oil DATSUN 210 1979 Workshop Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 76 of 548

Not

Pump

rotors

and

body

are

not

serv

iced

separatdy

If

pump

rotors

or

body

are

damaged

or

worn

replace

ment

of

the

entire

oil

pump

assembly

isnecessary

OIL

PRESSURE

REGULATOR

VALVE

The

oil

pressure

regulator

valve

is

not

adjustable

At

the

released

posi

tion

the

valve

permits

the

oil

to

by

pass

through

the

passage

in

the

pump

cover

to

the

inlet

side

of

the

pump

Check

regulator

valve

spring

to

ensure

that

spring

tension

is

correct

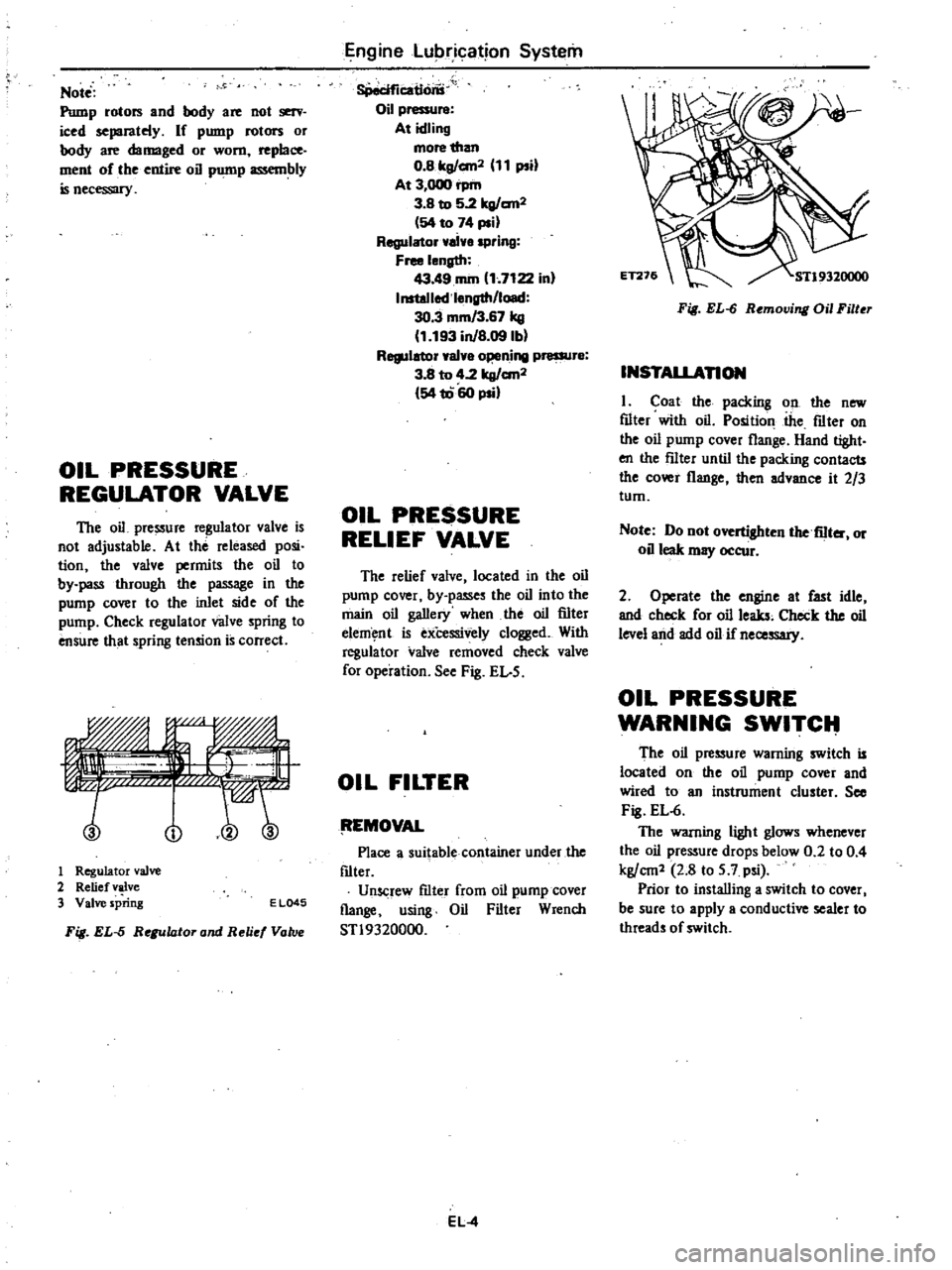

no

1

Regulator

valve

2

Relief

valve

3

Valve

spring

E

L045

Fig

EL

5

Regulator

and

Reli

Vatv

Engine

Lubrication

System

8Peciflcatlons

Oil

pressure

At

idling

more

than

O

Blrg

an2

11

psi

At

3

000

rpm

3

B

to

5

2lrg

an2

54

to

74

psi

Regulator

ai

spring

Free

length

43

49

rom

1

7122

in

InstoJlod

l

ngth

load

30

3

mm

3

67

kg

1

193

inJB

09lbl

Regulator

val

o

ning

pressur

3

8

to

4

2

lrg

an2

54

1060

psi

OIL

PRESSURE

RELIEF

VALVE

The

relief

valve

located

in

the

oil

pump

cover

by

passes

the

oil

into

the

main

oil

gallery

when

the

oil

filter

elem

nt

is

exCessively

clogged

With

regula

tor

valve

removed

check

valve

for

operation

See

Fig

EL

5

OIL

FILTER

tEMOVAL

Place

a

suitable

container

under

the

f1lter

Unscrew

f1lter

from

oil

pump

cover

flange

using

Oil

Filter

Wrench

STl9320000

EL

4

Fig

EL

6

Removing

Oil

Filter

INSTALLAnON

I

Coat

the

packing

on

the

new

f1lter

with

oil

Position

the

f1lter

on

the

oil

pump

cover

flange

Hand

tight

en

the

f11ter

until

the

packing

contacts

the

cover

flange

then

advance

it

2

3

tum

Note

Do

not

overtighten

the

fiIter

or

oil

leak

may

occur

2

Operate

the

engine

at

fast

idle

and

check

for

oil

leaks

Check

the

oil

level

and

add

oil

if

necessary

OIL

PRESSURE

WARNING

SWITCIt

The

oil

pressure

warning

switch

is

located

on

the

oil

pump

cover

and

wired

to

an

instrument

cluster

See

Fig

EL

6

The

warning

light

glows

whenever

the

oil

pressure

drops

below

0

2

to

0

4

kg

cm1

2

8

to

5

7

psi

Prior

to

installing

a

switch

to

cover

I

be

sure

to

apply

a

conductive

sealer

to

threads

of

switch

Page 77 of 548

Engine

Lubrication

System

SERVICE

DATA

AND

SPECIFICATIONS

Oil

pump

Standard

Wear

limit

Rotor

side

clearance

nun

in

0

04

to

0

08

0

20

0

0079

Rotor

to

bottom

cover

0

0016

to

0

0031

Rotor

tip

clearance

mm

in

less

than

0

20

0

0079

0

12

0

0047

Outer

rotor

to

body

clearance

nun

in

0

15

to

0

21

0

50

0

0197

0

0059

to

0

0083

Oil

pressure

regulator

valve

Oil

pressure

a

t

idling

Oil

pressure

at

3

000

rpm

Regulator

valve

spring

Free

length

Installed

length

load

kg

cm2

psi

kg

cm2

psi

more

than

0

8

II

3

8

to

5

2

54

to

74

nun

in

nun

kg

in

lb

43

49

I

7122

30

3

3

67

1

193

8

09

Tightening

torque

Oil

pump

securing

bolts

Oil

pump

cover

bolt

Regulator

valve

cap

nut

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

0

9

to

I

4

6

5

to

10

1

0

39

to

0

52

2

8

to

3

8

4

0

to

5

0

29

to

36

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Probable

cause

Corrective

action

Oil

leakage

Damaged

or

cracked

body

cover

Oil

leakage

from

gasket

Oil

leakage

from

regulator

valve

Oil

leakage

from

blind

plug

Replace

Replace

Tighten

or

replace

Replace

Decreased

oil

pressure

Leak

of

oil

in

engine

oil

pan

Dirty

oil

strainer

Damaged

or

worn

pump

rotors

Faulty

regulator

Used

of

poor

quality

engine

oil

Correct

Clean

or

replace

Replace

Adjust

or

replace

Replace

Noise

Excessive

backlash

in

pump

rotors

Replace

EL

5

Page 78 of 548

Engine

Lubrication

System

SPECIAL

SERVICE

TOOLS

Kent

Moore

No

I

Kent

Moore

No

Tool

number

tool

name

Reference

Pile

or

Fig

No

Tool

number

tool

name

Reference

page

or

Fig

No

STl9320000

Oil

filter

wrench

J2S664

Fig

EL

6

EL

6

Page 81 of 548

2

Loosen

belt

then

remove

fan

blade

from

torque

coupling

and

torque

coupling

and

pulley

from

hub

Air

conditioning

system

equipped

models

only

4

Remove

pump

assembly

and

gas

ket

from

front

cover

C0051

Fig

CO

3

Removing

Water

Pump

INSTALLATION

1

Be

sure

to

clean

the

gasket

sur

faces

in

contact

with

pU

flP

and

front

cover

Always

use

new

gaskets

when

installing

pump

assembly

Be

sure

to

tighten

bolts

i

l

Tightening

torque

Water

pump

securing

bolts

0

9

to

1

4

kg

m

6

5

to

10

1

ft

Ib

2

Fill

cooling

system

and

check

for

leaks

at

pump

3

InstaD

fan

pulley

spacer

or

torque

coupling

and

fan

blade

and

tighten

attaching

bolts

securely

Install

belt

and

adjust

for

specified

tension

4

Operate

the

engine

at

fast

idle

and

re

Check

for

leaks

S

Install

fan

shroud

Note

Ensure

that

clearance

between

shroud

and

fan

even

at

any

place

DISASSEMBLY

Water

pump

should

not

be

disas

sembled

Cooling

System

INSPECTION

Inspect

pump

assembly

for

the

following

conditions

and

replace

if

necessary

I

Badly

rusted

or

corroded

body

assembly

and

vane

2

Excessive

end

play

or

roughness

of

bearings

in

operation

Note

If

excessive

mechanical

seal

squeak

occurs

when

engine

is

mn

ning

use

suitable

water

pump

seal

lubricant

to

prevent

squeak

ADJUSTMENT

Check

belt

deflection

between

alternator

and

fan

pulley

by

a

force

of

10

kg

22

Ib

Fan

belt

deflection

8

to

12

mm

0

31

to

0

47

in

If

adjustment

is

necessary

loosen

bolt

retaining

alternator

adjusting

bar

to

alternator

Move

alternator

toward

or

away

from

engine

until

the

correct

tension

is

obtained

TORQUE

COUPLING

The

torque

coupling

keeps

the

fan

speed

at

2

900

rpm

rated

or

below

to

conserve

horsepower

at

high

engine

speed

It

also

helps

reduce

fan

noise

to

a

minimum

during

high

speed

opera

tion

This

unit

is

filled

with

a

special

silicone

oil

used

as

a

fluid

coupling

which

controls

the

fan

speed

Silicone

oil

can

not

be

replenished

The

torque

coupling

is

installed

only

on

the

model

equipped

with

the

air

conditioning

system

In

this

case

use

7

x

350

mm

13

78

in

diam

eter

cooling

fan

CO

3

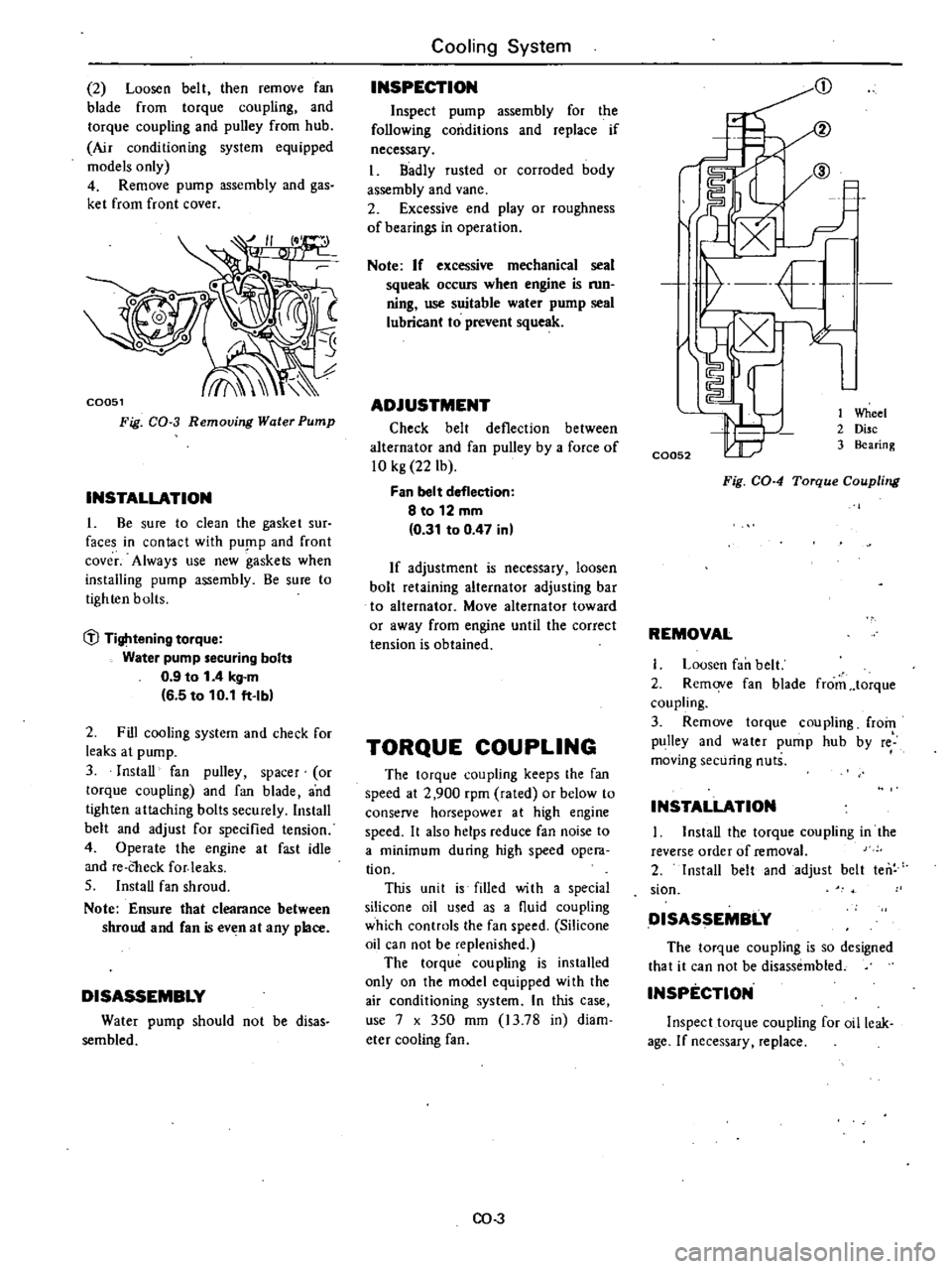

C0052

t

Wheel

2

Disc

3

Bearing

Fig

CO

4

Torque

Coupling

REMOVAL

Lousen

fan

belt

2

Remove

fan

blade

from

torque

coupling

3

Remove

torque

coupling

from

pulley

and

water

pump

hub

by

re

moving

securing

nuts

INSTALLATION

I

InstaD

the

torque

coupling

in

the

reverse

order

of

removal

2

Install

belt

and

adjust

belt

ten

sian

DISASSEMBLY

The

torque

coupling

is

so

designed

that

it

can

not

be

disassembled

INSPECTION

Inspect

torque

coupling

for

oil

leak

age

If

necessary

replace

Page 82 of 548

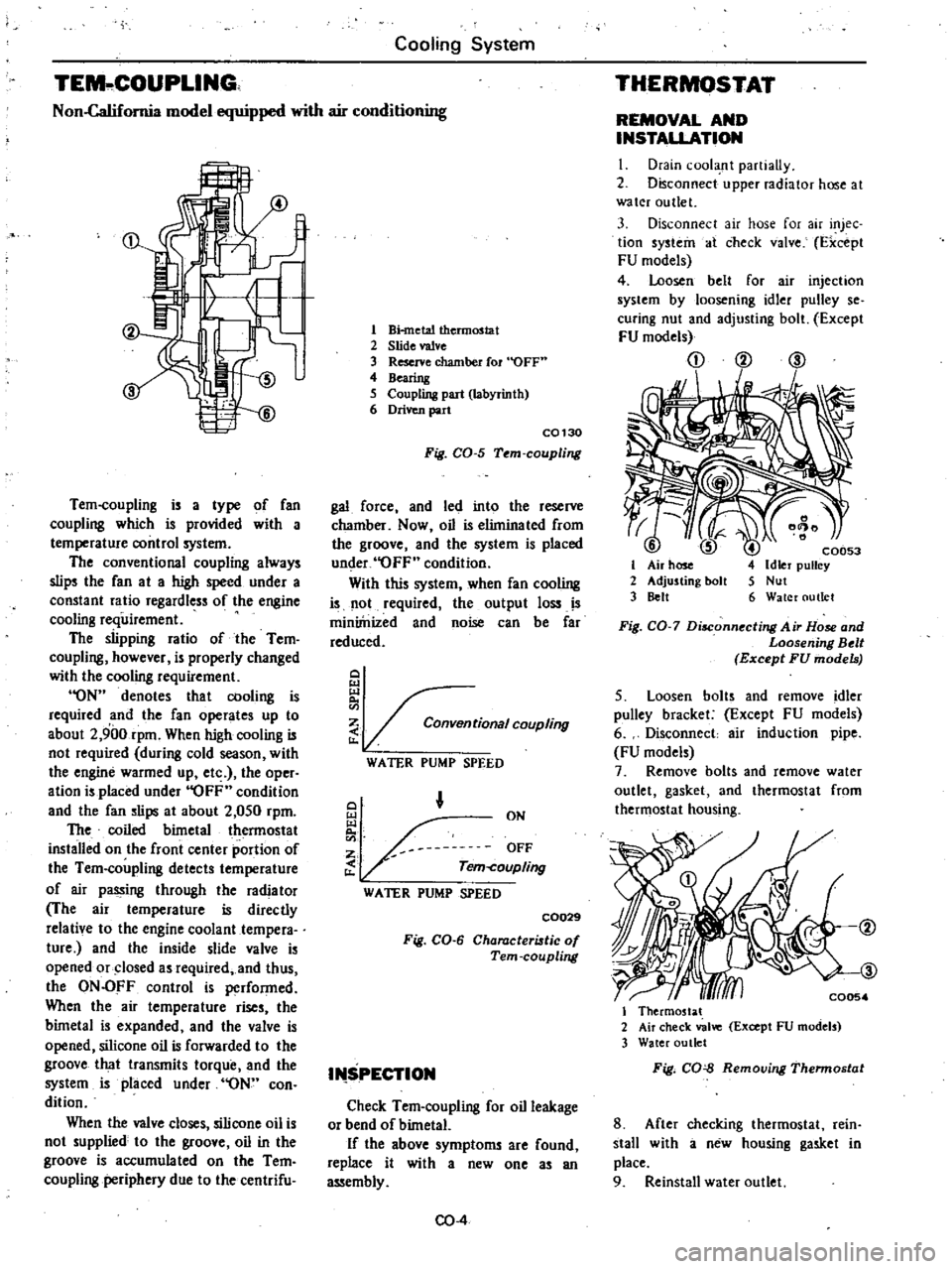

Cooling

System

TEM

COUPLlNG

Non

Califomia

model

equipped

with

air

conditioning

Tem

coupling

is

a

type

of

fan

coupling

which

is

provided

with

a

temperature

control

system

The

conventional

coupling

always

slips

the

fan

at

a

high

speed

under

a

constant

ratio

regardless

of

the

engine

cooling

requirement

The

slipping

ratio

of

the

Tem

coupling

however

is

properly

changed

with

the

cooling

requirement

ON

denotes

that

cooling

is

required

and

the

fan

operates

up

to

about

2

900rpm

When

high

cooling

is

not

required

during

cold

season

with

the

engine

warmed

up

etc

the

oper

ation

is

placed

under

OFF

condition

and

the

fan

slips

at

about

2

050

rpm

The

coiled

bimetal

thermostat

installed

on

the

front

center

portion

of

the

Tem

coupling

detects

temperature

of

air

passing

through

the

radiator

The

air

temperature

is

directly

relative

to

the

engine

coolant

tempera

ture

and

the

inside

slide

valve

is

opened

or

closed

as

required

and

thus

the

ON

OFF

control

is

performed

When

the

air

temperature

rises

the

bimetal

is

expanded

and

the

valve

is

opened

silicone

oil

is

forwarded

to

the

groove

that

transmits

torque

and

the

system

is

placed

under

ON

con

dition

When

the

valve

closes

silicone

oil

is

not

supplied

to

the

groove

oil

in

the

groove

is

accumulated

on

the

Tem

coupling

periphery

due

to

the

centrifu

1

Bi

metal

thermostat

2

Slide

valve

3

Reserve

chamber

fOl

OFF

4

Bearing

5

Coupling

part

labyrinth

6

Driven

part

C0130

Fig

CO

5

Tem

coupling

gal

force

and

led

into

the

reserve

chamber

Now

oil

is

eliminated

from

the

groove

and

the

system

is

placed

under

OFF

condition

With

this

system

when

fan

cooling

is

not

required

the

output

loss

IS

miniinized

and

noise

can

be

far

reduced

Q

i

tionalCOUPling

WATER

PUMP

SPEED

Q

ON

OFF

Tem

coupling

WATER

PUMP

SPEED

C0029

Fig

CO

6

Characteristic

of

Tern

coupling

I

SPECTION

Check

Tem

coupling

for

oil

leakage

or

bend

of

bimetaL

If

the

above

symptoms

are

found

replace

it

with

a

new

one

as

an

assembly

CO

4

THERMOSTAT

REMOVAL

AND

INSTALLATION

I

Drain

cool

nt

partiaUy

2

Disconnect

upper

radiator

hose

at

water

outlet

3

Disconnect

air

hose

for

air

injec

tion

systein

at

check

valve

Fxcept

FU

models

4

Loosen

belt

for

air

injechon

system

by

loosening

idler

pulley

se

curing

nut

and

adjusting

bolt

Except

FU

models

CD

@

ID

I

2

3

C0053

Idler

pulley

Nut

Water

outlet

Fig

CO

7

Disconnecting

Air

Hose

and

Loosening

Belt

Except

FU

models

5

Loosen

bolts

and

remove

idler

pulley

bracket

Except

FU

models

6

Disconnect

air

induction

pipe

FU

models

7

Remove

bolts

and

remove

water

outlet

gasket

and

thermostat

from

thermostat

housing

I

Thermostat

2

Air

check

valve

Except

FU

models

3

Water

outlet

Fig

CO

Removing

Thennostat

8

After

checking

thermostat

rein

stall

with

a

new

housing

gasket

in

place

9

Reinstall

water

outlet

Page 83 of 548

10

Replenish

coolant

and

check

for

leaks

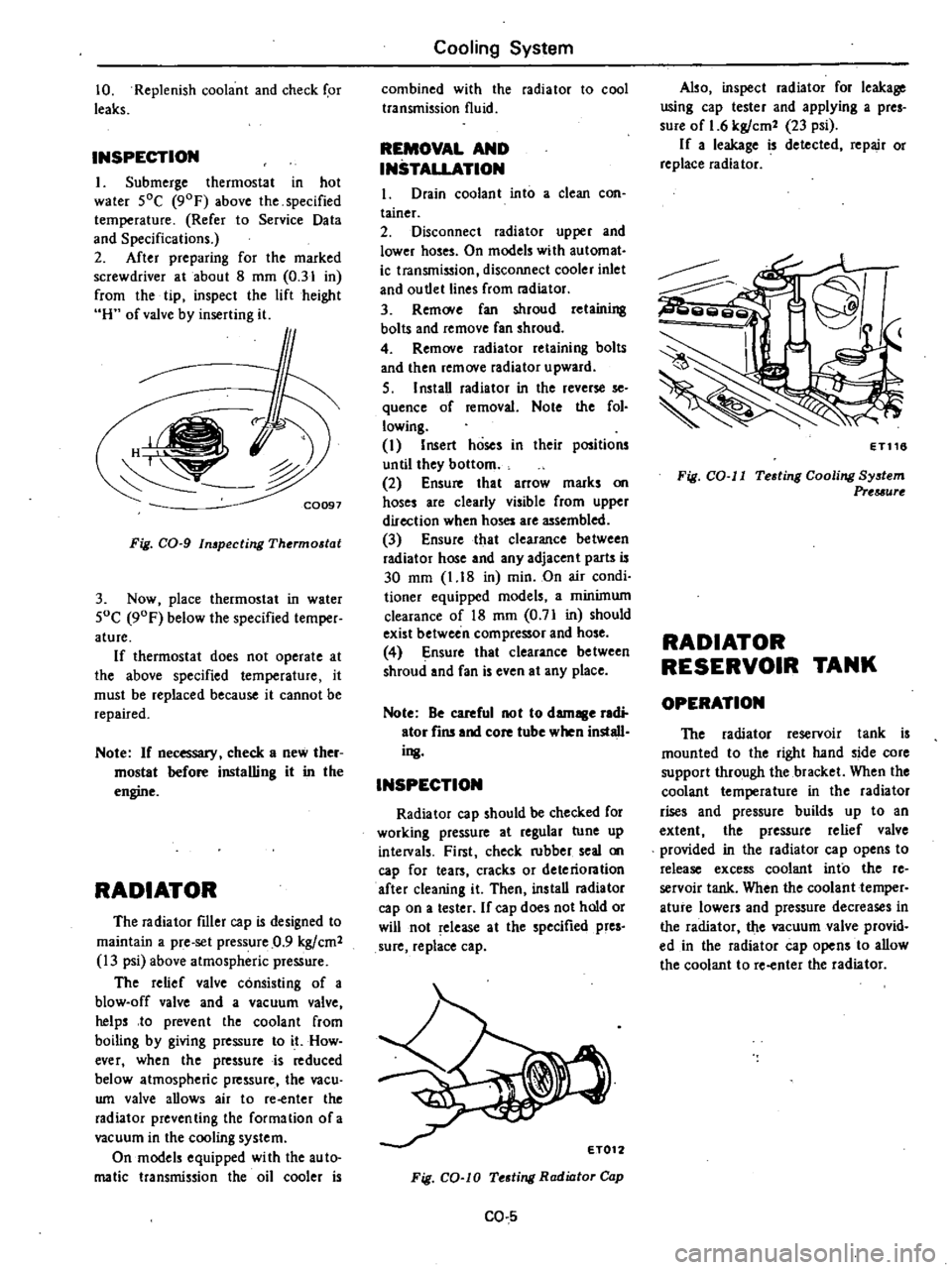

INSPECTION

I

Submerge

thermostat

in

hot

water

SOC

90F

above

the

specified

temperature

Refer

to

Service

Data

and

Specifications

2

After

preparing

for

the

marked

screwdriver

at

about

8

mm

0

31

in

from

the

tip

inspect

the

lift

height

H

of

valve

by

inserting

it

f

C0097

Fig

CO

g

In

pecting

Thermostat

3

Now

place

thermostat

in

water

SoC

90F

below

the

specified

temper

ature

If

thermostat

does

not

operate

at

the

above

specified

temperature

it

must

be

replaced

because

it

cannot

be

repaired

Note

If

necessary

check

a

new

ther

mostat

before

installing

it

in

the

engine

RADIATOR

The

radiator

filler

cap

is

designed

to

maintain

a

pre

set

pressure

0

9

kgfcm2

13

psi

above

atmospheric

pressure

The

relief

valve

consisting

of

a

blow

off

valve

and

a

vacuum

valve

helps

to

prevent

the

coolant

from

boiling

by

giving

pressure

to

it

How

ever

when

the

pressure

is

reduced

below

atmospheric

pressure

the

vacu

wn

valve

allows

air

to

re

enter

the

radiator

preventing

the

formation

ofa

vacuum

in

the

cooling

system

On

models

equipped

wi

th

the

au

to

malic

transmission

the

oil

cooler

is

Cooling

System

combined

with

the

radiator

to

cool

transmission

fluid

REMOVAL

AND

INSTALLATION

1

Drain

coolant

into

a

clean

con

tainer

2

Disconnect

radiator

upper

and

lower

hoses

On

models

with

automat

ic

transmission

disconnect

cooler

inlet

and

ou

tlet

lines

from

radiator

3

Rem

Ne

fan

shroud

retaining

bolts

and

remove

fan

shroud

4

Remove

radiator

retaining

bolts

and

then

remove

radiator

upward

S

I

nstaD

radiator

in

the

reverse

se

quence

of

removal

Note

the

fol

lowing

I

Insert

hoses

in

their

positions

until

they

bottom

2

Ensure

that

arrow

marks

on

hoses

are

clearly

visible

from

upper

direction

when

hoses

are

assembled

3

Ensure

that

clearance

between

radiator

hose

and

any

adjacent

parts

is

30

mm

1

18

in

min

On

air

condi

tioner

equipped

models

a

minimum

clearance

of

18

mm

0

71

in

should

exist

between

compressor

and

hose

4

Ensure

that

clearance

be

tween

shroud

and

fan

is

even

at

any

place

Note

Be

careful

not

to

damage

radi

ator

fins

and

core

tube

when

install

ing

INSPECTION

Radiator

cap

should

be

checked

for

working

pressure

at

regular

tune

up

intelVals

First

check

rubber

seal

on

cap

for

tears

cracks

or

deteriontion

after

cleaning

it

Then

ins

taD

radiator

cap

on

a

tester

If

cap

does

not

hold

or

will

not

release

at

the

specified

pres

sure

replace

cap

Fig

CO

lO

Testing

Radiator

Cap

CO

5

Also

inspect

radiator

for

leakage

using

cap

tester

and

applying

a

pres

sure

of

1

6

kgfcm2

23

psi

If

a

leakage

is

detected

repair

or

replace

radiator

ET116

Fig

CO

II

Testing

Cooling

System

Prtuurt

RADIATOR

RESERVOIR

TANK

OPERATION

The

radiator

reservoir

tank

is

mounted

to

the

right

hand

side

core

support

through

the

bracket

When

the

coolant

temperature

in

the

radiator

rises

and

pressure

builds

up

to

an

extent

the

pressure

relief

valve

provided

in

the

radiator

cap

opens

to

release

excess

coolant

into

the

re

servoir

tank

When

the

coolant

temper

ature

lowers

and

pressure

decreases

in

the

radiator

the

vacuum

valve

provid

ed

in

the

radiator

cap

opens

to

allow

the

coolant

to

re

enter

the

radiator

Page 84 of 548

u

V

O

I

MAX

Ii

1i

i

iT

1

I

I

11

1

i

MINij

o

f

G

p

rl

MAX

ii

i

p

It

ot

MINi

II

L

Cooling

System

l

CQ074

Pressure

relief

valve

opens

f

C007S

Vacuum

valve

opens

INSPECTION

1

Check

the

amount

of

coolant

in

the

reservoir

tank

If

the

coolant

level

is

below

the

MIN

level

remove

the

re

servoirtank

ruler

cap

and

add

enough

oolant

to

reach

MAX

level

If

the

reservoir

tank

is

empty

check

the

coolantlevel

in

the

radiator

If

the

coolant

in

the

radiator

is

insuf

ficient

pour

it

into

radiator

up

to

the

radiator

cap

and

also

pour

it

into

the

reservoir

tank

until

MAX

level

If

the

coolant

in

the

reservoir

tank

d

ecreases

abnormally

rapid

check

for

a

leak

in

the

cooling

system

REMOVAL

AND

INSTALLATION

1

Reservoir

tank

is

only

inserted

to

reservoir

tank

bracket

and

can

be

easily

removed

To

install

reservoir

tank

reverse

the

order

of

remova

Fig

CO

12

Opefation

of

ReserVoir

Tank

SERVICE

DATA

AND

SPECIFICATIONS

Thermostat

Valve

opening

temperature

Oc

OF

Maximum

valve

lift

mmjOC

in

oF

Radiator

Type

Manual

transmission

Automatic

tralUJ1lission

Cap

relief

pressure

kg

cm2

psi

Testing

pressure

kg

cm

2

psi

Fan

Fan

belt

deflection

mm

in

cO

6

Temperate

type

Frigid

type

Tropical

type

82

180

88

190

76

5

I

70

8

95

8

loo

8

90

0

3

I

203

0

31j2

i

2

0

31

194

Corrugated

fm

type

Corrugated

fm

type

equipped

with

oil

cooler

0

9

I

3

1

6

23

8

to

12

0

31

to

0

47

Page 85 of 548

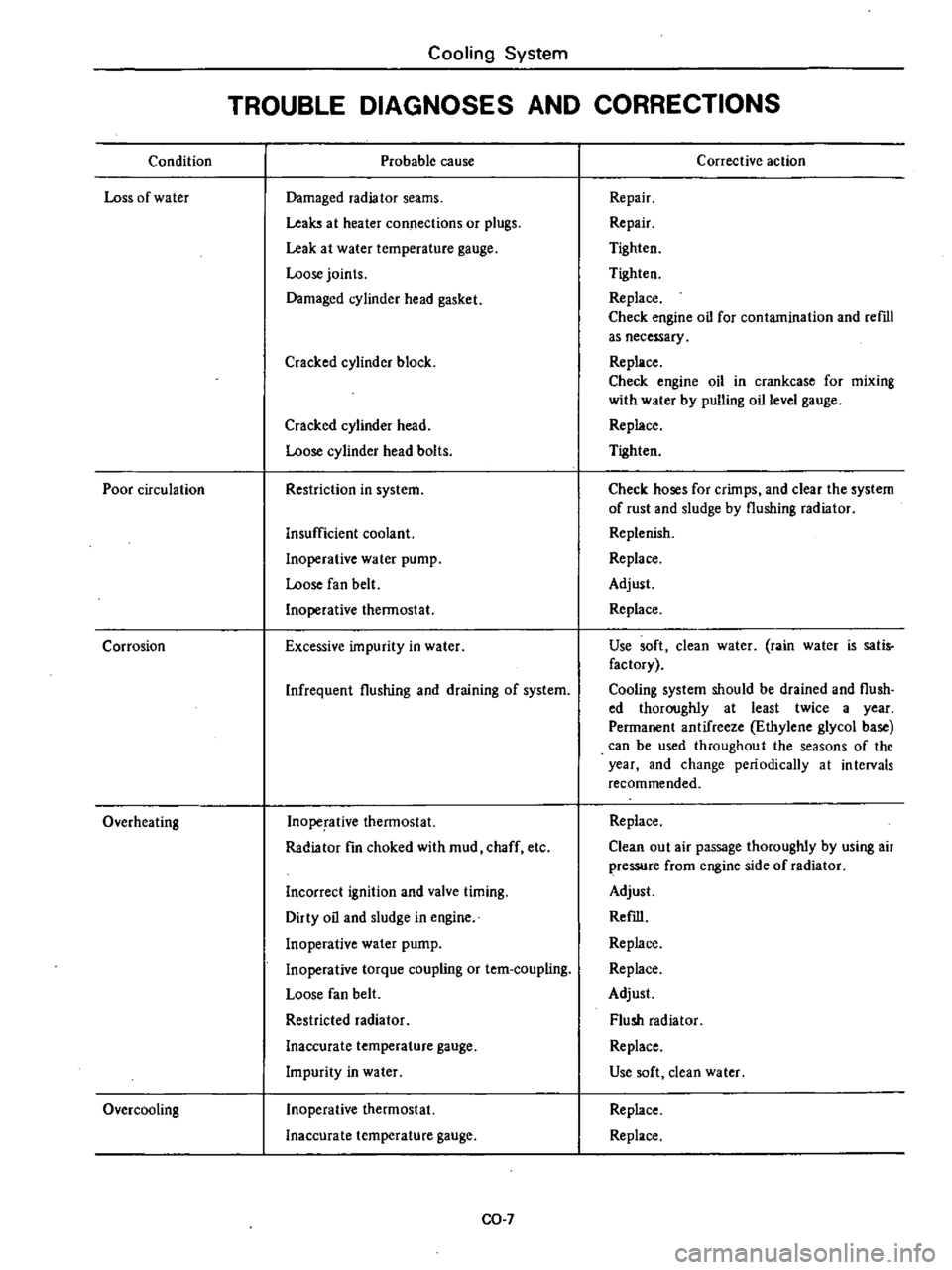

Condition

Loss

of

water

Poor

circulation

Corrosion

Overheating

Over

cooling

Cooling

System

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Probable

cause

Damaged

radiator

seams

Leaks

at

heater

connections

or

plugs

Leak

at

water

temperature

gauge

Loose

joints

Damaged

cylinder

head

gasket

Cracked

cylinder

block

Cracked

cylinder

head

Loose

cylinder

head

bolts

Restriction

in

system

Insufficient

coolant

Inoperative

water

pump

Loose

fan

belt

Inoperative

thermostat

Excessive

impurity

in

water

Infrequent

flushing

and

draining

of

system

Inoperative

thermostat

Radiator

fin

choked

with

mud

chaff

etc

Incorrect

ignition

and

valve

timing

Dirty

oil

and

sludge

in

engine

Inoperative

water

pump

Inoperative

torque

coupling

or

tem

coupling

Loose

fan

belt

Restricted

radiator

Inaccurate

temperature

gauge

Impurity

in

water

Inoperative

thermostat

Inaccurate

temperature

gauge

CO

7

Corrective

action

Repair

Repair

Tighten

Tighten

Replace

Check

engine

oil

for

contamination

and

reml

as

necessary

Replace

Check

engine

oil

in

crankcase

for

mixing

with

water

by

pulling

oil

level

gauge

Replace

Tighten

Check

hoses

for

crimps

and

clear

the

system

of

rust

and

sludge

by

flushing

radiator

Replenish

Replace

Adjust

Replace

Use

soft

clean

water

rain

water

is

satis

factory

Cooling

system

should

be

drained

and

flush

ed

thoroughly

at

least

twice

a

year

Permanent

antifreeze

Ethylene

glycol

base

can

be

used

throughout

the

seasons

of

the

year

and

change

periodically

at

intervals

recommended

Replace

Clean

out

air

passage

thoroughly

by

using

air

pressure

from

engine

side

of

radiator

Adjust

Refill

Replace

Replace

Adjust

Flush

radiator

Replace

Use

soft

dean

water

Replace

Replace

Page 92 of 548

5

The

pressure

gauge

indicates

static

fuel

pressure

in

the

line

The

gauge

reading

should

be

within

the

specified

value

Fuel

pump

pressure

0

21

to

0

27

kg

em2

3

0

to

3

8

pli

I

Note

If

the

fuel

in

the

carburetor

float

chamber

has

run

out

and

engine

has

stopped

remove

clip

and

pour

fuel

into

carburetor

Fasten

clip

securely

and

repeat

static

pres

sure

test

If

pressure

is

not

within

the

specifi

ed

limit

remove

pump

as

an

assembly

CAPACITY

TEST

The

capacity

test

is

conducted

only

when

static

pressure

is

within

the

specification

To

conduct

this

test

proceed

as

follows

1

Disconnect

pressure

gauge

from

T

connector

and

in

its

vacant

place

install

a

suitable

container

as

a

fuel

sump

2

Start

engine

and

run

at

1

000

pm

3

Pump

should

deliver

the

specified

amouni

of

fuel

If

little

or

no

fuel

flows

from

open

end

of

pipe

it

is

an

indication

that

fuel

line

is

clogged

or

pump

is

mal

functioning

Fuel

pump

capacity

450

cc

27

46

eu

inl

min

at

1

000

rpm

REMOVAL

AND

INSTALLATION

Note

When

disconnecting

fuel

lines

use

a

container

to

receive

fuel

remaining

in

fuel

hoses

I

Disconnect

inlet

and

outlet

fuel

hoses

from

fuel

pump

2

Remove

fuel

pump

3

To

install

reverse

the

order

of

removal

Engine

Fuel

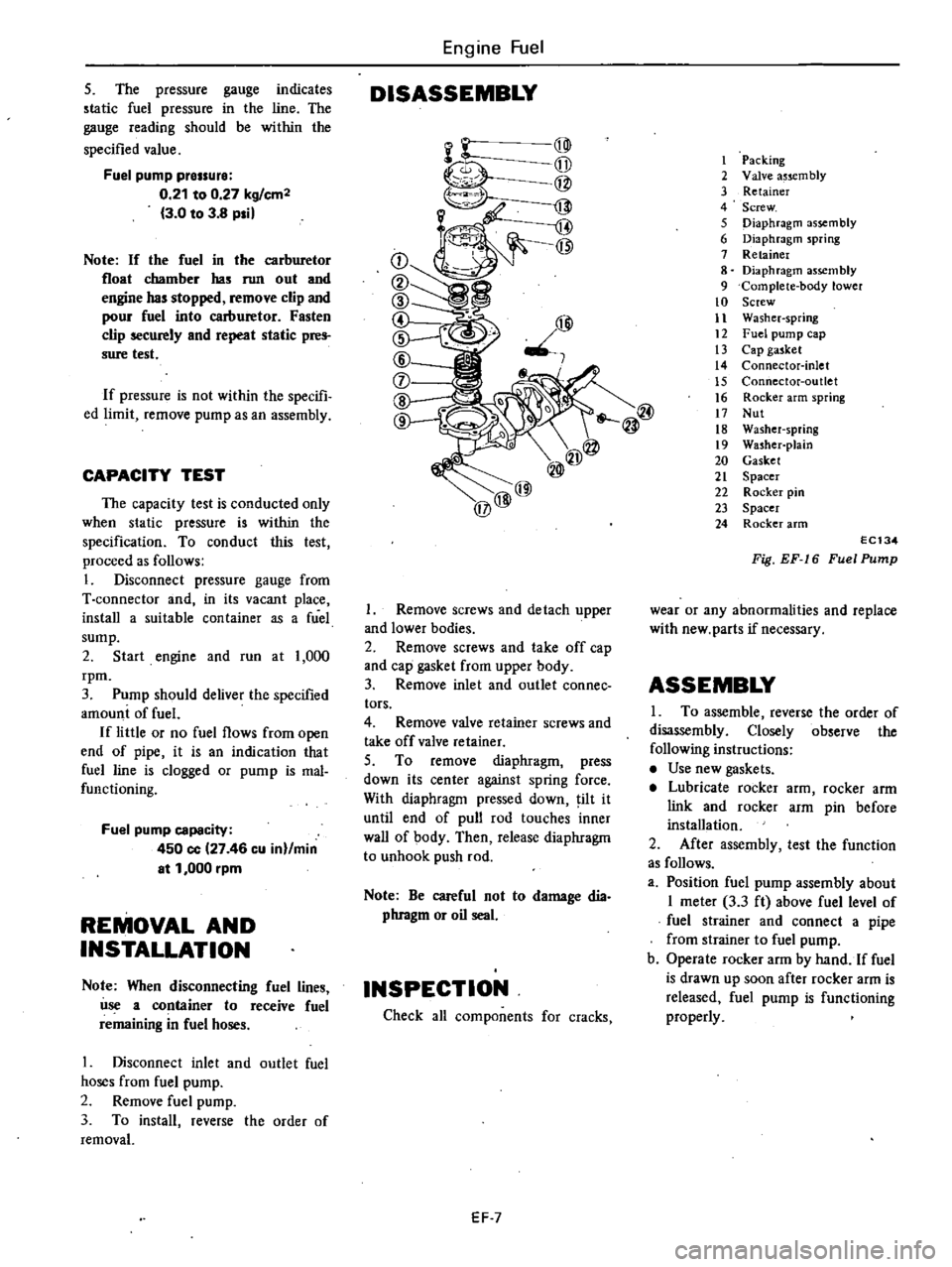

DISASSEMBLY

@@

@@

@

@@

1

Remove

screws

and

detach

upper

and

lower

bodies

2

Remove

screws

and

take

off

cap

and

cap

gasket

from

upper

body

3

Remove

inlet

and

outlet

connee

tors

4

Remove

valve

retainer

screws

and

take

off

valve

retainer

S

To

remove

diaphragm

press

down

its

center

against

spring

force

With

diaphragm

pressed

down

ilt

it

until

end

of

pull

rod

touches

inner

wall

of

body

Then

release

diaphragm

to

unhook

push

rod

Note

Be

careful

not

to

damage

dia

phragm

or

oil

seal

INSPECTION

Check

all

components

for

cracks

EF

7

I

Packing

2

Valve

a5scm

bly

3

Retainer

4

Screw

5

Diaphragm

assembly

6

Diaphragm

spring

7

Retainer

8

Diaphragm

assembly

9

Complete

body

lower

10

Screw

11

Washer

spring

12

Fuel

pump

cap

13

Cap

gasket

14

Connector

inlet

15

Connector

outlet

16

Rocker

arm

spring

17

Nut

18

Washer

spring

19

Washer

pJain

20

Gasket

21

Spacer

22

Rocker

pin

23

Spacer

24

Rocker

arm

EC134

Fig

EF

16

Fuel

Pump

wear

or

any

abnormalities

and

replace

with

new

parts

if

necessary

ASSEMBLY

I

To

assemble

reverse

the

order

of

disassembly

Closely

observe

the

following

instructions

Use

new

gaskets

Lubricate

rocker

arm

rocker

arm

link

and

rocker

arm

pin

before

installation

2

After

assembly

test

the

function

as

follows

a

Position

fuel

pump

assembly

about

I

meter

3

3

ft

above

fuel

level

of

fuel

strainer

and

connect

a

pipe

from

strainer

to

fuel

pump

b

Operate

rocker

arm

by

hand

If

fuel

is

drawn

up

soon

after

rocker

arm

is

released

fuel

pump

is

functioning

properly

Page 96 of 548

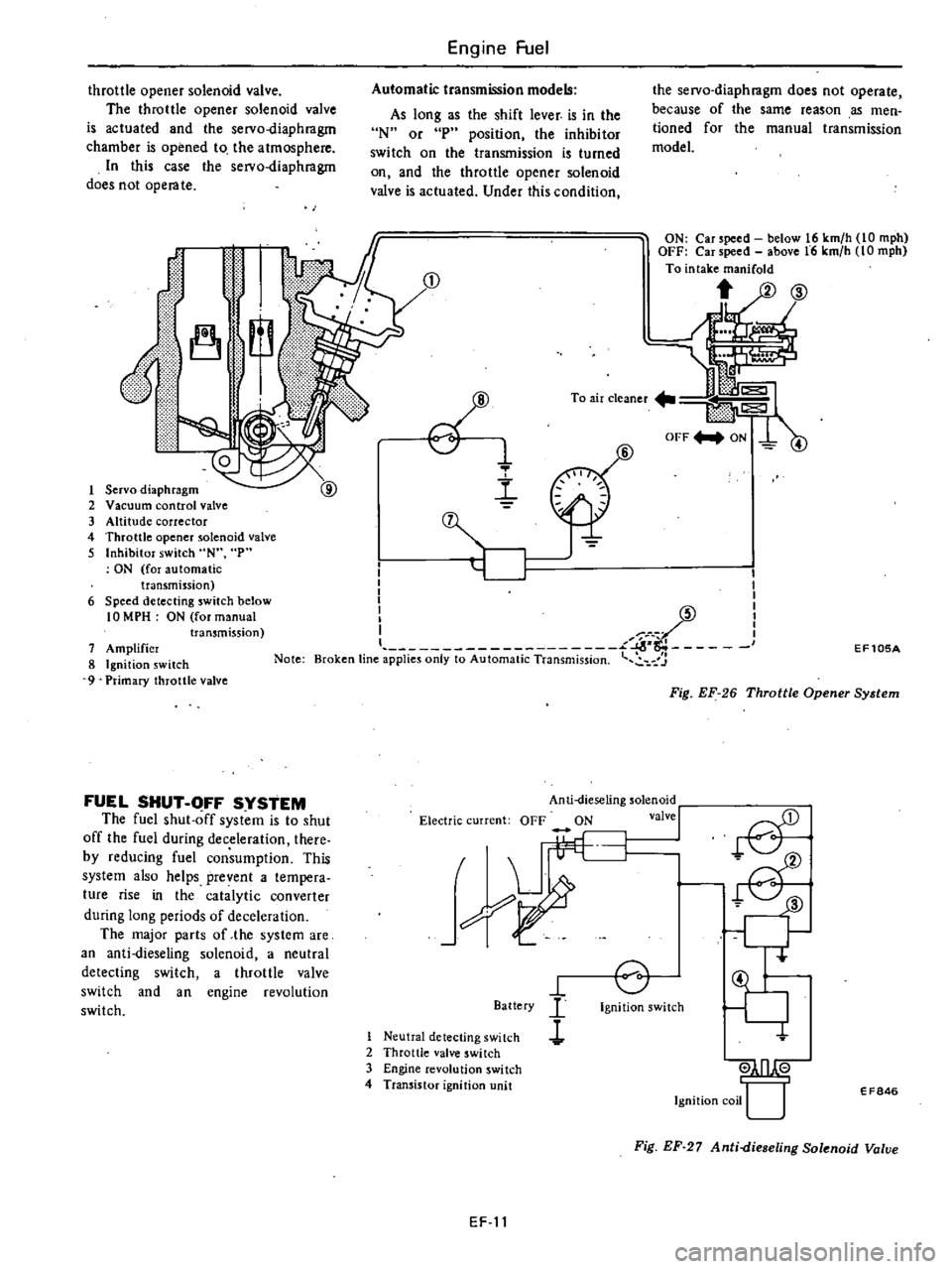

throttle

opener

solenoid

valve

The

throttle

opener

solenoid

valve

is

actuated

and

the

servo

diaphragm

chamber

is

opened

to

the

atmosphere

In

this

case

the

seIVo

diaphragm

does

not

opera

te

Engine

Fuel

Automatic

transmission

models

As

long

as

the

shift

lever

is

in

the

N

or

p

position

the

inhibitor

switch

on

the

transmission

is

turned

on

and

the

throttle

opener

solenoid

valve

is

actuated

Under

this

condition

the

seIVo

diaphragm

does

not

operate

because

of

the

same

reason

as

men

tioned

for

the

manual

transmission

model

ON

Car

peed

betow

t6

km

h

to

mph

OFF

Car

peed

above

16

km

h

to

mph

To

intake

manifold

j

lJl

11

1

ti

i

ljn

L

o

1

Servo

diaphragm

2

Vacuum

control

valve

3

Altitude

corrector

4

Throttle

opener

solenoid

valve

5

Inhibitor

switch

N

p

ON

for

automatic

transmission

6

Speed

detecting

switch

below

10

MPH

ON

for

manual

transmission

7

Amplifier

8

Ignition

switch

9

Primary

throttle

valve

Note

FUEL

SHUT

OFF

SYSTEM

The

fuel

shut

off

system

is

to

shut

off

the

fuel

during

deceleration

there

by

reducing

fuel

consumption

This

system

also

helps

prevent

a

tempera

ture

rise

in

the

catalytic

converter

during

long

periods

of

deceleration

The

major

parts

of

the

system

are

an

anti

dieseling

solenoid

a

neutral

detecting

switch

a

throttle

valve

switch

and

an

engine

revolution

switch

e

1

l

6

I

I

I

I

I

I

I

I

I

l

L

I

Broken

tine

applies

only

to

Automatic

Transmission

7

Anti

dieseling

solenoid

Electric

current

OFF

ON

valve

I

I

h

L

Battery

I

Neutral

detecting

switch

l

2

Throttle

valve

switch

3

Engine

revolution

switch

4

Transistor

ignition

unit

o

Ignition

switch

EF105A

Fig

EF

26

Throttle

Opener

System

ill

Ignition

coil

U

EF846

Fig

EF

27

Anti

dieseling

Solenoid

Valve

EF

11