torque DATSUN B110 1973 Service Manual PDF

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 205 of 513

BODY

Fig

BF

19

R

g

male

side

of

the

hood

lock

Fig

BF

20

Removing

female

side

of

the

hood

lock

3

Remove

three

screws

and

remove

the

hood

lock

control

lever

Fig

BF

21

Removing

hood

lock

control

lever

Adjustment

Centering

the

hood

lock

The

male

side

hook

lock

is

provided

with

a

3

mm

0

118

in

adjusting

stroke

toward

left

and

right

sides

of

the

vehicle

and

the

female

side

with

a

3

rnm

0

118

in

adjusting

stroke

toward

front

and

rear

sides

of

the

vehicle

Loosen

the

installation

bolts

and

align

the

center

correctly

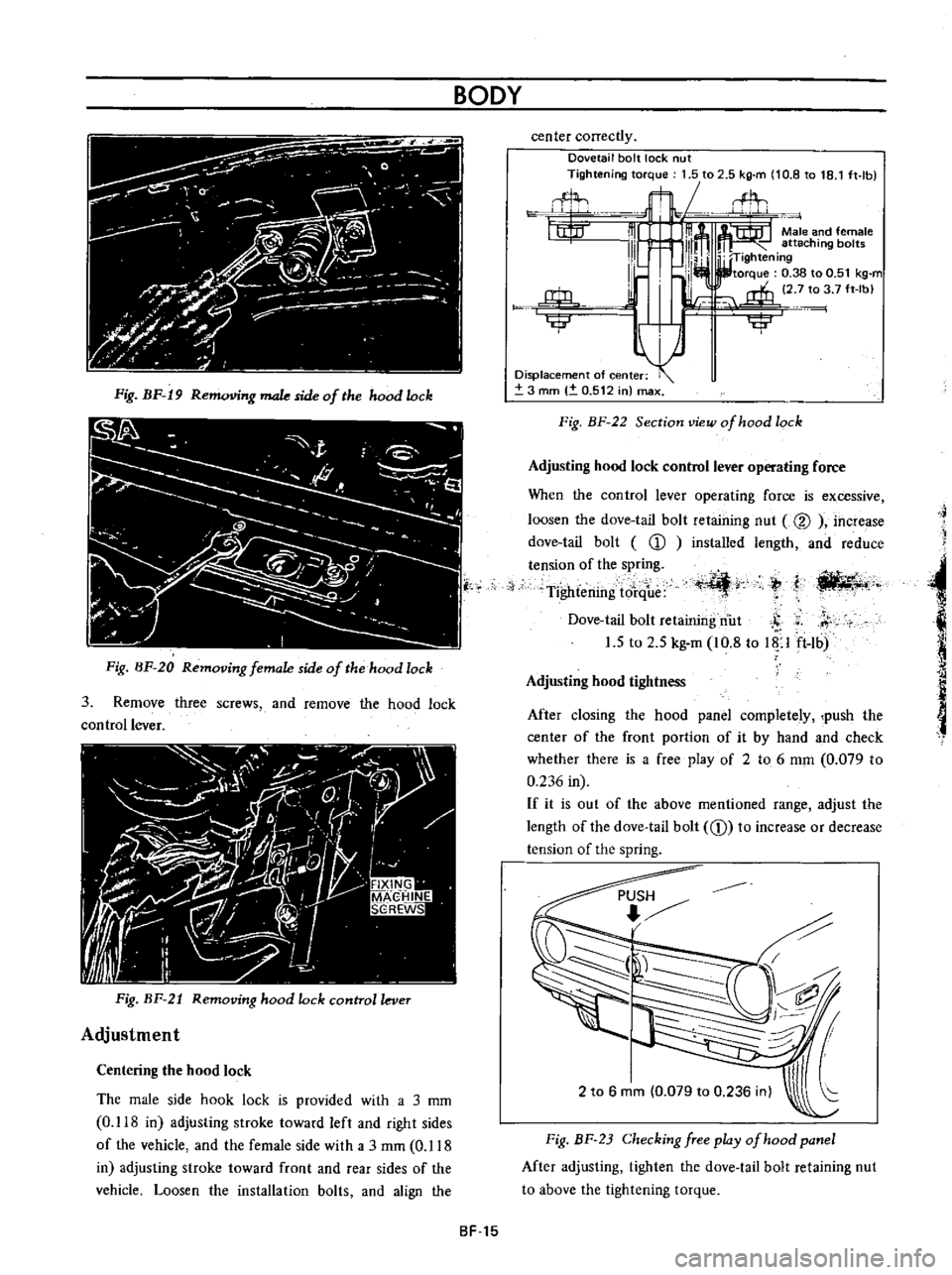

Dovetail

bolt

lock

nut

Tightening

torque

1

5

to

2

5

kg

m

10

8

to

18

1

ft

lb

flL

t1t

m

m

Male

and

female

111

l

111m

attaching

bol

W

TIghtening

I

lb

I

I

torque

0

38

to

0

51

kg

m

l

i

2

7

to

3

7

ft

Ibl

j

rffi

u

Ilillr

iji

Displacement

of

center

3

mm

0

512

in

max

Fig

BF

22

Section

view

of

hood

lock

Adjusting

hood

lock

control

lever

operating

force

When

the

control

lever

operating

force

is

excessive

loosen

the

dove

tail

bolt

retaining

nut

@

increase

dove

tail

bolt

CD

installed

length

and

reduce

tension

of

the

spring

Tightening

tore

ue

t

I

ili

4r

ti

llt4

t

j

Dove

tail

bolt

retaining

nut

S

r

1

5

to

2

5

kg

m

10

8

to

Up

ft

lb

Adjusting

hood

tightness

After

closing

the

hood

panel

completely

push

the

center

of

the

front

portion

of

it

by

hand

and

check

whether

there

is

a

free

play

of

2

to

6

mm

0

079

to

0

236

in

If

it

is

out

of

the

above

mentioned

range

adjust

the

length

of

the

dove

tail

bolt

CD

to

increase

or

decrease

tension

of

the

spring

2

to

6

mm

0

079

to

0

236

inl

Fig

BF

23

Checking

free

play

of

hood

panel

After

adjusting

tighten

the

dove

tail

bolt

retaining

nut

to

above

the

tightening

torque

SF

15

Page 206 of 513

BODY

Fig

BF

24

Adjusting

dove

tail

bolt

Notes

When

inspecting

the

hood

lock

note

the

following

a

Check

to

be

sure

that

dove

tail

bolt

retaining

nut

VI

is

tightened

securly

with

specified

tightening

torque

b

Check

catcher

of

the

safety

catch

lever

for

wear

and

the

spring

ID

I

for

weakness

and

break

If

the

spring

is

broken

the

hood

may

be

unlocked

and

rapidly

open

during

driving

c

Check

the

female

lever

for

smooth

and

conect

operation

and

the

spring

@

for

weakness

and

break

If

the

female

lever

does

not

mova

smoothly

angaging

stroka

with

tha

dove

tail

bolt

will

ba

reduced

and

it

may

be

disengaged

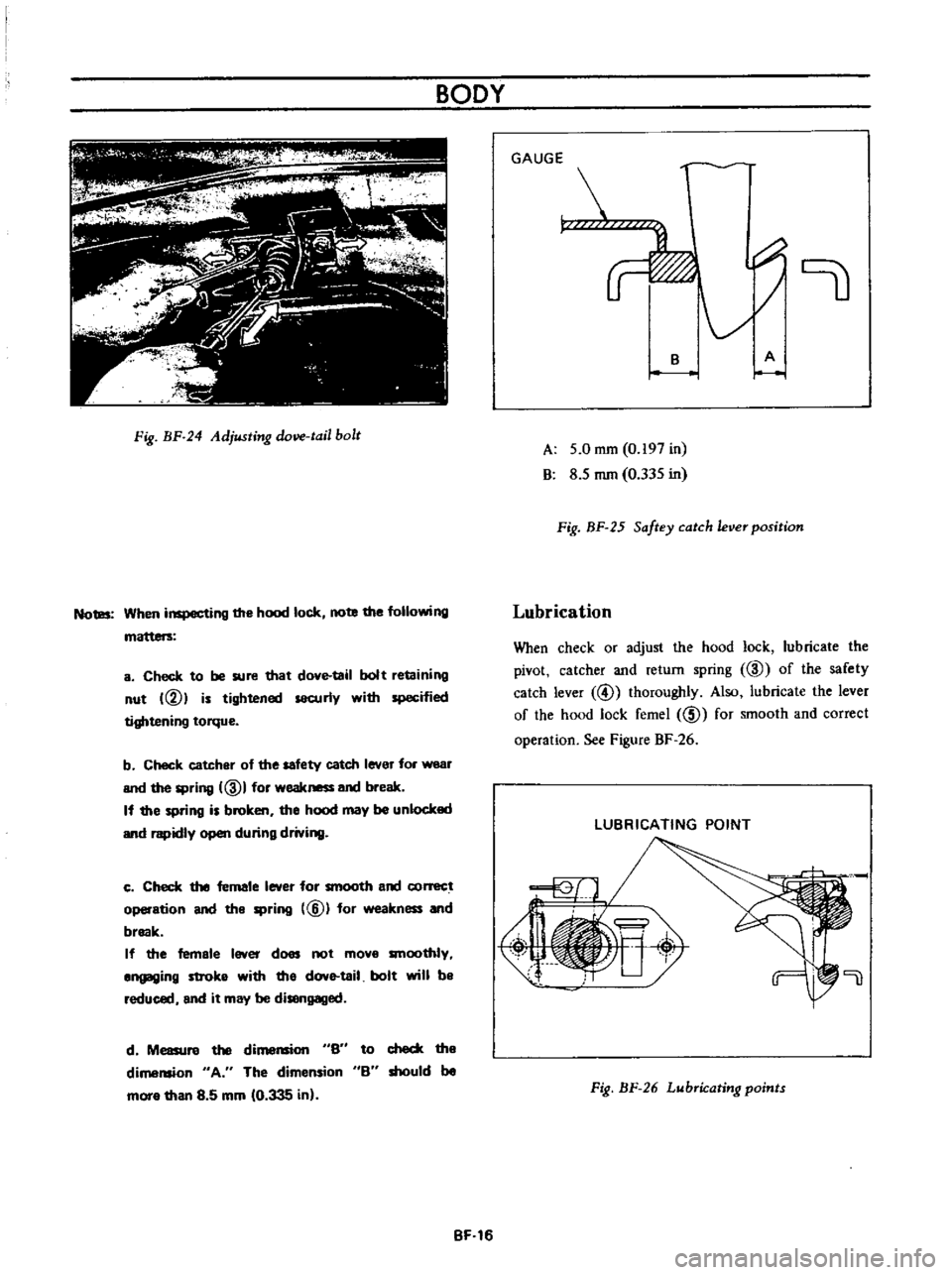

d

Measure

the

di

S6

to

check

the

dimension

A

The

dimension

B

should

be

mora

than

8

5

mm

10

335

in

BF

16

GAUGE

r

B

A

A

5

0

mm

0

197

in

B

8

5

mm

0

335

in

Fig

BF

25

Saftey

catch

ever

position

Lubrication

When

check

or

adjust

the

hood

lock

lubricate

the

pivot

catcher

and

return

spring

ID

of

the

safety

catch

lever

@

thoroughly

Also

lubricate

the

lever

of

the

hood

lock

femel

ID

for

smooth

and

correct

operation

See

Figure

BF

26

LUBRICATING

POINT

Fig

BF

26

Lubricating

points

Page 209 of 513

BODY

I

1

I

Ik

I

ro

I

W

a

21

zrl

l

11

J

1

3781

I

1

Ii

100

tJ94t

I

100

3

94

0

0551

A

I

10013

94

1

510

0984

100

13

94

I

J

10

1378

2010

787

L

I

l

0

433

O

I

l

JS

348

13

7

5

1

77

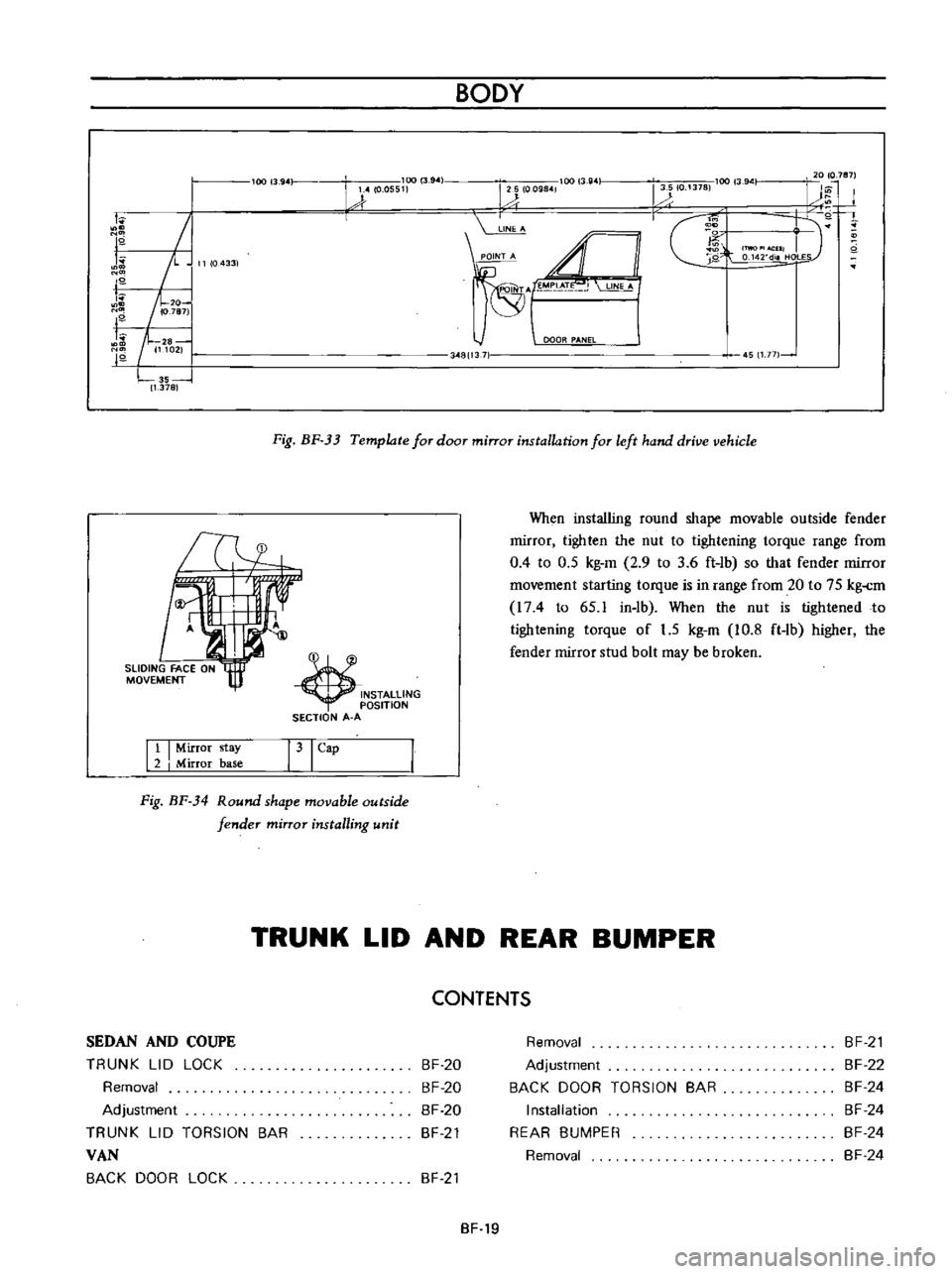

Fig

BF

33

Template

for

door

mirror

installation

for

left

hand

drive

vehicle

INSTALLING

OSITION

SECTION

A

A

When

installing

round

shape

movable

outside

fender

rnirror

tighten

the

nut

to

tightening

torque

range

from

0

4

to

0

5

kg

m

2

9

to

3

6

ft

lb

so

that

fender

rnirror

rnovernent

starting

torque

is

in

range

from

20

to

75

kg

rn

I74

to

65

1

in

lb

When

the

nut

is

tightened

to

tightening

torque

of

1

5

kg

m

10

8

ft

lb

higher

the

fender

mirror

stud

bolt

may

be

broken

Tl4

11

I

Mirror

stay

2

I

Mirror

base

31

Cap

Fig

BF

34

Round

shape

movable

outside

fender

mirror

installing

unit

TRUNK

LID

AND

REAR

BUMPER

CONTENTS

SEDAN

AND

COUPE

TRUNK

LID

LOCK

Removal

Adjustment

TRUNK

LID

TORSION

BAR

VAN

BACK

DOOR

LOCK

BF

20

BF

20

BF

20

BF

21

Removal

Adjustment

BACK

DOOR

TORSION

BAR

Installation

REAR

BUMPER

Removal

BF

21

BF

22

BF

24

BF

24

BF

24

BF

24

BF

21

BF

19

Page 210 of 513

BODY

SEDAN

AND

COUPE

CD

@

h

r

1

@

@

II

I

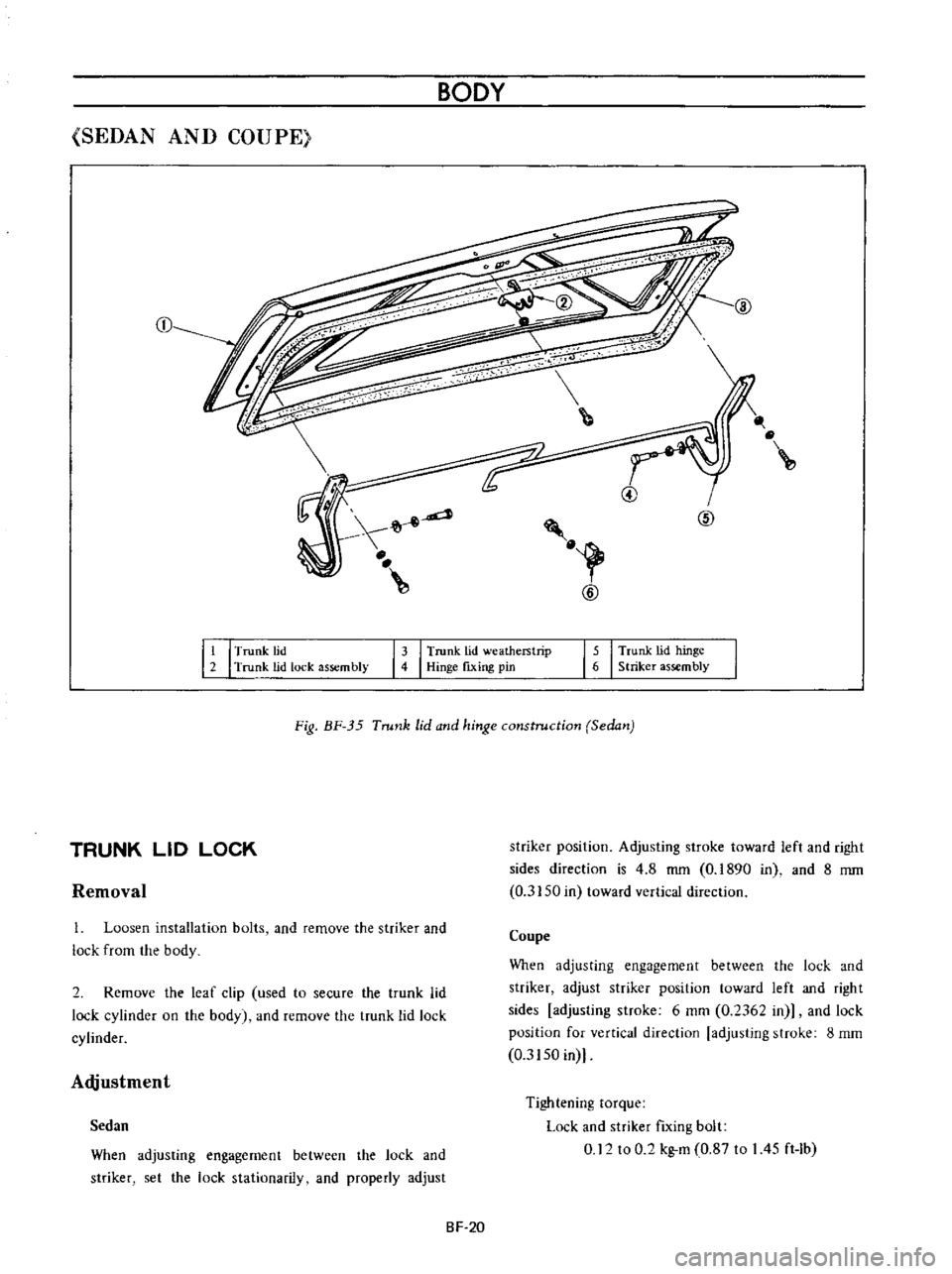

Trunk

lid

2

Trunk

lid

lock

assembly

13

I

Trunk

lid

weatherstrip

4

Hinge

fixing

pin

15

I

Trunk

lid

hinge

6

Striker

assembly

Fig

BF

35

Trunk

lid

and

hinge

construction

Sedan

Removal

striker

position

Adjusting

stroke

toward

left

and

right

sides

direction

is

4

8

mm

0

1890

in

and

8

mm

0

3150

in

toward

vertical

direction

TRUNK

LID

LOCK

1

Loosen

installation

bolts

and

remove

the

striker

and

lock

from

the

body

Coupe

When

adjusting

engagement

between

the

lock

and

striker

adjust

striker

position

toward

left

and

right

sides

adjusting

stroke

6

mm

0

2362

in

and

lock

position

for

vertical

direction

adjusting

stroke

8

mm

0

3150

in

2

Remove

the

leaf

clip

used

to

secure

the

trunk

lid

lock

cylinder

on

the

body

and

remove

the

trunk

lid

lock

cylinder

Adjustment

When

adjusting

engagement

between

the

lock

and

striker

set

the

lock

stationarily

and

properly

adjust

Tightening

torque

Lock

and

striker

fIxing

bolt

0

12

to

0

2

kg

m

0

87

to

I

45

ft

Ib

Sedan

SF

20

Page 212 of 513

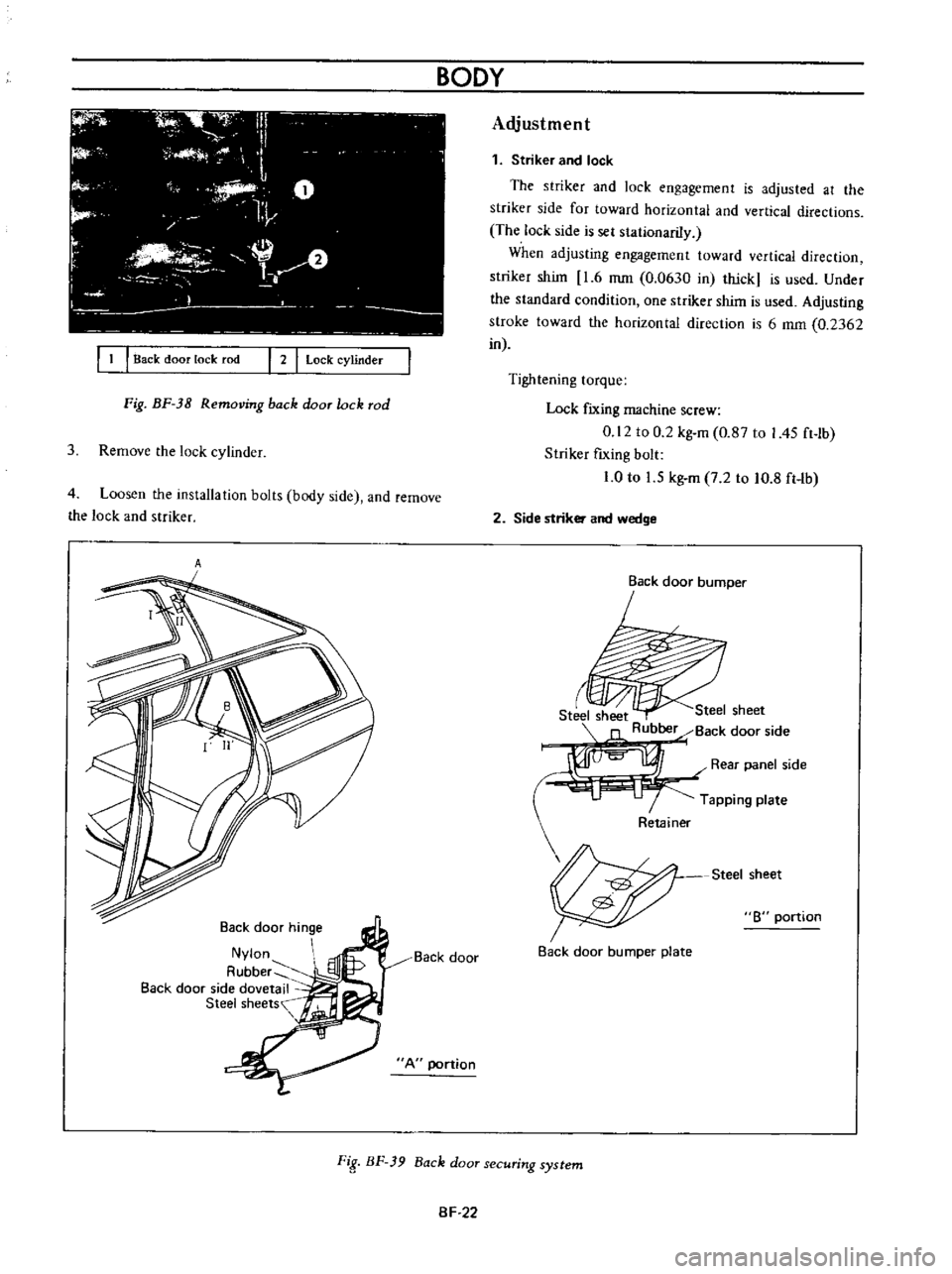

I

1

I

Back

door

lock

rod

I

2

I

Lock

cylinder

Fig

BF

38

Removing

back

door

lock

rod

3

Remove

the

lock

cylinder

4

Loosen

the

installation

bolts

body

side

and

remove

the

lock

and

striker

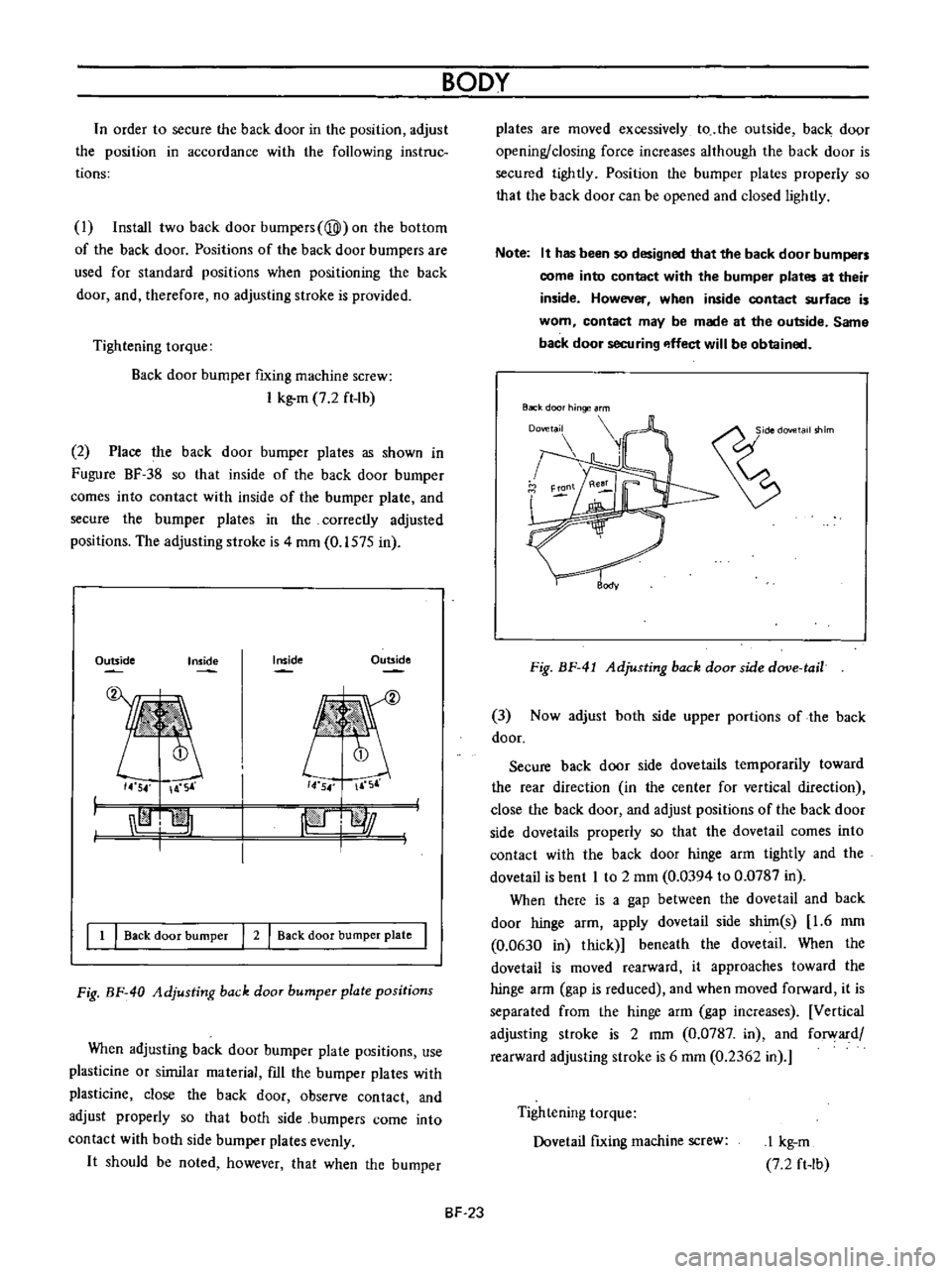

A

Back

door

hinge

Nylon

A

ubber

Back

door

side

dovetail

Steel

sheets

Back

door

A

portion

BODY

Adjustment

1

Striker

and

lock

The

striker

and

lock

engagement

is

adjusted

at

the

striker

side

for

toward

horizontal

and

vertical

directions

The

lock

side

is

sel

stationariIy

When

adjusting

engagement

toward

vertical

direction

striker

shim

1

6

mm

0

0630

in

thick

is

used

Under

the

standard

condition

one

striker

shim

is

used

Adjusting

stroke

toward

the

horizontal

direction

is

6

mm

0

2362

in

Tightening

torque

Lock

fIXing

machine

screw

0

12

to

0

2

kg

m

0

87

to

I

45

ft

lb

Striker

fIxing

bolt

1

0

to

1

5

kg

m

7

2

to

10

8

ft

Ib

2

Side

striker

and

wedge

Back

door

bumper

r

Steel

sheet

Steel

sheet

Rubber

Back

door

side

I

Rear

panel

side

Tapping

plate

Steel

sheet

8

portion

Back

door

bumper

plate

FiS

BF

39

Back

door

securing

system

SF

22

Page 213 of 513

n

order

to

secure

the

back

door

in

the

position

adjust

the

position

in

accordance

with

the

following

instruc

tions

I

Install

two

back

door

bumpers

@

on

the

bottom

of

the

back

door

Positions

of

the

back

door

bumpers

are

used

for

standard

positions

when

positioning

the

back

door

and

therefore

no

adjusting

stroke

is

provided

Tightening

torque

Back

door

bumper

fixing

machine

screw

I

kg

m

7

2

ft

lb

2

Place

the

back

door

bumper

plates

as

shown

in

Fugure

BF

38

so

that

inside

of

the

back

door

bumper

comes

into

contact

with

inside

of

the

bumper

plate

and

secure

the

bumper

plates

in

the

correctly

adjusted

positions

The

adjusting

stroke

is

4

mm

0

1575

in

Outside

Inside

Outside

Inside

14

54

A

S

14

54

F

r

I

I

jpiJ

l

l

j

I

1

I

Back

door

bumper

I

2

I

Back

door

bumper

plate

I

Fig

BF

40

Adjusting

back

door

bumper

plate

positions

When

adjusting

back

door

burnper

plate

positions

use

plasticine

or

sirnilar

material

fIll

the

bumper

plates

with

plasticine

close

the

back

door

observe

contact

and

adjust

properly

so

that

both

side

bumpers

come

into

contact

with

both

side

bumper

plates

evenly

It

should

be

noted

however

that

when

the

bumper

BODY

BF

23

plates

are

moved

excessively

to

the

outside

back

door

opening

closing

force

increases

although

the

back

door

is

secured

tightly

Position

the

bumper

plates

properly

so

that

the

back

door

can

be

opened

and

closed

lightly

Note

It

has

been

so

designed

that

the

back

door

bumpers

come

into

contact

with

the

bumper

plates

at

their

inside

However

when

inside

contact

surface

is

worn

contact

may

be

made

at

the

outside

Same

back

door

securing

p

ffect

will

be

obtained

Back

door

hinge

rm

Fig

BF

41

Adjusting

back

door

side

dove

tail

3

Now

adjust

both

side

upper

portions

of

the

back

door

Secure

back

door

side

dovetails

temporarily

toward

the

rear

direction

in

the

center

for

vertical

direction

close

the

back

door

and

adjust

positions

of

the

back

door

side

dovetails

properly

so

that

the

dovetail

comes

into

contact

with

the

back

door

hinge

arm

tightly

and

the

dovetail

is

bent

I

to

2

mm

0

0394

to

0

0787

in

When

there

is

a

gap

between

the

dovetail

and

back

door

hinge

arm

apply

dovetail

side

shim

s

1

6

mm

0

0630

in

thick

beneath

the

dovetail

When

the

dovetail

is

moved

rearward

it

approaches

toward

the

hinge

arm

gap

is

reduced

and

when

moved

forward

it

is

separated

from

the

hinge

arrn

gap

increases

Vertical

adjusting

stroke

is

2

mm

0

0787

in

and

forward

rearward

adjusting

stroke

is

6

mm

0

2362

in

Tightening

torque

Dovetail

fIxing

machine

screw

I

kg

m

7

2

ft

Ib

Page 216 of 513

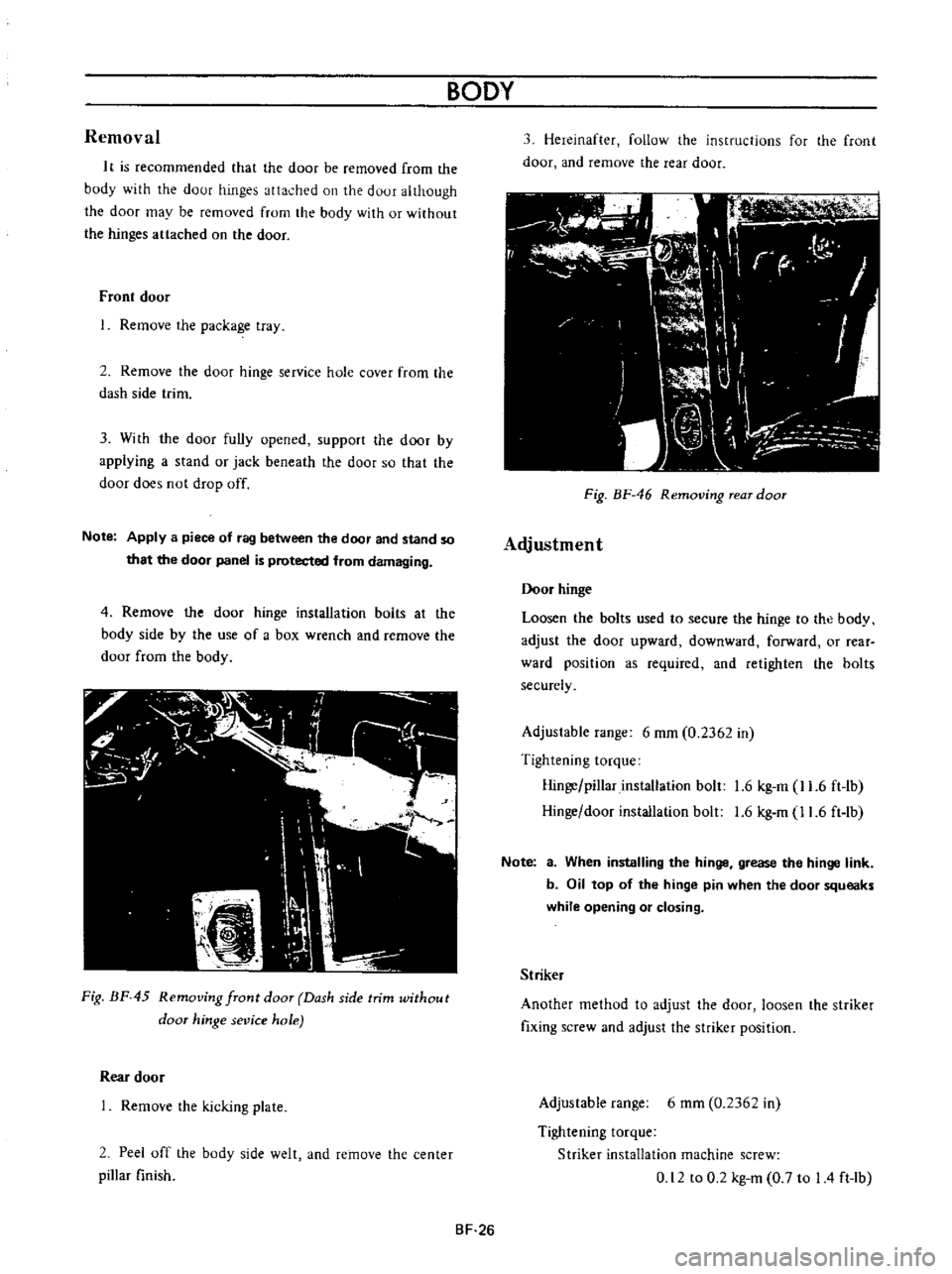

Removal

I

t

is

recommended

that

the

door

be

removed

from

the

body

with

the

door

hinges

attached

on

the

door

although

the

door

may

be

removed

from

the

body

with

or

without

the

hinges

attached

on

the

door

Front

door

Remove

the

package

tray

2

Remove

the

door

hinge

service

hole

cover

from

the

dash

side

trim

3

With

the

door

fully

opened

support

the

door

by

applying

a

stand

or

jack

beneath

the

door

so

that

the

door

does

not

drop

off

Note

Apply

a

piece

of

rag

between

the

door

and

stand

so

that

the

door

panel

is

protected

from

damaging

4

Remove

the

door

hinge

installation

bolts

at

the

body

side

by

the

use

of

a

box

wrench

and

remove

the

door

from

the

body

Fig

BF

45

Removing

front

door

Dash

side

trim

without

door

hinge

sevice

hole

Rear

door

Remove

the

kicking

plate

2

Peel

off

the

body

side

welt

and

remove

the

center

pillar

finish

BODY

3

Hereinafter

follow

the

instructions

for

the

front

door

and

remove

the

rear

door

11

I

fl

C

I

r

r

I

W

I

r

I

I

dl

J

Ik

I

h

I

l

i

J

n

Fig

BF

46

Removing

rear

door

Adjustment

Door

hinge

Loosen

the

bolts

used

to

secure

the

hinge

to

the

body

adjust

the

door

upward

downward

forward

or

rear

ward

position

as

required

and

retighten

the

bolts

securely

Adjustable

range

6

mm

0

2362

in

Tightening

torque

Hinge

pillar

installation

bolt

1

6

kg

m

11

6

ft

lb

Hinge

door

installation

bolt

1

6

kg

m

11

6

ft

lb

Note

a

When

installing

the

hinge

grease

the

hinge

link

b

Oil

top

of

the

hinge

pin

when

the

door

squeaks

while

opening

or

closing

Striker

Another

method

to

adjust

the

door

loosen

the

striker

fixing

screw

and

adjust

the

striker

position

Adjustable

range

6

mm

0

2362

in

Tightening

torque

Striker

installation

machine

screw

0

12

to

0

2

kg

m

0

7

to

I

4

ft

lb

BF

26

Page 219 of 513

the

outside

handle

rod

@

is

provided

with

2

to

3

mm

0

0787

to

0

1181

in

play

in

the

stroke

If

the

nylon

nut

@

is

positioned

too

low

the

locking

plate

@

is

depressed

at

the

full

ratch

the

locking

plate

does

not

intermesh

with

the

ratchet

completely

and

the

knob

cannot

be

locked

If

play

in

stroke

of

the

outside

handle

rod

@

is

excessive

may

be

unlocked

up

to

5

mm

0

1967

in

stroke

of

the

outside

handle

will

be

insufficient

If

the

nylon

nut

is

loosened

the

above

described

trouble

occurs

Be

sure

to

secure

the

nut

completely

by

means

of

adhesive

Check

the

springs

@

and

@

for

rust

and

replace

as

required

Tightening

torque

Door

lock

installation

screw

0

12

to

0

2

kg

m

0

9

to

I

4

ft

lb

Door

lock

remote

control

installation

screw

0

12

to

0

2

kg

m

0

9

to

14

ft

lb

Outside

handle

installation

nut

0

2

to

0

3

kg

m

1

4

to

2

2

ft

Ib

Rear

door

lock

removal

1

Remove

the

parts

up

to

the

seal

screen

2

Raise

the

door

glass

to

the

top

and

remove

the

door

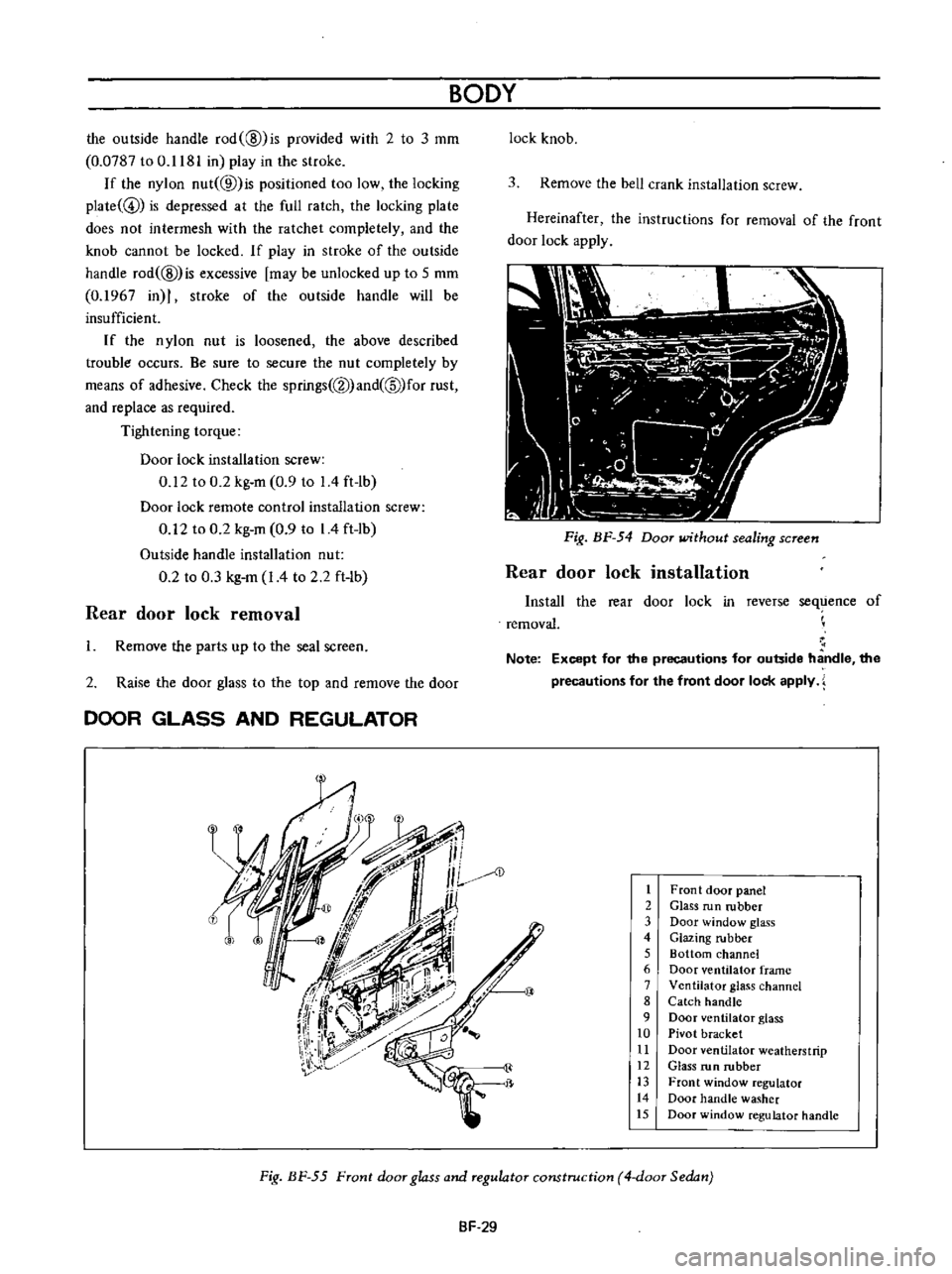

DOOR

GLASS

AND

REGULATOR

i

v

BODY

lock

knob

3

Remove

the

bell

crank

installation

screw

Hereinafter

the

instructions

for

removal

of

the

front

door

lock

apply

Fig

BF

54

Door

without

sealing

screen

Rear

door

lock

installation

Install

the

rear

door

lock

in

reverse

sequence

of

removal

Note

Except

for

the

precautions

for

outside

handle

the

precautions

for

the

front

door

lock

apply

AD

1

Front

door

panel

2

Glass

run

rubber

3

Door

window

glass

4

Glazing

rubber

5

Bottom

channel

6

Door

ventilator

frame

7

Ventilator

glass

channel

8

Catch

handle

9

Door

ventilator

glass

10

Pivot

bracket

11

Door

ventilator

weatherstrip

12

Glass

run

rubber

13

Front

window

regulator

14

Door

handle

washer

15

Door

window

regulator

handle

Fig

BF

55

Front

door

glass

and

regulator

construction

4

door

Sedan

SF

29

Page 262 of 513

BODY

ELECTRICAL

Wiper

motor

replacement

First

of

all

remove

the

connector

plug

from

the

wiper

motoI

2

Remove

a

nut

used

to

connect

wiper

motor

worm

wheel

shaft

to

the

connecting

rod

from

passenger

compartment

side

dash

panel

3

Loosen

three

bolts

used

to

install

the

wiper

motor

on

the

cowl

dash

remove

the

wiper

motor

4

Reinstall

a

new

wiper

motor

in

reverse

sequence

of

removal

Fig

BE

44

Wiper

motor

Q

V

rt

ir

o

y

At

Jllif

Fig

BE

45

Wiper

motor

linkage

Wiper

blade

operating

range

When

removing

the

wiper

arm

loosen

the

wiper

arm

attaching

nut

and

pull

out

the

wiper

arm

from

the

pivot

shaft

When

installing

the

wiper

arm

on

the

pivot

shaft

provide

the

arm

with

a

proper

installation

angle

so

that

the

windshield

wiper

blade

is

positioned

correctly

The

wiper

arm

attaching

nut

tightening

torque

is

60

5

kg

m

434

36

2lb

ft

Fig

BE

46

Removing

wiper

arm

00

I

i

Fig

BE

47

Wiper

arm

installation

Wiper

washer

switch

replacement

Remove

the

connector

from

back

of

the

wiper

washer

switch

2

Depressing

and

turning

the

wiper

switch

knob

counterclockwise

remove

it

3

Loosen

the

escutcheon

and

remove

the

wiper

switch

from

the

cluster

lid

Washer

nozzle

adjustment

When

the

washer

nozzle

is

installed

or

when

washer

fluid

is

not

sprayed

properly

adjust

the

nozzle

direction

so

that

fluid

is

sprayed

in

range

indicated

in

Figure

BE

48

BE

27

Page 280 of 513

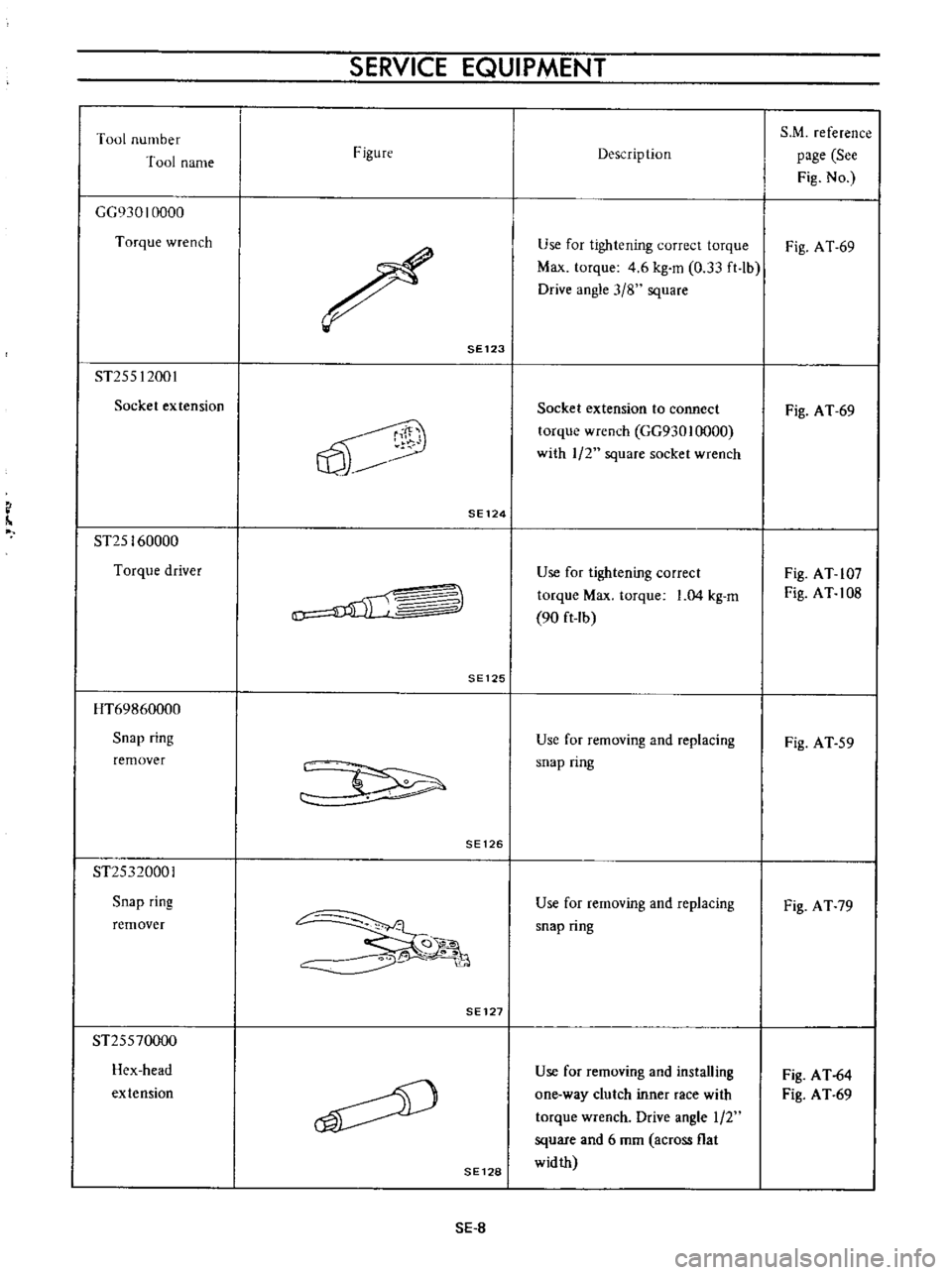

SERVICE

EQUIPMENT

Tool

number

S

M

reference

Tool

name

Figure

Description

page

See

Fig

No

GG930

10000

Torque

wrench

Use

for

tightening

correct

torque

Fig

A

T

69

Max

torque

4

6

kg

m

0

33

ft

lb

Drive

angle

3

8

square

SE123

ST255

12001

Socket

extension

Socket

extension

to

connect

Fig

A

T

69

0

torque

wrench

GG930

I

000

with

1

2

square

socket

wrench

SE124

ST25

160000

Torque

driver

Use

for

tightening

correct

Fig

AT

107

torque

Max

torque

1

04

kg

m

Fig

AT

108

u

90

ft

Ib

SE125

HT69860000

Snap

ring

Use

for

removing

and

replacing

Fig

AT

59

remover

snap

ring

SE126

ST25320001

Snap

ring

Use

for

removing

and

replacing

Fig

AT

79

snap

ring

remover

Go

O

SE127

ST25570000

Hex

head

Use

for

removing

and

installing

Fig

AT

64

extension

one

way

clutch

inner

race

with

Fig

AT

69

torque

wrench

Drive

angle

1

2

square

and

6

mm

across

flat

SE128

width

sE

8