torque DATSUN 210 1979 Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 234 of 548

o

Fig

MT

70

R

movi7l

lB

ar

Ensi

Mounting

Croum

mber

Manual

Transmission

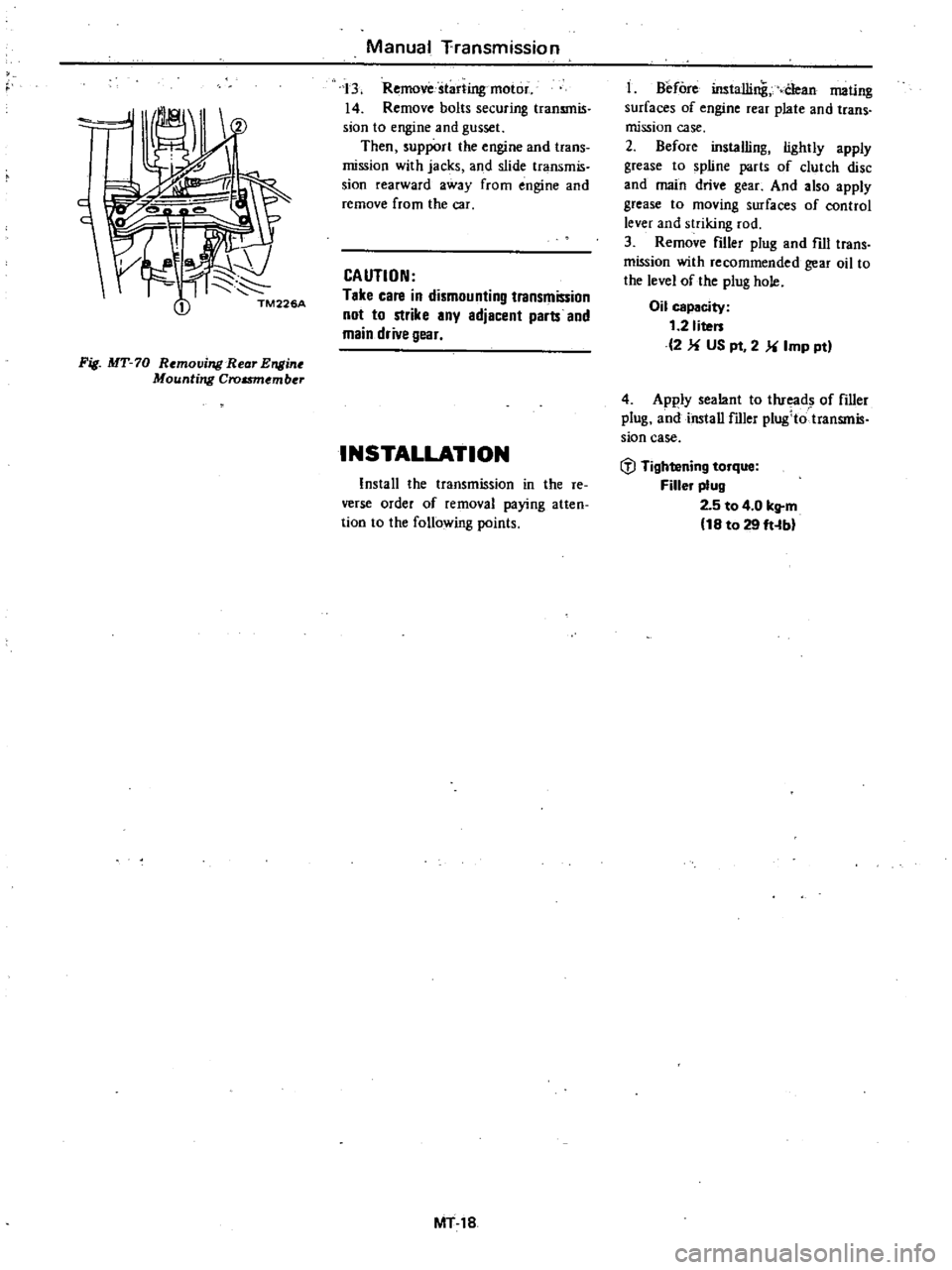

3

Remove

starting

motor

14

Remove

bolts

securing

transmis

sJon

to

engine

and

gusset

Then

support

the

engine

and

trans

mission

with

jacks

and

slide

transmis

sion

rearward

away

from

engine

and

remove

from

the

car

CAUTION

Take

cate

in

dismounting

transmission

not

to

strike

any

adjacenl

parts

and

main

drive

gear

INSTALLATION

Install

the

transmission

in

the

re

verse

order

of

removal

paying

atten

tion

to

the

following

points

MT18

t

Before

installing

Clean

mating

surfaces

of

engine

rear

plate

and

trans

mission

case

2

Before

installing

lightly

apply

grease

to

spline

parts

of

clutch

disc

and

main

drive

gear

And

also

apply

grease

to

moving

surfaces

of

control

lever

and

striking

rod

3

Remove

filler

plug

and

fill

trans

mission

with

recommended

gear

oil

to

the

level

of

the

plug

hole

Oil

capacity

t

2

liters

2

US

pt

2

Imp

ptl

4

Apply

sealant

to

thread

of

filler

plug

and

install

filler

plug

totransmis

sian

case

l

l

Tightening

torque

Filler

plug

2

5

to

4

0

kg

m

t8

to

29

ft

bl

Page 240 of 548

it

TMS06

Fig

MT

100

Baulk

Ring

to

Con

Gap

SHiniNG

IIUERT

Replace

if

WOrn

excessively

worn

unevenly

defonned

or

damaged

OIL

SEAL

I

Dis

r

l

O

ring

or

oil

seal

which

is

once

removed

Replace

oil

seal

if

sealing

lip

is

qefonned

or

cracked

Also

discard

oil

seal

if

spring

is

out

of

position

2

Check

tlie

oil

seal

lip

contacting

with

shaft

if

necessary

replace

oil

seal

and

shaft

as

a

set

REAR

ENGINE

MOUNTING

INSULATOR

Replace

rear

engine

mounting

insu

lator

if

weakened

deteriorated

or

cracked

ASSEMBLY

To

assemble

reverse

the

order

of

disassembly

Observe

the

following

in

structions

FRONT

COYER

ASSEMBLY

I

Make

sure

that

seal

mating

sur

face

is

clean

Using

a

press

and

Oil

Seal

Drift

ST23800000

drive

new

seal

into

place

on

front

cover

Nole

When

pressing

oil

seal

into

place

apply

coat

of

gear

oil

to

surface

adjoining

oil

seat

2

Lubrica

te

seal

lip

and

main

drive

shaft

with

gear

oil

when

installing

front

cover

Manual

Transmission

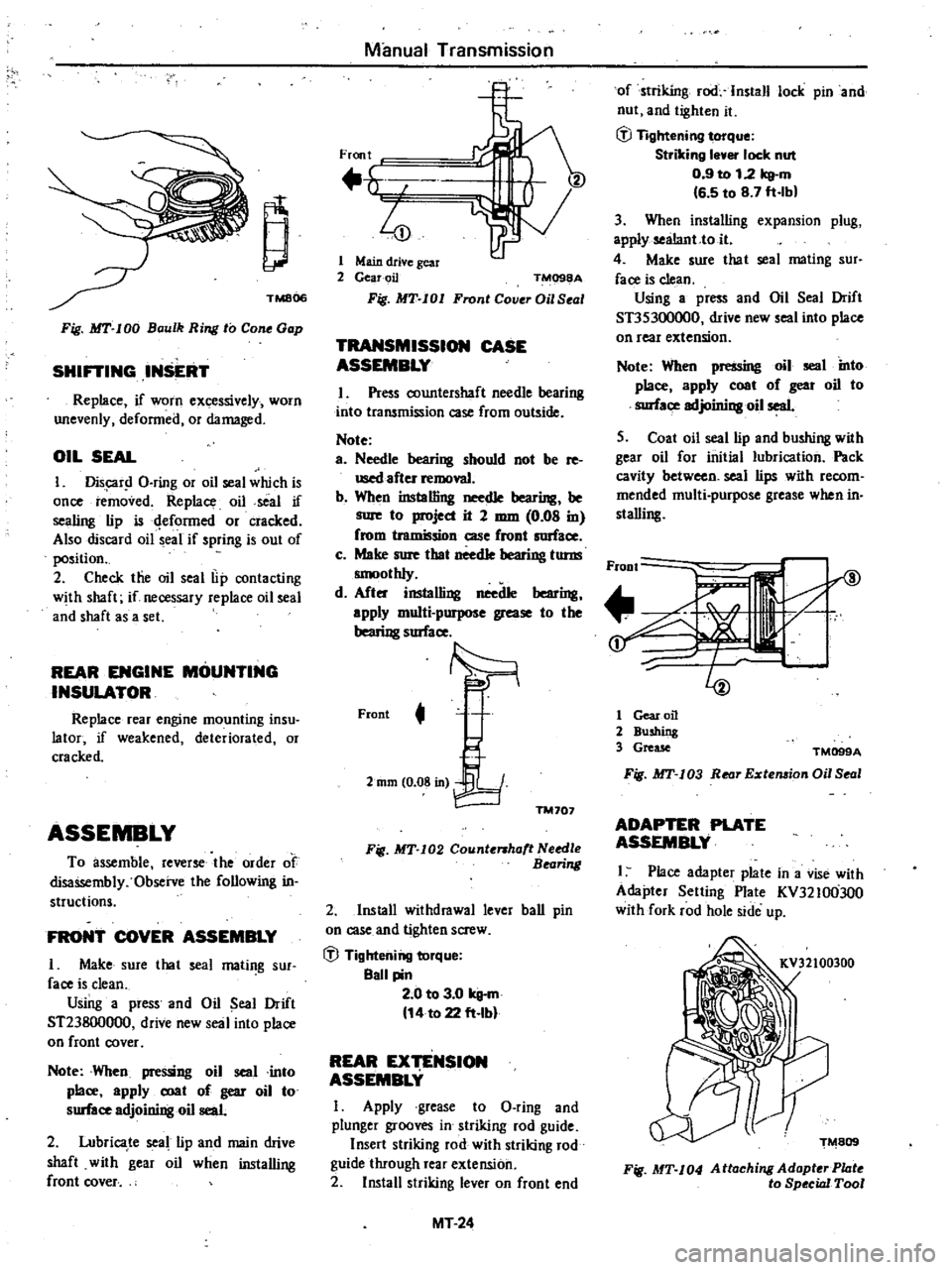

Front

h

I

4

1

Main

drive

gear

2

GearoiJ

TM098A

Fig

MT

101

Front

Cover

Oil

S

al

TRANSMISSION

CASE

ASSEMBLY

I

Press

countershaft

needle

bearing

into

transmission

case

from

outside

Note

a

Needle

bearing

should

not

be

re

used

after

removal

b

When

inslalling

needle

bearing

be

sure

to

project

it

2

mm

0

08

in

from

tramission

case

front

mace

c

Make

sure

that

needle

bearing

torm

smoothly

d

After

instal6ng

needle

bearing

apply

multi

purpose

grease

to

the

bearing

smace

Front

t

2mm

0

08

in

TM707

Fig

MT

I02

Count

haft

N

edle

Bearing

2

Install

withdrawal

lever

ball

pin

on

case

and

tighten

screw

ifl

Tightening

torque

Sail

pin

2

0

to

3

0

kg

m

14

to

22

ft

Ibl

REAR

EXTENSION

ASSEMBLY

I

Apply

grease

to

O

ring

and

plunger

grooves

in

striking

rod

guide

Insert

striking

rod

with

striking

rod

guide

through

rear

extension

2

Install

striking

lever

on

front

end

MT

24

of

striking

rod

Install

lock

pin

and

nut

and

tighten

it

ifl

Tightening

torque

Striking

I

er

lock

nut

0

9

to

12

kg

m

6

5

to

8

7

ft

lbl

3

When

installing

expansion

plug

apply

sealant

to

it

4

Make

sure

that

seal

mating

sur

face

is

clean

Using

a

press

and

Oil

Seal

Drift

ST35300000

drive

new

seal

into

place

on

rear

extension

Note

When

pressing

oil

seal

into

place

apply

coat

of

geat

oil

to

mace

adjoining

oil

seal

5

Coat

oil

seal

lip

and

bushing

with

gear

oil

for

initial

lubrication

Pack

cavity

between

seal

lips

with

recom

mended

multi

purpose

grease

when

in

slalling

FroDt

I

t

Cc

if

i

I

L

1

Gear

oil

2

Bushing

3

Grease

TM099A

Fig

MT

I03

Rear

Eztemion

Oil

Seal

ADAPTER

PLATE

ASSEMBLY

I

Place

adapter

plate

in

a

vise

with

Adapter

Setting

Plate

KV32100JOO

with

fork

rod

hole

side

up

Fig

MT

104

Attaching

AdopterPhlte

to

Special

Tool

Page 243 of 548

Note

Make

sure

smp

ring

fits

in

groove

5

Install

bearing

retainer

on

adapter

plate

Torque

screws

and

stake

each

screw

at

two

points

with

a

punch

@

Tightening

tOrque

Mainshaft

bearing

retainer

screw

0

8

to

3

kll

m

15

8

to

9

4

ft

lbl

TM246A

Fig

MT

117

Staking

Bearing

Retainer

Screws

6

Press

Ist

counter

gear

onto

counter

sltaft

using

Drift

ST22360002

TM583

Fig

MT

118

Installing

I

t

Counter

Gear

7

Fit

a

new

suitable

retaining

ring

in

place

so

th

t

there

exists

a

mininum

clearance

between

end

face

of

counter

gear

and

ring

Note

Make

sure

retaining

ring

f

It

in

groove

Available

retaining

rings

No

Thickness

mm

in

2

1

25

to

1

35

0

0492

to

0

0531

1

35

to

I

45

0

0531

to

0

0571

0

d

Converted

tor

q

e

j

Iim

ttine

7

7

7

Manua

Transmission

TM247

A

Fig

MT

119

Installing

Retaining

Ring

8

Install

thrust

washer

to

rear

of

mainshaft

and

idler

shaft

9

Install

synchro

hub

with

reverse

gear

I

st

gear

together

with

needle

bearing

and

bushing

and

idler

gear

together

with

needle

bearing

simulta

neously

OTT

o

1st

gear

side

Ui

Front

Fl

J

I

TM263A

Fig

MT

I20

In

talling

Ist

Reverse

Synchronizer

10

Install

mainshaft

nut

and

tighten

it

temporarily

E

S

f2

80

t1

o

c

v

0

S

v

5

c

o

o

u

10

70

9

60

50

II

With

I

st

and

2nd

gears

doubly

engaged

tighten

mainshaft

nut

to

con

verted

torque

en

See

Fig

MT

123

using

Wrench

ST22520000

Stake

mainshaft

nut

to

groove

of

mainshaft

with

a

punch

ST22520000

TM248A

Fig

MT

I2I

Tightening

Mainshaft

Nut

TM249A

Fig

MT

I22

Staking

Mainshaft

Nut

I

I

Upper

limit

line

40

0

2

0

3

0

4

0

5

0

6

0

7

0

8

m

1

0

1

5

2

0

2

5

ft

L

Effective

length

of

torque

wrench

MT

27

TM258A

Fig

MT

123

Converted

Torque

Page 244 of 548

J

xplanation

of

convet

ted

torque

Mainshaft

nut

should

be

tightened

to

10

to

11

kg

m

72

to

80

ft

Ib

torque

with

the

aid

of

Wrench

ST22520000

When

doing

w

the

amount

of

torque

to

be

read

on

wrench

needle

should

be

modified

according

to

the

following

formula

L

C

kg

m

10

x

L

O

I

to

11

L

x

L

O

I

or

C

ft

Ib

n

x

L

O

33

to

L

80

x

L

0

33

Where

C

Value

read

on

the

torque

wrench

kg

m

ft

Ib

L

Effective

length

of

torque

wrench

m

ft

ST22520000

Torque

wrench

r

Lm

ft

0

1

m

0

3

ft

TM587

Fig

MT

124

Setting

Wrench

Example

When

a

0

4

m

Iong

torque

wrench

is

used

the

C

in

Fig

MT

123

will

be

8

0

to

8

8

kg

m

58

to

64

ft

Ib

12

Measure

gear

end

play

Make

sure

that

they

are

held

within

the

specified

values

For

details

refer

to

Page

MT

23

for

Inspection

13

Fit

1

0

IDm

0

039

in

thick

snap

ring

10

the

front

side

of

main

shaft

end

bearing

14

Install

mainshaft

end

bearing

using

Bearing

Drift

ST22350000

Fit

thick

snap

ring

to

the

rear

side

of

bearing

to

eliminate

end

play

Manual

Transmission

Available

Sllap

ring

No

Thickness

IDm

in

1

1

0

0

039

2

1

2

0

047

on

LST22350000

TM250A

Fig

MT

125

In

talling

Main

haft

End

Bearing

Shift

forks

and

fork

rods

1

Insert

1st

reverse

fork

rod

into

its

shift

fork

and

adapter

plate

2

With

1st

reverse

fork

rod

set

at

Neutral

insert

interlock

plunger

into

adapter

plate

3

Insert

2nd

3rd

fork

rod

into

adapter

plate

2nd

3rd

and

4th

5th

shift

forks

4

With

2nd

3rd

fork

rod

set

at

Neutral

insert

interlock

plunger

into

adapter

plate

5

Insert

4th

5th

fork

rod

into

adapter

plate

and

its

s

Uft

fork

6

Secureshift

forks

and

fork

rOd

s

with

new

retaining

pins

Note

a

Be

sure

to

install

interlock

plunger

when

installing

any

adjacent

fork

rods

to

adapter

plate

Properly

align

the

groove

in

assem

bleMork

rod

with

inle

rlQck

plung

er

See

Fig

MT

SO

b

Be

su

to

align

4th

5th

shift

fork

with

the

groove

in

their

coupling

sleeve

befo

instalting

c

Also

align

2nd

3rd

shift

fork

with

their

coupling

sleeve

properly

be

fore

instalting

7

Install

check

balls

and

check

ball

springs

Applying

locking

sealer

to

check

ball

plug

and

install

in

place

Align

center

notch

in

each

fork

rod

with

check

ball

Note

a

Check

ball

plug

for

1st

reverse

fork

rod

is

longer

than

those

for

2nd

3rd

fork

rod

and

4th

5th

fork

rod

b

To

insure

that

interlock

plunger

i

installed

properly

slide

2nd

3rd

fork

rnd

andoperate

the

other

fork

rod

Make

sure

thaI

gear

except

20d

or

3rd

gear

doe

not

mesh

8

Apply

gear

oil

to

all

sliding

sur

faces

and

check

to

see

that

shift

rods

operate

correctly

and

gears

engage

smoothly

L

1

u

Revene

TM251A

Fig

MT

126

In

talling

Shift

Forks

and

Fork

Roth

MT

28

Page 245 of 548

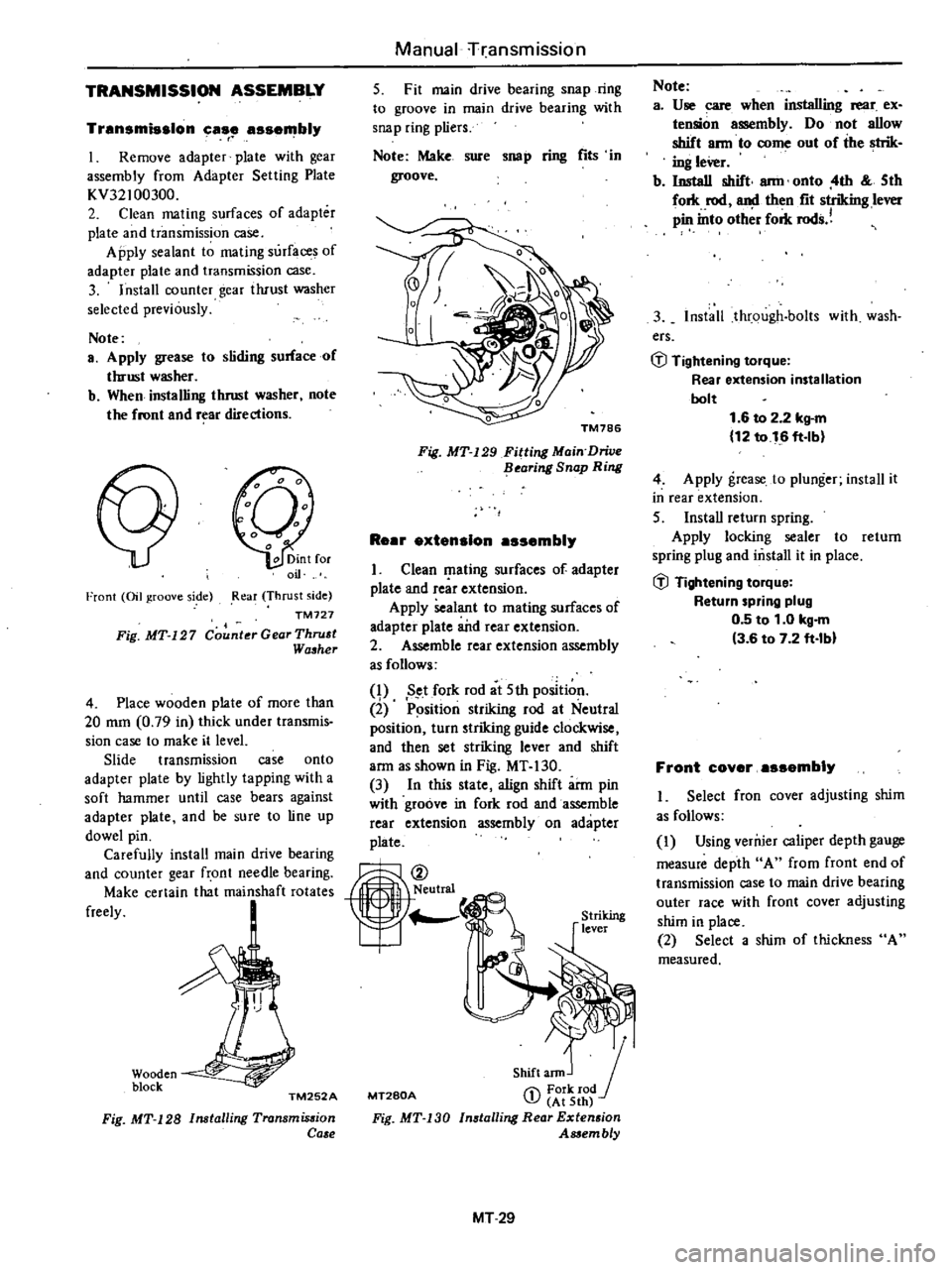

TRANSMISSION

ASSEMBLY

Transmission

case

assembly

r

I

Remove

adapter

plate

with

gear

assembly

from

Adapter

Setting

Plate

KV32100300

2

Clean

mating

surfaces

of

adapter

plate

and

transmission

case

Apply

sealant

to

mating

surfaces

of

adapter

plate

and

transmission

case

3

Install

counter

gear

tluust

washer

selected

previously

Note

a

Apply

grease

to

sliding

surface

of

thrust

washer

b

When

installing

thrust

washer

note

the

front

and

r

ar

directions

Front

Oil

groove

side

Rear

Thrust

side

TM727

Fig

MT

127

Counter

Gear

Thru

t

Wa

her

4

Place

wooden

plate

of

more

than

20

mm

0

79

in

thick

under

transmis

sion

case

to

make

it

level

Slide

transmission

case

onto

adapter

plate

by

lightly

tapping

with

a

soft

hammer

until

case

bears

against

adapter

plate

and

be

sure

to

line

up

dowel

pin

Carefully

install

main

drive

bearing

and

counter

gear

front

needle

bearing

Make

certain

that

mainshaft

rotates

freely

Wooden

block

TM252A

Fig

MT

128

Installing

Transmis

ion

Ca

e

Manual

rransmission

5

Fit

main

drive

bearing

snap

ring

to

groove

in

main

drive

bearing

with

snap

ring

pliers

Note

Make

sure

sno

p

ring

fits

in

groove

Fig

MT

129

Fitting

Main

Drive

flearing

Snap

Ring

ReBr

extension

assembly

I

Clean

I

lating

surfaces

of

adapter

plate

and

rcar

extension

Apply

sealant

to

mating

surfaces

of

adapter

plate

a

itd

rear

extension

2

Assemble

rear

extension

assembly

as

follows

q

Set

fork

rod

at

5th

position

2

P

sition

striking

rod

at

Neutral

position

turn

striking

guide

clockwise

and

then

set

striking

lever

and

shift

arm

as

shown

in

Fig

MT

130

3

In

this

state

align

shift

arm

pin

with

groove

in

fork

rod

and

assemble

rear

extension

assembly

on

adapter

plate

MT280A

Shift

ann

J

1

Fork

rod

J

At

5th

Installing

Rear

Extension

Assembly

Fig

MT

130

MT29

Note

a

Use

care

when

installing

rear

ex

tension

assembly

Do

not

allow

shift

ann

to

come

out

of

the

strik

ing

leVer

b

Install

shift

ann

onto

4th

5th

fork

rod

and

then

fit

striking

lever

pin

into

oth

r

fork

rods

3

Install

through

bolts

with

wash

ers

GJ

Tightening

torque

Rear

extension

installation

bolt

1

6

to

2

2

kg

m

12

to

16

ft

lb

4

Apply

grease

to

plunger

install

it

in

rear

extension

5

InstaU

return

spring

Apply

locking

sealer

to

return

spring

plug

and

mstall

it

in

place

GJ

Tightening

torque

Return

spring

plug

0

5

to

1

0

kg

m

3

6

to

7

2

ft

lbl

Front

coyer

assembly

I

Select

fron

cover

adjusting

shim

as

follows

I

Using

verruer

caliper

depth

gauge

measure

depth

A

from

front

end

of

transmission

case

to

main

drive

bearing

outer

race

with

front

cover

adjusting

shim

in

place

2

Select

a

shim

of

thickness

A

measured

Page 246 of 548

No

A

mm

in

Manual

Ttansniissio

n

Adjusting

shim

mm

in

0

50

0

0197

0

55

0

0217

0

60

0

0236

0

6

0

9756

0

70

0

0276

0

75

0

0295

0

80

0

0315

I

2

3

4

5

6

7

6

05

to

6

09

0

2382

to

0

2398

6

10to

6

14

0

2402

to

0

2417

6

15

to

6

19

0

2421

to

0

2437

6

20

to

6

2

4

9

1

41

t

19

2457

6

25

to

6

29

0

2461

to

0

2476

6

30

to

6

34

0

2480

to

0

2496

6

35

to

6

39

0

2500

to

0

2516

TM816

Fig

MT

131

MetuUring

Front

CoV

r

Adju

ting

Shim

1

Transmission

case

2

Main

drive

gear

3

Adjusting

shim

4

Bearing

TM817

Fig

MT

132

Selecting

Front

CoV

r

Adju

ti1l8

shim

2

Clean

maling

surfaces

of

front

cover

and

transmission

case

3

Install

front

cover

to

transmission

case

with

the

adjUsting

shim

and

0

ring

in

place

@

Tight

ning

torque

Front

co

erinstallation

bolt

1

0

to

1

6

kg

m

7

to

12

ft

Ib

Outer

parts

assembly

I

Install

speedometer

pinion

assem

bly

and

install

securing

bolt

and

tighten

@

Tightening

torque

Speedometer

sl

locking

plate

bolt

0

3

to

0

5

kg

m

2

2

to

3

6

ft

lb

2

Install

reverse

lamp

switch

and

tighten

At

the

same

time

install

top

detecting

switch

if

so

equipped

Be

sure

to

apply

locking

sealer

before

installation

MT30

@

Ti

ltening

torque

Rewene

lamp

switch

and

top

detecting

switch

2

0

to

3

5

kg

m

14

to

25

fHb

3

Apply

a

light

coat

of

multi

purpose

grease

to

withdrawal

lever

release

bearing

ahd

bearing

sleeve

in

stall

them

on

transmission

case

After

connecting

them

with

holder

spring

install

dust

cover

to

transmis

sion

case

4

Install

control

lever

temporarily

and

move

shift

coritrol

lever

through

all

gears

to

make

sure

that

gears

op

rate

smoothly

5

InstaU

draiiI

plug

coated

with

sealant

in

place

@

Tightening

torque

Drain

plug

2

5

to

4

0

kg

m

18

to

29

fHb

6

Make

sure

that

main

drive

shaft

rotates

smoothly

in

Neutral

v

Jin

drive

gear

routing

torque

less

than

1

8

leg

em

1

6

in

Ib

Page 248 of 548

Manual

Transmission

INSPECTION

AND

ADJUSTMENT

Transmission

model

Item

Ist

gear

2nd

gear

Gear

end

play

mm

in

3rd

gear

5th

gear

Counter

gear

Reverse

idler

gear

Clearance

between

baulk

ring

and

gear

rom

in

Main

drive

coupter

drive

gear

1st

gear

2nd

gear

Gear

backlash

mm

in

3rd

gear

5th

gear

Reverse

counter

to

reverse

idler

Reverse

idler

to

reverse

main

Main

drive

gear

rotating

torque

kg

cm

in

lb

F4W60L

0

15

to

0

25

0

0059

to

0

0098

0

30

to

0

40

0

0118

to

0

0157

0

15

to

0

30

0

0059

to

0

0118

0

10

to

0

20

0

0039

to

0

0079

0

1

0

to

0

27

0

0039

to

0

0106

0

80

to

1

65

0

0315

to

0

0650

0

05

to

0

15

0

0020

to

0

0059

0

05

to

0

15

0

0020

to

0

0059

0

05

to

0

15

0

0020

10

0

0059

0

05

to

0

15

0

0020

to

0

0059

0

05

to

0

18

0

0020

to

0

0071

0

05

to

0

18

0

0020

to

0

0071

Ie

thaI

1

8

1

6

MT32

FS5W60L

0

15

to

0

25

0

0059

to

0

0098

0

15

to

0

25

0

0059

to

0

0098

0

30

to

0

40

0

0118

to

0

0157

O

lSto

0

30

0

0059

to

0

Q118

0

1

0

to

0

20

0

0039

to

0

0079

0

15

to

0

40

0

0059

to

0

Q157

0

80

to

1

65

0

0315

1

0

0650

0

05

to

0

15

0

0020

to

0

0059

O

OSto

0

15

0

0020

to

0

0059

0

05

to

0

15

0

0020

to

0

0059

0

05

to

0

15

0

0020

to

0

0059

0

05

to

0

15

0

0020

to

0

0059

0

05

to

0

18

0

0020

to

0

071

0

05

to

0

18

0

0020

to

0

0071

less

than

1

8

I

6

Page 249 of 548

TIGHTENING

TORQUE

Ball

pin

Striking

lever

lock

nut

S

llft

arm

bracket

Mainshaft

bearing

retainer

screw

Mainshaft

lock

nut

Rear

extension

installation

bolt

Stopper

pin

bolt

Front

cover

installation

bolt

Speedometer

sleeve

lock

ing

plate

bolt

Top

detecting

switch

Reverse

lamp

switch

Neutral

switch

Return

spring

plug

Gear

oil

filler

plug

Gear

oil

drain

plug

Transmission

to

engine

installation

bolt

Tr

msmissiori

to

engihe

rear

plate

installation

bolt

Transmission

to

gusset

installation

bolt

Starting

motor

to

trans

inissi

n

installation

bolt

Rear

mounting

insulator

to

transmission

installation

bolt

Crossmember

mounting

bolt

Rear

engine

mount

installation

bolt

Clutch

operating

cylinder

installation

bolt

Propeller

shaft

to

differential

carrier

Control

lever

pin

installation

nut

Exhaust

mounting

bracket

to

exhaust

front

tube

FU

model

only

Manual

Transmission

F4W60L

2

0

to

3

0

14

to

22

0

9

to

1

2

6

5

to

8

7

0

7

to

1

0

5

1

to

7

2

1

6

to

2

2

12

to

16

0

5

to

0

8

3

6

to

5

8

1

0

to

1

6

7

to

12

0

3

to

0

5

2

2

to

3

6

2

0

to

3

5

14

to

25

2

0

to

3

5

14

to

25

0

5

to

1

0

3

6

to

7

2

2

5

to

4

0

18

to

29

2

5

to

4

0

18

to

29

1

6

to

2

2

12Jo

16

1

6

to

2

2

12

t

16

4

6

to

6

1

33

to

44

3

0

to

4

0

22

to

29

0

9

to

1

2

6

5

to

8

7

3

2

to

4

3

23

to

31

0

9

to

1

2

6

5

to

8

7

3

1

to

4

1

22

to

30

2

4

to

3

3

17

to

24

1

3

to

1

7

9

to

12

3

2

to

4

3

23

to

31

MT33

Unit

kg

m

ft

lb

FS5W60L

2

0

to

3

0

14

to

22

0

9

to

1

2

6

5

to

8

7

8

2

to

10

0

59

to

72

0

8

to

1

3

5

8

to

9

4

10

0

to

11

0

72

to

80

1

6

to

2

2

12

to

16

1

0

to

1

6

7

to

12

0

3

to

0

5

2

2

to

3

6

2

0

to

3

5

14

to

25

2

0

to

3

5

14

to

25

2

0

to

3

5

14

to

25

0

5

to

1

0

3

6

to

7

2

2

5

to

4

0

18

to

29

i

5

to

4

0

18

to

29

1

6

to

2

2

12

to

16

1

6

to

2

2

12

to

16

4

6

to

6

1

33

to

44

3

0

to

4

0

22

to

29

0

9

to

1

2

6

5

to

8

7

3

2

to

4

3

23

to

31

0

9

to

1

2

6

5

to

8

7

3

1

to

4

1

22

to

30

2

4

to

3

3

17

to

24

1

3

to

1

7

9

to

12

3

2

to

4

3

23

to

31

Page 253 of 548

DATSUN

210

Model

8310

Series

SECTION

AT

AUTOMATIC

TRANSMISSION

CONTENTS

DESCRIPTION

HYDRAULlC

CONTROL

UNIT

AND

VALVES

HYDRAULIC

CONTROL

CIRCUITS

REMOVAL

AND

INSTALLATION

TRANSMISSION

ASSEMBLY

MAJOR

REPAIR

OPERATION

SERVICE

NOTICE

FOR

DISASSEMBL

Y

AND

ASSEMBLY

TORQUE

CONVERTER

TRANSMISSION

COMPONENT

PARTS

AT

2

AT

3

AT

6

AT

25

AT

25

AT

27

AT

27

AT

27

AT

27

AT

31

TROUBLE

DIAGNOSIS

AN

ADJUSTMENT

INSPECTION

AND

ADJUStMENT

BEFORE

TROUBLE

DIAGNOSIS

STALL

TEST

ROAD

TEST

LINE

PRESSURE

TEST

TROUBLE

SHOOTING

CHART

SERVICE

DATA

AND

SPECIFICATIONS

SPECIAL

SERVICE

TOOLS

AT

39

AT

39

AT

41

AT

4i

AT

44

AT

45

AT

51

AT53

Page 254 of 548

The

3N71

B

trammission

is

a

fully

automatic

unit

consisting

primarily

of

a

3

element

hydraulic

torque

converter

and

two

planetary

gear

sets

Two

multiple

disc

c1utclies

a

multiple

disc

brake

brake

band

and

one

way

clutch

provide

the

friction

elements

necessary

to

obtain

the

desired

function

of

the

two

planetary

gear

ets

A

hydraulic

control

system

is

used

to

operate

the

friction

elements

and

automatic

shift

controls

TORQUE

CONVERTER

The

torque

converter

is

attached

to

the

crankshaft

through

a

flexible

drive

plate

Heat

generat

in

the

t

rque

converter

is

dissipated

by

circulating

the

transmission

fluid

through

an

oil

to

water

type

cooler

in

the

radiator

lower

tank

The

welded

comtruction

of

the

torque

co

verter

prevents

di

3

ssembly

or

service

unless

highly

specialized

equipment

is

available

Qj

gJ

Autpmatic

Trimsmissi6n

DEScRIPTION

FLUID

RECOMMENDAnON

Use

DEXRON

type

automatic

transmission

fluid

only

IDENTIFICATION

NUMBER

Stamped

position

The

plate

is

attached

to

the

right

han

side

of

transmission

case

AT

M

Fig

AT

l

Identification

Number

Identification

of

number

arranaemanta

JAPAJllUTOIlATlC

TRAJISIIISSIO

C8

Ull

MODEL

X

0

12

3

NO

7

6

0

1

2

34

Number

designation

76

0

I

2

34

L

Serial

productioo

number

for

the

month

Month

of

production

1

Jan

2

Feb

X

Oct

Y

Nov

Z

Dec

Lut

IJgUre

denotins

the

year

A

D

IJ

III

J

W

f

r

lrr

G

1

Transmission

case

2

Oil

pump

3

Front

clutch

4

Band

brake

5

Rear

dutch

6

Front

planetary

geat

7

Rear

planetary

gear

8

One

way

clutch

9

Low

4

Reverse

brake

10

Oil

distributor

11

Governor

12

utput

shaft

13

Rear

extension

14

Oil

pan

IS

Control

valve

16

Input

shaft

17

Torque

converter

18

Converter

housi

19

Drive

pia

te

Tightening

torque

T

of

bolts

and

nuts

kg

m

ft

lb

@

T

4

to

5

29

to

36

@

T

14

to

16

101

to

116

@

T

4

5

to

5

5

33

to

40

@

T

0

6

to

0

8

4

3

to

5

8

@

T

0

5

to

0

7

3

6

to

5

1

T

2

0

to

2

5

14

to

18

@

T

1

3

to

1

8

9

to

13

@

T

0

55

ta

0

75

4

0

to

5

4

CD

T

0

25

to

0

35

1

8

to

2

5

AT312

Fig

AT

2

3N71B

Automatic

Trammiuion

AT

2