carb DATSUN 210 1979 Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 153 of 548

REMOVAL

AND

INSTALLATION

I

Jack

up

the

car

Note

Apply

parking

brake

and

place

wheel

chocks

2

Remove

screws

securing

lower

shelter

of

catalytic

converter

Loosen

flange

bolt

connecting

catalytic

converter

to

front

and

rear

exhaust

tube

Catalytic

converter

assembly

can

then

be

taken

out

3

Installation

i

in

the

reverse

se

quence

of

removal

CAUTION

a

Be

careful

not

to

damage

catalytic

co

when

handliilg

b

Never

wet

catalyzer

with

water

oil

etc

t

J

Tightening

torque

Catalyti

converter

bolts

2

6

to

3

4

kg

m

19

to

25

ft

lb

Emission

Control

System

EC075A

EC076A

Fig

EC

103

Removing

Catalytic

Converter

INSPECTION

PrelimInary

In

pectlon

Vi

ually

check

condition

of

all

component

parts

including

hose

tubes

and

wires

replace

if

necessary

Refer

to

Air

Injection

System

for

inspection

EC

34

Catalytic

converter

Whether

catalytic

converter

is

nor

mal

or

not

can

e

checked

by

ob

serving

variation

in

CO

percentage

The

checking

procedure

is

as

follows

Apply

parking

brake

Shift

gears

into

Neutral

for

manual

transmis

sion

and

N

or

P

for

automatic

transmission

position

I

Adjust

engine

idling

speed

and

CO

percentage

Refer

to

Adjusting

Carburetor

Idle

RPM

and

Mixture

Ratio

for

adjustment

2

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

and

make

sure

that

specified

CO

percent

age

obtained

3

Remove

cap

and

connect

air

hose

to

air

check

valve

If

idling

speed

increases

readjust

it

to

specified

speed

with

throttle

adjusting

screw

4

Warm

up

engine

for

about

four

minutes

at

2

000

pm

under

no

load

S

Measure

Ci

percentage

at

idling

speed

After

stepAhas

been

complet

ed

wait

for

one

minute

before

making

CO

percentage

measurement

6

If

CO

percentage

measured

in

step

5

is

less

than

0

3

the

catalytic

converter

is

normaL

7

If

CO

percentage

measured

in

step

5

is

over

0

3

recheck

AJ

S

and

1

replace

air

check

valVe

The

perform

inspection

steps

4

and

S

8

If

CO

percentage

is

still

over

0

3

in

step

7

catalyt

iC

converter

i

mal

functioning

Replace

catalytic

con

verter

Page 154 of 548

Emission

Control

System

EvApORATIVE

EMISSION

CONTROL

SYSTEM

DESCRIPTION

carbons

is

accomplished

by

activated

charcoals

in

the

C

Ibon

canister

This

system

is

made

up

of

the

foUo

ing

I

I

Fuel

tank

with

positive

sealing

filler

cap

The

evaporative

emission

control

system

is

used

to

reduce

hydrocarbons

emitted

to

the

atmosphere

from

the

fuel

system

This

reduction

of

hydro

6

C

2

Fuel

check

valve

3

Vapor

vent

line

4

Carbon

canister

I

5

Vacuum

ignalline

6

Canister

purge

line

5

1

Fuel

tank

2

Fuel

filler

cap

with

vacuum

relief

valve

3

Fuel

check

valve

4

Vapor

vent

line

5

Canister

purge

line

6

Vacuum

signal

line

7

Carbon

canister

EC327

A

Fig

EC

104

Evaporative

Emission

Control

System

for

Sed

n

EC

35

t

Page 155 of 548

OPERATION

Fuel

vapors

from

the

sealed

fuel

tank

are

led

into

the

carbon

canister

The

canister

is

filled

with

activated

charcoals

to

absorb

the

fuel

vapors

when

the

engine

is

at

rest

or

at

idling

t

Fuel

tank

2

Fuel

filler

cap

with

vacuum

re1ief

va1ve

3

Fuel

check

vslve

4

Vapor

t

line

5

Vacuum

signal

line

6

Canister

purge

line

Emission

Control

System

As

the

throttle

Valve

opens

and

car

speed

increases

vacuum

pressure

in

the

vacuum

signajline

forces

the

purge

control

valve

to

open

and

admits

an

orifice

to

intake

manifold

and

fuel

vapor

is

then

drawn

into

the

intake

manifold

through

the

canister

purge

line

Fuel

vapor

7

Throttle

valve

IZ

Filter

8

Engine

13

Purge

control

valve

9

Carbon

cani5t

14

DiaphraP

spring

10

Activated

carbon

IS

Diaphngm

II

Screen

16

Fixed

orifice

EC785

Fig

EC

JOS

Evaporative

Emiuion

Control

System

Fuel

vapor

flow

when

ngine

is

at

rest

or

running

REMOVAL

AND

INSTALLAtiON

CARBON

CANISTER

FILTER

Check

for

a

contantinated

element

Elemenl

can

be

removed

at

the

bottom

of

canister

installed

on

car

body

EF201

Fig

EC

I06

Replacing

Carbon

Canilttr

Filter

CHECK

VALVE

The

check

valve

is

located

behind

the

luggage

compartment

board

on

the

fuel

tank

Remove

the

luggage

compartment

board

and

disconnect

the

vapor

tube

The

check

valve

can

then

be

taken

out

EC315A

Fig

EC

I07

Removing

Check

Volve

EC

36

INSPECTION

FUEL

TANK

AND

VAPOR

VENT

LINE

1

Check

all

hoses

and

fuel

tank

filler

cap

2

Disconnect

the

vapor

vent

line

connecting

carbon

canister

to

check

valve

3

Connect

a

3

w

y

connector

a

manometer

and

a

cock

or

an

equi

valent

3

way

charge

cock

to

the

end

of

the

vent

line

EC183A

Fig

EC

IOB

Vent

Line

4

Supply

fresh

air

into

the

vapor

vent

line

through

the

cock

little

by

little

until

pressure

becomes

368

mmHZO

14

5

inHZO

S

Shut

the

cock

completely

and

leave

it

unattended

6

After

2

5

minutes

measure

the

height

of

the

liquid

in

the

manometer

7

Variation

in

height

should

remain

with

25

mmHZO

0

98

inH20

8

When

filler

cap

does

not

close

completely

the

height

should

drop

to

zero

in

a

short

time

9

If

the

height

does

not

drop

to

zero

in

a

short

time

when

ruler

cap

is

d

it

is

the

cause

of

a

stuffy

hose

Note

In

case

the

vent

line

is

stuffy

the

breathing

in

fuel

tank

is

not

thoroughly

IIIIIde

thus

causing

in

sufficient

delivery

of

feul

to

engine

or

vapor

lock

It

must

therefore

be

repaired

or

replaced

Page 156 of 548

3

way

connector

ck

Air

@

Manometer

Carbon

canister

Emission

Control

System

400

mmH20

15

75

inH20

Check

valve

Fuel

filler

cap

r

EC091A

Fig

EC

I09

Checking

Evaporative

Emiuion

Control

Syatem

FUEL

CHECK

VALVE

I

Blow

air

through

connector

on

fuel

tank

side

A

considerable

resistance

should

be

felt

at

the

mouth

and

a

portion

of

air

flow

be

directed

toward

the

engine

2

Blow

air

through

connector

on

engine

side

Air

flow

should

be

smoothly

direct

ed

toward

fuel

tank

3

If

fuel

check

valve

is

suspected

of

not

being

properly

functioning

in

steps

I

and

2

above

replace

Engine

side

Fuel

tank

side

Q

Evaporative

fuel

flow

Fresh

air

flow

EC090A

Fig

EC

110

Checking

Fuel

Check

Valve

CARBON

CANISTER

PURGE

CONTROL

VALVE

Check

for

fuel

vapor

leakage

in

the

distributor

vacuum

line

at

diaphragm

of

carbon

canister

purge

control

valve

To

check

for

leakage

proceed

as

follows

I

Disconnect

rubber

hose

in

the

line

between

T

connector

and

carbon

canister

at

T

connector

2

Inhale

air

into

the

opening

of

rubber

hose

running

to

vacuum

hole

in

carbon

canister

and

ensure

that

there

is

no

leak

ET349

Fig

EC

lll

Checking

Carbon

Canister

Purge

Control

Valve

EC37

3

If

there

is

a

leak

remove

top

cover

from

purge

control

valve

and

check

for

dislocated

or

cracked

dia

phragm

If

necessary

replace

dia

phragrrt

kit

which

is

made

up

of

a

retainer

diaphragm

and

spring

i

ii

1

Cover

2

Diaphragm

3

Retainer

4

Diaphragm

spring

ET350

Fig

EC

112

Carbon

Canister

Purge

Control

Valve

FUEL

TANK

VACUUM

RELIEF

VALVE

Remove

fuel

filler

cap

and

see

it

functions

properly

I

Wipe

clean

valve

housing

and

have

it

in

your

mouth

2

Inhale

air

A

slight

resistance

ac

companied

by

valve

indicates

that

valve

is

in

good

mechanical

condition

Note

also

that

by

further

inhaling

air

the

resistance

should

be

disappeared

with

valve

clicks

3

If

valve

is

clogged

or

if

no

resist

ance

is

felt

replace

cap

as

an

assem

bled

unit

O

ET500

Fig

EC

1l3

Fuel

Filler

Cap

Page 181 of 548

CHECKING

AND

ADJUSTMENT

CAP

AND

ROTOR

HEAD

Cap

and

rotor

head

should

be

in

spected

periodically

as

specified

in

the

Main

teoanee

Schedule

Remove

cap

and

clean

all

dust

and

carbon

deposits

from

cap

and

rotor

from

time

to

time

If

cap

is

cracked

or

is

leaking

replace

wi

th

a

new

one

ADVANCE

MECHANISMS

SpecHlcatlons

Refer

to

Service

Data

and

Specifica

tions

for

distributor

Vacuum

advance

mechanism

mechanical

parts

If

vacuum

advance

mechanism

fails

to

operate

properly

check

for

the

followin

B

items

and

correct

the

mal

function

as

required

I

Check

vacuum

inlet

for

signs

of

leakage

at

its

connection

If

necessary

retighten

or

replace

with

a

new

one

2

Check

vacuum

diaphragm

for

air

leak

If

leak

is

found

replace

vacuum

controUer

assembly

3

Inspect

breaker

plate

for

smooth

moving

If

plate

does

not

move

smoothly

this

condition

could

be

due

to

sticky

steel

balls

or

pivot

Apply

grease

to

steel

halls

or

if

necessary

replace

breaker

plate

as

an

assembly

Centrifugal

advance

mechanical

parts

When

cause

of

engine

malfunction

is

traced

to

centrifugal

advance

mecha

nical

parts

use

distributor

tester

to

check

its

characteristics

If

nothing

is

wrong

with

its

charac

teristics

conceivable

causes

are

faulty

or

abnormal

wear

of

driving

part

or

others

So

do

not

disassemble

it

In

the

event

of

improper

character

istics

check

closely

rotor

shaft

assem

bly

governor

weight

and

shaft

If

any

of

the

above

parts

are

mal

functioning

replace

the

parts

Engine

Electrical

System

DISASSEMBLY

AND

ASSEMBLY

DISASSEMBLY

I

Take

off

cap

and

remove

rotor

head

2

Remove

Ie

ignition

unit

Refer

to

IC

Ignition

Unit

for

removal

and

in

stallation

3

Remove

stator

and

magnet

by

removing

stator

securing

screws

4

Remove

vacuum

controller

by

removing

securing

screws

EE746

Fig

EE

59

Removing

Vacuum

Controller

5

Using

two

pry

bars

or

suitable

puller

pry

reluctor

from

shaft

CAUTION

When

removing

reluctor

be

careful

not

10

distort

or

damage

the

teeth

6

Remove

roll

pin

7

Remove

pick

up

coil

assembly

8

Remove

breaker

plate

setscrews

and

remove

breaker

plate

assembly

EE703

Fig

EE

60

Removing

Breaker

Plate

Setscrews

9

Punch

knock

pin

out

and

remove

pinion

EE

23

EE704

Fig

EE

61

Removing

Knock

Pin

10

Remove

rotor

shaft

and

drive

shaft

assembly

EE705

Fig

EE

62

Removing

Rotor

Shaft

and

Drive

Shaft

Assembly

11

Mark

rotor

shaft

and

drive

shaft

Remove

packing

from

the

top

of

rotor

shaft

and

unscrew

rotor

shaft

setscrew

Remove

rotor

shaft

EE706

Fig

EE

63

Removing

Rotor

Shaft

12

Mark

one

of

the

governor

springs

and

its

bracket

Also

mark

one

of

the

governor

weights

and

its

pivot

pins

13

Carerully

unhook

and

remove

governor

springs

14

Remove

governor

weights

A

r

ply

grease

to

guvernor

weights

after

disassembling

Page 187 of 548

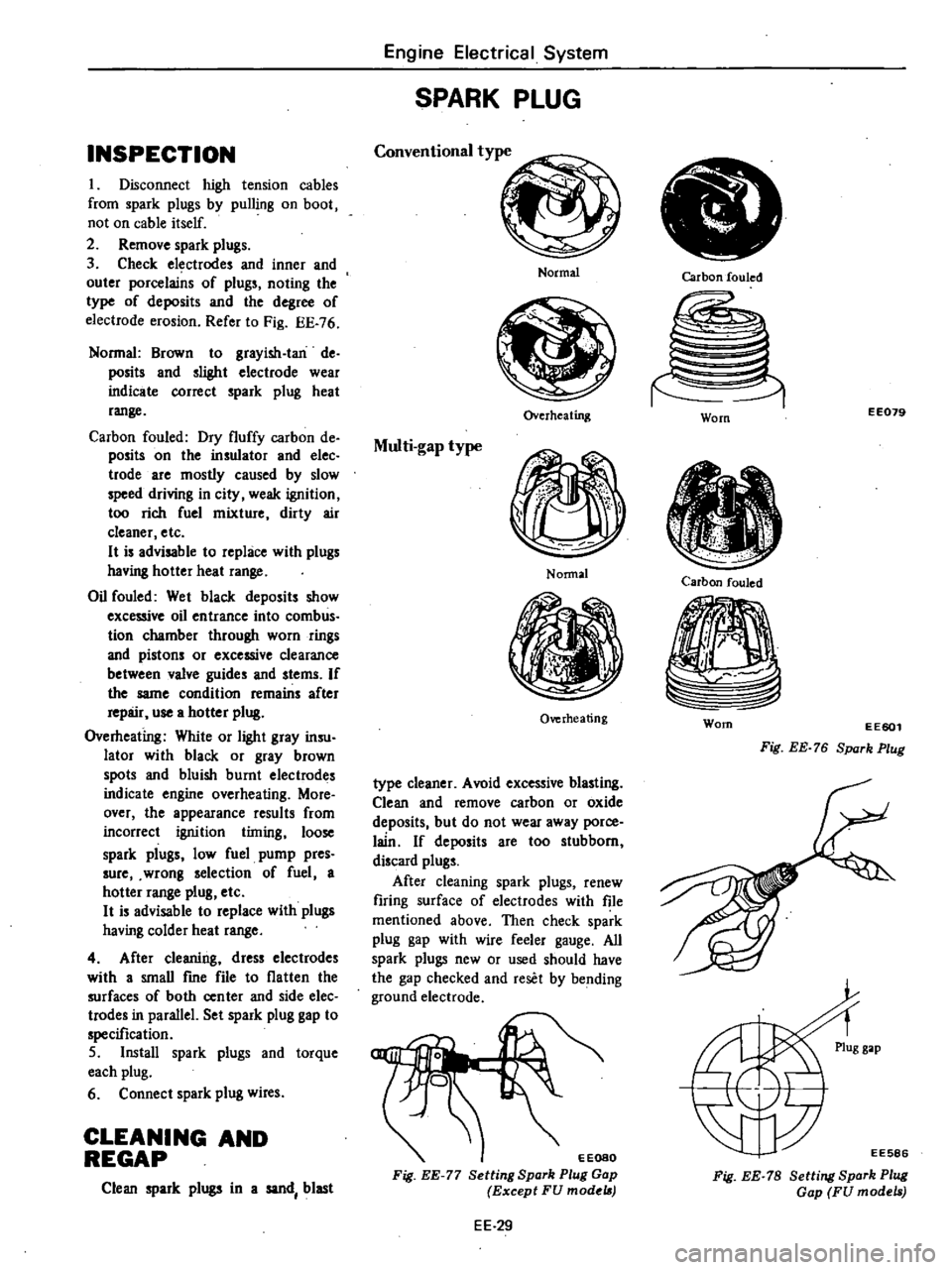

INSPECTION

I

Disconnect

high

tension

cables

from

spark

plugs

by

pulling

on

boot

not

on

cable

itself

2

Remove

spark

plugs

3

Check

electrodes

and

inner

and

outer

porcelains

of

plugs

noting

the

type

of

deposits

and

the

degree

of

electrode

erosion

Refer

to

Fig

EE

76

Normal

Brown

to

grayish

Ian

de

posits

and

slighl

electrode

wear

indicate

correct

spark

plug

heat

range

Carbon

fouled

Dry

fluffy

carbon

de

posits

on

the

insulator

and

elec

trode

are

mostly

caused

by

slow

speed

driving

in

city

weak

ignition

too

rich

fuel

mixture

dirty

air

cleaner

etc

H

is

advisable

to

replace

with

plugs

having

hotter

heat

range

Oil

fouled

Wet

black

deposits

show

excessive

oil

entrance

into

comb

us

tion

chamber

through

worn

rings

and

pistons

or

excessive

clearance

between

valve

guides

and

stems

If

the

same

condition

remains

after

repair

use

a

hotter

plug

Overheating

White

or

light

gray

insu

lator

with

black

or

gray

brown

spots

and

bluish

burnt

electrodes

indicate

engine

overheating

More

over

the

appearance

results

from

incorrect

ignition

timing

loose

spark

plugs

low

fuel

pump

pres

sure

wrong

selection

of

fuel

a

hotter

range

plug

etc

H

is

advisable

to

replace

with

plugs

having

colder

heat

range

4

After

cleaning

dress

electrodes

with

a

smaU

fme

file

to

flatten

the

surfaces

of

both

center

and

side

elec

trodes

in

parallel

Set

spark

plug

gap

to

specification

5

Install

spark

plugs

and

torque

each

plug

6

Connect

spark

plug

wires

CLEANING

AND

REGAP

Clean

spark

plugs

in

a

sand

blast

Engine

Electrical

System

SPARK

PLUG

Conventional

type

Normal

Overheating

Multi

gap

type

Nonnal

Overheating

type

cleaner

Avoid

excessive

blasting

Clean

and

remove

carbon

or

oxide

deposits

but

do

not

wear

away

porce

lain

If

deposits

are

too

stubborn

discard

plugs

After

cleaning

spark

plugs

renew

firing

surface

of

electrodes

with

file

mentioned

above

Then

check

spark

plug

gap

with

wire

feeler

gauge

All

spark

plugs

new

or

used

should

have

the

gap

checked

and

reset

by

bending

ground

electrode

EEOSO

Fig

EE

77

Setting

Spark

Plug

Gap

Except

FU

model

EE

29

Carbon

fouled

EE079

Worn

Carbon

fouled

Worn

EE601

Fig

EE

76

Spark

Plug

EE586

Fig

EE

78

Setting

Spark

Plug

Gap

FU

models

Page 190 of 548

Engine

Electrical

System

STARTING

MOTOR

Type

S1I4

160B

I

Sl14

163E

S114

253

Outer

diameter

of

commutator

mm

in

More

than

32

1

26

More

than

29

L14

Minimum

length

of

brush

mm

in

12

0

47

II

0

43

Brush

spring

tension

kg

Ib

1

4

to

1

8

3

1

to

4

0

1

6to

2

0

3

5

to

4

4

Clearance

between

bearing

metal

and

armature

shaft

mm

in

Less

than

0

2

0

008

Clearance

R

between

pinion

front

edge

and

pinioIl

stopper

mm

in

0

3

to

2

5

0

012

to

0

098

Difference

T

in

height

of

pinion

nun

in

0

3

to

1

5

0

012

to

0

059

ALTERNATOR

Type

LRI5049

Minimum

length

of

brush

mm

in

More

than

7

5

0

295

Brush

spring

pressure

gr

oz

255

to

345

8

99

to

12

17

Slip

ring

outer

diameter

nun

in

More

than

30

1

18

DISTRIBUTOR

Air

gap

mm

in

D4K8

19

I

D4K8

l3

I

D4K8

18

I

D4K8

02

D4K8

15

I

D4K8

16

0

3

to

0

5

0

012

to

0

020

Type

Cap

il1s

ation

resistance

M

1

More

than

50

Rotor

head

insulation

resistance

Mil

More

than

50

Cap

carbon

point

length

mm

in

10

0

39

Vacuum

advance

0

105

4

13

0

170

6

69

0

80

3

15

0

105

4

13

0

70

2

76

0

170

6

69

Distributor

degree

distributor

9

250

3

225

12

265

9

300

15

300

6

5

300

mmHg

inHg

9

84

8

86

10

43

11

81

11

81

11

81

Centrifugal

advance

0

550

6

550

0

550

0

550

0

750

0

750

Distributor

degree

distributor

14

2

300

14

2

300

13

5

2

400

13

5

2

400

10

2

400

10

2

400

rpm

EE

32

Page 195 of 548

Engine

Electrical

System

IV

IGNITION

CIRCUIT

When

engine

does

not

start

If

there

is

no

problem

in

fuel

system

ignition

system

should

be

checked

This

can

be

easily

done

by

detaching

a

high

tension

cable

from

distributor

starting

engine

and

ob

serving

oondition

of

spark

that

occurs

between

high

tension

cable

and

engine

block

After

checking

this

repair

as

necessary

tery

and

anti

dieseliilg

wlenoid

valve

connector

to

cuI

off

supply

of

fuel

10

engine

Then

observe

the

condition

of

sparks

while

starter

motor

is

in

operation

Note

Turn

ignilion

switch

off

and

disconnect

ground

cable

from

bat

Condition

Location

Probable

cause

Corrective

action

No

spark

at

all

Distributor

Breakage

of

lead

wire

on

low

tension

side

Repair

Poor

insulation

of

cap

and

rotor

head

Replace

Open

pick

up

coil

Replace

Air

gap

wider

than

specification

Adjust

Ignition

coil

Wire

breakage

or

short

circuit

of

coil

Replace

with

new

one

High

tension

cable

Wire

coming

off

Repair

Faulty

insulation

Replace

IC

ignition

unit

Faulty

IC

ignition

unit

Replace

Breakage

of

circuit

Replace

Detached

connection

Repair

Spark

length

Spark

plugs

Spark

plug

gap

too

wide

Correct

or

replace

More

than

6

mm

Too

much

carbon

Clean

or

replace

0

24

in

Broken

neck

of

insulator

Replace

Expiration

of

plug

life

Replace

Distributor

Air

gap

too

wide

Correct

IC

ignition

unit

Faulty

IC

ignition

unit

Replace

Breakage

of

circuit

Replace

Detached

connection

Repair

EE

37

Page 199 of 548

REMOVAL

It

is

much

easier

to

remove

engine

and

transmission

as

a

single

unit

than

to

remove

alone

After

removal

engine

can

be

separated

from

the

transmission

assembly

WARNING

a

Place

wheel

chocks

in

fronl

of

front

wheels

and

in

rear

of

rear

wheels

b

Be

sure

to

hoist

engine

in

a

safe

manner

c

You

should

not

remove

engine

until

exhaust

system

has

com

pletely

cooled

off

Otherwise

you

may

burn

your

self

and

or

fire

may

break

out

in

fuel

line

Note

Fender

coven

should

be

used

to

protect

car

body

1

Disconnect

battery

ground

cable

from

battery

terminal

and

fusible

link

at

wire

connector

2

Remove

hood

as

follows

CAUTION

Have

an

assistant

help

you

so

as

to

prevent

damage

to

body

I

Mark

hood

hinge

locations

on

hood

to

facilitate

reinstallation

2

Support

hood

by

ltand

and

re

move

bolts

securing

it

to

hood

hinge

being

careful

not

to

let

hood

slip

when

bolts

are

removed

See

Fig

ER

2

3

Remove

hood

from

hood

hinge

f

Il

I

BF133A

Fig

ER

2

Removing

Hood

Remove

under

cover

Drain

radiator

coolant

and

engine

3

4

oil

5

Disconnect

upper

and

lower

hoses

from

radiator

and

disconnect

oil

cooler

hoses

automatic

transmission

only

6

Remove

four

bolts

securing

radia

Engine

Removal

Installation

tor

to

body

and

detach

radiator

after

removing

radiator

shroud

7

Remove

air

cleaner

assembly

from

carburetor

as

follows

1

Remove

fresh

air

duct

from

air

cleaner

2

Remove

hot

air

duct

from

air

cleaner

3

Loosen

air

cleaner

band

bolt

4

Disconnect

air

cleaner

to

air

pump

hose

at

air

cleaner

5

Disconnect

air

cleaner

ta

rocker

cover

hose

at

rocker

cover

6

Disconnect

air

cleaner

to

A

B

valve

hose

at

air

cleaner

7

Disconnect

air

cleaner

to

related

vacuum

hoses

at

air

cleaner

8

Disconnect

accelerator

control

wire

from

carburetor

9

Disconnect

the

following

cables

wires

and

hoses

Wire

to

auto

choke

heater

Wire

to

throttle

opener

cut

solenoid

or

throttle

switch

Wire

to

fuel

cut

solenoid

Wire

to

vacuum

switching

valve

High

tension

cable

between

igni

tion

coil

and

distributor

Battery

cable

to

starter

motor

Wire

to

distributor

Wire

to

thermal

transmitter

Wire

to

alternator

Engine

ground

cable

oil

pressure

switch

and

engine

harness

No

2

See

Fig

ER

3

o

1

Ground

cable

2

Engine

harness

No

2

3

Oil

pressure

switch

Fig

ER

3

EA368

Disconnecting

Cable

and

Wire

Fuel

hose

at

fuel

pump

and

fuel

return

hose

at

connection

Air

pump

air

cleaner

hose

Carbon

canister

hoses

Heater

inlet

and

outlet

hoses

if

so

equipped

ER

3

Vacuum

hose

of

brake

booster

at

intake

manifold

Air

conditioner

equipped

model

10

Remove

compressor

belt

To

remove

loosen

idler

pulley

nut

and

adjusting

bolt

1

Remove

air

pump

2

Remove

compressor

retaining

bolts

and

move

compressor

toward

fender

to

facilitate

removal

of

engine

Nole

Never

discharge

gas

from

com

pressor

while

work

is

being

per

formed

II

Compressor

EA478

Fig

ER

4

Location

of

Air

Compressor

3

Disconnect

vacuum

hose

of

air

conditioner

from

connector

of

intake

manifold

4

Remove

F

i

C

D

actuator

from

bracket

II

Remove

clutch

operating

cylin

der

from

clutch

housing

manual

trans

mission

only

dJ

Tightening

torque

Clutch

operating

cylinder

E

A3

to

clutch

housing

3

1

to

4

1

kg

22

to

30

ft

lbl

Fig

ER

5

Removing

Clutch

Operating

Cylinder

Page 292 of 548

Place

the

vehicle

in

a

pit

and

by

sampling

the

lealeed

oil

deiermine

if

it

is

the

torque

converter

oil

The

torque

converter

oil

has

a

color

like

red

wine

so

it

is

easily

distinguished

from

engine

oil

or

gear

oil

Wipe

off

the

lealeing

oil

and

dust

and

detect

the

spot

of

ill

lell8e

nonflammable

organic

solvent

such

as

carbon

tetrachloride

for

wiping

Raise

the

oil

tcmperature

by

op

erating

the

engine

and

shift

the

lever

to

D

to

increase

the

oil

pressure

The

sp

Q

of

o

1

1I8

u

J1en

be

found

more

easily

Note

As

oil

leakage

from

the

breath

er

does

not

talee

place

except

when

running

at

high

peed

it

iSimpos

sible

to

ate

this

lealcage

with

vehicle

stationary

CHECKING

ENGINE

IDLING

REVOLunON

The

engine

idling

revolution

should

be

properly

adjusted

If

the

engine

revolution

is

too

low

the

e

gine

does

not

operate

smoothly

and

if

too

high

a

strong

shocle

or

creep

develops

when

changing

over

from

ON

to

Dn

or

R

CHECKING

AND

ADJUSTING

KICK

WN

SWITCH

AND

DOWNSH

FT

SOLENOID

When

the

Ieickdown

operation

is

not

made

properly

or

the

speed

chang

ingpoint

is

too

high

check

the

kick

down

switch

downshift

solenoid

and

wiring

between

them

When

the

igni

tion

Ieey

is

po

iti

ned

at

the

1st

stage

and

the

accelerator

pedal

is

depressed

deeply

the

switch

contact

hould

be

closed

and

the

solenoid

should

clicle

If

it

does

not

click

it

indicates

a

defect

Then

check

each

part

with

the

testing

inatrumen15

Auto

lT1atic

Transmissiqn

Fi

J

A

T

84

Down

ltift

Sole

id

Note

Watch

for

oil

leekage

from

tnnsmission

case

INSPECTION

AND

ADJUSTMENT

OF

MANUAL

LINKAGE

The

adjustmcnt

of

manual

linkage

i

equany

important

as

Inspection

of

Oil

Level

for

the

automatic

transmis

sion

Therefore

great

care

should

be

cxercised

oecause

incorrect

adjustment

will

result

in

the

breakdown

of

the

transmission

Inspection

pun

the

selector

lever

toward

you

and

turn

it

as

far

as

p

to

range

where

clicks

will

be

ell

by

the

hand

This

is

the

detent

of

manual

valve

in

the

valve

body

and

indicates

the

corrett

position

of

the

lever

Inspect

whether

the

pointer

of

selector

dial

corresponds

to

this

point

and

also

whether

the

lever

comes

in

alignment

with

the

stepping

of

posi

iion

plate

when

itis

released

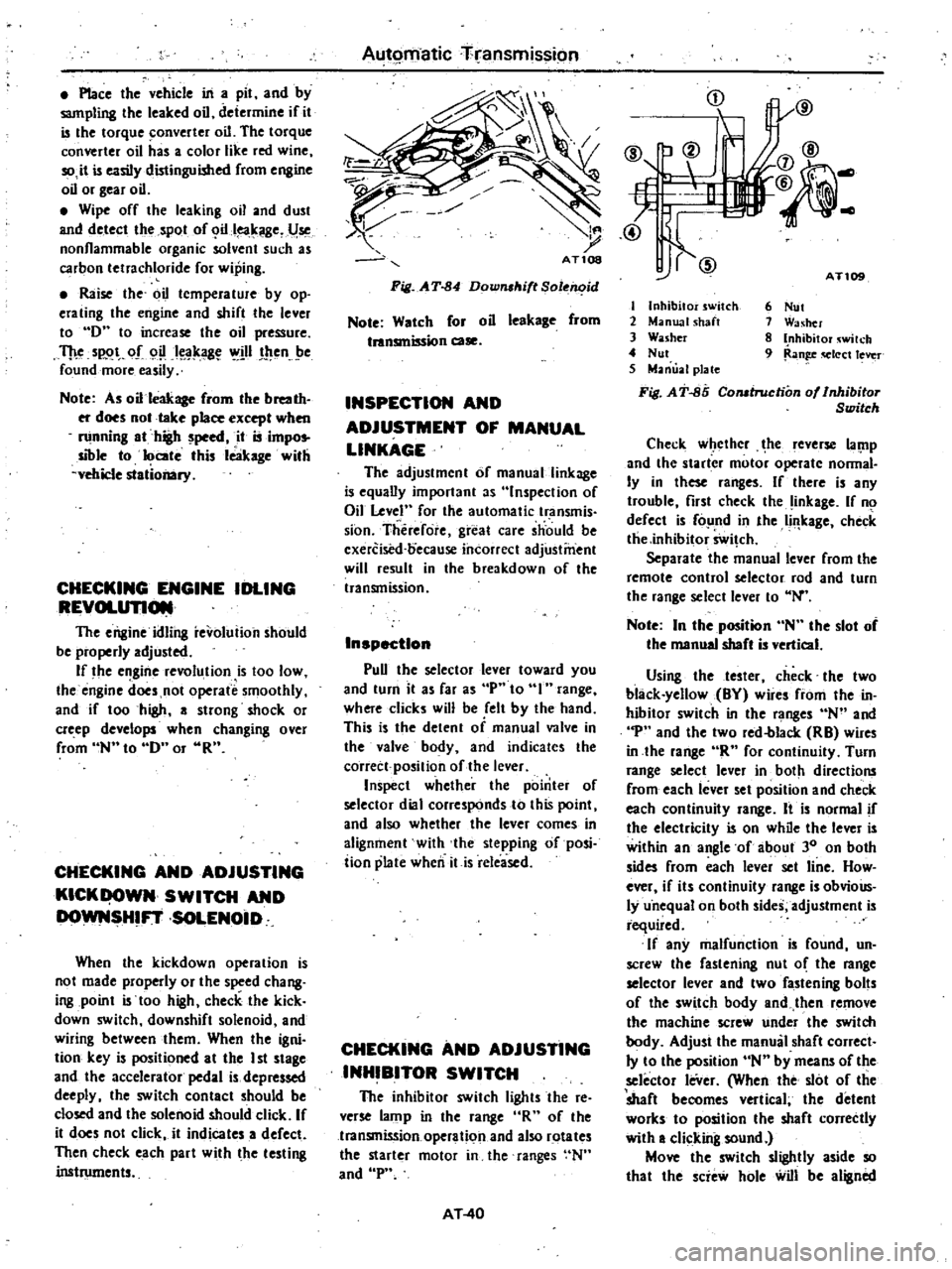

CHECKING

AND

ADJUSTING

INHIBITOR

SWITCH

The

inhibitor

switch

lights

the

re

verse

lamp

in

the

range

R

of

the

transmission

operation

and

also

rotates

the

starter

motor

in

the

ranges

N

and

P

AT

40

i

j

tI

IlV

@

@

AT

I

Inhibitor

switch

2

Manual

shaft

3

Washer

4

Nut

5

Manual

plate

Fi

J

AT

85

Comtruction

of

Inhibitor

Switch

6

Nut

1

Washer

8

Inhibitor

wilch

9

Ran

q

Iect

lever

Check

w

ethcr

he

leverse

lal

1p

and

the

starter

motor

operate

nonnal

Iy

in

these

ranges

If

there

is

any

trouble

first

check

the

inkage

If

no

defect

is

fo

nd

in

the

Ii

leage

check

tlie

inhibitor

Swi

ch

Separate

the

manual

lever

from

the

remote

control

selector

rod

and

turn

the

range

select

lever

to

N

Note

In

the

position

N

the

slot

of

the

manual

shaft

is

vertical

Using

the

tester

check

the

two

black

yellow

BY

wire

from

the

in

hibitor

switch

in

the

ranges

N

and

p

and

the

two

red

blacle

RB

wires

in

the

lange

R

for

continuity

Turn

range

select

lever

in

both

directions

from

each

lever

set

position

and

check

each

continuity

range

It

is

normal

if

the

electricity

is

on

while

the

lever

is

within

an

angle

of

about

30

on

both

sides

from

each

lever

set

line

How

ever

if

its

continuity

range

is

obvioUs

ly

u

nequal

on

both

sides

adjustment

is

required

If

any

malfunction

is

found

un

screw

the

fastening

nut

o

the

range

selector

lever

and

two

fastening

bolts

of

the

switch

body

and

then

remove

the

machine

screw

under

the

switch

body

Adjust

the

manual

shaft

correct

Iy

to

the

position

N

by

means

of

the

selector

leVer

When

the

slot

of

the

shaft

becomes

vertical

the

detent

worles

to

position

the

shaft

correctly

with

a

clicking

sound

Move

the

switch

slightly

aside

so

that

the

scie

hole

will

be

aligned