DATSUN 510 1968 Service Repair Manual

Manufacturer: DATSUN, Model Year: 1968, Model line: 510, Model: DATSUN 510 1968Pages: 252, PDF Size: 12.2 MB

Page 111 of 252

106

CHAPTER

NINE

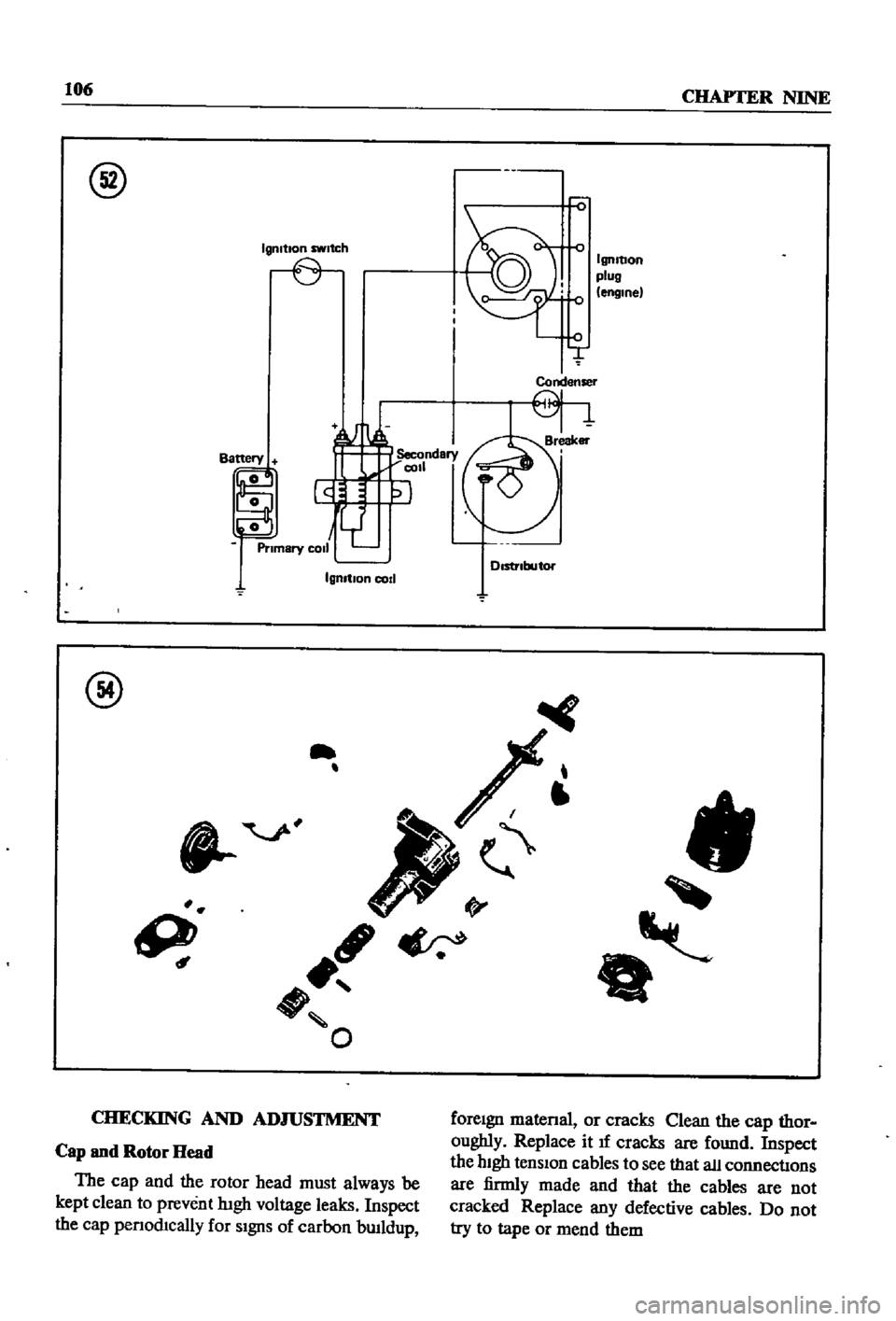

@

Igmtlon

switch

IgnItion

plug

engine

Condenser

IgnItIon

cod

@

II

9

ft

O

CHECKING

AND

ADJUSTMENT

foreIgn

matenal

or

cracks

Qean

the

cap

thor

oughly

Replace

it

If

cracks

are

found

Inspect

the

hIgh

tensIon

cables

to

see

that

all

connectIons

are

firmly

made

and

that

the

cables

are

not

cracked

Replace

any

defective

cables

Do

not

try

to

tape

or

mend

them

Cap

and

Rotor

Head

The

cap

and

the

rotor

head

must

always

be

kept

clean

to

prevent

lugh

voltage

leaks

Inspect

the

cap

penod1cally

for

SIgnS

of

carbon

bwldup

Page 112 of 252

24

21

TO

oto

25

1

17

18

19

o

15

16

20

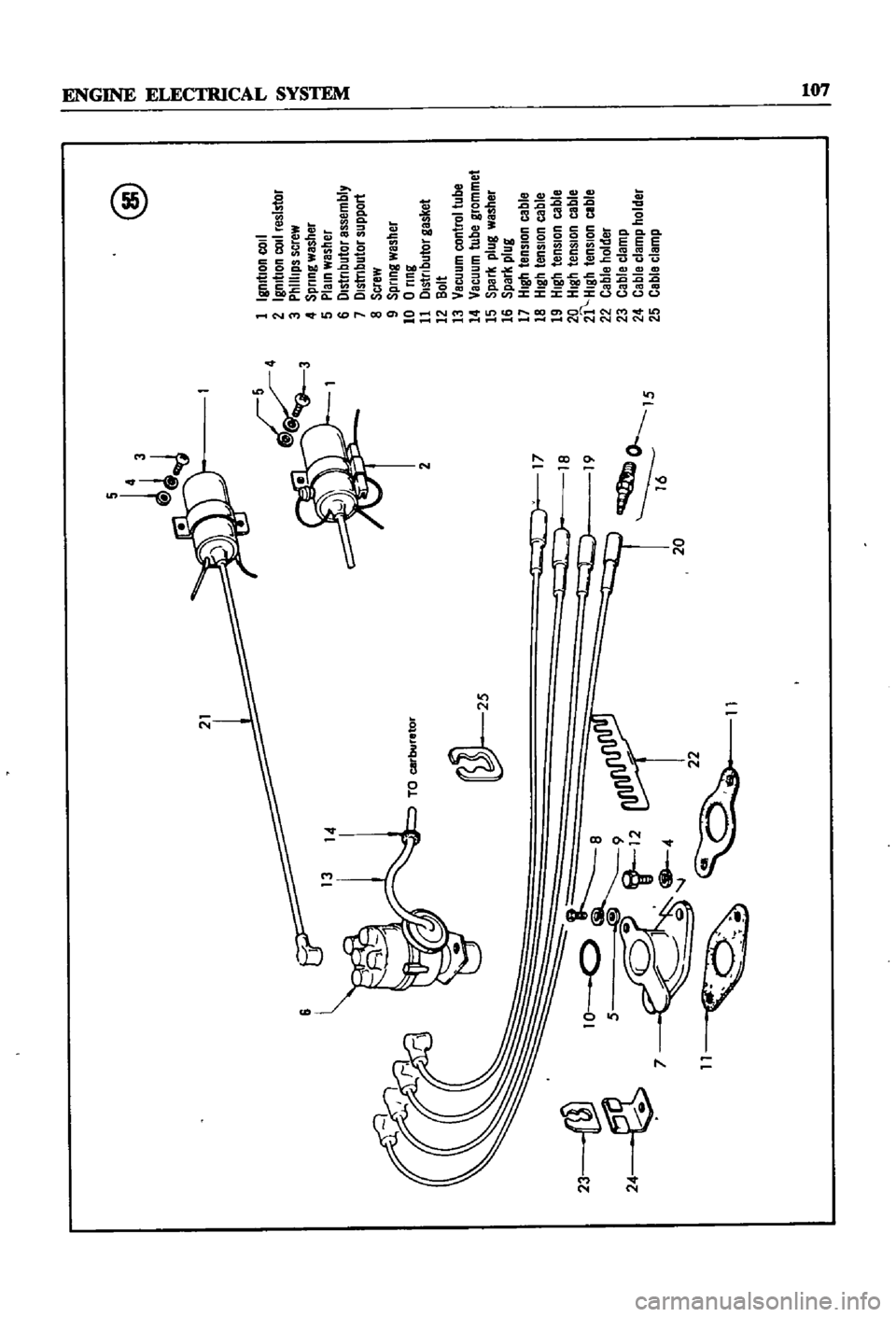

@

1

IgnItIon

coIl

2

Ignlllon

COIl

resls

Ol

3

p

II

lS

sere

ll

4

spnng

lles1

Br

5

PlaIn

wesner

6

illstl

OUtor

assembly

1

illstllbu

Ol

sUP

rt

II

sere

ll

9

spnng

wesner

10

0

ling

11

Ills

nbutor

gasket

12

llolt

13

VaCUum

control

tube

14

Vecuum

tube

grommet

IS

spar

plug

IIeslIer

1

sperll

plug

11

111gb

tenSIon

cable

18

IIlglllenSIOn

cable

19

lI

gll

tensIon

cable

20

IIlgII

tensIon

cable

ii

lIlgII

tenSion

cable

22

Ceble

older

23

Cable

c1emp

24

cable

clempllOlder

25

Ceble

clemp

J

Page 113 of 252

9

10

4

17

141

18

I

19

21

8

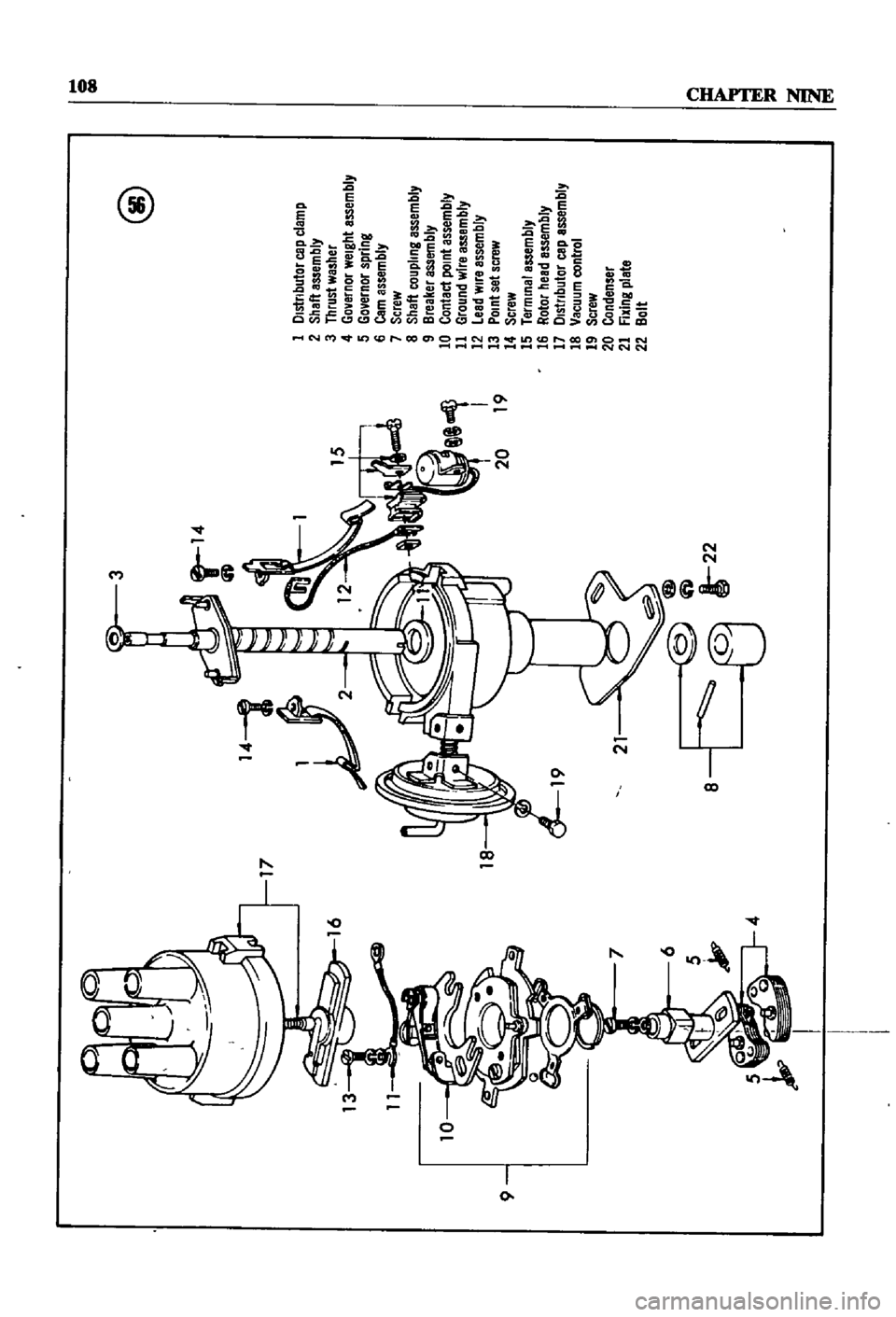

@

1

Distributor

cap

clamp

2

Shaft

assembly

3

Thrust

washer

4

Governor

weight

assembly

5

Governor

spring

6

Cam

assembly

7

Screw

8

Shaft

coupling

assembly

9

Breaker

assembly

10

Contact

POint

assembly

11

Ground

wire

assembly

12

Lead

wire

assembly

13

POlntset

screw

14

Screw

15

Terminal

assembly

16

Rotor

head

assembly

17

Dlstllbutor

cap

assambly

18

Vacuum

control

19

Screw

20

Condensar

21

fixing

plate

22

Bolt

e

OIl

Page 114 of 252

21

b

14

1

8

6

L

5

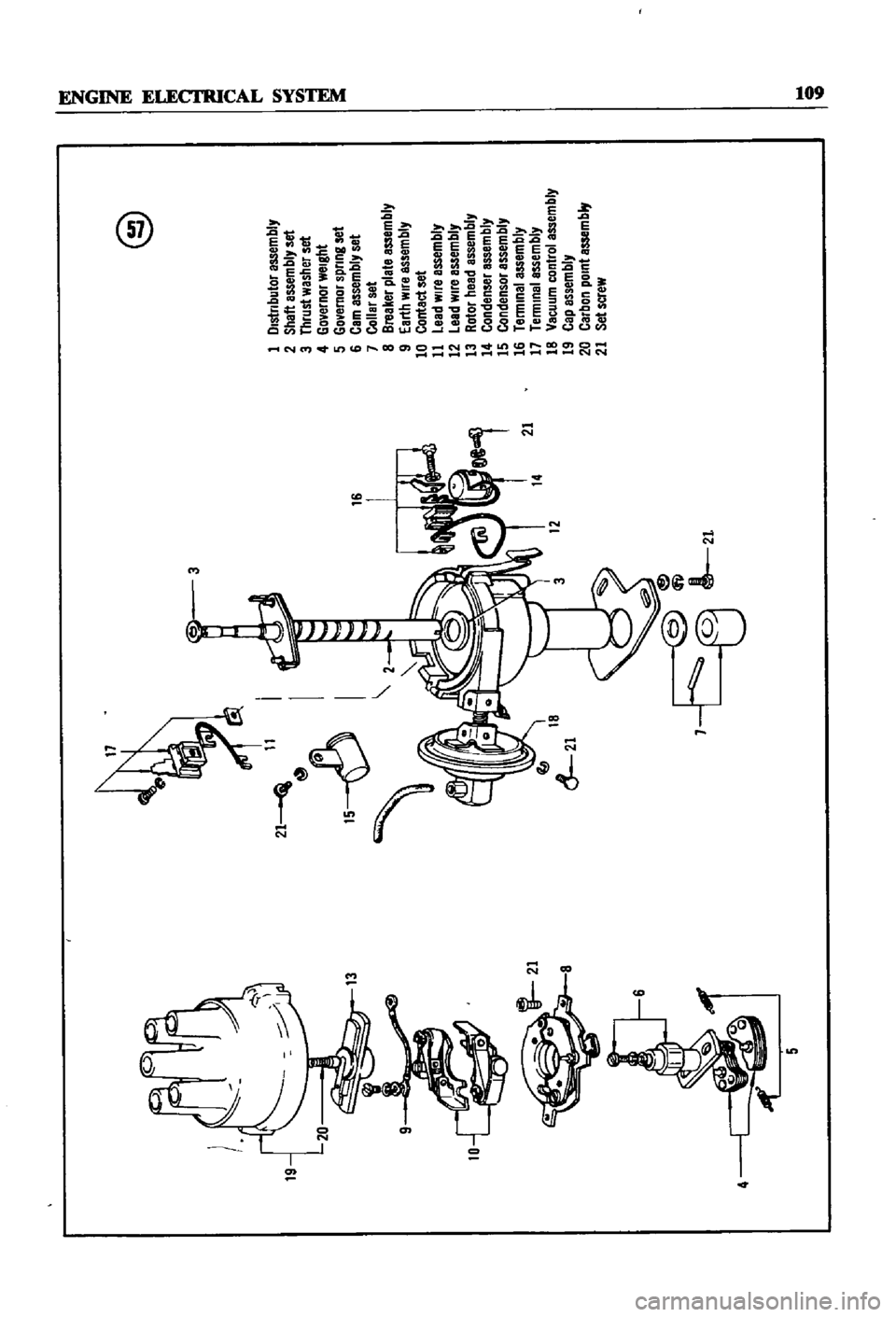

@

21

1

Dlstllbutor

assembly

2

Shaft

assemblY

set

3

tbrust

washer

set

4

Go

ernor

W81g1lt

5

Govemor

BPllng

set

6

Cem

assemblY

set

1

co

leT5at

8

Breeker

plete

essembly

9

Eartn

Wile

essembly

10

contect

set

11

lead

Wile

essemblY

12

lead

Wile

assemblY

13

Rotor

need

assembly

14

Condenser

essembly

15

Condensor

essembly

16

lemllna

BSSembly

11

lennlnel

BSSembly

18

Vacuum

control

assemblY

19

Cep

essemblY

20

Carbon

pOint

essemb

21

set

screVl

12

i

Page 115 of 252

110

CHAPTER

NINE

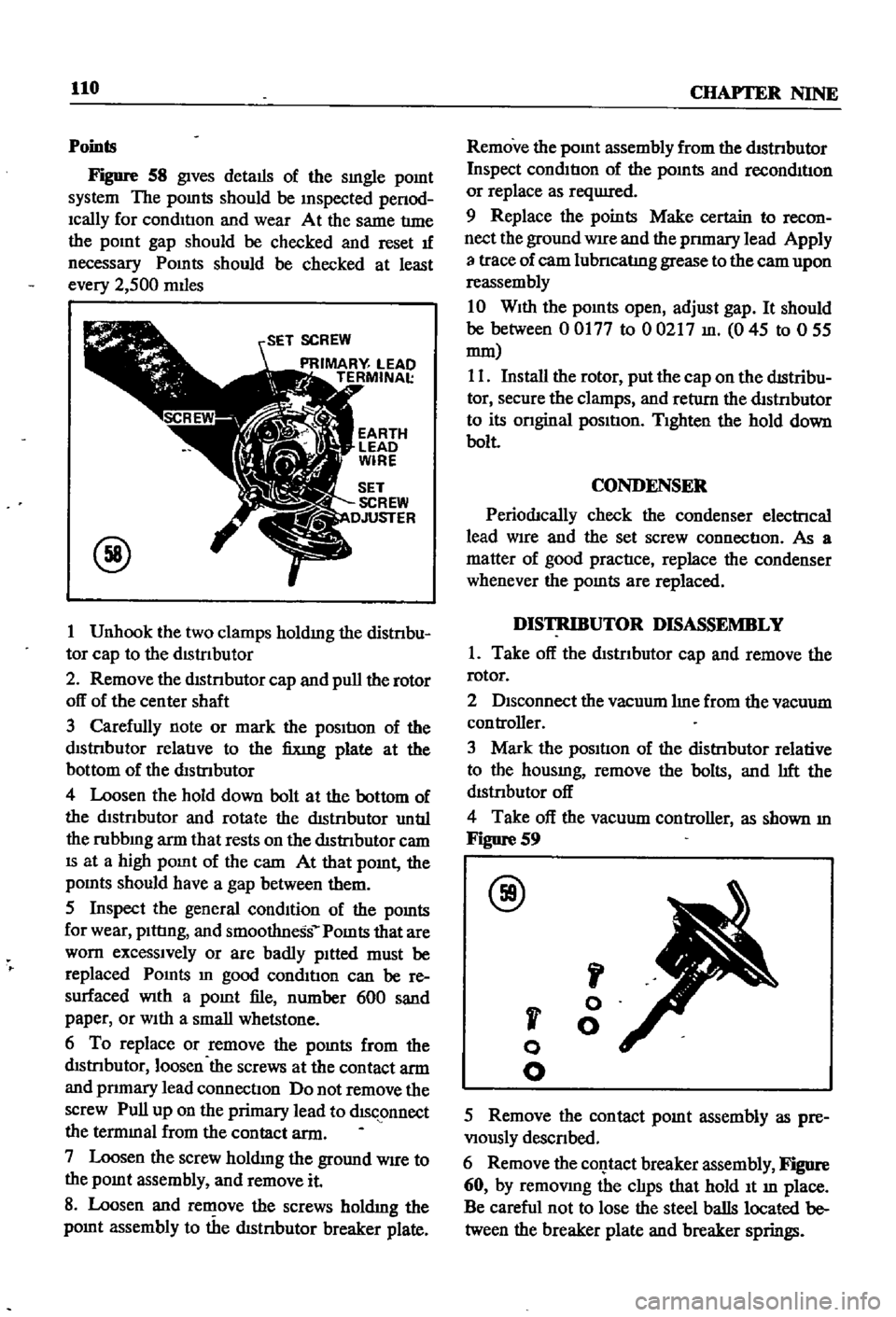

Points

Figure

S8

gives

details

of

the

sIngle

pomt

system

The

pomts

should

be

Inspected

penod

Ically

for

condItIon

and

wear

At

the

same

tlme

the

pOInt

gap

should

be

checked

and

reset

1f

necessary

Pomts

should

be

checked

at

least

every

2

500

mIles

SET

SCREW

PRIMARY

LEAD

TERMINAl

@

1

Unhook

the

two

clamps

holdmg

the

distnbu

tor

cap

to

the

dIStrIbutor

2

Remove

the

dlstnbutor

cap

and

pull

the

rotor

off

of

the

center

shaft

3

Carefully

note

or

mark

the

pOSItIon

of

the

dIStrIbutor

relatIve

to

the

fixmg

plate

at

the

bottom

of

the

distrIbutor

4

Loosen

the

hold

down

bolt

at

the

bottom

of

the

dlstnbutor

and

rotate

the

dIStnbutor

untIl

the

rubbmg

arm

that

rests

on

the

dIStrIbutor

cam

IS

at

a

high

pomt

of

the

cam

At

that

pomt

the

pomts

should

have

a

gap

between

them

5

Inspect

the

general

condItion

of

the

pomts

for

wear

pIttIng

and

smoot1mess

Pomts

that

are

worn

excessIvely

or

are

badly

pItted

must

be

replaced

Pomts

In

good

condItIon

can

be

re

surfaced

With

a

pOInt

file

number

600

sand

paper

or

WIth

a

small

whetstone

6

To

replace

or

remove

the

pomts

from

the

dIStrIbutor

loosen

the

screws

at

the

contact

arm

and

pnmary

lead

connectIOn

Do

not

remove

the

screw

Pull

up

on

the

primary

lead

to

dISc

onnect

the

termmal

from

the

contact

arm

7

Loosen

the

screw

holdmg

the

ground

WIre

to

the

pOInt

assembly

and

remove

it

S

Loosen

and

rell

ove

the

screws

holdIng

the

pomt

assembly

to

the

dIStnbutor

breaker

plate

Remove

the

pOInt

assembly

from

the

dIStrIbutor

Inspect

condItIon

of

the

pOInts

and

reconditIon

or

replace

as

reqUIred

9

Replace

the

points

Make

certain

to

recon

nect

the

ground

WIre

and

the

pnmary

lead

Apply

3

trace

of

cam

lubncatlng

grease

to

the

cam

upon

reassembly

10

WIth

the

pOInts

open

adjust

gap

It

should

be

between

00177

to

00217

In

045

to

055

mm

11

Install

the

rotor

put

the

cap

on

the

dIStribu

tor

secure

the

clamps

and

return

the

dtstrIbutor

to

its

onginal

pOSItIon

TIghten

the

hold

down

bolt

CONDENSER

PeriodJcally

check

the

condenser

electrIcal

lead

wire

and

the

set

screw

connectIon

As

a

matter

of

good

practIce

replace

the

condenser

whenever

the

pomts

are

replaced

DISTRIBUTOR

DISASSEMBLY

1

Take

off

the

dIstrIbutor

cap

and

remove

the

rotor

2

DIsconnect

the

vacuum

me

from

the

vacuum

con

troller

3

Mark

the

pOSItIon

of

the

distrIbutor

relative

to

the

housmg

remove

the

bolts

and

lIft

the

dIstrIbutor

off

4

Take

off

the

vacuum

controller

as

shown

m

F1gDre

S9

@

J

I

v

o

o

o

o

5

Remove

the

contact

pOInt

assembly

as

pre

VIously

descnbed

6

Remove

the

c01Jtact

breaker

assembly

Figure

60

by

remOVIng

the

clIps

that

hold

It

m

place

Be

careful

not

to

lose

the

steel

balls

located

be

tween

the

breaker

plate

and

breaker

springs

Page 116 of 252

ENGINE

ELECTRICAL

SYSTEM

111

@

7

WIth

a

hammer

and

punch

knock

out

the

pm

holdmg

the

collar

set

to

the

shaft

Be

certain

to

mark

the

relatIve

locatIon

of

the

collar

set

to

the

shaft

before

removal

See

Figure

61

@

8

Remove

the

shaft

and

cam

as

shown

m

Figure

62

@

V

t

0

ao

9

Remove

the

cam

by

removmg

the

set

screw

at

the

top

of

the

shaft

and

pulling

the

cam

off

Be

certam

to

mark

the

cam

location

relatIve

to

the

shaft

before

removal

See

Figure

63

@

10

Inspect

all

parts

carefully

for

SIgnS

of

wear

or

damage

Replace

defectIve

parts

Assembly

of

the

dIStrIbutor

IS

the

reverse

of

disassembly

Make

certam

all

parts

are

rein

stalled

m

the

same

relative

location

to

the

shaft

1S

when

removed

Refer

to

Figure

64

for

setting

the

governor

springs

and

cam

See

Table

1

page

112

for

Distributor

SpecIficatIons

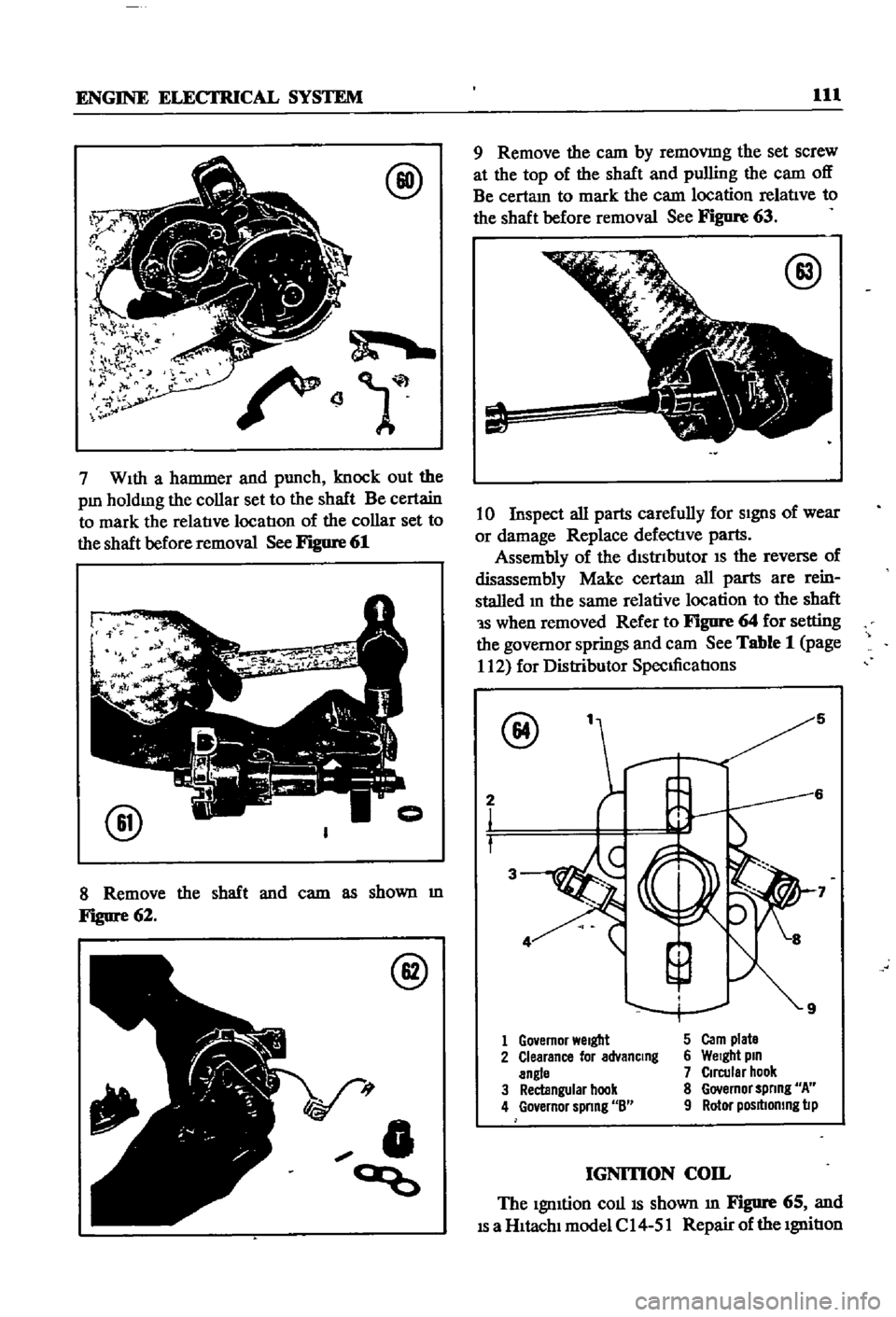

@

5

2

3

1

Go

emor

Welgbt

5

Carn

plate

2

Clearance

lor

advanCing

6

Welgbt

pin

angle

7

Circular

hook

3

Rectangular

hook

8

Governor

spnng

A

4

Go

ernor

spnng

8

9

Rotor

posltlomng

lip

IGNITION

COIL

The

IgnItion

COllIS

shown

m

Figure

65

and

IS

a

HItachI

model

C

14

51

Repair

of

the

IgnitIon

Page 117 of 252

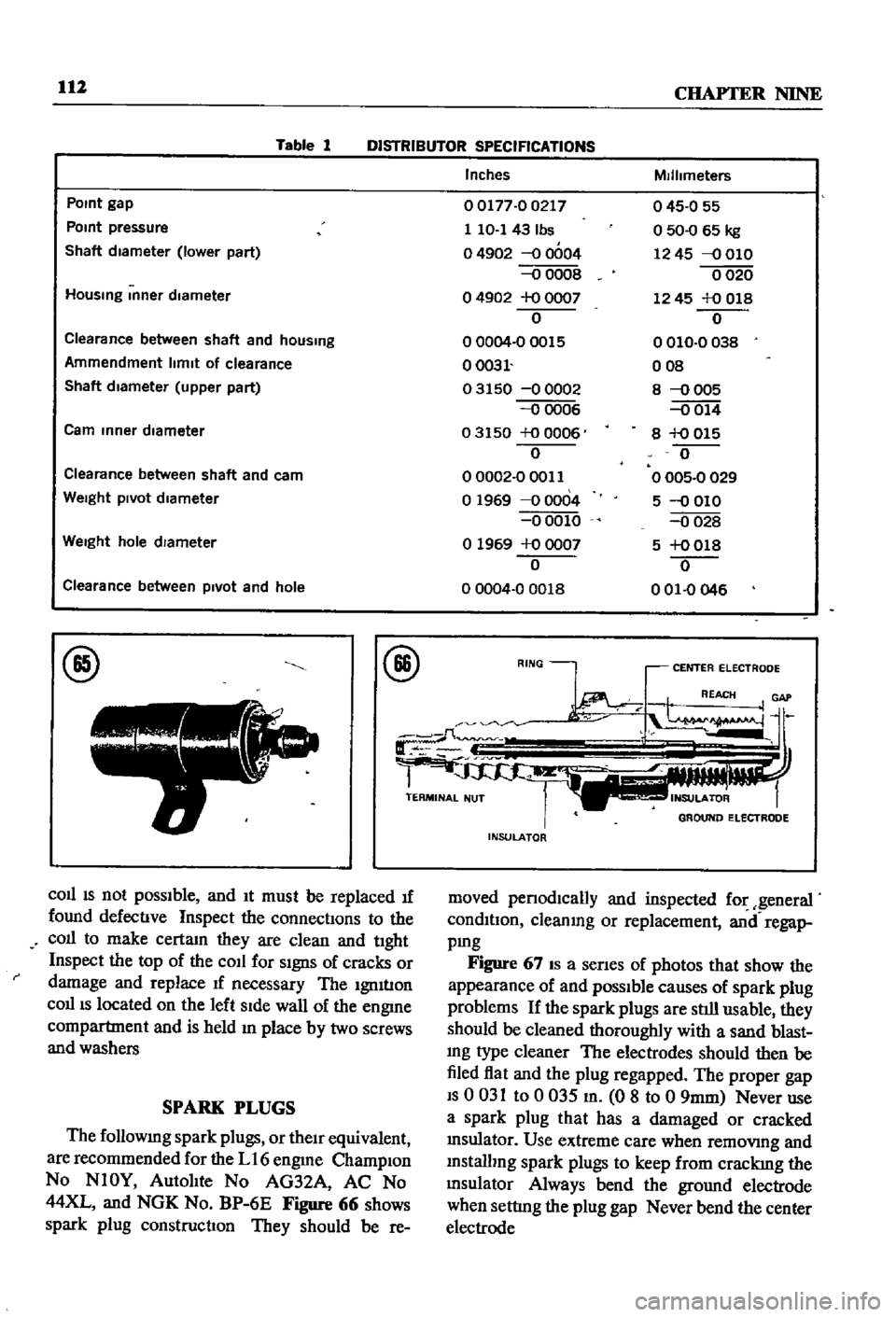

112

Table

1

CHAPTER

NINE

DISTRIBUTOR

SPECIFICATIONS

POint

gap

POint

pressure

Shaft

diameter

lower

part

HOUSing

Inner

diameter

Clearance

between

shaft

and

hOUSing

Ammendment

limit

ot

clearance

Shaft

diameter

upper

part

Cam

Inner

diameter

Clearance

between

shaft

and

cam

Weight

piVOt

dIameter

Weight

hole

dIameter

Clearance

between

piVOt

and

hole

Inches

Millimeters

00177

00217

1

10

143

Ibs

o

4902

0004

0008

o

4902

0

0007

o

00004

00015

00031

03150

0002

0006

03150

0

0006

o

00002

00011

o

1969

00004

00010

01969

0

0007

o

o

0004

0

0018

o

45

0

55

o

50

0

65

kg

1245

010

0020

1245

0

018

o

OlD

O

038

008

8

005

014

8

0

015

o

o

005

0

029

5

010

028

5

0

018

0

001

0046

@

@

r

COllIS

not

pOSSIble

and

It

must

be

replaced

1f

found

defectIve

Inspect

the

connectIons

to

the

coll

to

make

certaIn

they

are

clean

and

tIght

Inspect

the

top

of

the

coIl

for

SIgnS

of

cracks

or

damage

and

replace

1f

necessary

The

Ignluon

COllIS

located

on

the

left

SIde

wall

of

the

engme

compartment

and

is

held

In

place

by

two

screws

and

washers

SPARK

PLUGS

The

followmg

spark

plugs

or

then

equivalent

are

recommended

for

the

L16

engme

ChampIon

No

NlOY

AutolIte

No

AG32A

AC

No

44XL

and

NGK

No

BP

6E

Figure

66

shows

spark

plug

constroctIon

They

should

be

re

RING

CENTER

ELECTRODE

TERMINAL

NUT

IS

r

1

n

f

INSULATOR

moved

penodlcally

and

inspected

for

general

condItIon

cleanmg

or

replacement

anl

regap

pmg

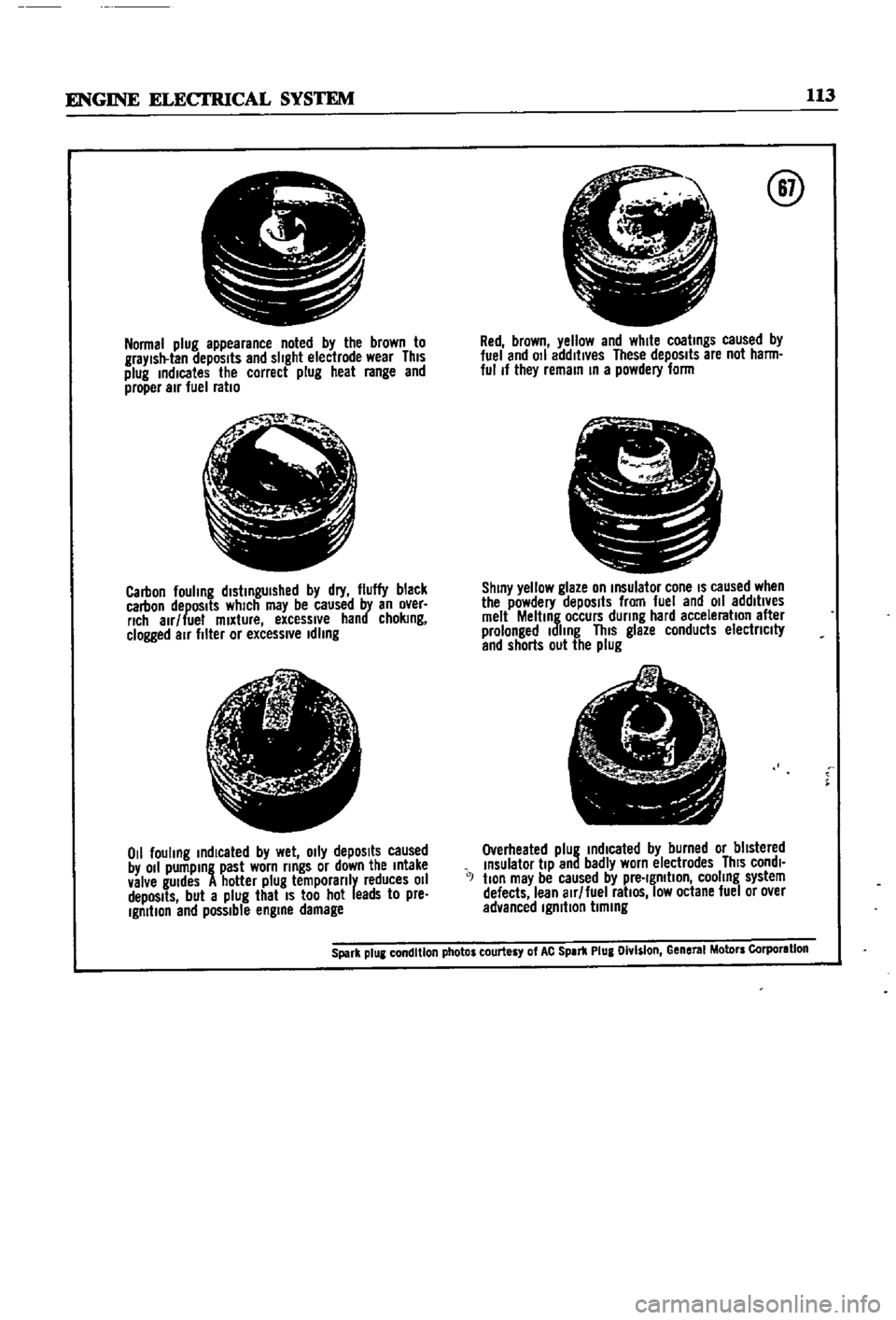

Figure

67

IS

a

senes

of

photos

that

show

the

appearance

of

and

pOSSIble

causes

of

spark

plug

problems

If

the

spark

plugs

are

still

usable

they

should

be

cleaned

thorougWy

with

a

sand

blast

Ing

type

cleaner

The

electrodes

should

then

be

filed

flat

and

the

plug

regapped

The

proper

gap

IS

0

031

to

0035

m

0

8

to

0

9mm

Never

use

a

spark

plug

that

has

a

damaged

or

cracked

msulator

Use

extreme

care

when

remOVIng

and

mstallmg

spark

plugs

to

keep

from

crackIng

the

msulator

Always

bend

the

ground

electrode

when

settmg

the

plug

gap

Never

bend

the

center

electrode

Page 118 of 252

ENGINE

ELECI

RICAL

SYSTEM

113

i

Normal

plug

appearance

noted

by

the

brown

to

graYlsll

lan

depOSits

and

slight

eleclrode

wear

This

plug

indicates

the

correct

plug

heal

range

and

proper

air

fuel

ratio

jI

Jo

t

Ql

i

Carbon

fouhng

distinguished

by

dry

fluffy

black

carbon

depOSits

which

may

be

caused

by

an

over

rich

alr

lue

mixture

excessive

hand

choking

clogged

air

filler

or

excessl

e

Idling

t

I

j

if

r

l

1

tfc

ji

0

1

fouling

indicated

by

wet

o

ly

depOSits

caused

by

011

pumping

past

worn

rings

or

down

the

Intake

valve

gUIdes

A

hotter

plug

temporanly

reduces

011

depOSits

but

a

plug

that

IS

too

hot

leads

to

pre

Ignition

end

possible

engine

damage

@

Red

brown

yellow

and

white

coatings

caused

by

luel

and

011

addltl

es

These

depOSits

are

not

harm

ful

If

they

remain

In

a

powdery

lorm

pr

11

L

J

J

S

C

ShinY

yellow

glaze

on

Insulalor

cone

IS

caused

when

the

powdery

depOSits

from

fuel

and

011

addltl

es

melt

Melting

occurs

during

hard

acceleration

alter

prolonged

Idling

This

glaze

conducts

electnclty

and

shorts

out

the

plug

e

1

A

I

A

I

7

Overheated

plug

indIcated

by

burned

or

blistered

Insulator

tiP

and

badly

worn

electrodes

ThiS

condl

J

tlon

may

be

caused

by

pre

Ignition

cooling

system

defects

lean

alr

luel

ratiOS

low

octane

luel

or

o

er

advanced

Ignition

timing

Spark

plUI

condition

photos

courtesy

of

AC

SPIr1l

Plug

Olv

s

on

Gene

MolDrs

Corporlllon

Page 119 of 252

CHAPTER

TEN

EMISSION

CONTROL

SYSTEM

ThIs

chapter

covers

emission

control

and

exhaust

systems

The

emission

devices

used

in

clude

crankcase

ermssion

controls

an

exhaust

ermssion

system

and

evaporative

emission

con

trols

EXHAUST

EMISSION

CONTROL

SYSTEM

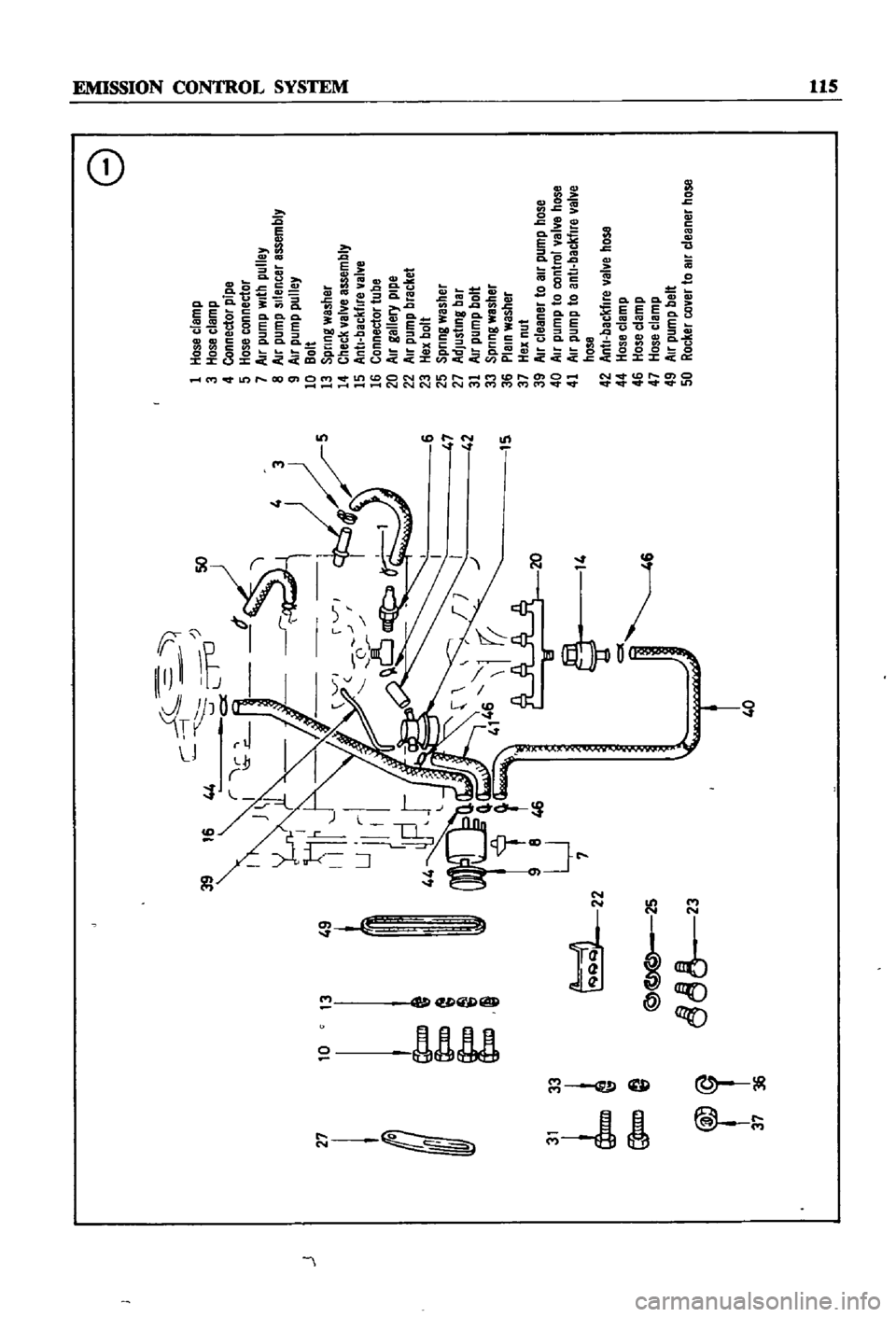

Two

methods

of

exhaust

emission

control

are

used

on

the

Datsun

One

is

an

aIr

injection

system

the

other

consists

of

engine

modifica

tIons

Datsuns

were

equipped

With

the

air

injec

tIon

system

only

through

1970

SInce

then

all

models

have

combined

aIr

mjection

with

engine

modIficatIons

EmisSIon

servicing

IS

complex

and

should

be

left

to

qualIfied

professionals

Figure

1

Illustrates

the

system

used

through

model

year

1969

Figure

2

IS

the

system

used

after

1970

Figures

3

through

7

offer

detaIls

of

various

emission

components

Maintenance

and

Testing

Penodlc

mspection

and

service

should

be

done

every

12

months

or

12

000

miles

The

engine

must

be

in

good

working

order

to

main

tain

a

low

level

of

harmful

emissions

There

fore

perform

a

general

tune

up

as

spec1fied

in

Chapter

Four

before

followmg

the

procedures

below

CRANKCASE

EMISSION

CONTROL

SYSTEM

The

crankcase

emission

control

system

is

shown

in

FlgDre

8

It

IS

a

closed

system

that

pre

vents

crankcase

gases

from

escaping

to

the

at

mosphere

Blowby

gases

are

dIrected

to

the

intake

manifold

through

the

ventilation

control

valve

Normally

capacity

of

the

valve

is

suffi

cient

to

handle

the

blowby

gas

plus

a

small

amount

of

ventIlating

air

drawn

from

the

air

cleaner

through

a

tube

leading

to

the

crankcase

Under

fun

throttle

condItIons

manifold

vacuum

is

Insufficient

to

draw

the

blowby

through

the

valve

When

this

happens

b10wby

flows

through

the

system

In

the

reverse

dIrection

General

1

Start

the

engine

and

bring

up

to

operating

temperature

2

Check

hoses

and

hose

connections

for

leaks

3

Examine

the

hoses

for

signs

of

cracks

or

de

terioraoon

Replace

as

required

Crankcase

Ventilation

Control

Valve

1

Start

the

engme

2

Remove

the

ventIlator

hose

from

the

crank

case

ventilatIon

control

valve

A

htssmg

nOISe

Page 120 of 252

27

10

13

49

j

l

e

1

1

31

33

22

@

@

25

f

1

d

37

36

6

40

ell

o

z

o

o

t

1

Hose

clamp

3

Hose

clamp

4

Connector

pipe

5

Hose

connector

7

Air

pump

With

pulley

8

Air

pump

silencer

assembly

9

Air

pump

pulley

10

Bolt

13

Spring

washer

14

Check

al

e

assembly

15

Anti

backfire

alve

16

Connector

tube

20

Air

gallery

pipe

22

Air

pump

bracket

23

Hex

bolt

25

Spring

washer

27

Adjusting

bar

31

Air

pump

bolt

33

Spring

washer

36

Plain

washer

37

Hex

nut

39

Air

cleaner

to

all

pump

hose

40

All

pump

to

control

al

e

hose

41

Air

pump

to

anti

backfire

val

e

hose

42

Anti

backfire

al

e

hose

44

Hose

clam

p

46

Hose

clam

p

47

Hose

clamp

49

Air

pum

p

belt

50

Rocker

co

er

to

air

cleaner

hose

VI