Alternator relay DATSUN 210 1979 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 98 of 548

ELECTRIC

AUTOMATIC

CHOKE

An

electric

heater

warms

a

bi

metal

interconnected

to

the

choke

valve

and

controls

the

position

of

c

oke

valve

and

throttle

valve

in

accordance

with

the

time

elapsed

the

warm

up

condi

tion

of

the

engine

and

the

outside

ambient

temperature

Electric

heater

The

electric

heater

is

made

up

of

a

semiconductor

and

installed

in

the

automatic

choke

cover

in

the

body

2

Bi

metal

Electric

current

flows

through

the

heater

as

the

engine

starts

and

warms

the

bi

metal

The

deflection

of

the

bi

metal

is

transmitted

to

the

choke

valve

through

the

choke

valve

lever

3

Fast

idle

cam

The

fast

idle

cam

determines

the

opening

of

the

throttle

valve

SQ

that

the

proper

amount

of

mixture

cor

responding

to

the

opening

of

the

choke

valve

will

be

obtained

The

opening

of

the

choke

valve

is

de

pendent

upon

the

warm

up

condition

of

the

engine

4

Choke

unloader

When

accelerating

the

engine

during

the

warm

up

period

that

is

before

the

choke

valve

opens

sufficiently

this

unloader

forces

the

choke

valve

open

a

little

so

as

to

obtain

an

adequate

air

fuel

mixture

S

Vacuum

break

diaphragm

After

the

engine

has

been

started

by

cranking

this

diaphragm

forces

the

choke

valve

open

to

the

predetermined

extent

so

as

to

provide

the

proper

air

fuel

ratio

A

two

stage

acting

type

vacuum

diaphragm

is

employed

6

Si

metal

case

index

mark

The

bi

metal

case

index

mark

is

used

for

selling

the

moment

of

the

bi

metal

which

controls

the

air

fuel

mixture

ratio

required

for

starting

Engine

Fuel

r

m

2

3

4

5

6

r

3

1

@

@

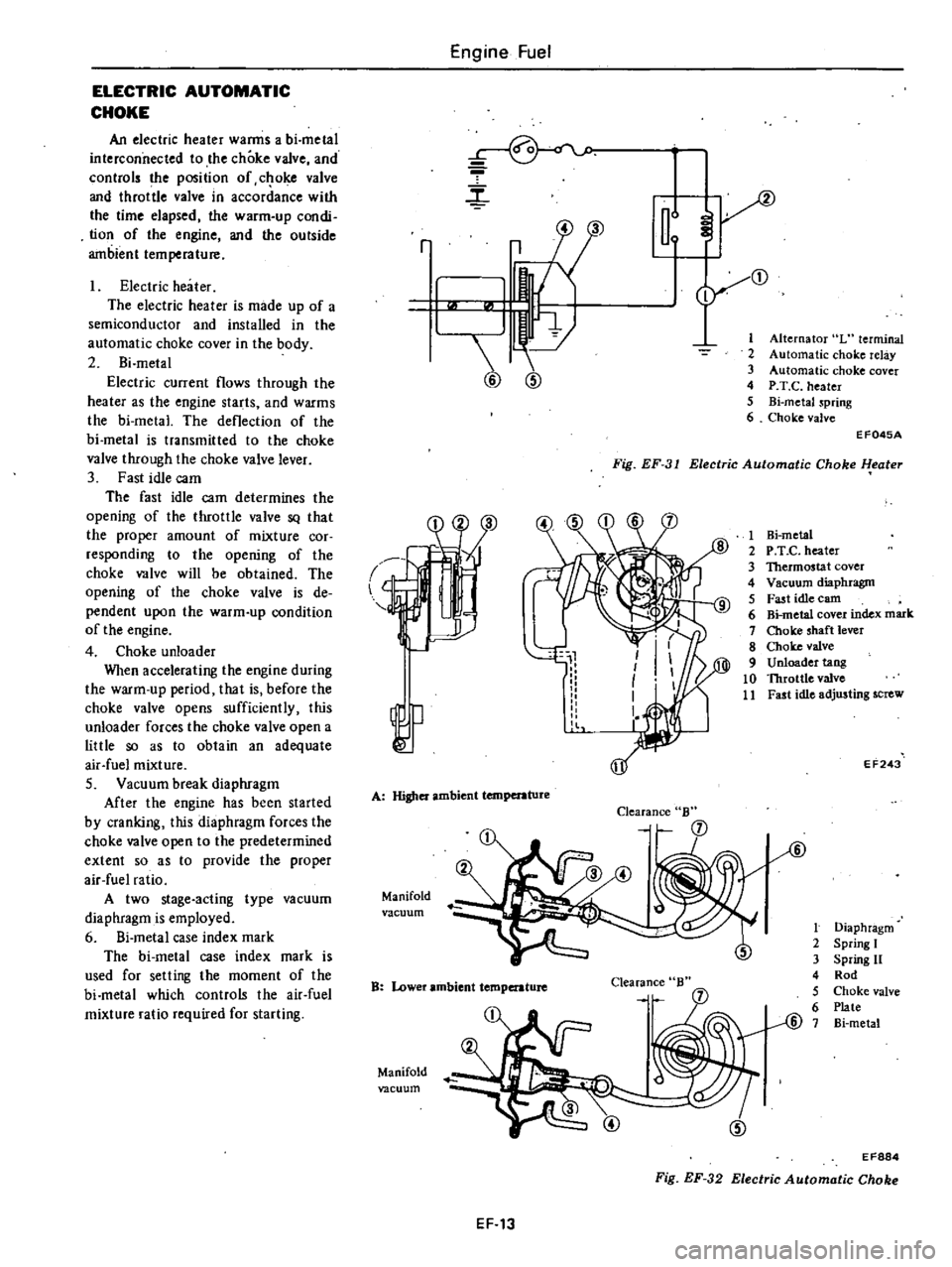

Alternator

L

terminal

Automatic

choke

relay

Automatic

choke

cover

P

T

C

heater

Bi

metaJ

spring

Choke

valve

Fig

EF

31

Electric

Automatic

Choke

l

eater

EF045A

l

A

Higher

ambient

temperature

Manifold

vacuum

Clearance

B

B

Lower

ambient

temperature

Clearance

Manifold

vacuum

1

Hi

metal

2

P

T

e

heater

3

Thermostat

cover

4

Vacuum

diaphragm

5

Fast

idle

earn

6

Bi

metal

cover

index

mark

7

Choke

shaft

lever

8

Choke

valve

9

Unloader

tang

10

Throttle

valve

11

Fast

idle

adjusting

screw

EF243

t

Diaphragm

2

Spring

I

3

Spring

11

4

Rod

5

Choke

valve

6

Plate

@

7

Bi

metal

EF884

Fig

EF

32

Electric

Automatic

Choke

EF

13

Page 101 of 548

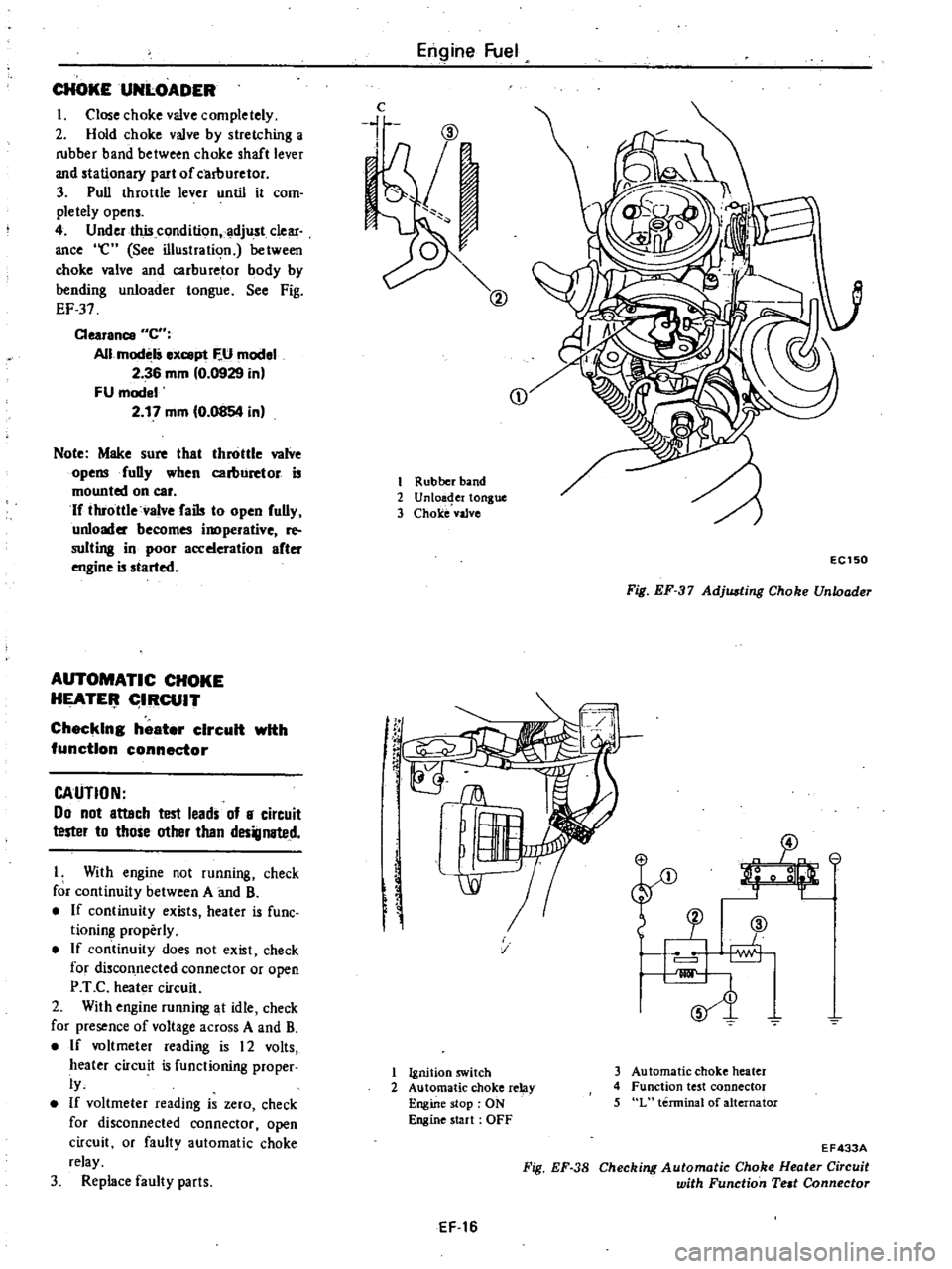

CHOKEUNLOADER

I

Close

choke

valve

completely

2

Hold

choke

valve

by

stretching

a

rubber

band

between

choke

shaft

lever

and

stationary

part

of

carllUretor

3

Pull

throttle

lever

until

it

com

pletely

opens

4

Under

this

condition

adjust

clear

ance

e

See

illustration

between

choke

valve

and

carburetor

body

by

bending

unloader

tongue

See

Fig

EF

37

Clearance

C

All

modelS

ex

pt

F

U

model

2

36

mm

0

0929

in

FU

model

2

17

mm

0

0854

in

Note

Make

sure

that

throttle

valve

opensfuDy

when

carburetor

is

mounted

on

car

If

throttle

valve

fails

to

open

fully

unloader

becomes

inoperative

re

suiting

in

poor

acceleration

after

engine

is

started

AUTOMATIC

CHOKE

HEATE

IRCUIT

Checking

heater

circuit

with

function

connector

CAUTION

00

not

attach

test

leads

of

8

circuit

tester

to

those

other

than

designated

I

With

engine

not

running

check

for

continuity

between

A

and

B

If

continuity

exists

heater

is

fune

tioning

properly

If

continuity

does

not

exist

check

for

discon

nected

connector

or

open

P

T

C

heater

circuit

2

With

engine

running

at

idle

check

for

presence

of

voltage

across

A

and

B

If

voltmeter

reading

is

12

volts

heater

circuit

is

functioning

proper

ly

If

voltmeter

reading

is

zero

check

for

disconnected

connector

open

circuit

or

faulty

automatic

choke

relay

3

Replace

faulty

parts

Engine

Fuel

c

i

CD

1

Rubber

band

2

Unloa

er

tongue

3

Choke

vaJve

f

rC

EC150

Fig

EF

37

Adjusting

Choke

Unloader

SJ

v

1

Ignition

switch

2

Automatic

choke

relay

Engine

stop

ON

Engine

start

OFF

3

Automatic

choke

heater

4

Function

test

connector

5

L

terminal

of

alternator

EF

16

Fig

EF

38

EF433A

Checking

Automatic

Choke

Heater

Circuit

with

Function

Teat

Connector

Page 170 of 548

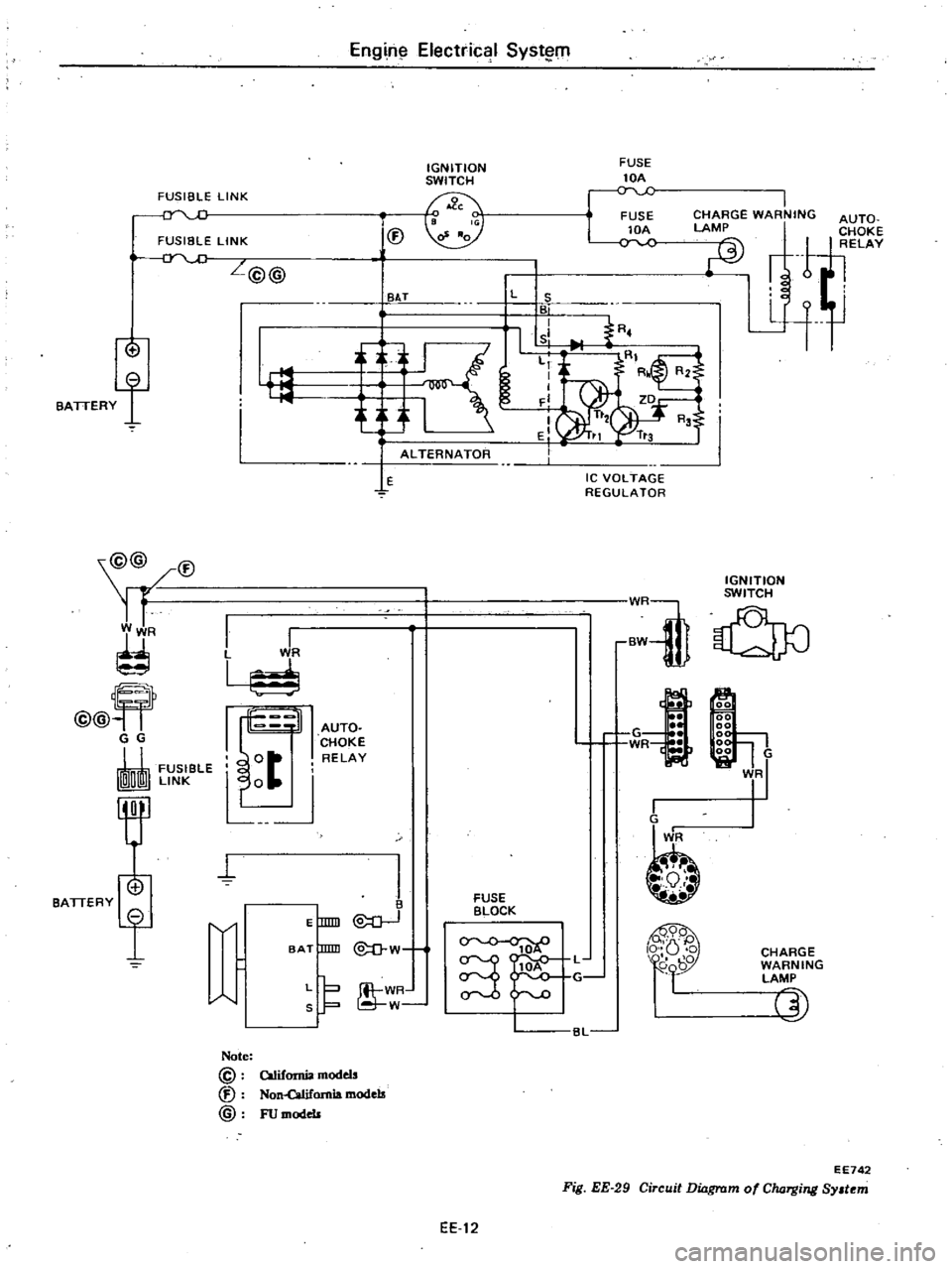

FUSIBLE

LINK

FUSIBLE

LINK

f

BATTERY

@@

V

R

@@

G

G

FUSleLE

ImrnI

LI

NK

MTI

I

En

g

n

l

Electrical

Syst

lOl

IGNITION

SWITCH

FUSE

lOA

o

v

FUSE

lOA

C

V

L@@

BAT

f

L

S

BI

I

I

sl

fRO

L

I

I

F

I

EI

i

K

a

ALTERNATOR

lE

Ie

VOLTAGE

REGULATOR

I

I

L

WR

I

1

d

I

t

J

t

IGNITION

WR

SWITCH

BW

U

0

AUTO

CHOKE

RELAY

G

1

WR

J

I

00

00

gg

1

00

VR

1

E

lDID

I

@

O

BAT

mID

W

J

WR

W

FUSE

BLOCK

CHARGE

WARNING

LAMP

5J

BL

Note

@

V

@

California

models

Non

Qilifomo

18

models

FU

models

Fig

EE

29

Circuit

Dinrswr

EE742

mofCIuJ

Tg

ng

Sy

t

m

EE

12

Page 176 of 548

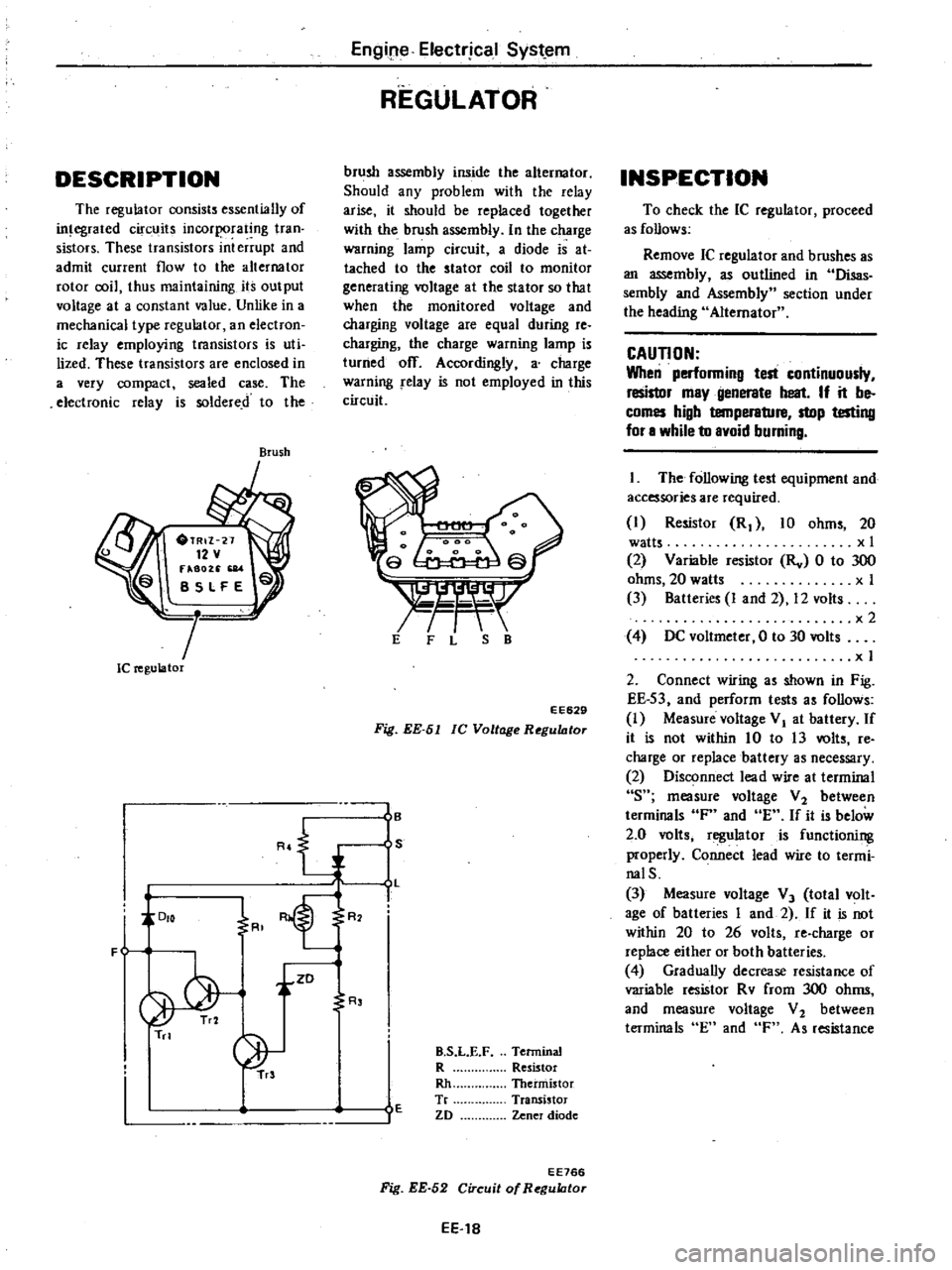

DESCRIPTION

The

regulator

consists

essentially

of

in

egrated

circuits

incorporating

tran

sistors

These

transistors

int

errupt

and

admit

current

flow

to

the

alternator

rotor

coil

thus

maintaining

its

output

voltage

at

a

constant

value

Unlike

in

a

mechanical

type

regulator

an

electron

ic

relay

employing

transistors

is

uti

lized

These

transistors

are

enclosed

in

a

very

compact

sealed

case

The

electronic

relay

is

soldered

to

the

Brush

Ie

regulator

R

J

DIO

F

i

ZD

Tn

Engipe

Electrjcal

Syst

em

REGULATOR

brush

assembly

inside

the

alternator

Should

any

problem

with

the

relay

arise

it

should

be

replaced

together

with

the

brush

assembly

In

the

charge

warning

lamp

circuit

a

diode

is

at

tached

to

the

stator

coil

to

monitor

generating

voltage

at

the

stator

so

that

when

the

monitored

voltage

and

charging

voltage

are

equal

during

re

charging

the

charge

warning

lamp

is

turned

off

Accordingly

a

charge

warning

relay

is

not

employed

in

this

circuit

s

r

t

E

F

L

S

B

EE629

Fig

EE

51

lC

Voltage

RegultJtor

I

B

S

L

I

R

R

E

B

S

L

E

F

Terminal

R

Resistor

Rh

Thermistor

Tr

Transistor

ZD

Zener

diode

EE766

Fig

EE

52

Circuit

of

RegultJtor

EE

18

INSPECTION

To

check

the

IC

regulator

proceed

as

follows

Remove

IC

regulator

and

brushes

as

an

assembly

as

outlined

in

Disas

sembly

and

Assembly

section

under

the

heading

Alternator

CAUTION

When

performing

test

continuously

resistor

may

generate

heat

If

it

be

comes

high

temperature

stop

testing

for

a

while

to

avoid

burning

The

following

test

equipment

and

accessories

are

required

I

Resistor

R

10

ohms

20

watts

x

I

2

Variable

resistor

Rv

0

to

300

ohms

20

watts

x

I

3

Batteries

I

and

2

12

volts

x2

4

DC

voltmeter

0

to

30

volts

x

I

2

Connect

wiring

as

shown

in

Fig

EE

S3

and

perform

tests

as

follows

I

Measure

voltage

VI

at

battery

If

it

is

not

within

10

to

13

volts

re

charge

or

replace

battery

as

necessary

2

Disconnect

lead

wire

at

terminal

s

measure

voltage

V

2

between

terminals

F

and

E

If

it

is

below

2

0

volts

regulator

is

functioning

properly

Connect

lead

wire

to

termi

nalS

3

Measure

voltage

V

3

total

volt

age

of

batteries

I

and

2

If

it

is

not

within

20

to

26

volts

re

charge

or

replace

either

or

both

batteries

4

Gradually

decrease

resistance

of

variable

resistor

Rv

from

300

ohms

and

measure

voltage

V

2

between

terminals

En

and

F

As

resistance

Page 450 of 548

m

c

n

to

l

l

I

g

iF

0

1

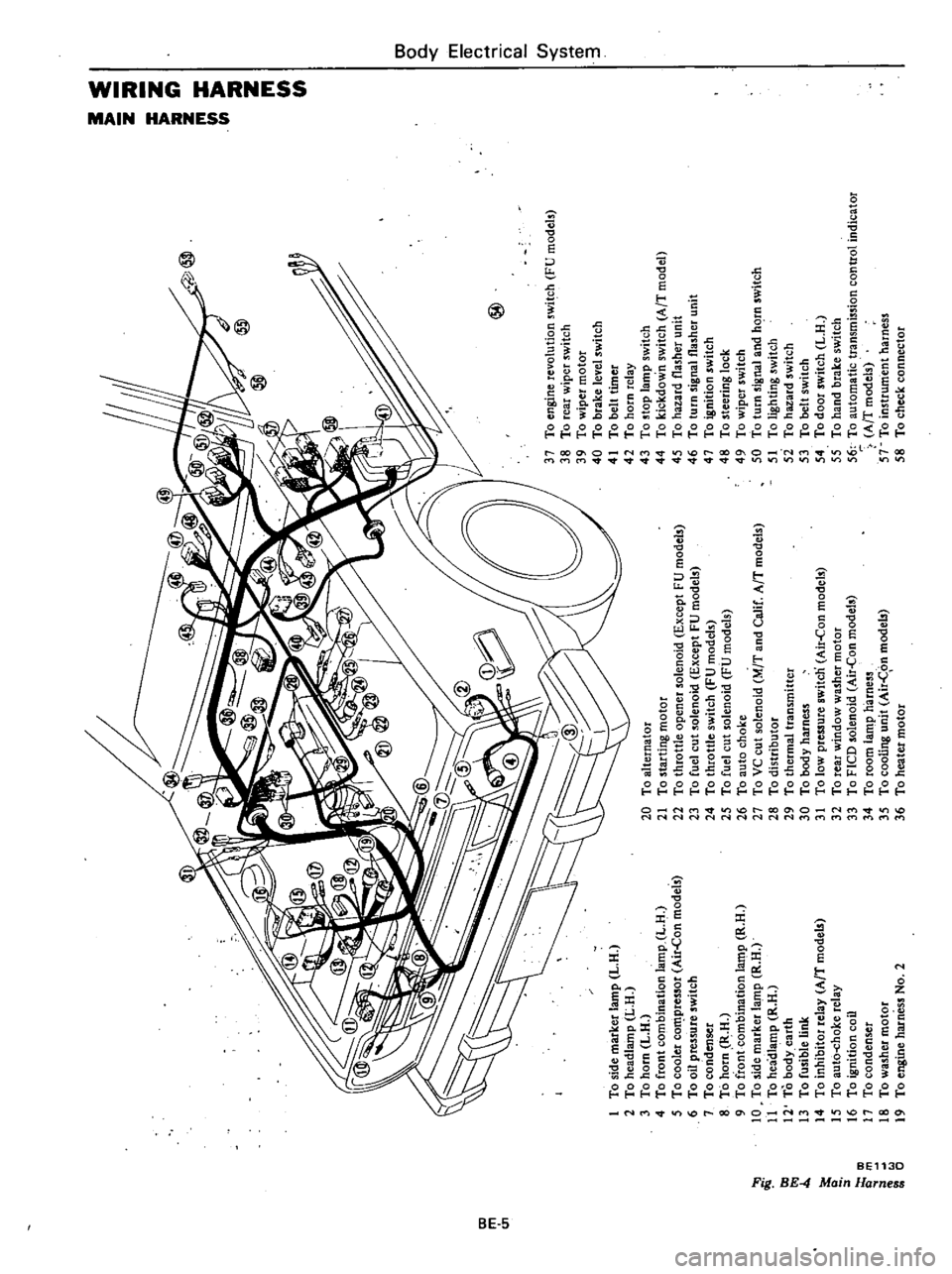

To

side

marker

lamp

L

H

2

To

headlamp

L

H

3

To

horn

L

H

4

To

front

combination

lamp

L

H

5

To

cooler

co

pressor

Air

Con

models

6

To

oil

pressure

switch

7

To

condenser

8

To

horn

R

H

9

To

front

combination

la

t11p

R

H

10

To

side

marker

lamp

R

H

11

To

headlamp

R

H

12

To

body

earth

13

To

fusible

link

14

To

inhibitor

relay

AfT

model

15

To

aut6

choke

relay

16

To

ignition

coil

17

To

condenser

18

To

washer

motor

19

To

engine

harness

No

2

@

20

To

alternator

21

To

starting

motor

22

To

throttle

opener

solenoid

Except

FU

models

23

To

fuel

cut

solenoid

Except

FU

models

24

To

throttle

switch

FU

models

25

To

fuel

cut

solenoid

FU

models

26

To

auto

choke

27

To

VC

cut

solenoid

M

T

and

Calif

AfT

models

28

To

distributor

29

To

thermal

transmitter

30

To

body

harness

31

To

low

pressure

switcn

Air

Con

models

32

To

rear

window

washer

motor

33

To

FICO

solenoid

Air

Con

models

34

To

room

lamp

harness

35

To

cooling

unit

Air

C

on

models

36

To

heater

motor

37

To

engine

revolution

switch

FU

models

38

To

rear

wiper

switch

39

To

wiper

motor

40

To

brake

level

switch

41

To

belt

timer

42

To

horn

relay

43

To

stop

lamp

switch

44

To

kickdown

switch

AfT

model

45

To

hazard

flasher

unit

46

To

turn

signal

flasher

unit

47

To

ignition

switch

48

To

steering

lock

49

To

wiper

switch

50

To

turn

signal

and

hC

rn

switch

51

To

lighting

switch

5i

To

hazard

switch

53

To

belt

switch

54

To

door

switch

L

H

55

To

hand

brake

switch

56

To

automatic

transmission

control

indicator

AfT

models

57

To

instrument

harness

58

To

check

connector

I

0

i

a

z

Z

G

z

tIl

tIl

a

Z

Il

I

to

o

Co

m

16

n

n

OJ

1

3

Page 474 of 548

m

ii

I

ll

i

f

r

3

0

tl

i

a

iO

3

o

J

r

L

8

ffi

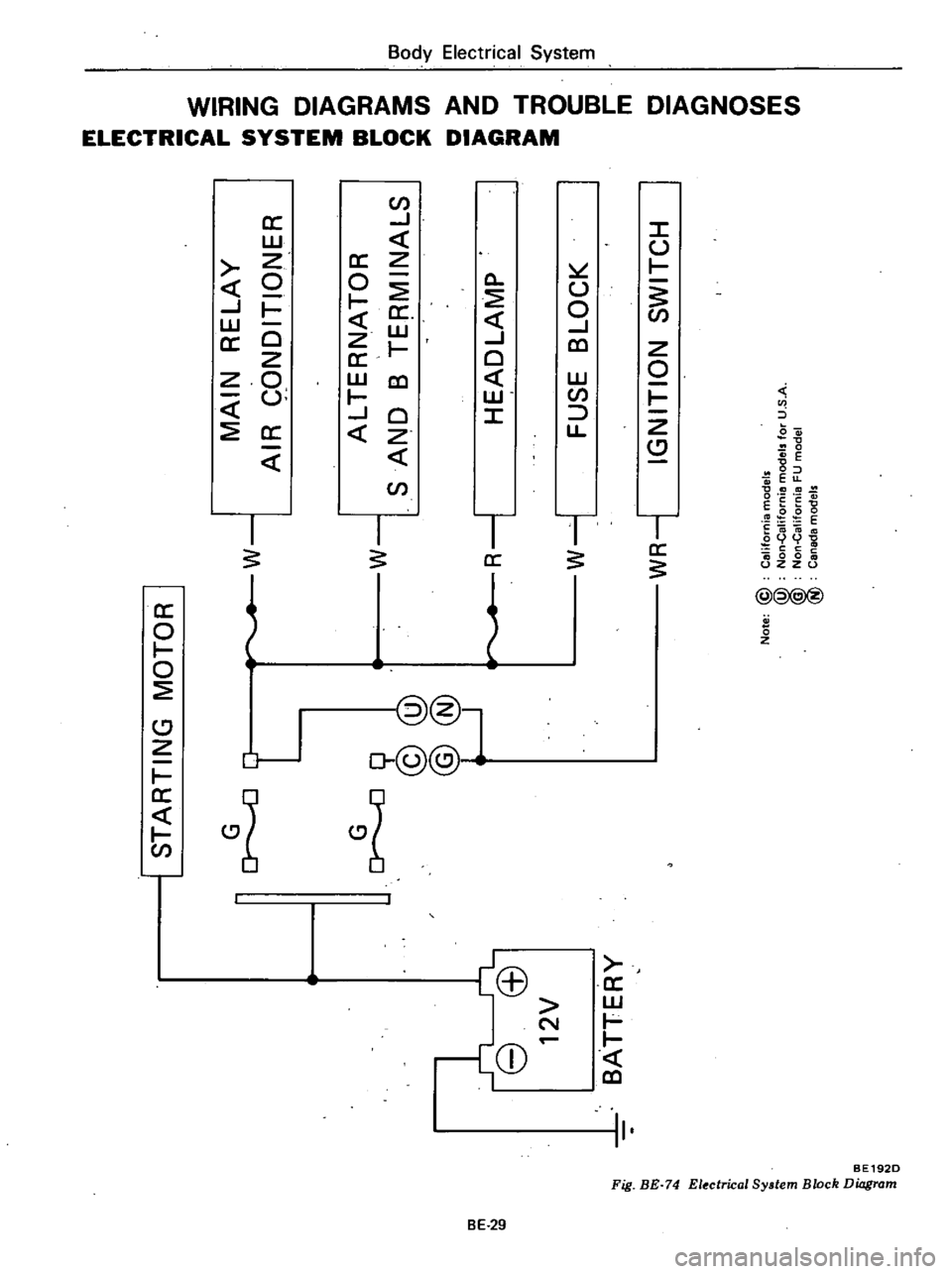

12V

BATTERY

I

STARTING

MOTOR

I

I

G

0

0

9

@@

@@

L

J

W

MAIN

RELAY

AIR

CONDITIONER

w

ALTERNATOR

SAND

B

TERMINALS

HEADLAMP

FUSE

BLOCK

I

WR

1

IGNITION

SWITCH

R

1

Note

@

i

W

Californta

models

Non

alifornt8

models

for

U

S

A

Non

CaliforOlB

FU

model

Canada

models

II

II

n

I

a

n

e

xI

ltZ

O

C

It

10

II

I

l

C

m

xl

0

l

OJ

3

0

n

CJ

II

m

al

CD

Z

0

2

a

t

CIl

xI

I

0

c

l

OJ

3

m

2

l

C

Z

o

CJ

m

CJ

Page 489 of 548

cIo

CD

m

t

tl

3

Cl

4

Ii

ii

C

l

I

i

I

ll

g

toom

a

ll

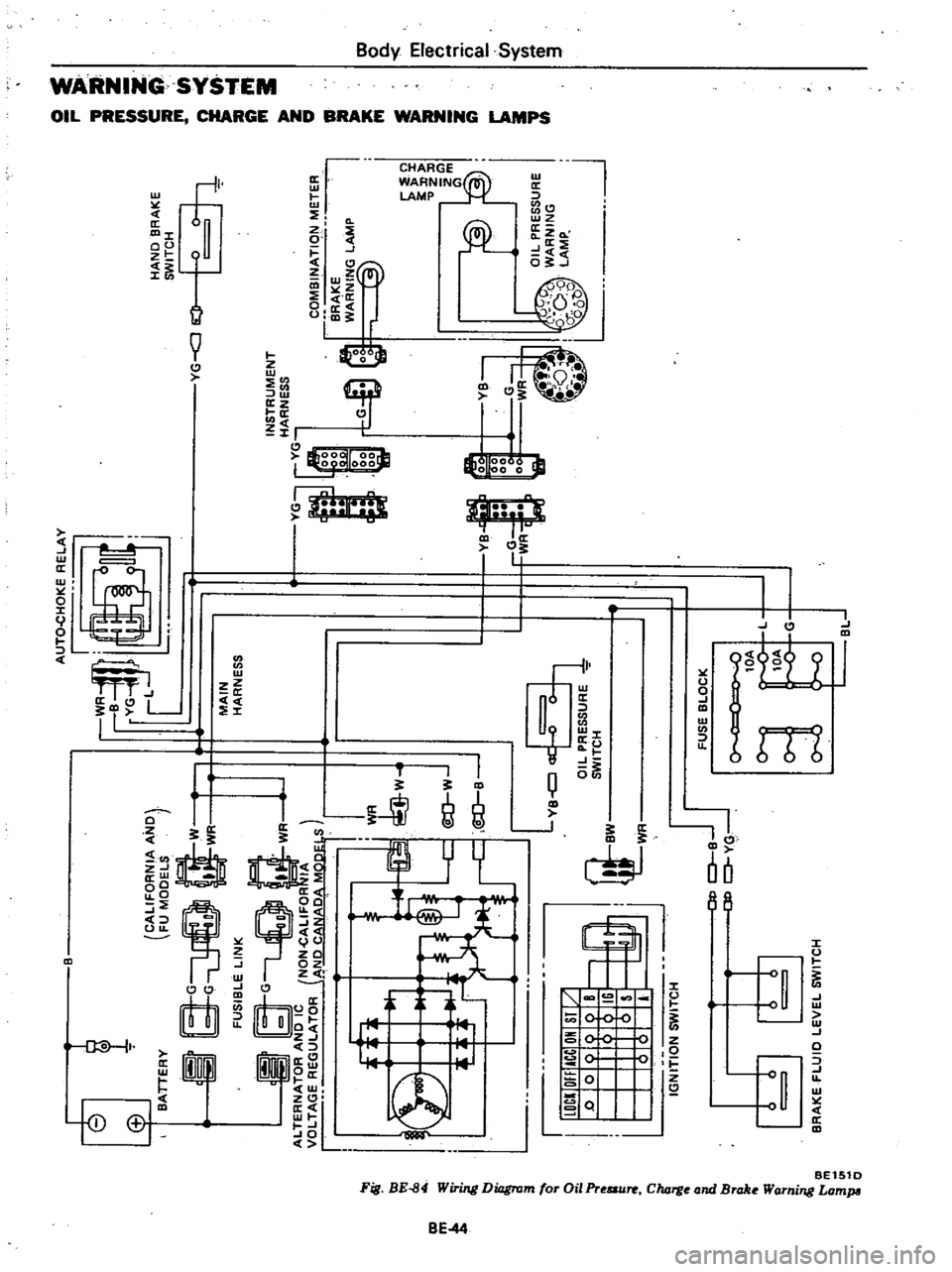

CALIFORNIA

ANO

BATTERY

FU

MOOELS

R

G

ff

w

G

M

wr

N

Q

WR

ALTERNATOR

ANO

IC

NON

cALIFOR

IA

VOLTAGE

REGULATOR

ANO

CANAOA

MO

S

I

fh

WR

B

i

W

i

C

@

J

W

l

9

i

j

@

Q

B

LB

OIL

PRESSURE

SWITCH

0

I

I

l

lOCI

OfflACC

OH

SI

Ys

j

D

01

mQ

IS

i

I

l

I

s

II

10

J

J

SWITCH

IGNITION

iji

BY

wr

1

I

1

IW

BRAKE

FLUIO

LEVEL

SWITCH

Ot

o

BJ

JO

0

Y

l

I

AUTO

cHOKE

RELAY

V

I

r

I

MAIN

HARNESS

FUSE

BLOCK

0

0

lOA

cr

L

lOA

cr

G

1

r

L

BL

HANO

BRAKE

SWITCH

G

J

i

INSTRUMENT

HARN

ESS

fG

YG

10

OMB

N

AT

qN

ETER

o

BRAKE

0

WARNING

LAMP

100

G

O

00

3

YB

f

G

WR

J

I

0

1

Fo

o

e

i

1

z

YB

OIL

PRESSURE

WARNING

LAMP

J

lI

a

Ill

z

11

1

III

Z

G

Ill

11

1

Ut

0

iUt

Ill

alii

11

1

I

a

i

l

i

Ill

Z

i

a

X

OJ

o

Cl

m

CD

o

CIl

l

3

Page 491 of 548

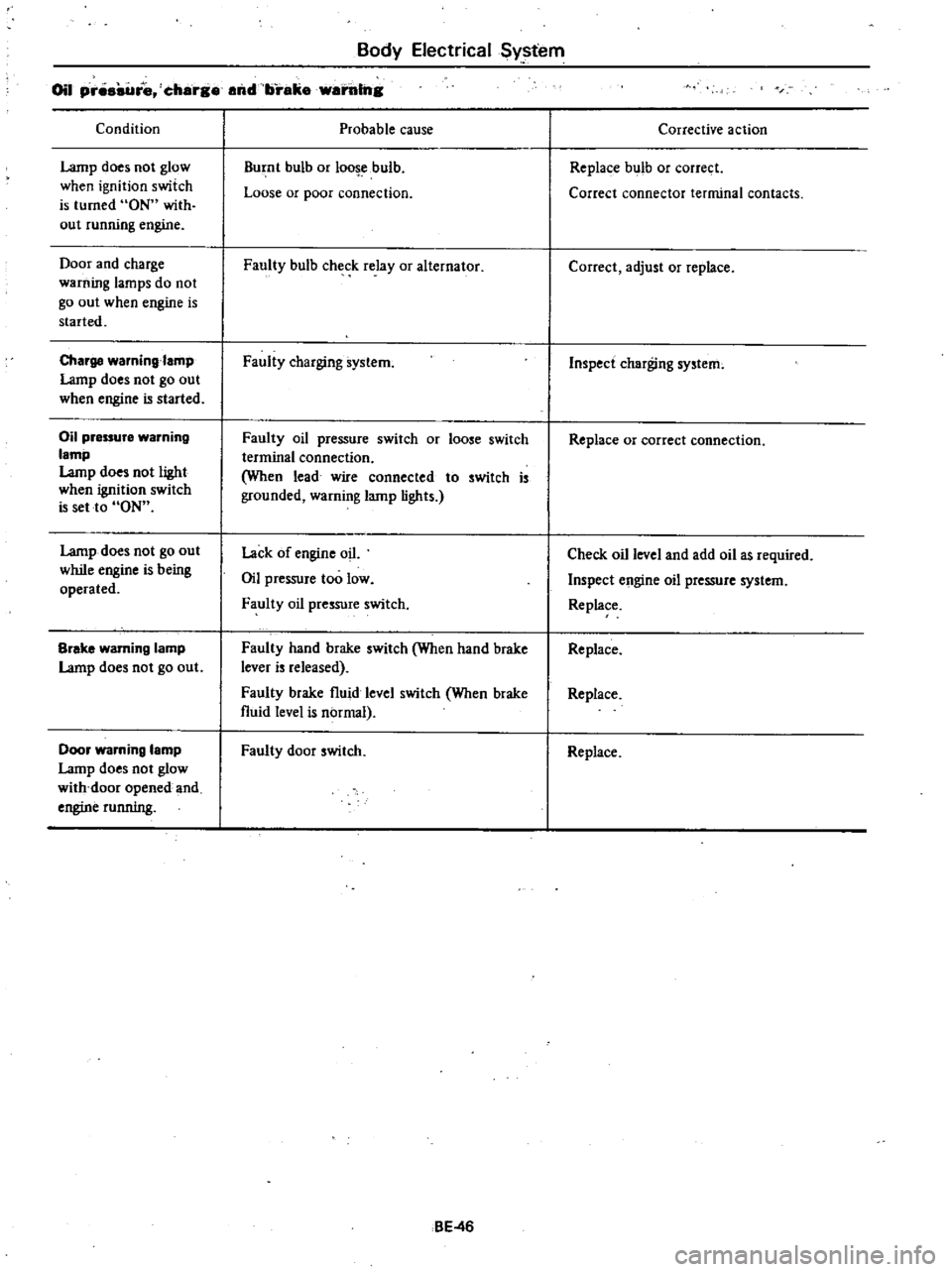

Body

Electrical

Sy

tem

Oil

pr

re

charg

and

brake

warillng

Condition

Lamp

does

not

glow

when

ignition

switch

is

turned

ON

with

out

running

engine

Door

and

charge

warning

lamps

do

not

go

out

when

engine

is

started

Charge

waming

amp

Lamp

does

not

go

out

when

engine

is

started

Oil

pressure

warning

lamp

Lamp

does

not

light

when

ignition

switch

is

set

to

ON

Lamp

does

not

go

out

while

engine

is

being

operated

Brake

warning

lamp

Lamp

does

not

go

out

Door

warning

lamp

Lamp

does

not

glow

with

door

opened

and

engine

running

Probable

cause

Burnt

bulb

or

loo

ebulb

Loose

or

poor

connection

Faully

bulb

check

relay

or

alternator

Faully

charging

system

Faully

oil

pressure

switch

or

loose

switch

terminal

connection

When

lead

wire

connected

to

switch

is

grounded

warning

lamp

lights

Lack

of

engine

oil

Oil

pressure

too

low

Faully

oil

pressure

switch

Faulty

hand

brake

switch

When

hand

brake

lever

is

released

Faully

brake

fluid

level

switch

When

brake

fluid

level

is

normal

Faully

door

switch

BE

46

Corrective

action

Replace

bulb

or

correct

Correct

connector

terminal

contacts

Correct

adjust

or

replace

Inspect

charging

system

Replace

or

correct

connection

Check

oil

level

and

add

oil

as

required

Inspect

engine

oil

pressure

system

Replace

Replace

Replace

Replace

Page 499 of 548

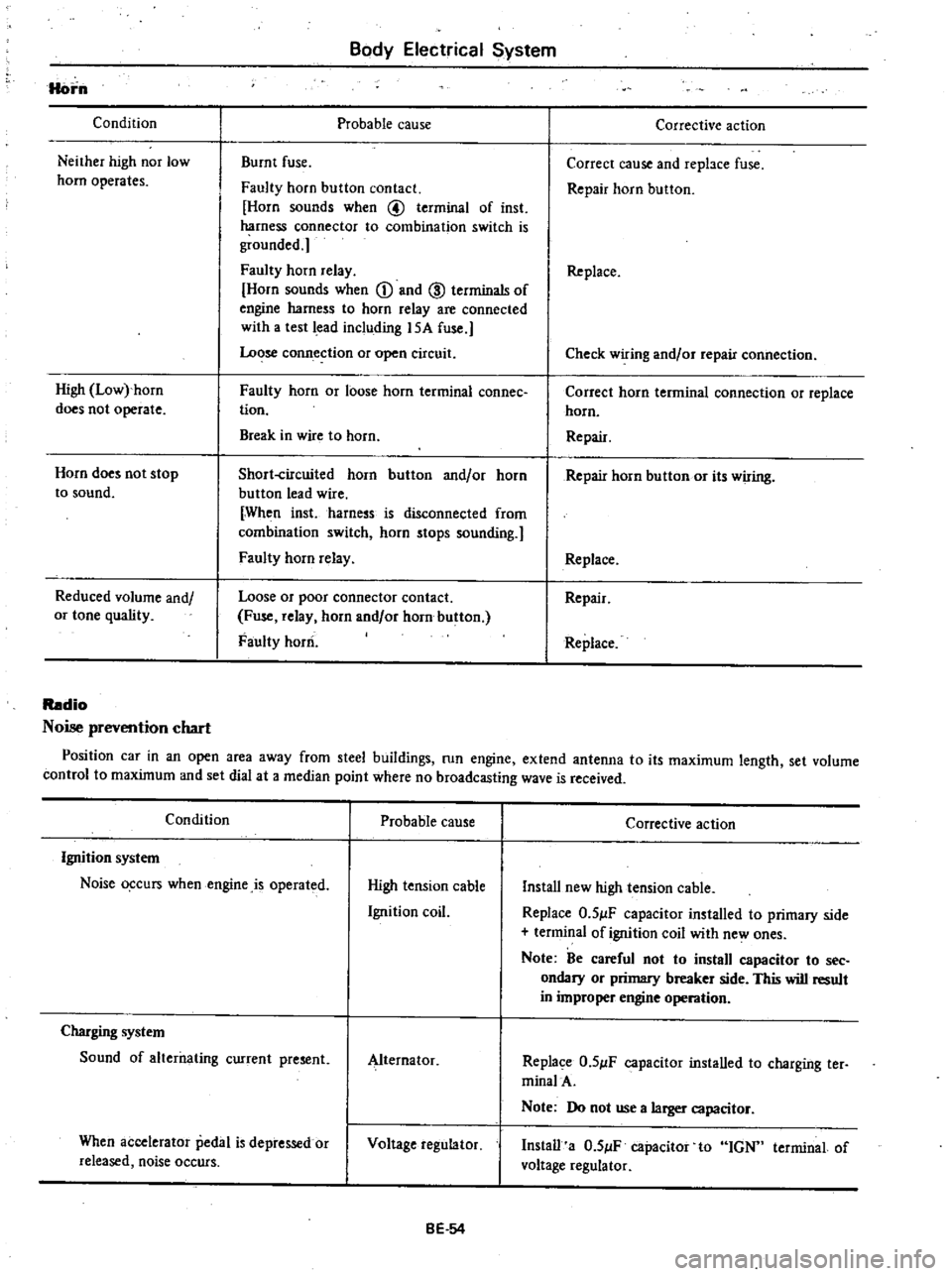

Horn

Condition

Neither

high

nor

low

horn

operates

High

Low

horn

does

not

operate

Horn

does

not

stop

to

sound

Reduced

volume

and

or

tone

quality

Body

Electrical

System

Probable

cause

Burnt

fuse

Faulty

horn

button

contact

Horn

sounds

when

@

terminal

of

inst

harness

connector

to

combination

switch

is

grounded

Faulty

horn

relay

Horn

sounds

when

CD

and

ID

terminals

of

engine

harness

to

horn

relay

are

connected

with

a

test

lead

including

15A

fuse

Lo

se

conn

ection

or

open

circuit

Faulty

horn

or

loose

horn

terminal

connee

tion

Break

in

wire

to

horn

Short

circuited

horn

button

and

or

horn

button

lead

wire

When

inst

harness

is

disconnected

from

combination

switch

horn

stops

sounding

Faulty

horn

relay

Loose

or

poor

connector

contact

Fuse

relay

horn

and

or

horn

button

Faulty

horn

Corrective

action

Correct

cause

and

repbce

fuse

Repair

horn

button

Replace

Check

wiring

and

or

repair

connection

Correct

horn

terminal

connection

or

replace

horn

Repair

Repair

horn

button

or

its

wiring

Replace

Repair

Replace

Radio

Noise

prevention

chart

Position

car

in

an

open

area

away

from

steel

buildings

run

engine

extend

antenna

to

its

maximum

length

set

volume

control

to

maximum

and

set

dial

at

a

median

point

where

no

broadcasting

wave

is

received

Condition

Probable

cause

Ignition

system

Noise

o

curs

when

engine

is

operated

High

tension

cable

Ignition

coil

Charging

system

Sound

of

alterilating

current

present

Alternator

When

accelerator

pedal

is

depressed

or

released

noise

occurs

Voltage

regulator

BE

54

Corrective

action

Install

new

high

tension

cable

Replace

O

5

lF

capacitor

installed

to

primary

side

terminal

of

ignition

coil

with

ne

ones

Note

Be

careful

not

to

install

capacitor

to

see

ondary

or

primary

breaker

side

This

will

result

in

improper

engine

operation

Replace

O

5

lF

capacitor

installed

to

charging

ter

minalA

Note

Do

not

use

a

larger

capacitor

Install

a

O

5

lF

capacitor

to

IGN

terminal

of

voltage

regulator

Page 526 of 548

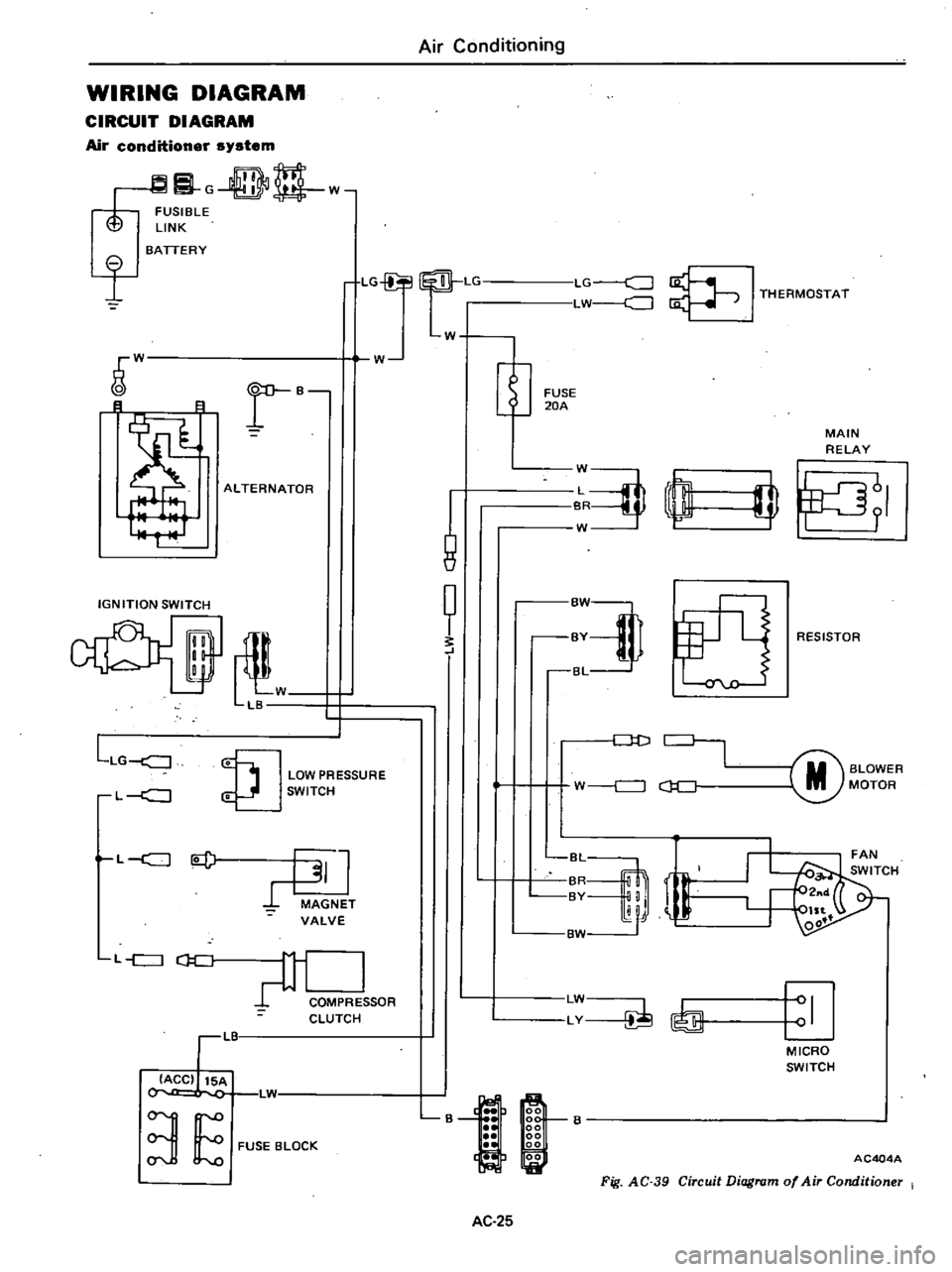

WIRING

DIAGRAM

CIRCUIT

DIAGRAM

Air

conditioner

system

G

DD

w

FUSIBLE

LINK

I

BATTERY

LG

Lr

LG

c

J

LW

J

I

THERMOSTAT

W

W

r

B

B

8

ALTERNATOR

IGNITION

SWITCH

il

W

LB

LLG

J

LOW

PRESSURE

SWITCH

L

c

J

L

c

J

l

J

MAGNET

VALVE

L

c

J

CJ

C

COMPRE

SOR

CLUTCH

LIT

IACC

15A

L1

3

E

FUSE

BLOCK

Air

Conditioning

W

1

8

t

FUSE

20A

MAIN

RELAY

J

rn

W

I

fJ

RESISTOR

Dt

J

M

BLOWER

MOTOR

W

c

J

c

J

C

r

BvM

LW

LY

I

MICRO

SWITCH

B

AC404A

Fig

AC

39

Circuit

Diagram

of

Air

Conditioner

I

AC

25