engine DATSUN 210 1979 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 250 of 548

Manual

Transmission

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Difficult

to

intermesh

gears

Causes

for

difficult

gear

shifting

are

classi

fie

t

o

ro

lb

c

QncerlJing

coJltr

1

syste

and

transmission

When

gear

shift

lever

is

heavy

and

it

is

difficult

to

shift

gears

clutch

disengagement

may

also

be

unsmooth

First

make

sure

that

clutch

operates

correctly

and

inspect

transmjssion

Gear

slips

out

of

mesh

In

most

cases

this

troubk

occurs

when

check

baD

and

or

spring

is

waIn

or

weaken

ed

or

when

control

system

is

faulty

In

this

case

the

troubk

cannot

be

correct

by

replacing

gears

and

therefore

trouble

shoot

ing

must

be

carried

out

carefuDy

It

should

also

be

noted

that

gear

slips

out

of

mesh

due

to

vibration

generated

by

weakened

front

and

rear

enigne

mounts

Noise

When

noise

occurs

with

engine

idling

and

ceases

when

clutch

is

disengaged

or

when

noise

occurs

while

shifting

gears

it

is

an

indication

that

the

noise

is

from

trans

mission

Transmission

may

rallk

during

engine

idling

Check

air

fuel

mixture

and

ignition

timing

After

above

procedure

readjust

engine

idling

Probable

cause

Worn

gears

shaft

and

or

bearing

Insufficient

operating

stroke

due

to

worn

or

loose

sliding

part

Worn

or

damaged

syncluonizer

Worn

check

baD

and

or

weakened

or

broken

spring

Worn

fork

rod

baU

groove

Worn

or

damaged

bearing

Worn

or

damaged

gear

Insufficient

or

improper

lubricant

Oil

leaking

due

to

damaged

oil

seal

or

sealant

clogged

breather

etc

Worn

bearing

High

humming

occurs

at

a

high

speed

Damaged

bearing

Cyclic

knocking

sound

occurs

also

at

a

low

speed

Worn

spline

Worn

bushing

MT34

Corrective

action

Replace

Repair

ClI

replace

Replace

Replace

Replace

Replace

Replace

Add

oil

or

replace

with

designated

oil

Clean

or

replace

Replace

Replace

Replace

Replace

as

a

rear

ex

tension

assembly

Page 255 of 548

Automatic

Transmission

HYDRAULIC

CONTROL

UNIT

AND

VALVES

The

hydraulic

or

a

tomatic

control

system

is

comprised

of

four

4

basic

groups

the

pressure

supply

system

the

pressure

regulating

system

the

flow

control

valves

and

the

friction

elements

PRESSURE

SUPPLY

SYSTEM

The

pressure

supply

system

consists

of

a

gear

type

oil

pwnp

driven

by

the

engine

through

the

torque

converter

The

pump

provides

pressure

for

aU

hydraulic

and

lubrication

needs

PRESSURE

REGULATOR

VALVES

The

pressure

regulating

valves

con

trol

the

output

pressure

of

the

oil

pump

Pre

ure

rellulator

valve

The

pressure

regulator

valve

con

trois

mainline

pressure

based

on

throttle

opening

for

the

operation

of

the

band

clutches

and

brake

Governor

valve

The

governor

valve

transmits

re

gulated

pressure

based

on

car

peed

to

the

shift

valves

to

control

upshifts

and

downshifts

Vacuum

throttle

valve

The

vacuum

throttle

valve

transmits

regulated

pressure

based

on

engine

load

vacuum

This

pressure

controls

the

pressure

regulator

valve

Also

this

pressure

is

applied

to

one

end

of

the

shift

valves

in

opposition

to

governor

pressure

which

acts

on

the

other

end

of

the

shift

valves

controlling

upshift

and

downshift

speeds

FLOW

CONTROL

VALVES

Manual

valve

The

manual

valve

is

moved

manual

Iy

by

the

car

operator

to

select

the

different

drive

ranges

1

2

ShHt

valve

The

1

2

shift

valve

automaticaIly

shifts

the

transmission

from

first

to

second

or

from

second

to

first

depend

ing

upon

governor

and

throttle

pres

sure

along

with

accelerator

position

solenoid

downshift

valve

See

Hy

draulic

Control

Circuits

Drive

2

2

3

ShHt

valve

The

2

3

shift

valve

automaticaIly

shifts

the

transmission

from

second

to

top

gear

or

from

top

to

second

de

pending

upon

governor

and

throttle

pressure

or

accelerator

position

sole

noid

downshift

valve

See

Hydraulic

Control

Circuits

Drive

3

Range

2

3

Tlmlnll

valve

For

2

3

shifts

a

restrictive

orifice

slows

the

application

fluid

to

the

front

clutch

while

the

slower

reacting

band

is

allowed

to

release

This

prevents

a

hard

2

3

or

3

2

shift

Under

heavy

load

however

the

engine

will

tend

to

run

away

during

the

2

3

or

3

2

shift

pause

therefore

a

2

3

timing

valve

using

throttle

and

governor

pressure

is

used

to

bypass

the

restrictive

orifice

during

such

heavy

load

conditions

Solenoid

down

hHt

valve

The

solenoid

downshift

valve

is

activated

electrically

when

the

ac

celerator

is

f1oor

d

causing

a

forced

downshift

from

top

to

second

top

to

first

or

second

to

first

gear

depending

upon

car

speed

governor

pressure

AT

3

Pre

ure

modified

valve

The

pressure

modifier

valve

assists

the

mainline

pressure

regulator

valve

in

lowering

mainline

pressure

during

high

speed

light

load

conditions

such

as

steady

speed

cruise

Governor

pres

sure

working

against

a

spring

opens

the

valve

which

aUows

modified

throt

tle

pressure

to

work

against

the

pres

sure

regulator

valve

spring

lowering

mainline

pressure

Lower

operating

pressure

under

light

load

reduces

oil

temperature

and

increases

transmis

sian

life

Throttle

back

up

valve

The

throttle

back

up

valve

assists

the

vacuum

throttle

valve

to

increase

line

pressure

when

the

manual

valve

is

shifted

either

to

2

or

I

range

Second

lock

valve

The

second

lock

valve

is

used

to

bypa

the

1

2

shift

valve

to

maintain

the

band

apply

pressure

in

2

posi

tion

The

valve

is

also

used

as

an

oil

passage

for

the

1

2

shift

valve

band

apply

pressure

in

D2

D3

and

12

Range

CLUTCHES

AND

BAND

SERVOS

The

servo

pistons

of

the

clutches

low

reverse

brake

and

band

are

moved

hydraulically

to

engage

the

clutches

brake

and

apply

the

band

The

clutch

and

brake

istons

are

released

by

spring

tension

and

band

piston

is

released

by

spring

tension

and

hy

draulic

pressure

Page 257 of 548

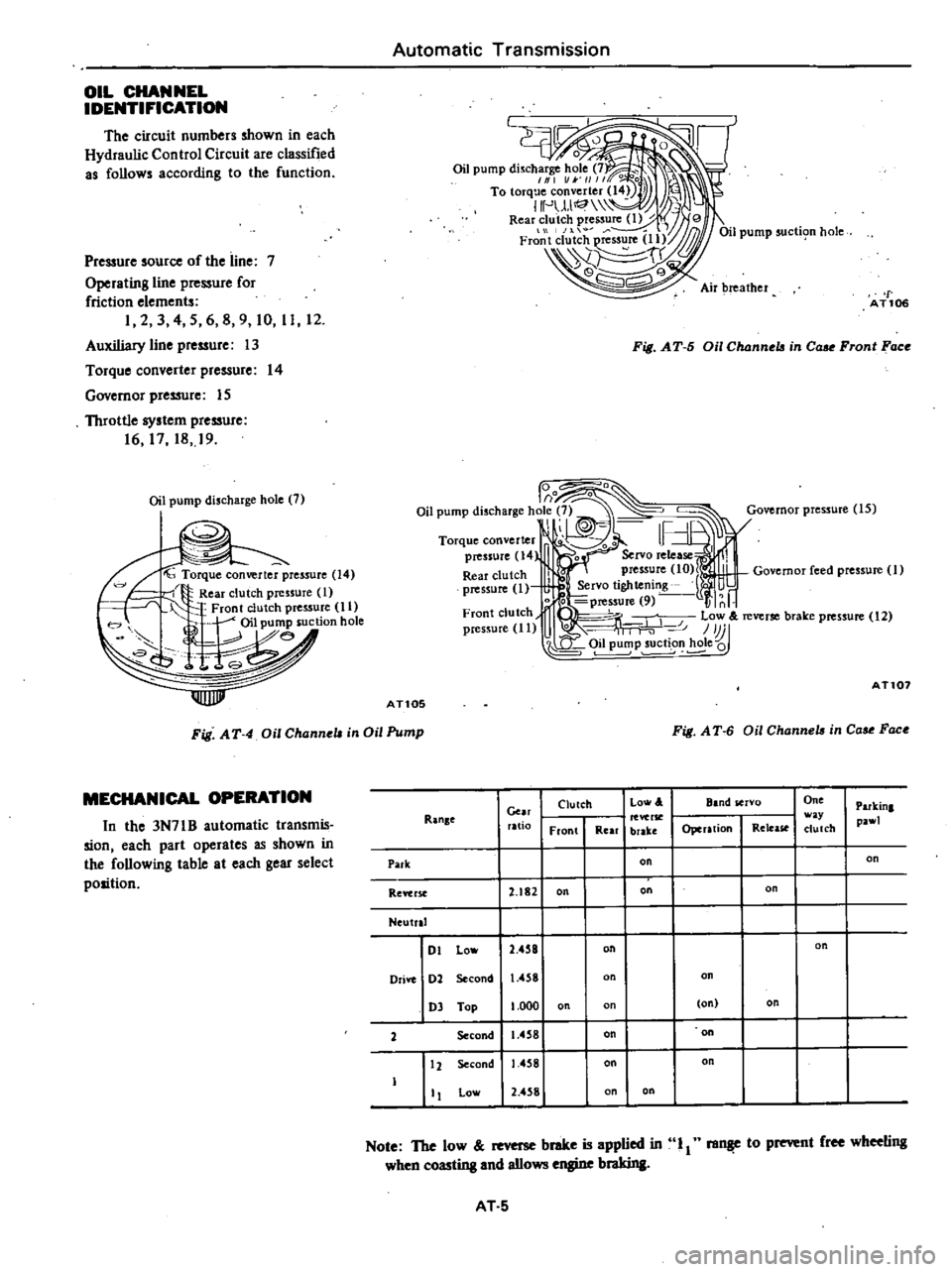

OIL

CHANNEL

IDENTIFICATION

The

circuit

numbers

shown

in

each

Hydraulic

Control

Circuit

are

classified

as

follows

according

to

the

function

Pressure

source

of

the

line

7

Operating

line

pressure

for

friction

elements

I

2

3

4

5

6

g

9

10

11

12

Auxiliary

line

pressure

13

Torque

converter

pressure

14

Governor

pressure

15

Throttle

system

pressure

16

17

18

19

Oil

pump

discharge

hole

7

f

Torque

converter

pressure

14

Rear

clutch

pressure

1

Front

clutch

pressure

11

W

h0i1

pu

6

suction

hote

e

8

IIlIlJJIII

Automatic

Transmission

L

f

AT106

Fig

AT

5

Oil

Channela

in

Cou

Front

Face

lo

o

o

0

Oil

pump

discharge

hole

7

Governor

pressure

15

1

h

Torque

converter

I

pressure

14

0

0

Servo

release

Rear

clutch

l

press

re

10

r

L

Governor

reed

pressure

1

pressure

1

Servo

tlghtemng

li

nb

o

0

pressure

9

r

Front

clutch

fI

Low

reverse

brake

pressure

12

pressure

11

U

0

111

1

1

P

u

n

e

AT107

ATlOS

Fig

A

T

4

Oil

Channell

in

Oil

Pump

Fig

A

T

6

Oil

Channell

in

Cou

Fac

MECHANICAL

OPERATION

In

the

3N71B

automatic

transmis

sion

each

part

operates

as

shown

in

the

following

table

at

each

gear

select

position

RanKe

Cm

ratio

Clutch

Low

A

Front

Rear

brake

One

w

y

dutch

Parkin

pa

l

Band

servo

Operation

Release

Park

on

on

Reftrst

2

182

on

on

on

Neutral

Dl

Lo

2

458

on

on

Drift

02

Second

1

458

on

03

Top

1

000

on

on

on

2

Second

1

4

8

on

on

12

Second

1458

on

on

Low

2

4

8

on

on

Note

The

low

brake

is

applied

in

11

raiW

to

prevent

free

whee6ng

when

coasting

and

aIlows

engine

braking

AT

5

Page 258 of 548

Automatic

Transmission

HYDRAULIC

CONTROL

CIRCUITS

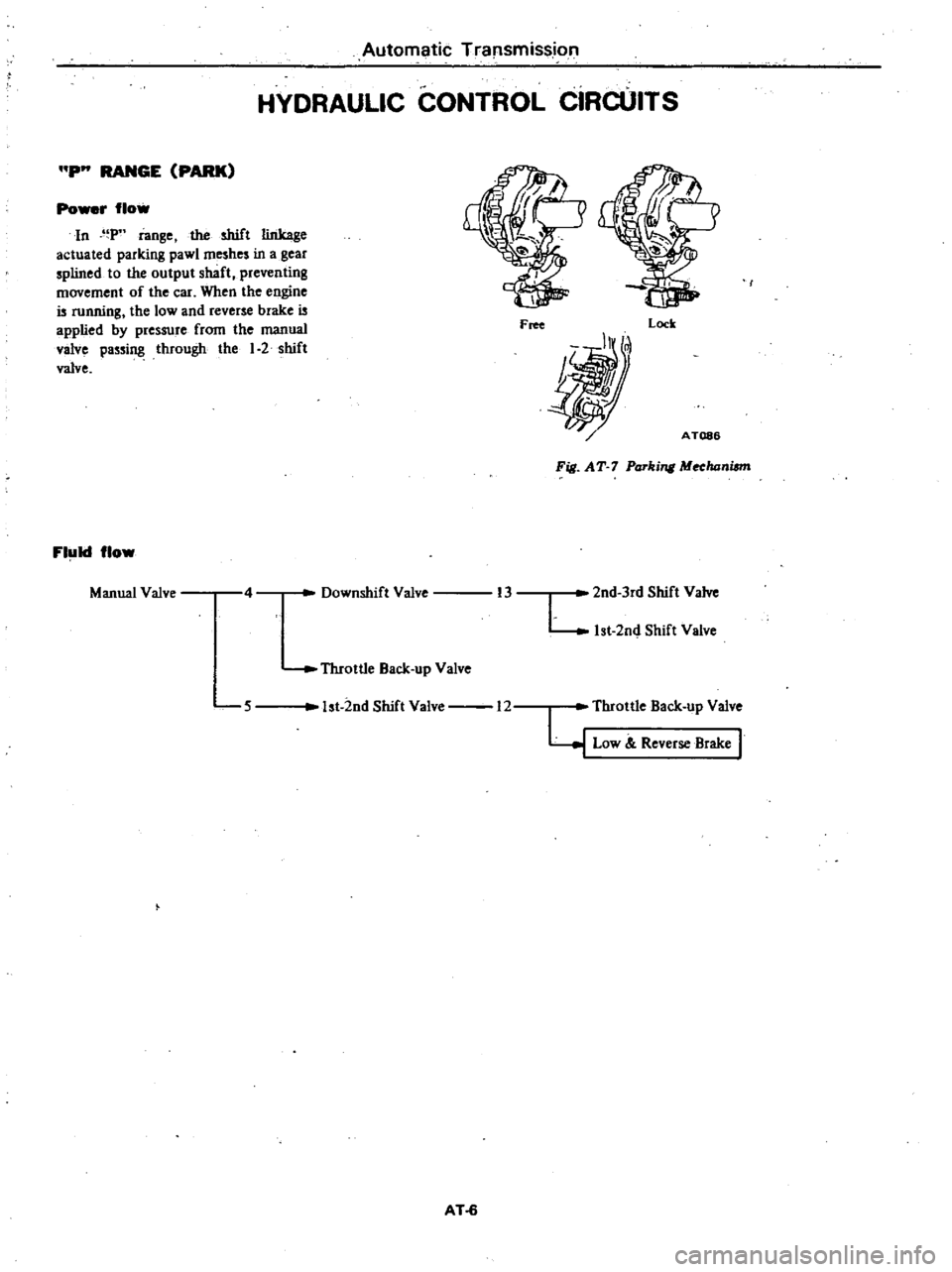

P

RANGE

PARK

Po

r

flow

In

P

range

the

shift

linkage

actuated

parking

pawl

meshes

in

a

gear

splined

to

the

output

shaft

preventing

movement

of

the

car

When

the

engine

is

running

the

low

and

reverse

brake

is

applied

by

pressure

from

the

manual

valve

passing

through

the

1

2

shift

valve

Free

Lock

II

AT086

Fig

AT

7

Parking

M

haniml

FI

1d

flow

Manual

Valve

4

Downshift

Valve

13

2nd

3rd

Shift

Valve

L

1st

2nd

Shift

Valve

Throttle

Back

up

Valve

5

1st

2nd

Shift

Valve

12

I

Throttle

Back

up

Valve

Y

Low

Reverse

Brake

I

AT

6

Page 260 of 548

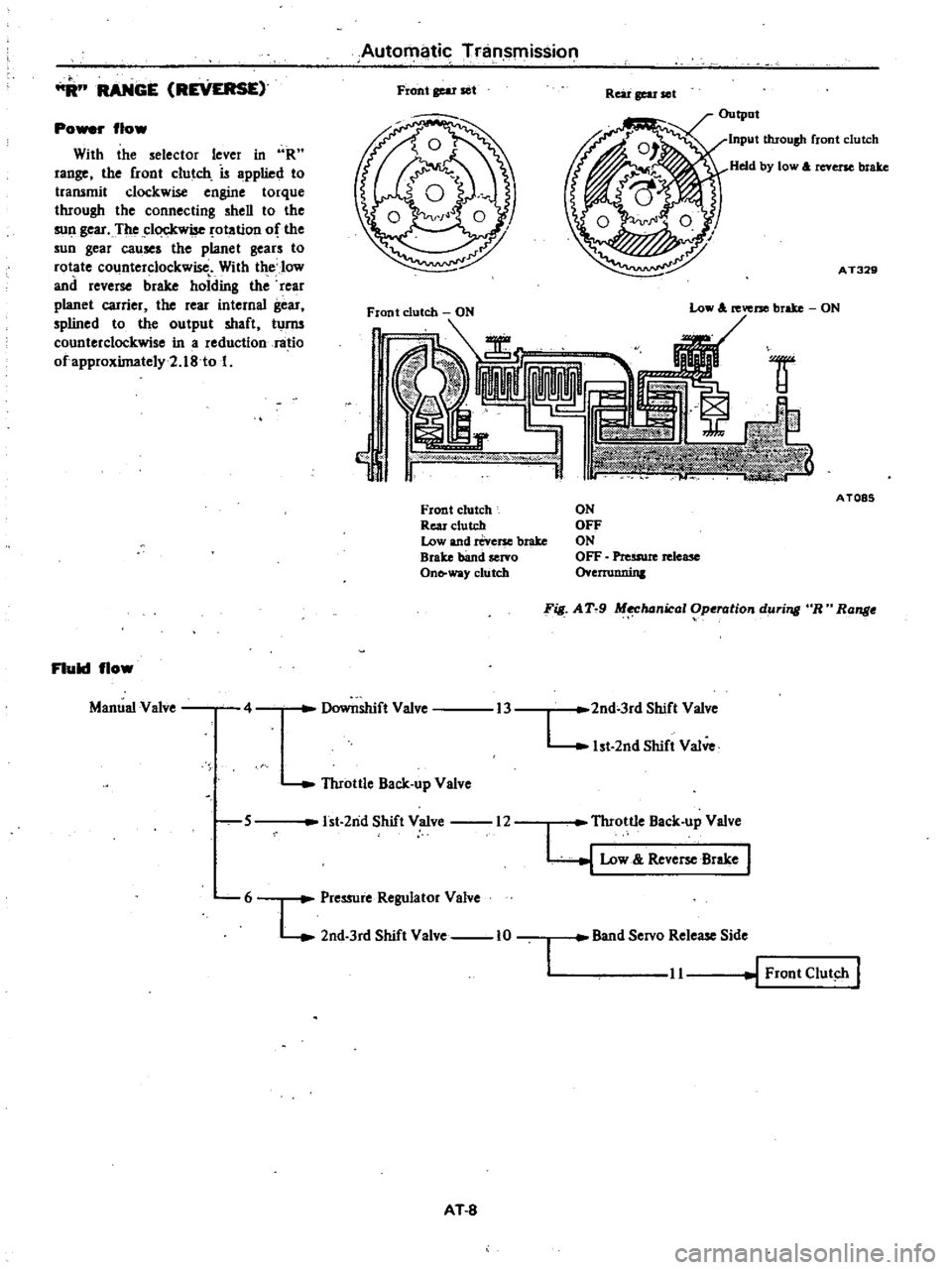

RANGE

REVERSE

Po

r

flow

With

the

selector

lever

in

R

range

the

front

clutch

is

applied

to

transmit

clockwise

engine

torque

through

the

connecting

shell

to

the

sull

gear

The

clockwise

otation

of

the

sun

gear

causes

the

planet

gears

to

rotate

counterclockwise

With

the

low

and

reverse

brake

holding

the

rear

planet

carrier

the

rear

internal

gear

splined

to

the

output

shaft

turm

counterclockwise

in

a

reduction

ratio

ofapproximately2

18

to

1

Fluid

flow

Manual

Valve

4

Automatic

Tninsmission

Front

gear

set

Rear

gear

ell

Output

Input

throush

front

clutch

Held

by

low

A

reverse

brake

AT329

lW

w

Y

Front

clutch

Rear

clutch

Low

and

reverse

brake

Brake

band

servo

On

way

clutch

5

Throttle

Back

up

Valve

Low

A

reverse

brake

ON

Downshift

Valve

1st

2nd

Shift

Valve

12

6

L

Pressure

Regulator

Valve

2nd

3rd

Shift

Valve

10

AT

8

AT085

ON

OFF

ON

OFF

Preuwe

release

o

ernmnin

F

AT

9

M

hanical

Operation

during

R

Range

13

2nd

3rd

Shift

Valve

L

1st

2nd

Shift

Valve

I

Throttle

Back

up

Valve

y

Low

Reve

Brake

Band

Servo

Release

Side

11

Front

Clut

h

I

Page 264 of 548

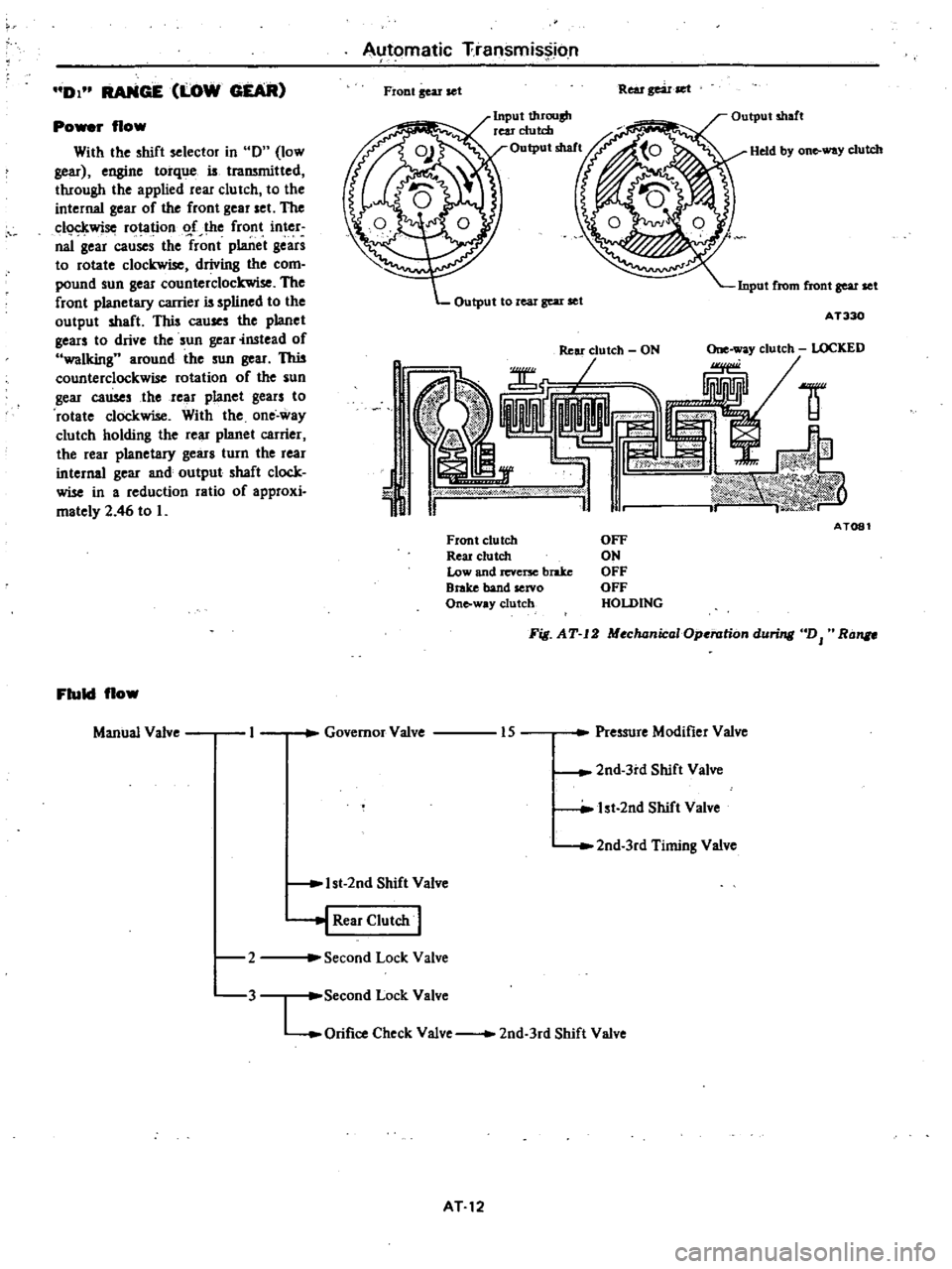

DI

RANGE

LOW

GEAR

Po

r

flow

With

the

shift

selector

in

0

low

gear

engine

torque

is

traJWnitted

through

the

applied

rear

clu

tch

to

the

internal

gear

of

the

front

gear

set

The

c1o

kwise

rotation

o

f

the

front

inter

naI

gear

causes

the

front

planet

gears

to

rotate

clockwise

driving

the

com

pound

sun

gear

counterclockwise

The

front

planetary

carrier

is

splined

to

the

output

shaft

This

cau

the

planet

gears

to

drive

the

sun

gear

instead

of

walking

around

the

sun

gear

This

counterclockwise

rotation

of

the

sun

gear

causes

the

rear

planet

gears

to

rotate

clockwise

With

the

one

way

clutch

holding

the

rear

planet

carrier

the

rear

planetary

gears

turn

the

rear

internal

gear

and

output

shaft

clock

wise

in

a

reduction

ratio

of

approxi

mately

2

46

to

L

Fluid

flow

Manual

Valve

2

3

Automatic

Transmission

Fiont

gear

set

Rear

gear

set

Input

t1uOllsh

rear

clutch

Output

shaft

Held

by

on

way

clutch

Input

from

front

gear

set

Output

to

real

gear

set

AT330

1

J

ld

AT081

Front

clutch

Reu

clutch

Low

and

revcrx

brake

Brake

band

servo

Onto

way

clutch

OFF

ON

OFF

OFF

HOLDING

Fig

AT

12

MochanicaIOp

rationduri

DJ

Ra

Governor

Valve

Pressure

Modifier

Valve

15

2nd

3rd

Shift

Valve

lst

2nd

Shift

Valve

2nd

3rd

Timing

Valve

1st

2nd

Shift

Valve

j

Rear

Clutch

I

Second

Lock

Valve

Second

Lock

Valve

LOrifice

Check

Valve

2nd

3rd

Shift

Valve

AT12

Page 266 of 548

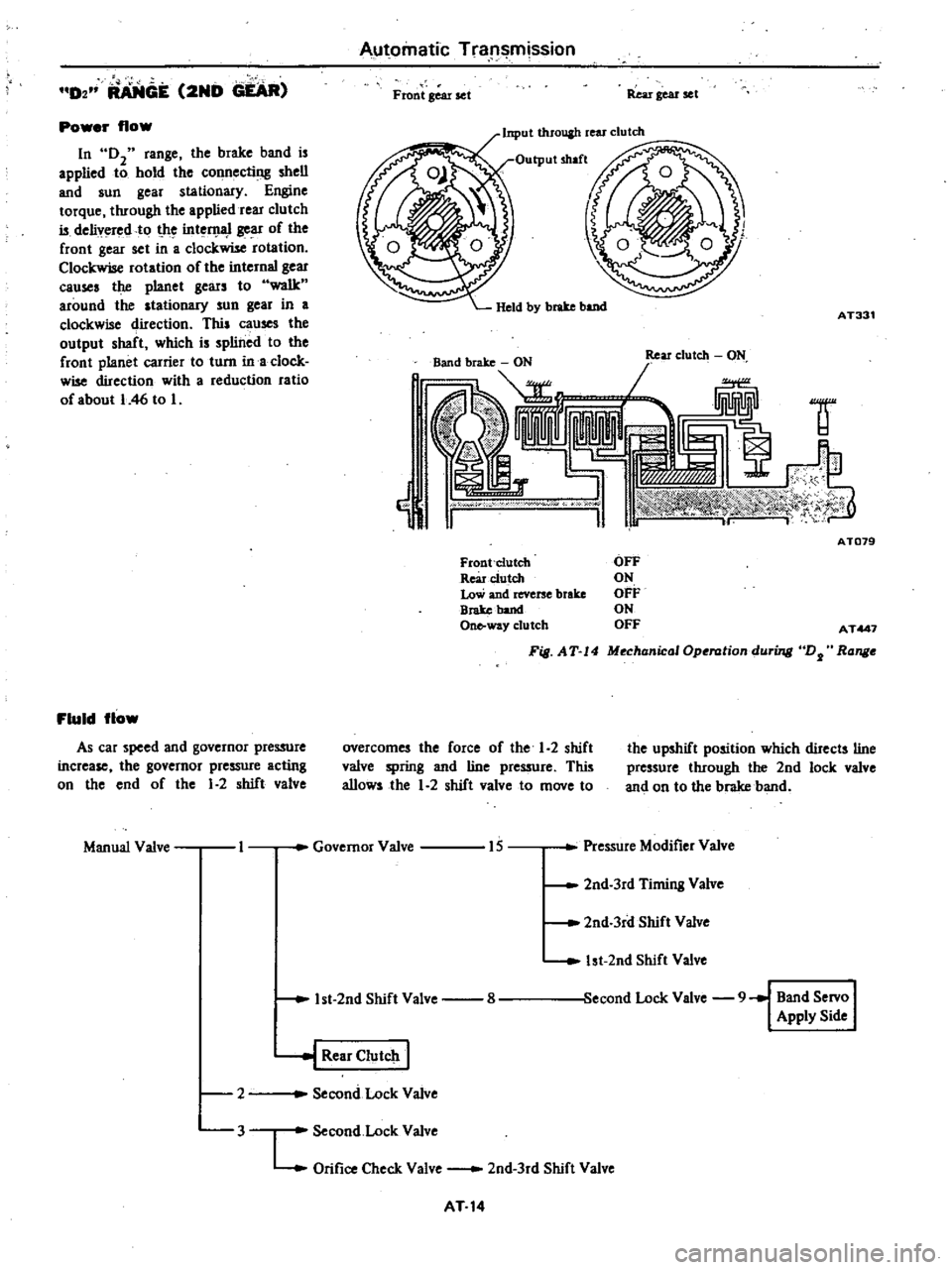

D2

RA

NGE

2ND

GEAR

Power

flow

In

02

range

the

brake

band

is

applied

to

hold

the

connecting

shell

and

sun

gear

stationary

Engine

torque

through

the

applied

rear

clutch

is

delivered

to

t

he

int

D

1l

1

gear

of

the

front

gear

set

in

a

clockwise

rotation

Clockwise

rotation

of

the

internal

gear

causes

the

planet

gears

to

walk

around

the

stationary

sun

gear

in

a

clockwise

direction

This

causes

the

output

shaft

which

is

splined

to

the

front

planet

carrier

to

turn

ina

clock

wise

direction

with

a

reduction

ratio

of

about

I

46

to

I

Fluid

flow

As

car

speed

and

governor

pressure

increase

the

governor

pressure

acting

on

the

end

of

the

1

2

shift

valve

Manual

Valve

I

Automatic

Tra

l

mission

Front

Bear

set

Rear

gear

set

Input

throuah

rear

clutch

AT331

1f

j

cW

oo

w

I

ATD79

Front

Clutch

Rearc1utch

Low

and

reverse

brake

Broke

band

One

way

clutch

OFF

ON

OFF

ON

OFF

AT447

F

S

AT

14

MechanicalOperation

during

DJ

Range

overcomes

the

force

of

the

1

2

shift

valve

spring

and

line

pressure

This

allows

the

1

2

shift

valve

to

move

to

the

upshift

position

which

directs

line

pressure

through

the

2nd

lock

valve

and

on

to

the

brake

band

Governor

Valve

15

Pressure

Modifier

Valve

2nd

3rd

Timing

Valve

2nd

3rd

Shift

Valve

1st

2nd

Shift

Valve

econd

Lock

Valve

9

Band

Servo

I

Apply

Side

1st

2nd

Shift

Valve

8

l

Rear

CIutclt

I

Second

Lock

Valve

2

3

Second

Lock

Valve

L

Orifice

Check

Valve

2nd

3rd

Shift

Valve

AT

14

Page 268 of 548

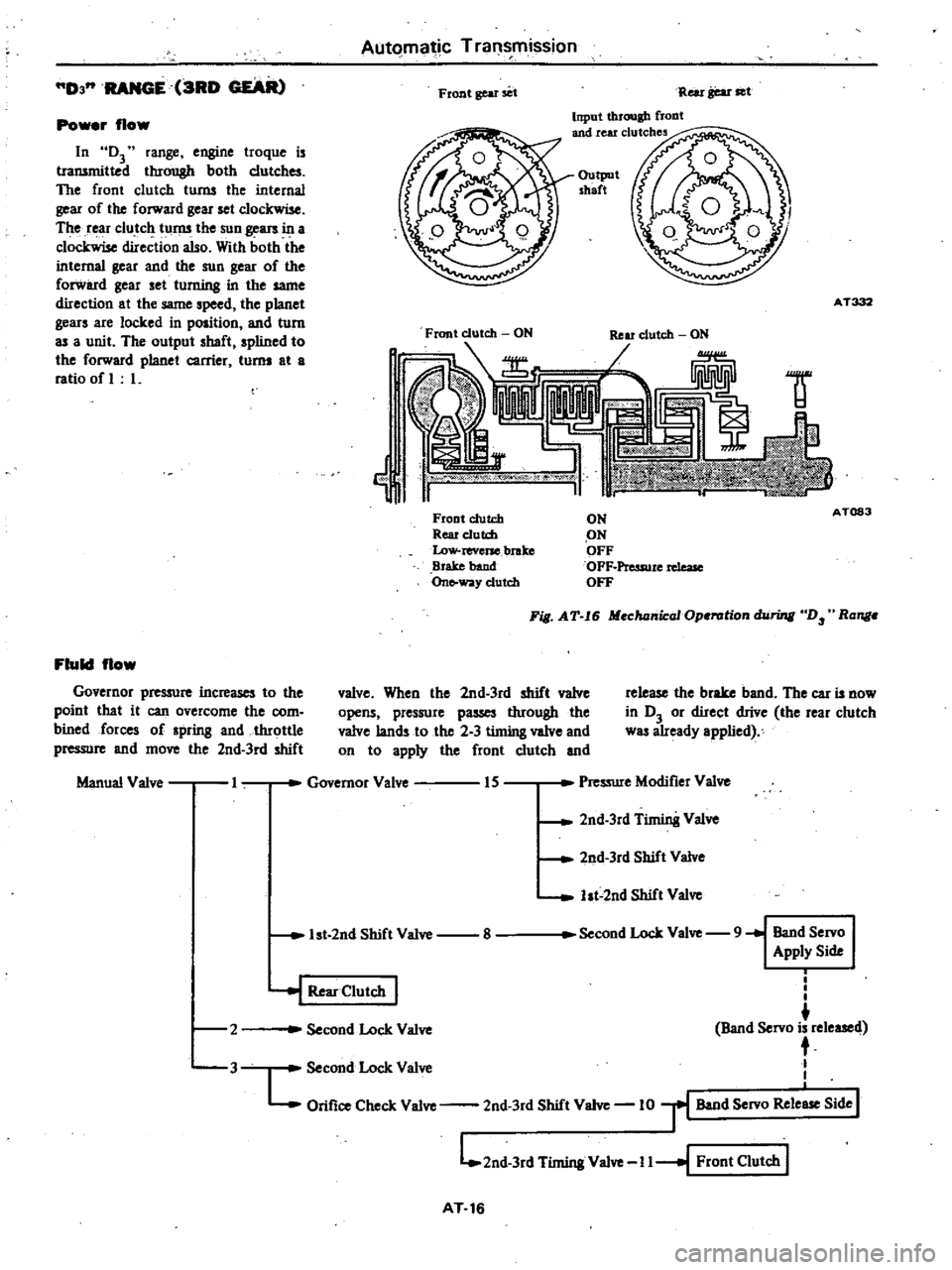

Automatic

Transmission

D3

RANGE

3RD

GEAR

Front

gear

set

Rei

r

gear

set

Input

through

flODt

and

rear

clutches

Power

flow

In

D3

range

engine

troque

is

transmitted

through

both

clutches

The

front

clutch

turns

the

internal

gear

of

the

forward

gear

set

clockwise

The

rear

clutch

turns

the

sun

gears

in

a

clockwise

direction

also

With

both

the

internal

gear

and

the

sun

gear

of

the

forward

gear

set

turning

in

the

same

direction

at

the

same

speed

the

planet

gears

are

locked

in

position

and

turn

as

a

unit

The

output

shaft

spIined

to

the

forward

planet

carrier

turns

at

a

ratio

of

L

Output

shaft

AT332

Front

clutch

ON

Ij

1f

Front

clutch

Rear

e1utd

Low

reverse

brake

Brake

band

On

way

clutch

ON

ON

OFF

OFF

Pressure

rdeaJe

OFF

A

T083

Fill

AT

I6

Mechanical

Operation

hiring

D

Ronge

Fluid

flow

Governor

pre

ure

increases

to

the

poinl

that

it

can

overcome

the

com

bined

forces

of

spring

and

throttle

pressure

and

move

the

2nd

3rd

shift

valve

When

the

2nd

3rd

shift

valve

opens

pressure

passes

through

the

valve

lands

to

the

2

3

timing

valve

and

on

to

apply

the

front

clutch

and

release

the

brake

band

The

car

is

now

in

D3

or

direct

drive

the

rear

clutch

was

already

applied

Manual

Valve

I

Governor

Valve

IS

Pressure

Modifier

Valve

2nd

3rd

Timin8

Valve

2nd

3rd

Shift

Valve

ht

2nd

Shift

Valve

1st

2nd

Shift

Valve

8

Second

Lock

Valve

9

Band

Servo

Apply

Side

2

i

I

I

Band

Servo

is

released

t

Second

Lock

Valve

L

Orifice

Check

Valve

2nd

3rd

Shift

Valve

10

r

Band

Servo

Rele

Side

I

L

2nd

3rd

Timing

Valve

I

I

I

Front

Clutch

I

J

Second

Lock

Valve

I

Rear

Clutch

I

3

AT

16

Page 274 of 548

Automatic

Transmission

l

RANGE

LOW

AND

2ND

GEAR

second

12

afwvernor

preSsure

pre

vents

the

I

2

shift

valve

from

closing

The

range

1

position

is

used

to

lock

the

car

in

1st

gear

preventing

any

upshifts

If

the

selector

lever

is

moved

to

the

I

position

while

the

car

is

moving

at

high

speeds

the

transmis

sion

w

ill

not

shift

into

first

gear

until

car

speed

slows

to

approxiniately

55

km

h

35

mph

Instead

it

will

shift

to

Po

r

flow

The

power

flow

in

11

differs

slight

ly

from

01

in

that

the

low

and

reverse

band

is

applied

to

hold

the

rear

gear

set

planet

carrier

providing

engine

hraking

Power

flow

in

12

is

the

same

a

io02

Manual

Valve

Governor

Valve

15

Pressure

Modifier

Valve

I

Fluid

flow

Lolft

ar

Manual

pressure

passing

through

the

1

2

shift

valve

is

used

to

close

the

1

2

shift

valve

preventing

a

1

2

up

shift

Manual

pressure

pusing

through

the

downshift

valve

lock

the

2

3

siuit

valve

closed

along

with

applying

addi

tional

closing

pressure

to

the

I

2

shift

valve

2nd

3rd

Timing

Valve

2nd

3rd

Shift

Valve

lst

2ndSti

ft

Valve

1st

2nd

Shift

Valve

iRea

Clutcb

I

4

Solenoid

Downshift

Valve

13

I2nd

3rd

Shift

Valve

ht

2nd

Shift

Valve

Throttle

Back

up

Valve

5

C

1st

2nd

Shift

Valve

12

I

Throttle

Back

up

Valve

y

Low

Reverse

Bra1ce

I

Fluid

flow

2nd

ar

Manual

Valve

Governor

Valve

15

Preuurc

Modjfier

Valve

2nd

3rd

Timing

Valve

2nd

3rd

Shift

Valve

1st

2nd

Shift

Valve

8

1st

2nd

Shift

Valve

Second

Lock

Valve

9

I

Band

Servo

I

Apply

Side

4

t

Rear

Clutch

I

Solenoid

Downshift

Valve

13

I

2nd

3rd

Shift

Valve

ht

2nd

Shift

Valve

Throttle

Back

up

Valve

17

PreSlure

Modifier

Valve

2nd

3rd

Shift

Valve

2nd

3rd

Timing

Valve

Throttle

Drain

Valve

s

ht

2nd

Shift

Valve

Pressure

Regulator

Valve

AT

22

Page 277 of 548

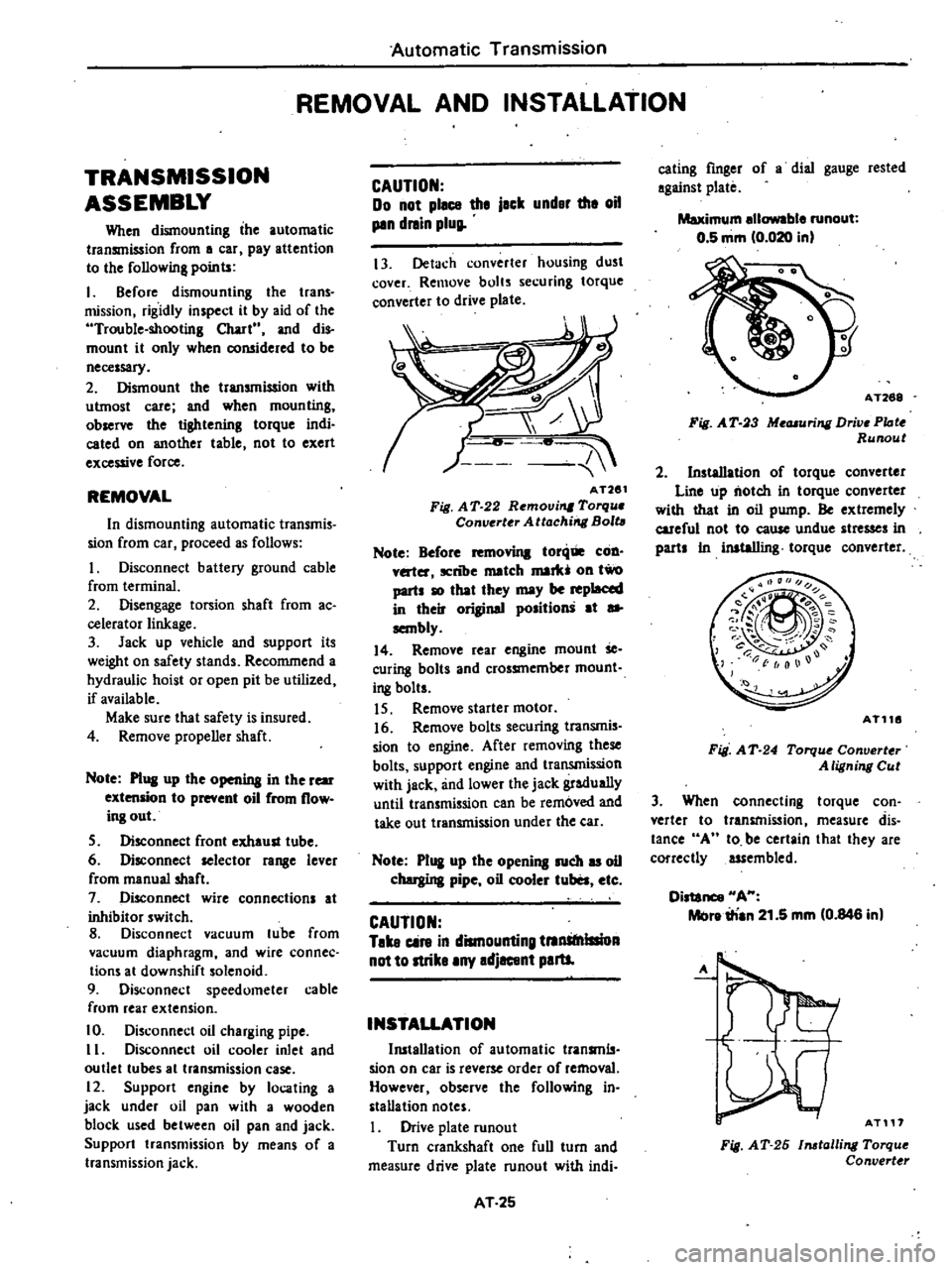

Automatic

Transmission

REMOVAL

AND

INSTALLATION

TRANSMISSION

ASSEMBLY

When

dismounting

the

automatic

transmission

from

a

car

pay

attention

to

the

following

points

I

Before

dismounting

the

trans

mission

rigidly

inspect

it

by

aid

of

the

Trouble

shooting

Chart

and

dis

mount

it

only

when

coll5idered

to

be

necessary

2

Dismount

the

transmission

with

utmost

care

and

when

mounting

observe

the

tightening

torque

indi

cated

on

another

table

not

to

exert

excessive

force

REMOVAL

In

dismounting

automatic

transmis

sion

from

car

proceed

as

follows

I

Disconnect

battery

ground

cable

from

terminal

2

Disengage

torsion

shaft

from

ac

eelerator

linkage

3

Jack

up

vehicle

and

support

its

weight

on

safety

stands

Recommend

a

hydraulic

hoist

or

open

pit

be

utilized

if

available

Make

sure

that

safety

is

insured

4

Remove

propeller

shaft

Note

Pl

ll

up

the

openina

in

the

rear

extension

to

prevent

oil

from

flow

ing

out

S

Disconnect

front

exhaust

tube

6

Disconnect

selector

ra

8e

lever

from

manual

shaft

7

Disconnect

wire

connections

at

inhibitor

switch

8

Disconnect

vacuum

lube

from

vacuum

diaphragm

and

wire

connee

tions

at

downshift

solenoid

9

Disconnect

speedometer

cable

from

rear

exlension

10

Disconnect

oil

charging

pipe

II

Disconnect

oil

cooler

inlet

and

outlet

tubes

al

transmission

case

12

Support

engine

by

locating

a

jack

under

oil

pan

with

a

wooden

block

used

between

oil

pan

and

jack

Support

transmission

by

means

of

a

transmission

jack

CAUTION

Do

not

plecs

the

jack

under

the

oil

pin

dnin

plug

13

Detach

converter

housing

dust

cover

Remove

bolts

securing

torque

converter

to

drive

plate

AT261

Fig

A

T

22

Removi

Torqu

Converter

Attachirrg

Bolt

Note

Before

toni

COD

v

ter

ICnlJe

match

mark

011

two

parts

10

that

they

may

be

replaced

in

their

original

position

at

sa

sembly

14

Remove

rear

engine

mount

Se

curing

bolts

and

crossmember

mount

i

8

bolts

IS

Remove

starter

motor

16

Remove

bolts

securing

transmis

sion

to

engine

After

removing

these

bolts

support

engine

and

transmission

with

jack

and

lower

the

jack

gradually

until

transmission

can

be

removed

and

take

out

transmission

under

the

ear

Note

P1

I

up

the

opening

such

u

oil

chergina

pipe

oil

cooler

tuba

etc

CAUTION

Take

cin

in

dismounting

tnnStnlllioA

not

to

strike

any

adjacent

paru

INSTALLATION

Ill5tallation

of

automatic

transmls

sian

on

car

is

reverse

order

of

removal

However

observe

the

following

in

stallation

notes

Drive

plate

runout

Turn

crankshaft

one

full

turn

and

measure

drive

plate

runout

with

indi

AT

25

eating

finger

of

a

dial

gauge

rested

against

plate

Maximum

ellowable

runout

0

5

mm

0

020

in

AT268

Fig

A

T

3

Me

uring

Drive

PIote

Runout

2

Installation

of

torque

converter

Line

up

notch

in

torque

converter

with

that

in

oil

pump

Be

extremely

careful

not

to

eause

undue

stresses

in

parts

In

inataIIing

torque

converter

AT116

Fig

A

T

24

Torqu

Converter

A

ligning

Cut

3

When

connecting

torque

con

verter

to

transmission

measure

dis

tance

A

10

be

certain

that

they

are

correctly

assembled

Distance

HA

Melre

irian

21

5

mm

0

846

in

A

AT117

Fig

AT

26

1116talling

Torque

Convert

r