torque DATSUN 210 1979 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 314 of 548

EX

2

A

0

B

3

C

I

D

2

E

O

I

F

0

08

H

I

Left

side

T

A

C

D

H

xO

OI

0

20

E

0

H

2

1

x

0

01

0

20

0

11

0

0

20

0

1

0

31

The

correct

shims

are

0

10

plus

lI

re

e

pi

ce

s

of

9

Q7

I

Il1I

thick

Right

side

T2

B

D

H

xO

OI

020

F

3

2

I

xO

01

0

20

0

08

0

02

0

20

0

08

0

30

The

correct

shims

are

0

10

plus

0

20

mm

thick

Note

If

w1ues

sigoifying

A

B

C

D

and

H

are

not

giVen

regard

them

as

zero

end

compote

After

essembly

clteek

to

see

that

preload

and

backlesb

ere

correct

If

not

readjust

Side

bearing

adjusting

shim

Thickness

mm

in

0

05

0

0020

0

07

0

0028

0

1

0

0

0039

0

20

0

0079

0

50

0

0197

2

Fit

determined

side

bearing

ad

justing

shim

on

differential

case

and

press

fit

left

and

right

side

bearing

inner

races

on

it

using

Side

Bearing

Drift

ST3322OO00

and

Adapter

ST33052000

3

Install

differential

case

assembly

into

gear

carrier

tapping

with

a

rubber

mallet

4

Align

mark

on

bearing

cap

with

that

on

gear

carrier

and

install

bearing

cap

on

carrier

And

tighten

bolts

to

specified

torque

Propeller

Shaft

Differential

Carrier

@Tightenirig

tOrque

Side

bealingcap

bolts

5

0

to

6

0

kg

m

36

to

43

ft

b

5

M

easure

L

dimension

between

left

and

right

bearing

cap

edges

with

a

micrometer

e

cljmension

153

40

to

153

45

mm

6

0394

to

6

0413

inl

PD271

Fig

PD

20

Measuring

L

Dimension

6

Measure

ring

gear

to

drive

pinion

backlash

If

backlash

is

too

smaU

decrease

thickness

of

left

shim

and

increase

thickness

of

right

shim

by

the

same

amount

If

backlash

is

too

great

reverse

the

above

procedure

Ring

gear

to

drive

pinion

backlash

0

10

to

0

15

mm

0

0039

to

0

0059

in

PD272

Fig

PD

21

Mea

uring

Backlash

7

At

the

same

time

check

side

bearing

preload

Bearing

preload

should

be

specified

torque

If

preload

does

not

accord

with

tJiis

specification

adjust

it

with

side

bear

ing

shims

PD

B

Side

bealing

preload

8

to

10

kg

cm

6

9

to

8

7

in

bl

At

ring

geer

bolt

1

5

to

1

9

kg

3

3

to

4

2

Ibl

8

Check

and

adjust

the

tooth

con

t

c

pattern

of

ring

gear

and

drive

pinion

I

Thoroughly

clean

ring

and

drive

pinion

gear

teeth

2

Paint

ring

gear

teeth

lightly

and

evenly

with

a

mixture

of

recommend

ed

powder

and

oil

of

a

suitable

consist

ency

to

produce

a

contactpaUern

3

Rotate

pinion

through

several

revolutions

in

the

forward

and

reverse

direction

until

a

definite

contact

pat

tern

i

developed

on

ring

gear

4

When

contact

pattern

is

in

correct

readjust

thickness

oLadjust

ing

shim

Be

sure

to

wipe

off

powder

com

pletely

upon

completion

of

adjust

ment

5

Incorrect

contact

pattern

of

teeth

can

be

adjusted

in

the

foUowing

manner

Contact

pettern

a

Heel

contact

To

correct

increase

thickness

of

drive

pinion

adjusting

washer

in

order

to

bring

drive

pinion

close

to

ring

gear

P0193

Fig

PD

22

Heel

Contact

b

Toe

contact

To

correct

reduce

thickness

of

drive

pinion

adjusting

washer

in

order

to

make

drive

pinion

go

away

from

ring

gear

t

PD194

Fig

PD

23

Toe

Contact

Page 315 of 548

c

Flank

contact

Adjust

in

the

same

manner

as

in

b

t

P019S

Fig

PD

24

Flank

Contact

d

Face

contact

Adjust

in

the

same

manner

as

in

3

cf

P0196

Fig

PD

25

Face

Contact

e

Correct

tooth

contact

P0197

Fig

PD

26

Correct

Contact

Note

Change

in

thickness

of

adjust

ing

WlI8her

is

accompanied

by

change

in

backlash

Check

it

when

insteIIing

gear

Propeller

Shaft

Differential

Carrier

INSTALLATION

Installation

can

be

done

in

the

re

verse

order

of

removal

ifl

Tightening

torque

Gear

carrier

to

rear

axle

case

fixing

bolt

1

7

to

2

4

kg

m

12

to

17

ft

lbl

Drain

and

filler

plug

6

to

10

kg

m

43

to

72

ft

lbl

Gear

oil

quantity

0

9

liter

1

U

US

pt

1

Imp

pt

Note

a

Discard

gear

carrier

gasket

after

remom

Do

not

apply

sealant

to

the

gasket

b

Apply

sealant

to

bolts

securing

gear

carrier

case

to

rear

axle

housing

REPLACEMENT

OF

FRONT

OIL

SEAL

When

replacing

front

oil

seal

do

as

follows

1

Remove

differential

carrier

assem

bly

and

mount

it

on

Differential

Car

rier

Attachment

ST06320000

This

work

can

be

done

by

referring

to

Removal

procedure

2

Remove

side

bearing

caps

and

take

out

differential

case

assembly

Remove

drive

pinion

nut

and

extract

drive

pinion

assembly

Remove

oil

seal

These

works

can

be

done

by

re

ferring

to

Disassembly

procedure

PD

9

3

Install

a

new

oil

seal

in

gear

car

rier

using

Oil

Seal

Fitting

Tool

ST3340000l

Lubricate

cavity

between

seal

lips

with

recommended

multi

purpose

grease

when

installing

4

Place

a

new

collapsible

spacer

on

drive

pinion

and

lubricate

pinion

rear

bearing

with

gear

oil

5

Insert

companion

flange

into

oil

seal

Insert

drive

pinion

into

com

panion

flange

from

rear

of

gear

carrier

and

secure

them

in

position

by

tightening

nut

to

given

torque

con

firming

specified

preload

These

works

can

be

done

by

re

ferring

to

Adjustment

of

Drive

Pinion

Preload

procedure

6

Install

differential

case

assembly

into

gear

carrier

Measure

L

dimen

sion

backlash

with

specification

adjust

them

with

side

bearing

shims

The

works

can

be

done

by

re

ferring

to

Adjustment

of

Side

Bearing

Shims

procedure

7

Reinstall

differential

gear

carrier

assembly

rear

axle

shafts

and

pro

peller

shaft

Fill

up

differential

carrier

with

correct

gear

oil

CAUTION

a

Replacement

of

front

oil

seal

with

differential

carrier

assembly

install

ed

on

car

must

not

be

ellowed

due

to

used

collapsible

spacer

on

iu

model

b

Whenever

front

oil

seal

is

replaced

collepsible

spacer

must

be

replaced

Page 316 of 548

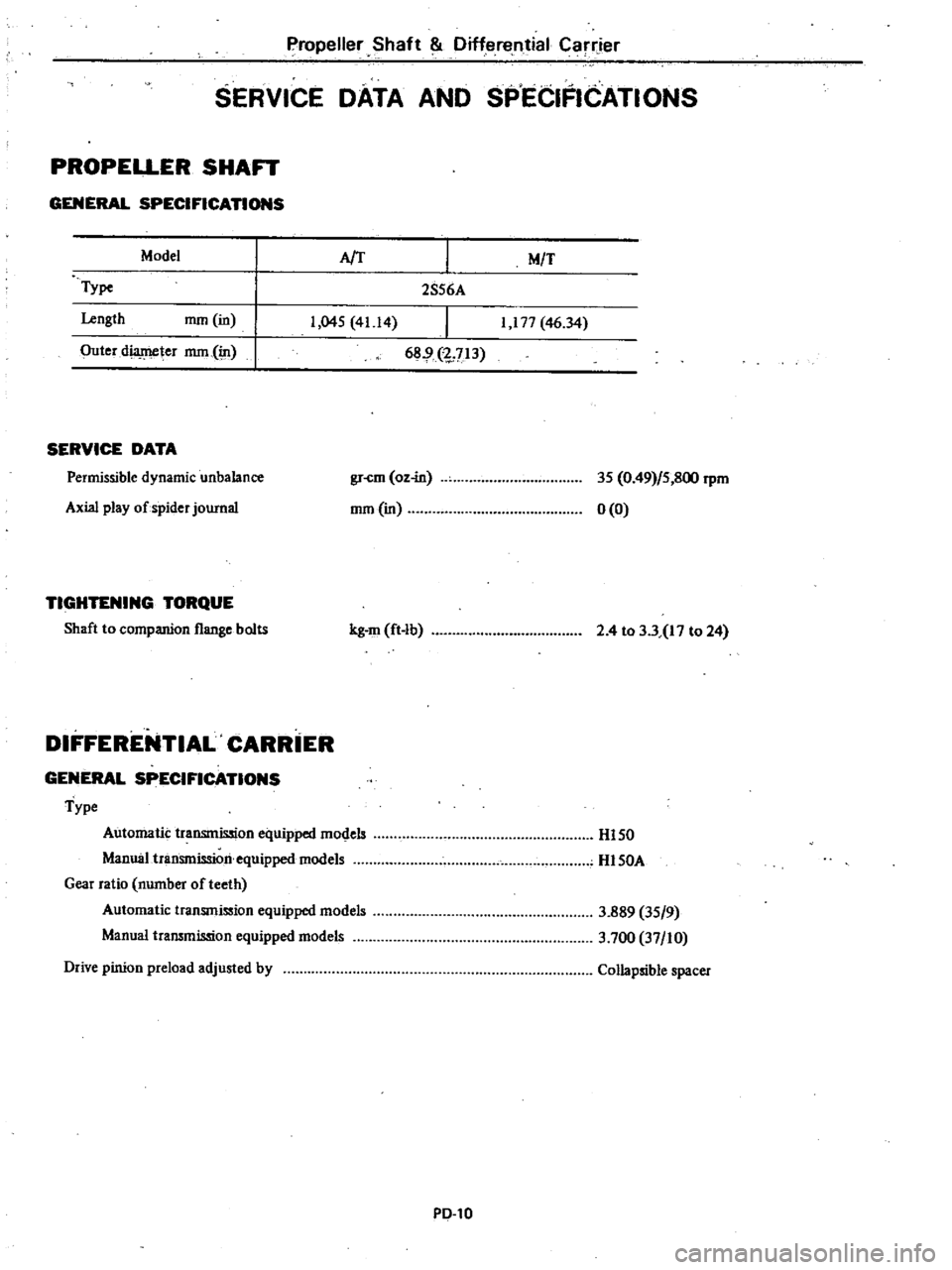

Propeller

Shaft

Diffe

ntial

Carrier

SERVICE

DATA

AND

SPECIFICATIONS

PROPEL1

ER

SHAFT

GENERAL

SPECIRCATIONS

Model

A

T

M

T

Type

Length

rnrn

in

2856A

1

045

4Ll4

1

177

46

34

68

1

713

Outer

dil

lluJ

er

rnrn

jn

SERVICE

DATA

Permissible

dynamic

unbalance

gr

cm

oz

in

rnrn

in

Axial

play

of

spider

journal

TIGHTENING

TORQUE

Shaft

to

companion

flange

bollS

kg

fil

ft

lb

DIFFERENTIAL

CARRiER

GENERAL

SPECIFICATIONS

Type

Automatic

transmission

equipped

models

Manual

transmission

equipped

models

Gear

ratio

number

of

teeth

Automatic

transmission

equipped

models

Manual

transmission

equipped

models

Drive

pinion

preload

adjusted

by

PO

tO

35

0

49

5

800

rpm

0

0

2

4

to

3

3l17

to

24

HI50

HI50A

3

889

35

9

3

700

37

10

Collapsible

spacer

Page 317 of 548

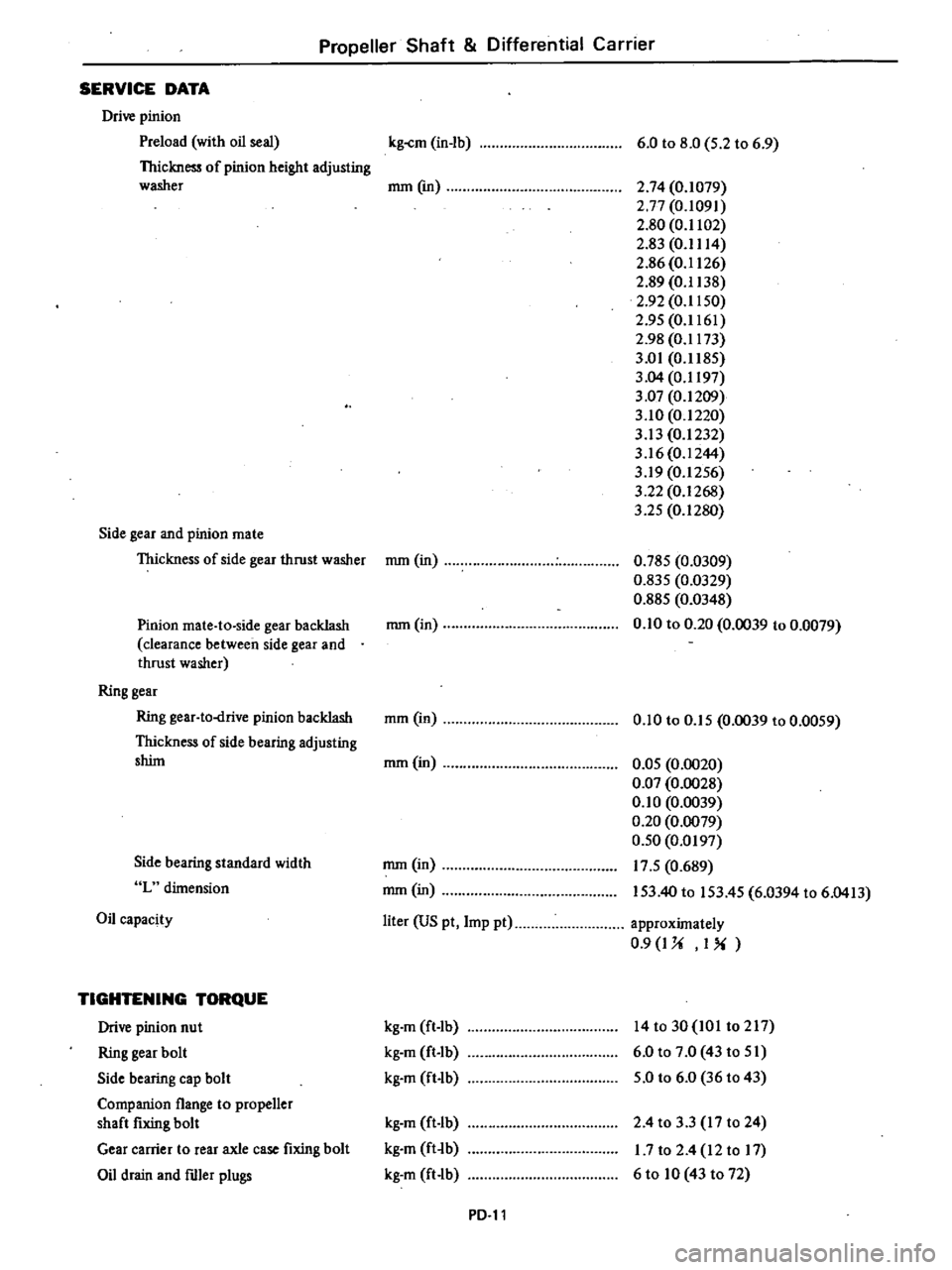

Propeller

Shaft

Differential

Carrier

SERVICE

DATA

Drive

pinion

Preload

with

oil

seal

Thickness

of

pinion

height

adjusting

washer

Side

gear

and

pinion

mate

Thickness

of

side

gear

thrust

washer

Pinion

mate

to

side

gear

backlash

clearance

between

side

gear

and

thrust

washer

Ring

gear

Ring

gear

to

drive

pinion

backlash

Thickness

of

side

bearing

adjusting

shint

Side

bearing

standard

width

L

dimension

Oil

capacity

TIGHTENING

TORQUE

Drive

pinion

nut

Ring

gear

bolt

Side

bearing

cap

bolt

Companion

flange

to

propener

shaft

fixing

bolt

Gear

carrier

to

rear

axle

case

fixing

bolt

Oil

drain

and

ftller

plugs

kg

cm

in

lb

6

0

to

8

0

5

2

to

6

9

mm

em

2

74

0

1079

2

77

0

1091

2

80

0

1102

2

g3

0

1114

2

86

0

1126

2

89

0

1138

2

92

0

1150

2

95

0

1161

2

98

0

1173

3

01

0

1185

3

04

0

1197

3

07

0

1209

3

10

0

1220

3

13

0

1232

3

16

0

1244

3

19

0

1256

3

22

0

1268

3

25

0

1280

mm

in

0

785

0

0309

0

835

0

0329

0

885

0

0348

0

10

to

0

20

0

0039

to

0

0079

mmOn

mm

in

0

10

to

0

15

0

0039

to

0

0059

mm

in

0

05

0

0020

0

Q7

0

0028

0

10

0

0039

0

20

0

0079

0

50

0

0197

17

5

0

689

153

40

to

153

45

6

0394

to

6

0413

mm

in

mm

in

liter

US

pt

Imp

pt

approximately

0

9

I

U

I

kg

m

ft

Ib

kg

m

ft

Ib

kg

m

ft

lb

14to30

IOI

t0217

6

0

to

7

0

43

to

51

5

0

to

6

0

36

to

43

kg

m

ft

Ib

kg

m

ft

b

kg

m

ft

lb

2

4

to

3

3

17

to

24

1

7

to

2

4

12

to

17

6

to

10

43

to

72

PD

ll

Page 319 of 548

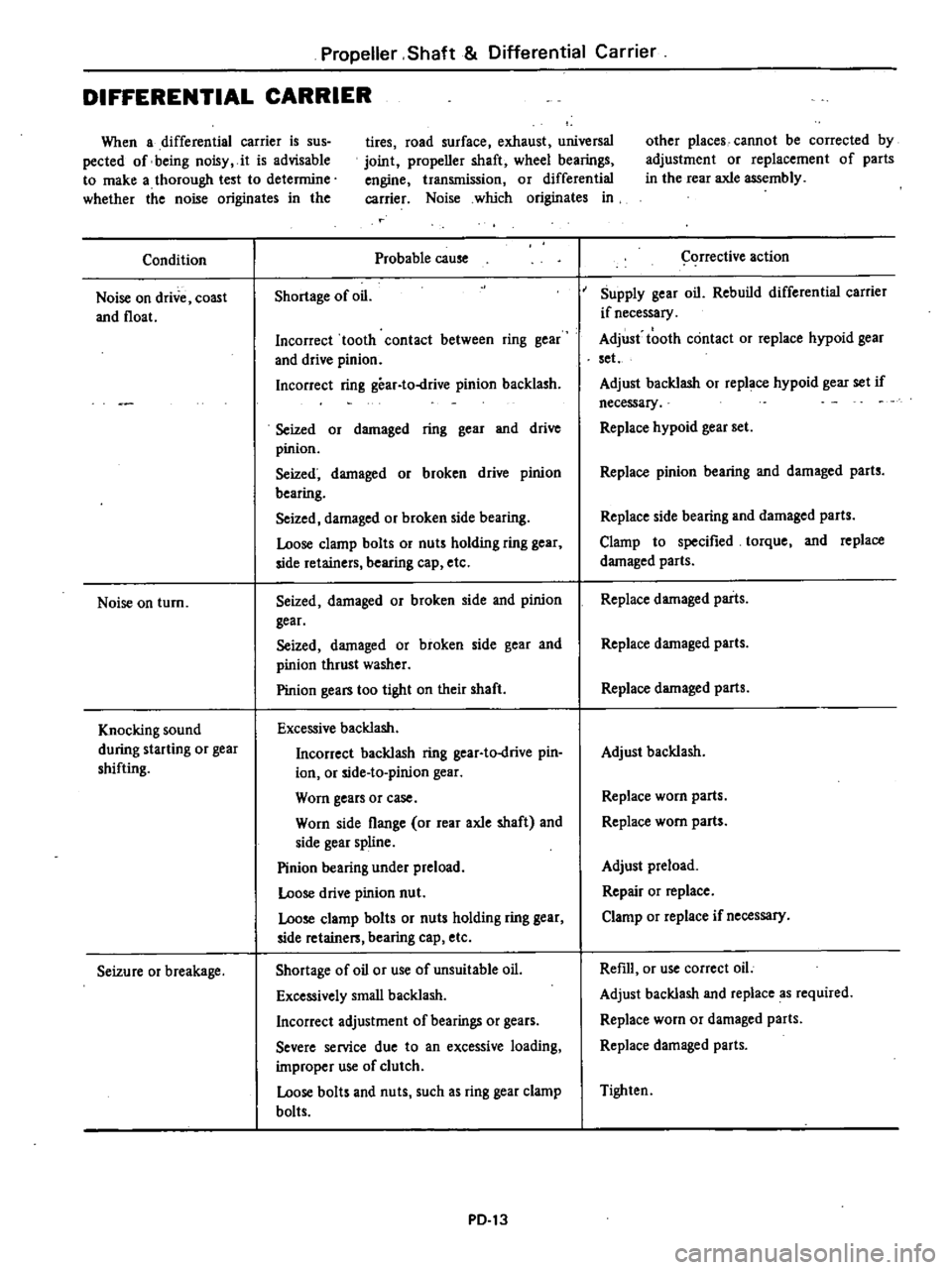

Propeller

Shaft

Differential

Carrier

DIFFERENTIAL

CARRIER

When

a

differential

carrier

is

sus

pected

of

being

noisy

it

is

advisable

to

make

a

thorough

test

to

determine

whether

the

noise

originates

in

the

tires

road

surface

exhaust

universal

joint

propeller

shaft

wheel

bearings

engine

transmission

or

differential

carrier

Noise

which

originates

in

Condition

Noise

on

drive

coast

and

float

Noise

on

turn

Knocking

sound

during

starting

or

gear

shifting

Seizure

or

breakage

Probable

cause

Shortage

of

oil

Incorrect

tooth

contact

between

ring

gear

and

drive

pinion

Incorrect

ring

gear

to

drive

pinion

backlash

Seized

or

damaged

ring

gear

and

drive

pinion

Seized

damaged

or

broken

drive

pinion

bearing

Seized

damaged

or

broken

side

bearing

Loose

clamp

bolts

or

nuts

holding

ring

gear

side

retainers

bearing

cap

etc

Seized

damaged

or

broken

side

and

pinion

gear

Seized

damaged

or

broken

side

gear

and

pinion

thrust

washer

Pinion

gears

too

tight

on

their

shaft

Excessive

backlash

Incorrect

backlash

ring

gear

to

drive

pin

ion

or

side

ta

pinion

gear

Worn

gears

or

case

Worn

side

flange

or

rear

axle

shaft

and

side

gear

spline

Pinion

bearing

under

preload

Loose

drive

pinion

nut

Loose

clamp

bolts

or

nuts

holding

ring

gear

side

retainers

bearing

cap

etc

Shortage

of

oil

or

use

of

unsuitable

oil

Excessively

small

backlash

Incorrect

adjustment

of

bearings

or

gears

Severe

service

due

to

an

excessive

loading

improper

use

of

clutch

Loose

bolts

and

nuts

such

as

ring

gear

clamp

bolts

PD

13

other

places

cannot

be

corrected

by

adjustment

or

replacement

of

parts

in

the

rear

axle

assembly

orrective

action

Supply

gear

oil

Rebuild

differential

carrier

if

necessary

Adjust

tooth

contact

or

replace

hypoid

gear

set

Adjust

backlash

or

replace

hypoid

gear

set

if

necessary

Replace

hypoid

gear

set

Replace

pinion

bearing

and

damaged

parts

Replace

side

bearing

and

damaged

parts

Clamp

to

specified

torque

and

replace

damaged

parts

Replace

damaged

parts

Replace

damaged

parts

Replace

damaged

parts

Adjust

backlash

Replace

worn

parts

Replace

worn

parts

Adjust

preload

Repair

or

replace

Clamp

or

replace

if

necessary

Refill

or

use

correct

oil

Adjust

backlash

and

replace

as

required

Replace

worn

or

damaged

parts

Replace

damaged

parts

Tighten

Page 320 of 548

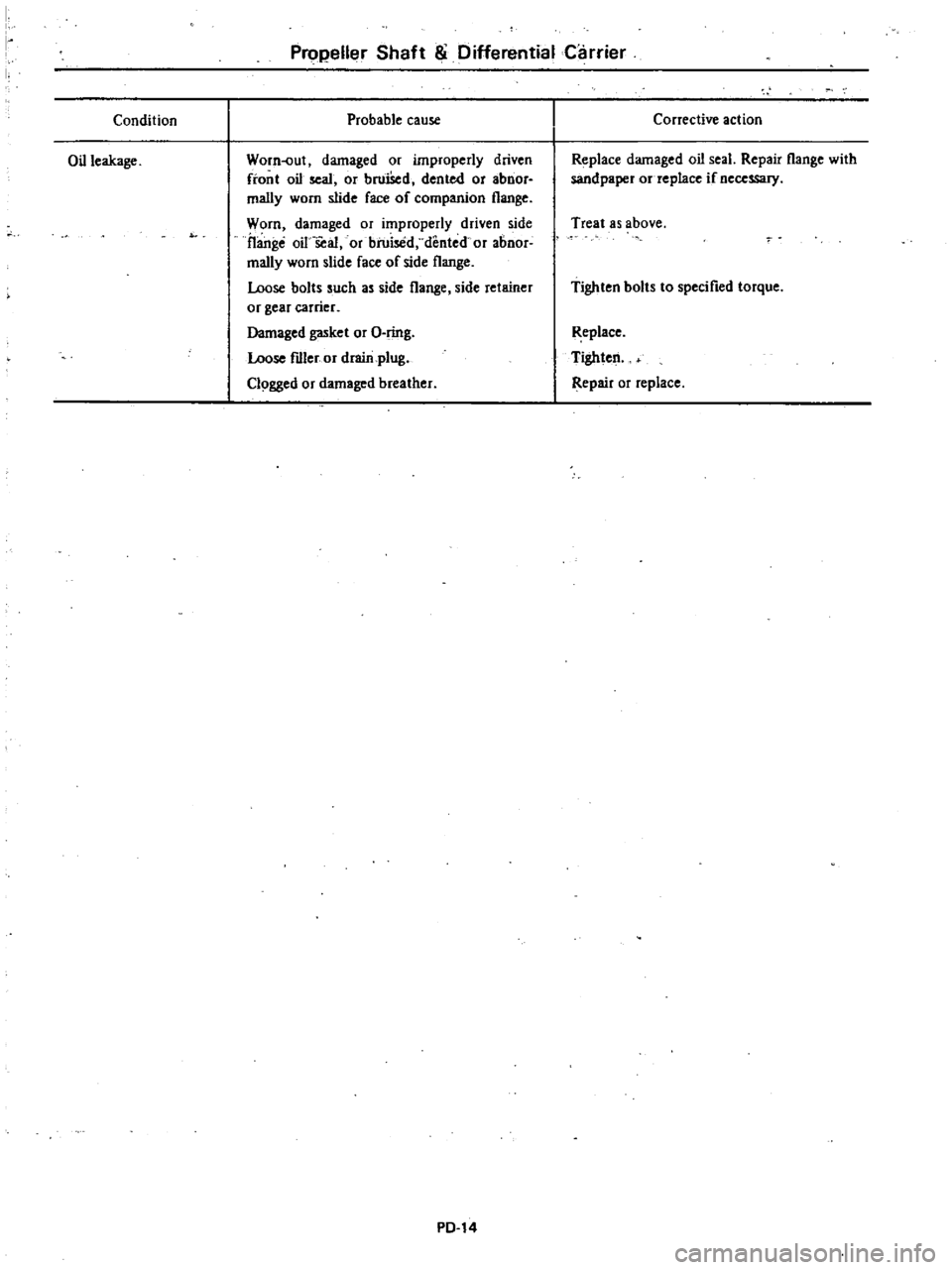

Condition

Oil

leakage

Pro

eller

Shaft

8i

Differential

Carrier

Probable

cause

Worn

Jut

damaged

or

improperly

driven

front

oil

seal

or

bruiSed

dented

or

abnor

mally

worn

slide

face

of

companion

flange

Worn

damaged

or

improperly

driven

side

flange

oil

seal

or

bruised

dented

or

abnor

mally

worn

slide

face

of

side

flange

Loose

bolts

such

as

side

flange

side

retainer

or

gear

carrier

Damaged

gasket

or

O

ring

Loose

fdler

or

drain

plug

Cl9gged

or

damaged

breather

PD

14

Corrective

action

Replace

damaged

oil

seal

Repair

flange

with

sandpapel

or

replace

if

necessary

Treat

as

above

Tighten

bolts

to

specified

torque

Replace

Tighten

Repair

or

replace

Page 322 of 548

Propeller

Shaft

o

ifferential

Carrier

Tool

number

tool

name

ST3070

I

000

Drive

pinion

outer

race

drift

5

ST3112S000

Drive

pinion

setting

gauge

set

Height

gauge

Dummy

shaft

CD

ST31121

000

@ST31122000

@

KV38103500

Height

gauge

spacer

KV38103600

Dummy

shaft

spacer

@

IKent

Mooro

No

Reference

page

or

Fig

No

Unit

applic

auon

J

25742

2

Pag

PD

6

J

25269

01

CD

J

25269

01

@

J

25269

01

Fig

PD

14

Fig

PD

14

Fig

PD

14

Tool

number

tool

name

ST30600000

Drive

pinion

bearing

drift

bar

ST33400001

Oil

seal

fitting

tool

ST3127S000

Preload

gauge

CD

GG91030000

Torque

wrench

@

HT62940000

Socket

adapter

ID

HT6290oo00

Socket

adapter

t

t

o

H172400000

Slide

hammer

I

K

e

nt

Moore

No

Reference

page

or

Fig

No

Unit

application

J

25741

P

1ge

PD

6

I

J

26082

Page

PD

6

J

25765

CD

J

25765

@

ID

Page

PD

7

Page

PD

4

PD

16

Applicable

to

all

8310

series

models

Page 323 of 548

DATSUN

210

Model

8310

Series

SECTIONFA

FRONT

AXLE

FRONT

SUSPENSION

CONTENTS

INSPECTION

AND

ADJUSTMENT

INSPECTION

ADJUSTMENT

FRONT

AXLE

REMOVAL

INSPECTION

INSTAllATION

FRONT

SUSPENSION

SPRING

AND

STRUT

ASSEMBLY

TENSION

ROD

AND

STABILIZER

BAR

FA

2

FA

2

FA

2

FA

4

FA

4

FA

5

FA

5

FA

6

FA

6

FA

9

lOWER

ARM

AND

lOWER

BAll

JOINT

SUSPENSION

CRDSSMEMBER

SERVICE

DATA

AND

SPECIFICATIONS

GENERAL

SPECIFICATIONS

INSPECTION

AND

ADJUSTMENT

TIGHTENING

TORQUE

TROUBLE

DIAGNOSES

AND

CORRECTIONS

SPECIAL

SERVICE

TOOLS

FA

lO

FA

12

FA

13

FA

13

FA

13

FA

14

FA

16

FA

19

Page 324 of 548

Front

Axle

Front

Suspension

INSPECTION

AND

ADJUSTIVIENT

INSPECTION

Inspect

in

accordance

with

periodic

maintenance

schedule

Block

rear

wheels

with

chocks

2

Jack

up

the

front

of

car

and

support

it

with

safety

stands

Refer

to

Section

GI

for

lifting

points

and

towing

3

Shaking

each

fiont

wheel

by

grasping

the

upper

and

lower

surfaces

of

the

tires

check

suspension

parts

for

looseness

wear

or

damage

Tighten

aU

loose

bolts

and

nuts

to

the

specified

torque

Replace

all

worn

parts

as

described

under

Front

Suspension

4

Check

wheel

bearings

If

there

is

any

axial

end

play

adjust

bearings

to

specifications

Replace

worn

or

damaged

bearings

as

described

under

Front

Axle

S

Check

strut

for

oil

leakage

or

damage

ADJUSTMENT

WHEEL

BEARING

Block

rear

wheels

with

chocks

2

Jack

up

the

front

of

car

and

support

it

with

safety

stands

3

Remove

brake

pads

Refer

to

Section

BR

for

pad

replacement

4

Remove

hub

cap

cotter

pin

ad

justing

cap

and

wheel

bearing

nut

S

Sparingly

apply

recommended

multi

purpose

grease

to

threaded

por

tion

of

spindle

and

contact

surface

between

wheel

bearing

washer

and

outer

wheel

bearing

6

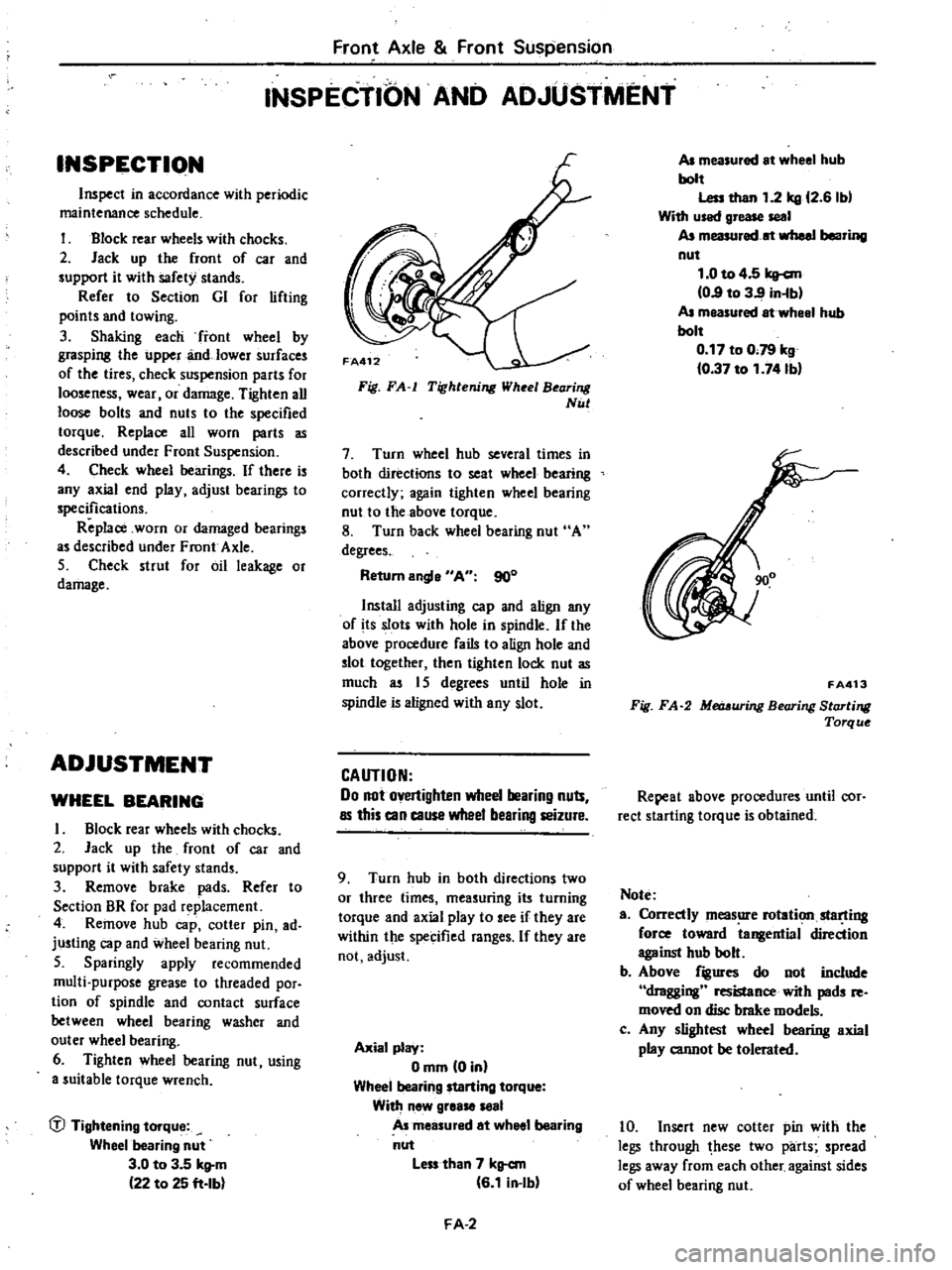

Tighten

wheel

bearing

nut

using

a

suitable

torque

wrench

P

Tightening

torque

Wheel

bearing

nut

3

0

to

3

5

kll

m

22

to

25

ft

Ibl

Fig

FA

Tighlening

Wheel

Bearing

Nul

7

Turn

wheel

hub

several

times

in

both

directions

to

seat

wheel

bearing

correctly

again

tighten

wheel

bearing

nut

to

the

above

torque

8

Turn

back

wheel

bearing

nut

A

degrees

Return

engle

AU

900

Install

adjusting

cap

and

align

any

of

its

slots

with

hole

in

spindle

If

the

above

procedure

fails

to

align

hole

and

slot

together

then

tighten

lock

nut

as

much

as

I

S

degrees

until

hole

in

spindle

is

aligned

with

eny

slot

CAUTION

00

not

overtighten

wheel

bearing

nuts

as

this

can

cause

wheel

bearing

seizure

9

Turn

hub

in

both

directions

two

or

three

times

measuring

its

turning

torque

and

axial

play

to

ee

if

they

are

within

the

specified

range

If

they

are

not

adjust

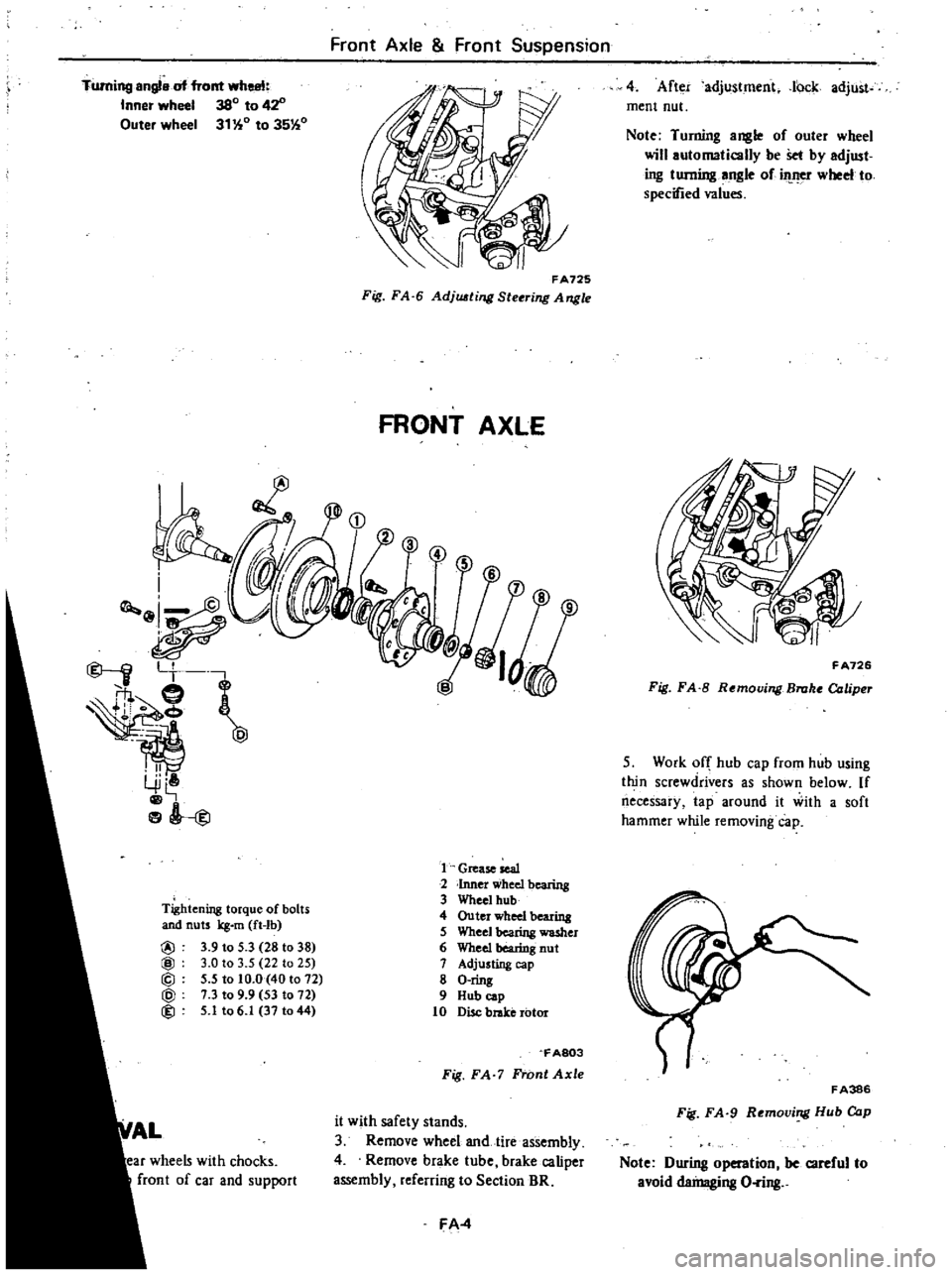

Axial

play

Omm

Din

Wheel

bealing

starting

torque

With

new

gleaS8

l8al

A

measured

et

wheel

bearing

nut

less

than

7

kg

cm

G

1

in

Ibl

FA

2

AJ

measuled

et

wheel

hub

bolt

Less

then

1

2

kg

12

G

Ibl

With

u

ed

gr

seal

AJ

measured

at

wheel

bealing

nut

1

0

to

4

5

kg

cm

0

9

to

3

9

in

b

AJ

measuled

at

wheel

hub

bolt

0

17

to

0

79

kg

0

37

to

1

741bl

FA413

Fig

FA

2

Metr

uring

Bearing

Starting

Torq

ue

Repeat

above

procedures

until

cor

rect

starting

torque

is

obtained

Note

a

Correctly

meas

e

rotation

slar

ting

force

toward

tangential

direction

against

hub

bolt

b

Above

figures

do

not

include

dragging

resistance

with

pads

re

moved

on

disc

brake

models

c

Any

slightest

wheel

bearing

axial

play

cannot

be

tolerated

10

Insert

new

cotter

pin

with

the

legs

through

hese

two

parts

spread

legs

away

from

each

other

against

sides

of

wheel

bearing

nut

Page 326 of 548

Turning

engie

of

front

wheel

Inner

wheel

380

to

42

Outel

wheel

31

0

to

35

0

Tightening

torque

of

bolts

and

nuts

kg

m

ft

lb

@

3

9

to

5

3

28

to

38

@

3

0

to

3

5

22

to

25

@

5

5

to

10

0

40

to

72

@

7

3

to

9

9

53

to

72

@

5

1

to

6

1

371044

ear

wheels

with

chocks

fron

t

of

car

and

support

Front

Axle

Front

Suspension

FA125

Fig

FA

6

AdjU

ting

Steering

Angle

FRONT

AXLE

1

Grease

seal

2

Inner

wbeel

bearin

3

Wheel

hub

4

Outer

wheel

bearins

5

Wheel

bearing

washer

6

Wheel

bearing

nut

7

Adjusting

cap

8

O

ring

9

Hub

cap

10

Disc

brake

rotor

FA803

Fig

FA

7

Front

Axle

it

with

safety

stands

3

Remove

wheel

and

tire

assembly

4

Remove

brake

tube

brake

caliper

assembly

referring

to

Section

DR

FA

4

4

After

adjustment

l

ck

adju

ment

nut

Note

Turning

angle

of

outer

wheel

will

automatically

be

Set

by

adjust

ing

turning

angle

ofin

f

U

wheel

to

specified

values

FA726

Fig

FA

8

RemouingBroke

Caliper

5

Work

off

hub

cap

from

hub

using

t

n

screwdrivers

as

shown

below

If

necessary

tap

around

it

with

a

soft

hammer

while

removing

cap

F

A386

Fig

FA

9

Remouing

Hub

Cap

Note

During

operation

be

careful

to

avoid

deinaging

O

ring