torque DATSUN B110 1973 Service Manual PDF

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 148 of 513

Lining

material

Front

disc

brake

Pad

width

x

thickness

x

length

Total

braking

area

Rear

brake

Lining

width

x

thickness

x

length

Total

braking

area

Tightening

torque

Brake

pedal

fulcrum

pin

Master

cylinder

installation

bolt

Brake

tube

installation

flare

nut

Rear

brake

hose

and

connector

installation

nut

Front

wheel

cylinder

installation

bolt

Brake

warning

switch

installation

bolt

Front

brake

disc

installation

bolt

Caliper

assembly

installation

bolt

Rear

brake

adjuster

installation

bolt

Hand

brake

cable

hanger

strap

installation

bolt

Hand

brake

lever

installation

bolt

Rotor

and

hub

installation

bolt

CHASSIS

mm

in

cm2

sq

in

mm

in

cm2

sq

in

kg

m

ft

1b

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

Ib

B40

Akebuno

make

42

5

x

10

3

x

53

I

1

673

x

0

406

x

2

091

90

3

14

0

35

x

4

8

x

195

1

378

x

0

1890

x

7

68

273

42

3

2

0

to

3

0

11

6

to

217

2

1

to

2

9

15

2

to

21

0

1

5

to

1

8

l

0

8

to

13

0

1

5

to

1

8

10

8

to

13

0

a

0

5

to

0

7

3

6

to

5

I

b

1

6

to

2

2

I

1

6

to

15

9

0

32

to

0

44

2

31

to

3

18

2

7

to

3

7

19

5

to

26

8

4

6

to

6

1

33

3

to

44

1

1

6

to

2

2

11

6

to

15

9

0

32

to

0

44

2

31

to

3

18

1

0

to

I

4

7

23

to

10

1

44

to

59

31

8

to

42

7

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Spongy

pedal

Air

in

brake

lines

Probable

cause

Swollen

hose

due

to

deterioration

or

use

of

poor

quality

brake

fluid

BR

24

Corrective

action

Bleed

thoroughly

Replace

hose

and

bleed

the

system

Page 158 of 513

WHEEL

AND

TIRE

Note

In

replacing

tire

take

extra

care

not

to

damage

tire

bead

rim

flange

and

bead

seat

Do

not

use

tire

irons

to

force

beads

away

from

wheel

rim

flange

that

is

always

use

tire

replace

ment

device

whenever

tire

is

removed

WT005

2

Discard

when

any

of

the

following

trouble

occurs

I

Broken

or

damaged

bead

wire

2

Ply

or

tread

separation

3

Worn

febric

damage

on

tubeless

tire

4

Cracked

or

damaged

side

wall

etc

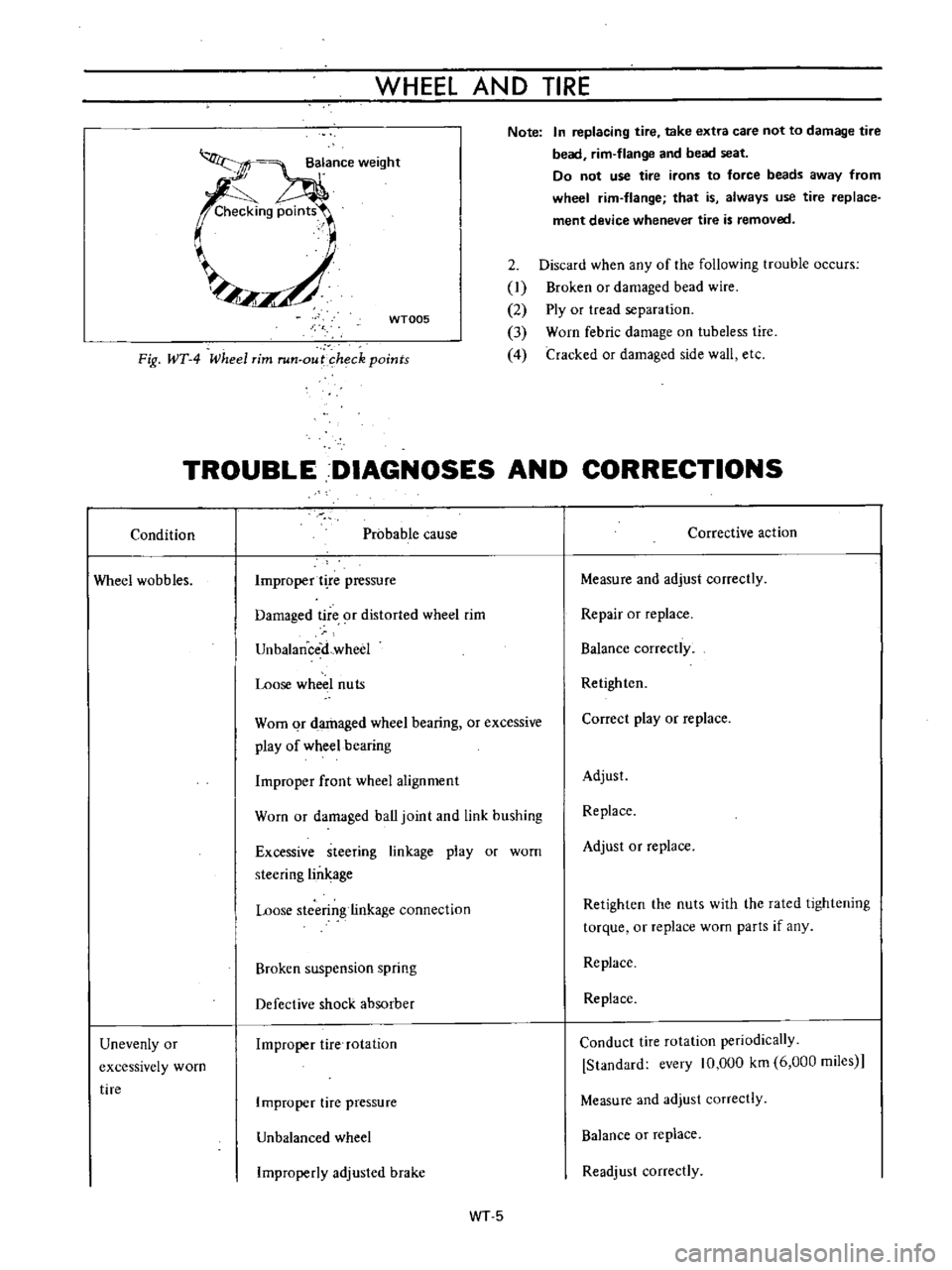

Fig

WT

4

Wheel

rim

run

out

heck

points

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Probable

cause

Corrective

action

Wheel

wobbles

Improper

t

re

pressure

Measure

and

adjust

correctly

Damaged

tire

9f

distorted

wheel

rim

Repair

or

replace

UnbalanceiLwheel

Balance

correctly

Loose

wheel

nuts

Retighten

Worn

qr

damaged

wheel

bearing

or

excessive

play

of

wheel

bearing

Correct

play

or

replace

Improper

front

wheel

alignment

Adjust

Worn

or

damaged

ball

joint

and

link

bushing

Replace

Excessive

steering

linkage

play

or

worn

steering

lin

age

Adjust

or

replace

Loose

stcerin

linkage

connection

Retighten

the

nuts

with

the

rated

lightening

torque

or

replace

worn

parts

if

any

Broken

suspension

spring

Replace

Defective

shock

absorber

Replace

Unevenly

or

excessively

worn

tire

Improper

tire

rotation

Conduct

tire

rotation

periodically

Standard

every

10

000

km

6

000

miies

Improper

tire

pressure

Measure

and

adjust

correctly

Unbalanced

wheel

Balance

or

replace

Improperly

adjusled

brake

Readjust

correctly

WT5

Page 165 of 513

STEERING

ASSEMBLY

AND

AD

JUSTMENT

Tightening

torque

1

5

to

2

5

kg

m

110

8

to

18

1

ft

lb

II

1

r

I

II

U

J

Standard

shim

O

5mm

0

0197

in

1

Press

in

oil

seal

into

the

housing

Tightening

torque

1

7

to

2

8

kg

m

12

3

to

20

2

ft

Ib

Tightening

torque

2

0

to

3

0

kg

m

14

5

to

21

7

ft

Ib

Clearance

of

adjusting

screw

to

sector

shaft

0

05

mm

0

0020

in

L

Apply

grease

here

I

when

assembling

Pitman

arm

Tightening

torque

14kg

rn

101

ft

Ib

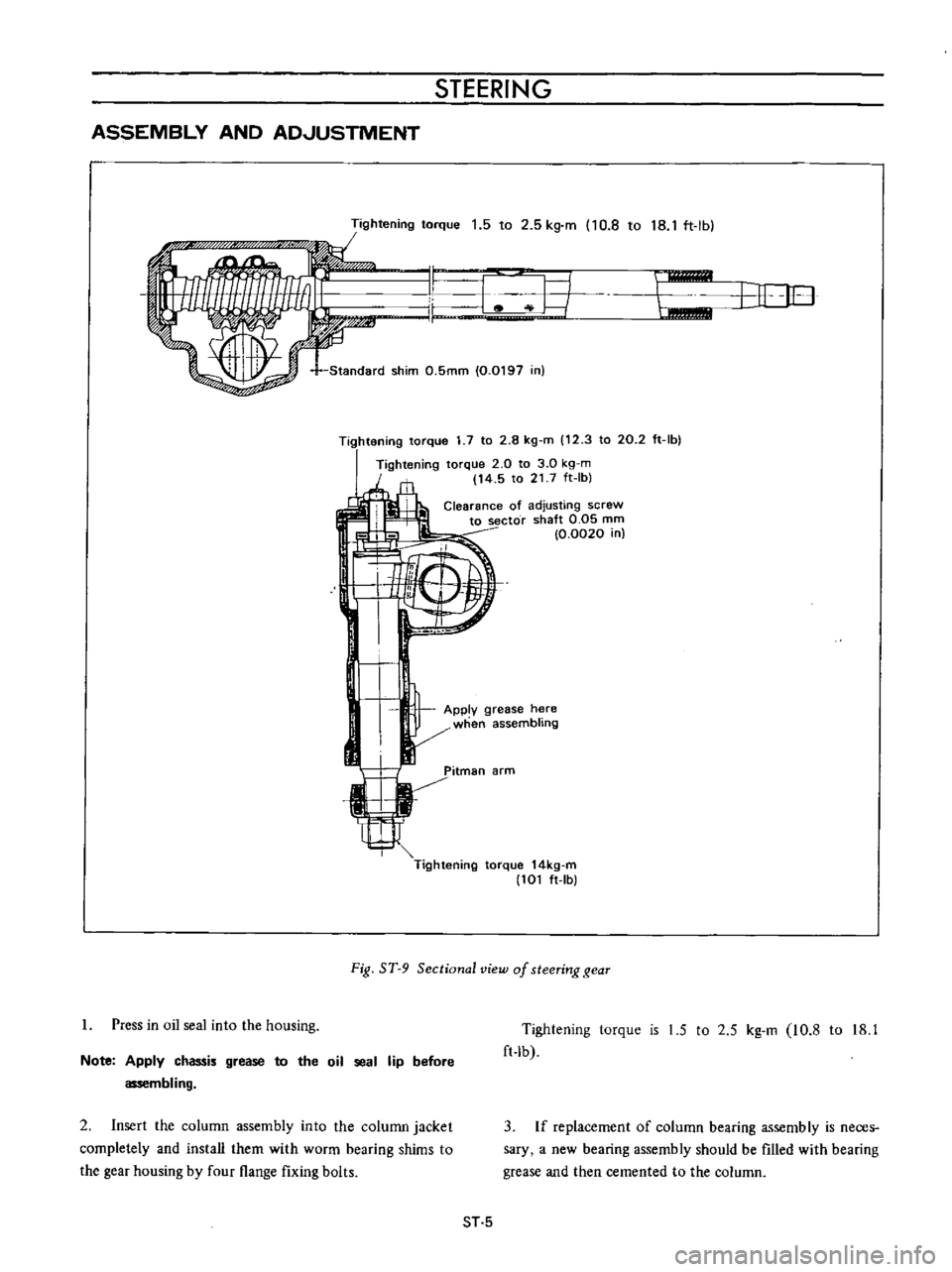

Fig

ST

9

Sectional

view

of

steering

gear

Note

Apply

chassis

grease

to

the

oil

seal

lip

before

assembling

2

Insert

the

column

assembly

into

the

column

jacket

completely

and

install

them

with

worm

bearing

shims

to

the

gear

housing

by

four

flange

fixing

bolts

Tightening

torque

is

1

5

to

2

5

kg

m

10

8

to

18

1

ft

lb

3

If

replacement

of

column

bearing

assembly

is

nece

r

sary

a

new

bearing

assembly

should

be

filled

with

bearing

grease

and

then

cemented

to

the

column

ST

5

Page 166 of 513

I

CHASSIS

4

Adjust

the

preload

of

the

worm

bearing

by

selecting

the

thickness

of

he

worm

bearing

shim

five

kinds

0

05

to

0

20

mm

0

0020

to

0

0079

in

so

that

the

initial

torque

of

the

steering

wheel

is

2

0

to

5

0

kg

cm

27

8

to

694

in

oz

without

sector

shaft

J

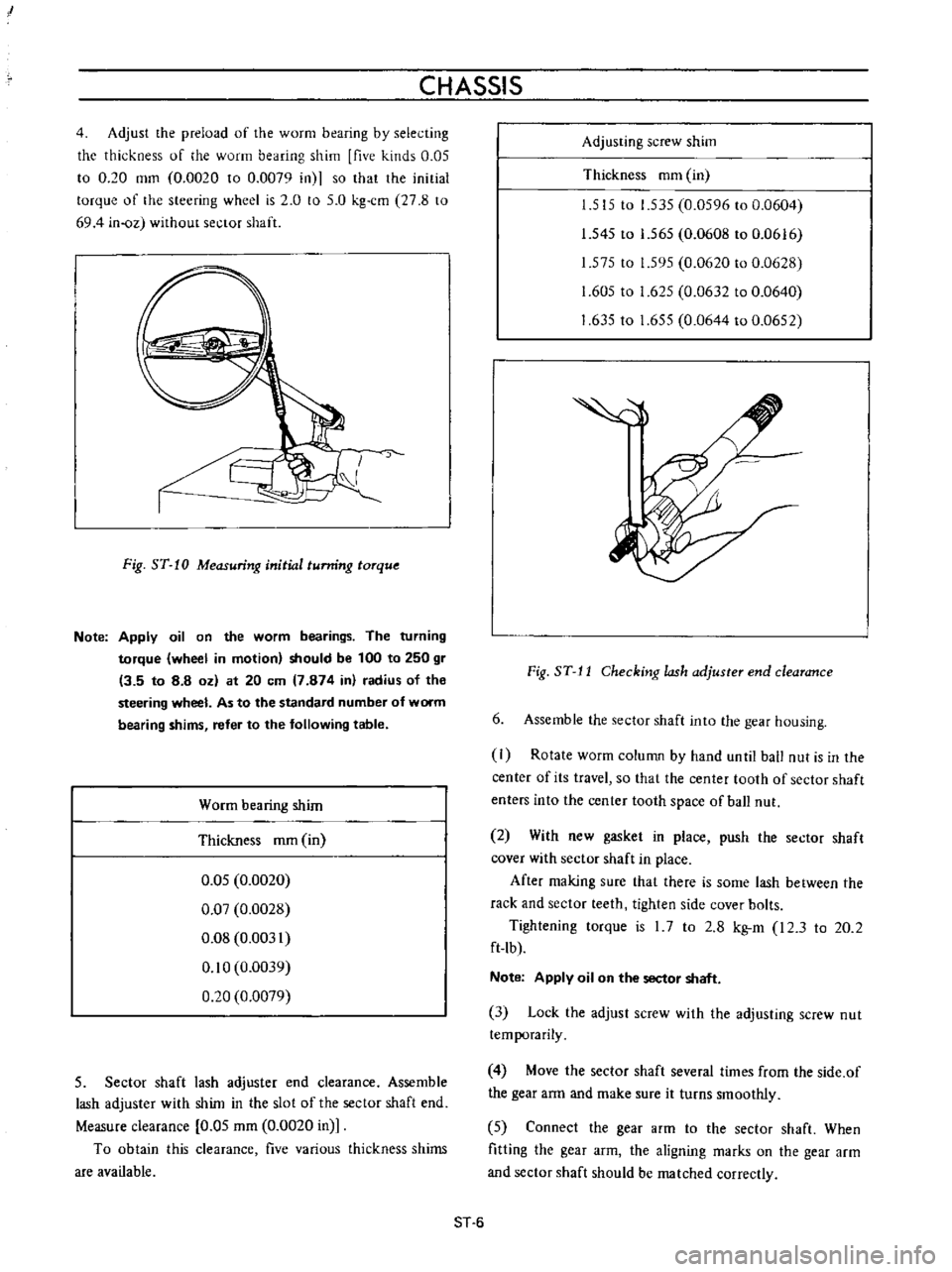

Fig

ST

10

Measuring

initial

tunring

torque

Note

Apply

oil

on

the

worm

bearings

The

turning

torque

wheel

in

motion

should

be

100

to

250

gr

13

5

to

8

8

oz

at

20

em

7

874

in

radius

of

the

steering

wheel

As

to

the

standard

number

of

worm

bearing

shims

refer

to

the

following

table

Worm

bearing

shim

Thickness

mm

in

0

05

0

0020

0

07

0

0028

0

08

0

0031

0

10

0

0039

0

20

0

0079

5

Sector

shaft

lash

adjuster

end

clearance

Assemble

lash

adjuster

with

shim

in

the

slot

of

the

sector

shaft

end

Measure

clearance

0

05

mm

0

0020

in

To

obtain

this

clearance

five

various

thickness

shims

are

available

Adjusting

screw

shim

Thickness

mm

in

1

515

to

1

535

0

0596

to

0

0604

1

545

to

1

565

0

0608

to

0

0616

1

575

to

1

595

0

0620

to

0

0628

1

605

to

1

625

0

0632

to

0

0640

1

63510

1

655

0

0644

to

0

0652

Fig

ST

J

J

Checking

lash

adjuster

end

clearance

6

Assemble

the

sector

shaft

into

the

gear

housing

I

Rotate

worm

column

by

hand

unlil

ball

nut

is

in

the

center

of

its

travel

so

that

the

center

tooth

of

sector

shaft

enters

into

the

center

tooth

space

of

ball

nut

2

With

new

gasket

in

place

push

the

sector

shaft

cover

with

sector

shaft

in

place

After

making

sure

that

there

is

some

lash

between

the

rack

and

sector

teeth

tighten

side

cover

bolts

Tightening

torque

is

I

7

to

2

8

kg

m

I2

3

to

20

2

ft

lb

Note

Apply

oil

on

the

sector

shaft

3

Lock

the

adjust

screw

with

the

adjusting

screw

nut

temporarily

4

Move

the

sector

shaft

several

times

from

the

side

of

the

gear

arm

and

make

sure

it

turns

smoothly

5

Connect

the

gear

arm

to

the

sector

shaft

When

fitting

the

gear

arm

the

aligning

marks

on

the

gear

arm

and

sector

shaft

should

be

matched

correctly

ST

6

Page 170 of 513

CHASSIS

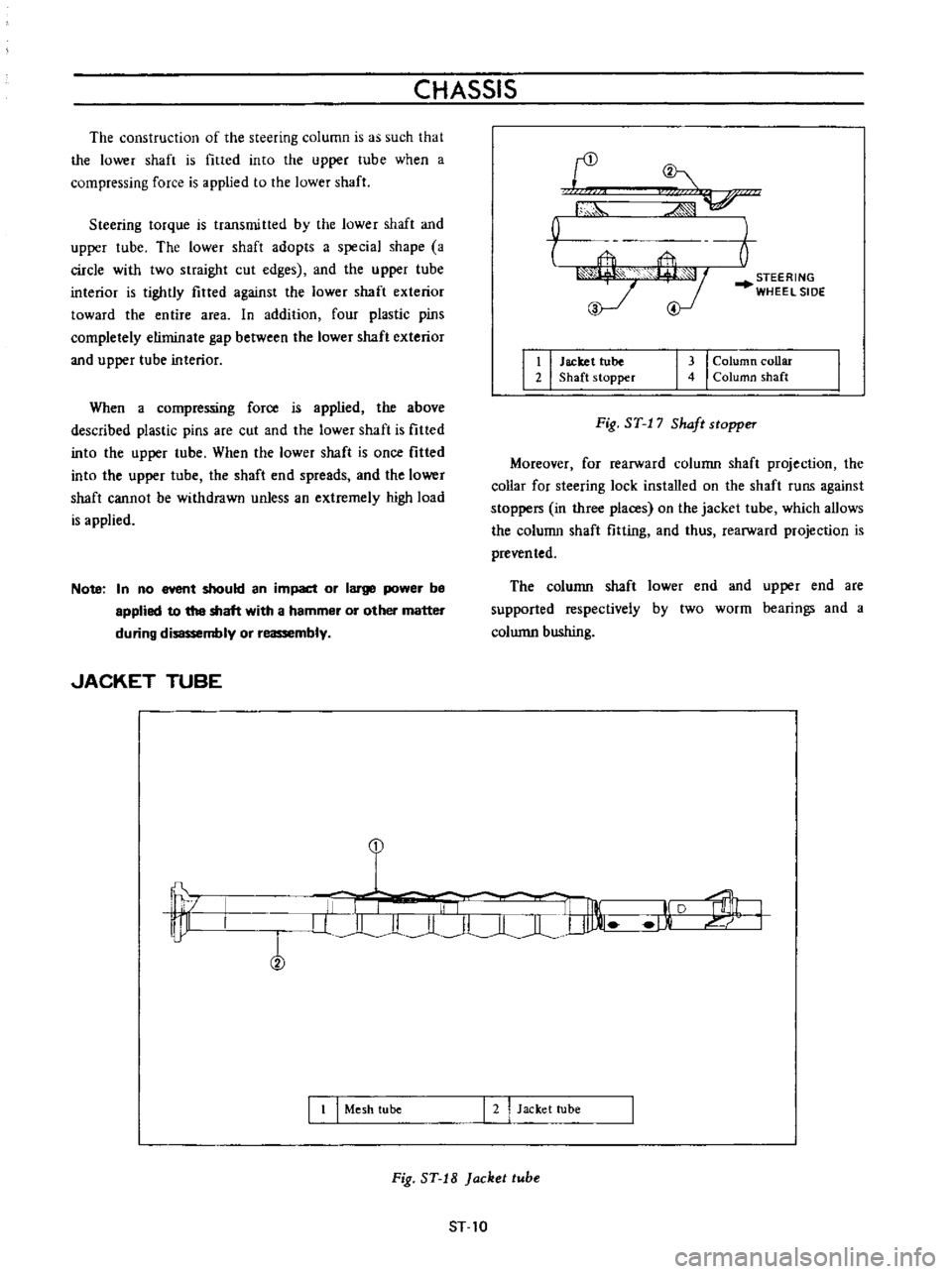

The

construction

of

the

steering

column

is

as

such

that

the

lower

shaft

is

fitted

into

the

upper

tube

when

a

compressing

force

is

applied

to

the

lower

shaft

r

I

1

V

f

7

Steering

torque

is

transmitted

by

the

lower

shaft

and

upper

tube

The

lower

shaft

adopts

a

special

shape

a

circle

with

two

straight

cut

edges

and

the

upper

tube

interior

is

tightly

fitted

against

the

lower

shaft

exterior

toward

the

entire

area

In

addition

four

plastic

pins

completely

eliminate

gap

between

the

lower

shaft

exterior

and

upper

tube

interior

I

I

Jacket

lube

2

Shaft

stopper

I

3

I

Column

coUar

4

Column

shaft

When

a

compressing

force

is

applied

the

above

described

plastic

pins

are

cut

and

the

lower

shaft

is

fitted

into

the

upper

tube

When

the

lower

shaft

is

once

fitted

into

the

upper

tube

the

shaft

end

spreads

and

the

lower

shaft

cannot

be

withdrawn

unless

an

extremely

high

load

is

applied

Fig

ST

1

7

Shaft

stopper

Moreover

for

rearward

column

shaft

projection

the

collar

for

steering

lock

installed

on

the

shaft

runs

against

stoppers

in

three

places

on

the

jacket

tube

which

allows

the

column

shaft

fitting

and

thus

reaIWard

projection

is

prevented

Note

In

no

event

should

an

impact

or

large

power

be

applied

to

the

shaft

with

a

hammer

or

other

matter

during

disassembly

or

reassembly

The

column

shaft

lower

end

and

upper

end

are

supported

respectively

by

two

worm

hearings

and

a

colwnn

bushing

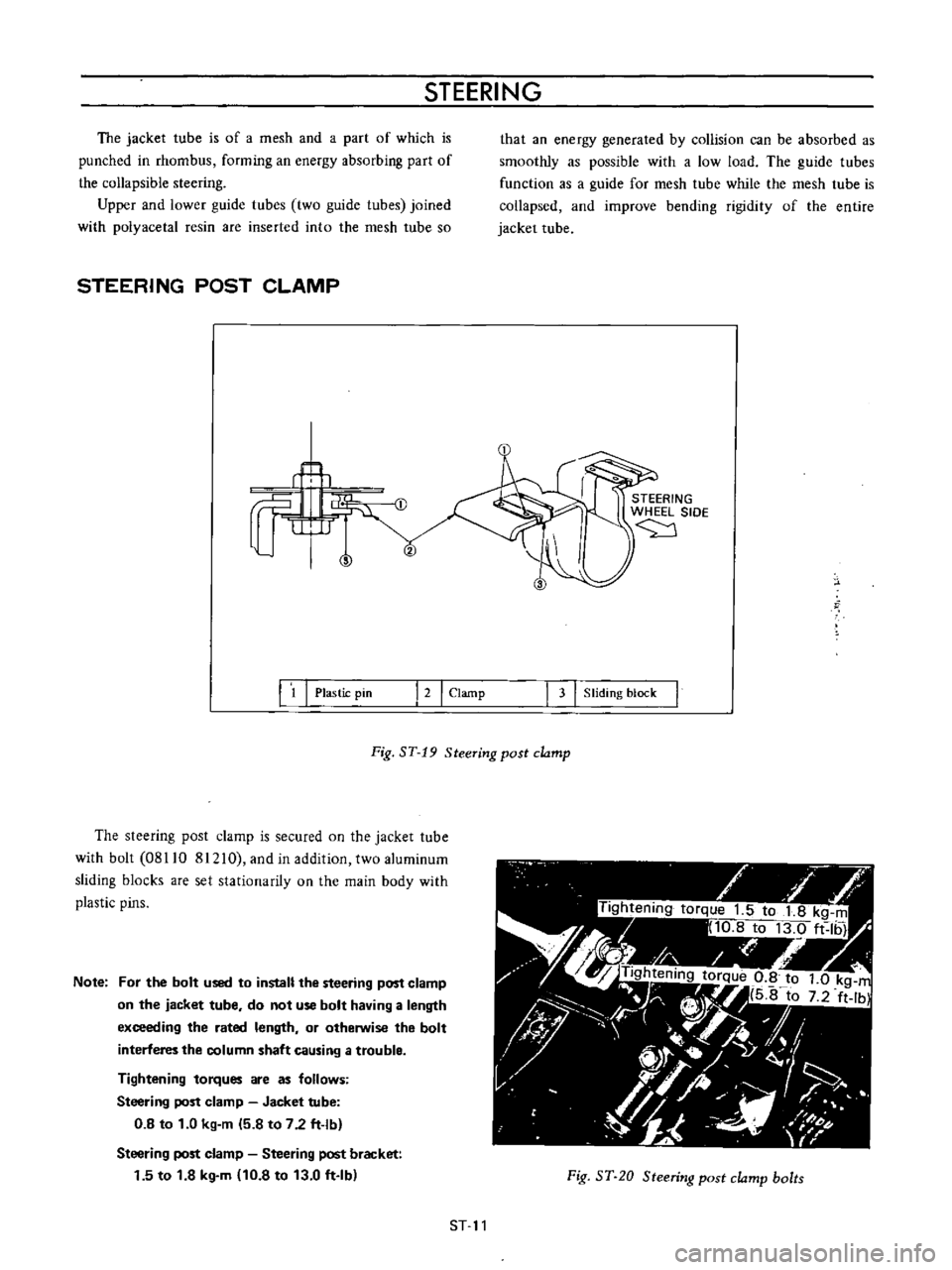

JACKET

TUBE

w

1

U

II

I

II

I

r

liJl

I

I

D

I

1

1

Mesh

tube

I

2

Jacket

tube

Fig

ST

18

Jacket

tube

ST

10

Page 171 of 513

STEERING

The

jacket

tube

is

of

a

mesh

and

a

part

of

which

is

punched

in

rhombus

forming

an

energy

absorbing

part

of

the

collapsible

steering

Upper

and

lower

guide

tubes

two

guide

tubes

joined

with

polyacetal

resin

are

inserted

into

the

mesh

tube

so

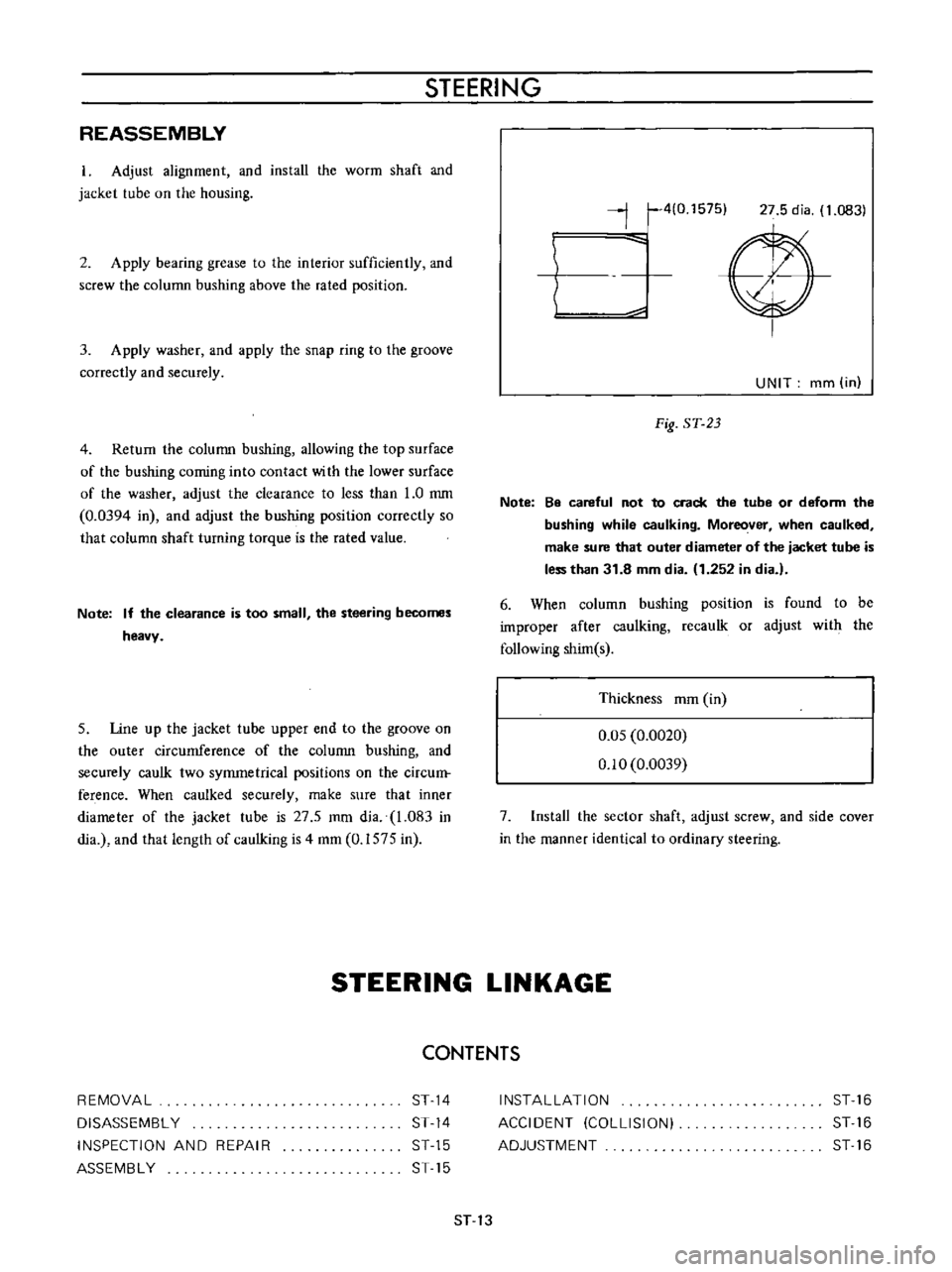

STEERING

POST

CLAMP

that

an

energy

generated

by

collision

can

be

absorbed

as

smoothly

as

possible

with

a

low

load

The

guide

tubes

function

as

a

guide

for

mesh

tube

while

the

mesh

tube

is

collapsed

and

improve

bending

rigidity

of

the

entire

jacket

tube

1

1

Plastic

pin

I

2

I

Clamp

1

3

I

Sliding

block

Fig

ST

19

Steering

post

clamp

The

steering

post

clamp

is

secured

on

the

jacket

tube

with

bolt

08110

81210

and

in

addition

two

aluminum

sliding

blocks

are

set

stationarity

on

the

main

body

with

plastic

pins

Note

For

the

bolt

used

to

install

the

steering

post

clamp

on

the

jacket

tube

do

not

use

bolt

having

a

length

exceeding

the

rated

length

or

otherwise

the

bolt

interferes

the

column

shaft

causing

a

trouble

Tightening

torques

are

as

follows

Steering

post

clamp

Jacket

tube

0

8

to

1

0

kg

m

5

8

to

7

2

ft

lb

Steering

post

clamp

Steering

post

bracket

1

5

to

1

8

kg

m

10

8

to

13

0

ft

Ib

Fig

ST

20

Steering

post

clamp

bolts

ST

11

Page 173 of 513

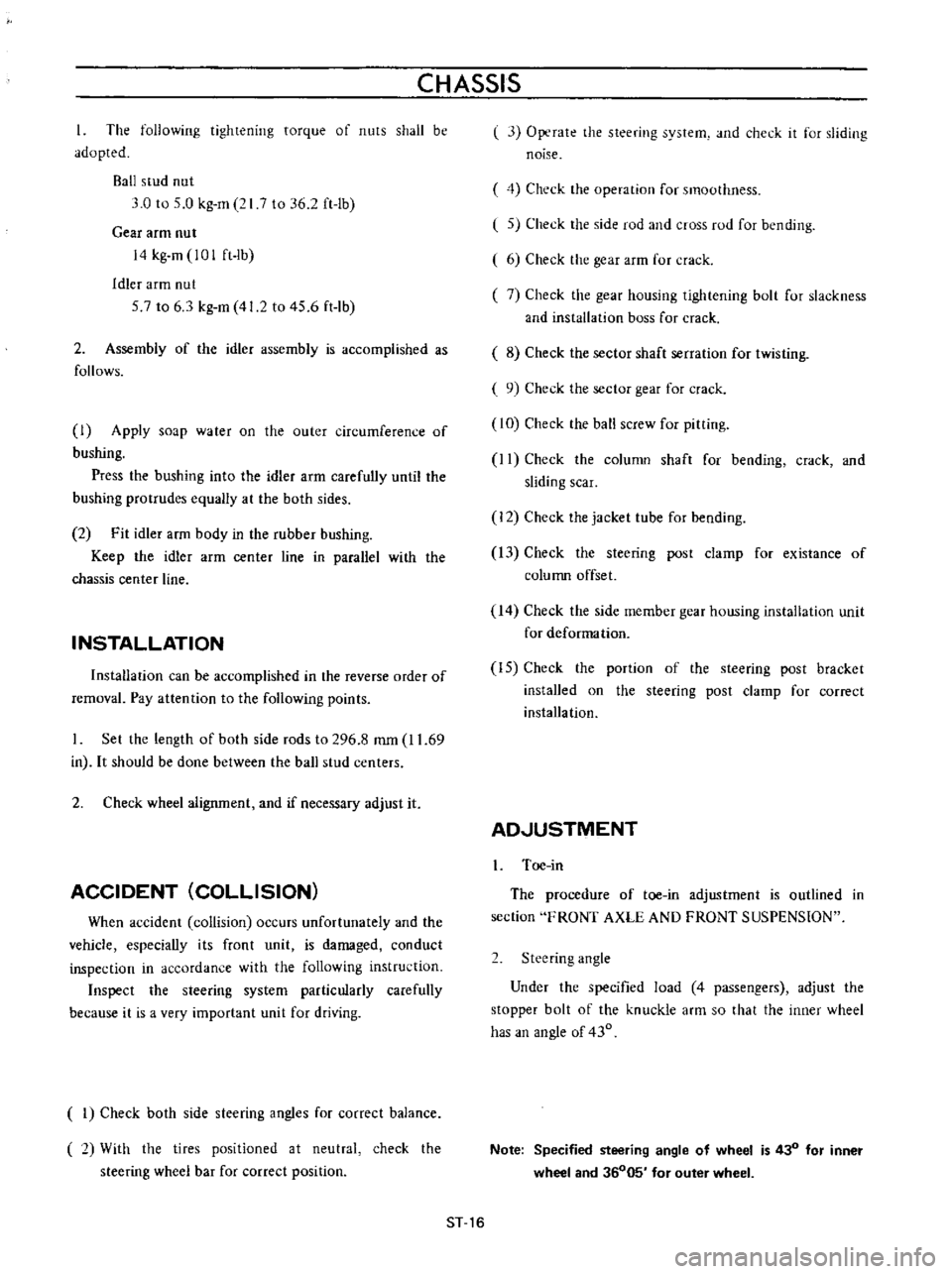

STEERING

REASSEMBLY

Adjust

alignment

and

install

the

worm

shaft

and

jacket

tube

on

the

housing

2

Apply

bearing

grease

to

the

interior

sufficiently

and

screw

the

column

bushing

above

the

rated

position

3

Apply

washer

and

apply

the

snap

ring

to

the

groove

correctly

and

securely

4

Return

the

column

bushing

allowing

the

top

surface

of

the

bushing

coming

into

contact

wi

th

the

lower

surface

of

the

washer

adjust

the

clearance

to

less

than

1

0

mm

0

0394

in

and

adjust

the

bushing

position

correctly

so

that

column

shaft

turning

torque

is

the

rated

value

Note

If

the

clearance

is

too

small

the

steering

becomes

heavy

5

Line

up

the

jacket

tube

upper

end

to

the

groove

on

the

outer

circumference

of

the

column

bushing

and

securely

caulk

two

symmetrical

positions

on

the

circum

ference

When

caulked

securely

make

sure

that

inner

diameter

of

the

jacket

tube

is

27

5

mm

dia

1

083

in

dia

and

that

length

of

caulking

is

4

mm

0

1575

in

j

410

1575

27

5

dia

1

0831

V

UNIT

mm

in

Fig

ST

23

Note

Be

careful

not

to

crack

the

tube

or

deform

the

bushing

while

caulking

Moreover

when

caulked

make

sure

that

outer

diameter

of

the

jacket

tube

is

less

than

31

8

mm

dia

1

252

in

dia

6

When

column

bushing

position

is

found

to

be

improper

after

caulking

recaulk

or

adjust

with

the

following

shim

s

Thickness

mm

in

0

05

0

0020

0

10

0

0039

7

Install

the

sector

shaft

adjust

screw

and

side

cover

in

the

manner

identical

to

ordinary

steering

STEERING

LINKAGE

CONTENTS

REMOVAL

DISASSEMBl

Y

INSPECTION

AND

REPAIR

ASSEMBl

Y

ST

14

ST

14

ST

15

ST

15

INSTAllATION

ACCIDENT

COLLISION

ADJUSTMENT

ST

16

ST

16

ST

16

ST

13

Page 176 of 513

CHASSIS

The

following

tightening

torque

of

nuts

shall

be

adopted

Ball

stud

nut

3

0

to

5

0

kg

m

21

7

to

36

2

ft

lb

Gear

arm

nut

14

kg

m

101

ft

lb

Idler

arm

nut

57

to

6

3

kg

m

41

2

to

45

6

ft

lb

2

Assembly

of

the

idler

assembly

is

accomplished

as

follows

I

Apply

soap

water

on

the

outer

circumference

of

bushing

Press

the

bushing

into

the

idler

arm

carefully

until

the

bushing

protrudes

equally

at

the

both

sides

2

Fit

idler

arm

body

in

the

rubber

bushing

Keep

the

idler

arm

center

line

in

parallel

with

the

chassis

center

line

INSTALLATION

Installation

can

be

accomplished

in

the

reverse

order

of

removal

Pay

attention

to

the

following

points

Set

the

length

of

both

side

rods

to

296

8

mm

11

69

in

It

should

be

done

between

the

ball

stud

centers

2

Check

wheel

alignment

and

if

necessary

adjust

it

ACCIDENT

COLLISION

When

accident

collision

occurs

unfortunately

and

the

vehicle

especially

its

front

unit

is

damaged

conduct

inspection

in

accordance

with

the

following

instruction

Inspect

the

steering

system

particularly

carefully

because

it

is

a

very

important

unit

for

driving

I

Check

both

side

steering

angles

for

correct

balance

2

With

the

tires

positioned

at

neutral

steering

wheel

bar

for

correct

position

check

the

l

3

Operate

the

steering

system

and

check

it

for

sliding

noise

4

Check

the

operation

for

smoothness

l

5

Check

the

side

rod

and

cross

rod

for

bending

6

Check

the

gear

arm

for

crack

7

Check

the

gear

housing

tiglltening

bolt

for

slackness

and

installation

boss

for

crack

8

Check

the

sector

shaft

serration

for

twisting

9

Check

the

sector

gear

for

crack

10

Check

the

ball

screw

for

pitting

II

Check

the

column

shaft

for

bending

crack

and

sliding

scar

12

Check

the

jacket

tube

for

bending

13

Check

the

steering

post

clamp

for

existance

of

column

offset

14

Check

the

side

member

gear

housing

installation

unit

for

deformation

IS

Check

the

portion

of

the

steering

post

bracket

installed

on

the

steering

post

clamp

for

correct

installation

AD

JUSTMENT

I

Toe

in

The

procedure

of

toe

in

adjustment

is

outlined

in

section

FRONT

AXLE

AND

FRONT

SUSPENSION

2

Steering

angle

Under

the

specified

load

4

passengers

adjust

the

stopper

bolt

of

the

knuckle

arm

so

that

the

inner

wheel

has

an

angle

of

430

Note

Specified

steering

angle

of

wheel

is

430

for

inner

wheel

and

36005

for

outer

wheel

ST

16

Page 177 of 513

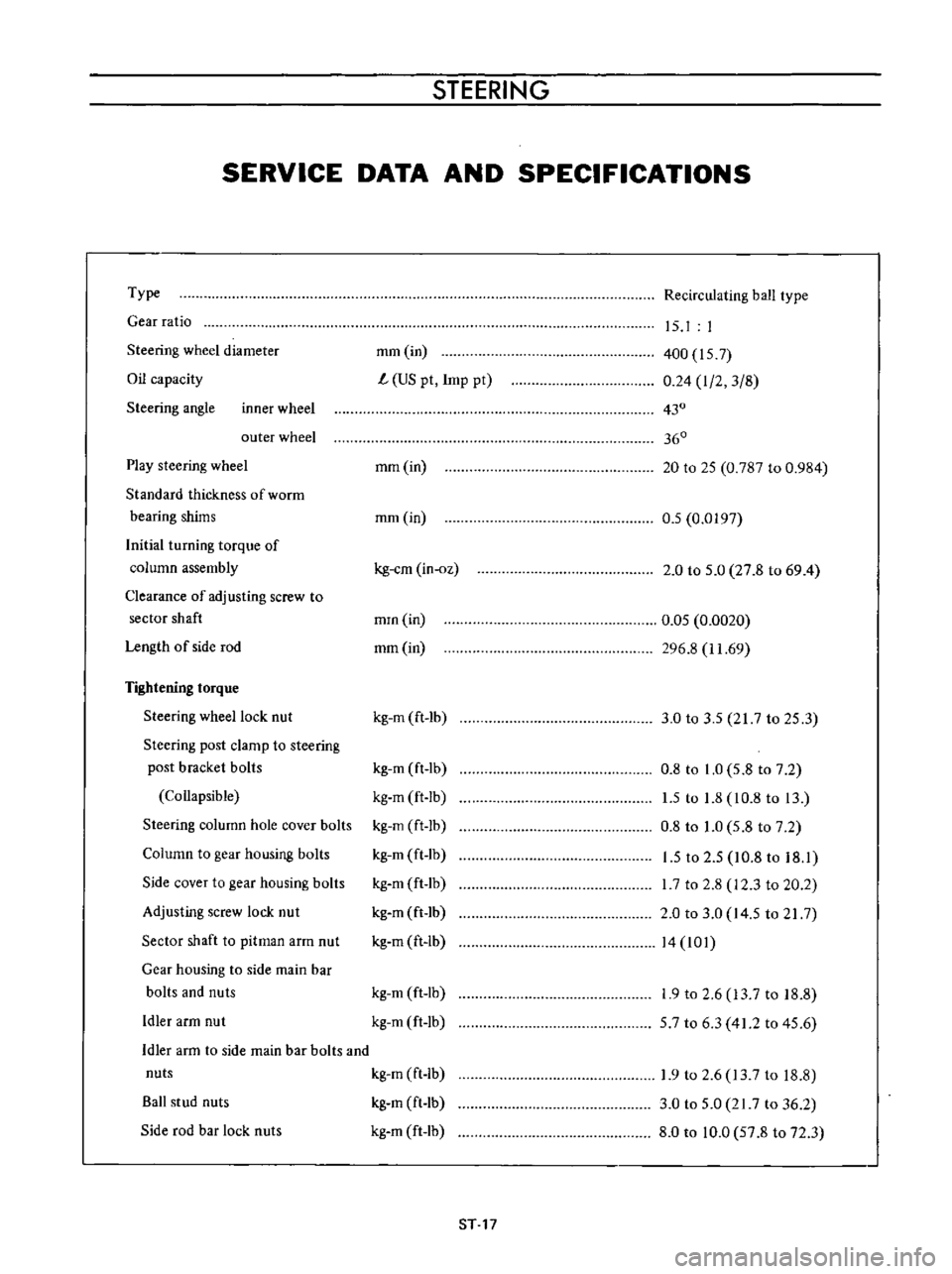

STEERING

SERVICE

DATA

AND

SPECIFICATIONS

Type

Gear

ratio

Steering

wheel

diameter

Oil

capacity

Steering

angle

inner

wheel

outer

wheel

Play

steering

wheel

Standard

thickness

of

worrn

bearing

shims

Initial

turning

torque

of

column

assembly

Clearance

of

adjusting

screw

to

sector

shaft

Length

of

side

rod

Tightening

torque

Steering

wheel

lock

nut

Steering

post

clamp

to

steering

post

bracket

bolls

Collapsible

Steering

column

hole

cover

bolts

Column

to

gear

housing

bolts

Side

cover

to

gear

housing

bolts

Adjusting

screw

lock

nut

Sector

shaft

to

pitman

arm

nut

Gear

housing

to

side

main

bar

bolts

and

nuts

Idler

arm

nut

Recirculating

ball

type

mm

in

L

US

pt

Imp

pt

15

I

I

400

157

0

24

I

2

3

8

430

360

mm

in

20

to

25

0

787

to

0

984

mm

in

0

5

0

0197

kg

em

in

oz

2

0

to

5

0

27

8

to

69

4

mrn

in

mm

in

0

05

0

0020

296

8

11

69

kg

m

ft

lb

3

0

to

3

5

217

to

25

3

kg

m

ft

lb

kg

m

ft

Ib

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

0

8

to

1

0

5

8

to

7

2

1

5

to

1

8

10

8

to

13

0

8

to

1

0

5

8

to

7

2

1

5

to

2

5

10

8

to

18

1

I

7

to

2

8

12

3

to

20

2

2

0

to

3

0

14

5

to

21

7

14

101

kg

m

ft

lb

kg

m

ft

lb

1

9

to

2

6

13

7

to

18

8

57

to

6

3

41

2

to

45

6

Idler

arm

to

side

main

bar

bolts

and

nuts

kg

m

ft

Ib

Ball

stud

nuts

kg

m

ft

lb

Side

rod

bar

lock

nuts

kg

m

ft

lb

1

9

to

2

6

13

7

to

18

8

3

0

to

5

0

21

7

to

36

2

8

0

to

10

0

57

8

to

72

3

ST

17

Page 178 of 513

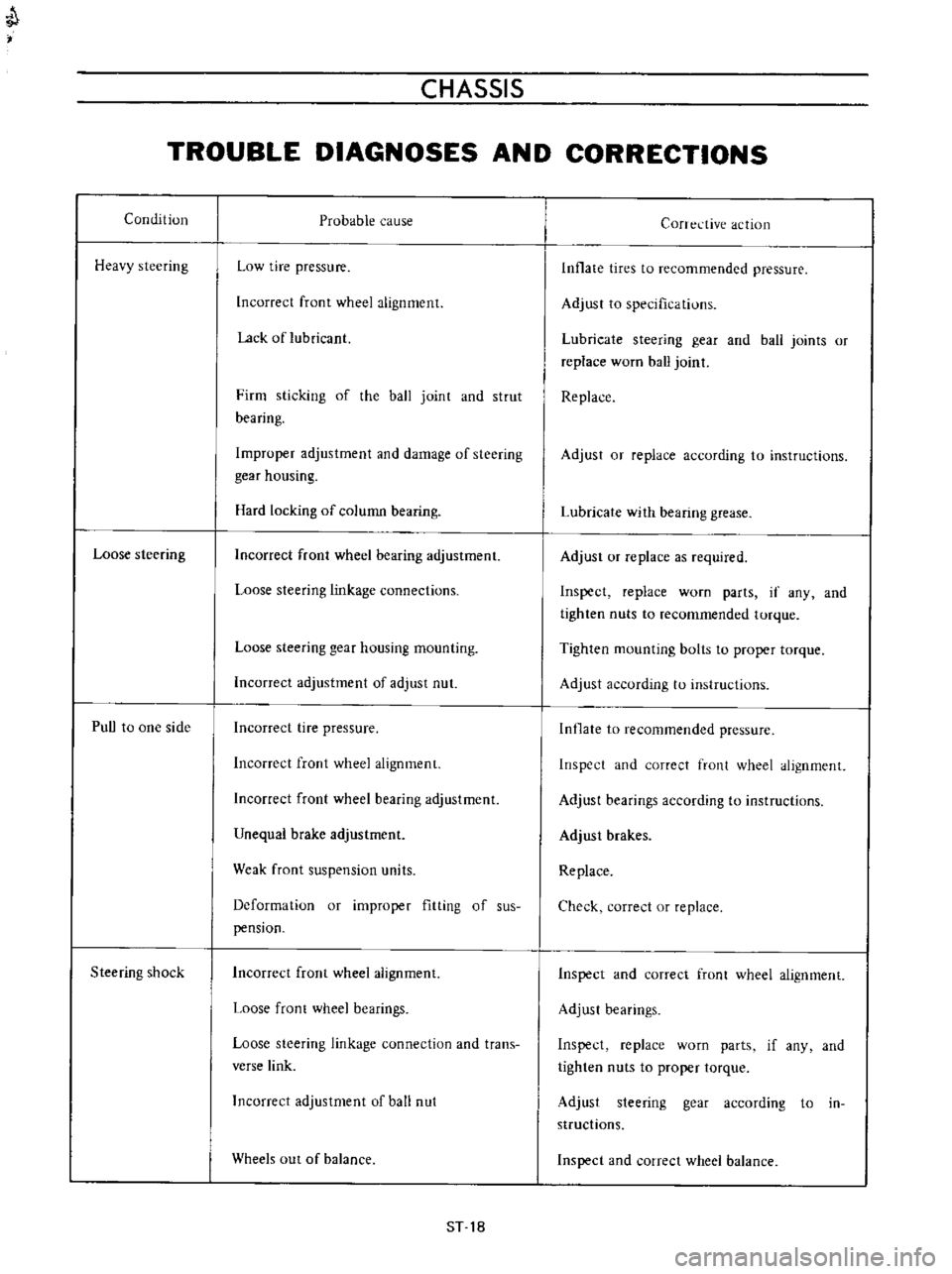

CHASSIS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Heavy

steering

Loose

steering

PuU

to

one

side

Steering

shock

Probable

cause

Low

tire

pressure

Incorrect

front

wheel

alignment

Lack

of

lubricant

Firm

sticking

of

the

ball

joint

and

strut

bearing

Improper

adjustment

and

damage

of

steering

gear

housing

Hard

locking

of

column

bearing

Incorrect

front

wheel

bearing

adjustment

Loose

steering

linkage

connections

Loose

steering

gear

housing

mounting

Incorrect

adjustment

of

adjust

nut

Incorrect

tire

pressure

Incorrect

front

wheel

alignment

Incorrect

front

wheel

bearing

adjustment

Unequal

brake

adjustment

Weak

front

suspension

units

Deformation

or

improper

fitting

of

sus

pension

Incorrect

front

wheel

alignment

Loose

front

wheel

bearings

Loose

steering

linkage

connection

and

trans

verse

link

Incorrect

adjustment

of

ball

nut

Wheels

out

of

balance

ST

18

Corrective

action

Inflate

tires

to

recommended

pressure

Adjust

to

specifications

Lubricate

steering

gear

and

ball

joints

or

replace

worn

ball

joint

Replace

Adjust

or

replace

according

to

instructions

Lubricate

with

bearing

grease

Adjust

or

replace

as

required

Inspect

replace

worn

parts

if

any

and

tighten

nuts

to

recommended

torque

Tighten

mounting

bolts

to

proper

torque

Adjust

according

to

instructions

Inflate

to

recommended

pressure

Inspect

and

correct

front

wheel

alignment

Adjust

bearings

according

to

instructions

Adjust

brakes

Replace

Check

correct

or

replace

Inspect

and

correct

front

wheel

alignment

Adjust

bearings

Inspect

replace

worn

parts

if

any

and

tighten

nuts

to

proper

torque

Adjust

steering

gear

according

to

in

structions

Inspect

and

correct

wheel

balance