuity

range

is

obvioUs

ly

u

nequal

on

both

sides

adjustment

is

required

If

any

malfunction

is

found

un

screw

the

fastening

nut

o

the

range

selector

lever

and

two

fastening

bolts

of

the

switch

body

and

then

remove

the

machine

screw

under

the

switch

body

Adjust

the

manual

shaft

correct

Iy

to

the

position

N

by

means

of

the

selector

leVer

When

the

slot

of

the

shaft

becomes

vertical

the

detent

worles

to

position

the

shaft

correctly

with

a

clicking

sound

Move

the

switch

slightly

aside

so

that

the

scie

hole

will

be

aligned

Page 293 of 548

with

the

pin

hole

of

the

internal

rotor

combined

with

the

manual

shaft

and

check

their

alignment

by

inserting

a

1

5

mm

0

059

in

diameter

pin

into

the

holes

If

the

alignment

is

correct

fasten

the

switch

body

with

the

bolts

pull

out

the

pin

tighten

up

the

screw

in

the

hole

and

fasten

the

selector

lever

as

before

Check

the

continuity

pin

with

the

lesler

If

Ihe

malfunc

tion

still

remains

replace

the

inhibitor

switch

STALL

TEST

The

purpose

of

this

test

is

to

check

the

transmission

and

engine

for

trou

ble

by

measuring

the

maximum

num

bers

of

revoiutions

o

the

cngine

while

vehicle

is

held

in

a

stalled

condition

The

carburetor

is

in

fullthrollle

opera

tion

with

the

selector

lever

in

ranges

1

2

and

I

respectively

Com

pale

the

measured

results

with

the

standard

values

Components

to

be

tested

and

test

itelJUl

I

Clutches

brake

and

band

in

trans

mission

for

slipping

2

Torque

converter

for

proper

func

tioning

3

Engine

for

overall

properly

STAU

TEST

PROCEDURES

Before

testing

check

the

engine

oil

and

torque

converter

oil

warm

up

the

engine

cooling

w

ter

to

suitable

tem

perature

by

running

at

1

200

rpm

with

the

selector

lever

in

the

range

P

for

sevcral

minutes

Warm

up

the

torque

converter

oil

to

suitable

temperature

60

to

lOOoC

140

to

2120F

I

Mount

the

engine

tachometer

at

a

location

that

allows

good

visibility

from

the

driver

s

seat

and

put

a

mark

on

specified

revolutions

on

the

meter

2

Secure

the

front

and

rear

wheels

with

chocks

and

apply

the

hand

brake

Be

SIIre

to

depress

the

brake

pedal

firmly

with

the

left

foot

before

de

pressing

the

accelerator

pedal

3

Throw

the

selector

lever

into

the

range

11

4

Slowly

depress

the

accelerator

pedal

until

the

throttle

valvc

is

fully

Automatic

Transmission

opened

Quickly

read

and

record

the

engine

revolution

when

the

engine

begins

to

rotate

steadily

and

then

release

the

accelerator

pedal

5

Shift

the

selector

lever

to

N

and

operate

the

engine

at

approxi

mately

1

200

rpm

for

more

than

one

minute

to

cool

down

the

torque

con

verter

oil

and

coolant

6

Make

similar

staU

tests

in

ranges

2

I

and

R

CAUTION

The

dill

test

operstion

81

specified

in

i18m

4

should

be

I118de

within

fiv

lIeonds

If

it

tBkes

too

long

the

oil

If

and

the

cluti

hn

blllke

and

b

nd

elll

ly

I

Suf

ficient

cooling

time

should

be

given

r

eech

test

for

the

four

IlInges

0

Z

1

end

R

JUDGEMENT

High

stall

revolution

more

than

staitdard

revolution

If

the

engine

levolulion

in

stall

condi

ion

is

higher

than

the

standard

values

it

indicates

that

onc

or

more

clutches

in

the

transmission

are

slipping

and

therefore

no

further

test

is

required

For

the

following

abnormalities

the

respective

causes

are

presumed

High

rpm

in

all

ranges

low

line

pr

ssure

High

rpm

in

0

2

and

I

and

normal

rpm

in

6R

Rear

clutch

slipping

High

rpm

in

D

and

2

and

normal

rpm

in

One

way

clutch

slipping

High

Ipm

in

R

only

Front

clutch

or

low

and

reverse

brake

slipping

To

determine

which

is

slipping

front

clutch

or

low

and

reverse

brake

a

road

test

is

needed

If

while

coasting

after

starting

with

the

levcr

in

I

range

engine

braking

does

not

work

properly

the

low

and

reverse

brake

is

slipping

Otherwise

the

front

clutch

is

slipping

Slipping

of

the

band

brake

is

diffi

cuJt

to

ascertain

However

jf

it

occurs

with

the

lever

in

1

range

engine

AT

41

revolution

increases

up

to

the

same

level

as

in

1st

range

It

is

impossible

to

check

it

in

the

stall

test

2

Standard

stall

rnoluiion

If

the

engine

revoluiion

in

stall

ondition

is

within

he

standard

values

the

control

elements

are

nOf

mally

operating

in

the

ranges

D

2n

I

and

R

Also

the

engine

and

one

way

clutch

of

the

torque

converter

are

norinal

in

performance

and

operation

The

one

way

clutch

of

the

torque

converter

however

sometimes

sticks

This

is

determined

in

the

road

test

3

Lower

stall

revolution

than

lIand

ard

revolution

If

the

engine

revolution

in

stall

condition

is

lower

than

the

standard

values

it

indicates

that

the

engine

is

in

abnormal

condition

or

the

torque

con

verter

s

one

way

clutch

is

slipping

4

O

hers

I

If

the

accelerating

performance

is

poor

until

vehicle

speed

of

approxi

mately

SO

kmfh

30

MPH

is

attained

and

then

normal

beyond

that

speed

it

can

be

judged

that

the

torque

con

verte

c

s

one

way

clutch

is

slipping

2

If

the

torque

converter

sane

way

dutch

sticks

vehicle

speed

can

not

exceed

approximately

80

kmfh

SO

MPH

in

the

road

tesl

In

such

a

case

the

torque

converter

oil

tem

perature

rises

abnormally

and

so

special

care

is

required

3

If

the

transmission

does

not

op

erate

properly

at

all

vehicle

speeds

it

indicates

poor

engine

performance

ROAD

TEST

An

accurate

knowledge

of

the

au

to

matic

transmission

is

required

for

an

exact

diagnosis

II

is

recommended

that

a

diagnosis

guide

chart

with

the

standard

vehicle

speeds

for

each

stage

of

the

up

and

down

shiftings

be

prepared

Measured

vehicle

speeds

are

to

be

filled

in

the

adjoining

column

after

each

testing

Also

it

is

advisable

to

mount

a

stopper

for

positioning

the

throttle

opening

Page 295 of 548

CHECKING

SPEED

CHANGING

CONDITION

The

driver

s

feeling

during

gear

changes

should

also

be

checked

atten

lively

J

A

sharp

shock

or

unsrnoothness

is

felt

duting

a

gear

change

Tlus

indicates

that

the

throttle

pres

sure

is

too

high

or

some

valve

con

nected

to

the

throttle

is

faulty

2

A

gear

change

is

made

with

a

long

and

dragging

feeling

This

indicates

that

the

throttle

pres

sure

is

too

low

or

some

valve

con

nected

to

the

throttle

is

faulty

Automatic

Transmission

CHECKING

ITEMS

DURING

SPEED

CHANGE

I

In

D

range

gear

changes

DJ

D

D3

are

effected

In

R

range

the

speed

does

not

increase

2

The

kickdown

operates

properly

3

By

moving

the

lever

from

D

to

I

gearchangesD3

2

1

1

are

effected

In

the

ranges

j

and

I

the

engine

braking

works

prop

erly

4

In

I

the

speed

does

not

in

crease

S

Should

be

quickly

fixed

at

2

SHI

SCHEDULE

Non

Cellfornla

models

Sedan

end

Hetchbeck

1

2

1

l

2

I

I

2

L

3

1

1

1

0

E

I

Kickdown

range

I

T

7

87f

1

500

2

000

2

500

Output

shaft

speed

rpm

km

h

9

1P

29

30

4

0

50

6

0

70

80

MPH

6

1

0

io

30

40

5

0

California

models

All

models

and

Non

Callfornie

models

Wegon

0

E

c

E

3

00

11

81f

5

400

u

a

15

75

0

u

If

z

5

0

0

19

69

0

500

I

c

I

100

3

94

E

I

1

000

I

Kickdown

range

1

2

1

2

1

2

2

3

2

0

0

7

87

E

c

E

300

11

81

5

400

15

75

a

500

0

19

0

0

i

z

km

h

9

MPH

6

3

1

1

1

1

11

12

1

1

1

range

6

In

P

vehicle

can

be

parked

properly

If

any

malfunction

occurs

in

second

gear

during

the

road

test

thai

is

if

vehicle

shakes

drags

or

slings

while

shifting

up

from

D

directly

to

D3

or

in

shifting

up

from

D

to

D

the

braKe

band

should

be

ad

justed

If

these

troubles

remain

after

the

brake

band

is

adjusted

check

the

servo

piston

seal

for

oil

leakage

2

32

3

3

0

00

4

000

3

50

0

9

0

60

100

AT434

2

321

3

500

1

000

1

500

2

600

2

50

0

3

600

3

500

4

000

Output

shaft

speed

rpm

10

20

30

40

50

6

0

70

80

90

100

1

0

io

3

0

4

0

50

60

AT435

Fig

A

T

86

Shift

Schedule

AT

43