DATSUN B110 1973 Service Repair Manual

Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 101 of 513

FRONT

AXLE

FRONT

SUSPENSION

I

f

f

ij

Reassembly

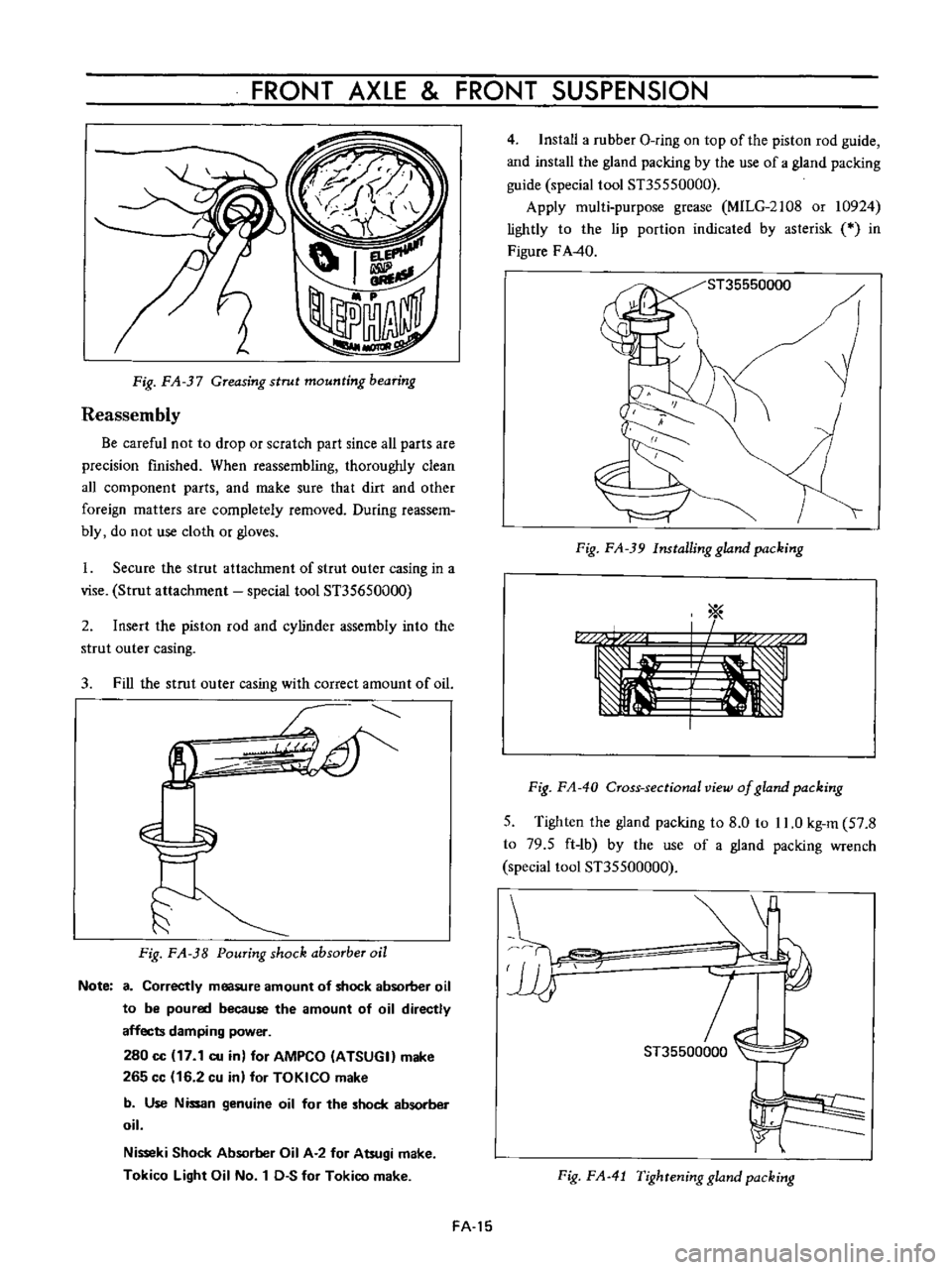

Fig

FA

37

Greasing

strut

mounting

bearing

Be

careful

not

to

drop

or

scratch

part

since

all

parts

are

precision

finished

When

reassembling

thoroughly

clean

all

component

parts

and

make

sure

that

dirt

and

other

foreign

matters

are

completely

removed

During

reassem

bly

do

not

use

cloth

or

gloves

I

Secure

the

strut

attachment

of

strut

Quter

casing

in

a

vise

Strut

attachment

special

tool

ST35650000

2

Insert

the

piston

rod

and

cylinder

assembly

into

the

strut

outer

casing

3

Fill

the

strut

outer

casing

with

correct

amount

of

oil

1

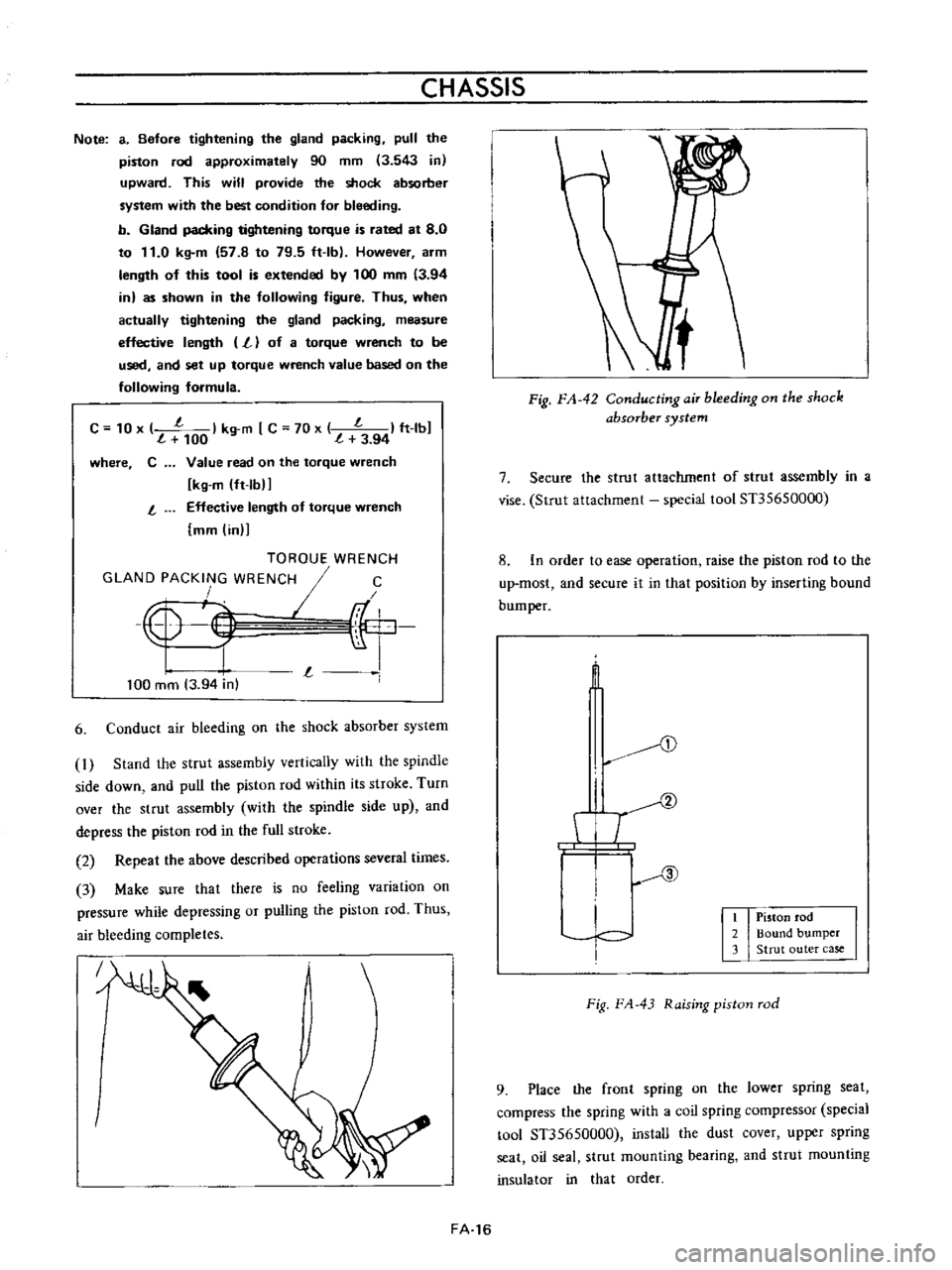

Fig

FA

38

Pouring

shock

absorber

oil

Note

a

Correctly

measure

amount

of

shock

absorber

oil

to

be

poured

because

the

amount

of

oil

directly

affects

damping

power

280

cc

17

1

cu

in

for

AMPCO

ATSUGI

make

265

cc

16

2

cu

in

for

TOKICO

make

b

Use

Nissan

genuine

oil

for

the

shock

absorber

oil

Nisseki

Shock

Absorber

Oil

A

2

for

Atsugi

make

Tokico

light

Oil

No

1

D

S

for

Tokico

make

FA

15

4

Install

a

rubber

O

ring

on

top

of

the

piston

rod

guide

and

install

the

gland

packing

by

the

use

of

a

gland

packing

guide

special

tool

ST35550000

Apply

multi

purpose

grease

MILG

2108

or

10924

lightly

to

the

lip

portion

indicated

by

asterisk

0

in

Figure

F

A40

ST35550000

1

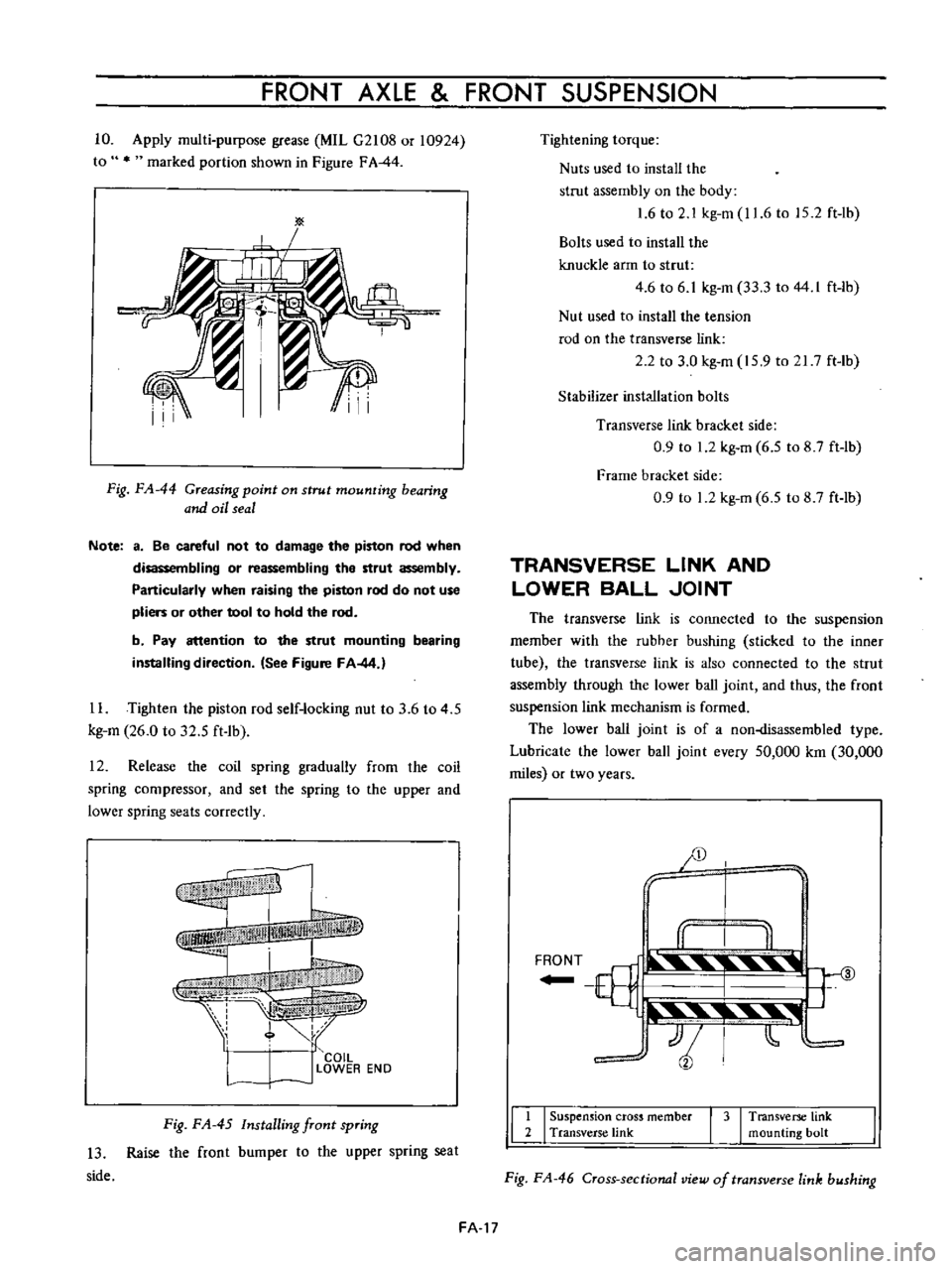

Fig

FA

39

Installing

gland

packing

a

1

c

I

Fig

FA

40

Cross

sectional

view

of

gland

packing

5

Tighten

the

gland

packing

to

8

0

to

11

0

kg

m

57

8

to

79

5

ft

1b

by

the

use

of

a

gland

packing

wrench

special

tool

ST35500000

ST35500000

Fig

FA

41

Tighrening

gland

packing

Page 102 of 513

CHASSIS

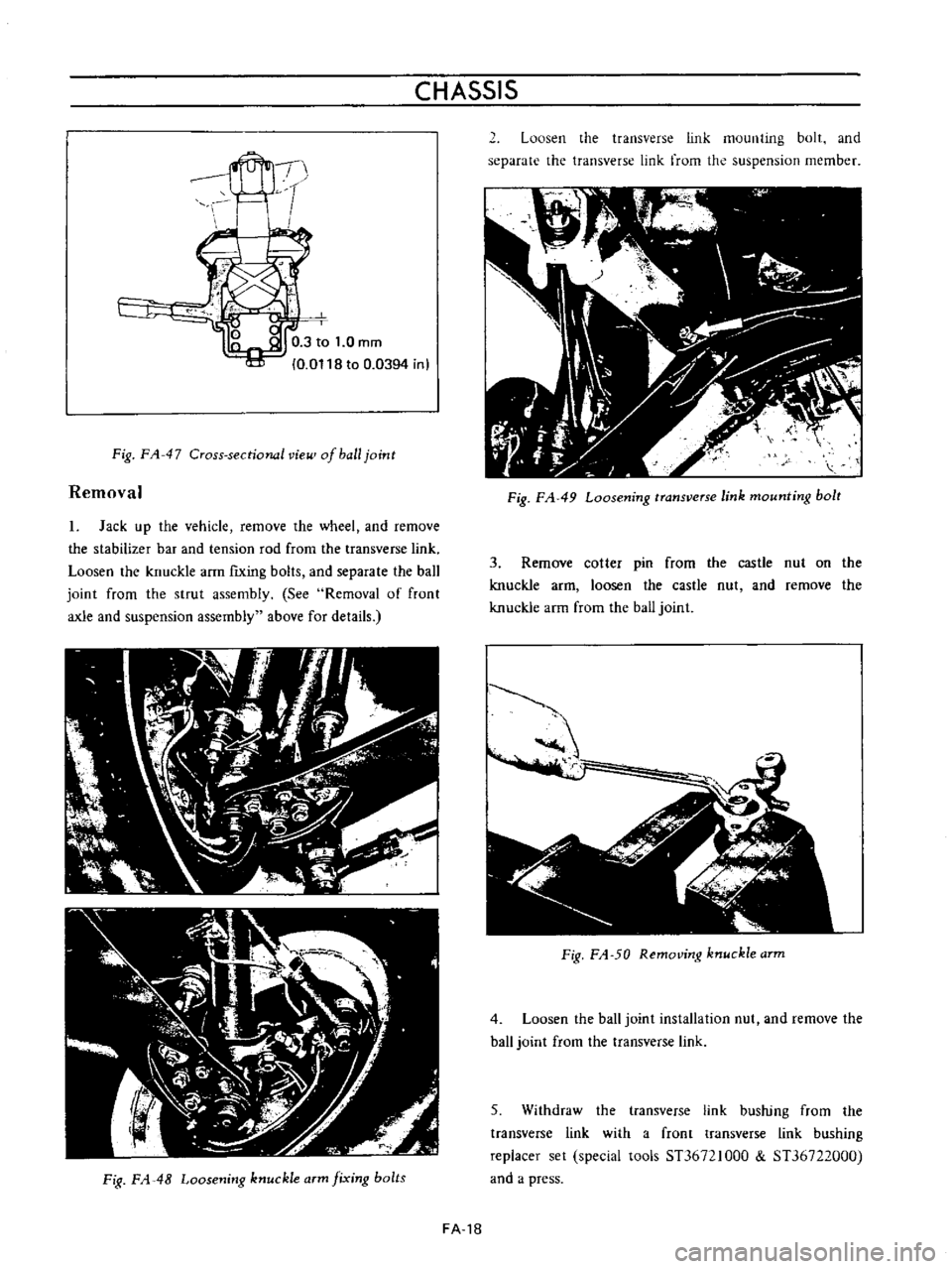

Note

a

Before

tightening

the

gland

packing

pull

the

piston

rod

approximately

90

mm

3

543

in

upward

This

will

provide

the

shock

absorber

system

with

the

best

condition

for

bleeding

b

Gland

packing

tightening

torque

is

rated

at

8

0

to

11

0

kg

m

57

8

to

79

5

ft

Ib

However

arm

length

of

this

tool

is

extended

by

100

mm

3

94

in

as

shown

in

the

following

figure

Thus

when

actually

tightening

the

gland

packing

measure

effective

length

L

of

a

torque

wrench

to

be

used

and

set

up

torque

wrench

value

based

on

the

following

formula

C

10

x

l

I

kg

m

C

70

x

l

I

ft

lbJ

100

l

3

94

where

C

Value

read

on

the

torque

wrench

kg

m

ft

lbIJ

Effective

length

of

torque

wrench

mm

in

l

TOROUE

WRENCH

GLAND

PACKING

WRENCH

I

C

4

F

r

I

L

I

100

mm

3

94

in

6

Conduct

air

bleeding

on

the

shock

absorber

system

1

Stand

the

strut

assembly

vertically

with

the

spindle

side

down

and

pull

the

piston

rod

within

its

stroke

Turn

over

the

strut

assembly

with

the

spindle

side

up

and

depress

the

piston

rod

in

the

full

stroke

2

Repeat

the

above

described

operations

several

times

3

Make

sure

that

there

is

no

feeling

variation

on

pressure

while

depressing

or

pulling

the

piston

rod

Thus

air

bleeding

completes

J

FA

16

Fig

FA

42

ConductingaiT

bleeding

on

the

shock

absorber

system

7

Secure

the

strut

attachment

of

strut

assembly

in

a

vise

Strut

attachment

special

tool

Sn5650000

8

In

order

to

ease

operation

raise

the

piston

rod

to

the

up

most

and

secure

it

in

that

position

by

inserting

bound

bum

per

t

D

I

T

I

c

I

Piston

rod

2

Bound

bumper

3

Strut

outer

case

Fig

FA

43

Raising

piston

rod

9

Place

the

front

spring

on

the

lower

spring

seat

compress

the

spring

with

a

coil

spring

compressor

special

tool

Sn5650000

install

the

dust

cover

upper

spring

seat

oil

seal

strut

mounting

bearing

and

strut

mounting

insulator

in

that

order

Page 103 of 513

FRONT

AXLE

FRONT

SUSPENSION

10

Apply

multi

purpose

grease

MIL

G2108

or

10924

to

marked

portion

shown

in

Figure

FA

44

Fig

FA

44

Greasing

point

on

strut

mounting

bearing

and

oil

seal

Note

a

Be

careful

not

to

damage

the

piston

rod

when

disassembling

or

reassembling

the

strut

assembly

Particularly

when

raising

the

piston

rod

do

not

use

pliers

or

other

tool

to

hold

the

rod

b

Pay

attention

to

the

strut

mounting

bearing

installing

direction

See

Figure

FA

44

1

L

Tighten

the

piston

rod

self

locking

nut

to

3

6

to

4

5

kg

m

26

0

to

32

5

ft

1b

12

Release

the

coil

spring

gradually

from

lhe

coil

spring

compressor

and

set

the

spring

to

the

upper

and

lower

spring

seats

correctly

f

I

I

COIL

l

J

LOWER

EN

D

Fig

FA

45

Installing

front

spring

13

Raise

the

front

bumper

to

the

upper

spring

seat

side

Tightening

torque

Nuts

used

to

install

the

strut

assembly

on

the

body

1

6

to

2

1

kg

m

11

6

to

15

2

ft

lb

Bolts

used

to

install

the

knuckle

arm

to

strut

4

6

to

6

1

kg

m

33

3

to

44

I

ft

lb

Nut

used

to

install

the

tension

rod

on

the

transverse

link

2

2

to

3

0

kg

m

15

9

to

21

7

ft

Ib

Stabilizer

inst

llation

bolts

Transverse

link

bracket

side

0

9

to

1

2

kg

m

6

5

to

8

7

ft

lb

Frame

bracket

side

0

9

to

1

2

kg

m

6

5

to

8

7

ft

lb

TRANSVERSE

LINK

AND

LOWER

BALL

JOINT

The

transverse

link

is

connected

to

the

suspension

member

with

the

rubher

bushing

sticked

to

the

inner

tube

the

transverse

link

is

also

connected

to

the

strut

assembly

through

the

lower

ball

joint

and

thus

the

front

suspension

link

mechanism

is

formed

The

lower

ball

joint

is

of

a

non

lisassembled

type

Lubricate

the

lower

ball

joint

every

50

000

km

30

000

miles

or

two

years

JD

y

I

II

I

II

F

T

ill

3

YJ

t

tjli

t

11

I

Suspension

cross

member

I

3

I

Transverse

link

2

Transverse

link

mounting

bolt

Fig

FA

46

Cross

sectional

view

of

transverse

link

bushing

FA

17

Page 104 of 513

CHASSIS

r

I

El

0

3

to

1

0

mm

0

0118

to

0

0394

in

Fig

FA

47

Cross

sectional

vie

of

ball

joint

Removal

1

Jack

up

the

vehicle

remove

the

wheel

and

remove

the

stabilizer

bar

and

tension

rod

from

the

transverse

link

Loosen

the

knuckle

arm

fiXing

bolts

and

separate

the

ball

joint

from

the

strut

assembly

See

Removal

of

front

axle

and

suspension

assembly

above

for

details

Fig

FA

48

Loosening

knuckle

arm

fixing

bolts

2

Loosen

the

transverse

link

mounting

bolt

and

separate

the

transverse

link

from

the

suspension

member

Fig

FA

49

Loosening

transverse

link

mounting

bolt

3

Remove

cotter

pin

from

the

castle

nut

on

the

knuckle

arm

loosen

the

castle

nut

and

remove

the

knuckle

arm

from

the

ball

joint

J

iIP

A

i

Fig

FA

50

Removing

knuckle

arm

4

Loosen

the

ball

joint

installation

nut

and

remove

the

haJJ

joint

from

the

transverse

Jink

5

Withdraw

the

transverse

link

bushing

from

the

transverse

link

with

a

front

transverse

link

bushing

replacer

set

special

tools

ST36721000

ST36722000

and

a

press

FA

18

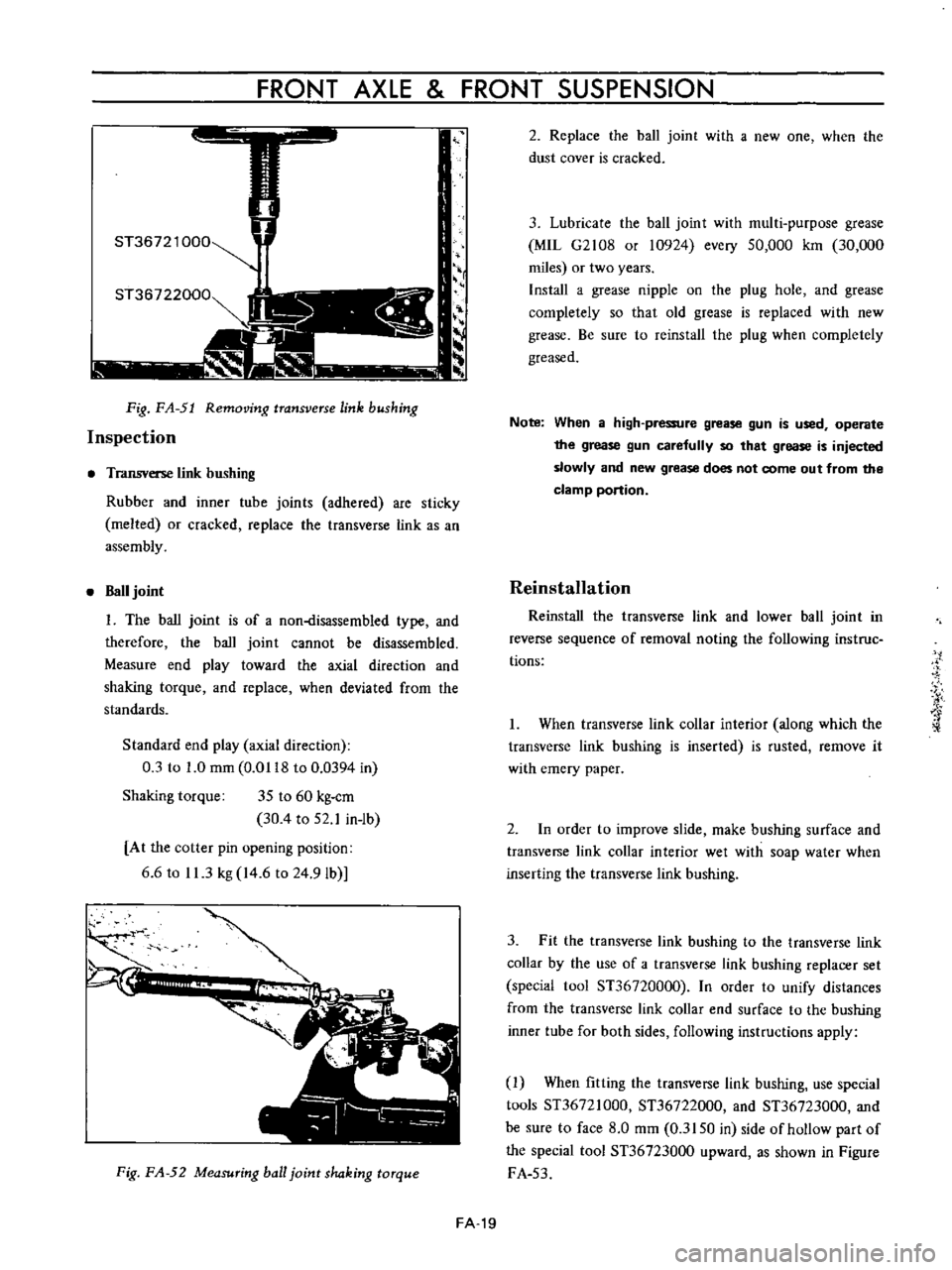

Page 105 of 513

FRONT

AXLE

FRONT

SUSPENSION

I

ST36721

000

ST36722000

Fig

FA

51

Removing

transverse

link

bushing

Inspection

Transverse

link

bushing

Rubber

and

inner

tube

joints

adhered

are

sticky

melted

or

cracked

replace

the

transverse

link

as

an

assembly

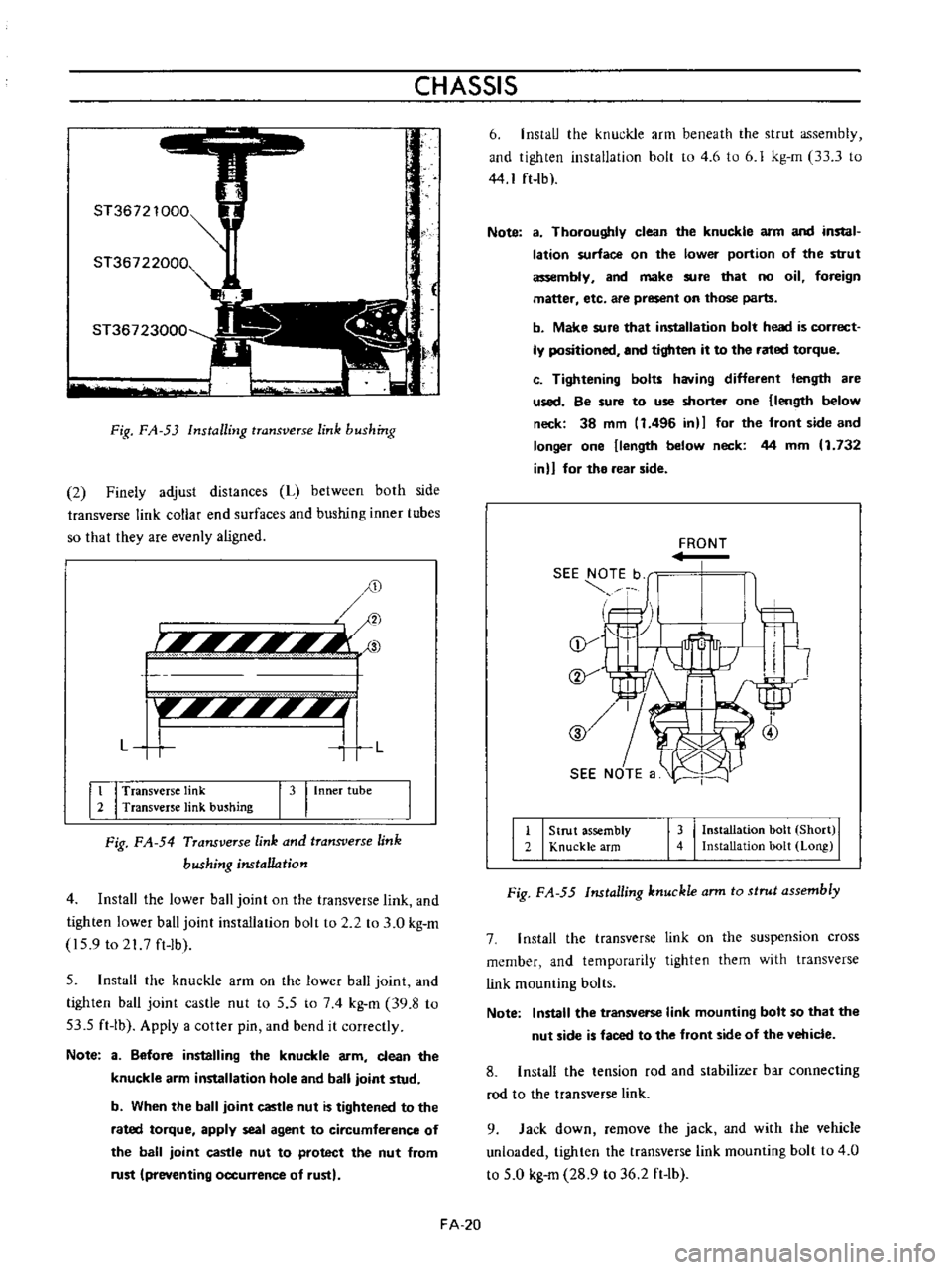

Ball

joint

I

The

ball

joint

is

of

a

non

disassembled

type

and

therefore

the

ball

joint

cannot

be

disassembled

Measure

end

play

toward

the

axial

direction

and

shaking

torque

and

replace

when

deviated

from

the

standards

Standard

end

play

axial

direction

0

3

to

1

0

mm

0

0118

to

0

0394

in

Shaking

torque

35

to

60

kg

cm

30

4

to

52

1

in

ib

At

the

cotter

pin

opening

position

6

6

to

11

3

kg

14

6

to

24

9Ib

I

Fig

FA

52

Measuring

ball

joint

shaking

torque

2

Replace

the

ball

joint

with

a

new

one

when

the

dust

cover

is

cracked

3

Lubricate

the

ball

joint

with

multi

purpose

grease

MIL

G2108

or

10924

every

50

000

km

30

000

miles

or

two

years

Install

a

grease

nipple

on

the

plug

hole

and

grease

completely

so

that

old

grease

is

replaced

with

new

grease

Be

sure

to

reinstall

the

plug

when

completely

greased

Note

When

a

high

pressure

grease

gun

is

used

operate

the

grease

gun

carefully

so

that

grease

is

injected

slowly

and

new

grease

does

not

come

out

from

the

clamp

portion

Reinstallation

Reinstall

the

transve

l

e

link

and

lower

ball

joint

in

reverse

sequence

of

removal

noting

the

following

ins

true

tions

I

When

transverse

link

collar

interior

along

which

the

transverse

link

bushing

is

inserted

is

rusted

remove

it

with

emery

paper

2

In

order

to

improve

slide

make

bushing

surface

and

transverse

link

collar

interior

wet

with

soap

water

when

inserting

the

transverse

link

bushing

3

Fit

the

transverse

link

bushing

to

the

transverse

link

collar

by

the

use

of

a

transverse

link

bushing

replacer

set

special

1001

ST36720000

In

order

to

unify

distances

from

the

transverse

link

collar

end

surface

to

the

bushing

inner

tube

for

both

sides

following

instructions

apply

1

When

fitting

the

transve

l

e

link

bushing

use

special

tools

ST36721000

ST36722000

and

ST36723000

and

be

sure

to

face

8

0

mm

0

3150

in

side

of

hollow

part

of

the

special

tool

ST36723000

upward

as

shown

in

Figure

FA

53

FA

19

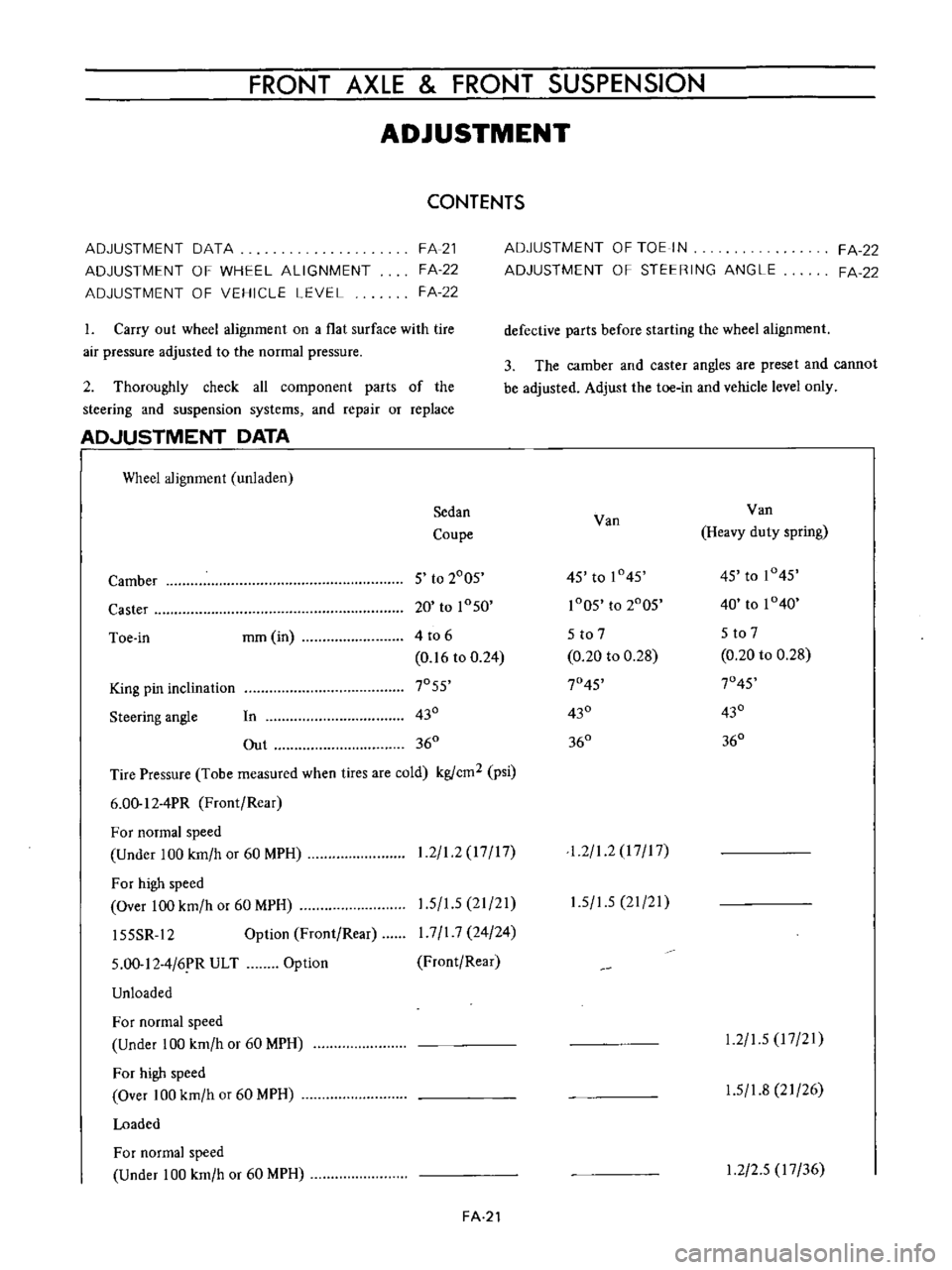

Page 106 of 513

CHASSIS

ST36721000

ST36722000

I

ST36723000

r

Fig

FA

53

Installing

transverse

link

bushing

2

Finely

adjust

distances

L

between

both

side

transverse

link

collar

end

surfaces

and

bushing

inner

tubes

so

that

they

are

evenly

aligned

D

r

Ii

l

Ii

3

F

f

IIII

I

I

L

T

L

It

I

Transverse

link

2

Transverse

link

bushing

I

3

I

Inner

tube

Fig

FA

54

Transverse

link

and

transverse

link

bushing

nstal1o

tion

4

Install

the

lower

ball

joint

on

the

transverse

link

and

tighten

lower

ball

joint

installation

bolt

to

2

2

to

3

0

kg

m

159

to

21

7

ft

Ib

5

Install

the

knuckle

arm

on

the

lower

ball

joint

and

tighten

ball

joint

castle

nut

to

5

5

to

74

kg

m

39

8

to

53

5

ft

Ib

Apply

a

cotter

pin

and

bend

it

correctly

Note

3

Before

installing

the

knuckle

arm

clean

the

knuckle

arm

installation

hole

and

ball

joint

stud

b

When

the

ball

joint

castle

nut

is

tightened

to

the

rated

torque

apply

seal

agent

to

circumference

of

the

ball

joint

castle

nut

to

protect

the

nut

from

rust

preventing

occurrence

of

rust

FA

20

6

InstaIJ

the

knuckle

arm

beneath

the

strut

assembly

and

tighten

instaIJation

bolt

to

4

6

to

6

J

kg

m

33

3

to

44

I

ft

lb

Note

a

Thoroughly

clean

the

knuckle

arm

and

instal

lation

surface

on

the

lower

portion

of

the

strut

assembly

and

make

sure

that

no

oil

foreign

maner

etc

are

present

on

those

parts

b

Make

sure

that

installation

bolt

head

is

correct

ly

positioned

and

tighten

it

to

the

rated

torque

c

Tightening

bolu

having

different

length

are

used

Be

sure

to

use

shorter

one

length

below

neck

38

mm

11496

in

for

the

front

side

and

longer

one

length

below

neck

44

mm

1

132

in

for

the

rear

side

FRONT

II

I

Strut

assembly

2

Knuckle

arm

143

I

Installation

bolt

Short

I

Installation

bolt

Long

Fig

FA

55

Installing

knuckle

ann

to

strut

assembly

7

I

nstall

the

transverse

link

on

the

suspension

cross

member

and

temporarily

tighten

them

with

transverse

link

mounting

bolts

Note

Install

the

transverse

link

mounting

bolt

so

that

the

nut

side

is

faced

to

the

front

side

of

the

vehicle

8

Install

the

tension

rod

and

stabilizer

bar

connecting

rod

to

the

transverse

link

9

Jack

down

remove

the

jack

and

with

the

vehicle

unloaded

tighten

the

transverse

link

mounting

bolt

to

4

0

to

5

0

kg

m

28

9

to

36

2

ft

lb

Page 107 of 513

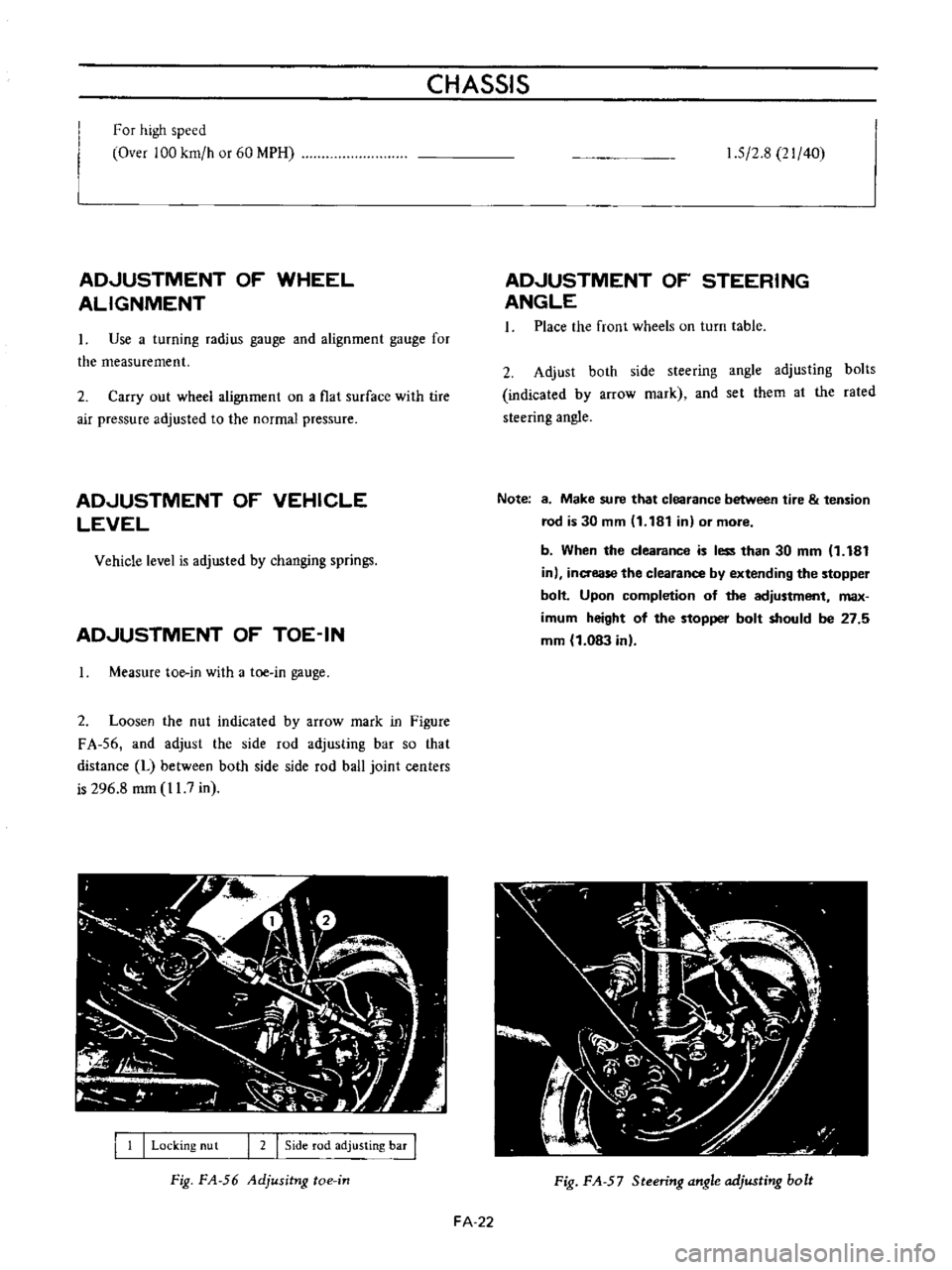

FRONT

AXLE

FRONT

SUSPENSION

ADJUSTMENT

CONTENTS

ADJUSTMENT

DATA

ADJUSTMENT

OF

WHEEL

ALIGNMENT

ADJUSTMENT

OF

VEHICLE

LEVEL

FA

21

FA

22

FA

22

1

Carry

out

wheel

alignment

on

a

flat

surface

with

tire

air

pressure

adjusted

to

the

normal

pressure

2

Thoroughly

check

all

component

parts

of

the

steering

and

suspension

systems

and

repair

or

replace

AD

JUSTMENT

DATA

I

Wheel

alignment

unladen

Sedan

Coupe

Camber

5

to

2005

Caster

20

to

1050

Toe

in

mm

in

4

to

6

0

16

to

0

24

King

pin

inclination

7055

Steering

angle

In

430

Out

360

Tire

Pressure

Tobe

measured

when

tires

are

cold

kgfcm2

psi

6

00

12

4PR

Front

Rear

For

normal

speed

Under

100

km

h

or

60

MPH

For

high

speed

Over

100

km

h

or

60

MPH

15SSR

12

Option

Front

Rear

1

2

1

2

17

17

1

5

1

5

21

21

I

7

I

7

24

24

Front

Rear

5

00

12

4

6

R

ULT

Unloaded

Option

For

normal

speed

Under

100

km

h

or

60

MPH

For

high

speed

Over

100

km

h

or

60

MPH

Loaded

For

normal

speed

Under

100

km

h

or

60

MPH

FA

21

ADJUSTMENT

OF

TOE

IN

ADJUSTMENT

OF

STEERING

ANGLE

FA

22

FA

22

defective

parts

before

starting

the

wheel

alignment

3

The

camber

and

caster

angles

are

preset

and

cannot

be

adjusted

Adjust

the

toe

in

and

vehicle

level

only

Van

Van

Heavy

duty

spring

45

to

1045

45

to

1045

1005

to

2005

40

to

1040

5

to

7

5

to

7

0

20

to

0

28

0

20

to

0

28

7045

7045

430

430

360

360

1

2

1

2

I

7

I

7

1

5

1

5

21

21

1

2

1

5

17

21

1

5

1

8

21

26

1

2

2

5

17

36

Page 108 of 513

CHASSIS

For

high

speed

Over

100

km

h

or

60

MPH

ADJUSTMENT

OF

WHEEL

ALIGNMENT

Use

a

turning

radius

gauge

and

alignment

gauge

for

the

measurement

2

Carry

out

wheel

alignment

on

a

flat

surface

with

tire

air

pressure

adjusted

to

the

normal

pressure

ADJUSTMENT

OF

VEHICLE

LEVEL

Vehicle

level

is

adjusted

by

changing

springs

ADJUSTMENT

OF

TOE

IN

Measure

toe

in

with

a

toe

in

gauge

2

Loosen

the

nut

indicated

by

arrow

mark

in

Figure

FA

56

and

adjust

the

side

rod

adjusting

bar

so

that

distance

L

between

both

side

side

rod

ball

joint

centers

is

296

8

mm

11

7

in

I

1

I

Locking

nu

t

I

2

I

Side

rod

adjusting

bar

I

Fig

FA

56

Adjusitng

toe

in

1

5

2

8

21

40

ADJUSTMENT

OF

STEERING

ANGLE

1

Place

the

front

wheels

on

turn

table

2

Adjust

both

side

steering

angle

adjusting

bolts

indicated

by

arrow

mark

and

set

them

al

the

rated

steering

angle

Note

8

Make

sure

that

clearance

between

tire

tension

rod

is

30

mm

11

181

in

or

more

b

When

the

clearance

is

less

than

30

mm

1

181

in

inaease

the

clearance

by

extending

the

stopper

bolt

Upon

completion

of

the

adjustment

max

imum

height

of

the

stopper

bolt

should

be

27

5

mm

1

083

in

Fig

FA

57

Steering

angle

adjusting

bolt

FA

22

Page 109 of 513

FRONT

AXLE

FRONT

SUSPENSION

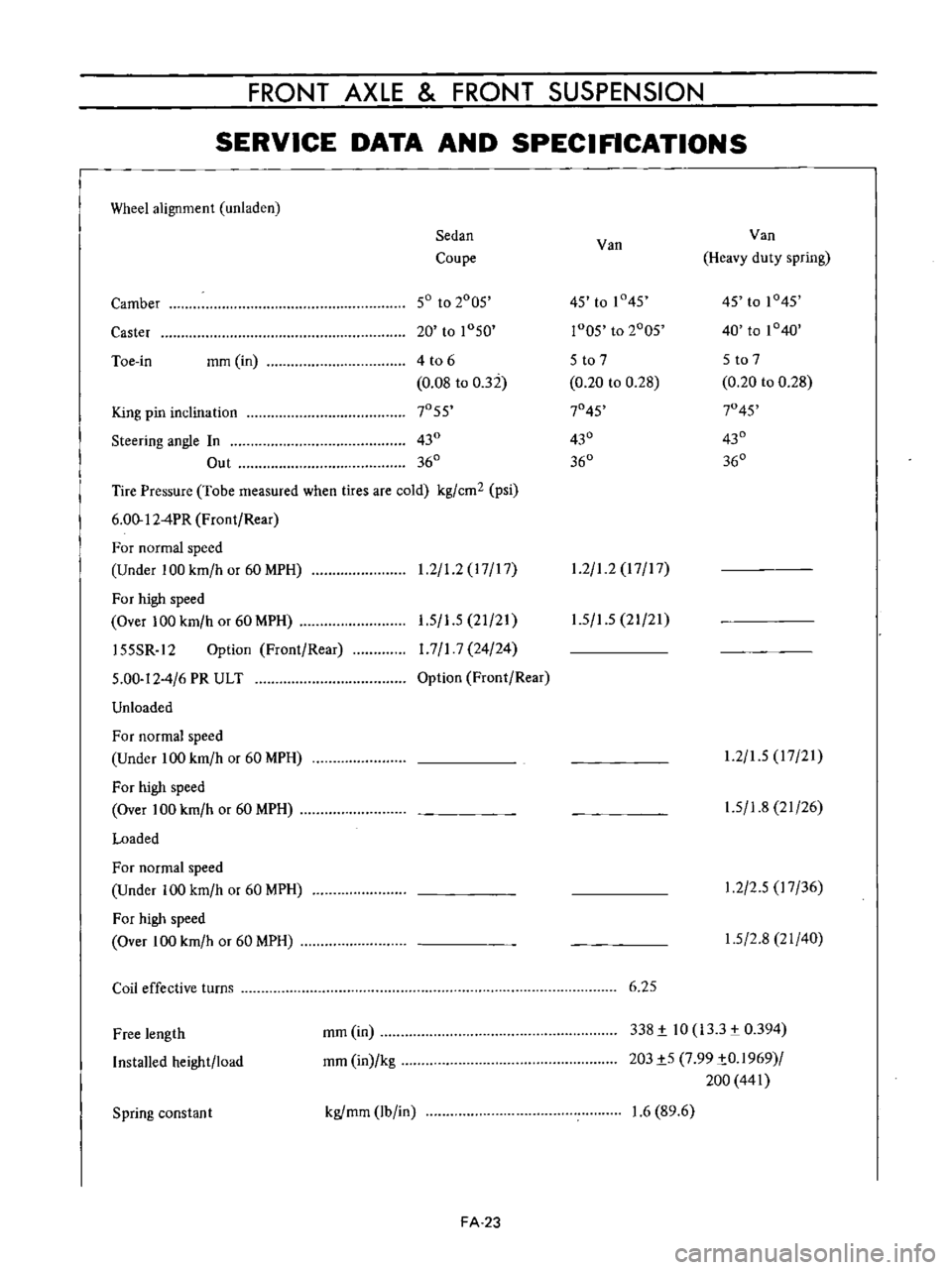

SERVICE

DATA

AND

SPECIFICATIONS

Wheel

alignment

unladen

Sedan

Van

Van

Coupe

Heavy

duty

spring

Camber

50

to

2005

45

to

1

45

45

to

1045

Caster

20

to

1050

r005

to

2005

40

to

1040

Toe

in

mm

in

4

t06

5

to

7

5

to

7

0

08

to

032

0

20

to

0

28

0

20

to

0

28

King

pin

inclination

7055

7045

7045

Steering

angle

In

430

430

430

Out

360

360

360

Tire

Pressure

Tobe

measured

when

tires

are

cold

kg

cm2

psi

6

00

12

4PR

Front

Rear

For

normal

speed

Under

100

km

h

or

60

MPH

1

2

1

2

17

17

1

2

1

2

17

17

For

high

speed

Over

100

km

h

or

60

MPH

155SR

12

Option

Front

Rear

5

00

12

4

6

PR

ULT

Unloaded

1

5

1

5

21

21

1

7

1

7

24

24

Option

Front

Rear

1

5

1

5

21

21

For

normal

speed

Under

100

km

h

or

60

MPH

For

high

speed

Over

100

km

h

or

60

MPH

Loaded

1

2

1

5

17

21

1

5

1

8

21

26

For

normal

speed

Under

100

km

h

or

60

MPH

For

high

speed

Over

100

km

h

or

60

MPH

1

2

2

5

17

36

1

5

2

8

21

40

Coil

effective

turns

6

25

Free

length

Installed

height

load

mm

in

mm

in

kg

338

i

10

133

0394

203i5

7

99

iO

1969

200

441

Spring

constan

t

kgfmm

lb

in

1

6

89

6

FA

23

Page 110 of 513

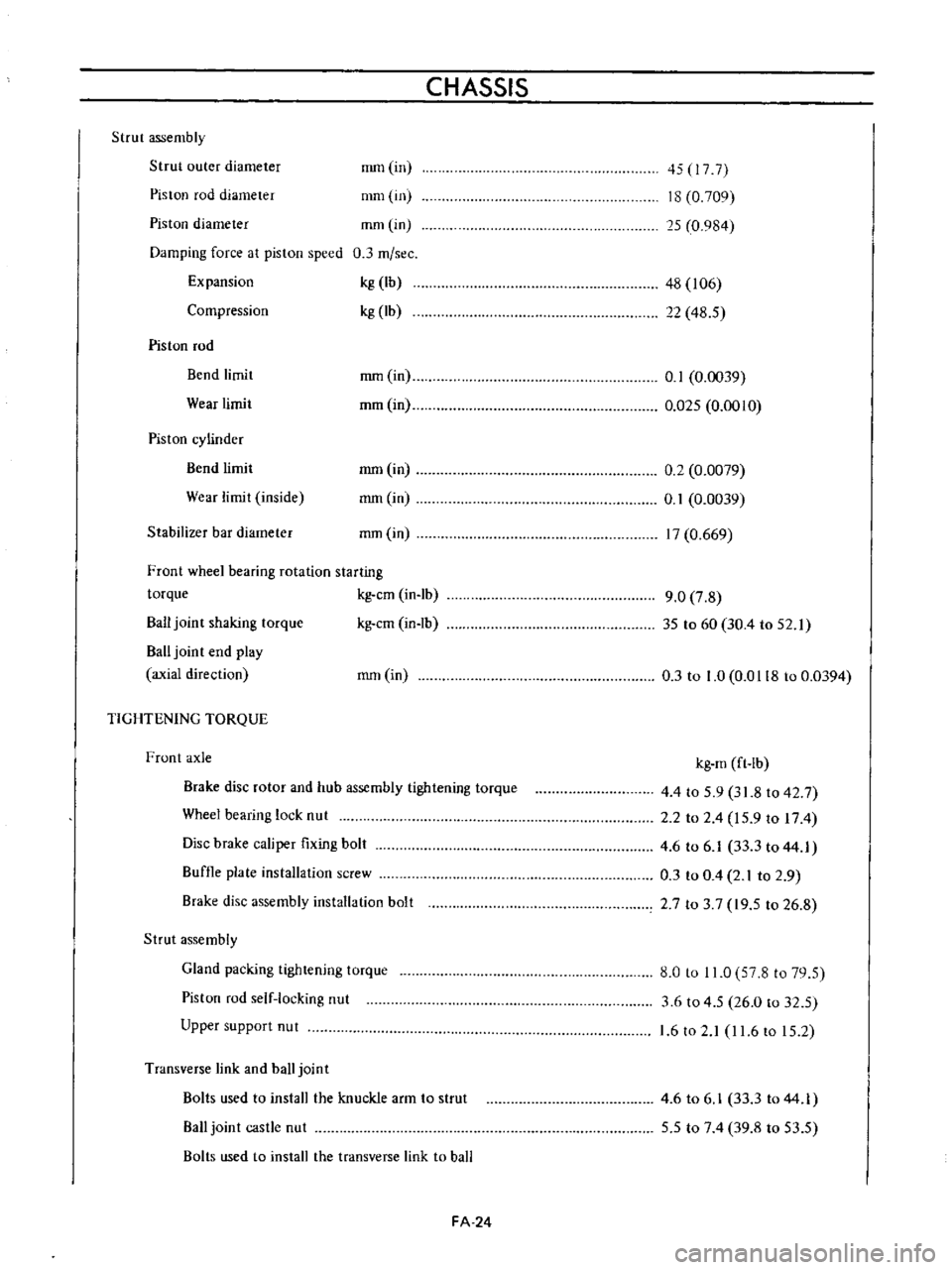

CHASSIS

Strut

assembly

Strut

outer

diameter

Piston

rod

diameter

mmlin

nml

in

45

17

7

18

0

709

15

0

984

Piston

diameter

mmlin

Damping

force

at

piston

speed

0

3

m

sec

Expansion

kg

Ib

Compression

kg

lb

48

106

22

48

5

Piston

rod

Bend

limit

Wear

limit

mm

in

0

1

0

0039

mm

in

0

025

0

0010

Piston

cylinder

Bend

limit

Wear

limit

inside

mm

in

mm

in

0

2

0

0079

0

1

0

0039

17

0

669

Stabilizer

bar

diameter

mm

in

Front

wheel

bearing

rotation

starting

torque

kg

cm

in

lb

Ball

joint

shaking

torque

kg

cm

in

lb

Ball

joint

end

play

axial

direction

mm

in

9

0

7

8

35

to

60

30

4

to

52

1

0

3

to

1

0

0

0118

to

0

0394

TIGHTENING

TORQUE

Front

axle

Brake

disc

rotor

and

hub

assembly

tightening

torque

Wheel

bearing

lock

nut

Disc

brake

caliper

fixing

bolt

Buffle

plate

installation

screw

Brake

disc

assembly

installation

bolt

kg

m

ft

lb

4

4

to

5

9

31

8

to

42

7

2

2

to

2

4

15

9

to

174

4

6

to

6

1

33

3

to

44

1

0

3

to

0

4

2

1

to

2

9

2

7

to

3

7

19

5

to

26

8

Strut

assembly

Gland

packing

tightening

torque

Piston

rod

self

locking

nut

Upper

support

nut

8

0

to

11

0

57

8

to

79

5

3

6

to

4

5

26

0

to

32

5

1

6

to

2

1

I

1

6

to

15

2

Transverse

link

and

ball

joint

Bolts

used

to

install

the

knuckle

arm

to

strut

Ball

joint

castle

nut

Bolts

used

to

install

the

transverse

link

to

ball

4

6

to

6

1

33

3

to

44

1

5

5

to

7

4

39

8

to

53

5

FA

24