fuel filter DATSUN 210 1979 Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 138 of 548

Air

Induction

v

lve

filter

The

air

induction

valve

filter

is

installed

at

the

dust

side

of

the

air

cleaner

It

purifies

secondary

air

to

be

sent

to

the

exhaust

tube

The

fIlter

element

should

be

replaced

periodical

ly

in

accordance

with

the

Maintenance

Schedule

EC921

Fig

EC

54

Air

Induction

Valve

Filter

Antl

beckflre

v

lve

A

B

v

lve

Tltis

valve

is

controlled

by

intake

manifold

vacuum

to

prevent

backfire

in

the

exhaust

system

at

the

initial

period

of

deceleration

At

this

period

the

mixture

in

the

intake

manifold

becomes

too

rich

to

ignite

and

burn

in

the

combustion

chamber

and

burns

easily

in

the

ex

haust

system

with

injected

air

in

the

exhaust

manifold

The

anti

backfire

valve

provides

air

to

the

intake

manifold

to

make

the

air

fuel

mixture

leaner

and

prevents

backfire

If

the

valve

does

not

work

properly

unburned

ntixture

will

be

emitted

from

the

combustion

chambers

and

burns

with

the

aid

of

high

temperature

and

injected

air

which

causes

backfrre

To

intake

manifold

vacuum

To

intake

manifold

From

air

cleaner

EC069

Fig

EC

55

Anti

backfire

Value

Emission

Control

System

Air

Induction

Into

exhaust

port

The

secondary

air

fed

from

the

air

induction

valve

goes

through

the

check

valve

to

the

air

gallery

in

the

cylinder

head

It

is

then

distributed

to

each

exhaust

port

and

injected

near

the

exhaust

valve

I

Air

gallery

2

Exhaust

port

3

Exhaust

manifold

EC316

Fig

EC

56

Sectional

View

of

Exhaust

Port

REMOVAL

AND

INSTALLATION

Air

Induction

valve

and

filter

Remove

the

screws

securing

the

valve

and

filter

to

the

air

cleaner

body

The

air

induction

valve

and

valve

filter

can

then

be

taken

out

easily

Installa

tion

is

in

the

reverse

sequence

of

removal

EC922

Fig

EC

57

Removing

Air

Induction

Valve

and

Filter

EC

19

Air

Induction

pipe

Loosen

out

a

nut

securing

the

pipe

to

the

engine

cylinder

head

At

the

same

time

remove

the

screws

securing

the

bracket

and

rubber

hose

clamp

The

air

induction

pipe

can

then

be

taken

out

Installation

is

in

the

reverse

sequence

of

removal

Fig

EC

58

A

B

valve

The

A

B

valve

is

located

at

the

rear

side

of

the

air

cleaner

Remove

the

air

hoses

and

vacuum

tube

The

A

B

valve

can

then

be

taken

out

Installation

is

in

the

reverse

se

quence

of

removal

EC152A

Fig

EC

59

Removing

A

B

Valve

INSPECTION

Preliminary

Inspection

Check

hose

for

looseness

flatting

damage

or

faulty

connections

and

each

part

for

proper

installation

If

necessary

replace

Air

Induction

valve

and

filter

I

Disconnect

air

induction

hose

at

air

induction

pipe

side

Suck

or

blow

hose

to

make

sure

that

air

flows

only

on

the

air

induction

pipe

side

Page 155 of 548

OPERATION

Fuel

vapors

from

the

sealed

fuel

tank

are

led

into

the

carbon

canister

The

canister

is

filled

with

activated

charcoals

to

absorb

the

fuel

vapors

when

the

engine

is

at

rest

or

at

idling

t

Fuel

tank

2

Fuel

filler

cap

with

vacuum

re1ief

va1ve

3

Fuel

check

vslve

4

Vapor

t

line

5

Vacuum

signal

line

6

Canister

purge

line

Emission

Control

System

As

the

throttle

Valve

opens

and

car

speed

increases

vacuum

pressure

in

the

vacuum

signajline

forces

the

purge

control

valve

to

open

and

admits

an

orifice

to

intake

manifold

and

fuel

vapor

is

then

drawn

into

the

intake

manifold

through

the

canister

purge

line

Fuel

vapor

7

Throttle

valve

IZ

Filter

8

Engine

13

Purge

control

valve

9

Carbon

cani5t

14

DiaphraP

spring

10

Activated

carbon

IS

Diaphngm

II

Screen

16

Fixed

orifice

EC785

Fig

EC

JOS

Evaporative

Emiuion

Control

System

Fuel

vapor

flow

when

ngine

is

at

rest

or

running

REMOVAL

AND

INSTALLAtiON

CARBON

CANISTER

FILTER

Check

for

a

contantinated

element

Elemenl

can

be

removed

at

the

bottom

of

canister

installed

on

car

body

EF201

Fig

EC

I06

Replacing

Carbon

Canilttr

Filter

CHECK

VALVE

The

check

valve

is

located

behind

the

luggage

compartment

board

on

the

fuel

tank

Remove

the

luggage

compartment

board

and

disconnect

the

vapor

tube

The

check

valve

can

then

be

taken

out

EC315A

Fig

EC

I07

Removing

Check

Volve

EC

36

INSPECTION

FUEL

TANK

AND

VAPOR

VENT

LINE

1

Check

all

hoses

and

fuel

tank

filler

cap

2

Disconnect

the

vapor

vent

line

connecting

carbon

canister

to

check

valve

3

Connect

a

3

w

y

connector

a

manometer

and

a

cock

or

an

equi

valent

3

way

charge

cock

to

the

end

of

the

vent

line

EC183A

Fig

EC

IOB

Vent

Line

4

Supply

fresh

air

into

the

vapor

vent

line

through

the

cock

little

by

little

until

pressure

becomes

368

mmHZO

14

5

inHZO

S

Shut

the

cock

completely

and

leave

it

unattended

6

After

2

5

minutes

measure

the

height

of

the

liquid

in

the

manometer

7

Variation

in

height

should

remain

with

25

mmHZO

0

98

inH20

8

When

filler

cap

does

not

close

completely

the

height

should

drop

to

zero

in

a

short

time

9

If

the

height

does

not

drop

to

zero

in

a

short

time

when

ruler

cap

is

d

it

is

the

cause

of

a

stuffy

hose

Note

In

case

the

vent

line

is

stuffy

the

breathing

in

fuel

tank

is

not

thoroughly

IIIIIde

thus

causing

in

sufficient

delivery

of

feul

to

engine

or

vapor

lock

It

must

therefore

be

repaired

or

replaced

Page 403 of 548

Engine

Control

Fuel

Exhaust

Systems

REMOVAL

WARNING

When

replacing

fuel

line

parts

be

sure

to

observe

the

following

a

Put

a

CAUTION

INFLAM

MABLE

sign

in

workshop

b

Be

sure

to

furnish

workshop

with

In

asphyxiator

c

Be

sure

to

disconnect

battery

ground

cable

before

conducting

operations

d

Put

drained

fuel

in

an

explosion

proof

container

and

put

on

lid

securely

FUEL

TANK

Sedan

I

Disconnect

battery

ground

cable

2

Drain

fuel

from

fuel

tank

then

disconnect

fuel

hose

3

Remove

filler

hose

protector

and

inspection

cover

in

luggage

com

i

tl

f

I

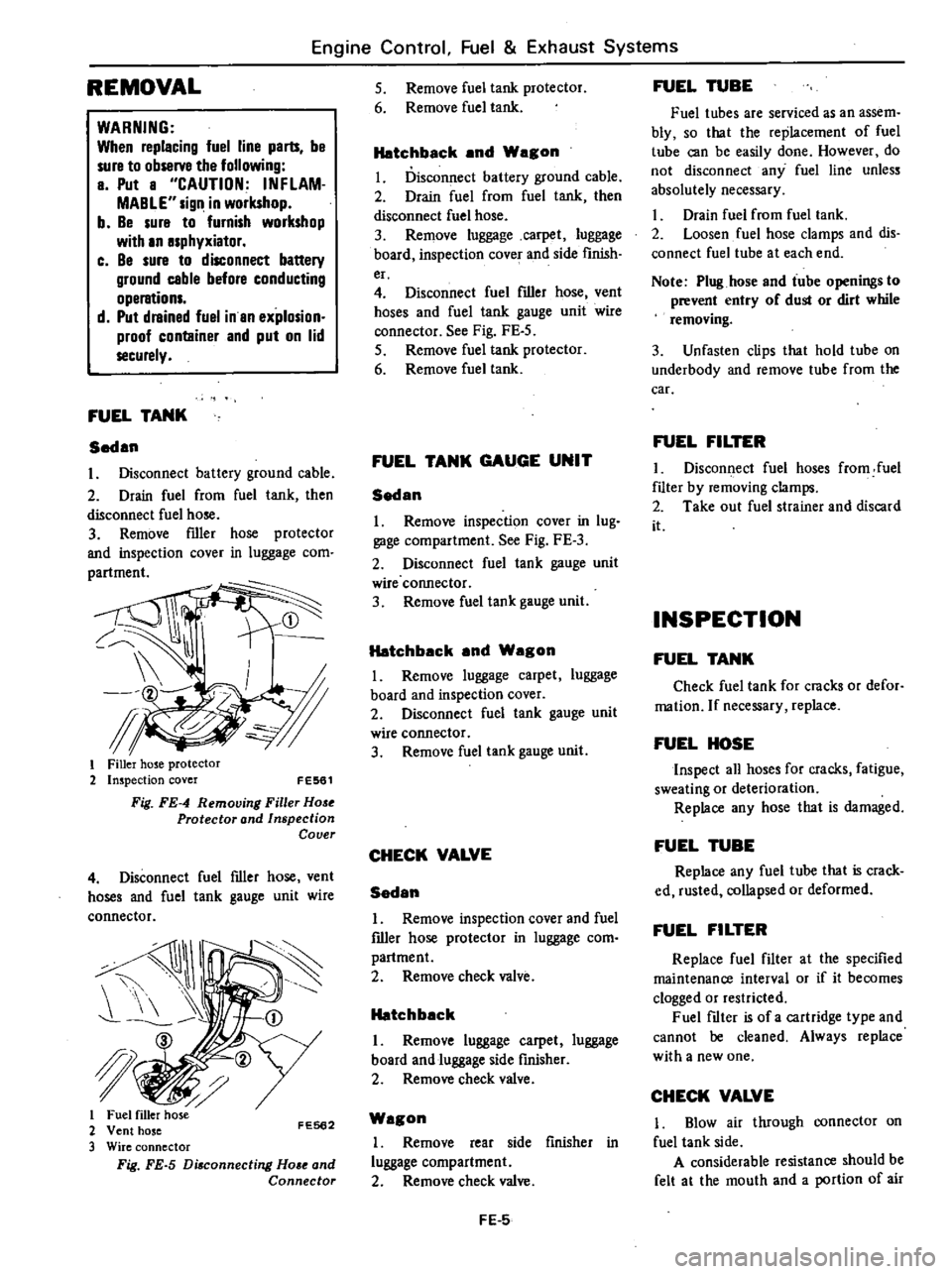

Filler

hose

protector

2

Inspection

cover

FE561

Fig

FE

4

Removing

Filler

Hose

Protector

and

Inspection

Cover

4

Disconnect

fuel

filler

hose

vent

hoses

and

fuel

tank

gauge

unit

wire

connector

I

JI

I

2

FE562

3

Fig

FE

5

Di

connecting

Ho

e

and

Connector

5

Remove

fuel

tank

protector

6

Remove

fuel

tank

Hatchback

and

Wagon

I

Disconnect

battery

ground

cable

2

Drain

fuel

from

fuel

tank

then

disconnect

fuel

hose

3

Remove

luggage

carpet

luggage

board

inspection

covef

and

side

finish

er

4

Disconnect

fuel

filler

hose

vent

hoses

and

fuel

tank

gauge

unit

wire

connector

See

Fig

FE

5

5

Remove

fuel

tank

protector

6

Remove

fuel

tank

FUEL

TANK

GAUGE

UNIT

Sedan

1

Remove

inspection

cover

in

lug

gage

compartment

See

Fig

FE

3

2

Disconnect

fuel

tank

gauge

unit

wire

connector

3

Remove

fuel

tank

gauge

unit

Hatchback

and

Wagon

I

Remove

luggage

carpet

luggage

board

and

inspection

cover

2

Disconnect

fuel

tank

gauge

unit

wire

connector

3

Remove

fuel

tank

gauge

unit

CHECK

VALVE

Sedan

I

Remove

inspection

cover

and

fuel

filler

hose

protector

in

luggage

com

partment

2

Remove

check

valve

Hatchback

I

Remove

luggage

carpet

luggage

board

and

luggage

side

finisher

2

Remove

check

valve

Wagon

I

Remove

rear

side

finisher

in

luggage

compartment

2

Remove

check

valve

FE

5

FUEL

TUBE

Fuel

tubes

are

serviced

as

an

assem

bly

so

that

the

replacement

of

fuel

tube

can

be

easily

done

However

do

not

disconnect

any

fuel

line

unless

absolutely

necessary

Drain

fuel

from

fuel

tank

2

Loosen

fuel

hose

clamps

and

dis

connect

fuel

tube

at

each

end

Note

Plug

hose

and

tube

openings

to

prevent

entry

of

dust

or

dirt

while

removing

3

Unfasten

clips

that

hold

tube

on

underbody

and

remove

tube

from

the

car

FUEL

FILTER

I

Disconnect

fuel

hoses

from

fuel

filter

by

removing

clamps

2

Take

out

fuel

strainer

and

discard

it

INSPECTION

FUEL

TANK

Check

fuel

tank

for

cracks

or

defor

mation

If

necessary

replace

FUEL

HOSE

Inspect

all

hoses

for

cracks

fatigue

sweating

or

deterioration

Replace

any

hose

that

is

damaged

FUEL

TUBE

Replace

any

fuel

tube

that

is

crack

ed

rusted

collapsed

or

deformed

FUEL

FILTER

Replace

fuel

filter

at

the

specified

maintenance

interval

or

if

it

becomes

clogged

or

restricted

Fuel

filter

is

of

a

cartridge

type

and

cannot

be

cleaned

Always

replace

with

a

new

one

CHECK

VALVE

1

Blow

air

through

connector

on

fuel

tank

side

A

considerable

resistance

should

be

felt

at

the

mouth

and

a

portion

of

air