torque DATSUN B110 1973 Service Manual Online

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 307 of 513

ENGINE

operating

mechanism

Adjust

valve

clearance

at

following

four

points

while

engine

is

still

hot

G

Exhaust

valve

of

No

1

cylinder

CV

Intake

valve

of

No

1

cylinder

CID

Intake

valve

of

No

2

cylinder

CID

Exhaust

valve

of

No

3

cylinder

Note

Numbers

in

parenthesis

agree

with

those

in

ac

companying

sketch

I

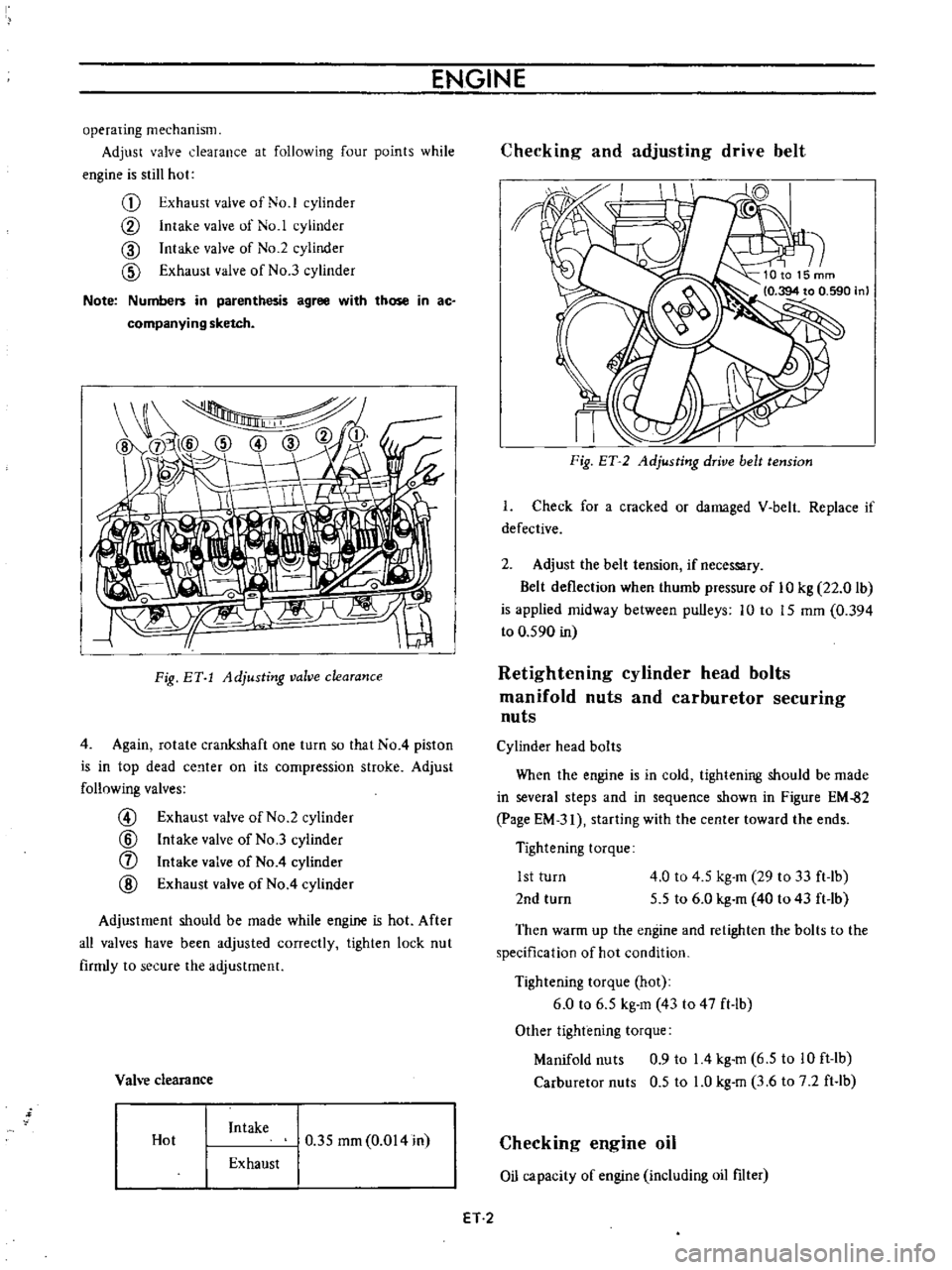

Fig

BY

1

Adjusting

valve

clearance

4

Again

rotate

crankshaft

one

turn

so

that

No

4

piston

is

in

top

dead

ce

lter

on

its

compression

stroke

Adjust

follnwing

valves

@

Exhaust

valve

of

No

2

cylinder

@

Intake

valve

of

No

3

cylinder

f

Intake

valve

of

No

4

cylinder

@

Exhaust

valve

of

No

4

cylinder

Adjustment

should

be

made

while

engine

is

hot

After

all

valves

have

been

adjusted

correctly

tighten

lock

nut

firmly

to

secure

the

adjustment

Vah

e

clearance

Hot

Intake

0

35

mm

0

014

in

Exhaust

Checking

and

adjusting

drive

belt

II

I

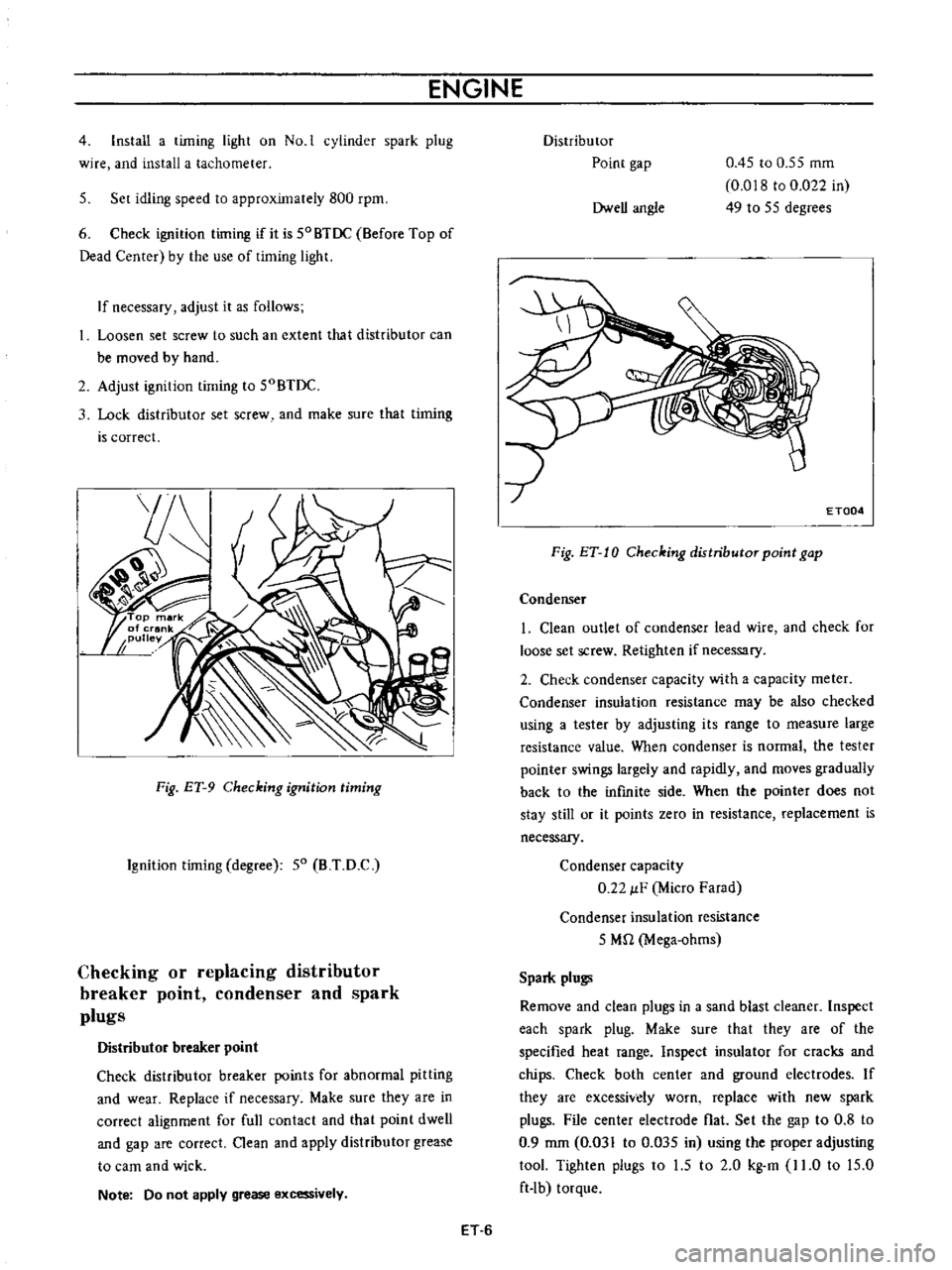

Fig

ET

2

Adjusting

drive

belt

tension

I

Check

for

a

cracked

or

damaged

V

belt

Replace

if

defective

2

Adjust

the

belt

tension

if

necessary

Belt

deflection

when

thumb

pressure

of

10

kg

22

0

lb

is

applied

midway

between

pulleys

10

to

15

mm

0

394

to

0

590

in

Retightening

cylinder

head

bolts

manifold

nuts

and

carburetor

securing

nuts

Cylinder

head

bolts

When

the

engine

is

in

cold

tightening

should

be

made

in

several

steps

and

in

sequence

shown

in

Figure

EM

82

page

EM

31

starting

with

the

center

toward

the

ends

Tightening

torque

1st

turn

2nd

turn

4

0

to

4

5

kg

m

29

to

33

ft

lb

5

5

to

6

0

kg

m

40

to

43

ft

lb

Then

warm

up

the

engine

and

retighten

the

bolts

to

the

specification

of

hot

condition

Tightening

torque

hot

6

0

to

6

5

kg

m

43

to

47

ft

lb

Other

tightening

torque

Manifold

nuts

0

9

to

14

kg

m

6

5

to

10

ft

lb

Carburetor

nuts

0

5

to

LO

kg

m

3

6

to

7

2

ft

lb

Checking

engine

oil

Oil

capacity

of

engine

including

oil

filter

ET

2

Page 311 of 513

ENGINE

4

Install

a

timing

light

on

No

cylinder

spark

plug

wire

and

install

a

tachometer

5

Set

idling

speed

to

approximately

800

rpm

6

Check

ignition

timing

if

it

is

50BTDC

Before

Top

of

Dead

Center

by

the

use

of

timing

light

If

necessary

adjust

it

as

follows

Loosen

set

screw

to

such

an

extent

that

distributor

can

be

moved

by

hand

2

Adjust

ignition

timing

to

50BTDC

3

Lock

distributor

set

screw

and

make

sure

that

timing

is

correct

Fig

ET

9

Checking

ignition

timing

Ignition

timing

degree

50

B

T

D

C

Checking

or

replacing

distributor

breaker

point

condenser

and

spark

plugs

Distributor

breaker

point

Check

distributot

breaker

points

for

abnormal

pitting

and

wear

Replace

if

necessary

Make

sure

they

are

in

correct

alignment

for

full

contact

and

that

point

dwell

and

gap

are

correct

Clean

and

apply

distributor

grease

to

earn

and

wick

Note

Do

not

apply

grease

excessively

Distributor

Point

gap

0

45

to

0

55

mm

0

018

to

0

Q22

in

49

to

55

degrees

Dwell

angle

ET004

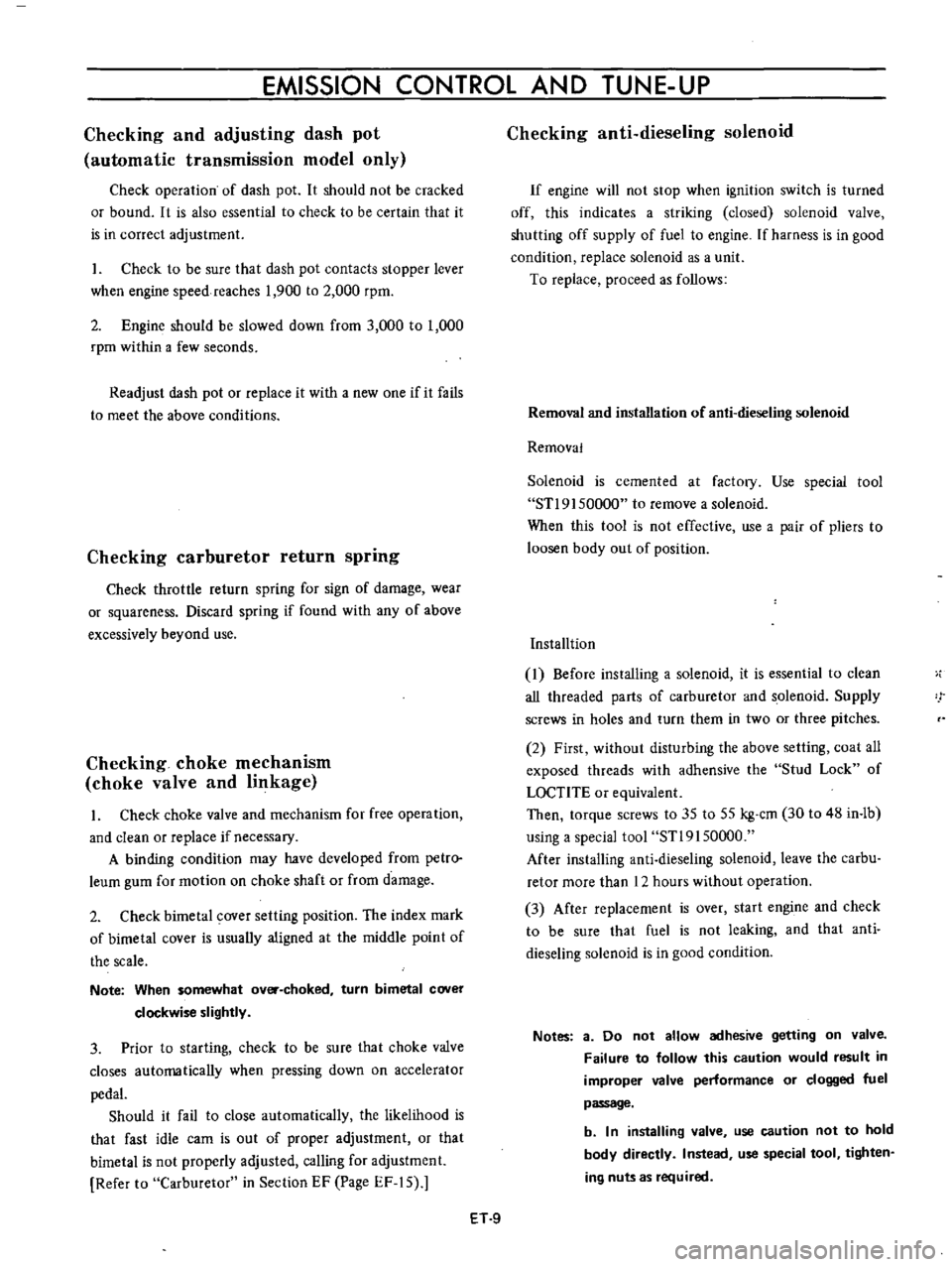

Fig

ET

10

Checking

distributor

point

gap

Condenser

I

Clean

outlet

of

condenser

lead

wire

and

check

for

loose

set

screw

Retighten

if

necessary

2

Check

condenser

capacity

with

a

capacity

meter

Condenser

insulation

resistance

may

be

also

checked

using

a

tester

by

adjusting

its

range

to

measure

large

resistance

value

When

condenser

is

normal

the

tester

pointer

swings

largely

and

rapidly

and

moves

gradually

back

to

the

infmite

side

When

the

pointet

does

not

stay

still

or

it

points

zero

in

resistance

replacement

is

necessary

Condenser

capacity

0

221LF

Micro

Farad

Condenser

insulation

resistance

5

Mn

Mega

ohms

Spark

plugs

Remove

and

clean

plugs

in

a

sand

blast

cleaner

Inspect

each

spark

plug

Make

sure

that

they

are

of

the

specified

heat

tange

Inspect

insulator

for

cracks

and

chips

Check

both

center

and

ground

electrodes

If

they

are

excessi

ely

worn

replace

with

new

spark

plugs

File

center

electrode

flat

Set

the

gap

to

0

8

to

0

9

rom

0

031

to

0

035

in

using

the

proper

adjusting

tool

Tighten

plugs

to

1

5

to

2

0

kg

m

11

0

to

15

0

ft

lb

torque

ET

6

Page 314 of 513

EMISSION

CONTROL

AND

TUNE

UP

Checking

and

adjusting

dash

pot

automatic

transmission

model

only

Check

operation

of

dash

pot

It

should

not

be

cracked

or

bound

It

is

also

essential

to

check

to

be

certain

that

it

is

in

correct

adjustment

L

Check

to

be

sure

that

dash

pot

contacts

stopper

lever

when

engine

speed

reaches

1

900

to

2

000

rpm

2

Engine

should

be

slowed

down

from

3

000

to

1

000

rpm

within

a

few

seconds

Readjust

dash

pot

or

replace

it

with

a

new

one

if

it

fails

to

meet

the

above

conditions

Checking

carburetor

return

spring

Check

throttle

return

spring

for

sign

of

damage

wear

or

squareness

Discard

spring

if

found

with

any

of

above

excessively

beyond

use

Checking

choke

mechanism

choke

valve

and

linkage

1

Check

choke

valve

and

mechanism

for

free

operation

and

clean

or

replace

if

necessary

A

binding

condition

may

have

developed

from

petro

leum

gum

for

motion

on

choke

shaft

or

from

damage

2

Check

bimetal

cover

setting

position

The

index

mark

of

bimetal

cover

is

usually

aligned

at

the

middle

point

of

the

scale

Note

When

somewhat

over

choked

turn

bimetal

caver

clockwise

slightly

3

Prior

to

starting

check

to

be

sure

that

choke

valve

closes

automatically

when

pressing

down

on

accelerator

pedal

Should

it

fail

to

close

automatically

the

likelihood

is

that

fast

idle

cam

is

out

of

proper

adjustment

or

that

bimetal

is

not

properly

adjusted

calling

for

adjustment

Refer

to

Carburetor

in

Section

EF

Page

EF

15

Checking

anti

dieseling

solenoid

If

engine

will

not

stop

when

ignition

switch

is

turned

off

this

indicates

a

striking

closed

solenoid

valve

shutting

off

supply

of

fuel

to

engine

If

harness

is

in

good

condition

replace

solenoid

as

a

unit

To

replace

proceed

as

follows

Removal

and

installation

of

anti

dieseling

solenoid

Removal

Solenoid

is

cemented

at

factory

Use

special

tool

STl

91

50000

to

remove

a

solenoid

When

this

tool

is

not

effective

use

a

pair

of

pliers

to

loosen

body

out

of

position

lnstalltion

I

Before

installing

a

solenoid

it

is

essential

to

clean

all

threaded

parts

of

carburetor

and

solenoid

Supply

screws

in

holes

and

turn

them

in

two

or

three

pitches

2

First

without

disturbing

the

above

setting

coat

all

exposed

threads

with

adhensive

the

Stud

Lock

of

LOCTlTE

or

equivalent

Then

torque

screws

to

35

to

55

kg

cm

30

to

48

in

lb

using

a

special

tool

STl9150000

After

installing

anti

dieseling

solenoid

leave

the

carbu

retor

more

than

12

hours

without

operation

3

After

replacement

is

over

start

engine

and

check

to

be

sure

that

fuel

is

not

leaking

and

that

anti

dieseling

solenoid

is

in

good

condition

Notes

a

Do

not

allow

adhesive

getting

on

valve

Failure

to

follow

this

caution

would

result

in

improper

valve

performance

or

clogged

fuel

passage

b

I

n

installing

valve

use

caution

not

to

hold

body

directly

Instead

use

special

tool

tighten

ing

nuts

as

required

ET

9

Page 330 of 513

EMISSION

CONTROL

AND

TUNE

UP

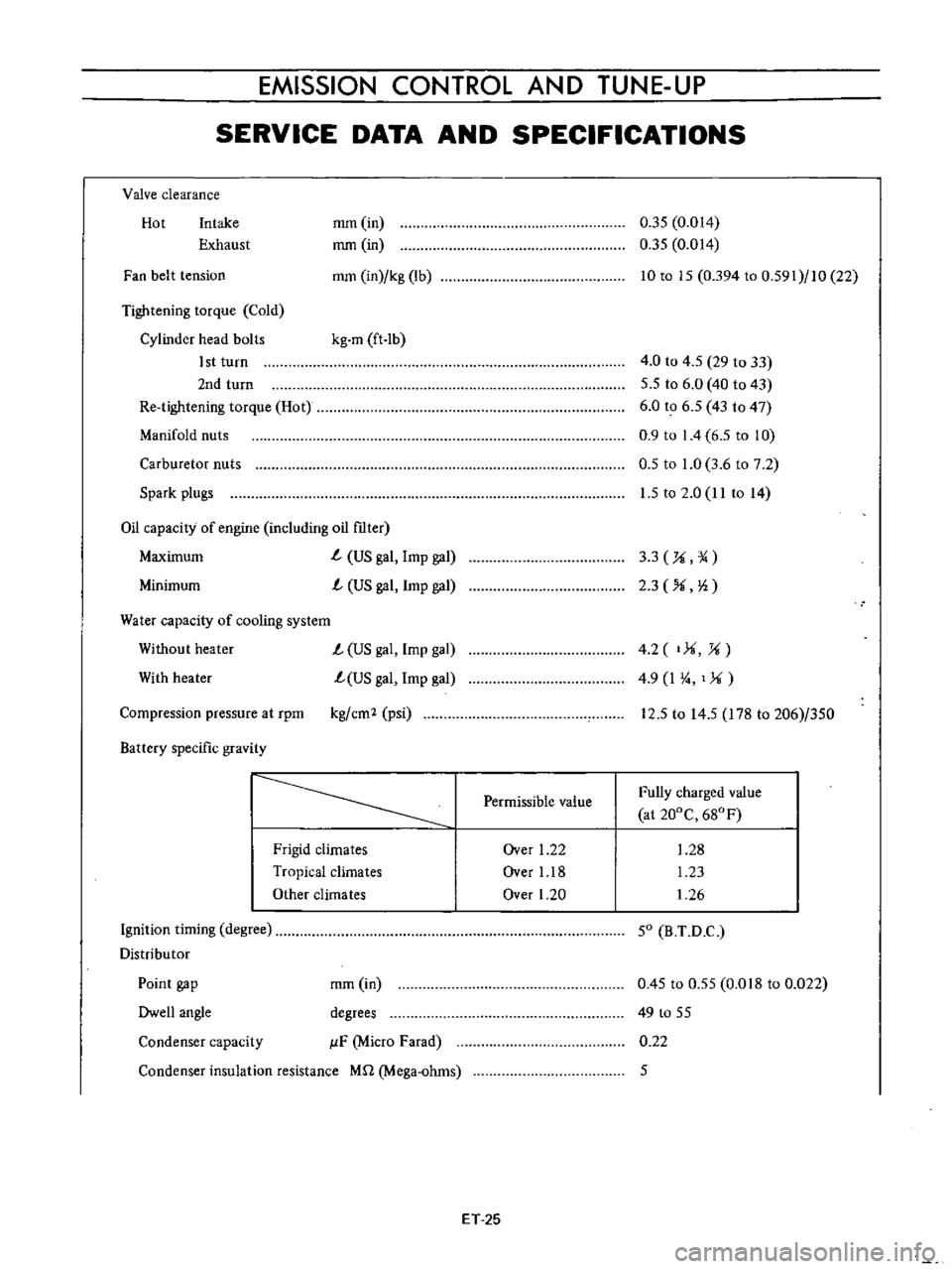

SERVICE

DATA

AND

SPECIFICATIONS

Valve

clearance

Hot

Intake

Exhaust

mm

in

rom

in

rom

in

kg

lb

0

35

0

014

0

35

0

014

10

to

15

0

394

to

0

591

10

22

Fan

belt

tension

Tightening

torque

Cold

Cylinder

head

bolts

kg

m

ft

lb

1st

turn

2nd

turn

Re

tightening

torque

Hot

Manifold

nuts

Carburetor

nuts

4

0

to

4

5

29

to

33

5

5

to

6

0

40

to

43

6

0

to

6

5

43

to

47

0

9

to

I

4

6

5

to

10

0

5

to

1

0

3

6

to

7

2

1

5

to

2

0

II

to

14

Spark

plugs

Oil

capacity

of

engine

including

oil

ftIter

Maximum

L

US

gal

Imp

gal

L

US

gal

Imp

gal

3

3

U

14

2

3

Ii

Minimum

Water

capacity

of

cooling

system

Without

heater

L

US

gal

Imp

gal

With

heater

L

US

gal

Imp

gal

4

2

1

U

4

9

I

4

11

12

5

to

14

5

I78

to

206

350

Compression

pressure

at

rpm

kg

em

psi

Battery

specific

gravity

Permissible

value

Fully

charged

value

at

200C

680F

Frigid

climates

Tropical

climates

Other

elima

tes

Over

1

22

Over

1

18

Over

1

20

1

28

1

23

1

26

Ignition

timing

degree

Distributor

50

B

T

D

C

Condenser

capacity

mm

in

degrees

IlF

Micro

Farad

0

45

to

0

55

0

018

to

0

022

49

to

55

0

22

5

Point

gap

Dwell

angle

Condenser

insulation

resistance

Mil

Mega

ohms

ET

25

Page 333 of 513

ENGINE

Defective

spark

plug

Improper

ignition

timing

Defective

ignition

coil

Disconnection

of

high

tension

cable

Loose

connection

or

disconnection

in

prima

ry

circuit

Lack

of

fuel

Dirty

fuel

strainer

Dirty

or

clogged

fuel

pipe

Fuel

pump

will

not

work

properly

Carburetor

auto

choke

will

not

work

prop

erly

Improper

float

level

adjustment

Improper

idling

Dirty

or

clogged

carburetor

Damaged

anti

dieseling

solenoid

Clogged

breather

pipe

Incorrect

spark

plug

tightening

or

defective

gasket

Improper

grade

engine

oil

or

viscosity

drop

ping

Incorrect

valve

clearance

Compression

leak

from

valve

seat

Sticky

valve

stem

Weak

or

defective

valve

springs

Compression

leak

at

cylinder

head

gasket

Sticked

or

defective

piston

ring

Worn

piston

ring

or

cylinder

Troubleshooting

procedure

Pour

engine

oil

from

plug

hole

and

then

measure

cylinder

compression

Clean

adjust

plug

gap

or

replace

Adjust

Replace

Replace

Repair

or

replace

Supply

Replace

Clean

Repair

or

replace

Check

and

adjust

Correct

Adjust

Disassemble

and

clean

Replace

Clean

Tighten

to

normal

torque

or

replace

spark

plug

assembly

Replace

with

proper

grade

oil

Adjust

Remove

cylinder

head

and

lap

valves

Correct

or

replace

valve

Replace

valve

springs

Replace

gasket

Replace

piston

ring

Overhaul

engine

Compression

increases

Trouble

in

cylinder

or

piston

ring

Compression

unchanged

Compression

leak

from

valve

cylinder

head

or

head

gasket

ET

28

Page 361 of 513

ENGINE

MECHANICAL

Standard

Maximum

Crankshaft

bend

mm

in

0

05

0

0020

0

015

0

0006

Note

When

measuring

bend

use

a

dial

gauge

Bend

value

is

a

half

of

the

reading

obtained

when

the

crankshaft

is

turned

once

with

the

dial

gauge

applied

to

its

center

journal

3

After

regrinding

the

crankshaft

fmish

it

to

the

necessary

size

indicated

in

the

lists

on

pages

EM

25

by

using

an

adequate

undersize

bearing

according

to

the

extent

of

required

repair

4

Install

the

crankshaft

in

the

cylinder

block

and

measure

the

thrust

clearance

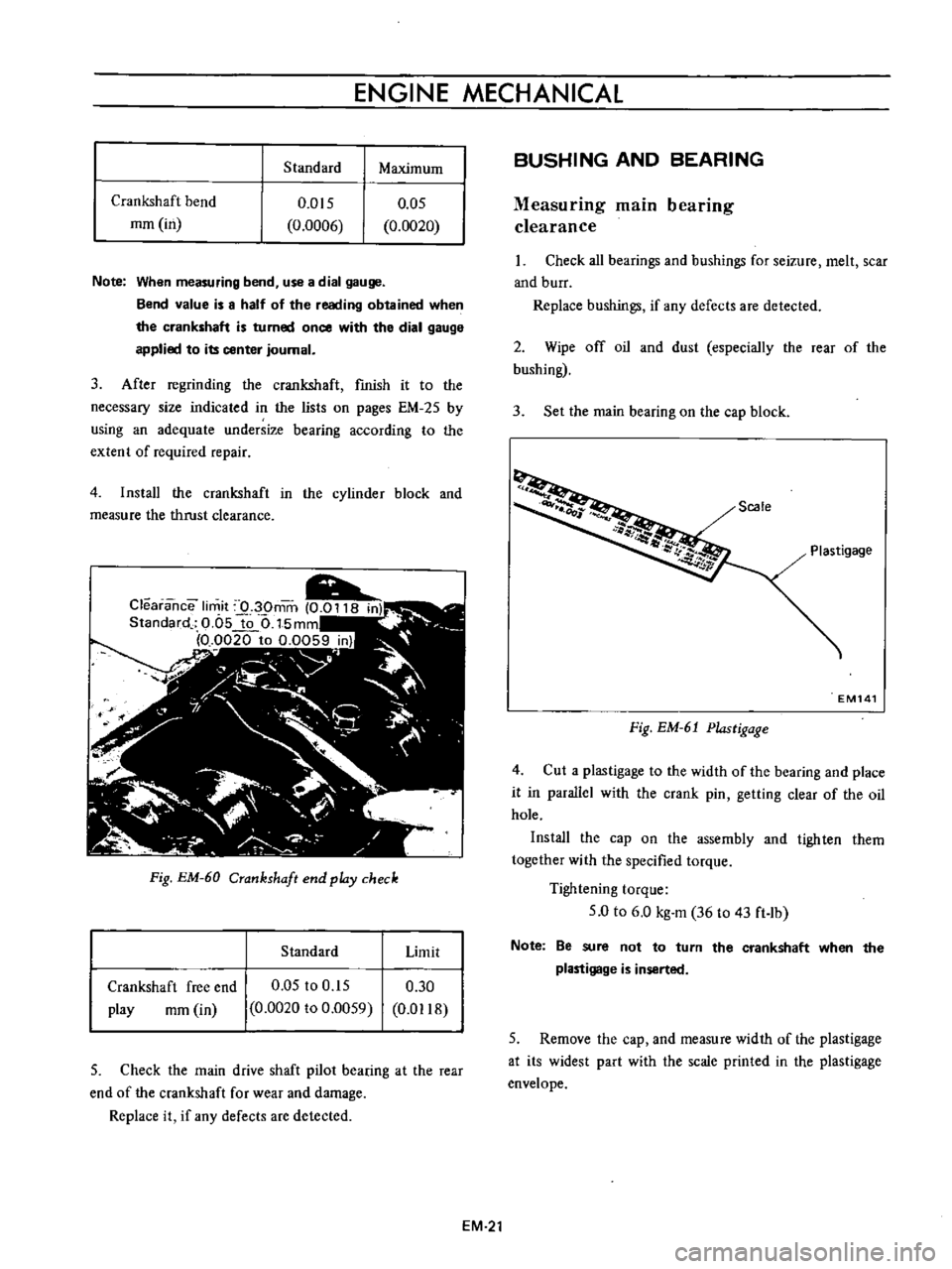

Fig

EM

60

Crankshaft

end

pldy

check

Standard

Limit

Crankshaft

free

end

play

rom

in

0

05

to

0

15

0

0020

to

0

0059

0

30

0

D118

5

Check

the

main

drive

shaft

pilot

bearing

at

the

rear

end

of

the

crankshaft

for

wear

and

damage

Replace

it

if

any

defects

are

detected

BUSHING

AND

BEARING

Measuring

main

bearing

clearance

Check

all

bearings

and

bushings

for

seizure

melt

scar

and

burr

Replace

bushings

if

any

defects

are

detected

2

Wipe

off

oil

and

dust

especially

the

rear

of

the

bushing

3

Set

the

main

bearing

on

the

cap

block

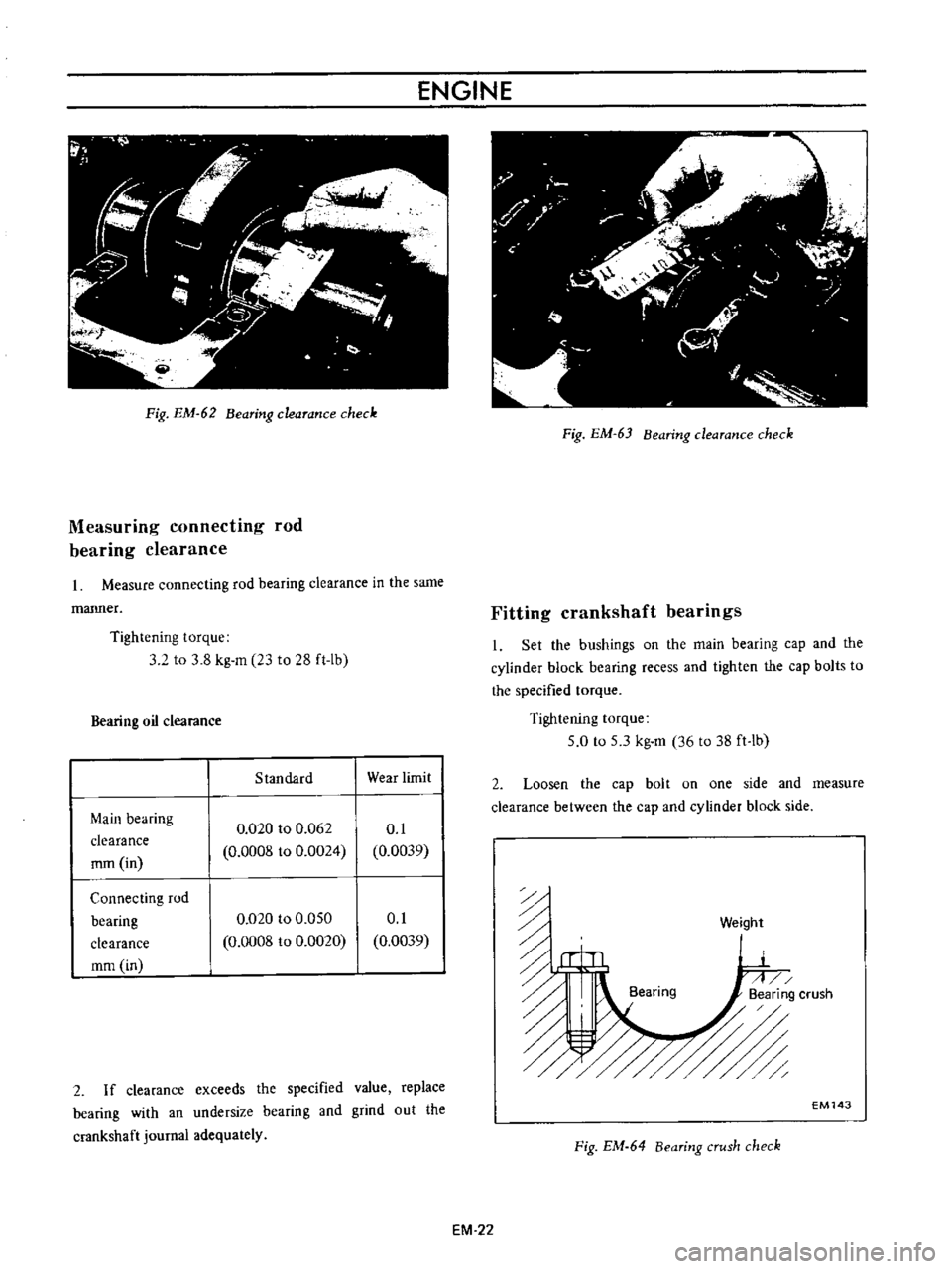

Scale

Plastigage

EM141

Fig

EM

61

Plastigage

4

Cut

a

plastigage

to

the

width

of

the

bearing

and

place

it

in

parallel

with

the

crank

pin

getting

clear

of

the

oil

hole

Install

the

cap

on

the

assembly

and

tighten

them

together

with

the

specified

torque

Tightening

torque

5

0

to

6

0

kg

m

36

to

43

ft

lb

Note

Be

sure

not

to

turn

the

crankshaft

when

the

plastigage

is

inserted

5

Remove

the

cap

and

measure

width

of

the

plastigage

at

its

widest

part

with

the

scale

printed

in

the

plastigage

envelope

EM

21

Page 362 of 513

ENGINE

Pig

EM

62

Bearing

clearance

check

Measuring

connecting

rod

bearing

clearance

Measure

connecting

rod

bearing

clearance

in

the

same

manner

Tightening

torque

3

2

to

3

8

kg

m

23

to

28

ft

Ib

Bearing

oil

clearance

Standard

Wear

limit

Main

bearing

clearance

rom

in

0

020

to

0

062

0

0008

to

0

0024

0

1

0

0039

Connecting

rod

bearing

clearance

mm

in

0

020

to

0

050

0

0008

to

0

0020

0

1

0

0039

2

If

clearance

exceeds

the

specified

value

replace

bearing

with

an

undersize

bearing

and

grind

out

the

crankshaft

journal

adequately

Fig

EM

63

Bearing

clearance

check

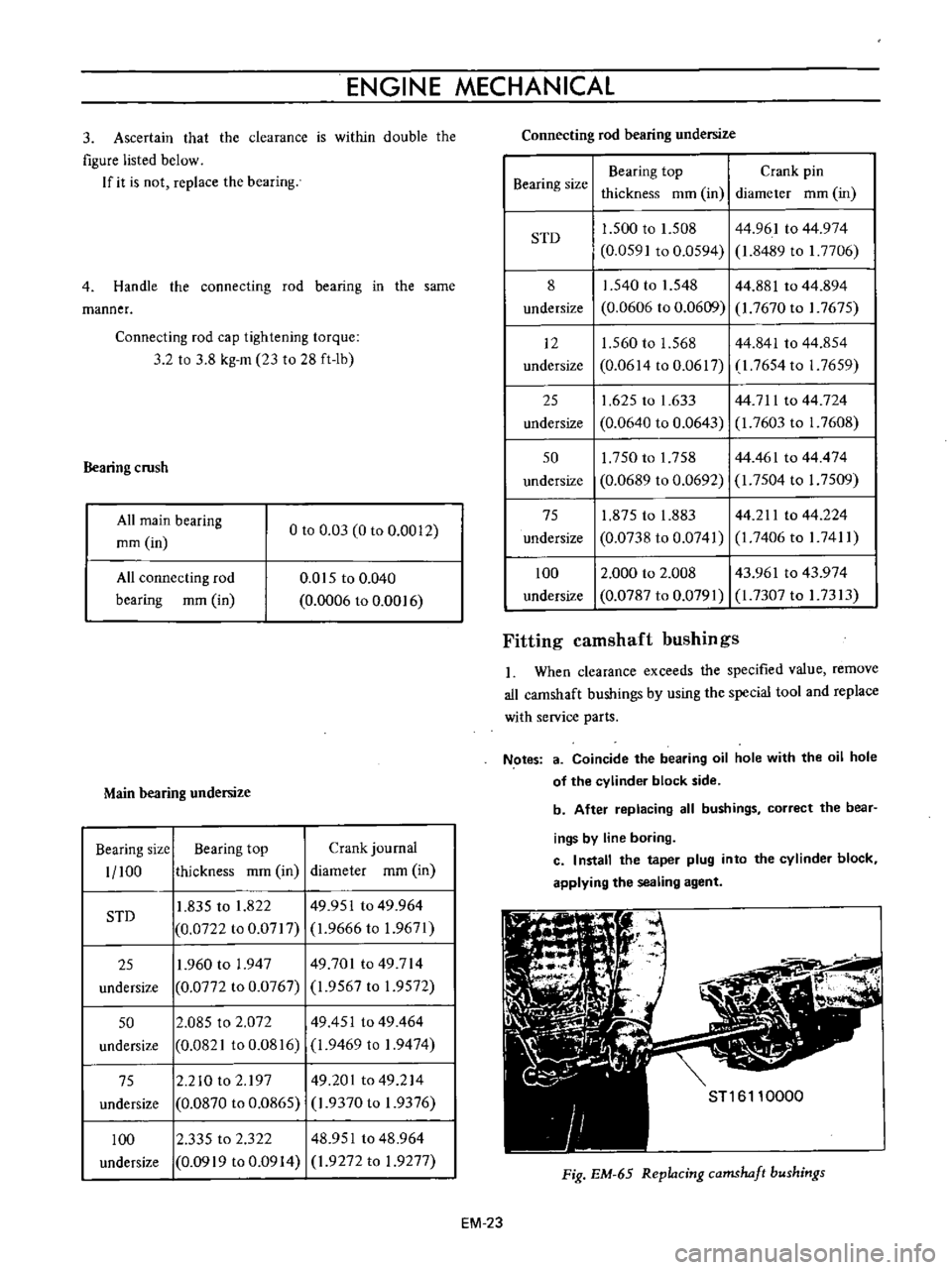

Fitting

crankshaft

bearings

I

Set

the

bushings

on

the

main

bearing

cap

and

the

cylinder

block

bearing

recess

and

tighten

the

cap

bolts

to

the

specified

torque

Tightening

torque

5

0

to

5

3

kg

m

36

to

38

ft

lb

2

Loosen

the

cap

bolt

on

one

side

and

measure

clearance

between

the

cap

and

cylinder

block

side

n

n

u

ii

Bearing

6

Weight

EM143

Fig

EM

64

Bearing

crush

check

EM

22

Page 363 of 513

ENGINE

MECHANICAL

3

Ascertain

that

the

clearance

is

within

double

the

figure

listed

below

If

it

is

not

replace

the

bearing

4

Handle

the

connecting

rod

bearing

in

the

same

manner

Connecting

rod

cap

tightening

torque

3

2

to

3

8

kg

m

23

to

28

ft

lb

Bearing

crush

All

main

bearing

mm

in

o

to

0

03

0

to

0

0012

All

connecting

rod

bearing

mm

in

0

Ql5

to

0

040

0

0006

to

0

0016

Main

bearing

undersize

Bearing

size

Bearing

top

Crank

journal

1

100

thickness

mm

in

diameter

mm

in

STD

1

835

to

1

822

49

951

to

49

964

0

0722

to

0

0717

1

9666

to

1

9671

25

1

960

to

1

947

49701

to

49

714

undersize

0

0772

to

0

0767

1

9567

to

1

9572

50

2

085

to

2

072

49451

to

49

464

undersize

0

0821

to

0

0816

1

9469

to

1

9474

75

2

210

to

2

197

49

201

to

49

214

undersize

0

0870

to

0

0865

1

9370

to

1

9376

100

2

335

to

2

322

48

951

to

48

964

undersize

0

0919

to

0

0914

1

9272

to

1

9277

Connecting

rod

bearing

undersize

Bearing

top

Crank

pin

Bearing

size

thickness

mm

in

diameter

mm

in

1

500

to

1

508

44

961

to

44

974

0

0591

to

0

0594

1

8489

to

I

7706

8

1

540

to

1

548

44

881

to

44

894

undersize

0

0606

to

0

0609

1

7670

to

I

7675

STD

12

1

560

to

1

568

44

841

to

44

854

undersize

0

0614

to

0

0617

I

7654

to

I

7659

25

1

625

to

1

633

44

711

to

44

724

undersize

0

0640

to

0

0643

1

7603

to

I

7608

50

I

750

to

1

758

44

461

to

44

474

undersize

0

0689

to

0

0692

1

7504

to

I

7509

75

1

875

to

1

883

44

211

to

44

224

undersize

0

0738

to

0

0741

1

7406

to

I

7411

100

2

000

to

2

008

43

961

to

43

974

undersize

0

0787

to

0

0791

1

7307

to

I

7313

Fitting

camshaft

bushings

When

clearance

exceeds

the

specified

value

remove

all

camshaft

bushings

by

using

the

special

tool

and

replace

with

service

parts

Notes

3

Coincide

the

bearing

oil

hole

with

the

oil

hole

of

the

cylinder

block

side

b

After

replacing

all

bushings

correct

the

bear

ings

by

line

boring

c

I

nstall

the

taper

plug

into

the

cylinder

block

applying

the

sealing

agent

Fig

EM

65

Replacing

camshaft

bushings

EM

23

Page 365 of 513

ENGINE

MECHANICAL

Standard

mm

in

Camshaft

sprocket

run

out

Thrust

deviation

O

OIS

0

0006

Locating

plate

thrust

clearance

0

02

to

0

08

0

0008

to

0

003

Wear

limit

mm

in

less

than

0

0

0039

O

OS

0

0020

0

1

0

0039

3

Check

the

chain

for

damage

excessive

wear

and

stretch

at

its

roller

links

Replace

chain

if

defective

Flyw

heel

I

Check

the

clutch

disc

contact

surface

of

the

flywheel

for

damage

and

wear

Repair

or

replace

if

necessary

2

Measure

deviation

of

the

clutch

disc

contact

surface

with

a

dial

gauge

If

it

exceeds

0

2

mm

0

0079

in

replace

it

3

Check

tooth

surfaces

of

the

ring

gear

for

flaw

and

wear

Replace

if

necessary

Note

Replace

the

ring

gear

at

about

180

to

2000C

356

to

3920

Fl

ENGINE

ASSEMBLY

PRECAUTION

CYLINDER

HEAD

PRECAUTION

CONTENTS

EM

25

EM

25

Use

thoroughly

cleaned

parts

Particularly

make

sure

that

oil

holes

are

clear

of

foreign

matter

2

When

installing

sliding

parts

such

as

bearings

be

sure

to

apply

engine

oil

to

them

3

Use

new

packings

and

oil

seals

4

Keep

tools

and

work

benches

clean

S

Keep

the

necessary

parts

and

tools

near

at

hand

6

Be

sure

to

follow

specified

tightening

torque

and

orders

CYLINDER

HEAD

Assembly

of

valve

and

valve

spring

Set

the

valve

spring

seat

in

position

and

fit

the

valve

guide

with

the

oil

lip

seal

Assemble

the

parts

in

order

valve

spring

spring

retainer

valve

collet

and

valve

rocker

guide

PISTON

AND

CONNECTING

ROO

ASSEMBLING

ENGINE

EM

25

EM

26

I

I

11

00

I

I

I

t

I

J

ftr

J

J

1

l

J

r

N

1

n

r

VI

I

I

C

I

L

I

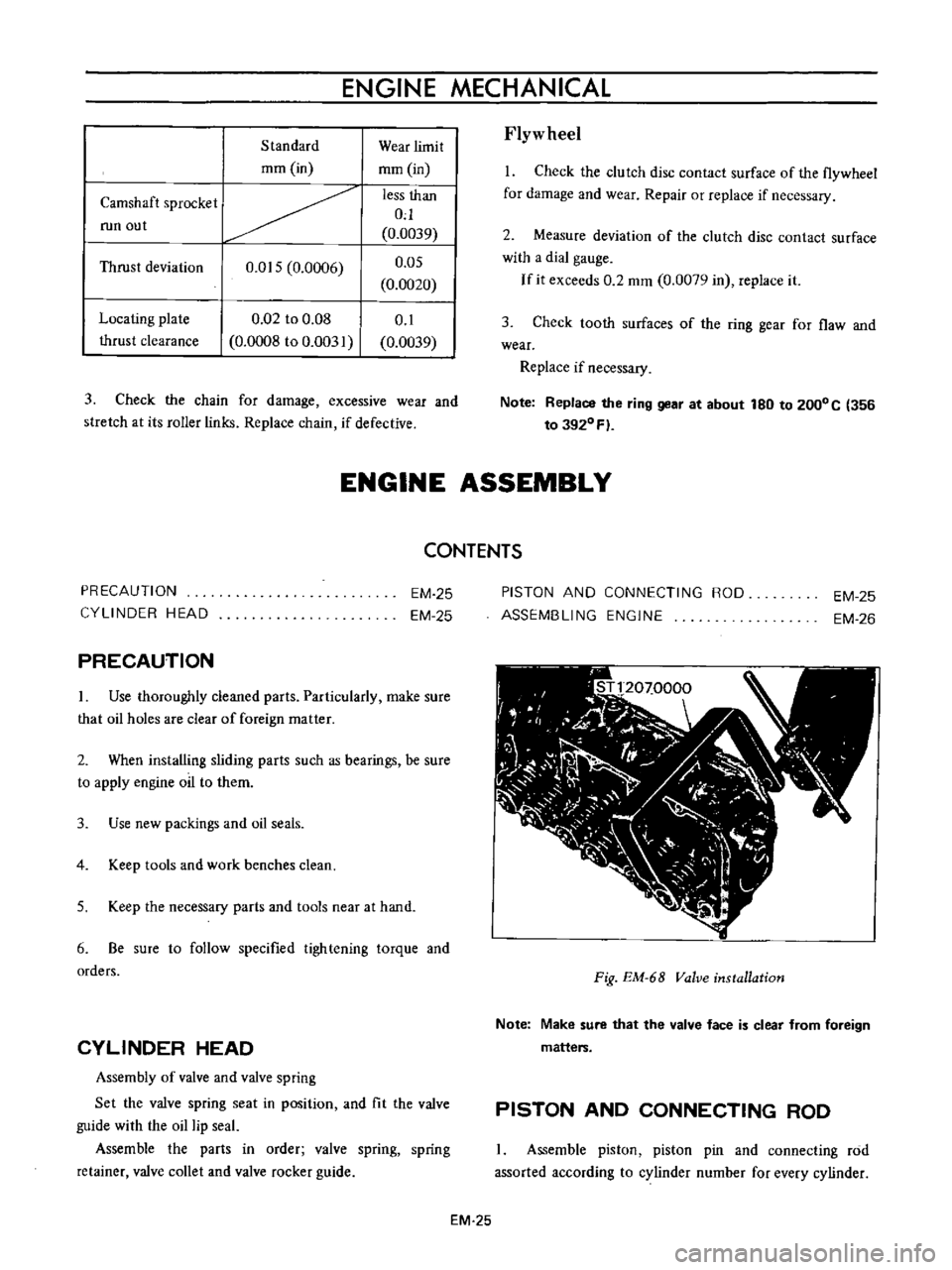

Fig

EM

68

Valve

installation

Note

Make

sure

that

the

valve

face

is

clear

from

foreign

matters

PISTON

AND

CONNECTING

ROD

Assemble

piston

piston

pin

and

connecting

rod

assorted

according

to

cylinder

number

for

every

cylinder

EM

25

Page 366 of 513

ENGINE

ST130300

1

EM156

Fig

EM

69

Piston

pin

installation

Fig

EM

70

Piston

and

connecting

rod

assembly

Notes

8

Piston

pin

is

press

fitted

to

the

connecting

rod

tightly

and

fitting

force

is

from

1

to

3

tons

When

fitting

piston

pin

special

tool

must

be

used

When

pressing

the

piston

pin

into

the

connecting

rod

apply

engine

oil

to

the

pin

and

the

small

end

of

the

connecting

rod

b

Arrange

the

connecting

rod

so

that

the

oil

jet

of

the

connecting

rod

large

end

is

directed

toward

the

right

side

of

the

cylinder

block

2

Installing

piston

rings

Install

the

top

and

second

fings

in

right

positions

so

that

the

marks

are

faced

upward

3

Fix

bearings

on

the

connecting

rod

and

the

con

necting

rod

cap

Note

Clean

the

back

side

of

the

bearing

carefully

ASSEMBLING

ENGINE

Set

the

cylinder

block

on

the

working

stand

with

the

engine

bottom

faced

upside

2

Install

the

valve

lifters

Install

the

camshaft

and

retain

by

the

camshaft

locate

plate

Locate

plate

tighten

ing

torque

is

0

4

to

0

5

kg

m

2

9

to

3

6

ft

lb

Note

Set

the

locate

plate

so

as

the

LOWER

mark

comes

to

the

engine

bottom

side

Set

the

main

bearings

on

their

positions

on

the

cylinder

block

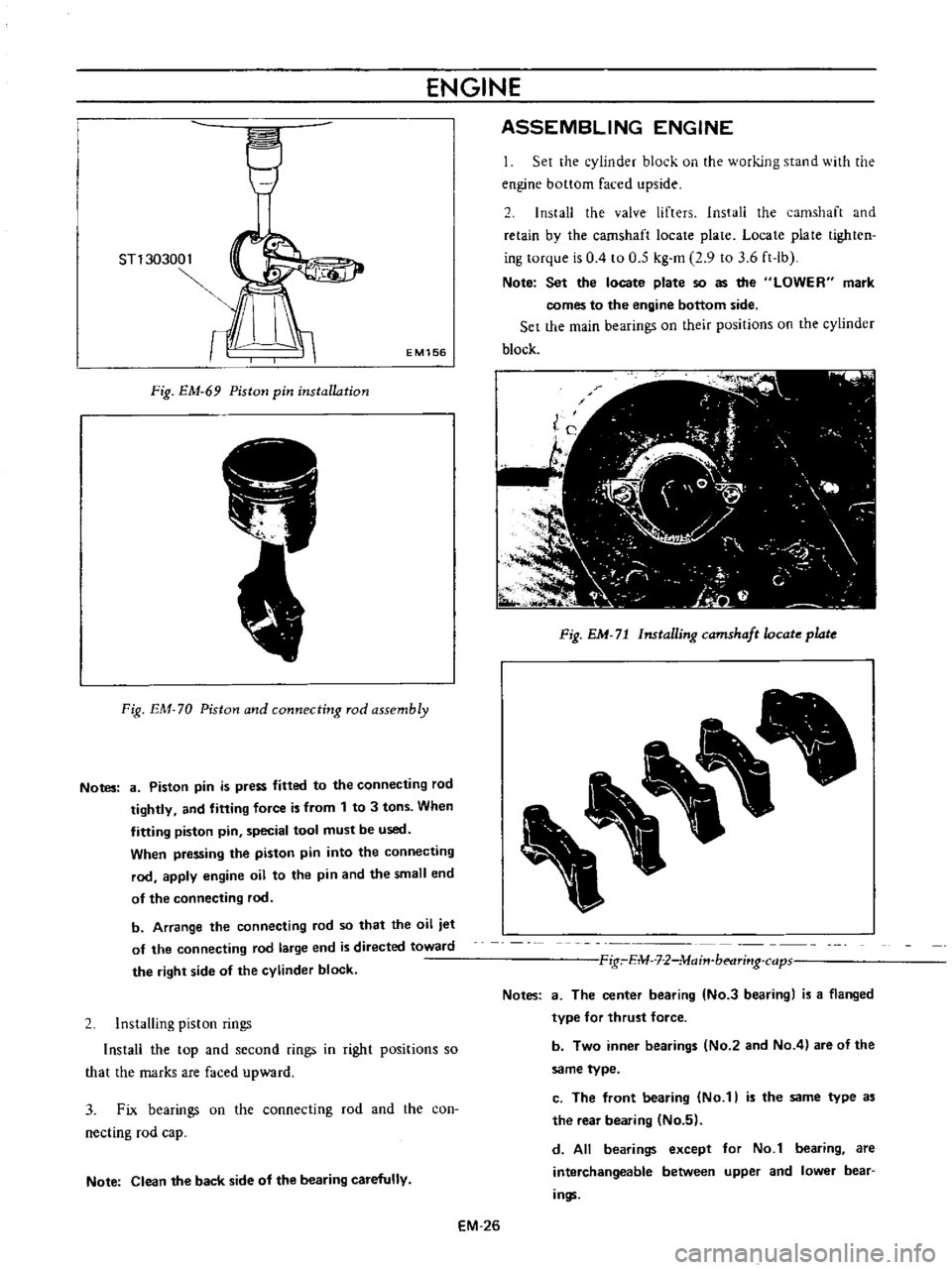

Fig

EM

71

Installing

camshaft

ocate

plate

Fig

E1U

7

2

lvlajn

betlrj

lg

cap

Notes

a

The

center

bearing

No

3

bearing

is

a

flanged

type

for

thrust

force

b

Two

inner

bearings

No

2

and

No

4

are

of

the

same

type

c

The

front

bearing

No

1

is

the

same

type

a

the

rear

bearing

No

5

d

All

bearings

except

for

No

1

bearing

are

interchangeable

between

upper

and

lower

bear

ings

EM

26