ignition DATSUN 210 1979 Workshop Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 196 of 548

2

Engine

rotates

but

does

not

run

smoothly

This

may

be

caused

by

the

ignition

Condition

Location

Engine

misses

Distributor

Ignition

coil

High

tension

cable

Spark

plugs

IC

ignition

unit

Engine

causes

knocking

very

often

Distributor

Spark

plugs

Engine

does

not

deliver

enough

power

Distributor

Spark

plugs

Engine

Electrical

System

system

or

other

engine

conditions

not

related

to

ignition

system

Therefore

first

complete

inspection

of

ignition

system

should

be

carried

out

Probable

cause

Foreign

matter

onpicl

up

coil

Improper

air

gap

Leak

of

electricity

at

cap

and

rotor

head

Breakage

of

pick

up

coil

lead

wire

Worn

or

shaky

breaker

plate

Worn

or

shaky

distributor

driVing

shaft

Layer

short

circuit

or

inferior

quality

coil

Deterioration

of

insulation

with

cense

quenlleak

of

electricity

Fouled

Leak

of

electricity

at

upper

porcelain

insulator

Spark

plug

gap

too

narrow

Faulty

IC

ignition

unit

Breakage

of

circuit

Detached

connection

Improper

ignition

timing

too

advanced

Coming

off

or

breakage

of

governor

spring

Worn

pin

or

hole

of

governor

Burnt

too

much

Improper

ignition

timing

too

retarded

Improper

functioning

governor

Foreign

particles

stuck

in

air

gap

Fouled

EE

38

Corrective

action

Clean

Correct

Repair

or

replace

Replace

Replace

assembly

Replace

aSsembly

Replace

with

good

one

Replace

Clean

Repair

or

replace

Correct

or

replace

Replace

Replace

Repair

Correct

Correct

or

replace

Replace

Replace

Correct

Replace

assembly

Clean

Clean

Page 250 of 548

Manual

Transmission

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Difficult

to

intermesh

gears

Causes

for

difficult

gear

shifting

are

classi

fie

t

o

ro

lb

c

QncerlJing

coJltr

1

syste

and

transmission

When

gear

shift

lever

is

heavy

and

it

is

difficult

to

shift

gears

clutch

disengagement

may

also

be

unsmooth

First

make

sure

that

clutch

operates

correctly

and

inspect

transmjssion

Gear

slips

out

of

mesh

In

most

cases

this

troubk

occurs

when

check

baD

and

or

spring

is

waIn

or

weaken

ed

or

when

control

system

is

faulty

In

this

case

the

troubk

cannot

be

correct

by

replacing

gears

and

therefore

trouble

shoot

ing

must

be

carried

out

carefuDy

It

should

also

be

noted

that

gear

slips

out

of

mesh

due

to

vibration

generated

by

weakened

front

and

rear

enigne

mounts

Noise

When

noise

occurs

with

engine

idling

and

ceases

when

clutch

is

disengaged

or

when

noise

occurs

while

shifting

gears

it

is

an

indication

that

the

noise

is

from

trans

mission

Transmission

may

rallk

during

engine

idling

Check

air

fuel

mixture

and

ignition

timing

After

above

procedure

readjust

engine

idling

Probable

cause

Worn

gears

shaft

and

or

bearing

Insufficient

operating

stroke

due

to

worn

or

loose

sliding

part

Worn

or

damaged

syncluonizer

Worn

check

baD

and

or

weakened

or

broken

spring

Worn

fork

rod

baU

groove

Worn

or

damaged

bearing

Worn

or

damaged

gear

Insufficient

or

improper

lubricant

Oil

leaking

due

to

damaged

oil

seal

or

sealant

clogged

breather

etc

Worn

bearing

High

humming

occurs

at

a

high

speed

Damaged

bearing

Cyclic

knocking

sound

occurs

also

at

a

low

speed

Worn

spline

Worn

bushing

MT34

Corrective

action

Replace

Repair

ClI

replace

Replace

Replace

Replace

Replace

Replace

Add

oil

or

replace

with

designated

oil

Clean

or

replace

Replace

Replace

Replace

Replace

as

a

rear

ex

tension

assembly

Page 297 of 548

JUDGEMENT

IN

MEASURING

LINE

PRESSURE

Low

idling

line

pressure

in

the

ranges

D

2

R

and

P

This

can

be

attributed

to

trouble

in

the

pressure

supply

system

or

too

low

output

of

power

caused

by

I

A

worn

oil

pump

2

An

oil

pressure

leak

in

the

oil

pump

valve

body

or

case

3

A

sticking

regulator

valve

2

Low

idling

line

pressure

i

n

cer

tain

ranges

only

This

is

presumably

caused

by

an

oil

leak

in

the

devices

or

circuits

con

nected

to

the

relevant

ranges

I

When

there

is

an

oil

leaJi

in

the

rear

clutch

and

governor

the

line

pressure

in

on

2

and

I

are

low

but

the

pressure

i

nonnal

in

R

2

When

an

oil

leak

occurs

in

the

low

and

reverse

brake

circuit

the

line

pressure

in

oR

and

P

are

low

b

t

the

pressure

is

normal

in

0

2

and

I

3

High

idling

line

pressure

Thi

is

presumably

caused

by

an

increased

aC

1ulT

t

rott

e

pr

ssure

owing

to

a

leak

in

the

vacuum

tube

or

diaphragin

or

by

an

increased

line

Automatic

Transmission

pressure

due

to

a

sticking

regulator

valve

Vacuum

leakage

is

checked

by

directly

measuring

the

negative

pres

sure

after

removing

the

vacuum

pipe

A

puncture

of

the

vacuum

dia

phragm

can

be

easily

ascertained

because

the

torque

converter

oil

is

absorbed

into

the

engine

and

the

exhaust

pipe

emits

white

smoke

4

Item

to

be

checked

when

the

Ii

e

pressure

is

increasing

In

this

c

1eck

the

line

pressure

should

be

measured

with

vacuums

of

300

mmHg

Il

SI

inHg

and

0

mmHg

0

inHg

in

accordance

with

the

staIl

test

procedure

i

If

the

line

pressure

does

not

in

crease

despite

the

vacuum

decrease

check

whether

the

vacuum

rod

is

i

corporated

2

If

the

line

pressure

does

not

meet

tile

standard

iUs

caused

mostly

by

a

sticking

pressure

regulating

valve

pres

sure

regulating

valve

plug

or

amplifier

TROUBLE

SHOOTING

CHART

INSPECTING

ITEMS

I

Inspection

with

automatic

trans

mission

on

vehicle

AT

45

A

Oil

level

B

Range

select

linkage

C

Inhibitor

switch

and

wiring

D

Vacuum

diaphragm

and

piping

E

Downshift

solenoid

kickdown

switch

and

wiring

F

Engine

idling

rpm

G

Oil

pressure

throttle

H

Engine

stall

rpm

I

Rear

lubrication

J

Control

valve

manual

K

Governor

valve

L

Band

servo

M

Transmission

air

check

N

Oil

quality

o

Ignition

switch

and

starter

motor

P

Engine

adjustment

and

brake

in

spection

2

Inspection

after

inspecting

auto

matic

transmission

on

vehicle

m

Rear

clutch

n

Front

clutch

q

Band

brake

r

Low

and

reverse

brake

s

Oil

pump

t

Leakage

of

oil

passage

u

One

way

clutch

of

troque

converter

v

One

way

clutch

of

transmission

w

Front

clutch

check

ball

x

Parking

linkage

y

Planetary

gear

Page 301 of 548

Automatic

Transmission

TROUBLE

SHOOTING

GUIDE

FOR

3N71B

AUTOMATIC

TRANSMISSION

Ordel

Test

item

Checking

Oil

level

gauge

j

Downshift

solenoid

3

Manual

linkage

4

Inhibitor

switch

5

Engine

idling

rpm

6

Vacuum

pressure

of

vacuum

pipe

7

Operation

in

each

range

g

Creep

of

vehicle

Stall

test

1

Oil

pressure

before

t

sting

2

Stall

test

3

Oil

pressure

after

teSling

Road

test

L

Slow

acceleration

Ist

2nd

2nd

3rd

2

Quick

acceleration

Ist

2nd

2nd

3rd

3

Kick

down

operation

3rd

2nd

or

2nd

1st

Procedure

Check

gauge

for

oil

level

and

leakage

before

and

after

each

test

Check

for

sound

of

operating

solenoid

when

depressing

accelerator

pedal

fully

with

ignition

key

ON

Check

by

shifting

into

P

R

N

0

2

and

ranges

with

selector

lever

Check

whether

starter

operates

in

N

and

p

ranges

only

and

whether

reverse

lamp

operates

in

R

range

only

Check

whether

idling

rpm

meet

slandard

Check

whether

vacuum

pressure

is

more

than

450

mmHg

17

72

inHg

in

idling

and

whether

it

decreases

with

increasing

rpm

Check

whether

transmission

engages

positively

by

shifting

N

0

N

2

N

to

I

and

N

R

range

while

idling

with

brake

applied

Check

whether

there

is

any

creep

in

0

2

and

R

ranges

Measure

line

pressures

in

D

2

I

and

R

range

while

idling

Measure

engine

rpm

and

line

pressure

in

0

2

t

and

R

ranges

during

full

throttle

operation

Note

Temperature

of

torque

con

erter

oil

used

in

test

should

be

from

6

to

lOO

C

140

to

2120F

i

e

suf

ficiently

1

up

but

not

o

heeted

CAUTION

To

cool

oil

between

IIch

mil

test

for

OH

ZH

1

H

Ind

RH

nnges

idle

engine

i

e

rpm

It

Ibout

1

200

rpm

for

more

thin

1

minutll

in

P

nnge

MeeRlr

ment

time

mUlt

not

be

more

then

5

seconds

Same

as

item

1

Check

vehicle

speeds

and

engine

rpm

in

shifting

up

1

st

2nd

range

and

2nd

3rd

range

while

running

with

lever

in

D

range

and

engine

vacuum

pressure

of

about

200

mmHg

7

87

inHg

Same

as

item

1

above

except

with

engine

vacuum

pressure

of

o

mrnHg

0

inHg

i

e

in

position

just

before

kickdown

Check

whether

the

kickdown

operates

and

measure

the

time

delays

while

running

at

30

40

50

60

70

km

h

19

25

31

37

43

MPH

in

OJ

range

AT

49

Page 446 of 548

DATSUN

210

Model

8310

Series

SECTIONBE

BODY

ELECTRICAL

SYSTEM

CONTENTS

BODY

ELECTRICAL

WIRING

DESCRIPTION

FUSE

AND

FUSIBLE

LINK

WIRING

WIRING

HARNESS

LOCATION

OF

ELECTRICAL

UNIT

ELECTRICAL

UNIT

OF

LIGHTING

SYSTEM

BULB

SPECIFICATIONS

REMOVAL

AND

INSTALLATION

For

lamp

IGNITION

SWITCH

COMBINATION

SWITCH

ILLUMINATION

CONTROL

UNIT

AIMING

ADJUSTMENT

ELECTRICAL

UNIT

OF

SIGNAL

SYSTEM

BE

12

TURN

SIGNAL

SWITCH

BE

12

HORN

RELAY

BE

12

HAZARD

SWITCH

BE

12

STOP

LAMP

SWITCH

BE

12

BACK

UP

LAMP

SWITCH

BE

12

DOOR

SWITCH

BE

12

METERS

AND

GAUGES

BE

13

COMBINATION

METER

BE

13

TACHOMETER

BE

14

FUEL

LEVEL

AND

WATER

TEMPERATURE

INDICATOR

SYSTEM

BE

14

WARNING

SYSTEM

BE

15

CHARGE

WARNING

SYSTEM

BE

15

BRAKE

WARNING

SYSTEM

BE

15

BE

2

BE

2

BE

2

BE

4

BE

5

BE

8

BE

9

BE

9

BE

10

BE

10

BE

10

BE

11

BE

11

OIL

PRESSURE

WARNING

SYSTEM

SEAT

BELT

WARNING

SYSTEM

ELECTRICAL

ACCESSORIES

WINDSHIELD

WIPER

AND

WASHER

REAR

WINDOW

WIPER

AND

WASHER

CIGARETTE

LIGHTER

RADIO

CLOCK

REAR

WINDOW

DEFOGGER

STARTING

SYSTEM

For

automatic

transmission

models

HEATER

DESCRIPTION

AIR

FLOW

REMOVAL

AND

INSTALLATION

ADJUSTING

HEATER

CONTROL

DISASSEMBLY

AND

ASSEMBLY

OF

HEATER

UNIT

INSPECTION

WIRING

DIAGRAMS

AND

TROUBLE

DIAGNOSES

ELECTRICAL

SYSTEM

BLOCK

DIAGRAM

FUSE

BLOCK

CIRCUIT

SUPPLY

ROUTING

LIGHTING

SYSTEM

SIGNAL

SYSTEM

METERS

AND

GAUGES

WARNING

SYSTEM

ELECTRICAL

ACCESSORY

SYSTEM

HEATER

BE

15

BE

15

BE

17

BE

17

BE

18

BE

20

BE

20

BE

21

BE

21

BE

23

BE

23

BE

23

BE

24

BE

26

BE

27

BE

27

BE

28

BE

29

BE

29

BE

30

BE

31

BE

36

BE

41

BE

44

BE

4B

BE

55

Page 447 of 548

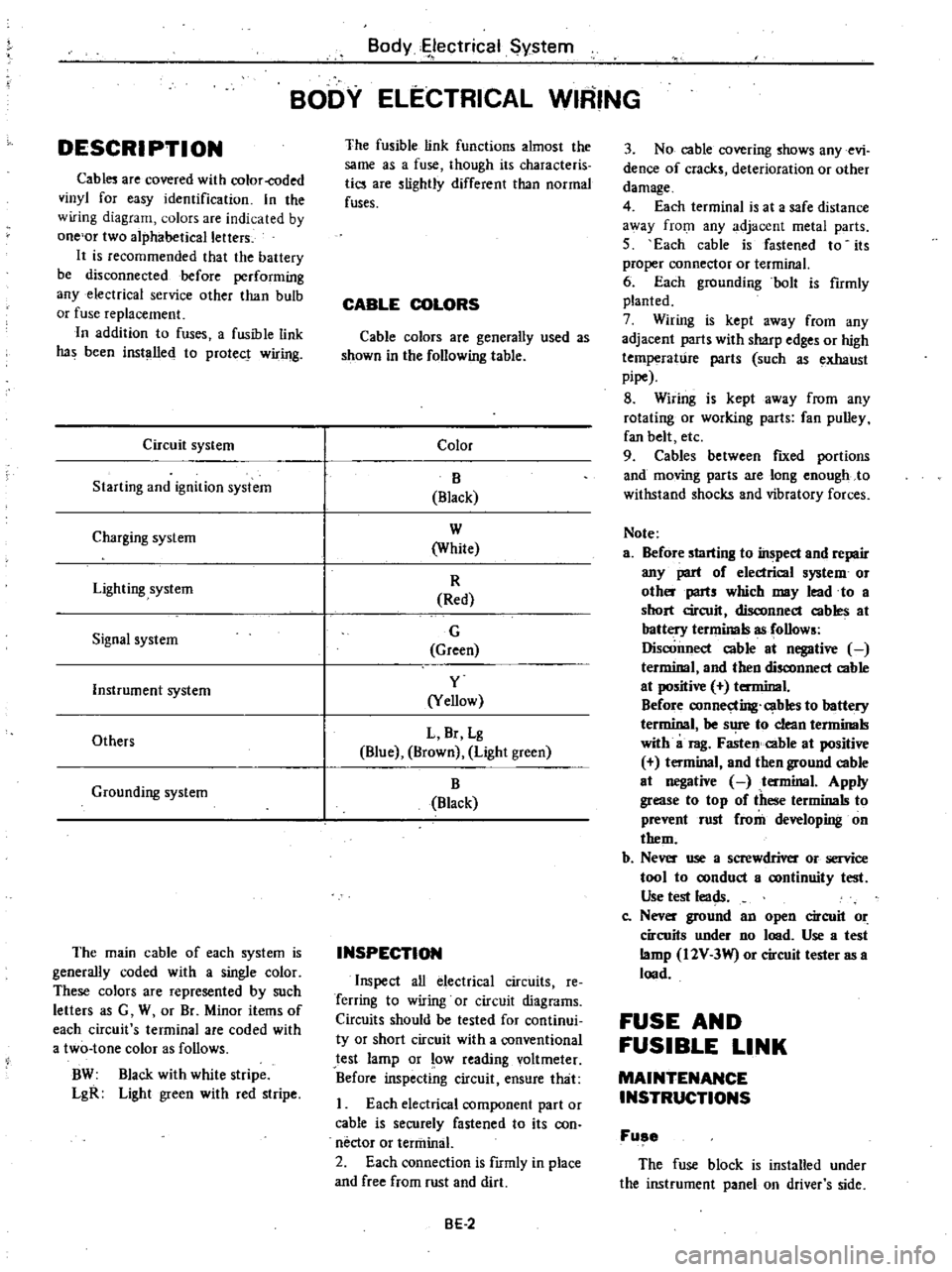

DESCRI

PTI

ON

Cabl

are

covered

with

color

coded

vinyl

for

easy

identification

In

the

wiring

diagram

olors

are

indicated

by

one

or

two

alphabetical

letters

It

is

recommended

that

the

battery

be

disconnected

before

performing

any

electrical

service

other

than

bulb

or

fuse

replacement

In

addition

to

fuses

a

fusible

link

has

been

installed

to

protect

wiring

Circuit

system

Starting

and

ignition

system

Charging

system

Lighting

system

Signal

system

Instrument

system

Others

Grounding

system

The

main

cable

of

each

system

is

generally

coded

with

a

single

color

These

colors

are

represented

by

such

letters

as

G

W

or

Br

Minor

items

of

each

circuit

s

terminal

are

coded

with

a

two

tone

color

as

follows

BW

Black

with

white

stripe

LgR

Light

green

with

red

stripe

Body

ectrical

System

BODY

ELECTRICAL

WIRING

The

fusible

link

functions

almost

the

same

as

a

fuse

though

its

characteris

tics

are

slightly

different

than

normal

fuses

CABLE

COLORS

Cable

colors

are

generally

used

as

shown

in

the

following

table

Color

B

Black

W

White

R

Red

G

Green

y

Yellow

L

Br

Lg

Blue

Brown

Light

green

B

Black

INSPECTION

Inspect

all

electrical

circuits

Ie

Terring

to

wiring

or

circuit

diagrams

Circuits

should

be

tested

for

continui

ty

or

short

circuit

with

a

conventional

test

lamp

or

low

reading

voltmeter

Before

inspecting

circuit

ensure

that

I

Each

electrical

component

part

or

cable

is

securely

fastened

to

its

con

nector

or

tenninal

2

Each

connection

is

fIrmly

in

place

and

free

from

rust

and

dirt

BE

2

3

No

cable

covering

shows

any

evi

dence

of

cracks

deterioration

or

other

damage

4

Each

terminal

is

at

a

safe

distance

3

Vay

from

any

adjacent

metal

parts

5

Each

cable

is

fastened

to

its

proper

connector

or

terminal

6

Each

grounding

bolt

is

fumly

planted

7

Wiring

is

kept

away

from

any

adjacent

parts

with

sharp

edges

or

high

temperature

parts

such

as

exhaust

pipe

8

Wiring

is

kept

away

from

any

rotating

or

working

parts

fan

pulley

fan

belt

etc

9

Cables

between

fIXed

portions

and

moving

parts

are

long

enough

to

withstand

shocks

and

vibratory

forces

Note

a

Before

starting

to

inspect

and

repair

any

part

of

electrical

system

or

oth

parts

which

may

lead

to

a

short

circuit

disconnect

cables

at

battery

terminals

as

follows

Disconnect

cable

at

negative

terminal

and

then

disconnect

cable

at

positive

terminal

Before

connecting

cables

to

battery

terminal

be

s

1

to

clean

tenninals

with

a

rag

Fasten

cable

at

positive

t

minal

and

then

ground

cable

at

negative

tenninal

Apply

grease

to

top

of

these

terminals

to

prevent

rust

from

developing

on

them

b

Ne

use

a

screwdriver

or

service

tool

to

oonduct

a

oontinuity

test

Use

test

leads

Co

Nev

ground

an

open

circuit

or

circuits

under

no

lood

Use

a

test

lamp

I2V

3W

or

circuit

tester

as

a

lood

FUSE

AND

FUSIBLE

LINK

MAINTENANCE

INSTRUCTIONS

Fuse

The

fuse

block

is

installed

under

the

instrument

panel

on

driver

s

side

Page 448 of 548

When

for

one

reason

or

another

fuse

has

melted

use

systematic

proce

dure

to

check

and

eliminate

cause

of

problem

before

installing

new

fuse

Note

a

If

fuse

is

blown

be

sure

to

elimi

nate

cause

of

problem

before

in

stalling

new

fuse

b

Use

fuse

of

specified

rating

Never

use

fuse

of

more

than

specified

rating

c

Check

condition

of

fuse

holders

If

much

rust

or

dirt

is

found

thereon

clean

metal

parts

with

fine

grained

sandpaper

until

proper

metal

to

metal

contact

is

made

Poor

contact

in

any

fuse

holder

will

often

lead

to

voltage

drop

or

heat

ing

in

the

circuit

and

could

result

in

improper

circuit

operation

Body

Electrical

System

W

BE1100

Fig

BE

l

FU

e

Block

Fusible

link

Fusible

link

protects

starting

he

d

lamp

ignition

and

charge

circuits

and

wiring

between

fuse

and

fusible

link

BE1110

Fig

BE

2

Fusible

Link

BE

3

CAUTION

a

If

fusible

link

should

melt

it

is

possible

that

critical

circuit

power

supply

or

large

current

carrying

circuit

is

shorted

In

such

a

case

carefully

check

and

eliminate

cause

of

problem

b

Never

wrap

periphery

of

fusible

link

with

vinyl

tape

Extreme

care

should

be

taken

with

this

link

to

ensure

that

it

does

not

come

into

contact

with

any

other

wiring

har

ness

or

vinyl

or

rubber

parts

A

melted

fusible

link

can

be

detect

ed

either

by

visual

inspection

or

by

feeling

with

finger

tip

If

its

condition

is

questionable

use

circuit

tester

or

test

lamp

as

required

to

conduct

continuity

test

This

continuity

test

can

be

performed

in

the

same

manner

as

for

any

conventional

fuse

Page 450 of 548

m

c

n

to

l

l

I

g

iF

0

1

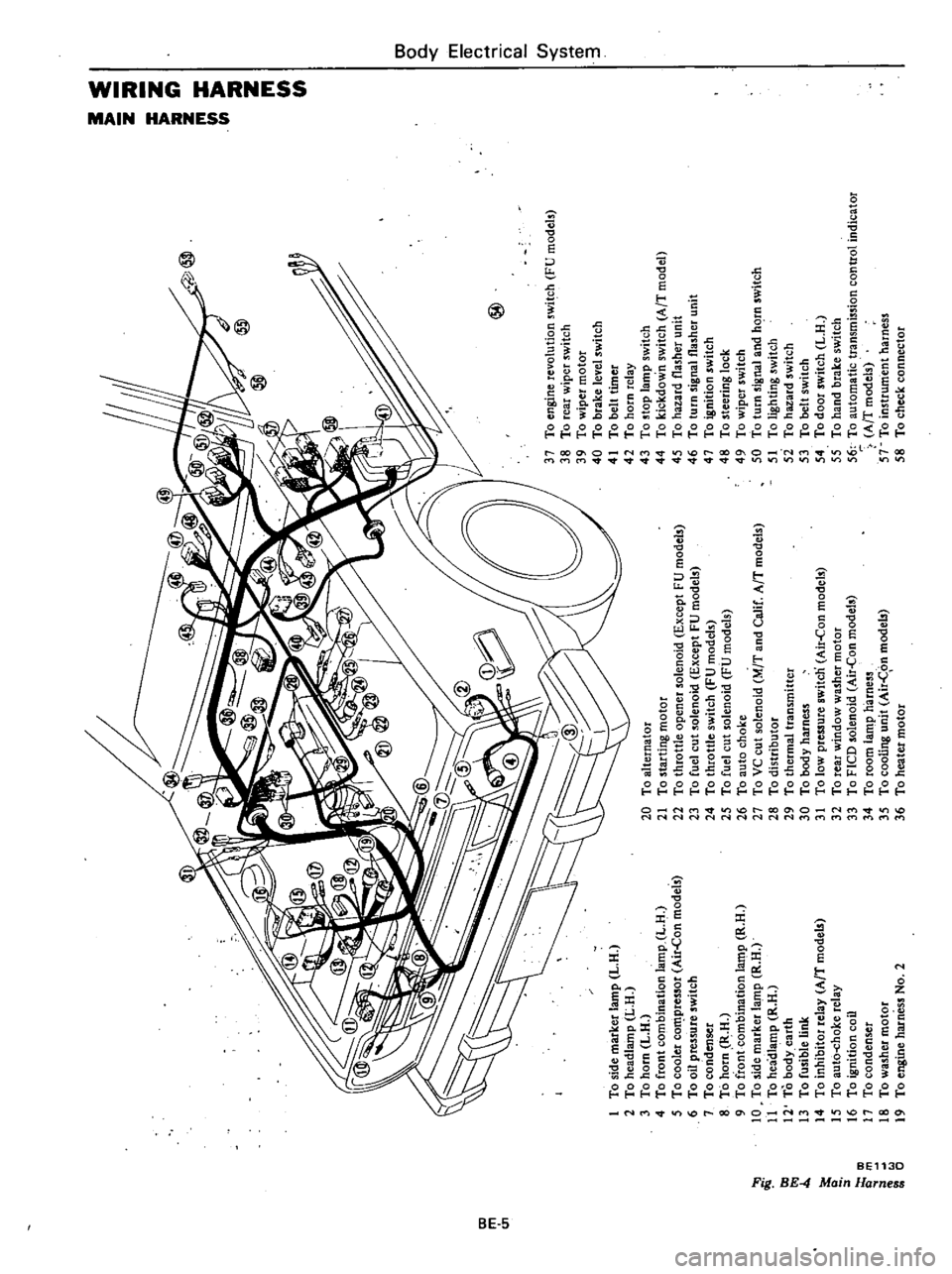

To

side

marker

lamp

L

H

2

To

headlamp

L

H

3

To

horn

L

H

4

To

front

combination

lamp

L

H

5

To

cooler

co

pressor

Air

Con

models

6

To

oil

pressure

switch

7

To

condenser

8

To

horn

R

H

9

To

front

combination

la

t11p

R

H

10

To

side

marker

lamp

R

H

11

To

headlamp

R

H

12

To

body

earth

13

To

fusible

link

14

To

inhibitor

relay

AfT

model

15

To

aut6

choke

relay

16

To

ignition

coil

17

To

condenser

18

To

washer

motor

19

To

engine

harness

No

2

@

20

To

alternator

21

To

starting

motor

22

To

throttle

opener

solenoid

Except

FU

models

23

To

fuel

cut

solenoid

Except

FU

models

24

To

throttle

switch

FU

models

25

To

fuel

cut

solenoid

FU

models

26

To

auto

choke

27

To

VC

cut

solenoid

M

T

and

Calif

AfT

models

28

To

distributor

29

To

thermal

transmitter

30

To

body

harness

31

To

low

pressure

switcn

Air

Con

models

32

To

rear

window

washer

motor

33

To

FICO

solenoid

Air

Con

models

34

To

room

lamp

harness

35

To

cooling

unit

Air

C

on

models

36

To

heater

motor

37

To

engine

revolution

switch

FU

models

38

To

rear

wiper

switch

39

To

wiper

motor

40

To

brake

level

switch

41

To

belt

timer

42

To

horn

relay

43

To

stop

lamp

switch

44

To

kickdown

switch

AfT

model

45

To

hazard

flasher

unit

46

To

turn

signal

flasher

unit

47

To

ignition

switch

48

To

steering

lock

49

To

wiper

switch

50

To

turn

signal

and

hC

rn

switch

51

To

lighting

switch

5i

To

hazard

switch

53

To

belt

switch

54

To

door

switch

L

H

55

To

hand

brake

switch

56

To

automatic

transmission

control

indicator

AfT

models

57

To

instrument

harness

58

To

check

connector

I

0

i

a

z

Z

G

z

tIl

tIl

a

Z

Il

I

to

o

Co

m

16

n

n

OJ

1

3

Page 455 of 548

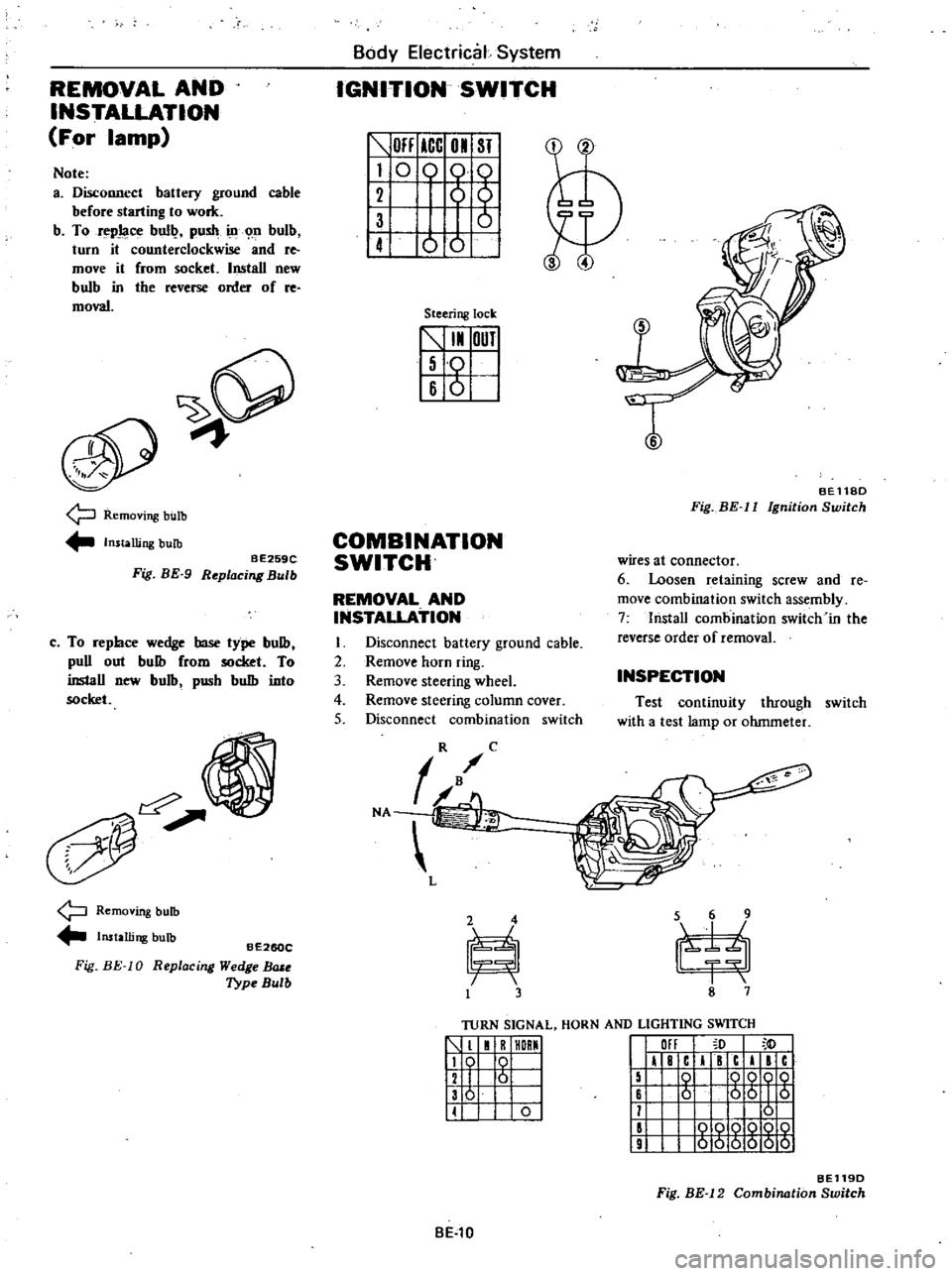

REMOVAL

AND

INSTALLATION

For

lamp

Note

a

Disconnect

battery

ground

cable

before

starting

to

work

b

To

repJaoe

bull

push

ill

n

bulb

turn

it

counterclockwise

and

re

move

it

from

socket

Install

new

bulb

in

tbe

reverse

order

of

re

moval

9

Removing

bulb

Installing

bulb

BE259C

Fig

BE

9

Replacing

Bulb

c

To

repbce

wedge

base

type

bulb

puD

out

bulb

from

socket

To

inslaD

new

bulb

pusb

bulb

into

socket

Removing

bulb

Installing

bulb

Fig

BE

10

BE260C

R

eplac

ing

Wedge

BlUe

Type

Bulb

Body

Electrical

System

IGNITION

SWITCH

OFF

ICC

01

ST

I

0

0

61

1

ot

Steering

lock

5

I

OUT

I

Iso

16

6

I

T

BEll8D

Fig

BE

II

Ignition

Switch

COMBINATION

SWITCH

wires

at

connector

6

Loosen

retaining

screw

and

Ie

move

combination

switch

assembly

7

lnstaD

combination

switch

in

the

reverse

order

of

removal

REMOVAL

AND

INSTALLATION

I

Disconnect

battery

ground

cable

2

Remove

horn

ring

3

Remove

steering

wheel

4

Remove

steering

column

cover

5

Disconnect

combination

switch

INSPECTION

Test

continuity

through

switch

with

a

test

lamp

or

ohmmeter

TURN

SIGNAL

HORN

AND

LIGHTING

SWITCH

1

1

R

HORMI

119

0

I

12

I

6

I

136

I

II

0

I

III

I

F

c

I

c

I

c

15

0

QQOQ

16

6

56

I

5

11

0

II

000Q

10

9

000000

BE119D

Fig

BE

12

Combination

Switch

BE

l0

Page 460 of 548

CHARGE

WARNING

SYSTEM

Refer

to

Section

EE

BRAKE

WARNING

SYSTEM

REPLACEMENT

Hand

brake

switch

I

Disconnect

battery

ground

cable

2

Remove

console

box

if

equipped

3

Disconnect

hand

brake

switch

lead

wire

at

connector

4

Remove

switch

from

switch

bracket

by

pulling

it

5

Install

new

switch

in

the

reverse

order

of

removal

BE

177C

Fig

BE

23

Hand

Brake

Switch

Brake

fluid

level

switch

Brake

fluid

level

switch

is

buiit

into

brake

master

cylinder

cap

The

cap

can

be

easily

removed

by

twisting

it

after

disconnecting

lead

wire

terminals

Then

replace

it

OIL

PRESSURE

WARNING

SYSTEM

REPLACEMENT

011

pressure

switch

To

replace

oil

pressure

switch

dis

Body

Electrical

System

WARNING

SYSTEM

connect

lead

wire

from

switch

termi

nal

and

unscrew

switch

Oil

pressureswltch

BE247

Fig

BE

24

Oil

Pres5ure

Switch

@

SEAT

BELT

WARNING

TIMER

8

SEAT

BELT

J

WARNING

LIGHT

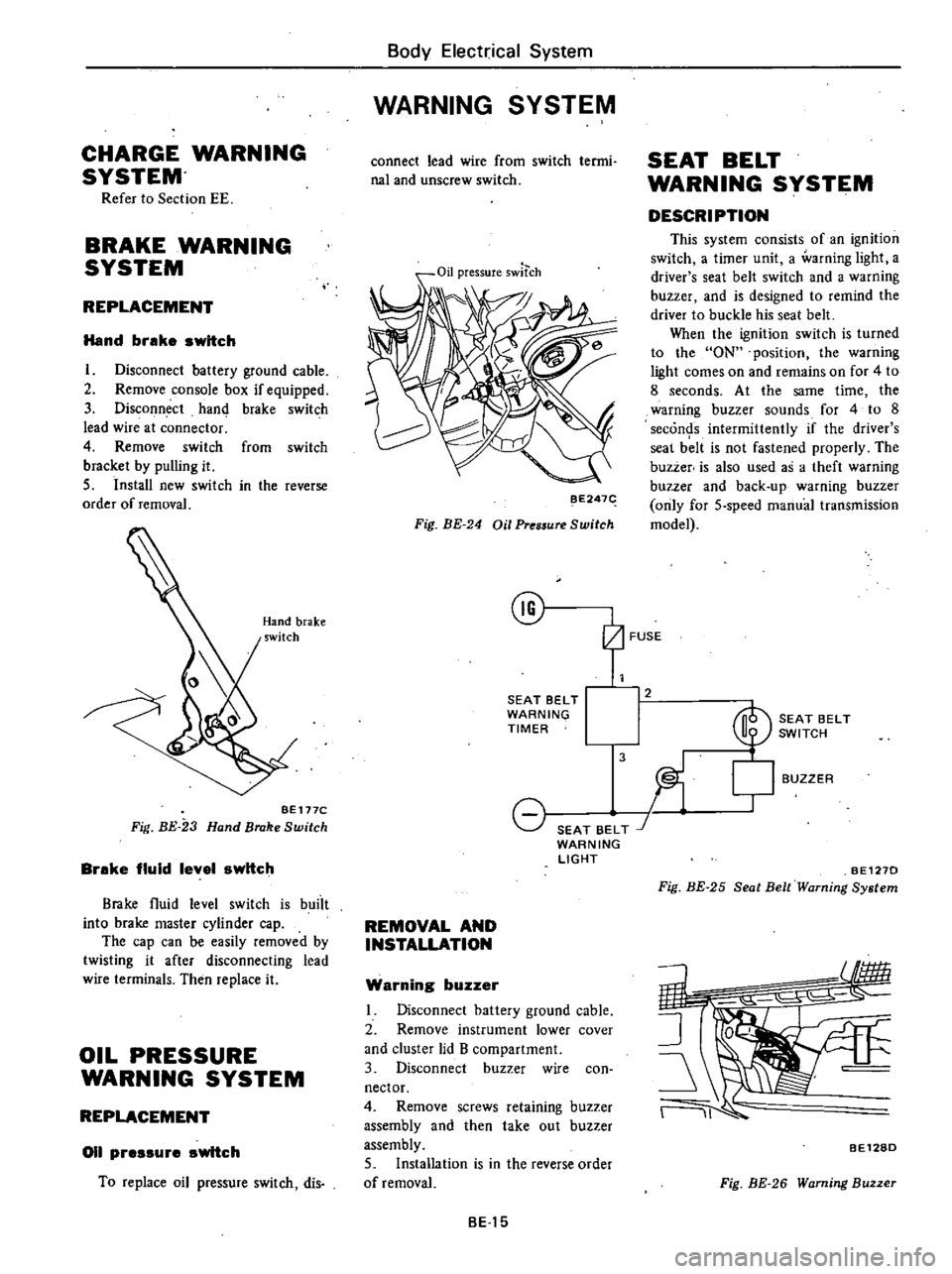

REMOVAL

AND

INSTALLATION

Warning

buzzer

Disconnect

battery

ground

cable

2

Remove

instrument

lower

cover

and

cluster

lid

B

compartment

3

Disconnect

buzzer

wire

con

nector

4

Remove

screws

retaining

buzzer

assembly

and

then

take

out

buzzer

assembly

5

Installation

is

in

the

reverse

order

of

removal

BE15

SEAT

BELT

WARNING

SYSTEM

DESCRIPTION

This

system

consists

of

an

ignition

switch

a

timer

unit

a

warning

light

a

driver

s

seat

belt

switch

and

a

warning

buzzer

and

is

designed

to

remind

the

driver

to

buckle

his

seat

belt

When

the

ignition

switch

is

turned

to

the

ON

position

the

warning

light

comes

on

and

remains

on

for

4

to

8

seconds

At

the

same

time

the

warning

buzzer

sounds

for

4

to

8

seconds

intermittently

if

the

driver

s

seal

b

lt

is

not

fastened

properly

The

buzzer

is

also

used

as

a

theft

warning

buzzer

and

back

up

warning

buzzer

only

for

5

speed

manual

transmission

model

2

3

BUZZER

SEAT

BELT

SWITCH

l

BE1270

Fig

BE

25

Seat

Belt

Warning

System

11

BE128D

Fig

BE

26

Warning

Buzzer