torque DATSUN B110 1973 Service Owners Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 367 of 513

ENGINE

MECHANICAL

3

Apply

engine

oil

to

the

main

bearing

surfaces

on

both

sides

of

the

cylinder

block

and

cap

Install

the

crankshaft

4

Install

the

main

bearing

cap

and

tighten

the

bolts

with

specified

torque

Tightening

torque

5

0

to

6

0

kg

m

36

to

43

ft

lb

Notes

a

Arrange

the

parts

so

that

the

arrow

mark

on

the

bearing

cap

is

faced

toward

the

front

of

the

engine

b

Prior

to

tightening

the

bearing

cap

bolts

place

the

bearing

cap

at

a

proper

position

by

shifting

the

crankshaft

in

the

axial

direction

c

Tighten

the

bearing

cap

bolts

gradually

in

separating

two

to

three

stages

and

outwardly

from

the

center

beari

ng

d

After

securing

the

bearing

cap

bolts

ascertain

that

the

crankshaft

can

be

easily

rotated

5

Make

sure

that

the

crankshaft

end

play

is

correct

Crankshaft

end

play

0

05

to

0

15

rom

0

0020

to

0

0059

in

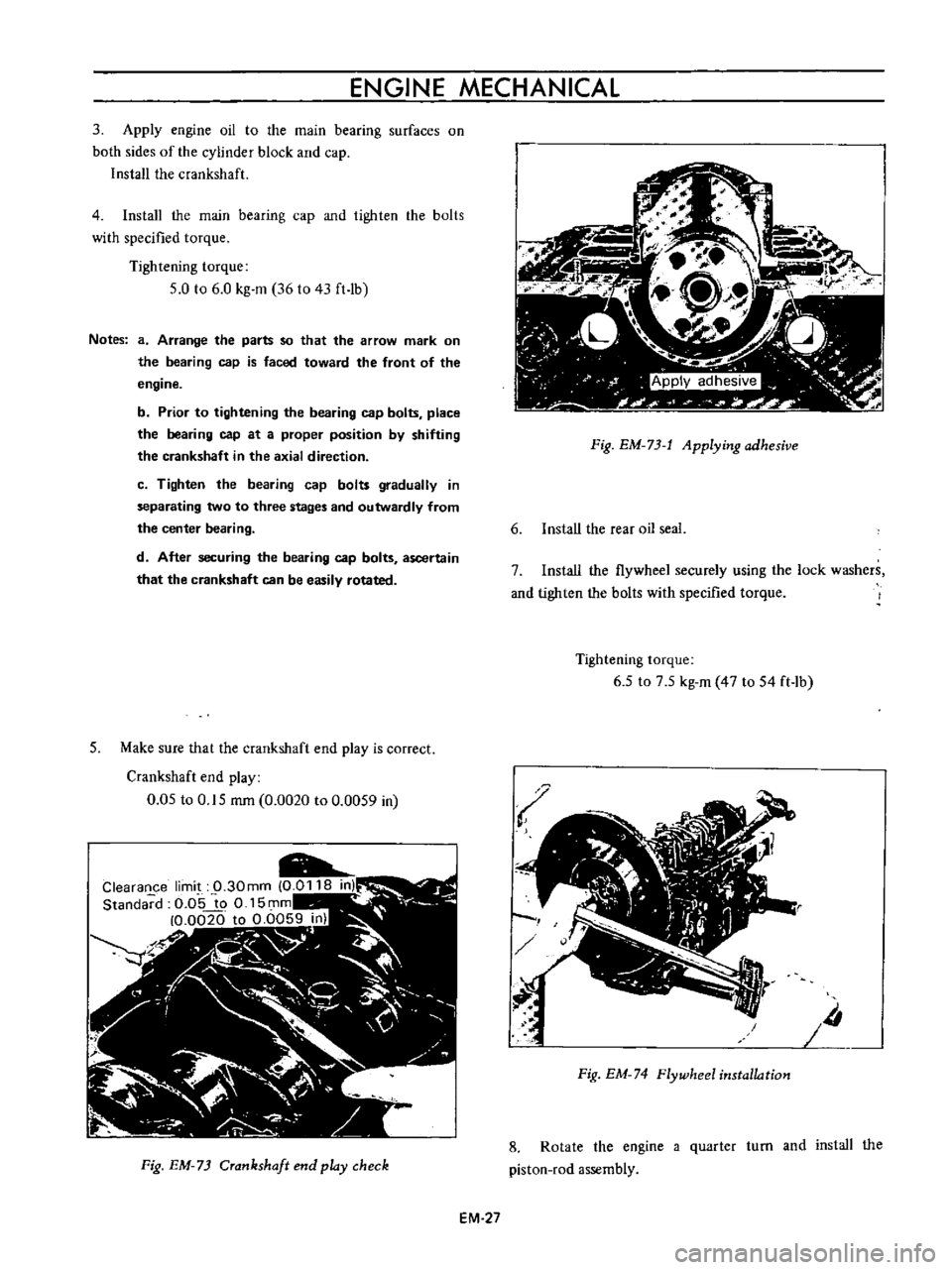

Fig

EM

73

Crankshaft

end

play

check

EM

27

Fig

EM

73

t

Applying

adhesive

6

Install

the

rear

oil

seal

7

Install

the

flywheel

securely

using

the

lock

washers

and

tighten

the

bolts

with

specified

torque

Tightening

torque

6

5

to

7

5

kg

m

47

to

54

ft

lb

Iii

Fig

EM

74

Flywheel

installation

8

Rotate

the

engine

a

quarter

turn

and

install

the

piston

rod

assembly

Page 368 of 513

ENGINE

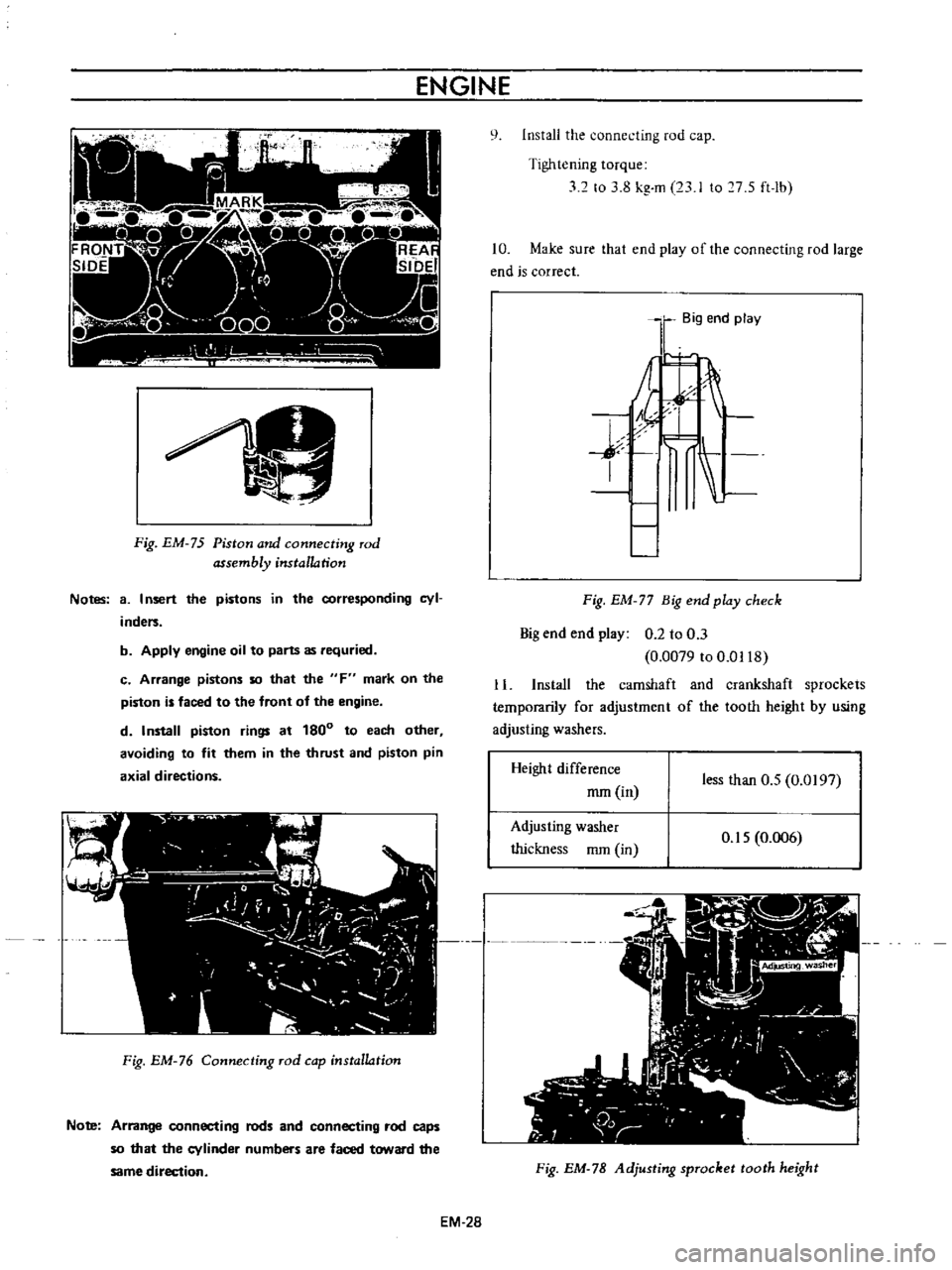

Fig

EM

75

Piston

and

connecting

rod

assembly

installation

Notes

8

I

nsert

the

pistons

in

the

corresponding

cyl

inders

b

Apply

engine

oil

to

parts

as

requried

c

Arrange

pistons

so

that

the

F

mark

on

the

piston

is

faced

to

the

front

of

the

engine

d

Install

piston

rings

at

180

to

each

other

avoiding

to

fit

them

in

the

thrust

and

piston

pin

axial

directions

Fig

EM

76

Connecting

rod

cap

installation

Note

Arrange

connecting

rods

and

connecting

rod

caps

so

that

the

cylinder

numbers

are

faced

toward

the

same

direction

EM

28

q

Install

the

connecting

rod

cap

Tightening

torque

32

to

3

8

kg

m

23

I

to

7

S

ft

lb

10

Make

sure

that

end

play

of

the

connecting

rod

large

end

is

correct

Big

end

play

j

I

Fig

EM

77

Big

end

play

check

Big

end

end

play

0

2

to

0

3

0

0079

to

0

0118

11

Install

the

camshaft

and

crankshaft

sprockets

temporarily

for

adjustment

of

the

tooth

height

by

using

adjusting

washers

Height

difference

mm

in

less

than

O

S

0

0197

Adjusting

washer

thickness

mm

in

O

IS

0

006

Fig

EM

78

Adjusting

sprocket

tooth

height

Page 369 of 513

ENGINE

MECHANICAL

o

Match

mark

Key

groove

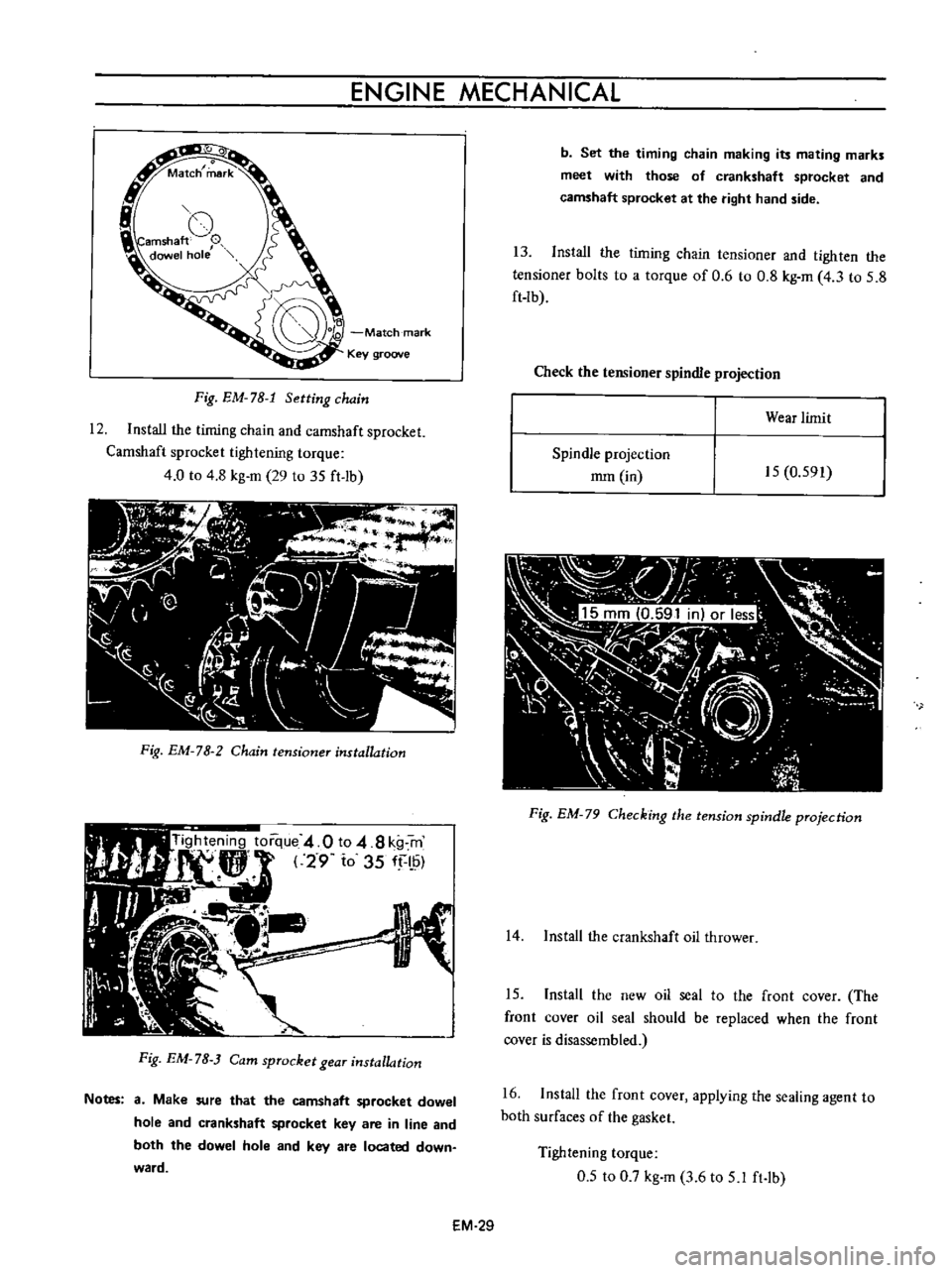

Fig

EM

78

1

Setting

chain

12

Install

the

timing

chain

and

camshaft

sprocket

Camshaft

sprocket

tightening

torque

4

0

to

4

8

kg

m

29

to

35

ft

lb

Fig

EM

78

2

Chain

tensioner

installation

Fig

EM

7B

Cam

sprocket

gear

installation

Notes

a

Make

sure

that

the

camshaft

sprocket

dowel

hole

and

crankshaft

sprocket

key

are

in

line

and

both

the

dowel

hole

and

key

are

located

down

ward

b

Set

the

timing

chain

making

its

mating

marks

meet

with

those

of

crankshaft

sprocket

and

camshaft

sprocket

at

the

right

hand

side

13

Install

the

timing

chain

tensioner

and

tighten

the

tensioner

bolts

to

a

torque

of

0

6

to

0

8

kg

m

4

3

to

5

8

ft

lb

Check

the

tensioner

spindle

projection

Wear

limit

Spindle

projection

mm

in

15

0

591

Fig

EM

79

Checking

the

tension

spindle

projection

14

Install

the

crankshaft

oil

thrower

15

Install

the

new

oil

seal

to

the

front

cover

The

front

cover

oil

seal

should

be

replaced

when

the

front

cover

is

disassembled

16

Install

the

front

cover

applying

the

sealing

agent

to

both

surfaces

of

the

gasket

Tightening

torque

0

5

to

0

7

kg

m

3

6

to

5

1

ft

lb

EM

29

Page 370 of 513

ENGINE

17

Install

the

oil

strainer

and

the

oil

pan

using

the

gasket

Apply

sealing

agent

on

hath

surfaces

of

the

gasket

especially

on

the

front

and

rear

portions

of

the

oil

pan

Oil

pan

tightening

torque

0

4

to

0

6

kg

m

I

9

to

4

3

ft

lbJ

I

R

I

nvcrt

the

engine

and

install

the

cylinder

head

assembly

and

gasket

Cylinder

head

gasket

with

O

ring

Cylinder

block

side

Steel

sheet

D

QCO

0

0

i

O

1

nrr

11

I

Li

I

I

Vo

o

f

C

C

r

c

Sealing

agent

not

required

Cylinder

head

side

Joint

sheet

Remarks

Install

without

applying

sealing

agent

Be

careful

not

to

damage

the

push

rod

side

because

this

side

has

previously

been

provided

with

sealing

agent

Fig

EM

80

Cy

linder

head

installatjo

1

Note

Apply

sealing

agent

overall

the

cylinder

block

surface

Place

the

gasket

on

it

and

apply

sealing

agent

to

the

gasket

top

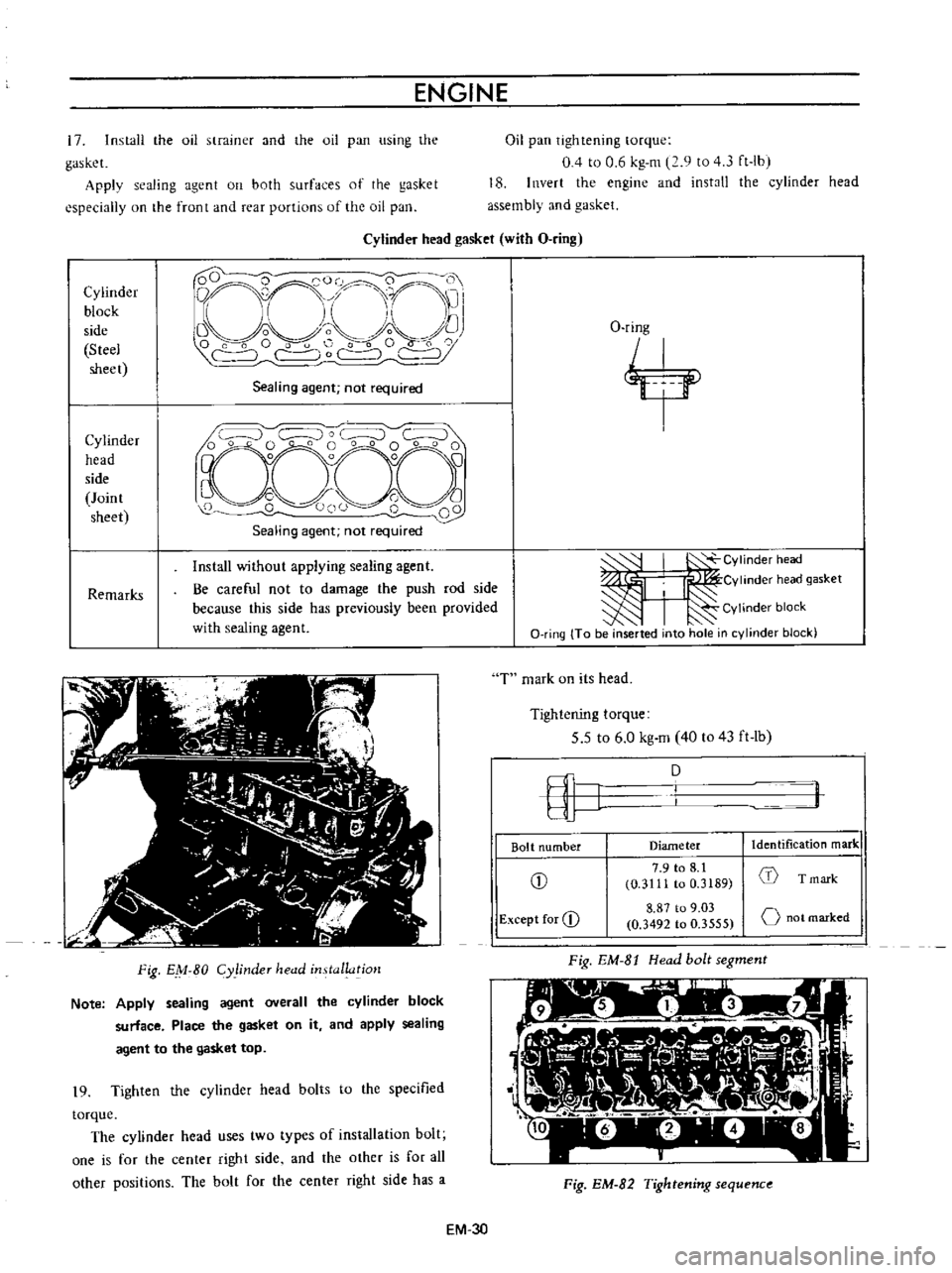

19

Tighten

the

cylinder

head

bolts

to

the

specified

torque

The

cylinder

head

uses

two

types

of

installation

bolt

one

is

for

the

center

right

side

and

the

other

is

for

all

other

positions

The

bolt

for

the

center

right

side

has

a

O

ring

j

I

Y

J

CYlinder

head

I

I

Cvlinderheadgasket

I

Cylinder

block

O

ring

To

be

inserted

into

hole

in

cylinder

block

T

mark

on

its

head

Tightening

torque

5

5

to

6

0

kg

m

40

to

43

ft

lb

fI

J

D

Bolt

number

Diameter

Identification

mark

CD

7

9

to

8

1

1

0

3111

to

0

3189

T

mark

Except

for

CD

8

87

to

9

03

o

not

marked

0

3492

to

0

3555

Fig

EM

8t

Head

bolt

segment

l

Fig

EM

82

Tightening

sequenc

EM

3D

Page 371 of 513

ENGINE

MECHANICAL

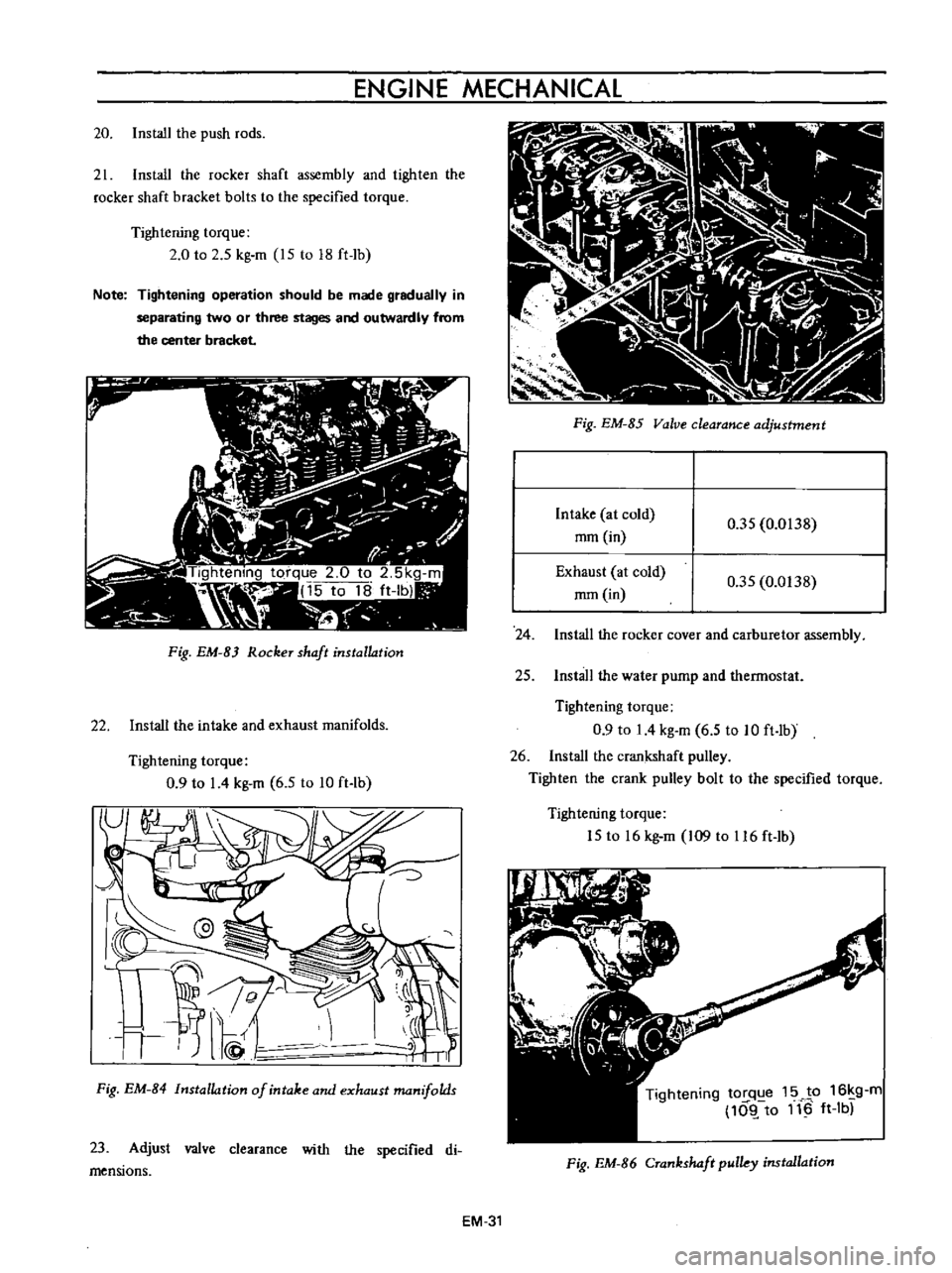

20

Install

the

push

rods

21

Install

the

rocker

shaft

assembly

and

tighten

the

rocker

shaft

bracket

bolts

to

the

specified

torque

Tightening

torque

2

0

to

2

5

kg

m

15

to

18

ft

Ib

Note

Tightening

operation

should

be

made

gradually

in

separating

two

or

three

stages

and

outwardly

from

the

center

bracket

Fig

EM

B

RockeT

shaft

installation

22

Install

the

intake

and

exhaust

manifolds

Tightening

torque

0

9

to

I

4

kg

m

6

5

to

10

ft

lb

Fig

EM

B4

Installation

of

intake

and

exhaust

manifolds

23

Adjust

valve

clearance

with

the

specified

di

mensions

Fig

EM

85

Valve

clearance

adjustment

Intake

at

cold

rom

in

0

35

0

0138

Exhaust

at

cold

rom

in

0

35

0

0138

24

Install

the

rocker

cover

and

carburetor

assembly

25

Install

the

water

pump

and

thermostat

Tightening

torque

0

9

to

I

4

kg

m

6

5

to

10

ft

lb

26

Install

the

crankshaft

pulley

Tighten

the

crank

pulley

bolt

to

the

specified

torque

Tightening

torque

15

to

16

kg

m

109

to

116

ft

lb

Tightening

tOI

q

e

15

JP

16

g

m

10l

to

11

ft

Ib

Fig

EM

B6

CTankshaft

pulky

installation

EM

31

Page 373 of 513

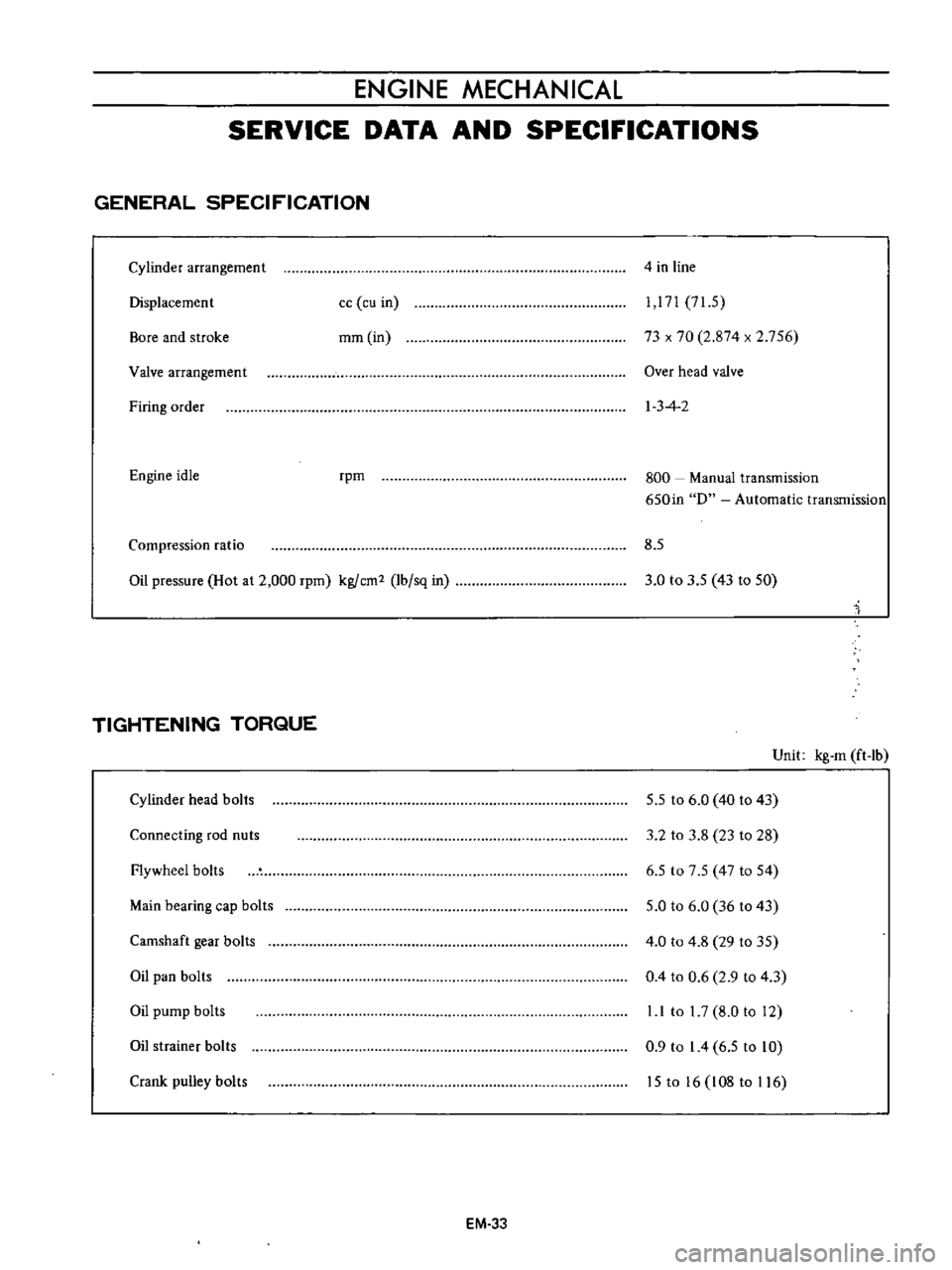

ENGINE

MECHANICAL

SERVICE

DATA

AND

SPECIFICATIONS

GENERAL

SPECIFICATION

Cylinder

arrangement

4

in

line

Displacement

cc

cu

in

mm

in

1

171

71

5

73

x

70

2

874

x

2

756

Bore

and

stroke

Valve

arrangemen

t

Over

head

valve

Firing

order

I

3

4

2

Engine

idle

rpm

800

Manual

transmission

650in

D

Automatic

transmission

Compression

ratio

8

5

Oil

pressure

Hot

at

2

000

rpm

kgfcm2

Ibfsq

in

3

0

to

3

5

43

to

50

TIGHTENING

TORQUE

Unit

kg

m

ft

lb

Cylinder

head

bolts

Flywheel

bolts

5

5

to

6

0

40

to

43

3

2

to

3

8

23

to

28

6

5

to

7

5

47

to

54

5

0

to

6

0

36

to

43

4

0

to

4

8

29

to

35

0

4

to

0

6

2

9

to

4

3

l

l

to

I

7

8

0

to

12

0

9

to

I

4

6

5

to

10

15

to

16

108

to

116

Connecting

rod

nuts

Main

bearing

cap

bolts

Camshaft

gear

bolts

Oil

pan

bolts

Oil

pump

bolts

Oil

strainer

bolts

Crank

pulley

bolts

EM

33

Page 384 of 513

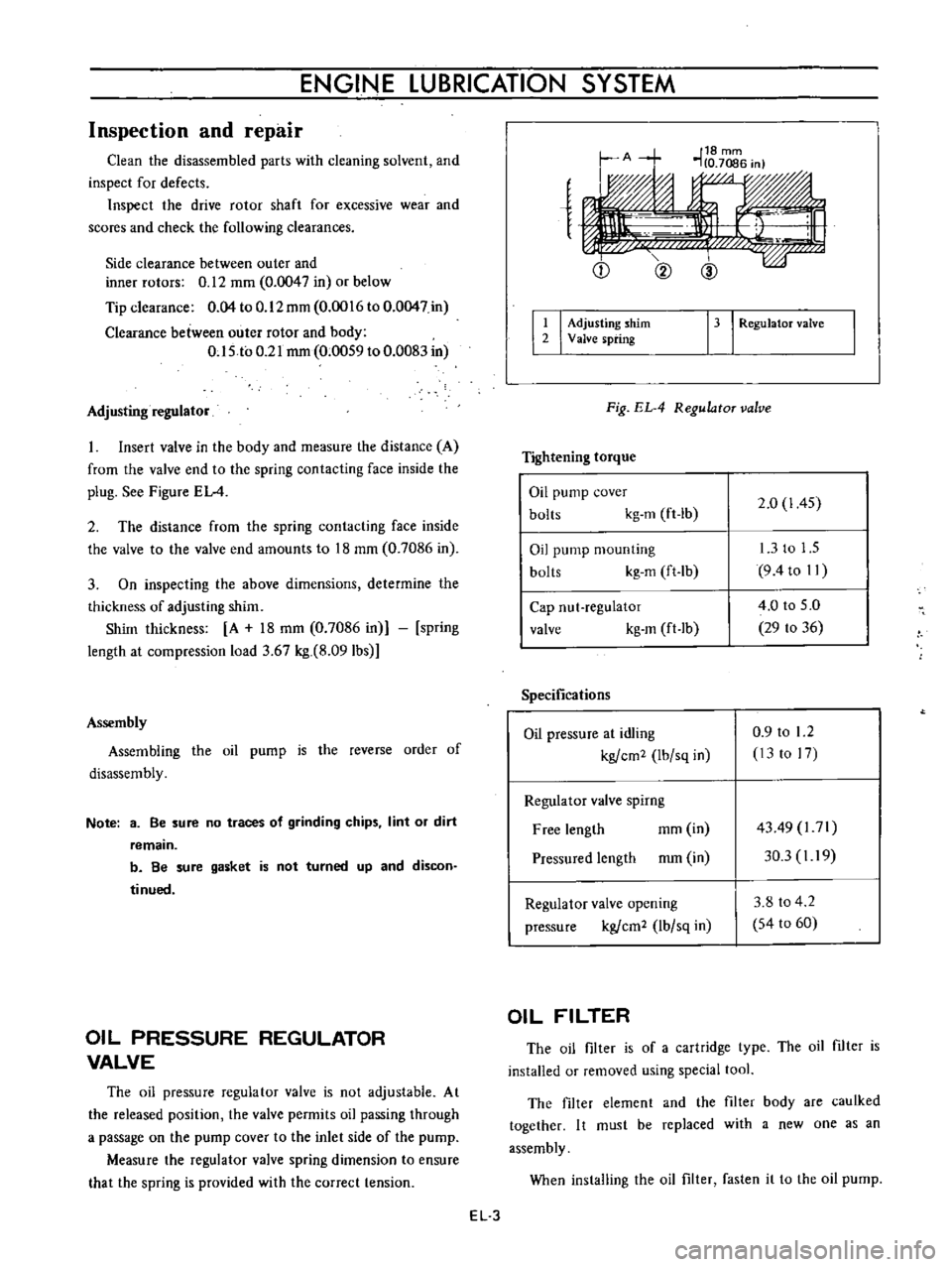

ENGINE

LUBRICATION

SYSTEM

Inspection

and

repair

Clean

the

disassembled

parts

with

cleaning

solvent

and

inspect

for

defects

Inspect

the

drive

rotor

shaft

for

excessive

wear

and

scores

and

check

the

following

clearances

Side

clearance

between

Quter

and

inner

rotors

0

12

mm

0

0047

in

or

below

Tip

clearance

0

04

to

0

I2mm

0

0016

to

0

0047

in

Clearance

between

outer

rotor

and

body

0

15

to

0

21

rom

0

0059

to

0

0083

in

Adjusting

regulator

Insert

valve

in

the

body

and

measure

the

distance

A

from

the

valve

end

to

the

spring

contacting

face

inside

the

plug

See

Figure

EL

4

2

The

distance

from

the

spring

contacting

face

inside

the

valve

to

the

valve

end

amounts

to

18

mm

0

7086

in

3

On

inspecting

the

above

dimensions

determine

the

thickness

of

adjusting

shim

Shim

thickness

A

18

mm

0

7086

in

spring

length

at

compression

load

3

67

kg

8

091bs

Assembly

Assembling

the

oil

pump

is

the

reverse

order

of

disassembly

Note

3

Be

sure

no

traces

of

grinding

chips

lint

or

dirt

remain

b

Be

sure

gasket

is

not

turned

up

and

discon

tinued

OIL

PRESSURE

REGULATOR

VALVE

The

oil

pressure

regulator

valve

is

not

adjustable

At

the

released

position

the

valve

permits

oil

passing

through

a

passage

on

the

pump

cover

to

the

inlet

side

of

the

pump

Measure

the

regulator

valve

spring

dimension

to

ensure

that

the

spring

is

provided

with

the

correct

tension

e

Q

@

I

I

Adjusting

shim

2

Valve

spring

13

I

RegulatoT

valve

Fig

EL

4

RegulatoT

valve

Tightening

torque

Oil

pump

cover

bolts

kg

m

ft

lb

2

0

1

45

Oil

pump

mounting

bolts

kg

m

ft

lb

13

to

1

5

9

4to

II

Cap

nut

regulator

valve

kg

m

ft

lb

4

0

to

5

0

29

to

36

Specifications

Oil

pressure

at

idling

kgfcm2

Ibfsq

in

0

9

to

1

2

13

to

17

Regulator

valve

spirng

Free

length

mm

in

Pressured

length

mm

in

4349

l71

30

3

I

19

Regulator

valve

opening

pressure

kgfcm2

lbfsq

in

3

8

to

4

2

54

to

60

OIL

FILTER

The

oil

filter

is

of

a

cartridge

type

The

oil

filter

is

installed

or

removed

using

special

tool

The

filter

element

and

the

filter

body

are

caulked

together

I

t

must

be

replaced

with

a

new

one

as

an

assembly

When

installing

the

oil

filter

fasten

it

to

the

oil

pump

EL

3

Page 403 of 513

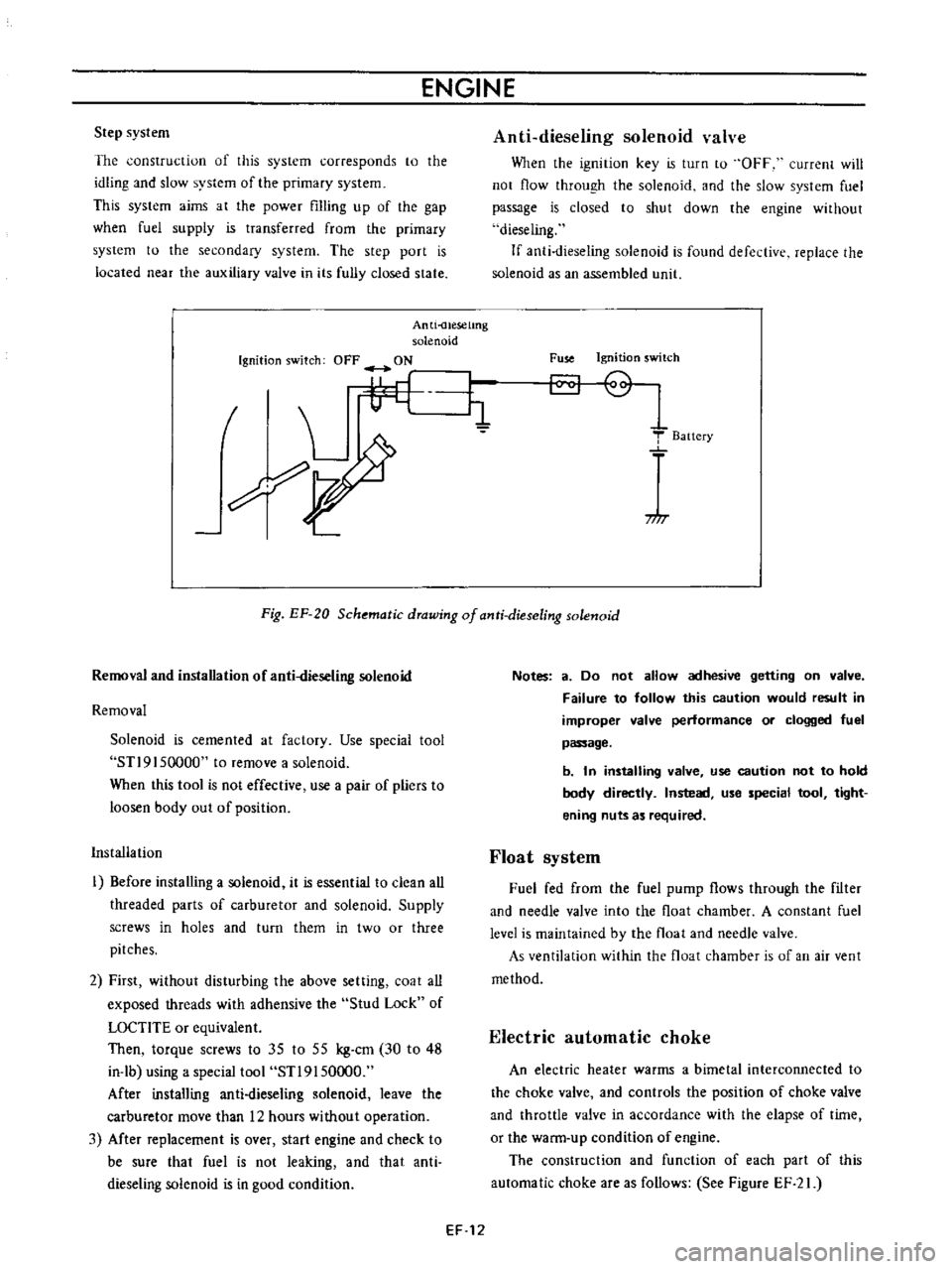

ENGINE

Step

system

The

construction

of

this

system

corresponds

to

the

idling

and

slow

system

of

the

primary

system

This

system

aims

at

the

power

filling

up

of

the

gap

when

fuel

supply

is

transferred

from

the

primary

system

to

the

secondary

system

The

step

port

is

located

near

the

auxiliary

valve

in

its

fully

closed

state

Anti

uesetmg

solenoid

Ignition

switch

OFF

ON

I

L

i1

7

I

Anti

dieseling

solenoid

valve

When

the

ignition

key

is

turn

to

OFF

current

will

not

flow

through

the

solenoid

and

the

slow

system

fuel

passage

is

closed

to

shut

down

the

engine

without

dieseling

If

anti

dieseling

solenoid

is

found

defective

replace

the

solenoid

as

an

assembled

llnit

Fuse

Ignition

switch

T

Baitery

717

Fig

EF

20

Schematic

drawing

of

anti

dieseling

solenoid

Removal

and

installation

of

anti

dieseling

solenoid

Removal

Solenoid

is

cemented

at

factory

Use

special

tool

STl9

I

50000

to

remove

a

solenoid

When

this

tool

is

not

effective

use

a

pair

of

pliers

to

loosen

body

out

of

position

Installation

I

Before

installing

a

solenoid

it

is

essential

to

clean

all

threaded

parts

of

carburetor

and

solenoid

Supply

screws

in

holes

and

turn

them

in

two

or

three

pitches

2

First

without

disturbing

the

above

setting

coat

all

exposed

threads

with

adhensive

the

Stud

Lock

of

LOCTlTE

or

equivalent

Then

torque

screws

to

35

to

55

kg

cm

30

to

48

in

lb

using

a

special

tool

STl9150000

After

installing

anti

dieseling

solenoid

leave

the

carburetor

move

than

12

hours

without

operation

3

Mter

replacement

is

over

start

engine

and

check

to

be

sure

that

fuel

is

not

leaking

and

that

anti

dieseling

solenoid

is

in

good

condition

Notes

a

Do

not

allow

adhesive

getting

on

valve

Failure

to

follow

this

caution

would

result

in

improper

valve

performance

or

clogged

fuel

passage

b

In

installing

valve

use

caution

not

to

hold

body

directly

Instead

use

special

tool

tight

ening

nuts

as

required

Float

system

Fuel

fed

from

the

fuel

pump

flows

through

the

filter

and

needle

valve

into

the

float

chamber

A

constant

fuel

level

is

maintained

by

the

float

and

needle

valve

As

ventilation

within

the

float

chamber

is

of

an

air

vent

method

Electric

automatic

choke

An

electric

heater

warms

a

bimetal

interconnected

to

the

choke

valve

and

controls

the

position

of

choke

valve

and

throttle

valve

in

accordance

with

the

elapse

of

time

or

the

warm

up

condition

of

engine

The

construction

and

function

of

each

part

of

this

automatic

choke

are

as

follows

See

Figure

EF

21

EF

12

Page 424 of 513

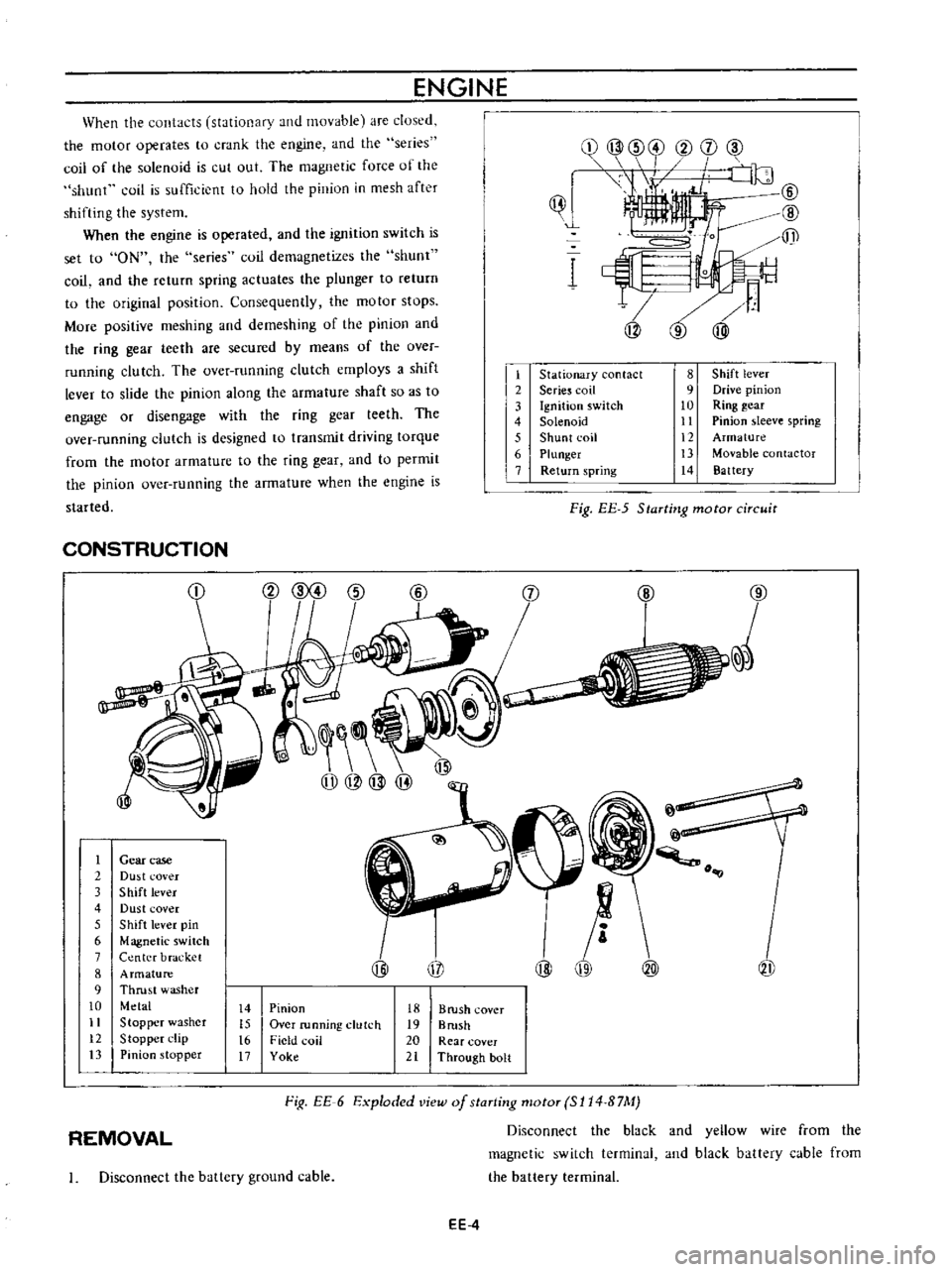

When

the

contacts

stationary

and

movable

are

dused

the

motor

operates

to

crank

the

engine

and

the

series

coil

of

the

solenoid

is

cut

out

The

magnetic

force

of

the

shunt

coil

is

sufficient

to

hold

the

pinion

in

mesh

after

shifting

the

system

When

the

engine

is

operated

and

the

ignition

switch

is

set

to

ON

the

series

coil

demagnetizes

the

shunt

coil

and

the

return

spring

actuates

the

plunger

to

return

to

the

original

position

Consequently

the

motor

stops

More

positive

meshing

and

demeshing

of

the

pinion

and

the

ring

gear

teeth

are

secured

by

means

of

the

over

running

clutch

The

over

running

clutch

employs

a

shift

lever

to

slide

the

pinion

along

the

armature

shaft

so

as

to

engage

or

disengage

with

the

ring

gear

teeth

The

over

running

clutch

is

designed

to

transmit

driving

torque

from

the

motor

armature

to

the

ring

gear

and

to

permit

the

pinion

over

running

the

armature

when

the

engine

is

started

ENGINE

ijJ

1

t

2

3

4

5

6

7

Stationary

contact

Serie

coil

Ignition

switch

Solenoid

Shunt

coil

Plunger

Return

spring

8

Shift

lever

9

Drive

pinion

10

Ring

gear

11

Pinion

sleeve

spring

12

Armature

13

Movable

contactor

14

Battery

Fig

EE

5

Starting

motor

circuit

CONSTRUCTION

1

2

3

4

5

6

7

8

9

10

11

12

13

j

@

Gear

case

Du

t

cover

Shift

lever

Dust

cover

Shift

lever

pin

Magnetic

switch

Center

bracket

Armature

Thrust

washer

Metal

Stopper

washer

Stopper

l

lip

Pinion

stopper

@

@

o

@

i

1I

@

@

@

14

15

t6

17

Pinion

Over

running

clutch

Field

coil

Yoke

18

B

rush

cover

19

Brush

20

Rear

cover

21

Through

bolt

Fig

EE

6

Exploded

view

of

staTting

motoT

SI14

B7M

Disconnect

the

black

and

yellow

wire

from

the

magnetic

switch

terminal

and

black

battery

cable

from

the

battery

terminal

REMOVAL

I

Disconnect

the

ballery

ground

cable

EE

4

Page 429 of 513

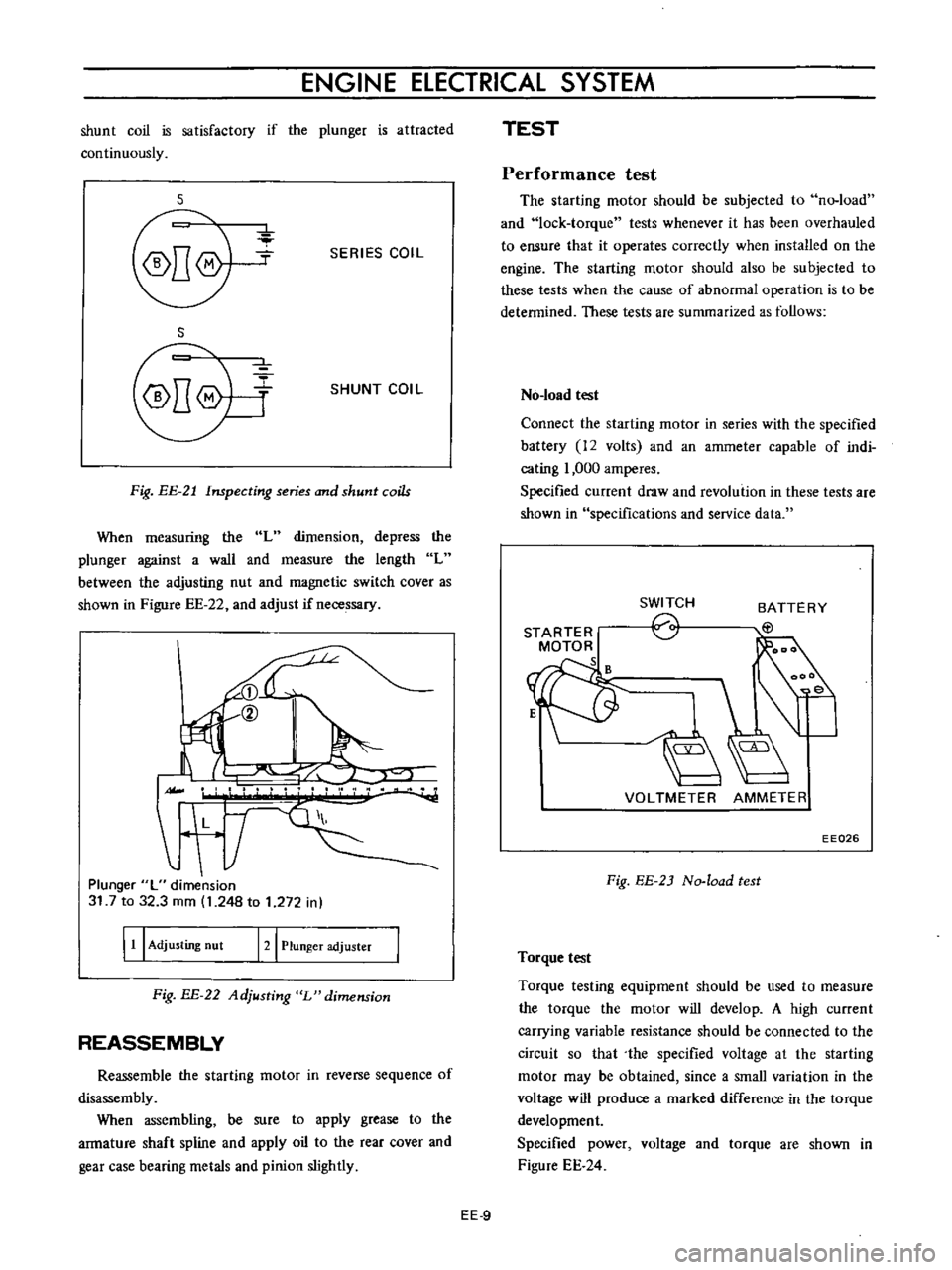

ENGINE

ElECTRICAL

SYSTEM

shunt

coil

is

satisfactory

if

the

plunger

is

attracted

continuously

s

SERIES

COIL

S

SHUNT

COIL

Fig

EE

21

Inspecting

series

and

shunt

coils

When

measuring

the

L

dimension

depress

the

plunger

against

a

wall

and

measure

the

length

L

between

the

adjusting

nut

and

magnetic

switch

cover

as

shown

in

Figure

EE

22

and

adjust

if

necessary

II

L

T

Plunger

L

dimension

31

7

to

32

3

mm

1

248

to

1

272

in

I

11

I

Adjusting

nut

121

Plunger

adjuster

Fig

BE

22

Adjusting

L

dimension

REASSEMBLY

Reassemble

the

starting

motor

in

reverse

sequence

of

disassembly

When

assembling

be

sure

to

apply

grease

to

the

armature

shaft

spline

and

apply

oil

to

the

rear

cover

and

gear

case

bearing

metals

and

pinion

slightly

TEST

Performance

test

The

starting

motor

should

be

subjected

to

no

load

and

lock

torque

tests

whenever

it

has

been

overhauled

to

ensure

that

it

operates

correctly

when

installed

on

the

engine

The

starting

motor

should

also

be

subjected

to

these

tests

when

the

cause

of

abnormal

operation

is

to

be

determined

These

tests

are

summarized

as

follows

No

load

test

Connect

the

starting

motor

in

series

with

the

specified

battery

12

volts

and

an

ammeter

capable

of

indi

cating

1

000

amperes

Specified

current

draw

and

revolution

in

these

tests

are

shown

in

specifications

and

service

data

STARTER

MOTOR

s

SWITCH

o

BATTERY

EtJ

VOLTMETER

AMMETER

EE026

Fig

EE

2J

No

load

test

Torque

test

Torque

testing

equipment

should

be

used

to

measure

the

torque

the

motor

will

develop

A

high

current

carrying

variable

resistance

should

be

connected

to

the

circuit

so

that

the

specified

voltage

at

the

starting

motor

may

be

obtained

since

a

small

variation

in

the

voltage

will

produce

a

marked

difference

in

the

torque

development

Specified

power

voltage

and

torque

are

shown

in

Figure

EE

24

EE

9