brake fluid DATSUN 210 1979 User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 266 of 548

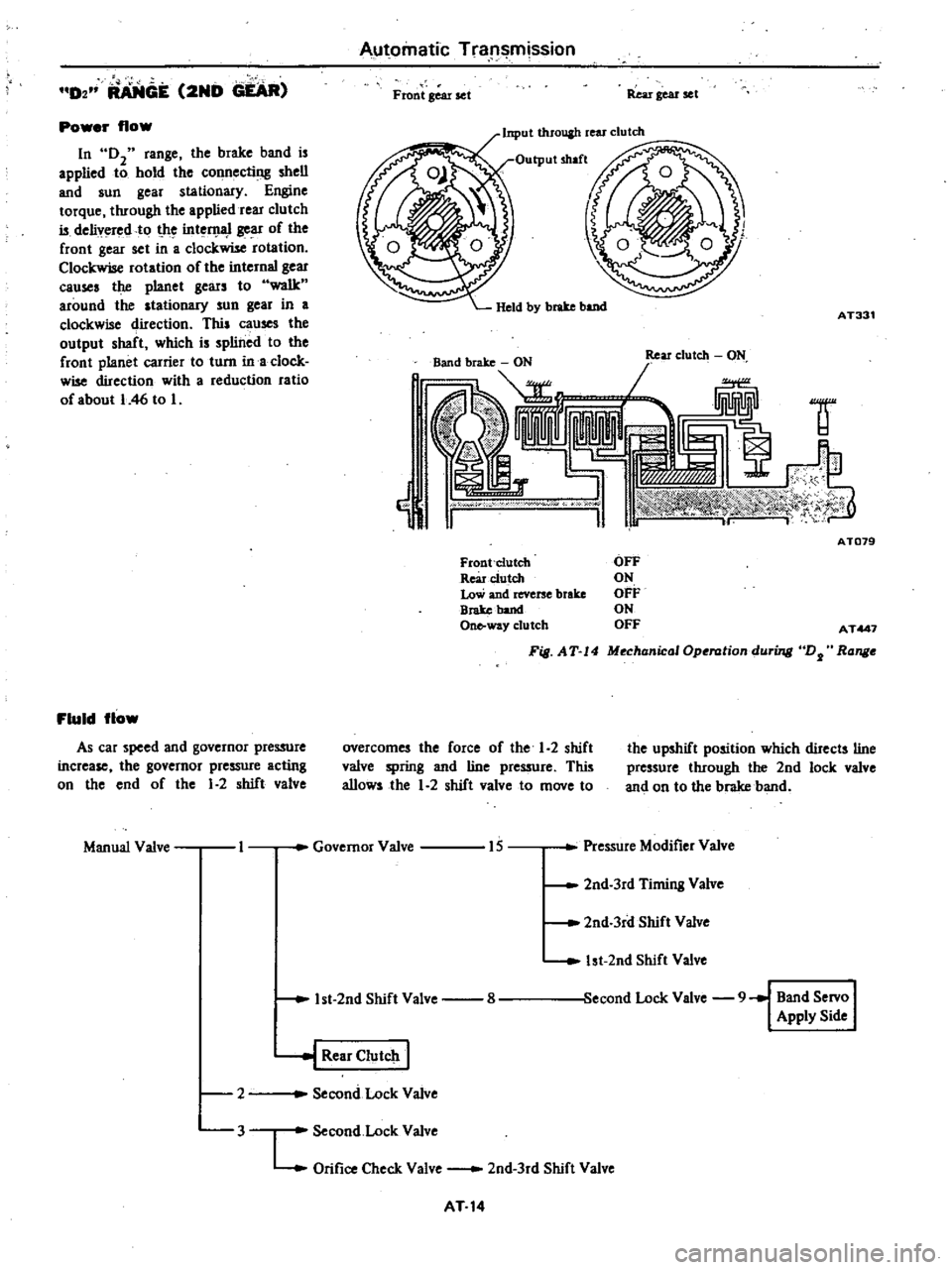

D2

RA

NGE

2ND

GEAR

Power

flow

In

02

range

the

brake

band

is

applied

to

hold

the

connecting

shell

and

sun

gear

stationary

Engine

torque

through

the

applied

rear

clutch

is

delivered

to

t

he

int

D

1l

1

gear

of

the

front

gear

set

in

a

clockwise

rotation

Clockwise

rotation

of

the

internal

gear

causes

the

planet

gears

to

walk

around

the

stationary

sun

gear

in

a

clockwise

direction

This

causes

the

output

shaft

which

is

splined

to

the

front

planet

carrier

to

turn

ina

clock

wise

direction

with

a

reduction

ratio

of

about

I

46

to

I

Fluid

flow

As

car

speed

and

governor

pressure

increase

the

governor

pressure

acting

on

the

end

of

the

1

2

shift

valve

Manual

Valve

I

Automatic

Tra

l

mission

Front

Bear

set

Rear

gear

set

Input

throuah

rear

clutch

AT331

1f

j

cW

oo

w

I

ATD79

Front

Clutch

Rearc1utch

Low

and

reverse

brake

Broke

band

One

way

clutch

OFF

ON

OFF

ON

OFF

AT447

F

S

AT

14

MechanicalOperation

during

DJ

Range

overcomes

the

force

of

the

1

2

shift

valve

spring

and

line

pressure

This

allows

the

1

2

shift

valve

to

move

to

the

upshift

position

which

directs

line

pressure

through

the

2nd

lock

valve

and

on

to

the

brake

band

Governor

Valve

15

Pressure

Modifier

Valve

2nd

3rd

Timing

Valve

2nd

3rd

Shift

Valve

1st

2nd

Shift

Valve

econd

Lock

Valve

9

Band

Servo

I

Apply

Side

1st

2nd

Shift

Valve

8

l

Rear

CIutclt

I

Second

Lock

Valve

2

3

Second

Lock

Valve

L

Orifice

Check

Valve

2nd

3rd

Shift

Valve

AT

14

Page 268 of 548

Automatic

Transmission

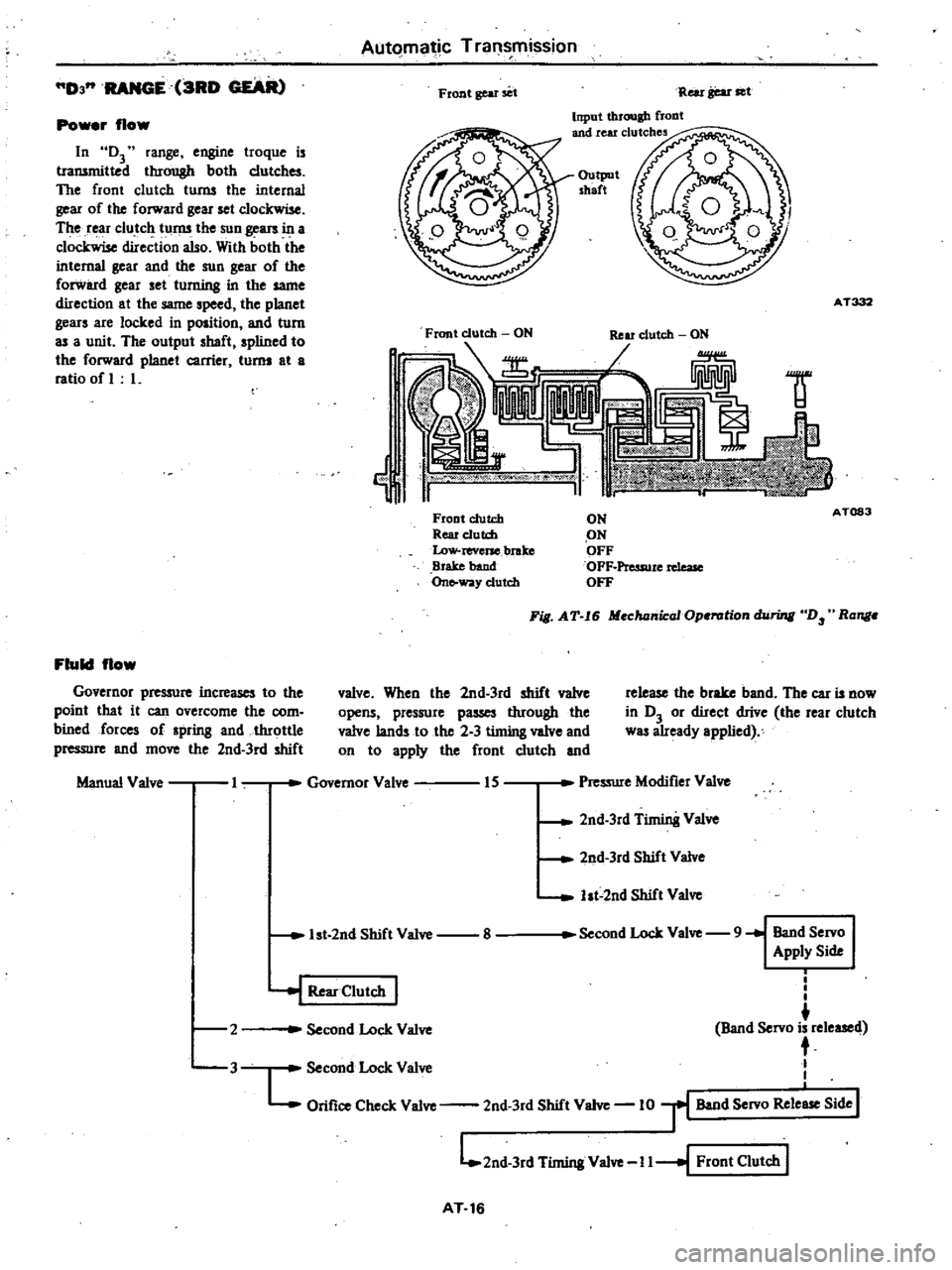

D3

RANGE

3RD

GEAR

Front

gear

set

Rei

r

gear

set

Input

through

flODt

and

rear

clutches

Power

flow

In

D3

range

engine

troque

is

transmitted

through

both

clutches

The

front

clutch

turns

the

internal

gear

of

the

forward

gear

set

clockwise

The

rear

clutch

turns

the

sun

gears

in

a

clockwise

direction

also

With

both

the

internal

gear

and

the

sun

gear

of

the

forward

gear

set

turning

in

the

same

direction

at

the

same

speed

the

planet

gears

are

locked

in

position

and

turn

as

a

unit

The

output

shaft

spIined

to

the

forward

planet

carrier

turns

at

a

ratio

of

L

Output

shaft

AT332

Front

clutch

ON

Ij

1f

Front

clutch

Rear

e1utd

Low

reverse

brake

Brake

band

On

way

clutch

ON

ON

OFF

OFF

Pressure

rdeaJe

OFF

A

T083

Fill

AT

I6

Mechanical

Operation

hiring

D

Ronge

Fluid

flow

Governor

pre

ure

increases

to

the

poinl

that

it

can

overcome

the

com

bined

forces

of

spring

and

throttle

pressure

and

move

the

2nd

3rd

shift

valve

When

the

2nd

3rd

shift

valve

opens

pressure

passes

through

the

valve

lands

to

the

2

3

timing

valve

and

on

to

apply

the

front

clutch

and

release

the

brake

band

The

car

is

now

in

D3

or

direct

drive

the

rear

clutch

was

already

applied

Manual

Valve

I

Governor

Valve

IS

Pressure

Modifier

Valve

2nd

3rd

Timin8

Valve

2nd

3rd

Shift

Valve

ht

2nd

Shift

Valve

1st

2nd

Shift

Valve

8

Second

Lock

Valve

9

Band

Servo

Apply

Side

2

i

I

I

Band

Servo

is

released

t

Second

Lock

Valve

L

Orifice

Check

Valve

2nd

3rd

Shift

Valve

10

r

Band

Servo

Rele

Side

I

L

2nd

3rd

Timing

Valve

I

I

I

Front

Clutch

I

J

Second

Lock

Valve

I

Rear

Clutch

I

3

AT

16

Page 278 of 548

4

Bolt

converter

to

drive

plate

Note

Align

chalk

mark

painted

a

cro5S

both

parts

during

disas

sembling

p

S

After

converter

is

installed

rotat

r

nkshait

veral

turns

and

check

to

be

sure

that

transmission

rotates

freely

without

binding

6

Pour

recommended

automatic

transmission

fluid

up

to

correct

level

through

oil

charge

pipe

7

Connect

manual

lever

to

shift

rod

Operation

should

be

carried

out

with

m

mual

and

selector

levers

in

N

8

Connect

inhibitor

switch

wires

Automatic

Transmission

NOte

a

Refer

to

page

AT40

for

Checking

and

Adjusting

Inhibitor

Switch

b

Inspect

end

edjust

switch

as

abo

whe

ever

it

has

to

be

removed

for

servi

e

9

Check

inhibitor

switch

for

op

eration

Starter

should

be

brought

into

op

eration

only

when

selector

lever

is

in

P

and

N

positions

it

should

not

be

started

when

lever

is

in

D

n

and

Ru

positions

Back

up

lamp

should

Iso

light

when

selector

lever

is

placed

in

R

position

10

Check

level

of

oil

in

transm

sion

For

detailed

procedure

see

page

AT39

AT

26

II

Move

selector

leve

through

all

positions

to

be

sure

that

transmission

operates

correctly

With

hand

brake

applied

rotate

engine

at

idling

Without

disturbing

the

above

seUlng

move

selector

lever

through

N

to

D

to

2

to

I

and

to

R

A

slight

shock

should

be

reU

by

handgripping

selector

each

time

transmission

is

shifted

Note

See

page

AT40

for

Checking

Engine

Idling

Revolution

12

Check

to

be

sure

that

line

pres

sure

is

correct

To

do

this

refer

to

page

AT

43

for

Line

Pressure

Test

13

Perform

stan

test

as

described

in

page

AT41

Page 285 of 548

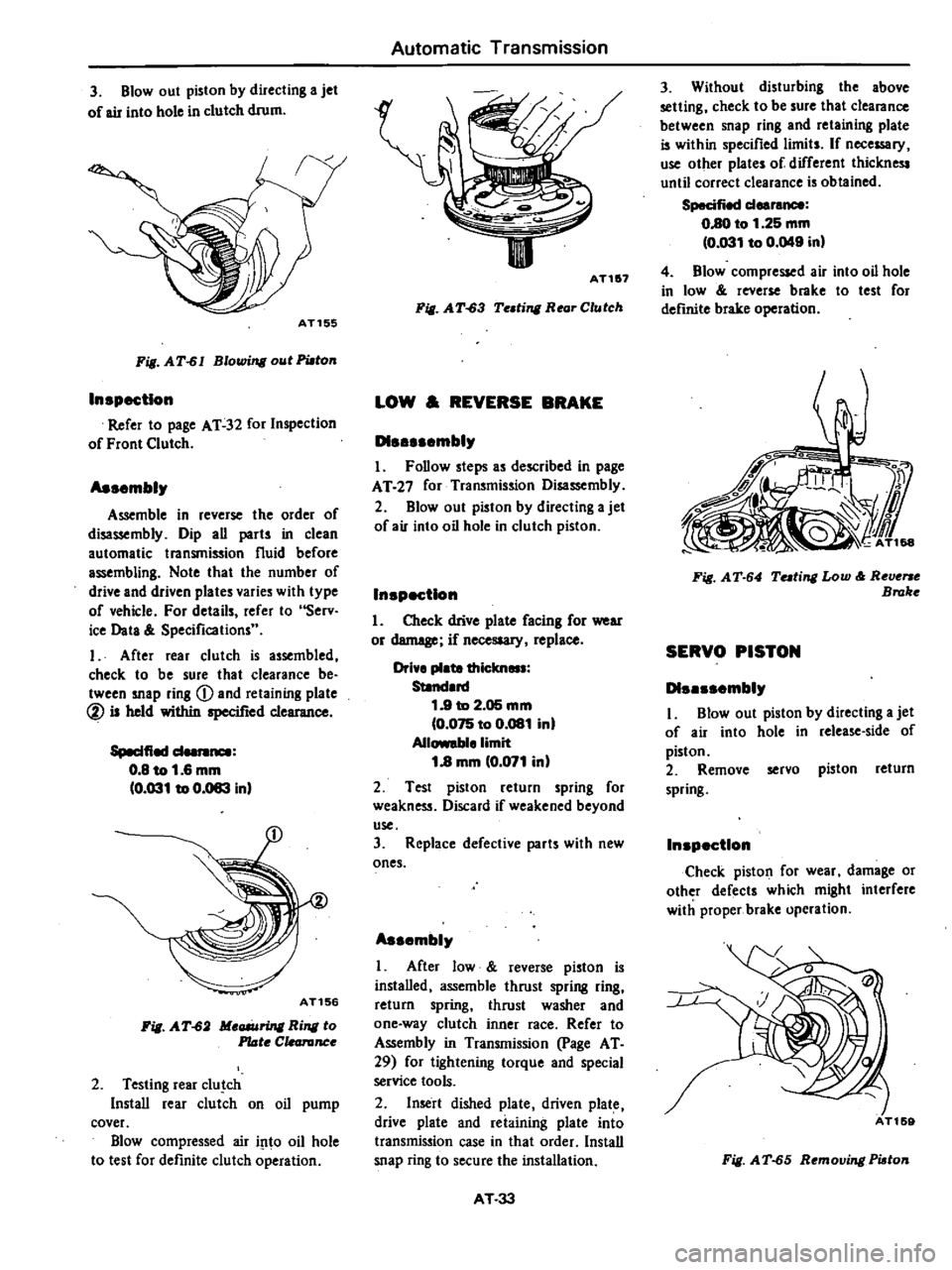

3

Blowout

piston

by

directing

a

jet

of

air

into

hole

in

clutch

drum

AT155

Fig

AT

61

Blowing

out

PWton

In

pectlon

Refer

to

page

AT

32

for

Inspection

of

Front

Clutch

As

mbly

Assemble

in

reverse

the

order

of

disassembly

Dip

all

parts

in

clean

automatic

transmission

fluid

before

assembling

Note

that

the

number

of

drive

and

driven

plates

varies

with

type

of

vehicle

For

details

refer

to

Serv

ice

Data

Specifications

I

After

rear

clutch

is

assembled

check

to

be

sure

that

clearance

be

tween

snap

ring

Q

and

retaining

plate

@

is

held

within

specified

clearance

Speelfied

d

0

8

to

1

6

mm

0

031

to

0

083

inl

AT156

Fig

AT

62

Meaiuring

Ring

to

Plate

C

canInce

2

Testing

rear

c1u

ch

Install

rear

clutch

on

oil

pump

cover

Blow

compressed

air

i

1to

oil

hole

to

test

for

definite

clutch

operation

Automatic

Transmission

II

AT1

7

Fill

A

T

63

Te

ting

Rear

Clutch

LOW

REVERSE

BRAKE

D1

mbly

I

Follow

steps

as

described

in

page

AT

27

for

Transmission

Disassembly

2

Blowout

piston

by

directing

a

jet

of

air

into

oil

hole

in

clutch

piston

In

pectlon

1

Check

drive

plate

facing

for

wear

or

demege

if

necesaary

replace

Drive

plate

thielm

Standard

1

9

to

2

05

mm

0

075

to

0

081

in

Allowable

limit

1

8

mm

0

071

inl

2

Test

piston

return

spring

for

weakness

Discard

if

weakened

beyond

use

3

Replace

defective

parts

with

new

ones

As

mbly

I

After

low

reverse

piston

is

installed

assemble

thrust

spring

ring

return

spring

thrust

washer

and

one

way

clutch

inner

race

Refer

to

Assembly

in

Transmission

page

AT

29

for

tightening

torque

and

special

service

tools

2

Insert

dished

plate

driven

plate

drive

plate

and

reiaining

plate

into

transmission

case

in

that

order

Install

snap

ring

to

secure

the

installation

AT

33

3

Without

disturbing

the

above

setting

check

to

be

sure

that

clearance

between

snap

ring

and

retaining

plate

is

within

specified

limits

If

nece

ry

use

other

plates

of

different

thickness

until

correct

clearance

is

obtained

Specified

deereM8

0

80

to

1

25

mm

0

031

to

0

049

inl

4

Blow

compressed

air

into

oil

hole

in

low

roverse

brake

to

test

for

deftnite

brake

operation

Fill

AT

64

Tuting

Low

Reverse

Broke

SERVO

PISTON

D1

mbly

I

Blowout

piston

by

dilecting

a

jet

of

air

into

hole

in

release

side

of

piston

2

Remove

servo

piston

return

spring

In

p

ctlon

Check

piston

for

wear

damage

or

other

defects

which

might

interfere

with

proper

brake

opcration

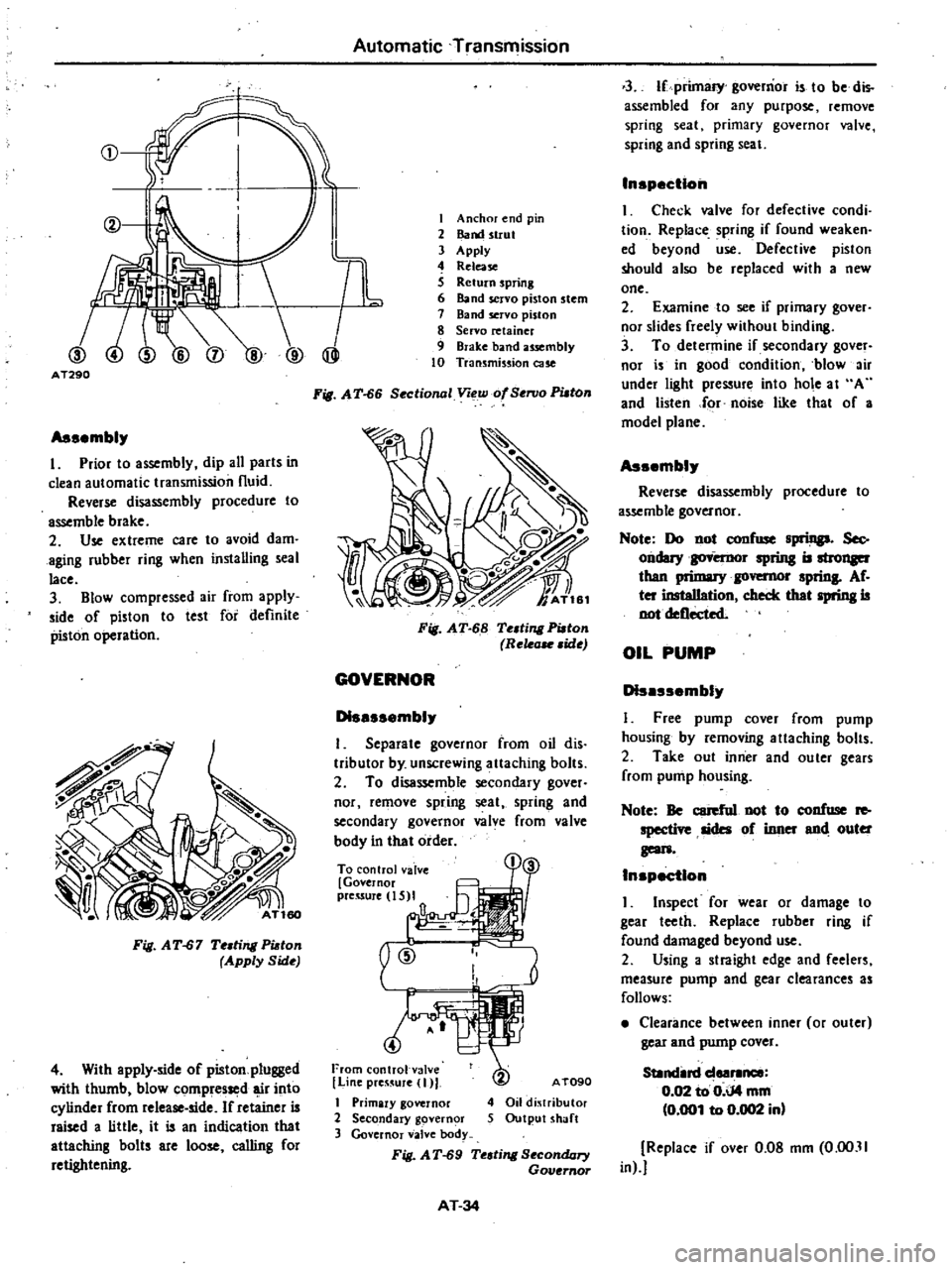

Fig

AT

65

Removing

Piaton

Page 286 of 548

CD

@

I

I

TL

@

@

AT290

Assembl

I

Prior

to

assembly

dip

all

parts

in

clean

automatic

transmission

fluid

Reverse

disassembly

procedure

to

assemble

brake

2

Use

extreme

care

to

avoid

dam

aging

rubber

ring

when

installing

seal

lace

3

Blow

compressed

air

from

apply

side

of

piston

to

test

for

definite

piston

operation

Fig

AT

67

Te

ling

Pi

ton

Apply

Side

4

With

apply

side

of

piston

plugged

with

thumb

blow

compressed

r

into

cylinder

from

release

side

If

retainer

is

raised

a

little

it

is

an

indication

that

attaching

bolts

are

loose

calling

for

retightening

Automatic

Transmission

I

Anchor

end

pin

2

Band

strut

3

Apply

4

Release

S

Return

spring

6

Band

servo

piston

stem

7

Band

servo

piston

8

Servo

retainer

9

Brake

band

usembly

10

Transmission

cue

Fig

A

T

66

Sectional

Voew

of

SenJo

PUlOn

Fig

AT

68

Te

ting

Pi

ton

Rele

ide

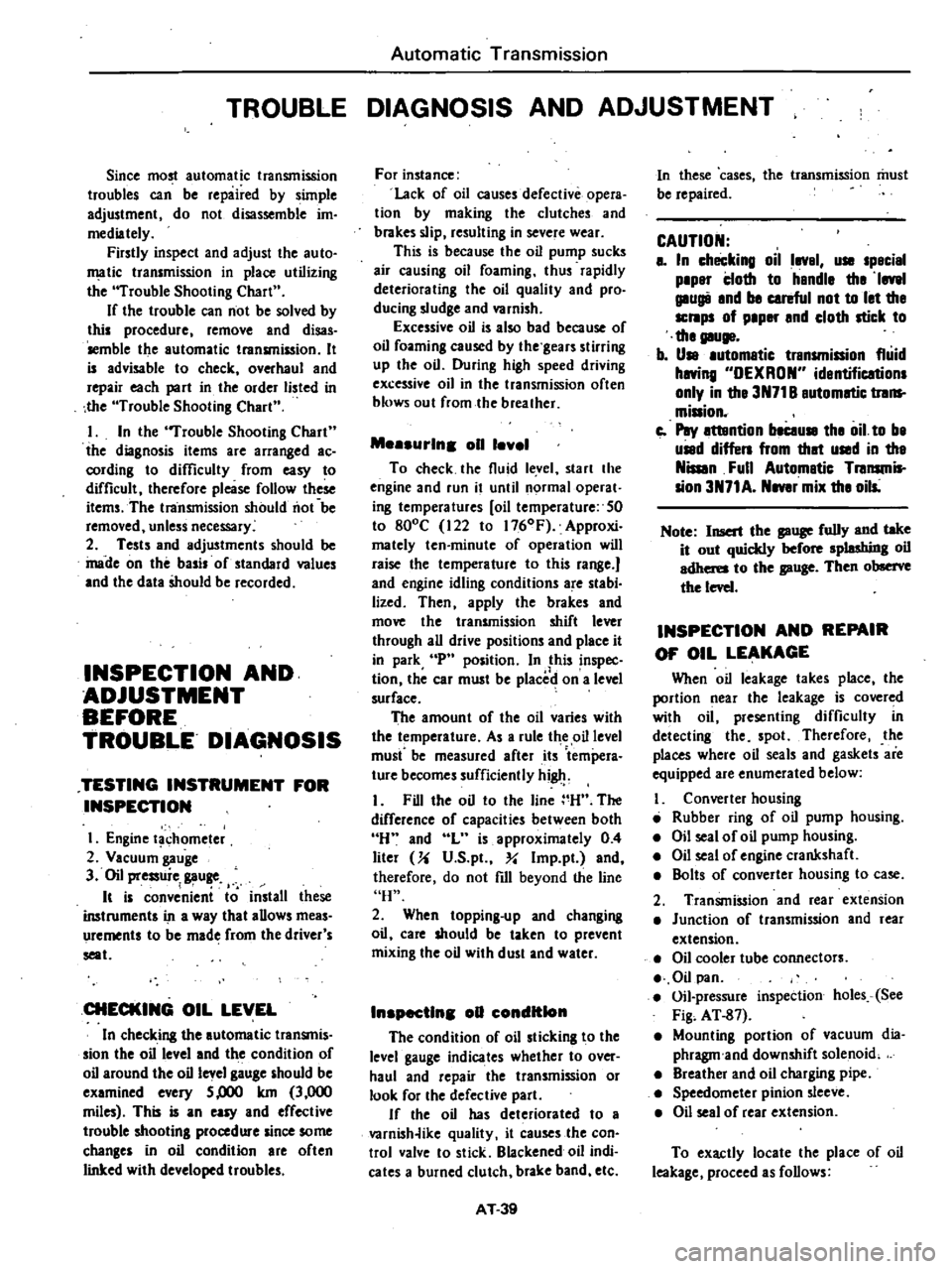

GOVERNOR

D1sessembl

I

Separate

governor

from

oil

dis

tributor

by

unscrewing

attaching

bolts

2

To

disassemble

secondary

gover

nor

remove

spring

seat

spring

and

secondary

governor

valve

from

valve

body

in

that

order

To

control

valve

Governor

preuure

IS

I

a

@

From

control

val

e

I

Line

preS

UJe

I

I

Primary

governor

2

Secondary

govern

r

3

Governor

valve

body

Fig

AT

69

Te

ling

SecondQry

Governor

AT090

4

Oil

dj

tributor

5

Output

shaft

AT

34

3

If

primary

governor

is

to

be

dis

assembled

for

any

purpose

remove

spring

seat

primary

governor

valve

spring

and

spring

seal

Inspection

I

Check

valve

for

defective

condi

tion

Replace

spring

if

found

weaken

ed

beyond

use

Defective

piston

should

also

be

replaced

with

a

new

one

2

Examine

to

see

if

primary

gover

nor

slides

freely

without

binding

3

To

determine

if

secondary

gover

nor

is

in

good

condition

blow

ir

under

light

pressure

into

hole

at

A

and

listen

for

noise

like

thaI

of

a

model

plane

Assembl

Reverse

disassembly

procedure

to

assemble

governor

Note

Do

not

confuse

spriDp

Sec

ondary

spring

is

than

1

governor

sprinS

Af

ter

insteIIation

check

thet

spring

is

not

deflected

OIL

PUMP

D1sessembl

I

Free

pump

cover

from

pump

housing

by

removing

allaching

bolts

2

Take

out

inner

and

ouler

gears

from

pump

housing

Note

Be

cerefnl

not

to

confuse

Ie

specti

sides

of

inner

end

outer

geon

Inspection

I

Inspect

for

wear

or

damage

to

gear

teeth

Replace

rub

bel

ring

if

found

damaged

beyond

use

2

Using

a

straight

edge

and

feelers

measure

pump

and

gear

clearances

as

follows

Clearance

between

inner

or

outer

gear

and

pump

cover

SUndin

deer1lnee

0

02

to

0

iJ4

mm

0

001

to

0

002

in

Replace

if

over

0

08

mm

0

00

11

in

Page 291 of 548

Automatic

Transmission

TROUBLE

DIAGNOSIS

AND

ADJUSTMENT

Since

mo

automatic

transmission

troubles

can

be

repaired

by

simple

adjustment

do

not

disassemble

im

media

tely

Firstly

inspect

and

adjust

the

auto

D1

3tic

transmission

in

place

utilizing

the

Trouble

Shooting

Chart

If

the

trouble

can

not

be

solved

by

this

procedure

remove

and

disas

semble

the

automatic

tlllnsmission

It

is

advisable

to

check

overhaul

and

repair

each

part

in

the

order

listed

in

the

Trouble

Shooting

Chart

In

the

Trouble

Shooting

Chart

the

diagnosis

items

are

arranged

ac

cording

to

difficulty

from

easy

to

difficult

therefore

please

follow

these

items

The

tlllnsmission

should

riot

be

removed

unless

necessary

2

Tests

and

adjustments

should

be

inade

on

the

basil

of

standard

values

and

the

data

Should

be

recorded

INSPECTION

AND

ADJUSTMENT

BEFORE

TROUBLE

DIAGNOSIS

TESTING

INSTRUMENT

FOR

INSPECTION

I

Engine

t

chometer

2

Vacuum

gauge

3

Oil

pressure

gauge

It

is

convenieni

to

install

these

instruments

in

a

way

that

allows

meas

urements

to

be

made

from

the

driver

s

seat

CHECKING

OIL

LEVEL

In

checkIng

the

automatic

transmis

sion

the

oil

level

and

the

condition

of

oil

around

the

oil

level

gauge

should

be

examined

every

S

ooo

Ion

3

000

miles

This

is

an

easy

and

effective

trouble

shooting

procedure

since

some

changes

in

oil

condition

are

often

linked

with

developed

troubles

For

instance

Lack

of

oil

causes

defective

opera

tion

by

making

the

clutches

and

brakes

slip

resulting

in

severe

wear

This

is

because

the

oil

pump

sucks

air

causing

oil

foaming

thus

rapidly

deteriorating

the

oil

quality

and

pro

ducing

sludge

and

varnish

Excessive

oil

is

also

bad

because

of

oil

foaming

caused

by

the

gears

stirring

up

the

oil

During

high

speed

driving

excessive

oil

in

the

transmission

often

hlows

out

from

the

brealher

Me

urlns

011

level

To

check

the

nuid

leyel

sian

Ihe

engine

and

run

it

until

normal

operat

ing

temperatures

oil

temperature

SO

to

800C

122

to

1160F

Approxi

mately

ten

minute

of

operation

will

raise

the

temperature

to

this

range

and

engine

idling

conditions

are

stabi

lized

Then

apply

the

brakes

and

move

the

transmission

shift

lever

through

aU

drive

positions

and

place

it

in

park

P

position

In

his

inspec

tion

the

car

must

be

placc

d

on

a

level

surface

The

amount

of

the

oil

varies

with

the

temperature

As

a

rule

the

oil

level

must

be

measured

after

its

tempera

ture

becomes

sufficiently

high

I

Fill

the

oil

to

the

line

H

The

difference

of

capacities

between

both

H

and

L

is

approximately

0

4

liter

J

U

S

pt

Y

Imp

pt

and

therefore

do

not

fill

beyond

the

line

H

2

When

topping

up

and

changing

oil

care

should

be

taken

to

prevent

mixing

the

oil

with

dusl

and

water

In

pectlns

oU

condition

The

condition

of

oil

sticking

to

the

level

gauge

indicates

whether

to

OVOl

haul

and

repair

the

transmission

or

luok

for

Ihe

defective

part

If

the

oil

has

deteriorated

to

a

varnish

ike

quality

it

causes

the

con

trol

valve

to

stick

Blackened

oil

indi

cates

a

burned

clutch

brake

band

etc

AT

39

In

these

cases

the

transmission

must

be

repaired

CAUTION

I

In

checking

oil

IlVal

use

special

piper

Cloth

tohandla

the

18V81

llIugi

Ind

be

careful

not

to

let

the

scraps

of

paper

end

cloth

stick

to

the

IlIUp

b

U

lutomatic

transmission

fluid

having

OEXRON

ida

ons

only

in

the

3N71

B

eutomatic

trans

mission

c

Pay

IttBntion

blcau

the

oil

to

be

used

differs

from

that

used

in

the

Nissen

Full

Autometic

TllInsmis

sion

3N71A

N8V8r

mill

thl

oils

Note

Insert

the

gauge

fully

and

take

it

out

quickly

before

splesbing

oil

edheres

to

the

gauge

Then

observe

the

level

INSPECTION

AND

REPAIR

OF

OIL

LEAKAGE

When

oil

leakage

takes

place

the

portion

near

the

leakage

is

covered

with

oil

presenting

difficulty

in

detecting

the

spot

Therefore

the

places

where

oil

seals

and

gaskets

are

equipped

are

enumerated

below

Converter

housing

Rubber

ring

of

oil

pump

housing

Oil

seal

of

oil

pump

housing

Oil

seal

of

engine

crankshaft

Bolts

of

converter

housing

to

case

2

Transmission

and

rear

extension

Junction

of

transmission

and

rear

extension

Oil

cooler

tube

connectors

Oil

pan

Oil

pressure

inspection

holes

See

Fig

AT

81

Mounting

portion

of

vacuum

dia

phragm

and

downshift

solenoid

Breather

and

oil

charging

pipe

Speedometer

pinion

sleeve

Oil

seal

of

rear

extension

To

exactly

locate

Ihe

place

of

oil

leakage

proceed

as

follows

Page 353 of 548

DATSUN

2

0

Model

83

0

Series

SECTIONBR

BRAKE

SYSTEM

CONTENTS

ADJUSTMENT

BRAKE

PEDAL

FRONT

DISC

BRAKE

REAR

BRAKE

HAND

BRAKE

BLEEDING

HYDRAULIC

SYSTEM

SERVICE

BRAKE

BRAKE

PEDAL

MASTER

CYLINDER

BRAKE

FLUID

LEVEL

GAUGE

BRAKE

LINE

NP

VALVE

FRONT

DISC

BRAKE

BR

2

BR

2

BR

2

BR

2

BR

2

BR

2

BR

3

BR

3

BR

4

BR

5

BR

5

BR

6

BR

6

ROTOR

REAR

BRAKE

BRAKE

BOOSTER

HAND

BRAKE

SERVICE

DATA

AND

SPECIFICATIONS

GENERAL

SPECIFICATIONS

INSPECTION

AND

ADJUSTMENT

TIGHTENING

TORQUE

TROUBLE

DIAGNOSES

AND

CORRECTIONS

SPECIAL

SERVICE

TOOL

BR

9

BR

l0

BR

12

BR

14

BR

16

BR

16

BR

17

BR

18

8R

19

8R

22

Page 354 of 548

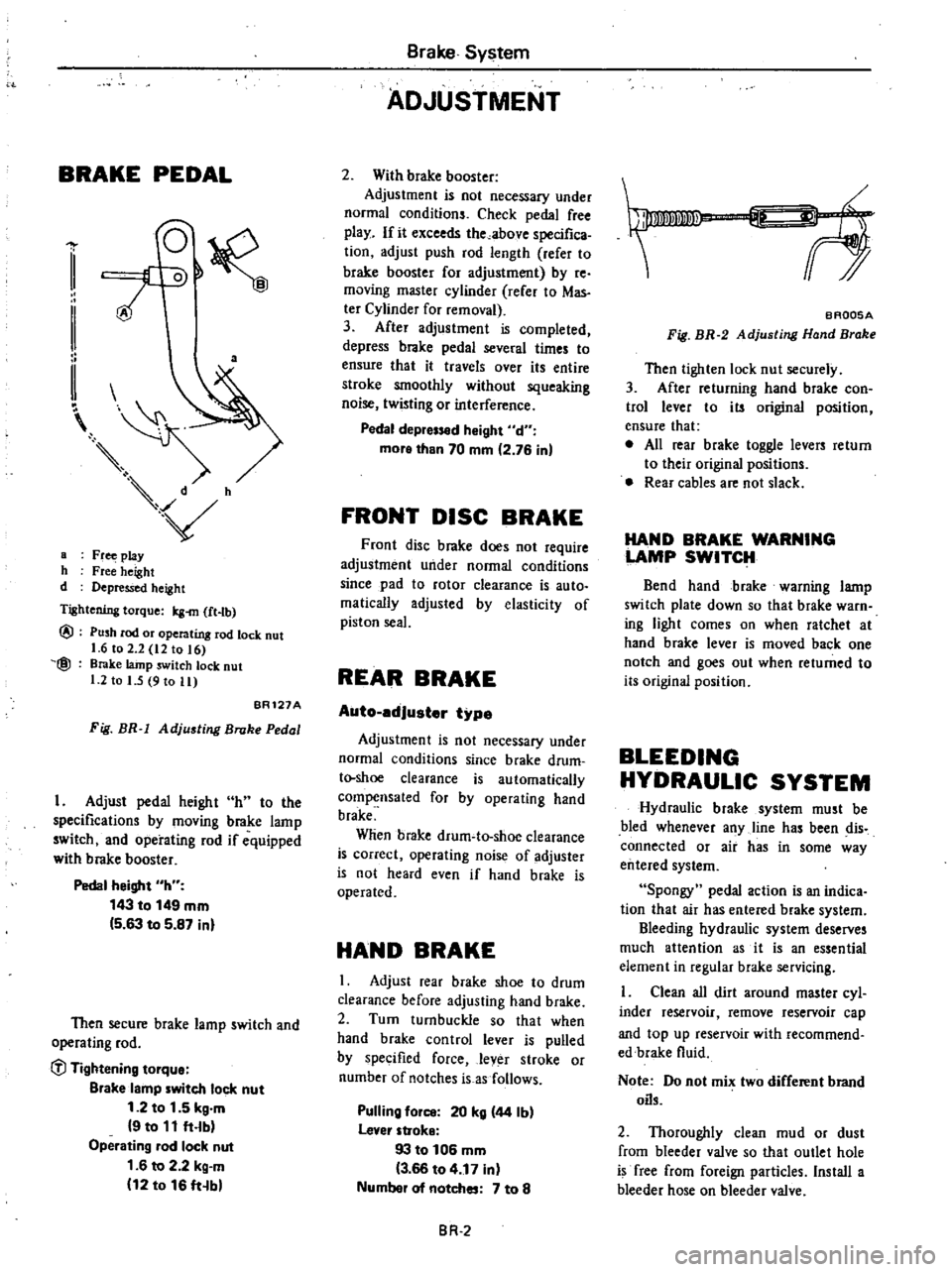

BRAKE

PEDAL

a

a

Fr

play

h

Free

height

d

Depressed

height

Tightening

torque

Icg

m

ft

tb

@

@

Push

rod

or

operating

rod

lock

nut

1

6

to

2

2

12

to

16

Brake

lainp

switch

lock

nut

1

2

to

I

5

9

to

11

BR121A

Fig

BR

1

Adjusting

Broke

Pedal

I

Adjust

pedal

height

h

to

the

specifications

by

moving

brake

lamp

switch

and

operating

rod

if

equipped

with

brake

booster

Pedal

height

h

143

to

149

mm

5

63

to

5

87

inl

Then

secure

brake

lamp

switch

and

operating

rod

C

l

Tightening

tOlque

Blake

lamp

witch

lock

nut

1

2

to

1

5

kg

m

9

to

11

ft

lb

Operating

lad

lock

nut

1

6

to

2

2

kg

m

12

to

16

ft

b

Brake

System

ADJUSTMENT

2

With

brake

booster

Adjustment

is

not

necessary

under

normal

conditions

Check

pedal

free

play

If

it

exceeds

the

above

specifica

tion

adjust

push

rod

length

refer

to

brake

booster

for

adjustment

by

re

moving

master

cylinder

rerer

to

Mas

ter

Cylinder

for

removal

3

After

adjustment

is

completed

depress

brake

pedal

several

times

to

ensure

that

it

travels

over

its

entire

stroke

smoothly

without

squeaking

noise

twisting

or

interference

Pedal

depr

d

Might

d

more

than

70

mm

2

76

in

FRONT

DISC

BRAKE

Front

disc

brake

does

not

require

adjustment

under

normal

conditions

since

pad

to

rotor

clearance

is

auto

malically

adjusted

by

elasticity

of

piston

seal

REAR

BRAKE

Auto

edJuster

type

Adjustment

is

not

necessary

under

normal

conditions

since

brake

drum

t

shoe

clearance

is

automatically

compensated

for

by

operating

hand

brake

Wlien

brake

drum

to

shoe

clearance

is

correct

operating

noise

of

adjuster

is

not

heard

even

if

hand

brake

is

operated

HAND

BRAKE

I

Adjust

rear

brake

shoe

to

drum

clearance

before

adjusting

hand

brake

2

Turn

turnbuckle

so

that

when

hand

brake

control

lever

is

pulled

by

specified

force

lever

stroke

or

number

of

notches

is

as

follows

Pulling

fOil

20

kg

44

Ib

lever

stroke

93

to

106

mm

3

66

to

4

17

in

Numbel

of

notches

7

to

8

BR

2

f

BAQ05A

Fig

BR

2

Adjusting

Hand

Brake

Then

tighten

lock

nut

securely

3

After

returning

hand

brake

con

trol

lever

to

its

original

position

ensure

that

e

All

rear

brake

toggle

levers

return

to

their

original

positions

Rear

cables

are

not

slack

HAND

BRAKE

WARNING

LAMP

SWITCH

Bend

hand

brake

warning

lamp

switch

plate

down

so

that

brake

warn

ing

light

comes

on

when

ratchet

at

hand

brake

lever

is

moved

back

one

notch

and

goes

out

when

returned

to

its

original

position

BLEEDING

HYDRAULIC

SYSTEM

Hydraulic

brake

system

must

be

bled

whenever

any

line

has

been

dis

connected

or

air

has

in

some

way

entered

system

Spongy

pedal

action

is

an

indica

tion

that

air

has

entered

brake

system

Bleeding

hydraulic

system

deserves

much

attention

as

it

is

an

essential

element

in

regular

brake

servicing

Clean

all

dirt

around

master

cyl

inder

reservoir

remove

reservoir

cap

and

top

up

reservoir

with

recommend

edbrake

fluid

Note

Do

not

mix

two

different

brand

oils

2

Thoroughly

clean

mud

or

dust

from

bleeder

valve

so

that

outlet

hole

is

free

from

foreign

particles

Install

a

bleeder

hose

on

bleeder

valve

Page 355 of 548

L

@

fl

JJ

l

f

m

ff

v

1

II

2

I

I

II

B

s1

r

Dip

other

end

of

hose

into

brake

fluid

bled

in

a

container

3

Pepress

brake

pedal

two

or

three

times

and

then

keep

pedal

fully

de

pressed

4

With

brake

pedal

fully

depressed

open

bleeder

valve

to

exhaust

air

Note

a

Carefully

monitor

brake

fluid

level

at

master

cylinder

during

bleeding

operation

BRAKE

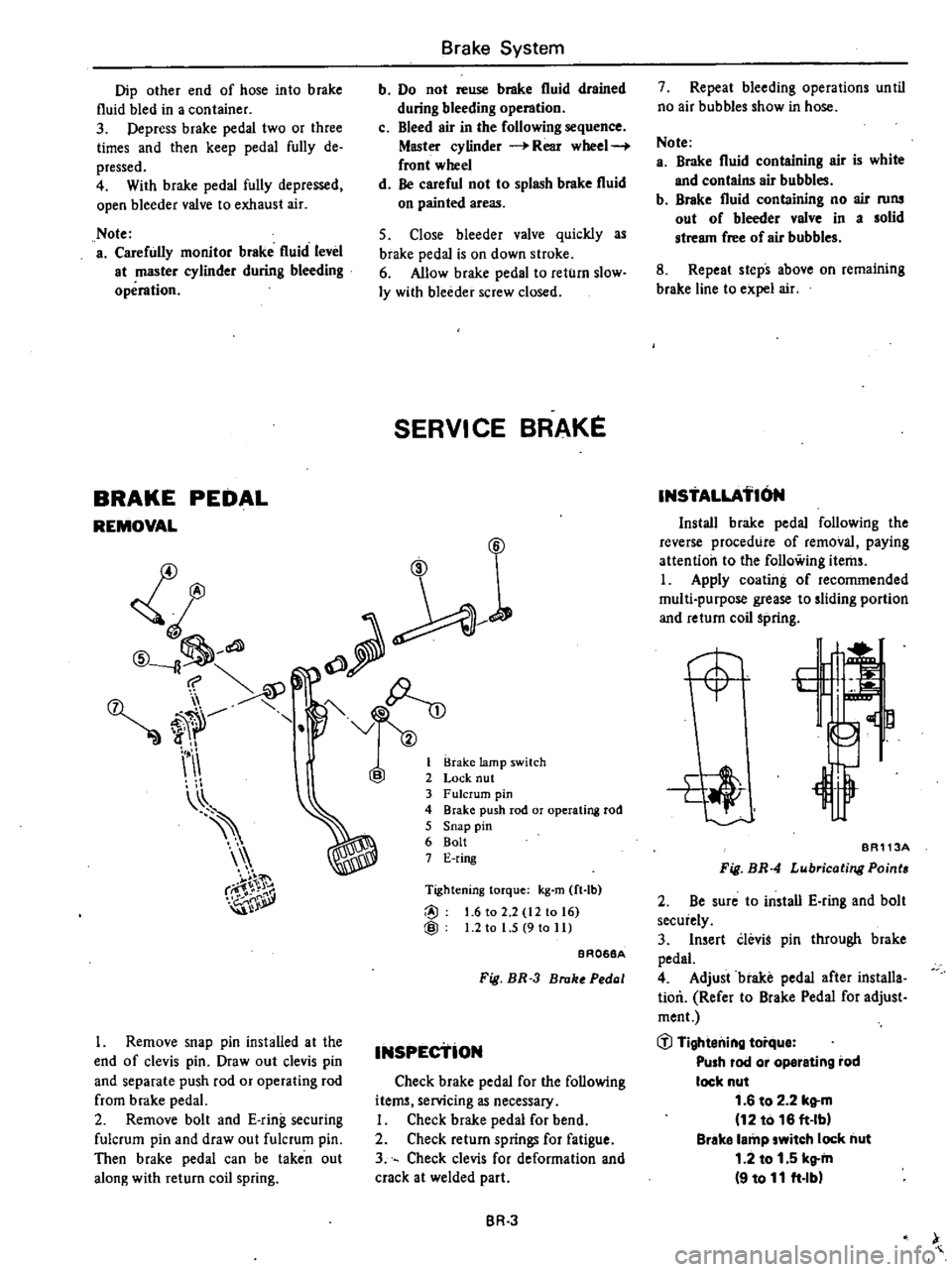

PEDAL

REMOVAL

I

Remove

snap

pin

installed

at

the

end

of

clevis

pin

Draw

out

clevis

pin

and

separate

push

rod

or

operating

rod

from

brake

pedal

2

Remove

bolt

and

E

ring

securing

fulcrum

pin

and

draw

out

fulcrum

pin

Then

brake

pedal

can

be

taken

out

along

with

return

coil

spring

Brake

System

b

Do

not

reuse

brake

fluid

drained

during

bleeding

operation

c

Bleed

air

in

the

following

sequence

Master

cylinder

Rear

wheel

front

wheel

d

Be

careful

not

to

splash

brake

fluid

on

painted

areas

5

Close

bleeder

valve

quickly

as

brake

pedal

is

on

down

stroke

6

Allow

brake

pedal

to

return

slow

ly

with

bleeder

screw

closed

SERVI

CE

BRAKE

fJ

Brake

lamp

switch

Lock

nut

Fulcrum

pin

Brake

push

rod

or

operating

rod

Snap

pin

Bolt

E

ring

Tightening

torque

kg

m

ft

Ib

@

1

6

to

2

2

12

10

16

@

1

2

to

l

S

9

to

II

BROS8A

Fig

BR

3

Broke

Pedal

INSPEctioN

Check

brake

pedal

for

the

following

items

servicing

as

necessary

I

Check

brake

pedal

for

bend

2

Check

return

springs

for

fatigue

3

Check

clevis

for

deformation

and

crack

at

welded

part

BR

3

7

Repeat

bleeding

operations

until

no

air

bubbles

show

in

hose

Note

a

Brake

fluid

containing

air

is

white

and

contalns

air

bubbles

b

Brake

fluid

containing

no

air

rons

out

of

bleeder

valve

in

a

solid

stream

free

of

air

bubbles

8

Repeat

steps

above

on

remaining

brake

line

to

expel

air

INSTALLATION

Install

brake

pedal

following

the

reverse

procedure

of

removal

paying

attention

to

the

following

items

I

Apply

coating

of

recommended

multi

purpose

grease

to

sliding

portion

and

return

coil

spring

BA113A

Fit

BR

4

Lubricating

Point

2

Be

sure

to

install

E

ring

and

bolt

securely

3

Insert

CleviS

pin

through

brake

pedal

4

Adjust

brake

pedal

after

installa

tion

Refer

to

Blake

Pedal

for

adjust

ment

j

Tightening

torque

Push

rod

or

op8leting

rod

lock

nut

1

6

to

2

2

kltm

12

to

16

ft

Ibl

Brake

lamp

switch

lock

nut

1

2

to

1

5

kltin

9

to

11

ft

lb

Page 357 of 548

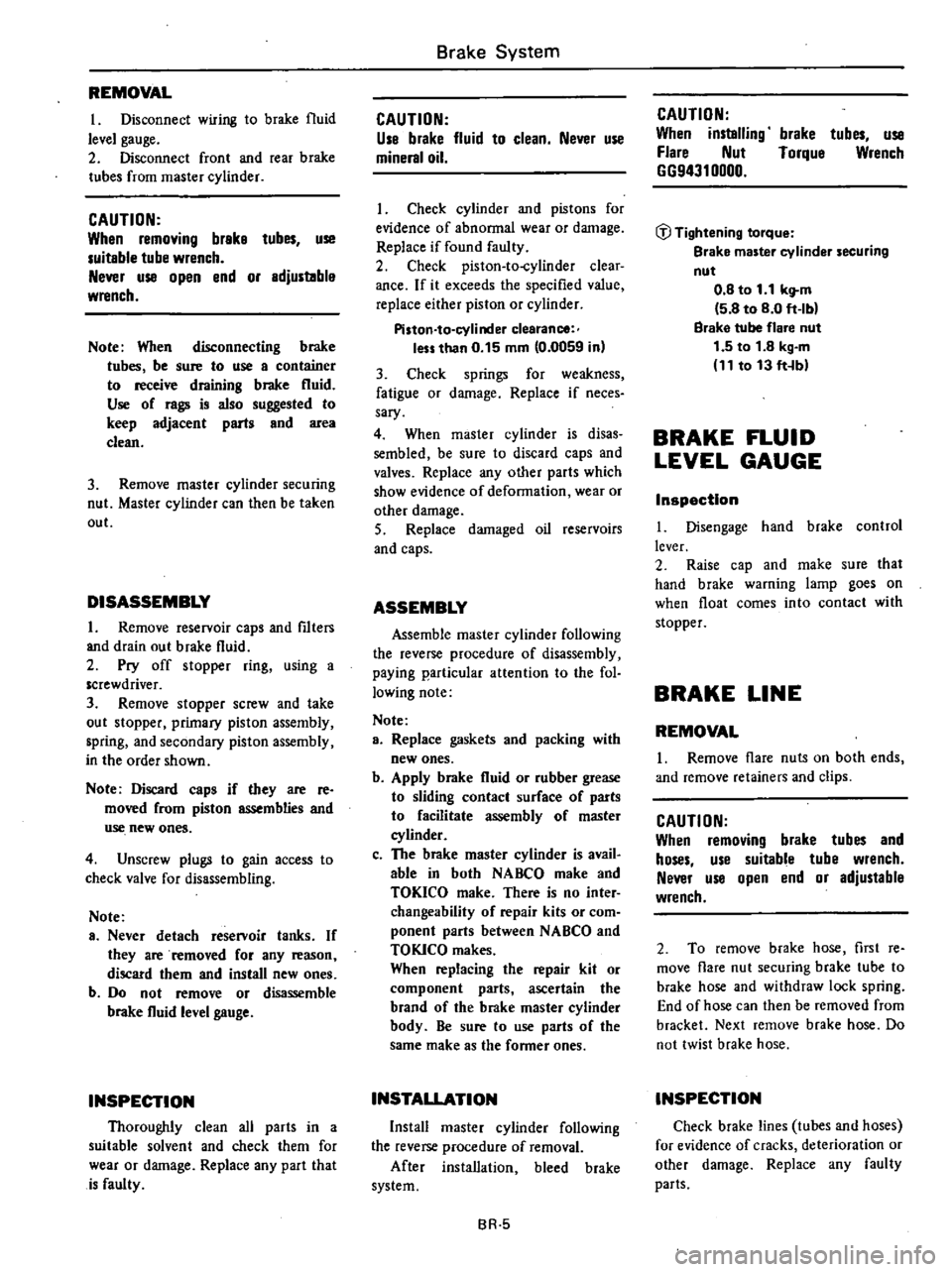

REMOVAL

I

Disconnect

wiring

to

brake

fluid

level

gauge

2

Disconnect

front

and

rear

brake

tubes

from

master

cylinder

CAUTION

When

removing

brake

tubes

use

suitable

tube

wrench

Never

use

open

end

or

edjustllble

wrench

Note

When

disconnecting

brake

tubes

be

sure

to

use

a

container

to

receive

draining

brake

fluid

Use

of

raga

is

also

suggested

to

keep

adjacent

perts

and

area

clean

3

Remove

master

cylinder

securing

nut

Master

cylinder

can

then

be

taken

out

DISASSEMBLY

1

Remove

reservoir

caps

and

filtern

and

drain

out

brake

fluid

2

Pry

off

stopper

ring

using

a

screwdriver

3

Remove

stopper

screw

and

take

out

stopper

primary

piston

assembly

spring

and

secondary

piston

assembly

in

the

order

shown

Note

Discard

caps

if

they

are

reo

moved

from

piston

assemblies

and

use

new

ones

4

Unscrew

pluga

to

gain

access

to

check

valve

for

disassembling

Note

a

Never

detach

reservoir

tanks

If

they

are

removed

for

any

reason

discard

them

and

install

new

ones

b

Do

not

remove

or

disassemble

brake

fluid

level

gauge

INSPECTION

Thoroughly

clean

all

parts

in

a

suitable

solvent

and

check

them

for

wear

or

damage

Replace

any

part

that

is

faulty

Brake

System

CAUTION

Use

brake

fluid

to

clean

Never

use

mineral

oil

I

Check

cylinder

and

pistons

for

evidence

of

abnonnal

wear

or

damage

Replace

if

found

faulty

2

Check

piston

to

cylinder

clear

ance

If

it

exceeds

the

specified

value

replace

either

piston

or

cylinder

Piston

to

cylinder

clearance

less

than

0

15

mm

0

0059

in

3

Check

springs

for

weakness

fatigue

or

damage

Replace

if

neces

sary

4

When

master

cylinder

is

disas

sembled

be

sure

to

discard

caps

and

valves

Replace

any

other

parts

which

show

evidence

of

deformation

wear

or

other

damage

S

Replace

damaged

oil

reservoirs

and

caps

ASSEMBLY

Assemble

master

cylinder

following

the

reverse

procedure

of

disassembly

paying

particular

attention

to

the

fol

lowing

note

Note

a

Replace

gaskets

and

packing

with

new

ones

b

Apply

brake

fluid

or

rubber

grease

to

sliding

contact

surface

of

parts

to

facilitate

assembly

of

master

cylinder

c

The

brake

master

cylinder

is

avail

able

in

both

NABCO

make

and

TOKICO

make

There

is

no

inter

changeability

of

repair

kits

or

com

ponent

parts

between

NABCO

and

TOKlCO

makes

When

replacing

the

repair

kit

or

component

parts

ascertain

the

brand

of

the

brake

master

cylinder

body

Be

sure

to

use

parts

of

the

same

make

as

the

fonner

ones

INSTALLATION

Install

master

cylinder

following

the

reverse

procedure

of

removal

After

installation

bleed

brake

system

BR

5

CAUTION

When

installing

Flare

Nut

6694310000

brake

tubes

use

Torque

Wrench

CiJ

Tightening

torque

Brake

master

cylinder

securing

nut

0

8

to

t

1

kg

m

5

8

to

8

0

ft

lb

Brake

tube

flare

nut

1

5

to

1

8

kg

m

11

to

13

ft

b

BRAKE

FLUID

LEVEL

GAUGE

Inspection

I

Disengage

hand

brake

control

lever

2

Raise

cap

and

make

sure

that

hand

brake

warning

lamp

goes

on

when

float

comes

into

contact

with

stopper

BRAKE

LINE

REMOVAL

I

Remove

flare

nuts

on

both

ends

and

remove

retainers

and

clips

CAUTION

When

removing

brake

tubes

and

hoses

use

suitable

tube

wrench

Never

use

open

end

or

adjustable

wrench

2

To

remove

brake

hose

first

re

move

flare

nut

securing

brake

tube

to

brake

hose

and

withdraw

lock

spring

End

of

hose

can

then

be

removed

from

bracket

Next

remuve

brake

hose

Do

not

twist

brake

hose

INSPECTION

Check

brake

lines

tubes

and

hoses

for

evidence

of

cracks

deterioration

or

other

damage

Replace

any

faulty

parts