wheel torque DATSUN 210 1979 Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 352 of 548

Rear

Axle

Rear

Suspension

SPECIAL

SERVICE

TOOLS

Tool

number

tool

name

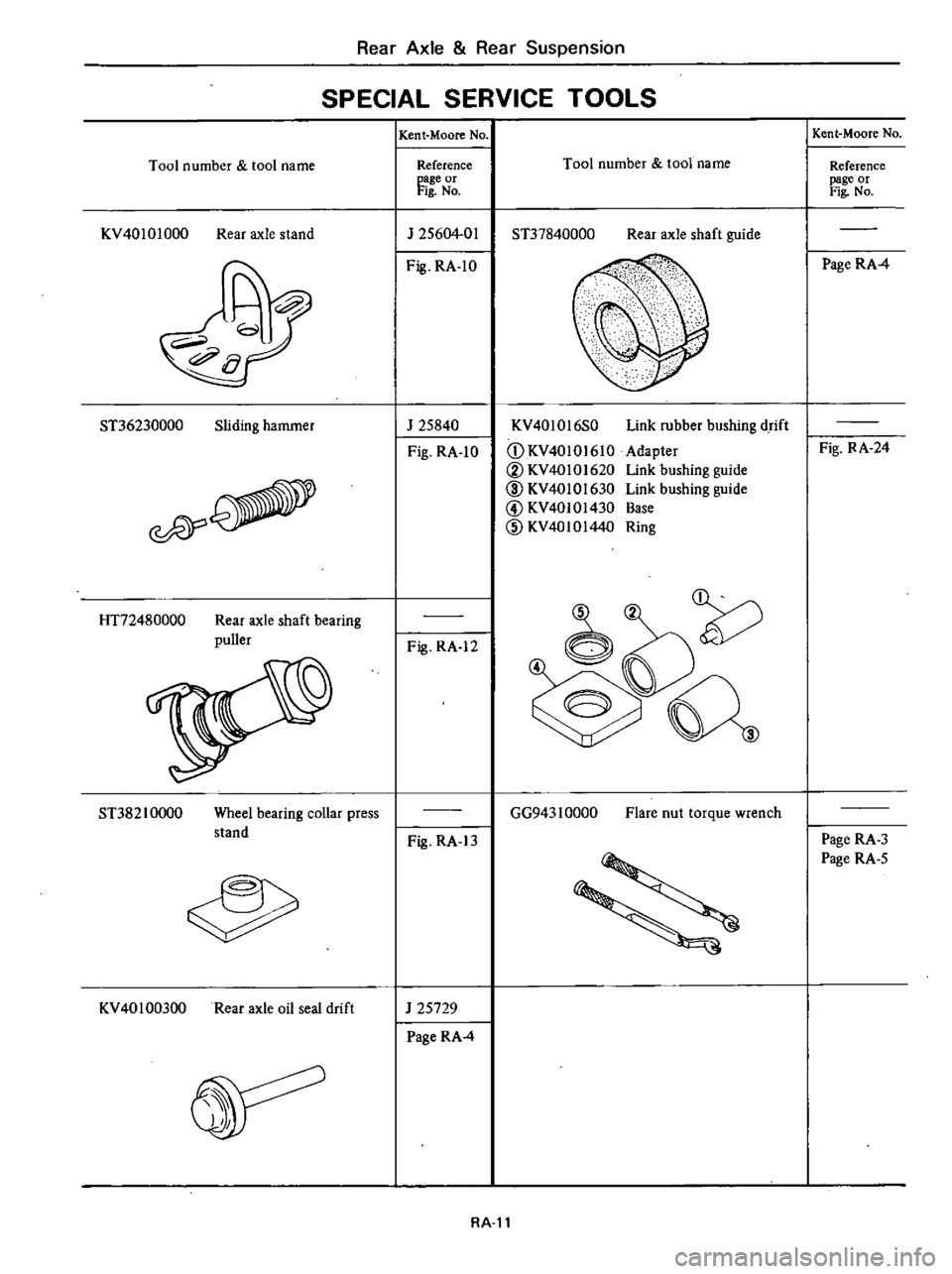

KV40101000

Rear

axle

stand

ST36230000

Sliding

hammer

esPY

HT72480000

Rear

axle

shaft

bearing

puller

ST38210000

Wheel

bearing

collar

press

stand

KV

401

00300

Rear

axle

oil

seal

drift

Kent

Moore

No

Reference

page

or

Fig

No

J

25604

01

Fig

RA

1O

J

25840

Fig

RA

1O

Fig

RA

12

Fig

RA

13

J

25729

Page

RA

4

Tool

number

tool

name

ST37840000

Rear

axle

shaft

guide

KV40l016S0

CD

KV40

10

I

610

V

KV40101620

ID

KV4010l630

@

KV40101430

CID

KV4010144

Link

rubber

bushing

drift

Adapter

Link

bushing

guide

Link

bushing

guide

Base

Ring

GG943

1

0000

Flare

nut

torque

wrench

RA

ll

Kent

Moore

No

Reference

page

or

Fig

No

Page

RA

4

Fig

RA

24

Page

RA

3

Page

RA

5

Page 355 of 548

L

@

fl

JJ

l

f

m

ff

v

1

II

2

I

I

II

B

s1

r

Dip

other

end

of

hose

into

brake

fluid

bled

in

a

container

3

Pepress

brake

pedal

two

or

three

times

and

then

keep

pedal

fully

de

pressed

4

With

brake

pedal

fully

depressed

open

bleeder

valve

to

exhaust

air

Note

a

Carefully

monitor

brake

fluid

level

at

master

cylinder

during

bleeding

operation

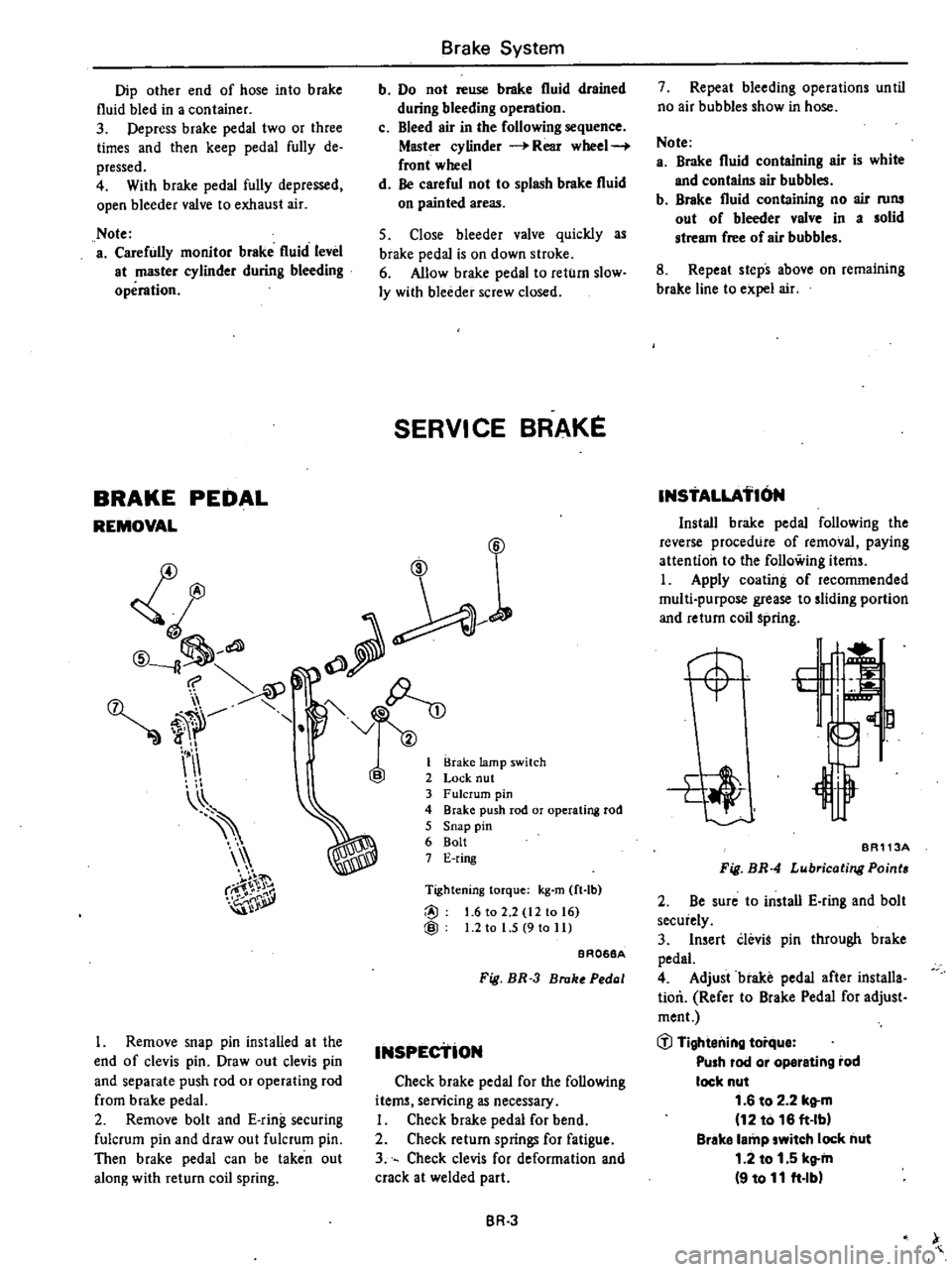

BRAKE

PEDAL

REMOVAL

I

Remove

snap

pin

installed

at

the

end

of

clevis

pin

Draw

out

clevis

pin

and

separate

push

rod

or

operating

rod

from

brake

pedal

2

Remove

bolt

and

E

ring

securing

fulcrum

pin

and

draw

out

fulcrum

pin

Then

brake

pedal

can

be

taken

out

along

with

return

coil

spring

Brake

System

b

Do

not

reuse

brake

fluid

drained

during

bleeding

operation

c

Bleed

air

in

the

following

sequence

Master

cylinder

Rear

wheel

front

wheel

d

Be

careful

not

to

splash

brake

fluid

on

painted

areas

5

Close

bleeder

valve

quickly

as

brake

pedal

is

on

down

stroke

6

Allow

brake

pedal

to

return

slow

ly

with

bleeder

screw

closed

SERVI

CE

BRAKE

fJ

Brake

lamp

switch

Lock

nut

Fulcrum

pin

Brake

push

rod

or

operating

rod

Snap

pin

Bolt

E

ring

Tightening

torque

kg

m

ft

Ib

@

1

6

to

2

2

12

10

16

@

1

2

to

l

S

9

to

II

BROS8A

Fig

BR

3

Broke

Pedal

INSPEctioN

Check

brake

pedal

for

the

following

items

servicing

as

necessary

I

Check

brake

pedal

for

bend

2

Check

return

springs

for

fatigue

3

Check

clevis

for

deformation

and

crack

at

welded

part

BR

3

7

Repeat

bleeding

operations

until

no

air

bubbles

show

in

hose

Note

a

Brake

fluid

containing

air

is

white

and

contalns

air

bubbles

b

Brake

fluid

containing

no

air

rons

out

of

bleeder

valve

in

a

solid

stream

free

of

air

bubbles

8

Repeat

steps

above

on

remaining

brake

line

to

expel

air

INSTALLATION

Install

brake

pedal

following

the

reverse

procedure

of

removal

paying

attention

to

the

following

items

I

Apply

coating

of

recommended

multi

purpose

grease

to

sliding

portion

and

return

coil

spring

BA113A

Fit

BR

4

Lubricating

Point

2

Be

sure

to

install

E

ring

and

bolt

securely

3

Insert

CleviS

pin

through

brake

pedal

4

Adjust

brake

pedal

after

installa

tion

Refer

to

Blake

Pedal

for

adjust

ment

j

Tightening

torque

Push

rod

or

op8leting

rod

lock

nut

1

6

to

2

2

kltm

12

to

16

ft

Ibl

Brake

lamp

switch

lock

nut

1

2

to

1

5

kltin

9

to

11

ft

lb

Page 358 of 548

If

leakage

oCcurs

at

end

around

joints

re

tighten

Of

if

necessary

re

place

faulty

parts

INSTALLATION

Pay

particular

attention

to

follow

ing

instructions

when

installing

brake

lines

I

Leave

a

sulfident

space

between

brake

lines

and

adjacent

parts

so

that

brake

lines

are

completely

free

from

vibration

during

driving

2

Be

careful

not

to

warp

or

twist

brake

lines

3

When

installing

brake

tube

keep

a

certain

distance

between

tube

and

adjacent

parts

as

follows

Tube

to

rotating

parts

30

mm

1

18

in

Tube

to

moving

parts

10

mm

10

39

in

Tube

to

other

palls

5

mm

10

20

in

4

Always

fasten

brake

tubes

with

mounting

clips

where

necessary

On

rear

axle

case

are

two

double

dips

which

should

be

used

to

secure

brake

tubes

in

manner

described

be

low

Bend

short

clip

straight

up

With

brake

tube

on

long

clip

bend

clip

up

and

around

tube

Finally

wrap

short

clip

around

tube

to

secure

the

in

slallation

f

J

i

2

BA141

Fig

BR

7

Fastening

Brake

Tube

Securely

with

Double

Clip

5

Do

not

tighten

brake

line

mount

ing

flare

nut

excessively

CAUTION

When

installing

Fla

e

Nut

6694310000

brake

tubes

use

Torque

Wrench

Brake

System

t

D

Tightening

torque

Brake

tube

flare

nut

1

5

to

1

8

kg

m

11

to

13

ft

lb

Brake

hose

connector

1

7

to

2

0

kg

m

112

to

14

ft

lb

J

way

connector

bolt

0

8

to

1

1

kltm

5

8

to

8

0

ft

Ib

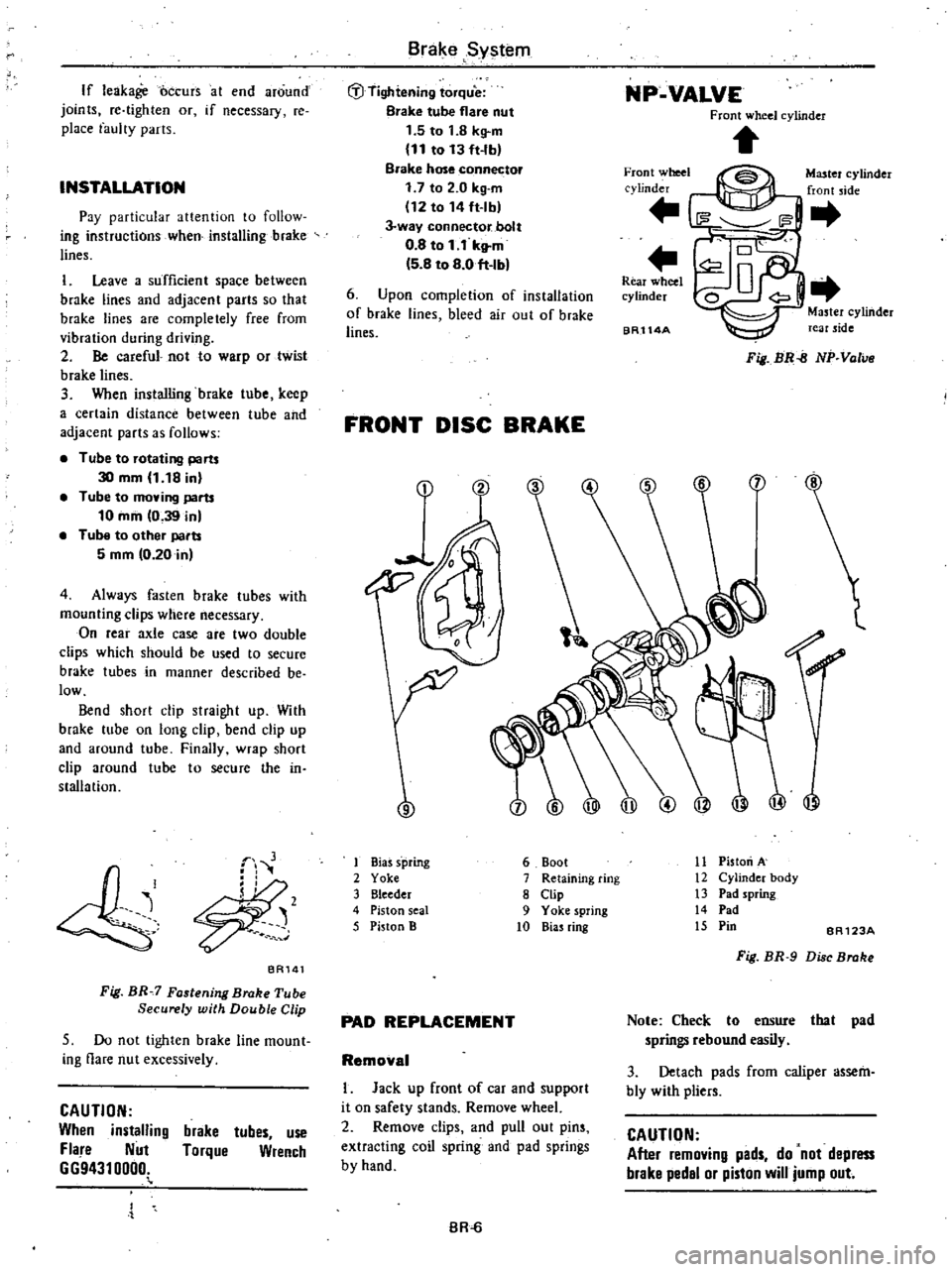

NP

VALVE

Front

wheel

cylinder

Front

wheel

cylinder

Master

cylinder

front

jde

6

Upon

completion

of

installation

of

brake

lines

bleed

air

out

of

brake

lines

Rear

wheel

cylinder

BR114A

Master

cylinder

rear

side

Fig

BR

B

NP

Valve

FRONT

DISC

BRAKE

9

ilJ

I

Bias

s

pring

2

Yoke

3

Bleeder

4

Piston

seal

5

Piston

B

11

Piston

A

12

Cylinder

body

13

Pad

spring

14

Pad

15

Pin

6

Boot

7

Retaining

ring

8

Clip

9

Yoke

spring

10

Bias

ring

BR123A

Fig

BR

9

Di

c

Broke

PAD

REPLACEMENT

Note

Check

to

ensure

that

pad

springs

rebound

easily

3

Detach

pads

from

caliper

assem

bly

with

pliers

Removal

I

Jack

up

front

of

car

and

support

it

on

safety

stands

Remove

wheel

2

Remove

clips

and

pull

out

pins

extracting

coil

spring

and

pad

springs

by

hand

CAUTION

After

removing

pads

do

not

depress

brake

pedal

or

piston

will

jump

out

BR

Page 363 of 548

6

Apply

P

B

C

grease

to

yoke

slid

ing

part

of

cylinder

Then

reposition

bias

ring

so

that

groove

of

bias

ring

coincides

with

yoke

7

Leaving

yoke

springs

inserted

lightly

into

cylinder

groove

assemble

cylinder

body

and

yoke

by

pushing

or

tapping

yoke

lightly

BA570

Fig

BR

19

A

embling

Yoke

and

Cylinder

8

Install

air

bleeder

valve

on

caliper

INSTAlLATION

1

Install

in

reverse

procedure

of

removal

CAUTION

When

installing

brake

tube

use

Flare

Nut

Torque

Wrench

6694310000

fJ

Tightening

tOlque

Calipel

securing

bolts

4

6

to

6

1

kll

m

33

to

44

ft

lb

Brake

tube

flere

nuts

1

5to

1

8

kg

m

11

to

13

ft

Ib

2

After

installing

pad

bleed

air

from

system

Brake

System

ROTOR

REMOVAL

Refer

to

Front

Axle

Section

FA

for

removal

Note

As

this

value

increases

wear

occurs

progressively

vibration

cor

responding

to

revolution

of

tire

may

often

be

tmnsmitted

to

in

terior

of

car

INSPECTION

Check

the

following

items

and

if

necessary

replace

Checks

can

be

made

by

removing

only

wheel

Sliding

surface

If

there

are

cracks

or

considerable

chips

replace

2

Runout

Adjust

wheel

bearing

correctly

Using

a

dial

gauge

measure

runout

at

the

center

of

rotor

pad

contact

sur

face

Runout

limit

less

than

0

12

mm

0

0047

in

Total

indicator

reading

BR025A

Fig

BR

20

Mecuuring

Runout

3

Parallelism

Measure

thickness

of

entire

periph

cry

of

rotor

using

a

micrometer

Parallelism

when

new

less

than

0

03

mm

0

0012

in

BR

9

Fig

BR

21

Measuring

Parallelism

4

Thickness

If

rotor

thickness

is

beyond

wear

limit

replace

rotor

When

correcting

thickness

be

sure

that

the

thickness

after

correction

does

not

exceed

the

limit

Standard

thickness

10

0

mm

0

394

in

Wear

limit

more

than

8

4

mm

0

331

in

INSTALLATION

Install

rotor

in

reverse

order

of

removal

Adjust

wheel

bearing

preload

correctly

Refer

to

Front

Axle

Sec

tion

FA

for

adjustment

ifl

Tightening

torque

Rotor

to

wheel

hub

3

9

to

5

3

kg

m

28

to

38

ft

rb

Page 364 of 548

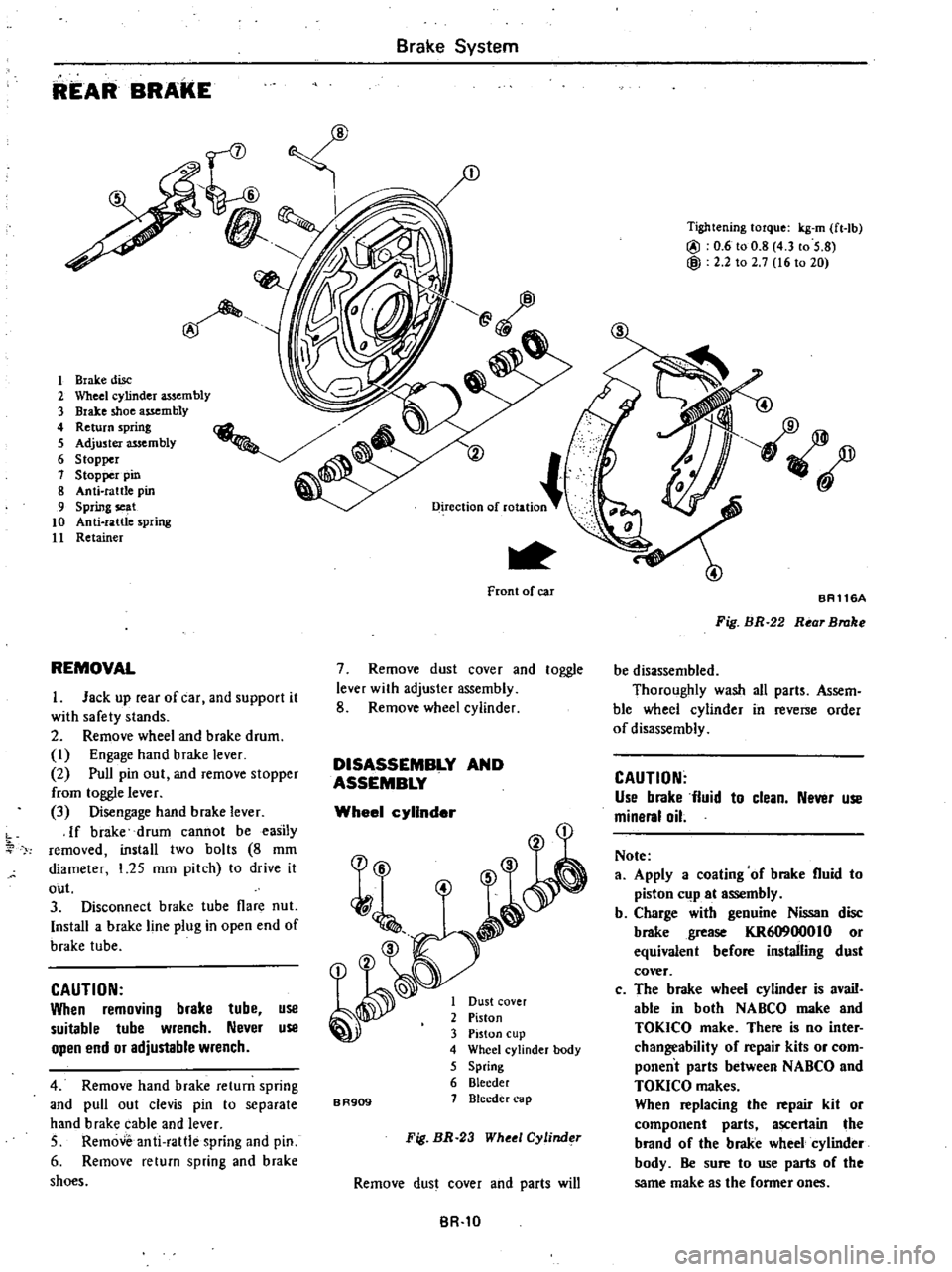

REAR

BRAKE

1

Brake

disc

2

Wheel

cylinder

assembly

3

Brake

shoe

assembly

4

Return

spring

5

Adjuster

assembly

6

Stopper

1

Stopper

pin

8

Anti

rattle

pin

9

Spring

se

t

10

Anti

rattle

spring

11

Retainer

REMOVAL

L

Jack

up

rear

of

car

and

support

it

with

safety

stands

2

Remove

wheel

and

brake

drum

I

Engage

hand

brake

lever

2

Pull

pin

out

and

remove

stopper

from

toggle

lever

3

Disengage

hand

brake

lever

If

brake

drum

cannot

be

easily

removed

install

two

baIts

8

mm

diameter

I

25

mm

pitch

to

drive

it

out

3

Disconnect

brake

tube

flare

nut

Install

a

brake

line

plug

in

open

end

of

brake

tube

CAUTION

When

removing

brake

tube

use

suitable

tube

wrench

Never

use

open

end

or

adjustable

wrench

4

Remove

hand

brake

return

spring

and

pull

out

clevis

pin

to

separate

hand

brake

cable

and

lever

5

Remove

anti

rattle

spring

and

pin

6

Remove

return

spring

and

brake

shoes

Brake

System

Dueetio

of

ro

tiO

Front

of

car

7

Remove

dust

cover

and

toggle

lever

with

adjuster

assembly

8

Remove

wheel

cylinder

DISASSEMBLY

AND

ASSEMBLY

Wheel

cylinder

BR909

I

Dust

cover

2

Piston

3

Piston

cup

4

Wheel

cylinder

body

5

Spring

6

Bleeder

1

Bleeder

cap

Fig

BR

23

Wheel

Cylinder

Remove

dust

cover

and

parts

will

BR

l0

Tightening

torque

kg

m

ft

lb

@

0

6

to

0

8

4

3

ro

5

8

@

2

2

to

2

7

16

to

20

BR116A

Fig

BR

22

Rear

Broke

be

disassembled

Thoroughly

wash

all

parts

Assem

ble

wheel

cylinder

in

reverse

order

of

disassembly

CAUTION

Use

brake

fluid

to

clean

Never

use

mineral

oil

Note

a

Apply

a

coating

of

brake

fluid

to

piston

cliP

at

assembly

b

Charge

with

genuine

Nissan

disc

brake

grease

KR60900010

or

equivalent

before

installing

dust

cover

c

The

brake

wheel

cylinder

is

avail

able

in

both

NABCO

make

and

TOKlCO

make

There

is

no

inter

changeability

of

repair

kits

or

com

ponent

parts

between

NABCO

and

TOKlCO

makes

When

replacing

the

repair

kit

or

component

parts

ascertain

the

brand

of

the

brake

wheel

cylinder

body

Be

sure

to

use

parts

of

the

same

make

as

the

fonner

ones

Page 365 of 548

INSPECTION

Brake

drum

I

Check

inner

diameter

of

brake

drum

to

make

sure

it

is

properly

round

and

tapered

If

it

is

not

repair

or

replace

brake

drum

Inner

diameter

Standard

diametel

203

2

mm

8

in

Maximum

diameter

204

5

mm

8

05

in

Out

of

loundness

ellipticity

less

than

0

02

mm

0

0008

in

Radial

runout

less

than

0

1

mm

0

004

in

Total

indicator

reading

Taper

less

than

0

02

mm

0

0008

in

Measured

at

a

point

40

mm

1

57

in

flam

inlet

2

Contact

surface

with

which

lin

ings

come

into

contact

should

be

fine

finished

with

No

120

to

150

sandpaper

3

Using

a

drum

racer

finish

brake

drum

by

machining

if

it

shows

any

sign

of

score

marks

partial

wear

or

stepped

wear

on

its

contact

surface

Note

After

brake

drum

has

been

completely

re

conditioned

or

re

placed

check

drum

and

shoes

for

proper

contact

pattern

Brake

e

embly

1

Replace

any

linings

which

are

cracked

worn

or

oil

stained

2

If

lining

is

worn

to

less

than

the

specified

value

replace

Lining

wear

limit

Minimum

thickness

1

5

mm

0

059

in

3

Replace

any

shoe

return

springs

which

are

broken

or

fatigued

4

Replace

fatigued

anti

rattle

spring

damaged

pin

and

or

retainer

Wheel

cylinder

I

Replace

any

cylinder

or

piston

which

is

scratched

scored

or

worn

on

its

sliding

contact

surface

Brake

System

2

Replace

worn

parts

if

piston

to

cylinder

clearance

is

beyond

limit

Piston

ta

cylinder

clearance

less

than

0

15

mm

0

0059

in

3

Replace

any

piston

cup

which

is

worn

or

otherwise

damaged

4

Replace

if

contacting

face

of

cyl

inder

and

shoe

is

worn

locally

or

in

step

5

Replace

any

damaged

dust

cover

fatigued

piston

spring

or

faulty

thread

ed

parts

6

Replace

any

tube

connector

which

is

worn

on

its

threaded

portion

INSTALLATION

Install

rear

brake

in

reverse

order

of

removal

closely

observing

the

follow

ing

1

Tighten

following

parts

to

speci

fied

torque

CAUTION

When

installing

brake

tube

use

Flare

Nut

Torque

Wrench

6694310000

ifl

Tightening

torque

Flared

nut

1

5

to

1

8

kg

m

11

to

13

fHb

Ail

bleedel

0

7

to

0

9

kg

m

15

1

to

6

5

ft

Ib

Wheel

cylinder

mounting

bolt

0

6

to

0

8

kg

m

4

3

to

5

8

ft

b

2

There

are

two

types

of

adjusters

which

have

right

thread

or

left

thread

R

H

brake

Right

thread

adjuster

L

H

brake

Left

thread

adjuster

3

Sparingly

apply

a

coat

of

brake

grease

to

the

following

points

Lubricating

points

e

Adjuster

nut

and

rod

threads

Mating

surfaces

between

adjuster

and

toggle

lever

and

pin

and

roller

BR

ll

0

J

o

BR

117

A

Fig

BR

24

Lubricating

Points

of

Adju

ter

4

Referring

to

Fig

BR

25

for

locations

of

lubricating

points

apply

a

coat

of

brake

grease

to

these

points

Exercise

care

not

to

allow

grease

to

come

into

contact

with

lining

or

ad

juster

screws

Lubricating

points

e

Contact

areas

between

wheel

cyl

inder

anchor

block

and

brake

shoe

e

Mating

surfaces

between

brake

shoe

and

brake

disc

Contact

areas

between

hand

brake

adjuster

and

brake

shoe

Contact

areas

between

brake

disc

brake

shoe

and

toggle

lever

Contact

areas

between

anti

rattle

pin

spring

retainer

and

brake

shoe

Fig

BR

25

Lubricating

Points

5

To

prevent

water

from

entering

brake

drum

apply

dry

sealant

to

brake

disc

mounting

surfaces

of

the

follow

ing

parts

Wheel

cylinder

Anti

rattle

spring

6

Make

sure

that

entire

brake

shoe

fits

in

place

7

Make

sure

that

adjuster

operates

properly

8

After

installation

is

completed

check

and

adjust

shoe

to

drum

clear

ance

by

operating

hand

brake

several

times

9

Bleed

brake

system

Page 372 of 548

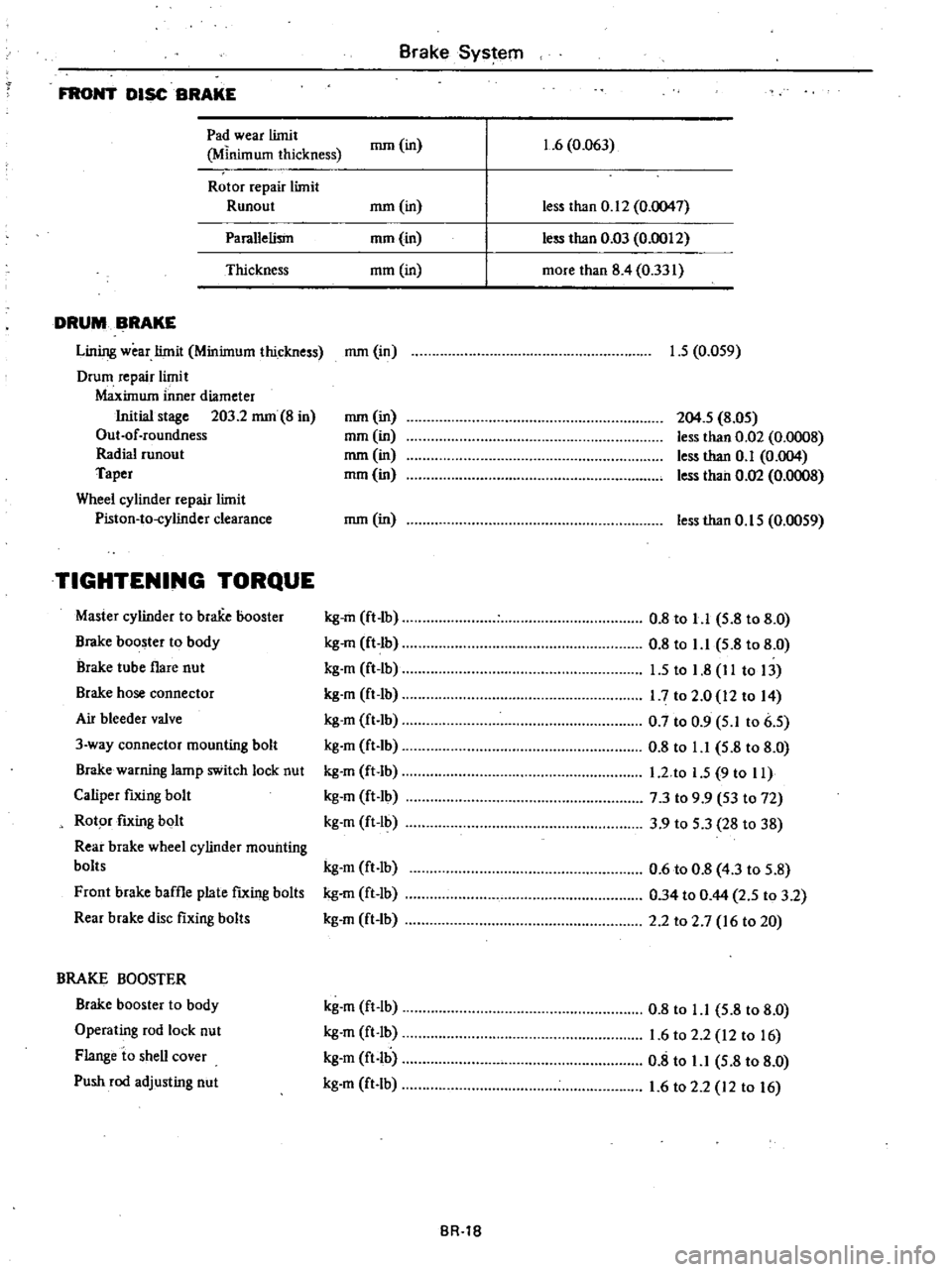

FRONT

DISC

BRAKE

Pad

wear

limit

Minim

urn

thickness

Rotor

repair

limit

Runout

Parallelism

Thickness

DRUM

BRAKE

Lining

wear

limit

Minimum

thickness

Drum

repair

limit

Maximum

inner

diameter

Initial

stage

203

2

nun

8

in

Out

of

roundness

Radial

cunout

Taper

Wheel

cylinder

repair

limit

Piston

to

cylinder

clearance

TIGHTENING

TORQUE

Master

cylinder

to

brake

booster

Brake

booster

to

body

Brake

tube

flare

nut

Brake

hose

connector

Air

bleeder

valve

3

way

connector

mounting

bolt

Brake

warning

lamp

switch

lock

nut

Caliper

fixing

bolt

Rotor

fixing

bolt

Rear

brake

wheel

cylinder

mounting

bolts

Front

brake

baffle

plate

fixing

bolts

Rear

brake

disc

fixing

bolts

BRAKE

BOOSTER

Brake

booster

to

body

Operating

rod

lock

nut

Flange

io

shell

cover

Push

rod

adjusting

nut

nun

in

nun

in

nun

in

mm

in

nun

in

nun

in

mm

in

nun

in

mm

in

nun

in

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

Ib

kg

m

ft

lb

kg

m

ft

Ib

kg

m

ft

lb

kg

m

ft

Ib

kg

m

ft

lb

kg

m

ft

Ib

kg

m

ft

lb

kg

m

ft

Ib

kg

m

ft

Ib

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

Brake

System

BR

1B

1

6

0

063

less

than

0

12

0

0047

less

than

0

03

0

0012

more

than

8

4

0

331

1

5

0

059

204

5

8

05

less

than

0

02

0

0008

less

than

0

1

0

004

less

than

0

02

0

0008

less

than

0

15

0

0059

0

8

to

1

1

5

8

to

8

0

0

8

to

1

1

5

8

to

8

0

1

5

to

1

8

II

to

13

1

7

to

2

0

12

to

14

0

7

to

0

9

5

1

to

6

5

0

8

to

1

1

5

8

to

8

0

l

2

to

1

5

9

to

II

7

3

to

9

9

53

to

72

3

9

to

5

3

28

to

38

0

6

to

0

8

4

3

to

5

8

0

34

to

0

44

2

5

to

3

2

2

2

to

2

7

16

to

20

0

8

to

1

1

5

8

to

8

0

1

6

to

2

2

12

to

16

0

8

to

1

1

5

8

to

8

0

1

6

to

2

2

12

to

16

Page 375 of 548

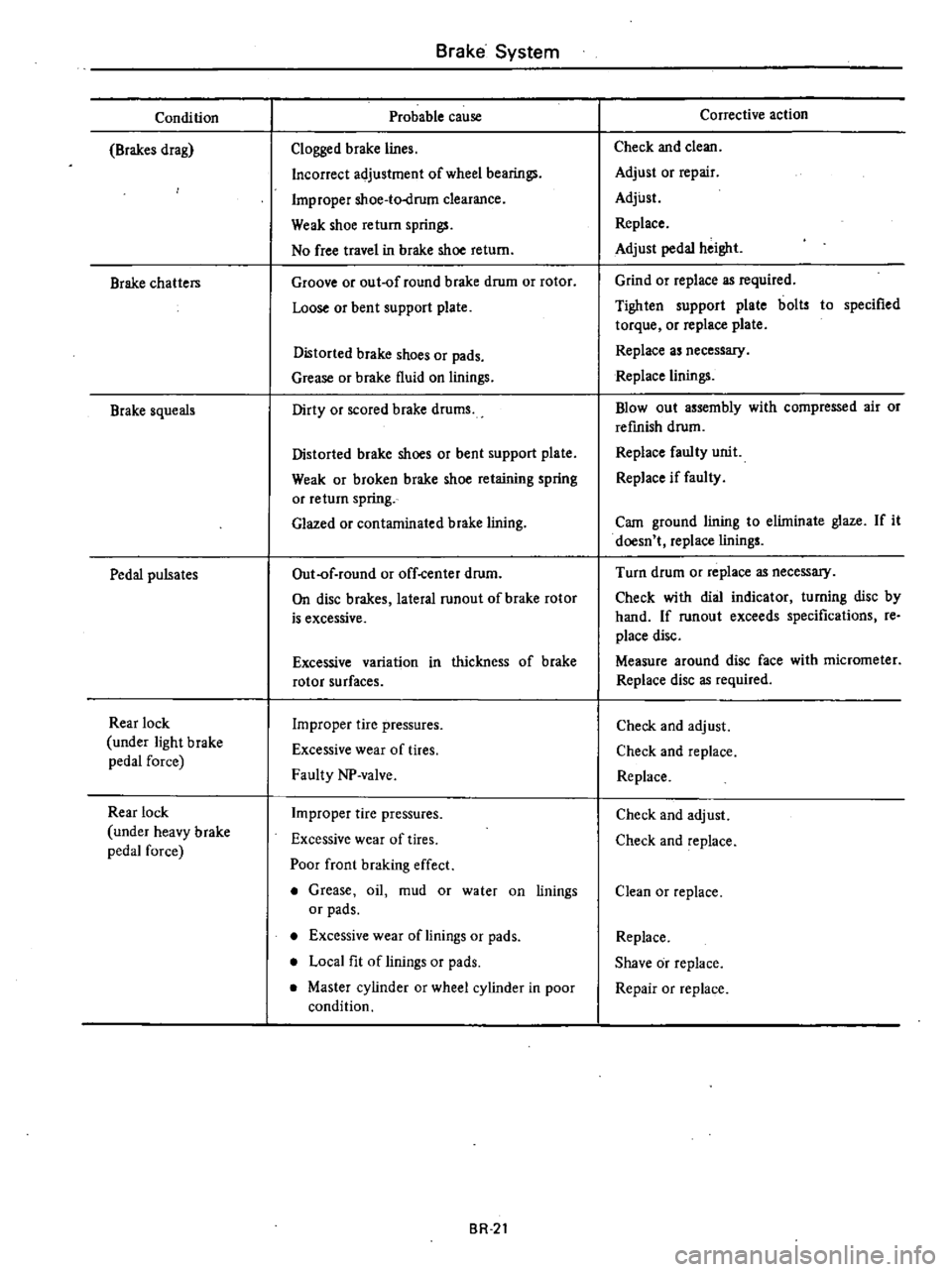

Condition

Brakes

drag

Brake

chatters

Brake

squeals

Pedal

pulsates

Rear

lock

under

light

brake

pedal

force

Rear

lock

under

heavy

brake

pedal

force

Brake

System

Probable

cause

Clogged

brake

lines

Incorrect

adjustment

of

wheel

bearings

Improper

shoe

to

drum

clearance

Weak

shoe

return

springs

No

free

travel

in

brake

shoe

return

Groove

or

out

of

round

brake

drum

or

rotor

Loose

or

bent

support

plate

Distorted

brake

shoes

or

pads

Grease

or

brake

fluid

on

linings

Dirty

or

scored

brake

drums

Distorted

brake

shoes

or

bent

support

plate

Weak

or

broken

brake

shoe

retaining

spring

or

return

spring

Glazed

or

contaminated

brake

lining

Out

of

round

or

off

center

drum

On

disc

brakes

lateral

runout

of

brake

rotor

is

excessive

Excessive

variation

in

thickness

of

brake

rotor

surfaces

Improper

tire

pressures

Excessive

wear

of

tires

Faulty

NP

valve

Improper

tire

pressures

Excessive

wear

of

tires

Poor

front

braking

effect

Grease

oil

mud

or

water

on

linings

or

pads

Excessive

wear

of

linings

or

pads

Local

fit

of

linings

or

pads

Master

cylinder

or

wheel

cylinder

in

poor

condition

BR

2t

Corrective

action

Check

and

clean

Adjust

or

repair

Adjust

Replace

Adjust

pedal

height

Grind

or

replace

as

required

Tighten

support

plate

bolts

to

specified

torque

or

replace

plate

Replace

as

necessary

Replace

linings

Blowout

assembly

with

compressed

air

or

refinish

drum

Replace

faulty

unit

Replace

if

faulty

Cam

ground

lining

to

elilninate

glaze

If

it

doesn

t

replace

linings

Turn

drum

or

replace

as

necessary

Check

with

dial

indicator

turning

disc

by

hand

If

runout

exceeds

specifications

re

place

disc

Measure

around

disc

face

with

micrometer

Replace

disc

as

required

Check

and

adjust

Check

and

replace

Replace

Check

and

adjust

Check

and

replace

Clean

or

replace

Replace

Shave

or

replace

Repair

or

replace

Page 377 of 548

DATSUN

210

Model

8310

Series

WHEEL

AND

TIRE

CONTENTS

WHEEL

AND

TIRE

MAINTENANCE

INSPECTION

SERVICE

DATA

AND

SPECIFICATIONS

WT5

GENERAL

SPECIFICATIONS

INSPECTION

ANO

ADJUSTMENT

TIGHTENING

TORQUE

TROUBLE

DIAGNOSES

AND

CORRECTIONS

WT5

WT5

WT

6

WT2

WT2

WT

3

WT

7

ell

Page 378 of 548

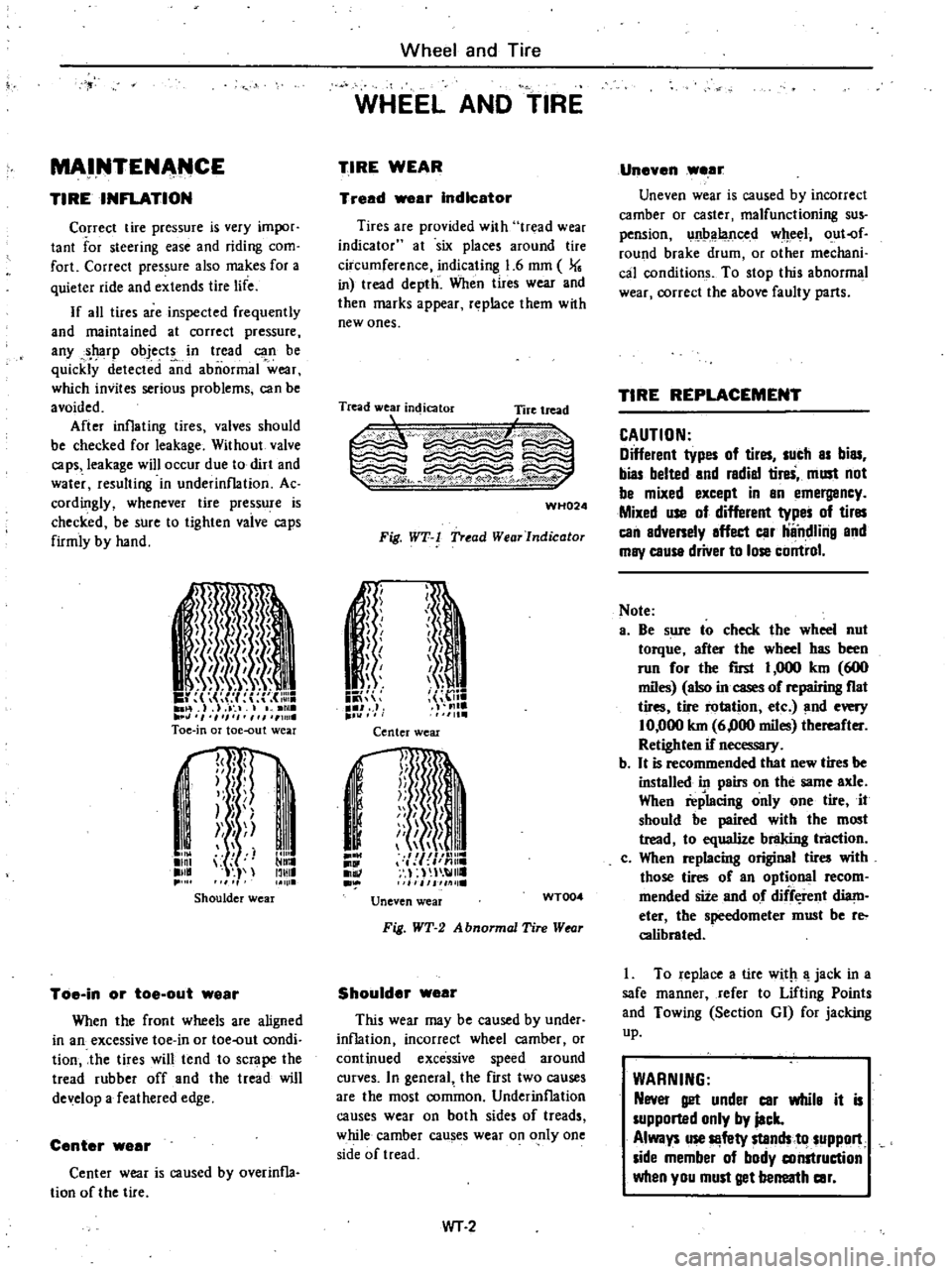

t

MAINTEN

NCE

TIRE

INFLATION

Correct

tire

pressure

is

very

impor

tant

for

steering

ease

and

riding

com

fort

Correct

pressure

also

makes

for

a

quieter

ride

and

extends

tire

life

If

all

tires

are

inspected

frequently

and

maintained

at

correct

pressure

any

sharp

objects

in

tread

can

be

quickiy

detected

nd

abnormal

wear

which

invites

serious

problems

can

be

avoided

After

inflating

tires

valves

should

be

checked

for

leakage

Without

valve

caps

leakage

will

occur

due

to

dirt

and

water

resulting

in

underinflation

Ac

cordingly

whenever

tire

pressure

is

checked

be

sure

to

tighten

vaive

caps

firmly

by

hand

JW

Sri

in

1

II

I

i

I

1

I

1

1

I

I

I

II

I

I

I

i

M

I

l

1

14

nl

01

I

II

Toe

in

or

toe

out

wear

I

J

I

I

p

rt

i

Ilnl

lll

11111

IllIlI

Shoulder

wear

Toe

in

or

toe

out

wear

When

the

front

wheels

are

aligned

in

an

excessive

toe

in

or

toe

out

condi

tion

the

tires

will

tend

to

scrape

the

tread

rubber

off

and

the

tread

will

de

elop

a

feathered

edge

Center

wear

Center

wear

is

caused

by

overinfla

tion

of

the

tire

Wheel

and

Tire

WHEEL

AND

TIRE

TIRE

WEAR

Tread

ar

Indicator

Tires

are

provided

with

tr

lad

wear

indicator

at

six

places

around

tire

circumference

indicating

1

6

mm

J

in

tread

depth

When

tires

wear

and

then

marks

appear

replace

them

wtth

new

ones

Tread

wear

indicator

Tire

tread

L

1

c

WH024

Fig

WT

l

Tread

WearJndicator

n

1

ii

J

J

f

J

I

h

I

me

1111

Center

wear

j

I

1II

mnr

I

j

n

Ii

Ii

i

I

Jil

111

lie

Uneven

wear

WT004

Fig

WT

2

A

bnormal

Tire

Wtor

Shoulder

wear

This

wear

may

be

caused

by

under

inflation

incorrect

wheel

camber

or

continued

excessive

speed

around

curves

In

general

the

first

two

causes

are

the

most

common

Underinflation

causes

wear

on

both

sides

of

treads

while

camber

causes

wear

on

only

one

side

of

tread

WT

2

Uneven

wear

Uneven

wear

is

caused

by

incorrect

camber

or

caster

malfunctioning

sus

pension

unbalanced

wheel

out

of

round

brake

drum

or

other

mechani

cal

conditions

To

stop

this

abnormal

wear

correct

the

above

faulty

parts

TIRE

REPLACEMENT

CAUTION

Different

types

of

tires

sucb

as

bias

bias

belted

and

radial

tireS

must

not

be

mixed

except

in

an

emergancy

Mixed

use

of

different

types

of

tires

can

adversely

affect

car

ilndlilig

and

may

cause

driver

to

lose

control

Note

a

Be

sure

to

check

the

wheel

nut

torque

after

the

wheel

has

been

run

for

the

rust

I

000

km

600

miles

also

in

cases

of

repairing

fiat

tires

tire

rotation

etc

and

every

10

000

km

6

000

miles

thereafter

Retighten

if

necessary

b

It

is

recommended

that

new

tires

be

installed

in

pairs

on

the

same

axle

When

replacing

only

one

tire

it

should

be

paired

with

the

most

tread

to

equalize

braking

tl1lction

c

When

replacing

original

tires

with

those

tires

of

an

optional

recom

mended

site

and

of

diff

rent

diam

eter

the

speedometer

must

be

reo

calibrated

I

To

replace

a

tire

with

a

jack

in

a

safe

manner

refer

to

Lifting

Points

and

Towing

Section

GI

for

jacking

up

WARNING

Never

get

under

car

whila

it

is

supported

only

by

jack

Always

use

Il

fety

stands

to

suppon

side

member

of

body

construction

when

you

must

get

berreatb

car