wheel DATSUN 210 1979 Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 383 of 548

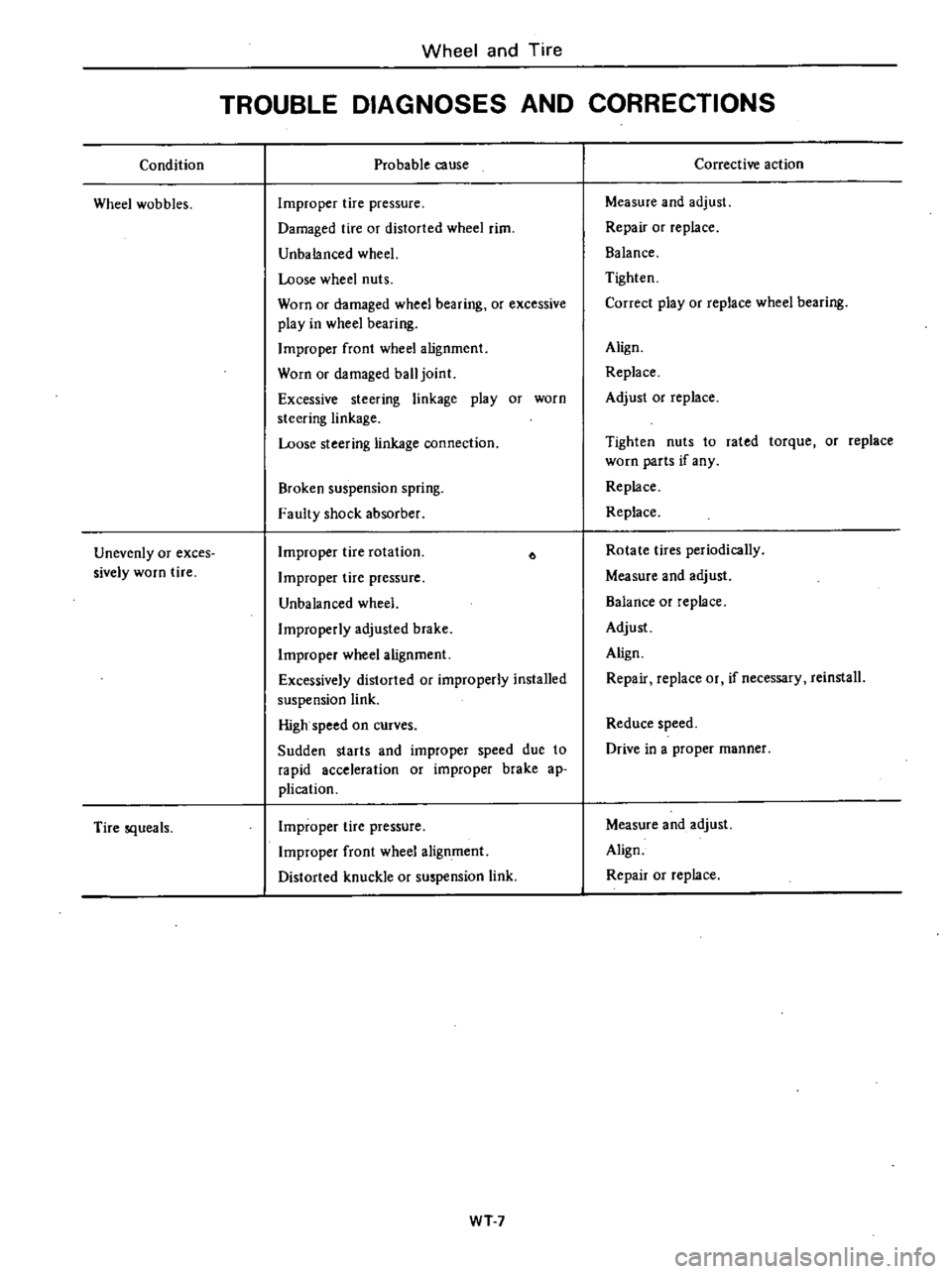

Condition

Wheel

wobbles

Unevenly

or

exces

sively

worn

tire

Tire

squeals

Wheel

and

Tire

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Probable

cause

Improper

tire

pressure

Damaged

tire

or

distorted

wheel

rim

Unbalanced

wheel

Loose

wheel

nuts

Worn

or

damaged

wheel

bearing

or

excessive

play

in

wheel

bearing

Improper

front

wheel

alignment

Worn

or

damaged

ball

joint

Excessive

steering

linkage

play

or

worn

steering

linkage

Loose

steering

linkage

connection

Broken

suspension

spring

Faulty

shock

absorber

Improper

tire

rotation

Improper

tire

pressure

Unbalanced

wheel

Improperly

adjusted

brake

Improper

wheel

alignment

Excessively

distorted

or

improperly

installed

suspension

link

High

speed

on

curves

Sudden

starts

and

improper

speed

due

to

rapid

acceleration

or

improper

brake

ap

plication

Improper

tire

pressure

Improper

front

wheel

alignment

Distorted

knuckle

or

suspension

link

WT7

Corrective

action

Measure

and

adjust

Repair

or

replace

Balance

Tighten

Correct

play

or

replace

wheel

bearing

Align

Replace

Adjust

or

replace

Tighten

nuts

to

rated

torque

or

replace

worn

parts

if

any

Replace

Replace

Rotate

tires

periodically

Measure

and

adjust

Balance

or

replace

Adjust

Align

Repair

replace

or

if

necessary

reinstall

Reduce

speed

Drive

in

a

proper

manner

Measure

and

adjust

Align

Repair

or

replace

Page 384 of 548

DATSUN

210

Model

8310

Series

SECTIONST

STEERING

SYSTEM

CONTENTS

STEERING

COLUMN

AND

GEAR

STEERING

WHEEL

STEERING

LOCK

STEERING

COLUMN

Collapsible

type

STEERING

GEAR

RB45L

STEERING

LINKAGE

SERVICE

DATA

AND

SPECIFICATIONS

ST

2

ST

2

ST

3

ST

3

ST

5

ST

9

GENERAL

SPECIFICATIONS

INSPECTION

AND

ADJUSTMENT

TIGHTENING

TORQUE

TROUBLE

DIAGNOSES

AND

CORRECTIONS

SPECIAL

SERVICE

TOOLS

ST

12

ST

12

ST

13

ST

14

ST

15

ST

12

Page 385 of 548

Steering

System

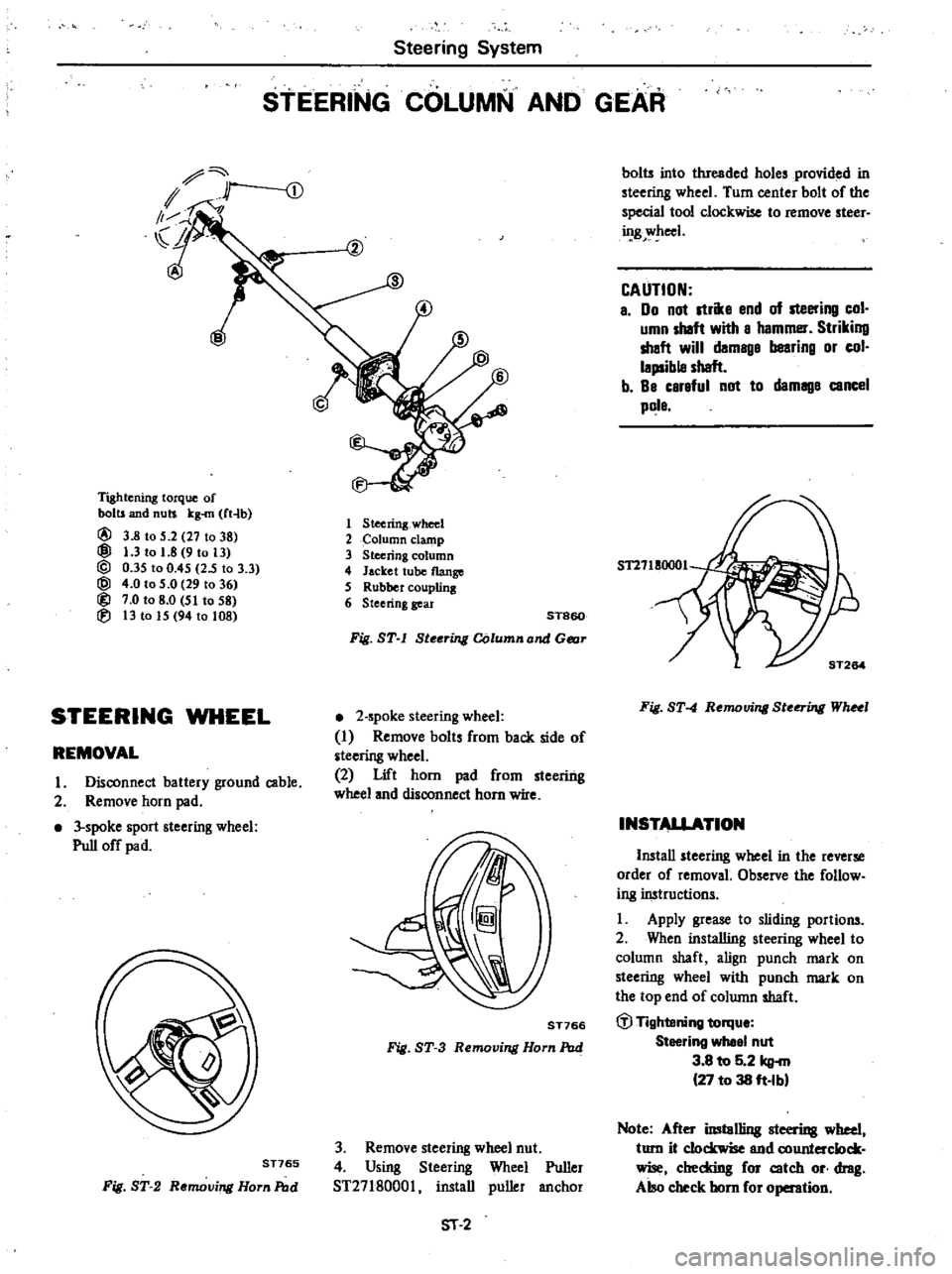

STEERING

COLUMN

AND

GEAR

Tightening

torque

of

bolts

and

nuts

kg

rn

ft4b

@

3

8

to

5

2

27

to

38

@

1

3

to

1

8

9

to

13

@

0

35

to

0

45

25

to

3

3

@

4

0

to

5

0

29

to

36

@

7

0

to

8

0

51

to

58

lEi

13

to

15

94

to

108

1

Steering

wheel

2

olumn

clamp

3

Steering

column

4

Jacket

tube

flange

S

RUbbercoupling

6

Steering

gear

ST860

Fig

ST

l

Steering

Column

and

Gear

STEERING

WHEEL

2

spoke

steering

wheel

I

Remove

bolts

from

back

side

of

steering

wheel

2

Lift

horn

pad

from

steering

wheel

and

disconnect

horn

wire

REMOVAL

I

Disconnect

battery

ground

cable

2

Remove

horn

pad

3

spoke

sport

steering

wheel

Pull

off

pad

ST766

Fig

ST

3

Removing

Horn

Pod

ST765

Fig

ST

2

Removing

Horn

Pod

3

Remove

steering

wheel

nut

4

Using

Steering

Wheel

Puller

ST2718000l

install

puller

anchor

51

2

bolts

into

threaded

holes

provided

in

steering

wheel

Turn

center

bolt

of

the

special

tool

clockwise

to

remove

steer

ing

wheel

CAUTION

a

00

not

strike

end

of

steering

col

umn

shaft

with

a

hammer

Striking

shaft

will

damage

bearing

or

col

lapsible

shaft

b

Be

careful

not

to

damage

cancel

pole

Fig

ST

4

Removing

Ste

ing

WhHl

INSTALLATION

Install

steering

wheel

in

the

reverse

order

of

removal

Observe

the

follow

ing

instructions

Apply

grease

to

sliding

portions

2

When

installing

steering

wheel

to

column

shaft

align

punch

mark

on

steering

wheel

with

punch

mark

on

the

top

end

of

column

shaft

til

Tightening

torqu

Steering

whee

nut

3

8

to

5

2

kg

27

to

38

ft

Ibl

Note

After

imtol1ing

steering

wheel

turn

it

clockwise

end

counterclock

wise

cheddng

for

catch

or

drag

Also

check

horn

for

operation

Page 386 of 548

STEERING

LOCK

To

provide

tamper

proof

self

shear

type

screws

are

used

and

their

heads

are

sheared

off

when

installed

so

that

the

steering

lock

system

cannot

be

removed

easily

REMOVAL

I

Break

two

self

shear

type

screws

with

a

drill

or

other

proper

tool

Steering

System

2

Remove

two

screws

and

dismount

steering

lock

from

steering

jacket

tube

ST393

Fig

ST

5

Removing

Steering

Lock

Securing

Screw

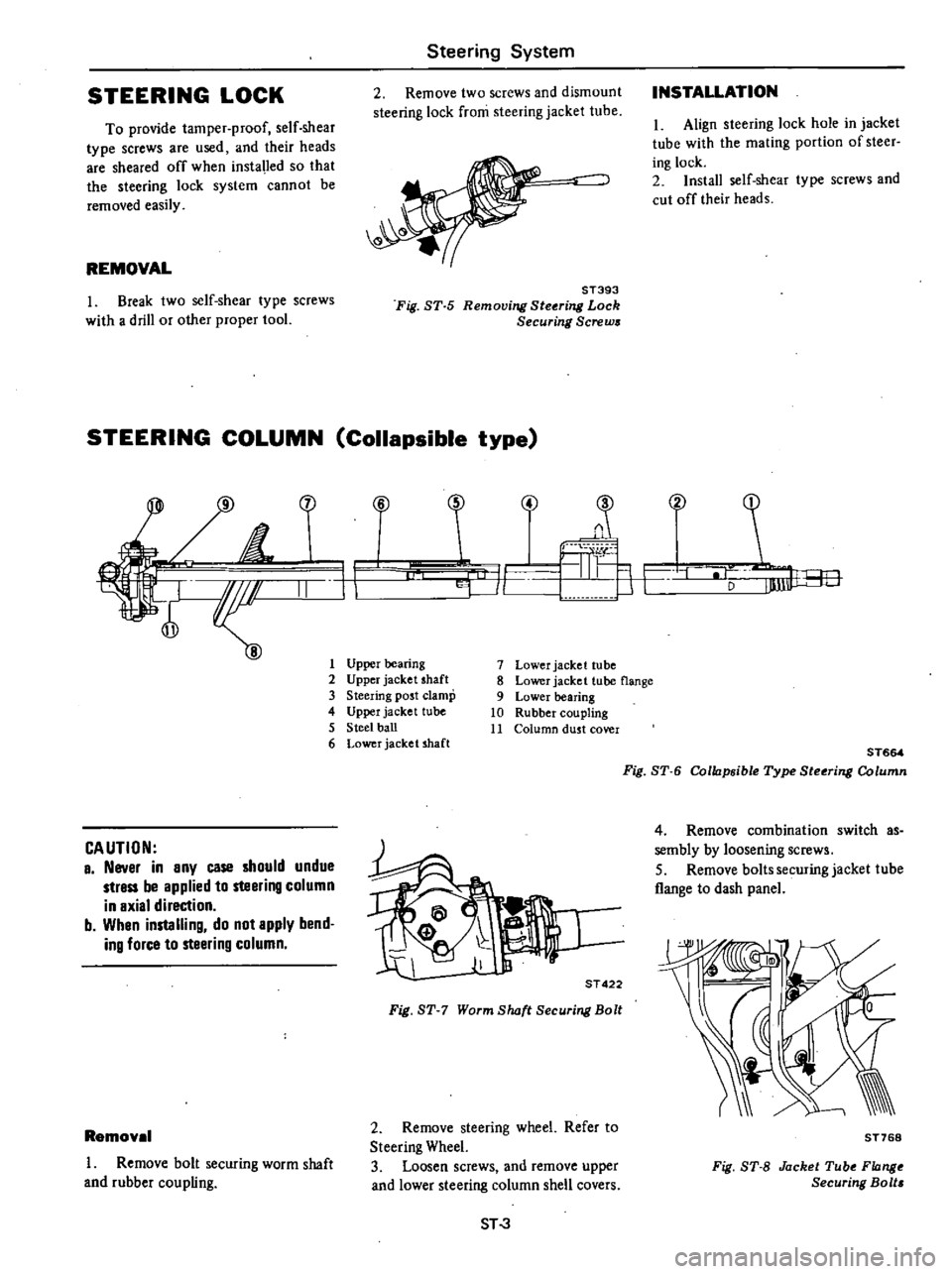

STEERING

COLUMN

Collapsible

type

1

H

f

II

CAUTION

a

Never

in

any

case

should

undue

strass

be

applied

to

steering

column

in

axial

direction

b

Whan

installing

do

not

apply

bend

ing

force

to

steering

column

Removel

I

Remove

bolt

securing

worm

shaft

and

rubber

coupling

INSTALLATION

I

Align

steering

lock

hole

in

jacket

tube

with

the

mating

portion

of

steer

ing

lock

2

Install

self

shear

type

screws

and

cut

off

their

heads

i

4

T

C

F

Lu

J

r

1

V

F

1

Upper

bearing

2

Upper

jacket

shaft

3

Steering

post

clamp

4

Upper

jacket

tube

5

Steel

ball

6

Lower

jacket

shaft

7

Lower

jacket

tube

8

Lower

jacket

tube

flange

9

Lower

bearing

10

Rubber

coupling

11

Column

dust

cover

it

j

a

ST

422

Fig

ST

7

Worm

8lwft

Securing

Bolt

2

Remove

steering

wheel

Refer

to

Steering

Wheel

3

Loosen

screws

and

remove

upper

and

lower

steering

column

shell

covers

ST

3

ST664

Fig

8T

6

Collapsibte

Type

Steoring

Column

4

Remove

combination

switch

as

sembly

by

loosening

screws

5

Remove

baIts

securing

jacket

tube

flange

to

dash

panel

ST768

Fig

8T

8

Jacket

Tube

Flange

Securing

Bolt

Page 387 of 548

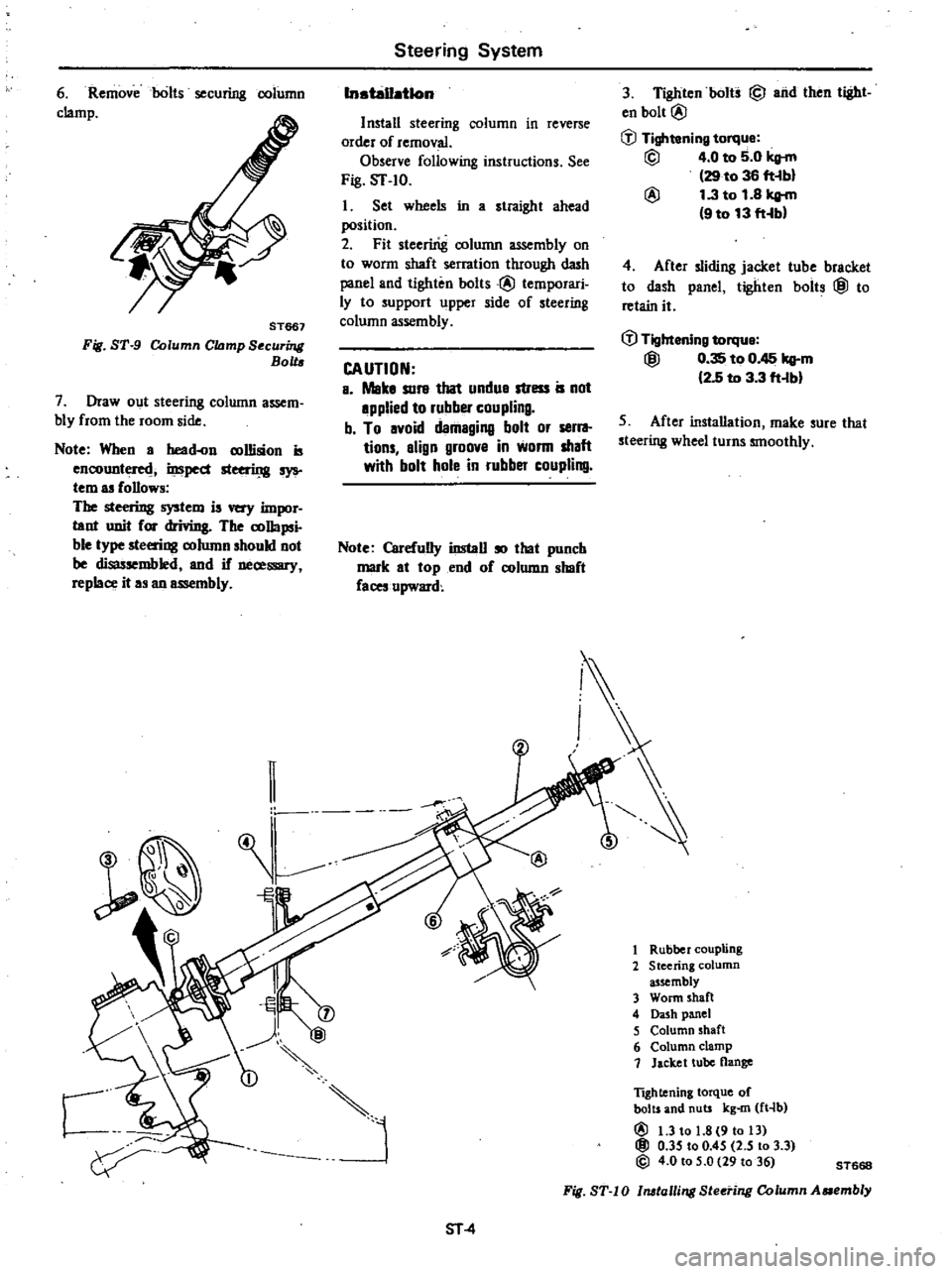

6

Removeoolts

securing

oolumn

clamp

ST661

Fig

ST

9

Column

CIDmp

Securing

BoU

7

Draw

out

steering

column

assem

bly

from

the

room

side

Note

When

a

head

n

rollision

is

encountere

inspect

steeriJ

tg

sys

tem

as

allow

The

steering

system

is

very

impor

lant

unit

or

driving

The

oollapsi

ble

type

steering

column

hould

not

be

disassembled

snd

if

necessary

replace

it

a

an

assembly

Steering

System

InstaU

tlon

Iostall

steering

column

in

reverse

order

of

removal

Observe

following

instructions

See

Fig

ST

IO

I

Set

wheels

in

a

straight

ahead

position

2

Fit

steeririg

column

assembly

on

to

worm

shaft

serration

through

dash

panel

and

tighti

bolts@

temporari

ly

to

support

upper

side

of

steering

column

assembly

CAUTION

a

Mata

sure

that

undue

stress

is

not

epplied

to

ruhber

coupling

b

To

evoid

damaging

bolt

or

serra

tions

align

groove

in

worm

shaft

with

bolt

hole

in

rubber

coupling

Note

Carefully

install

so

that

punch

mark

at

top

end

o

column

slmft

acesupwardc

C

VH

3

Tighten

bolts

@

rid

then

tight

en

bolt

@

liJ

Tightening

torque

@

4

0

to

5

0

kg

m

29

to

36

ft

lb

@

1

3

to

1

8

kg

m

9

to

13

ft

lbl

4

After

sliding

jacket

tube

bracket

to

dash

panel

tighten

bolt

@

to

retain

it

liJ

Tightening

torqu

@

0

35

to

0

45

kg

m

2

5

to

3

3

ft

lbl

5

After

installation

make

sure

that

steering

wheel

turns

smoothly

5

1

Rubber

coupling

2

Steering

column

8ncmbly

3

Worm

shaft

4

Dash

panel

5

Column

shaft

6

Column

clamp

1

Jacltct

tube

flange

Tightening

torque

of

bolts

and

nuts

kg

m

ft

lb

@

1

3

to

1

8

9

to

13

@

0

35

to

0

45

2

5

to

3

3

@

4

0

to

5

0

29

to

36

ST668

Fig

ST

IO

1

alling

Sleering

Column

Aaembly

ST

4

Page 388 of 548

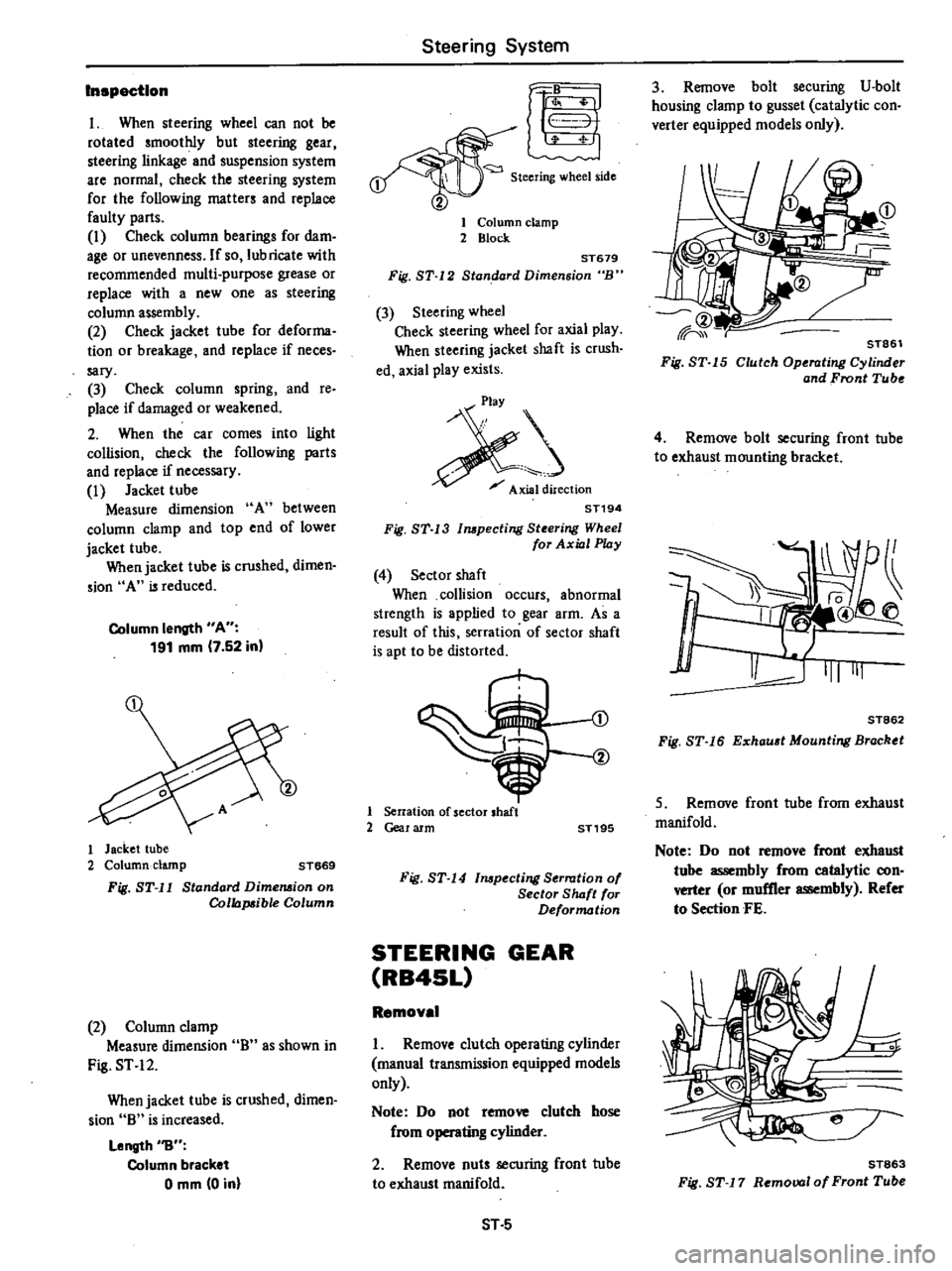

Inspection

I

When

steering

wheel

can

not

be

rotated

smoothly

but

steering

gear

steering

linkage

and

suspension

system

are

normal

check

the

steering

system

for

the

following

matters

and

replace

faulty

parts

I

Check

column

bearings

for

dam

age

or

unevenness

If

so

lubricate

with

recommended

multi

purpose

grease

or

replace

with

a

new

one

as

steering

column

assembly

2

Check

jacket

tube

for

deforma

tion

or

breakage

and

replace

if

neces

sary

3

Check

column

spring

and

re

place

if

damaged

or

weakened

2

When

the

car

comes

into

light

collision

check

the

following

parts

and

replace

if

necessary

I

Jacket

tube

Measure

dimension

A

between

column

clamp

and

top

end

of

lower

jacket

tube

When

jacket

tube

is

crushed

dimen

sion

A

is

reduced

Column

length

A

191

mm

7

52

in

1

Jacket

tube

2

Column

clamp

ST669

Fig

ST

l1

Standard

Dimension

on

Collapsible

Column

2

Column

clamp

Measure

dimension

0

as

shown

in

Fig

ST

12

When

jacket

tube

is

crushed

dimen

sion

0

is

increased

Length

1J

Column

bracket

o

mm

0

in

Steering

System

r

1

Steering

wheel

side

1

Column

clamp

2

Block

ST679

Fig

ST

12

Standard

Dimension

B

3

Steering

wheel

Check

steering

wheel

for

axial

play

When

steering

jacket

shaft

is

crush

ed

axial

play

exists

j

Axial

direction

ST194

Fig

ST

13

mpecting

Steering

Wheel

for

Axial

Play

4

Sector

shaft

When

collision

occurs

abnormal

strength

is

applied

to

gear

arm

As

a

result

of

this

serration

of

sector

shaft

is

apt

to

be

distorted

1

Serration

of

sector

shaft

2

Gear

arm

ST195

Fig

ST

14

mpeeting

Serration

of

Sector

S

IuJft

for

Deformation

STEERING

GEAR

RB4SL

Removal

I

Remove

clutch

operating

cylinder

manual

transmission

equipped

models

only

Note

Do

not

remove

clutch

hose

from

8

cylinder

2

Remove

nuts

securing

front

tube

to

exhaust

manifold

ST

5

3

Remove

bolt

securing

V

bolt

housing

clamp

to

gusset

catalytic

con

verter

equipped

models

only

STa6l

Fig

ST

5

Clutch

Operating

Cylinder

and

Front

Tube

4

Remove

bolt

securing

front

tube

to

exhaust

mounting

bracket

1

Q

I

II

@

J

111111

ST862

Fig

ST

16

Exhau

t

Mounting

Bracktt

5

Remove

front

tube

from

exhaust

manifold

Note

Do

not

remove

front

exhaust

tube

assembly

from

catalytic

con

verter

or

muffler

assembly

Refer

to

Section

FE

ST863

Fig

ST

7

Removal

of

Front

Tube

Page 393 of 548

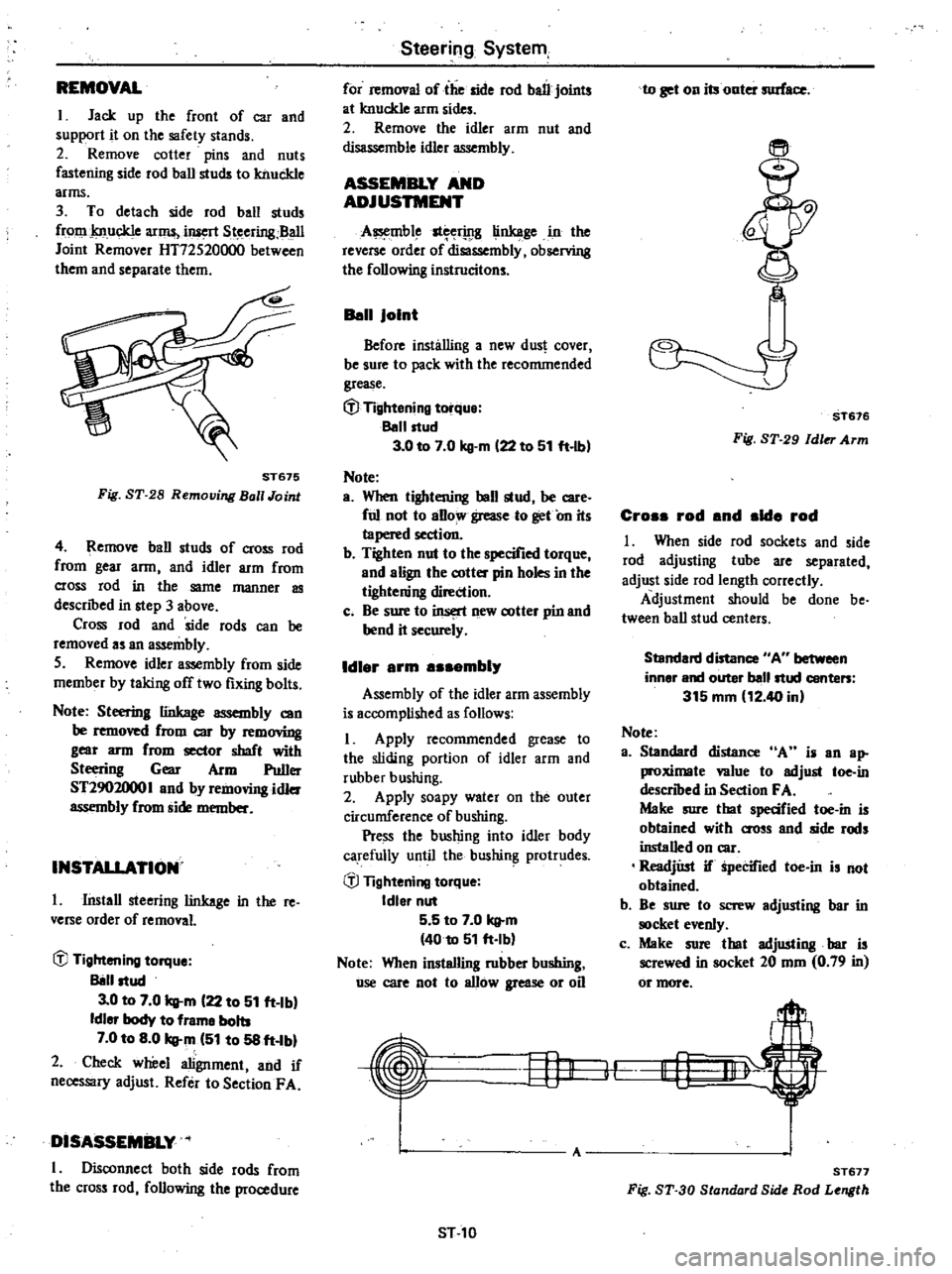

REMOVAL

I

Jack

up

the

front

of

car

and

support

it

on

the

safety

stands

2

Remove

cotter

pins

and

nuts

fastening

side

rod

ball

studs

to

knuckle

arms

3

To

detach

side

rod

ball

studs

from

knuckle

arms

iJuert

Steering

BaII

Joint

Remover

HT72520000

between

them

and

separate

them

ST675

Fig

ST

28

Remouing

Ball

Joint

4

Remove

ball

studs

of

cross

rod

from

gear

arm

and

idler

arm

from

cross

rod

in

the

same

manner

as

descnbed

in

step

3

above

Cross

rod

and

side

rods

can

be

removed

as

an

assembly

5

Remove

idler

assembly

from

side

member

by

taking

off

two

fixing

bolts

Note

Steering

linkage

assembly

can

be

removed

from

CIC

by

rem

mng

gear

arm

from

sector

shaft

with

Steering

Gear

Arm

Puller

ST2902000

I

and

by

removing

idler

assembly

from

side

member

INSTAllATION

I

Install

steering

linkage

in

the

re

verse

order

of

removal

iJJ

Tightening

torque

Il8l1ltud

3

0

to

7

0

q

m

122

to

51

ft

Ibl

Idler

body

to

frame

bolts

7

0

to

8

0

q

m

151

to

58

ft

Ibl

2

Check

wheel

alignment

and

if

necessary

adjust

Refer

to

SectionF

A

DISASSEMBLY

I

Disconnect

both

side

rods

from

the

cross

rod

following

the

procedure

Steering

System

for

removal

of

the

side

rod

ball

joints

at

knuckle

arm

sides

2

Remove

the

idler

arm

nut

and

disassemble

idler

assembly

ASSEMBLY

AND

ADJUSTMENT

A

mble

st

rwg

linkage

in

the

reverse

order

of

disassembly

observing

the

following

instrucitons

Ban

Joint

Before

installing

a

new

dus

cover

be

sure

to

pack

with

the

recommended

grease

t

J

Tightening

torque

Ballltud

3

0

to

7

0

kg

m

122

to

51

ft

lbl

Note

a

When

tightening

ball

stud

be

care

ful

not

to

aBow

grease

to

get

On

its

tapered

section

b

Tighten

nut

to

the

specified

torque

and

align

the

cotter

pin

holes

in

the

tightening

direction

c

Be

sure

to

insert

new

cotter

pin

and

bend

it

securely

Idl

r

rm

mbl

Assembly

of

the

idler

arm

assembly

is

accomplished

as

follows

I

Apply

recommended

grease

to

the

sliding

portion

of

idler

arm

and

rubber

bushing

2

Apply

soapy

water

on

the

outer

circumference

of

bushing

Pre

ss

the

bushing

into

idler

body

carefully

until

the

bushin

protrudes

iJJ

Tightening

torque

Idler

nut

5

5

to

7

0

q

m

4010

51

ft

Ib

Note

When

installing

rubber

bushing

use

care

not

to

allow

grease

or

oil

Hj1

ST

10

to

get

on

its

onter

surface

ST676

Fig

ST

29

Idler

Arm

Cro

rod

nd

Id

rod

I

When

side

rod

sockets

and

side

rod

adjusting

tube

are

separated

adjust

side

rod

length

correctly

Adjustment

should

be

done

be

tween

ball

stud

centers

Standard

distance

AU

between

inner

and

outer

ballltud

conte

315

mm

12

40

in

Note

a

Standard

distance

A

i

an

ap

proximale

value

to

adjust

toe

in

descnbed

in

Section

FA

Maire

sure

tbat

specified

toe

in

is

obtained

with

O

OSs

and

side

rods

installed

on

car

ReadjUst

if

Specified

toe

in

is

not

obtained

b

Be

sure

to

screw

adjusting

bar

in

clret

evenly

c

Make

sure

that

adjusting

bar

is

screwed

in

socket

20

mm

0

79

in

or

more

I

lf

A

ST

77

Fig

ST

30

Standard

Side

Rod

Length

Page 395 of 548

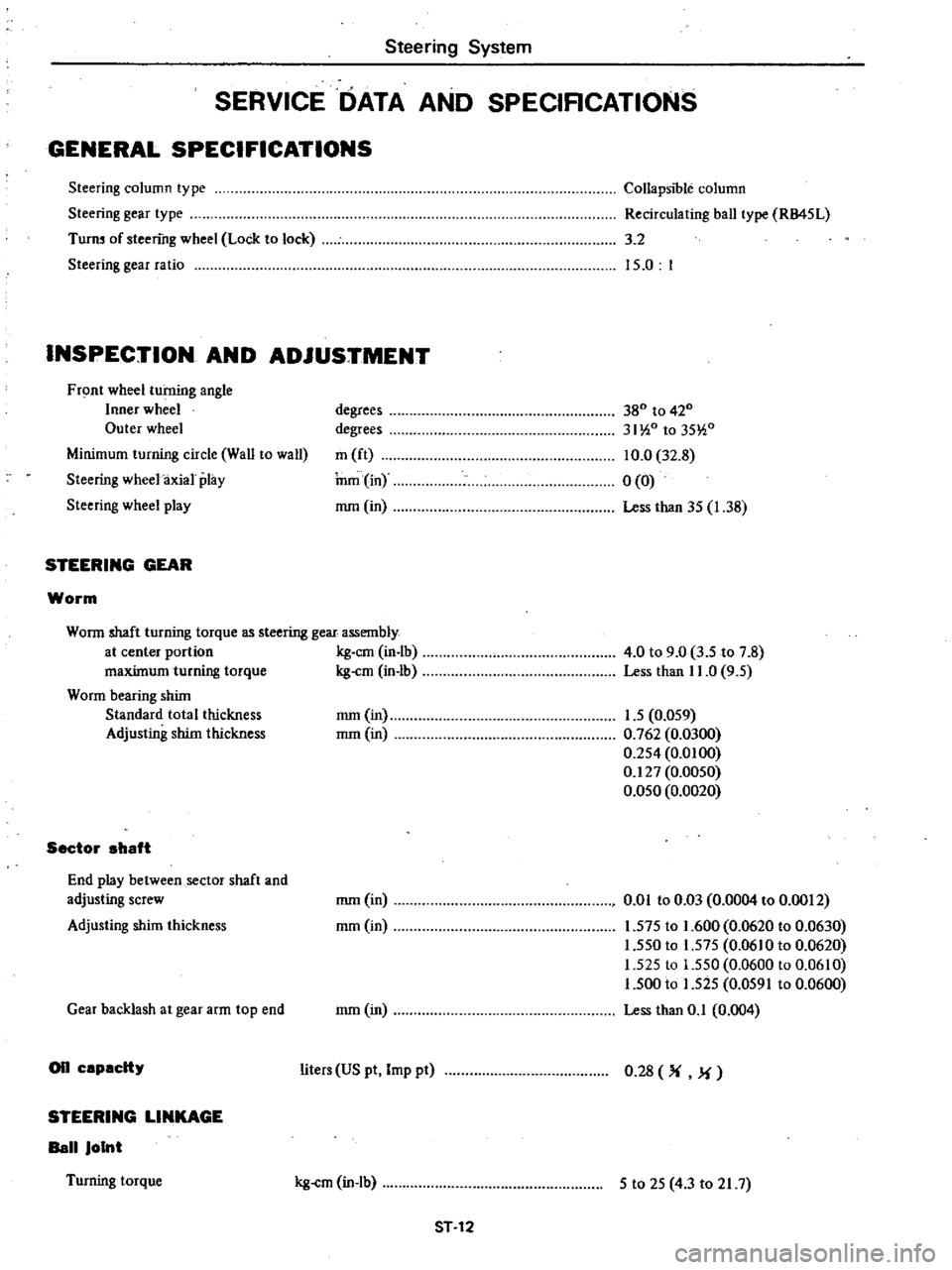

Steering

System

SERVICE

DATA

AND

SPECIRCATIONS

GENERAL

SPECIFICATIONS

Steering

column

type

Steering

gear

type

Turn

of

steering

wheel

Lock

to

lock

Steering

gear

ratio

CollapSIble

column

Recirculating

ball

type

RB45L

3

2

15

0

I

INSPECTION

AND

ADJUSTMENT

Front

wheel

turning

angle

Inner

wheel

Outer

wheel

Minimum

turning

circle

Wall

to

wall

Steering

wheel

axial

play

Steering

wheel

play

STEERING

GEAR

Worm

degrees

degrees

m

ft

nun

in

mm

in

380

to

420

31

i0

to

35

i0

10

0

32

8

0

0

Less

than

35

1

38

Worm

shaft

turning

torque

as

steering

gear

assembly

at

center

portion

kg

em

in

lb

maxUnum

turning

torque

kg

cm

in

lb

Worm

bearing

shUn

Standard

total

thickness

Adjusting

shim

thickness

Sector

ahaft

End

play

between

sector

shaft

and

adjusting

screw

Adjusting

shUn

thickness

Gear

backlash

at

gear

arm

top

end

on

capacity

STEERING

LINKAGE

Ball

Joint

Turning

torque

4

0

to

9

0

3

5

to

7

8

Less

than

11

0

9

5

mm

in

1

5

0

059

mm

in

0

762

0

0300

0

254

0

0100

0

127

0

0050

0

050

0

0020

mm

in

mm

in

om

to

0

Q3

0

0004

to

0

0012

1

575

to

1

600

0

0620

to

0

0630

1

550

to

1

575

0

06

0

to

0

0620

1

525

to

1

550

0

0600

to

0

0610

1

500

to

1

525

0

0591

to

0

0600

Less

than

0

1

0

004

mm

in

liters

US

pt

Imp

pt

0

28

M

kg

cm

in

lb

5

to

25

4

3

to

21

7

ST

12

Page 396 of 548

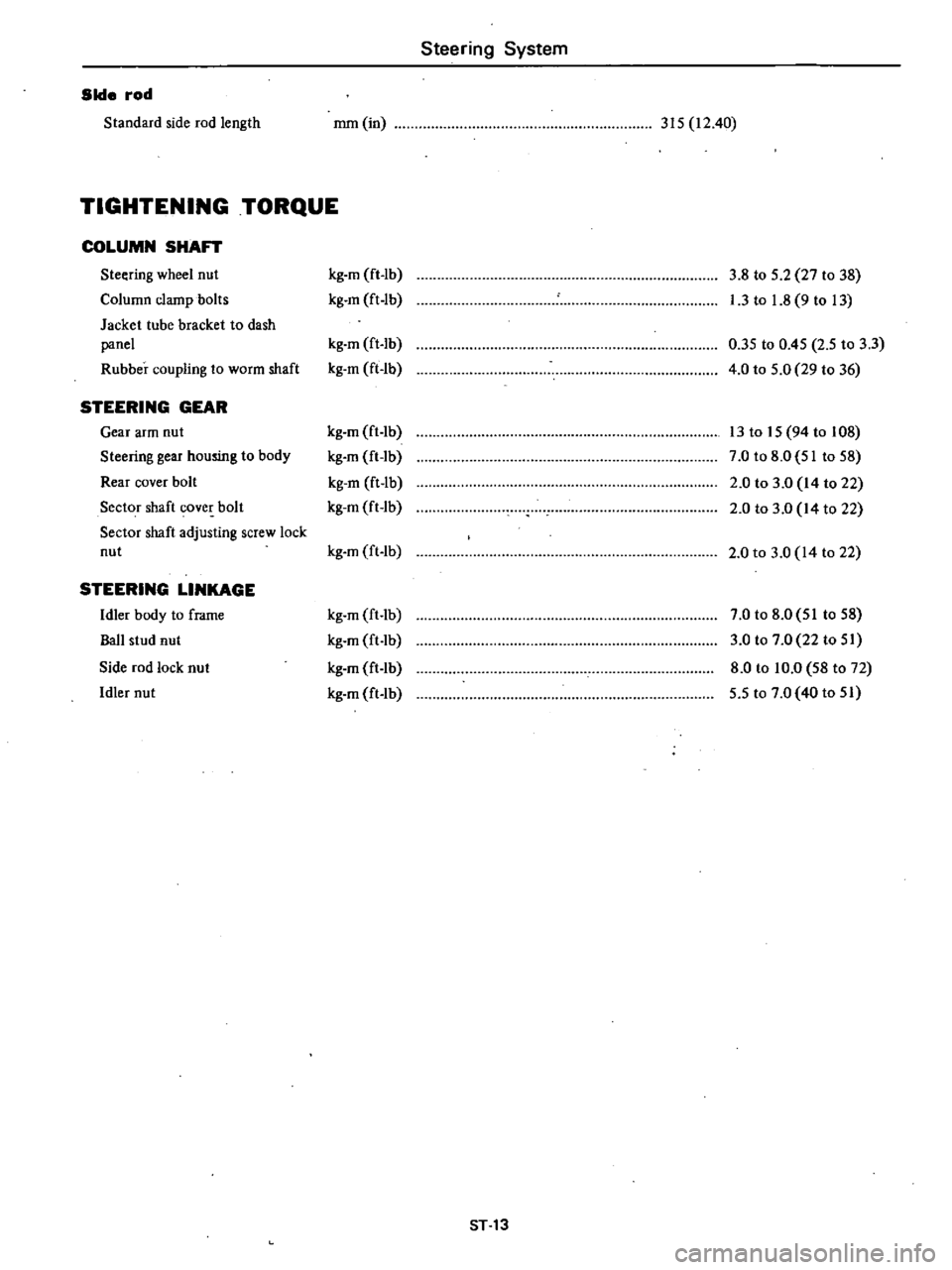

Steering

System

Side

rod

Standard

side

rod

length

mm

in

315

12

40

TIGHTENING

TORQUE

COLUMN

SHAFT

Steering

wheel

nut

kg

m

ft

lb

3

8

to

5

2

27

to

38

Column

clamp

bolts

kg

m

ft

lb

I

3

to

1

8

9

to

13

Jacket

tube

bracket

to

dash

panel

kg

m

ft

lb

0

35

to

0

45

2

5

to

3

3

Rubber

coupling

to

worm

shaft

kg

m

ft

lb

4

0

to

5

0

29

to

36

STEERING

GEAR

Gear

arm

nut

kg

m

ft

lb

13

to

15

94

to

108

Steering

gear

housing

to

body

kg

m

ft

lb

7

0

to

8

0

51

to

58

Rear

cover

bolt

kg

m

ft

lb

2

0

to

3

0

14

to

22

Sector

shaft

cover

bolt

kg

m

ft

lb

2

0

to

3

0

14

to

22

Sector

shaft

adjusting

screw

lock

nut

kg

m

ft

lb

2

0

to

3

0

14

to

22

STEERING

LINKAGE

Idler

body

to

frame

kg

m

ft

lb

7

0

to

8

0

51

to

58

Ball

stud

nut

kg

m

ft

lb

3

0

to

7

0

22

to

51

Side

rod

lock

nut

kg

m

ft

lb

8

0

to

10

0

58

to

72

Idler

nut

kg

m

ft

lb

5

5

to

7

0

40

to

51

ST

13

Page 397 of 548

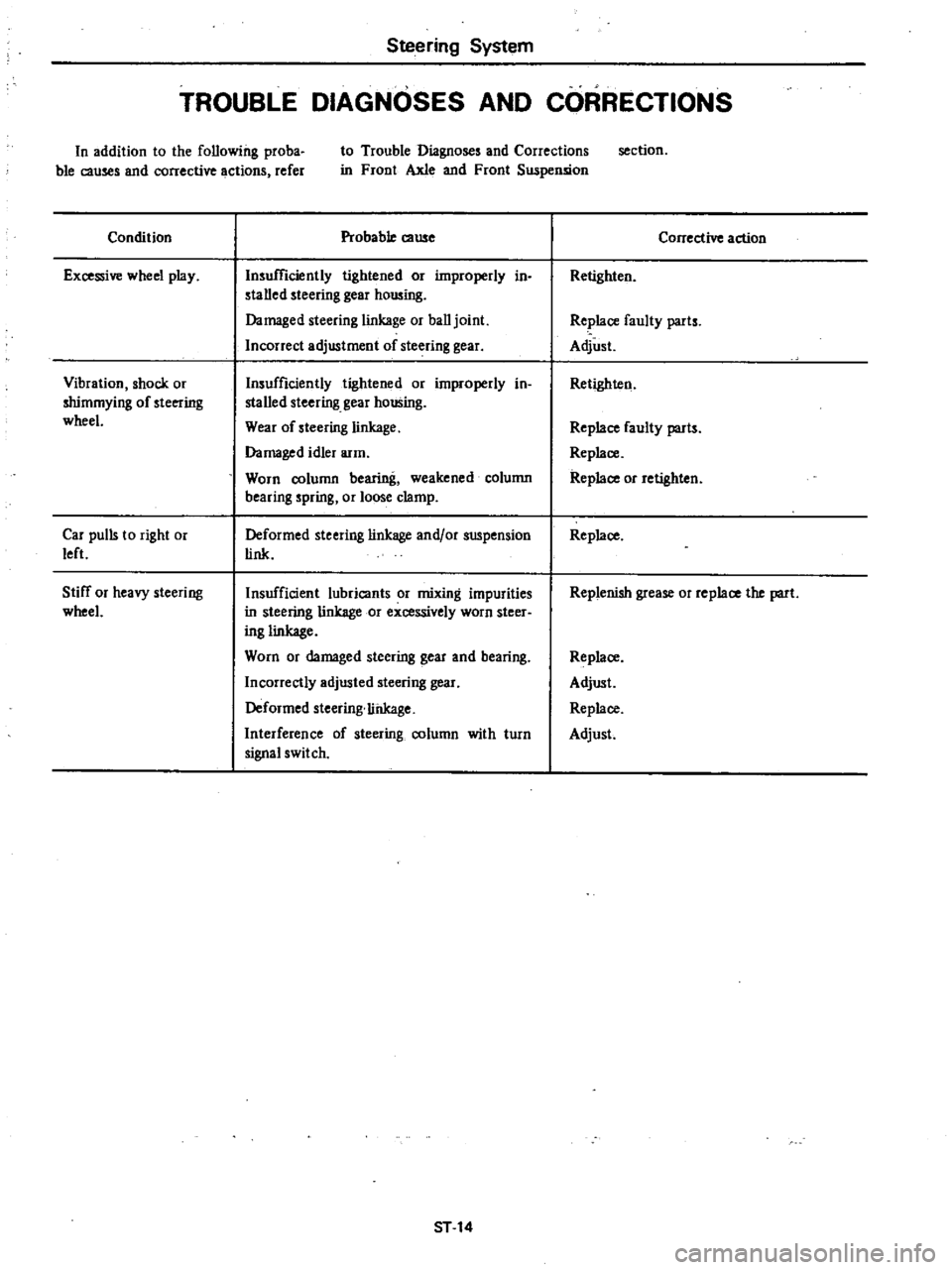

Steering

System

TROUBLE

DIAGNOSES

AND

CORRECTIONS

In

addition

to

the

following

proba

ble

causes

and

corrective

actions

refer

to

Trouble

Diagnoses

and

Corrections

in

Front

Axle

and

Front

Suspension

section

Condition

Excessive

wheel

play

Vibration

shock

or

shimmying

of

steering

wheel

Car

pulls

to

right

or

left

Stiff

or

heavy

steering

wheel

Probable

cause

Insufficiently

tightened

or

ilnproperly

in

stalled

steering

gear

housing

Damaged

steering

linkage

or

ball

joint

Incorrect

adjustment

of

steering

gear

Insufficiently

tightened

or

ilnproperly

in

stalled

steering

gear

housing

Wear

of

steering

linkage

Damaged

idler

arm

Worn

column

bearing

weakened

column

bearing

spring

or

loose

clamp

Deformed

steering

linkage

and

or

suspension

link

Insufficient

lubricants

or

mixing

impurities

in

steering

linkage

or

excessively

worn

steer

ing

linkage

Worn

or

damaged

steering

gear

and

bearing

Incorrectly

adjusted

steering

gear

Deformed

steering

liilkage

Interference

of

steering

column

with

turn

signal

switch

ST

14

Corrective

action

Retighten

Re

lace

faulty

parts

Adjust

Retighten

Replace

faulty

parts

Replace

Replace

or

retighten

Replace

Replenish

grease

or

replace

the

part

Replace

Adjust

Replace

Adjust