engine DATSUN 210 1979 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 371 of 548

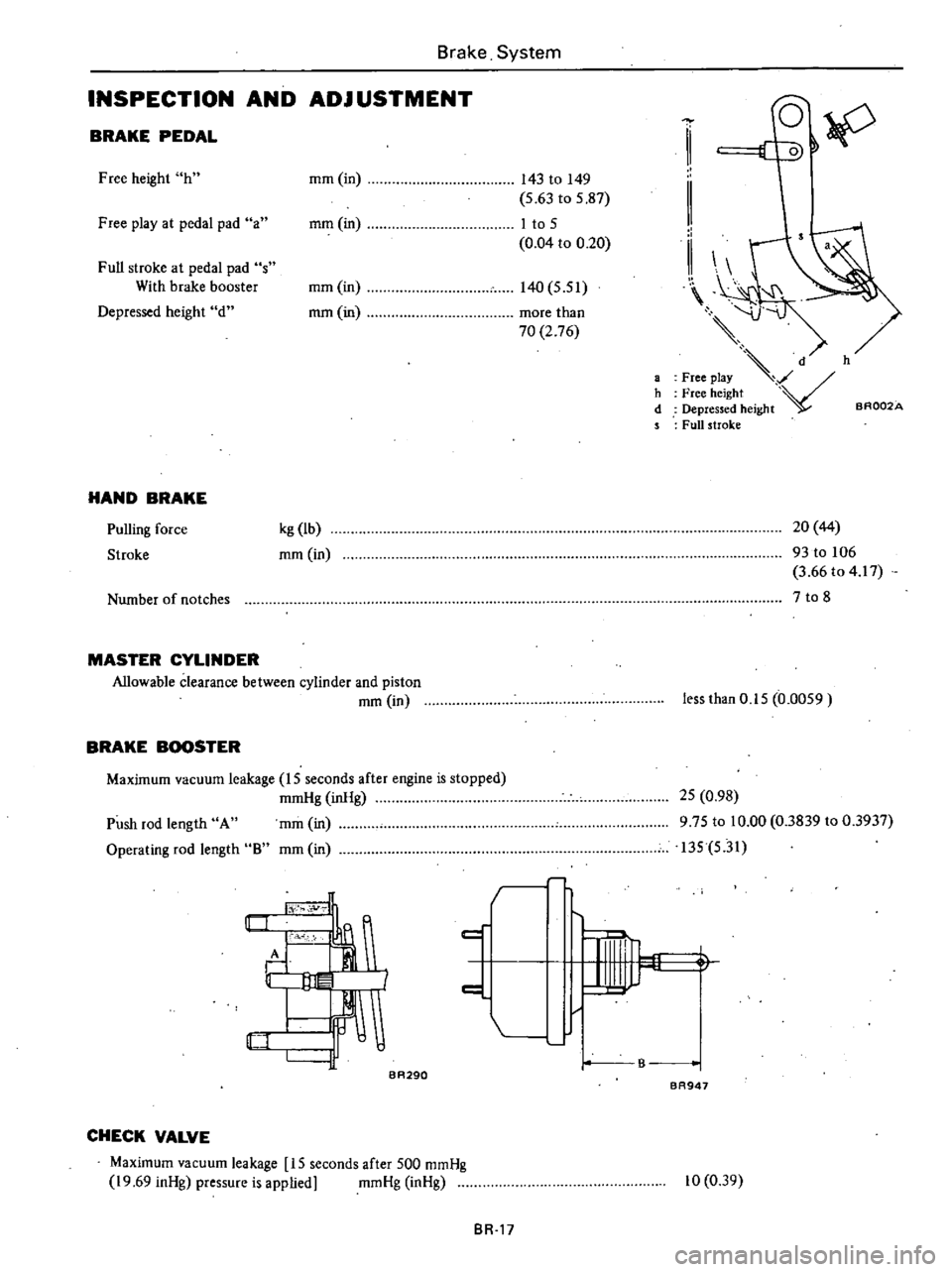

Brake

System

INSPECTION

AND

ADJ

USTMENT

BRAKE

PEDAL

Free

height

h

mm

in

143

to

149

5

63

to

5

87

Free

play

at

pedal

pad

a

mm

in

I

to

5

0

04

to

0

20

Full

stroke

at

pedal

pad

s

With

brake

booster

mm

in

140

5

51

Depressed

height

d

mm

in

more

than

70

2

76

HAND

BRAKE

Pulling

force

Stroke

kg

lb

mm

in

Number

of

notches

MASTER

CYLINDER

Allowable

clearance

between

cylinder

and

piston

mm

in

BRAKE

BOOSTER

Maximum

vacuum

leakage

15

seconds

after

engine

is

stopped

mmHg

inHg

mm

in

mm

in

Push

rod

length

A

Operating

rod

length

8

I

c

tY

1I1

fF

I

BA290

d

IF

CHECK

VALVE

Maximum

vacuum

leakage

15

seconds

after

500

mmHg

19

69

inHg

pressure

is

applied

mmHg

inHg

BR

17

h

d

1

II

II

d

h

Free

play

V

Free

height

Depressed

height

aR002A

Full

stroke

20

44

93

to

106

3

66

to

4

17

7

to

8

less

than

0

15

0

0059

25

0

98

975

to

10

00

0

3839

to

0

3937

135

5

31

1

B

BR947

10

0

39

Page 389 of 548

Steering

System

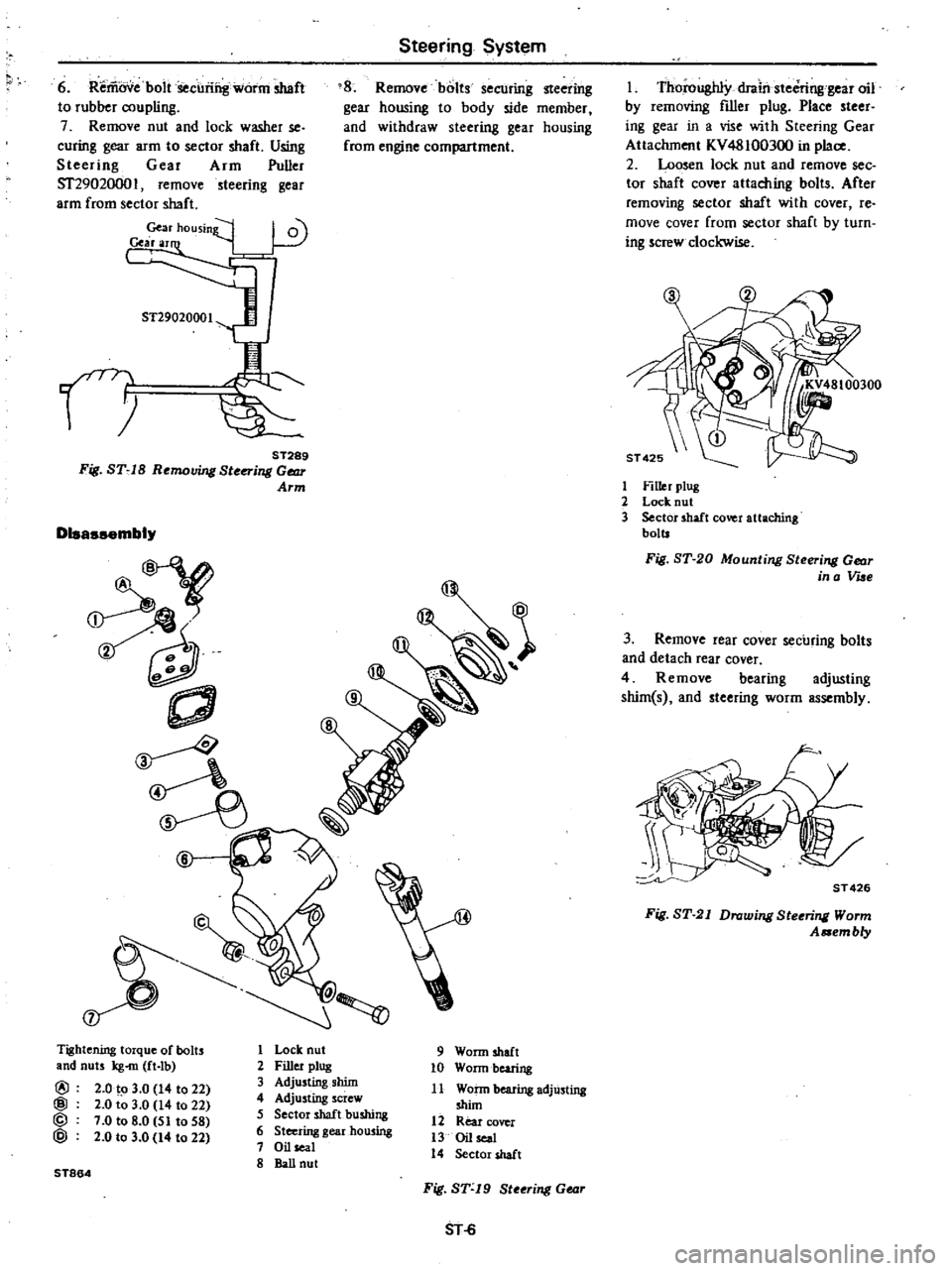

6

Reriiovebolt

Securing

worm

shaft

to

rubber

coupling

7

Remove

nut

and

lock

washer

se

curing

gear

arm

to

sector

shaft

Using

Steering

Gear

Arm

Puller

512902000

I

remove

steering

gear

arm

from

sector

shaft

Gear

housinif

I

0

Cearar

8

Remove

bolts

securing

steering

gear

housing

to

body

side

member

and

withdraw

steering

gear

housing

from

engine

compartment

n

ST289

Fig

ST

IB

Removing

Ste

i1l

Gear

Arm

Disassembly

f

Tightening

torque

of

bolts

and

nuts

kg

m

ft

Ib

@

2

0

to

3

0

14

to

22

@

2

0

to

3

0

14

to

22

@

7

0

to

8

0

51

to

58

@

2

0

to

3

0

14

to

22

ST864

1

Lock

nut

2

Filler

plug

3

Adjusting

shim

4

Adjusting

screw

5

Sector

shaft

bushing

6

Steering

gearhou

ing

7

Oil

seal

8

BaU

nut

9

Worm

shaft

10

Wonn

bearing

11

Wann

bearing

adjUsting

shim

12

Rear

cover

13

Oil

seal

14

Sector

shaft

Fig

ST

19

Steeri1l

Gear

SHi

Thoroughly

drail

steCring

gear

oil

by

removing

filler

plug

Place

steer

ing

gear

in

a

vise

with

Steering

Gear

Attachment

KV48100300

in

place

2

Loosen

lock

nut

and

remove

see

tor

shaft

cover

attaching

bolts

After

removing

sector

shaft

with

cover

re

move

cover

from

sector

shaft

by

turn

ing

screw

clockwise

1

Filler

plug

2

Lock

nut

3

Sector

shaft

cover

attaching

bolts

Fig

ST

20

Mounti1l

Steeri1l

Gear

in

a

Vue

3

Remove

rear

cover

securing

bolts

and

detach

rear

cover

4

Remove

bearing

adjusting

shim

s

and

steering

worm

assembly

ST

426

Fig

ST

21

Drawi1l

Steeri1l

Worm

A

em

b

y

Page 399 of 548

DATSUN

210

Model

8310

Series

SECTIONFE

ENGINE

CONTROL

FUEL

EXHAUST

SYSTEMS

CONTENTS

ENGINE

CONTROL

SYSTEM

ACCELERATOR

CONTROL

SYSTEM

FUEL

SYSTEM

REMOVAL

INSPECTION

FE

2

FE

2

FE

4

FE

5

FE

5

INSTALLATION

EXHAUST

SYSTEM

REMOVAL

INSPECTION

INSTALLATION

FE

Ii

FE

7

FE

8

FE

9

FE

9

Page 400 of 548

Engine

Control

Fuel

Exhaust

SYlltems

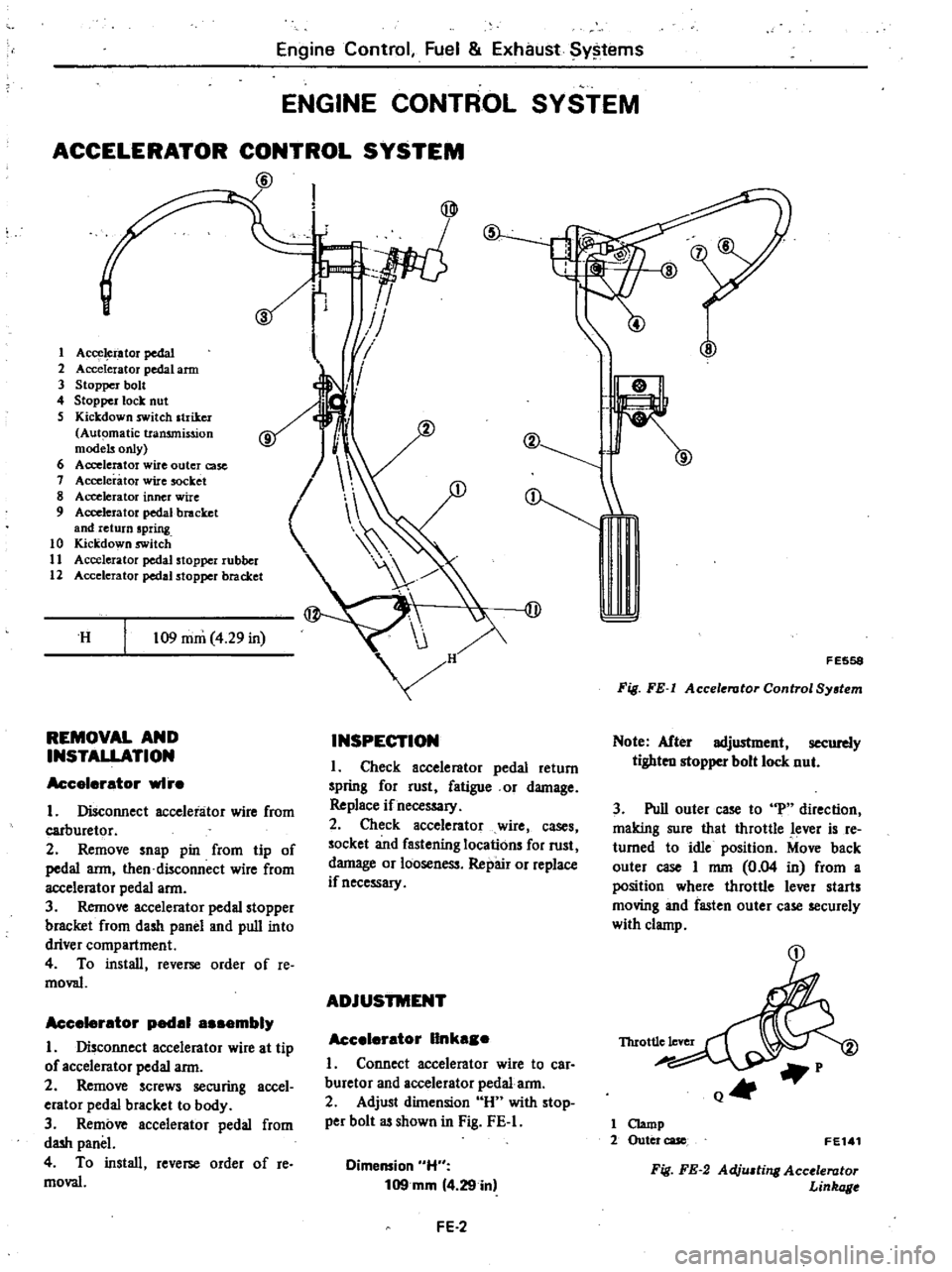

ENGINE

CONTROL

SYSTEM

ACCELERATOR

CONTROL

SYSTEM

@

s

1

Acce

i

ator

pedal

2

Accelerator

pedal

arm

3

Stopper

bolt

4

Stopper

lock

nut

S

Kickdown

switch

striker

Automatic

transmission

models

only

6

Accelerator

wire

outer

case

1

Accelerator

wire

socket

8

Accelerator

inner

wire

9

Accelerator

pedal

bracket

and

return

spring

10

Kickdown

switch

11

Accelerator

pedal

stopper

rubber

12

Accelerator

pedal

stopper

bracket

H

109

mm

4

29

in

REMOVAL

AND

INSTALLATION

Accelerator

wI

e

I

Disconnect

accelerator

wire

from

carburetor

2

Remove

snap

pin

from

tip

of

pedal

arm

then

disconnect

wire

from

accelerator

pedal

arm

3

Remove

accelerator

pedal

stopper

bracket

from

dash

panel

and

pull

into

driver

compartment

4

To

install

reverse

order

of

Ie

moval

Accelerator

pedal

a

embly

I

Disconnect

accelerator

wire

at

tip

of

accelerator

pedal

arm

2

Remove

screws

securing

accel

erator

pedal

bracket

to

body

3

Remove

accelerator

pedal

from

dash

panel

4

To

install

reverse

order

of

re

moval

I

IJ

1

II

I

V

J

v

I

@

INSPECTION

I

Check

accelerator

pedal

return

spring

for

rust

fatigue

or

damage

Replace

if

necessary

2

Check

accelerator

wire

cases

socket

and

fastening

locations

for

rust

damage

or

looseness

Repair

or

replace

if

necessary

ADJUSTMENT

Accelerator

IInka

e

I

Connect

accelerator

wire

to

car

buretor

and

accelerator

pedal

arm

2

Adjust

dilnension

H

with

stop

per

bolt

as

shown

in

Fig

FE

I

Dimension

H

109mm

4

29

in

FE

2

F

E558

Fig

FE

I

Accelerator

Control

System

Note

After

adjustment

securely

tighten

stopper

bolt

lock

nut

3

Pull

outer

case

to

uP

direction

making

sure

that

throttle

lever

is

re

turned

to

idle

position

Move

back

outer

case

I

mm

0

04

in

from

a

position

where

throttle

lever

starts

moving

and

fasten

outer

case

securely

with

clamp

Q4t

1

Clamp

2

Outer

case

FE1

1

Fig

FE

2

Adju

ting

Accolerator

Linkage

Page 401 of 548

Engine

Control

Fuel

Exhaust

Systems

4

When

accelerator

pedal

is

fully

depressed

make

sure

that

throttle

valve

opens

fuUy

5

After

above

adjustments

have

been

made

make

sure

that

accelerator

linkage

operates

smoothly

without

dragging

Make

sure

that

throttle

lever

returns

securely

to

idle

position

as

soon

as

accelerator

pedal

is

released

K1ckdown

switch

On

the

automatic

transmission

models

it

is

also

necessary

to

adjust

kickdown

switch

The

kickdown

FE

3

switch

adjustment

is

correct

if

kick

down

switch

is

actuated

by

the

stop

per

located

on

the

tip

end

of

pedal

arm

when

accelerator

pedal

is

de

pressed

fuUy

Always

tighten

lock

nut

securely

when

proper

adjustment

is

obtained

Page 403 of 548

Engine

Control

Fuel

Exhaust

Systems

REMOVAL

WARNING

When

replacing

fuel

line

parts

be

sure

to

observe

the

following

a

Put

a

CAUTION

INFLAM

MABLE

sign

in

workshop

b

Be

sure

to

furnish

workshop

with

In

asphyxiator

c

Be

sure

to

disconnect

battery

ground

cable

before

conducting

operations

d

Put

drained

fuel

in

an

explosion

proof

container

and

put

on

lid

securely

FUEL

TANK

Sedan

I

Disconnect

battery

ground

cable

2

Drain

fuel

from

fuel

tank

then

disconnect

fuel

hose

3

Remove

filler

hose

protector

and

inspection

cover

in

luggage

com

i

tl

f

I

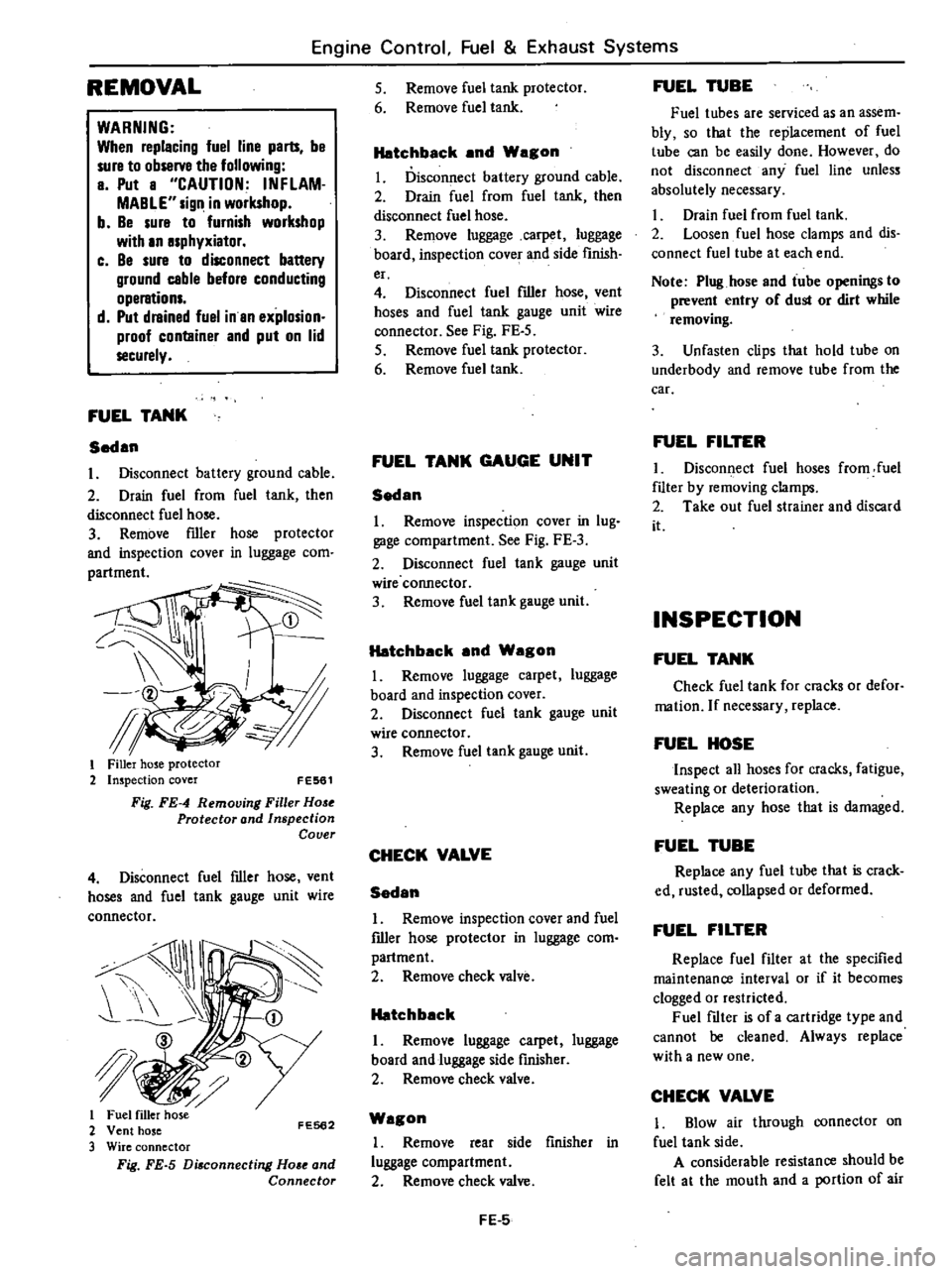

Filler

hose

protector

2

Inspection

cover

FE561

Fig

FE

4

Removing

Filler

Hose

Protector

and

Inspection

Cover

4

Disconnect

fuel

filler

hose

vent

hoses

and

fuel

tank

gauge

unit

wire

connector

I

JI

I

2

FE562

3

Fig

FE

5

Di

connecting

Ho

e

and

Connector

5

Remove

fuel

tank

protector

6

Remove

fuel

tank

Hatchback

and

Wagon

I

Disconnect

battery

ground

cable

2

Drain

fuel

from

fuel

tank

then

disconnect

fuel

hose

3

Remove

luggage

carpet

luggage

board

inspection

covef

and

side

finish

er

4

Disconnect

fuel

filler

hose

vent

hoses

and

fuel

tank

gauge

unit

wire

connector

See

Fig

FE

5

5

Remove

fuel

tank

protector

6

Remove

fuel

tank

FUEL

TANK

GAUGE

UNIT

Sedan

1

Remove

inspection

cover

in

lug

gage

compartment

See

Fig

FE

3

2

Disconnect

fuel

tank

gauge

unit

wire

connector

3

Remove

fuel

tank

gauge

unit

Hatchback

and

Wagon

I

Remove

luggage

carpet

luggage

board

and

inspection

cover

2

Disconnect

fuel

tank

gauge

unit

wire

connector

3

Remove

fuel

tank

gauge

unit

CHECK

VALVE

Sedan

I

Remove

inspection

cover

and

fuel

filler

hose

protector

in

luggage

com

partment

2

Remove

check

valve

Hatchback

I

Remove

luggage

carpet

luggage

board

and

luggage

side

finisher

2

Remove

check

valve

Wagon

I

Remove

rear

side

finisher

in

luggage

compartment

2

Remove

check

valve

FE

5

FUEL

TUBE

Fuel

tubes

are

serviced

as

an

assem

bly

so

that

the

replacement

of

fuel

tube

can

be

easily

done

However

do

not

disconnect

any

fuel

line

unless

absolutely

necessary

Drain

fuel

from

fuel

tank

2

Loosen

fuel

hose

clamps

and

dis

connect

fuel

tube

at

each

end

Note

Plug

hose

and

tube

openings

to

prevent

entry

of

dust

or

dirt

while

removing

3

Unfasten

clips

that

hold

tube

on

underbody

and

remove

tube

from

the

car

FUEL

FILTER

I

Disconnect

fuel

hoses

from

fuel

filter

by

removing

clamps

2

Take

out

fuel

strainer

and

discard

it

INSPECTION

FUEL

TANK

Check

fuel

tank

for

cracks

or

defor

mation

If

necessary

replace

FUEL

HOSE

Inspect

all

hoses

for

cracks

fatigue

sweating

or

deterioration

Replace

any

hose

that

is

damaged

FUEL

TUBE

Replace

any

fuel

tube

that

is

crack

ed

rusted

collapsed

or

deformed

FUEL

FILTER

Replace

fuel

filter

at

the

specified

maintenance

interval

or

if

it

becomes

clogged

or

restricted

Fuel

filter

is

of

a

cartridge

type

and

cannot

be

cleaned

Always

replace

with

a

new

one

CHECK

VALVE

1

Blow

air

through

connector

on

fuel

tank

side

A

considerable

resistance

should

be

felt

at

the

mouth

and

a

portion

of

air

Page 404 of 548

Engine

Control

f1lel

Exhaust

Systems

flow

be

directed

toward

atmosphere

side

2

Blow

air

tluough

connector

on

atmosphere

side

Air

flow

should

be

smoothly

directed

toward

fuel

tank

3

If

cbeck

valve

is

suspected

of

not

being

properly

functioning

in

steps

I

and

2

above

replace

To

fuel

tank

FE477

Pressure

valve

Vacuum

valve

Return

spring

Fig

FE

6

Checking

Check

Valve

INSTALLATION

Install

any

parts

of

the

fuel

system

in

the

reverse

order

of

removal

Ob

serve

the

following

notes

Note

a

Install

hose

clamps

securely

Do

not

tighten

excessively

to

avoid

dam

aging

hoses

b

Fasten

clips

holding

fuel

tube

on

underbody

securely

Failure

to

fol

low

this

caution

could

result

in

damage

to

the

surface

of

fuel

tube

c

Do

not

kink

or

twist

hOse

and

tube

when

they

are

routed

d

Run

the

engine

and

check

for

leaks

at

connections

FUEL

TANK

Not

InstaU

fuel

filler

hose

after

fuel

tank

has

been

mounted

in

place

Failure

to

foUow

this

rule

could

result

in

leakage

from

around

hose

connections

Do

not

twist

or

smash

vent

hoses

when

they

are

routed

Be

sure

to

retain

them

with

clips

securely

FE

6

@

Tightening

torque

Drain

plug

1

6

to

2

4

kg

m

112

tn

17

ft

bl

Fuel

tank

0

8

to

1

2

kll

m

15

8

to

8

7

ft

Ibl

FUEL

TANK

GAUGE

UNIT

Note

When

installing

fuel

tank

gauge

unit

aJign

the

projection

of

tank

gauge

unit

with

the

notch

in

fuel

tank

and

tighten

it

securely

Be

sure

to

instaU

tank

gauge

unit

with

O

ring

in

place

CHECK

VALVE

Note

When

installing

check

valve

be

careful

of

its

designated

direction

See

Fig

FE

Page 406 of 548

Engine

Control

fuel

Exhaust

Systems

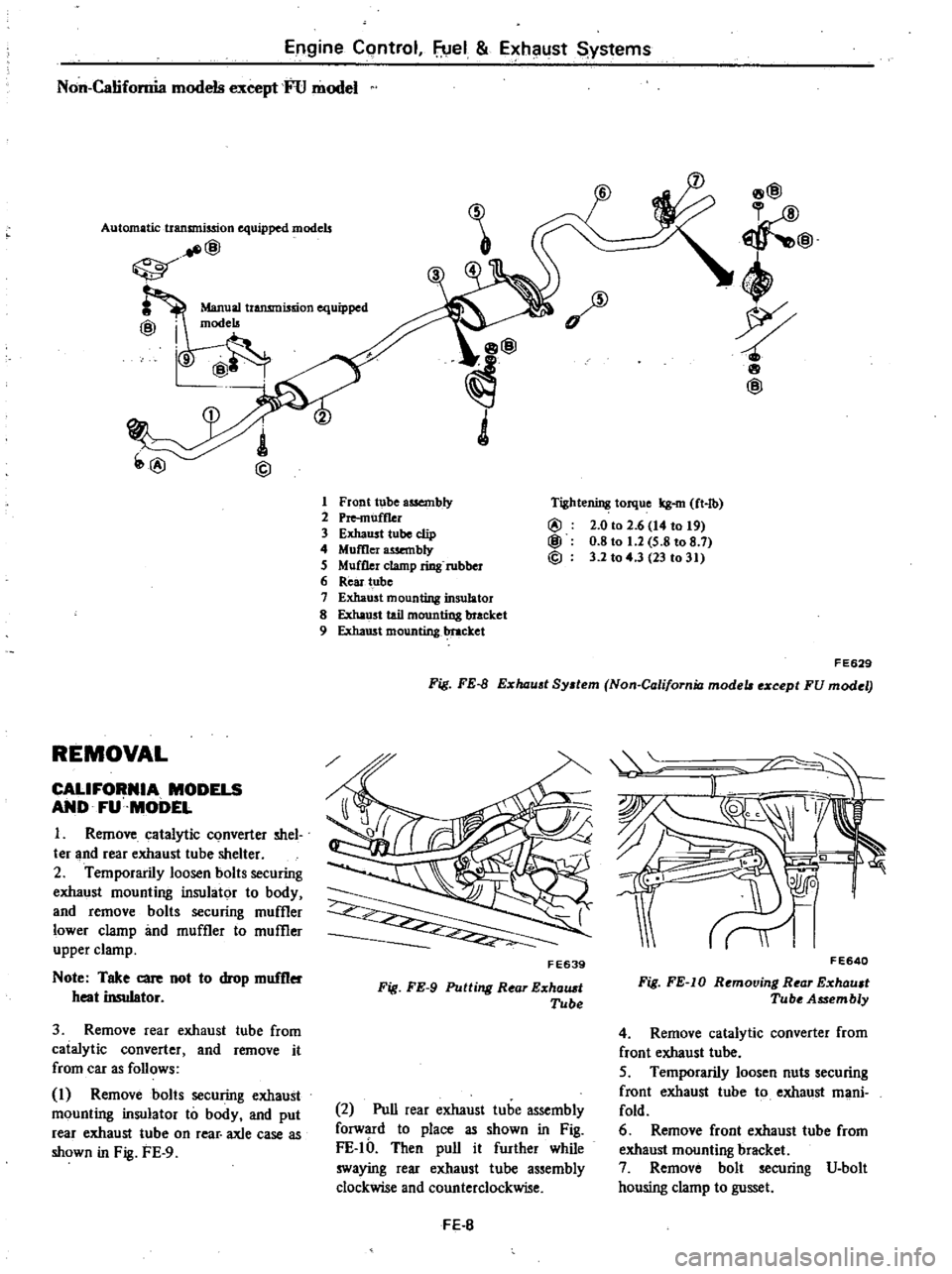

Non

California

models

except

FU

model

Automatic

transmission

equipped

models

@

REMOVAL

CALIFORNIA

MODELS

AND

FU

MODEL

I

Remove

catalytic

converter

shel

ter

and

rear

exhaust

tube

shelter

2

Temporarily

loosen

bolts

securing

exhaust

mounting

insulator

to

body

and

remove

bolts

securing

muffler

lower

clamp

imd

muffler

to

muffler

upper

clamp

Note

Take

care

Dot

to

drop

muffler

heat

insulator

3

Remove

rear

exhaust

tube

from

catalytic

converter

and

remove

it

from

car

as

follows

I

Remove

bolts

securing

exhaust

mounting

insulator

to

body

and

put

rear

exhaust

tube

on

rear

axle

case

as

shown

in

Fig

FE

9

1

Front

tube

assembly

2

Pre

muff1er

3

Exhaust

tube

clip

4

Momer

wembly

5

Muffler

clamp

ring

rubber

6

Rear

tube

7

Exhaust

mounting

insulator

8

Exha

st

tail

mounting

bracket

9

Exhaust

mounting

1

ttacket

8@

@

4

wp

8

@

Tightening

torque

kg

m

ft

lb

@

2

0

to

2

6

14

to

t9

@

0

8

to

1

2

5

8

to

8

7

@

3

2

to

4

3

23

to

31

FE629

Fig

FE

B

E

haust

System

Non

California

mode

e

cept

FU

modet

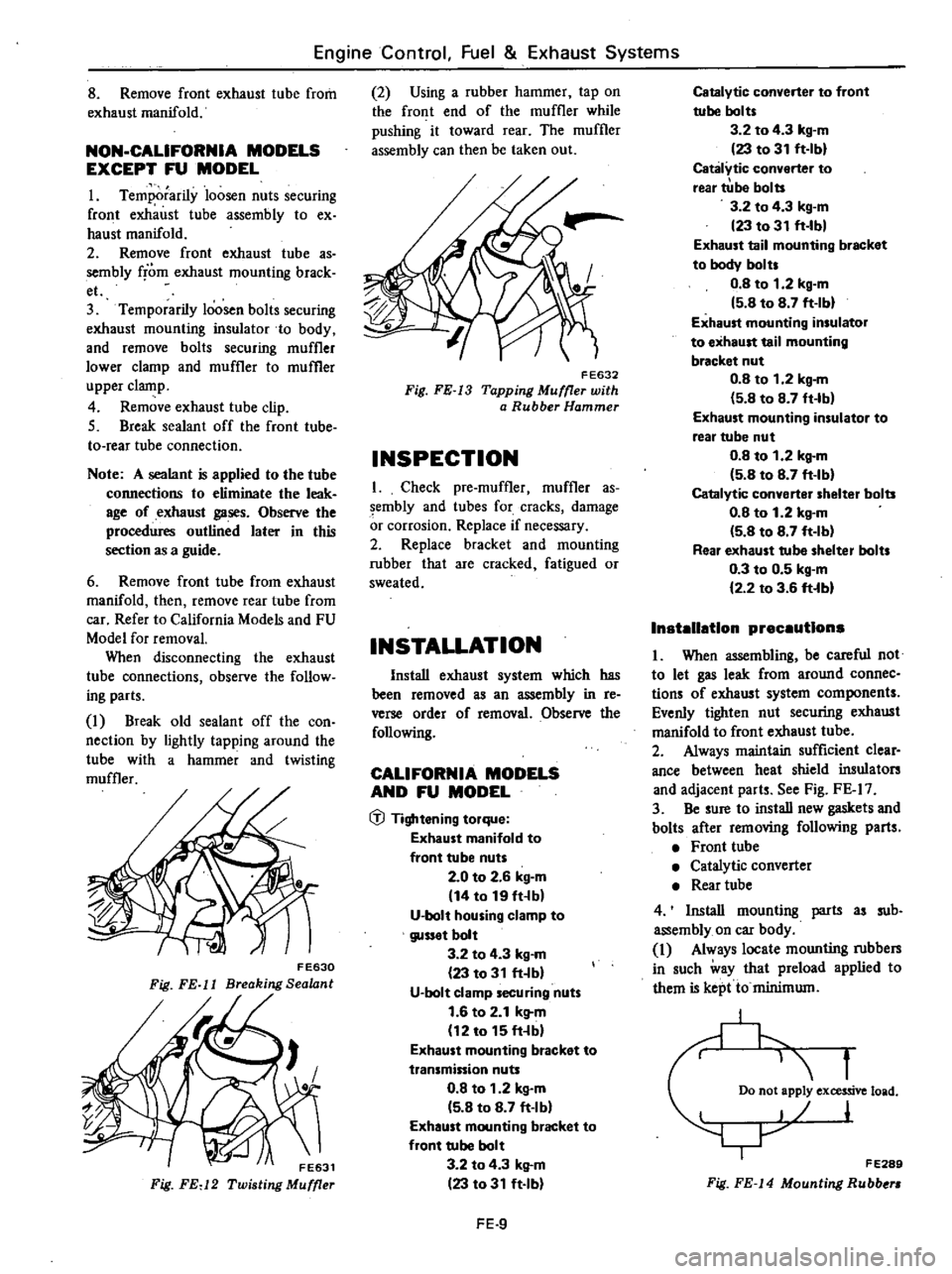

FE639

Fig

FE

9

Putting

Rear

E

halUt

Tube

2

Pull

rear

exhaust

tube

assembly

forward

to

place

as

shown

in

Fig

FE

IO

Then

pull

it

further

while

swaying

rear

exhaust

tube

assembly

clockwise

and

counterclockwise

FE

B

II

F

E640

Fig

FE

IO

Removing

Rear

E

xhault

Tube

Assembly

4

Remove

catalytic

converter

from

front

exhaust

tube

5

Temporarily

loosen

nuts

securing

f

root

exhaust

tube

to

exhaust

mani

fold

6

Remove

front

exhaust

tube

from

exhaust

mounting

bracket

7

Remove

bolt

securing

V

bolt

housing

clamp

to

gusset

Page 407 of 548

Engine

Control

Fuel

Exhaust

Systems

8

Remove

front

exhaust

tube

from

exhaust

manifold

NON

CALIFORNIA

MODELS

EXCEPT

FU

MODEL

I

Temporarily

loosen

nuts

securing

front

exhaust

tube

assembly

to

ex

haust

manifold

2

Remove

front

exhaust

tube

as

sembly

from

exhaust

mounting

brack

et

3

Temporarily

loosen

bolts

securing

exhaust

mounting

insulator

to

body

and

remove

bolts

securing

muffler

lower

clamp

and

muffler

to

muffler

upper

clamp

4

Remove

exhaust

tube

clip

5

Break

sealant

off

the

front

tube

to

rear

tube

connection

Note

A

sealant

is

applied

to

the

tube

connections

to

eliminate

the

leak

age

of

exhaust

gases

Observe

the

procedures

outlined

later

in

this

section

as

a

guide

6

Remove

front

tube

from

exhaust

manifold

then

remove

rear

tube

from

car

Refer

to

California

Models

and

FU

Model

for

removal

When

disconnecting

the

exhaust

tube

connections

observe

the

follow

ing

parts

I

Break

old

sealant

off

the

con

nection

by

lightly

tapping

around

the

tube

with

a

hammer

and

twisting

muffler

F

E630

Fig

FE

11

Breaking

Sealant

Fig

FEd

2

2

Using

a

rubber

hammer

tap

on

the

front

end

of

the

muffler

while

pushing

it

toward

rear

The

muffler

assembly

can

then

be

taken

out

FE632

Fig

FE

13

Tapping

Muffler

with

a

Rubber

Hammer

INSPECTION

I

Check

pre

muffler

muffler

as

sembly

and

tubes

for

cracks

damage

or

corrosion

Replace

if

necessary

2

Replace

bracket

and

mounting

rubber

that

are

cracked

fatigued

or

sweated

INSTALLATION

Install

exhaust

system

which

has

been

removed

as

an

assembly

in

re

verse

order

of

removal

Observe

the

following

CALIFORNIA

MODELS

AND

FU

MODEL

1Jl

Tightening

torque

Exhaust

manifold

to

front

tube

nuts

2

0

to

2

6

kg

m

14

to

19

fHb

U

bolt

housing

clamp

to

gusset

bolt

3

2

to

4

3

kg

m

23

to

31

ft

bl

U

bolt

clamp

securing

nuts

1

6

to

2

1

k

l

m

12

to

15

ft

bl

Exhaust

mounting

bracket

to

transmission

nuts

0

8

to

1

2

kg

m

5

8

to

8

7

ft

Ibl

Exhaust

mounting

bracket

to

front

tube

bolt

3

2

to

4

3

k

l

m

23

to

31

ft

Ib

FE

9

CatalytiC

converter

to

front

tube

bolts

3

2

to

4

3

kg

m

23

to

31

ft

Ibl

Catalytic

converter

to

rear

tUbe

bolts

3

2

to

4

3

kg

m

23

to

31

ft

Ibl

Exhaust

tail

mounting

bracket

to

body

bolts

0

8

to

1

2

kg

m

5

B

to

8

7

ft

Ibl

Exhaust

mounting

insulator

to

exhaust

tail

mounting

bracket

nut

0

8

to

1

2

kg

m

5

8

to

8

7

ft

Ib

Exhaust

mounting

insulator

to

rear

tube

nut

O

B

to

1

2

kg

m

5

8

to

8

7

ft

Ib

Catalytic

converter

shelter

bolts

O

B

to

1

2

kg

m

5

8

to

B

7

ft

Ib

Rear

exhaust

tube

shelter

bolts

0

3

to

0

5

kg

m

2

2

to

3

6

ft

bl

Installation

precautions

I

When

assembling

be

careful

not

to

let

gas

leak

from

around

connec

tions

of

exhaust

system

components

Evenly

tighten

nut

securing

exhaust

manifold

to

front

exhaust

tube

2

Always

maintain

sufficient

clear

ance

between

heat

shield

insulators

and

adjacent

parts

See

Fig

FE

I7

3

Be

sure

to

install

new

gaskets

and

bolts

after

removing

following

parts

Front

tube

Catalytic

converter

Rear

tube

4

Install

mounting

parts

as

sub

assembly

on

car

body

I

Always

locate

mounting

rubbers

in

such

way

that

preload

applied

to

them

is

kept

to

minimum

f

Do

not

apply

excessive

load

I

F

E289

Fig

FE

J4

Mounting

Rubbe

Page 408 of 548

Engine

Control

Fuel

Exhaust

Systems

2

For

inStallation

of

inounting

in

sulator

refer

to

Figs

FE

15

and

FE

16

D

l

FE600

2

t

2

mm

0

08

to

0

08

in

Fig

FE

IS

lrutalling

Mounting

lruulator

1

Front

2

to

8

mm

FE501

oS

to

0

31

in

Fig

FE

I6

l

tolling

Mounting

lmulator

2

o

t

J

1

Section

A

A

Oearance

mm

in

1

20

to

30

0

79

to

1

18

2

13

5

to

19

5

0

531

to

0

768

3

20

5

to

26

5

0

807

to

1

43

4

23

to

33

0

91

to

1

30

5

20

to

30

0

79

to

1

18

Note

Aft

instaDation

check

that

mOlmting

brackets

mounting

rub

bers

and

mounting

insoIator

are

free

from

undue

str

If

oYof

liboft

part

is

DOtinstalled

r

r

i

excessM

noises

or

wbra

tions

may

be

transmitted

to

car

body

b

Check

all

tube

colll1ections

for

ell

hanst

gas

leaks

and

entire

system

for

unusual

noises

witb

engine

run

ning

B

A

6

@

Section

B

B

6

Exhaust

fmisher

equipped

models

except

Wagon

20

to

30

0

79

to

1

18

Other

models

22

to

32

0

87

to

1

26

FE633

Fig

FE

I

7

Proper

Clea

nce

for

E

r

Must

System

Californw

models

and

FU

model

FE

tO