engine DATSUN B110 1973 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 468 of 513

ENGINE

REMOVAL

INSTAllATION

5

Disconnecting

clutch

wire

on

right

hand

drive

model

On

left

hand

drive

model

disconnect

hydraulic

line

from

the

clutch

slave

cylinder

Disconnect

the

clutch

wire

at

the

portion

of

the

withdrawal

lever

See

the

section

covering

the

clutch

6

Remove

the

exhaust

front

tube

ij

f

I

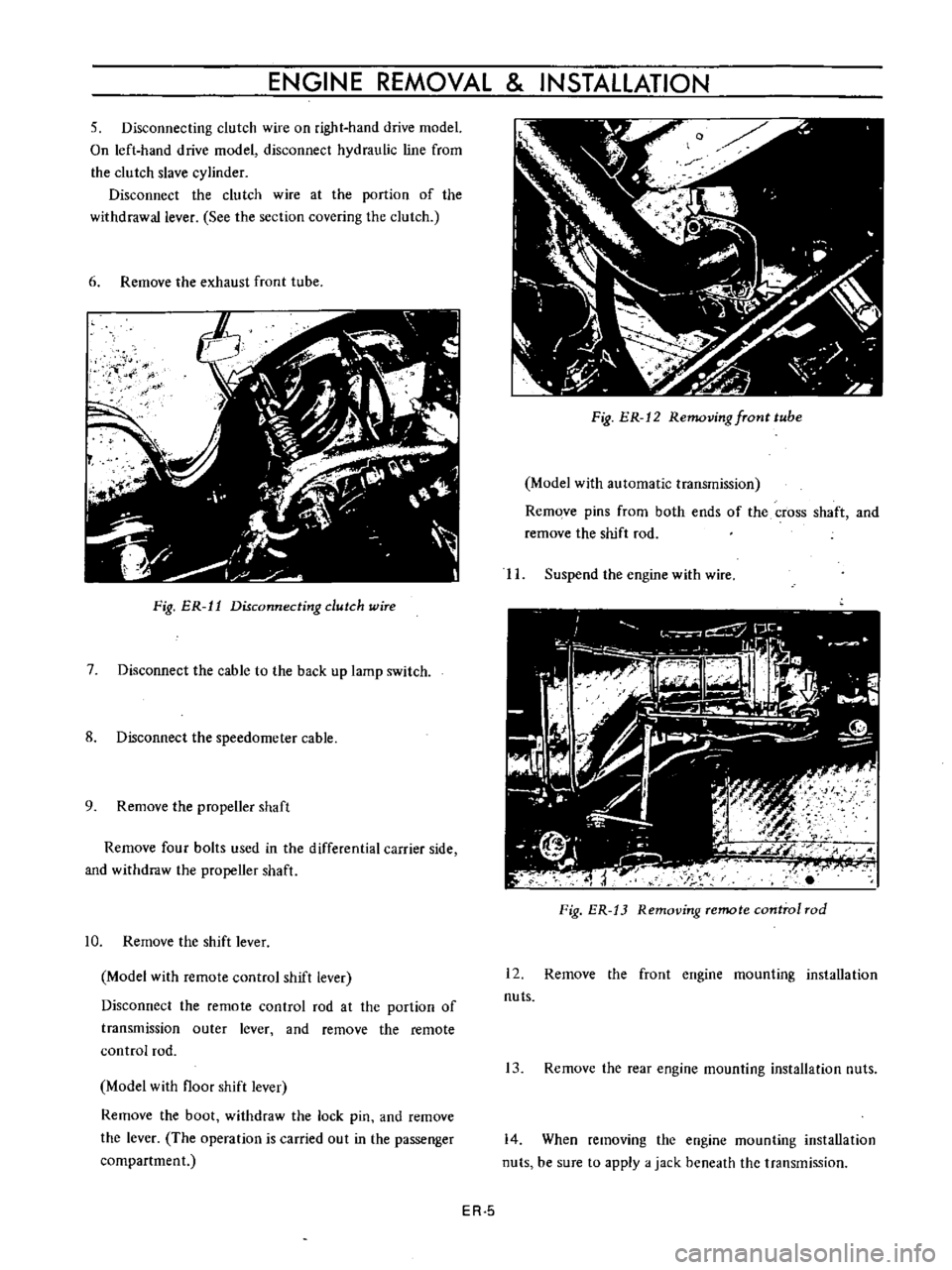

Fig

ER

11

Disconnecting

dutch

wire

7

Disconnect

the

cable

to

the

back

up

lamp

switch

8

Disconnect

the

speedometer

cable

9

Remove

the

propeller

shaft

Remove

four

bolts

used

in

the

differential

carrier

side

and

withdraw

the

propeller

shaft

10

Remove

the

shift

lever

Model

with

remote

control

shift

lever

Disconnect

the

remote

control

rod

at

the

portion

of

transmission

outer

lever

and

remove

the

remote

control

rod

Model

with

floor

shift

lever

Remove

the

boot

withdraw

the

lock

pin

and

remove

the

lever

The

operation

is

carried

out

in

the

passenger

compartment

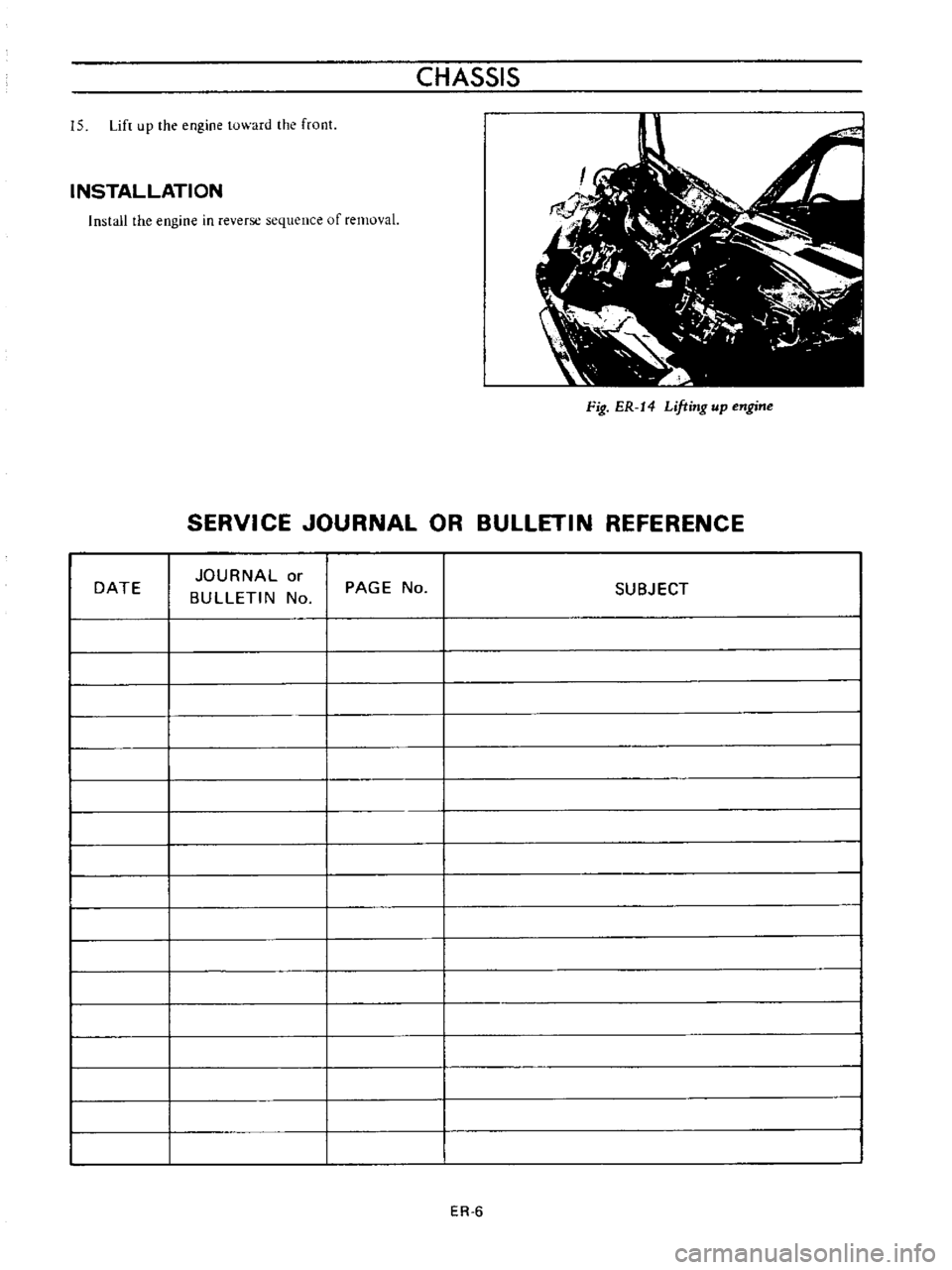

Fig

ER

12

Removing

fTont

tube

Model

with

automatic

transmission

Remove

pins

from

both

ends

of

the

cross

shaft

and

remove

the

shift

rod

II

Suspend

the

engine

with

wire

Fig

ER

13

Removing

remote

control

rod

12

Remove

the

front

engine

mounting

installation

nuts

13

Remove

the

rear

engine

mounting

installation

nuts

14

When

removing

the

engine

mounting

installation

nuts

be

sure

to

apply

a

jack

beneath

the

transmission

ER

5

Page 469 of 513

15

Lift

up

the

engine

toward

the

front

INSTALLATION

Install

the

engine

in

reverse

sequence

of

removal

CHASSIS

Fig

ER

14

Lifting

up

engine

SERVICE

JOURNAL

OR

BULLETIN

REFERENCE

DATE

JOURNAL

or

BULLETIN

No

PAGE

No

ER

6

SUBJECT

Page 472 of 513

CHASSIS

REMOVAL

The

clutch

assembly

is

dismounted

primarily

in

the

same

manner

as

the

engine

assembly

Thus

when

dis

mounting

the

clutch

assembly

refer

to

the

Section

TM

Transmission

Removal

and

other

relative

sections

W

II

11

I

Clutch

assembly

I

2

I

Clutch

disc

assembly

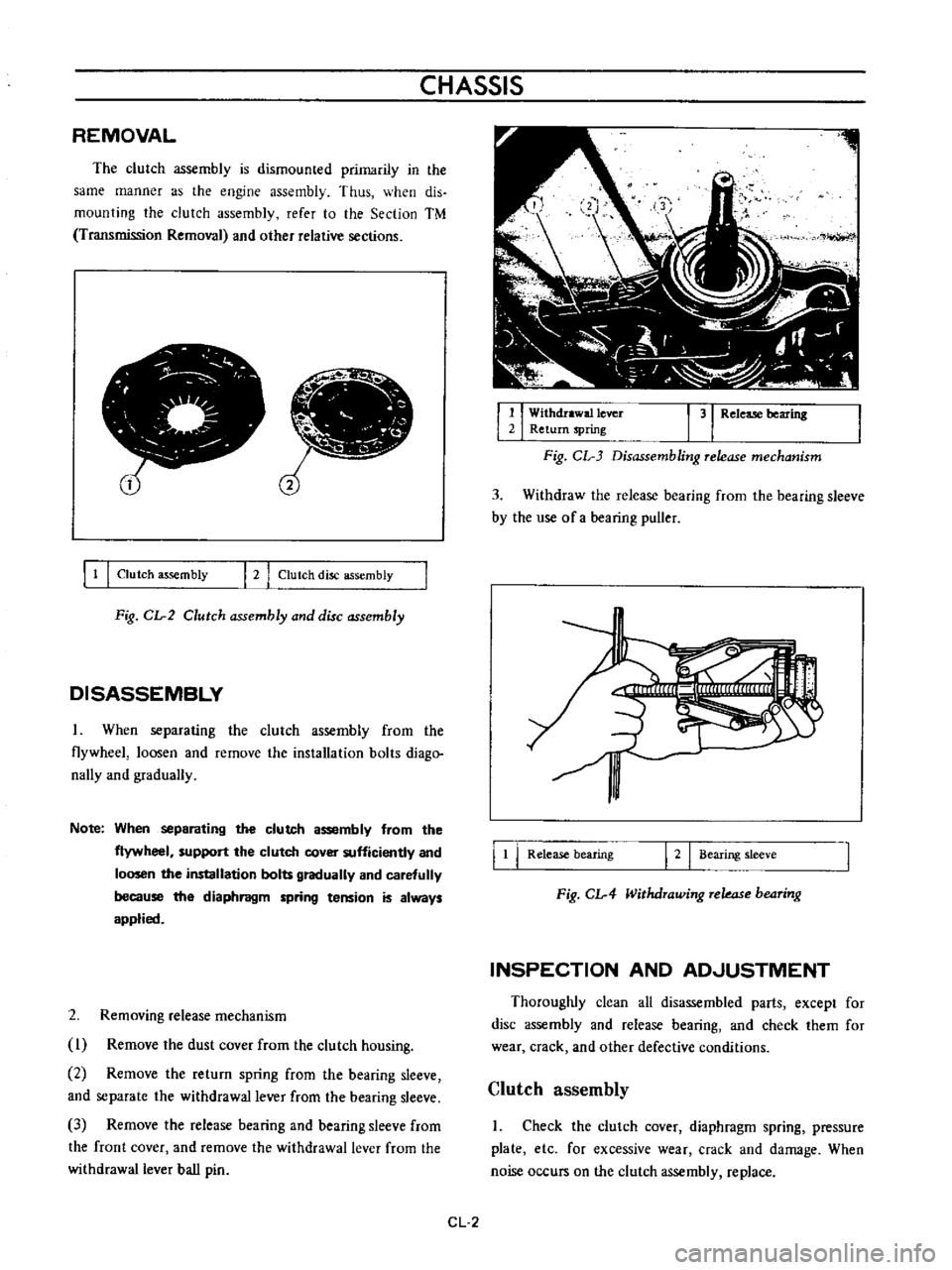

Fig

CIr2

Clutch

assembly

and

disc

assembly

DISASSEMBLY

When

separating

the

clutch

assembly

from

the

flywheel

loosen

and

remove

the

installation

bolts

diago

nally

and

gradually

Note

When

separating

the

clutch

assembly

from

the

flywheel

support

the

clutch

cover

sufficiently

and

loosen

the

installation

bolts

gradually

and

carefully

because

the

diaphragm

spring

tension

is

always

applied

2

Removing

release

mechanism

I

Remove

the

dust

cover

from

the

clutch

housing

2

Remove

the

return

spring

from

the

bearing

sleeve

and

separate

the

withdrawal

lever

from

the

bearing

sleeve

3

Remove

the

release

bearing

and

bearing

sleeve

from

the

front

cover

and

remove

the

withdrawal

lever

from

the

withdrawal

lever

ball

pin

1

I

Withdrawal

lever

3

Release

bearing

2

Return

spring

Fig

CL

3

Disassembling

release

mechanism

3

Withdraw

the

release

bearing

from

the

bearing

sleeve

by

the

use

of

a

bearing

puller

I

t

I

Release

bearing

I

2

I

Bearing

sleeve

Fig

CIr4

Withdrawing

rekas

b04ring

INSPECTION

AND

ADJUSTMENT

Thoroughly

clean

all

disassembled

parts

except

for

disc

assembly

and

release

bearing

and

check

them

for

wear

crack

and

other

defective

conditions

Clutch

assembly

I

Check

the

clutch

cover

diaphragm

spring

pressure

plate

etc

for

excessive

wear

crack

and

damage

When

noise

occurs

on

the

clutch

assembly

replace

CL

2

Page 483 of 513

CLUTCH

Operating

cylinder

clutch

Operating

cylinder

diameter

T

Ilhtening

torque

19

05

mm

0

750

in

Clutch

assembly

securing

bolt

1

5

to

2

2

kg

m

10

8

to

15

9

ft

Ib

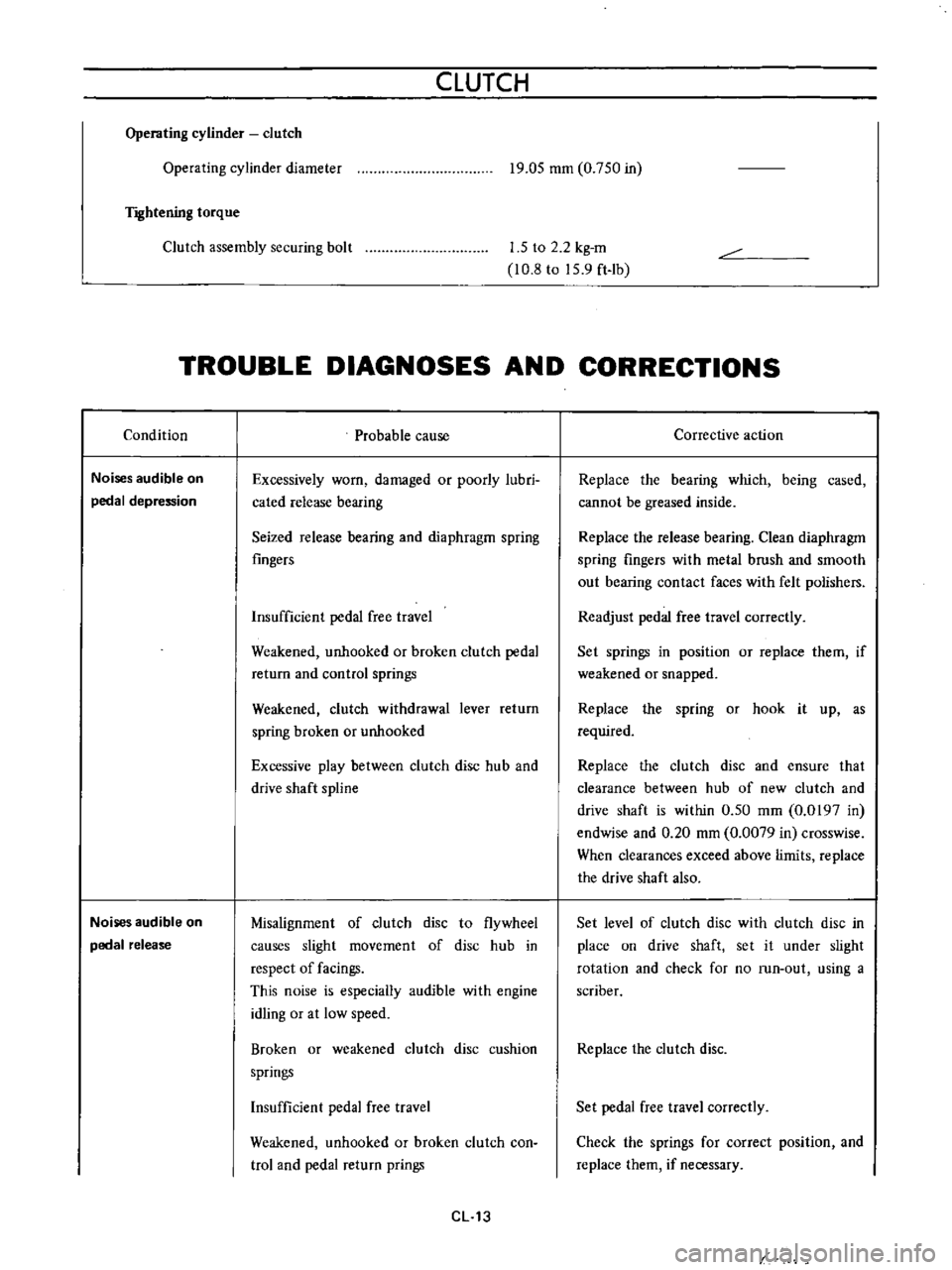

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Noises

audible

on

pedal

depression

Noises

audible

on

pedal

release

Probable

cause

Excessively

worn

damaged

or

poorly

lubri

cated

release

bearing

Seized

release

bearing

and

diaphragm

spring

fingers

Insufficient

pedal

free

travel

Weakened

unhooked

or

broken

clutch

pedal

return

and

control

springs

Weakened

clutch

withdrawal

lever

return

spring

broken

or

unhooked

Excessive

play

between

clutch

disc

hub

and

drive

shaft

spline

Misalignment

of

clutch

disc

to

flywheel

causes

slight

movement

of

disc

hub

in

respect

of

facings

This

noise

is

especially

audible

with

engine

idling

or

at

low

speed

Broken

or

weakened

clutch

disc

cushion

springs

Insufficient

pedal

free

travel

Weakened

unhooked

or

broken

clutch

con

trol

and

pedal

return

prings

CL

13

Corrective

action

Replace

the

bearing

which

being

cased

cannot

be

greased

inside

Replace

the

release

bearing

Clean

diaphragm

spring

fingers

with

metal

brush

and

smooth

out

bearing

contact

faces

with

felt

polishers

Readjust

pedal

free

travel

correctly

Set

springs

in

position

or

replace

them

if

weakened

or

snapped

Replace

the

spring

or

hook

it

up

as

required

Replace

the

clutch

disc

and

ensure

that

clearance

between

hub

of

new

clutch

and

drive

shaft

is

within

0

50

mm

0

0197

in

endwise

and

0

20

mm

0

0079

in

crosswise

When

clearances

exceed

above

limits

replace

the

drive

shaft

also

Set

level

of

clutch

disc

with

clutch

disc

in

place

on

drive

shaft

set

it

under

slight

rotation

and

check

for

no

run

out

using

a

scriber

Replace

the

clutch

disc

Set

pedal

free

travel

correctly

Check

the

springs

for

correct

position

and

replace

them

if

necessary

Page 488 of 513

TRANSMISSION

TRANSMISSION

CONTENTS

DESCRIPTION

Specifications

REMOVAL

DISASSEMBLY

INSPECTION

Transmission

case

and

rear

extension

Bearing

Gear

and

shaft

TM

l

TM

l

TM

2

TM

4

TM

7

TM

7

TM

8

TM

8

DESCRIPTION

Three

speed

and

four

speed

manual

transmission

are

available

for

BJ

10

series

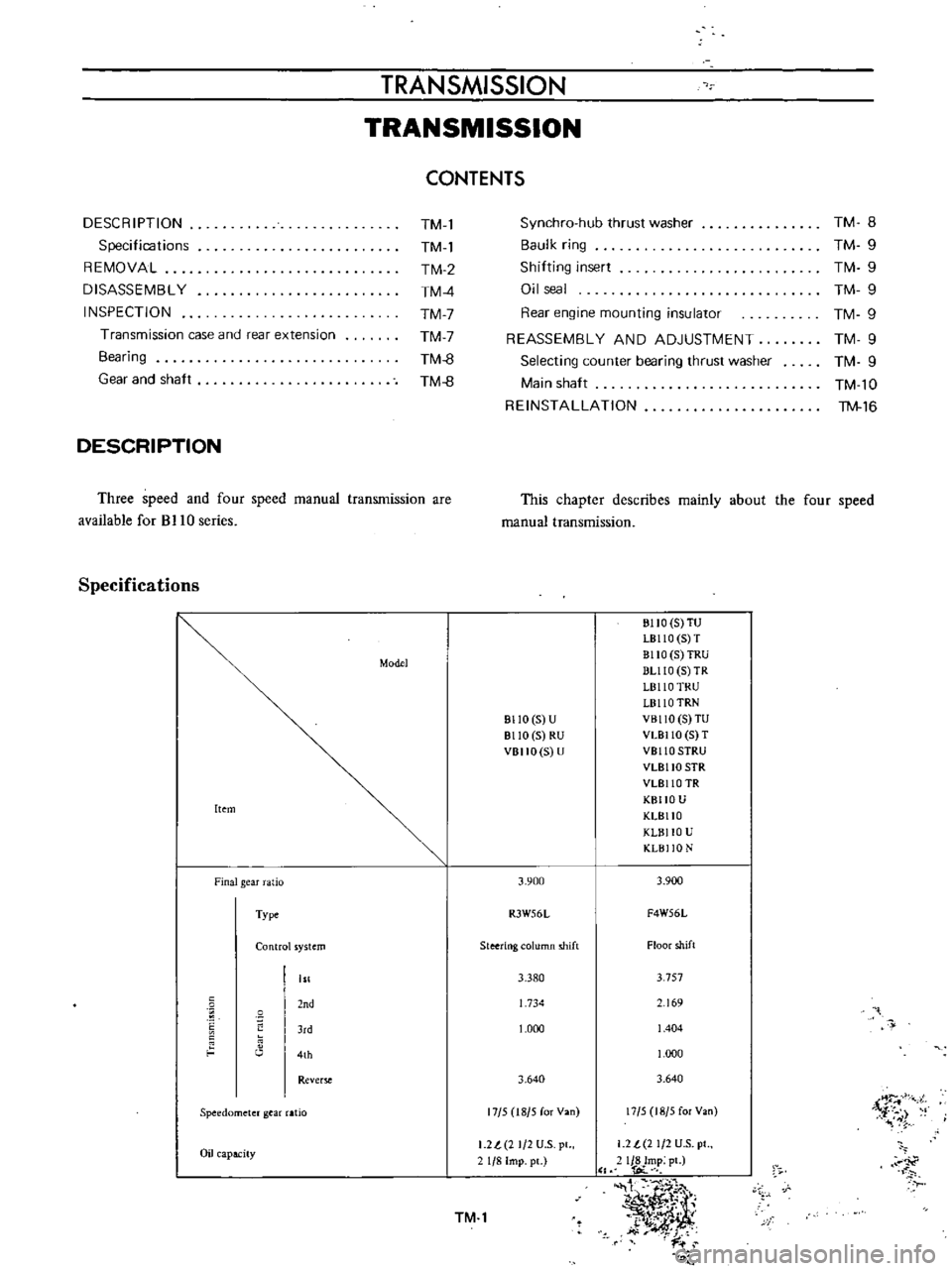

Specifications

Model

Item

Finalgear

atio

Type

Control

ystem

nd

J

d

4th

Rever

Speedometer

gear

aHo

Oil

apacity

TM

8

TM

9

TM

9

TM

9

TM

9

TM

9

TM

9

TM

l0

TM

16

Synchro

hub

thrust

washer

Baulk

ring

Shilting

insert

Oil

seal

Rear

engine

mounting

insulator

REASSEMBLY

AND

ADJUSTMENT

Selecting

counter

bearing

thrust

washer

Main

shaft

REINSTALLATION

This

chapter

describes

mainly

about

the

four

speed

manual

transmission

811O

5

U

8110

5

RU

VBIIO

S

U

3

900

R3W56L

Steering

olumn

shift

3

380

1

734

1

000

3

640

17

5

18

5

for

Van

I

2l

2

1

2

U

S

pl

1

8

Imp

pc

TM

l

BIIO

S

TU

LB110

S

T

BllO

5

TRU

DUlO

5

TR

L8110

TRU

L8110

TRN

VBllO

S

TU

VLBllO

5

T

VBllO

SIRU

VLBllO

SIR

VLBllO

TR

KBIIO

U

KLBllO

KLBllO

U

KLBI

O

N

3

900

F4W56L

Floor

shift

3

757

69

1

404

1

000

3

640

17

5

18

5

for

Van

i

r

i

1

2

t

2

1

2

U

S

pt

IJ8Imp

pt

l

OC

t

1

I

t

y

y

dt

k

J

t

i

r

Page 489 of 513

CHASSIS

25T31T

31T

19Ti

r

n

1

I

l111

0

ILJULj

I

J

ll

J

j

Ll

Jd

c

C

J

13TF

t4T

iST

22T

p

3

t7T

J

3T27T

31T

1

T

l

Jpflh

I

I

I

r

1

II

AE

j

t

I

r

t

L

8

I

U

b

J

251

9T

29T

I

I

T

13T

l

Fig

TM

l

RJW56

gear

train

Fig

TM

2

F4W56

gear

train

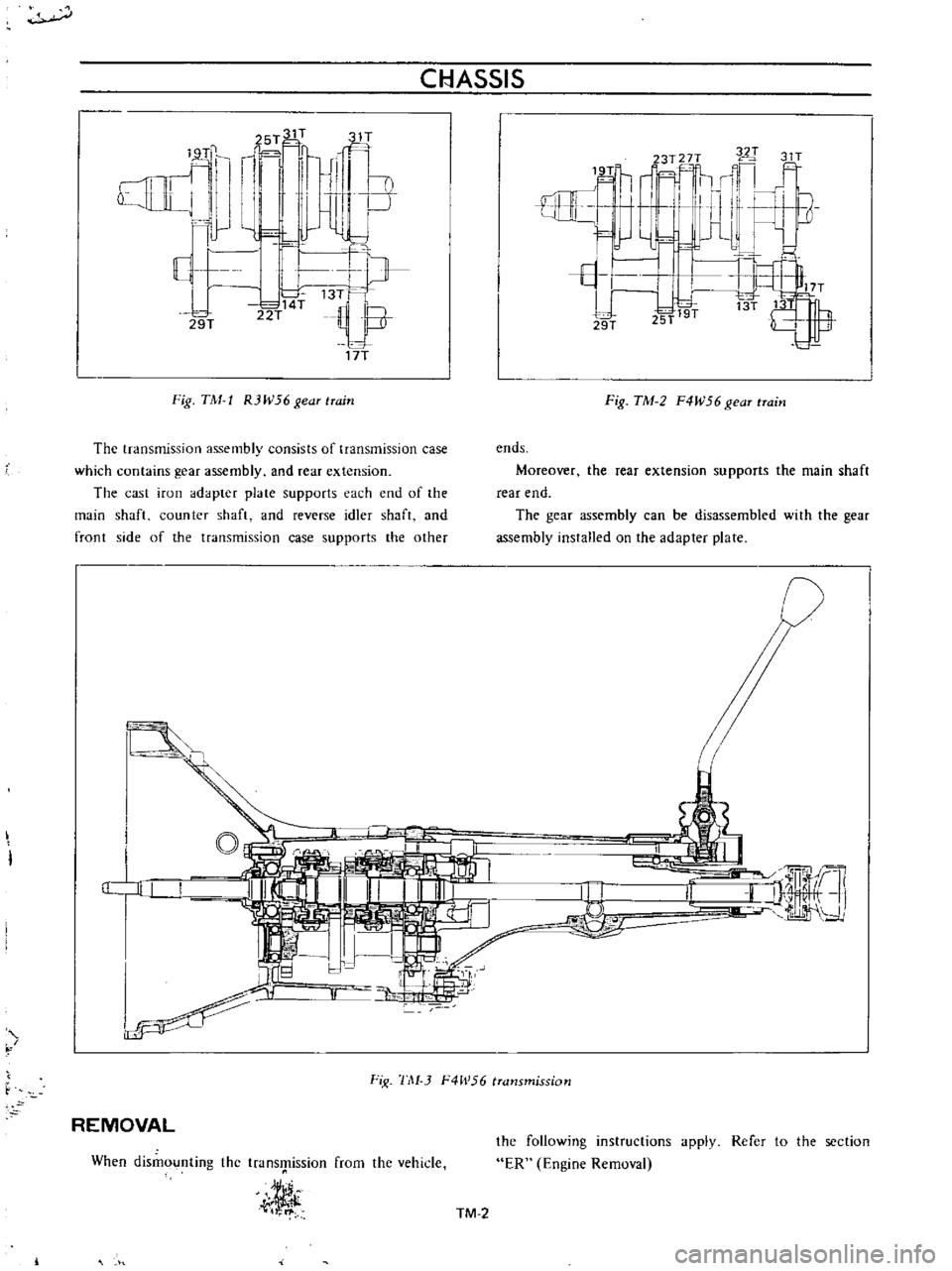

The

transmission

assembly

consists

of

transmission

case

which

contains

gear

assembly

and

rear

extension

The

cast

iron

adapter

plate

supports

each

end

of

the

main

shaft

counter

shaft

and

reverse

idler

shaft

and

front

side

of

the

transmission

case

supports

the

other

ends

Moreover

the

rear

extension

supports

the

main

shaft

rear

end

The

gear

assembly

can

be

disassembled

with

the

gear

assembly

installed

on

the

adapter

plate

j

I

a

JI

I

Ir

I

i

iiffq

J

1

f

Fi

1

1

1

J

F4h

56

transmission

REMOVAL

When

dismounting

the

transmission

from

the

vehicle

j

the

following

instructions

ER

Engine

Removal

apply

Refer

to

the

section

TM

2

Page 490 of 513

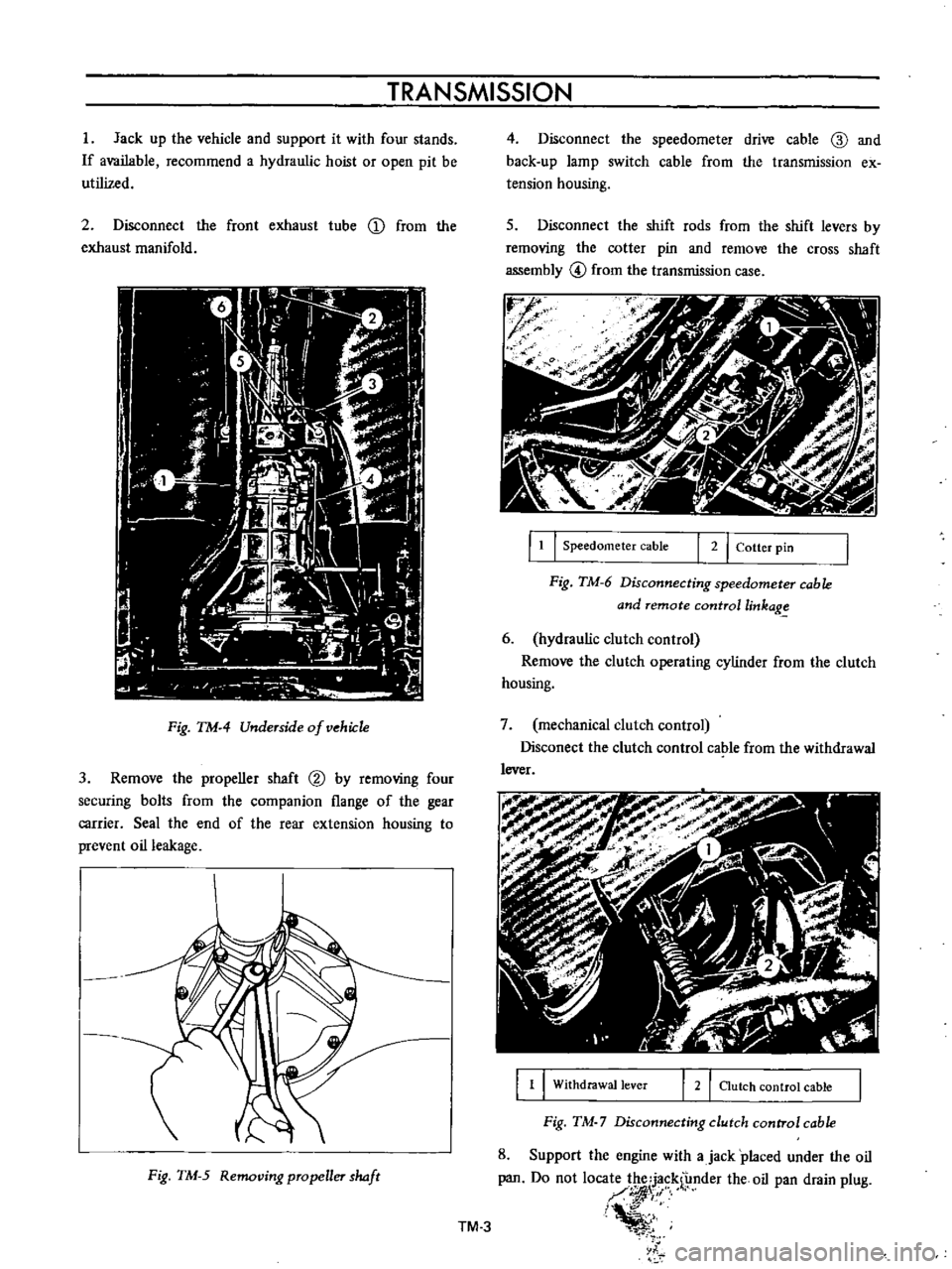

TRANSMISSION

I

Jack

up

the

vehicle

and

support

it

with

four

stands

If

available

recommend

a

hydraulic

hoist

or

open

pit

be

utilized

2

Disconnect

the

front

exhaust

tube

D

from

the

exhaust

manifold

Fig

TM

4

Underside

of

vehiJ

1e

3

Remove

the

propeller

shaft

@

by

removing

four

securing

bolts

from

the

companion

flange

of

the

gear

carrier

Seal

the

end

of

the

rear

extension

housing

to

prevent

oil

leakage

Fig

TM

5

Removing

propeller

haft

4

Disconnect

the

speedometer

drive

cable

ID

and

back

up

lamp

switch

cable

from

the

transmission

ex

tension

housing

s

Disconnect

the

shift

rods

from

the

shift

levers

by

removing

the

cotter

pin

and

remove

the

cross

shaft

assembly

@

from

the

transmission

case

r

J

f

f

1

I

Speedometer

cable

I

2

I

Cotter

pin

Fig

TM

6

Disconnecting

speedometer

cable

and

remote

controllinkag

6

hydraulic

clutch

control

Remove

the

clutch

operating

cylinder

from

the

clutch

housing

7

mechanical

clutch

control

Disconect

the

clutch

control

cable

from

the

withdrawal

lever

1

1

Withdrawal

lever

2

I

Clutch

control

cable

Fig

TM

7

Disconnecting

clutch

control

cable

8

Support

the

engine

with

ajack

placed

under

the

oil

pan

Do

not

loca

1

f

nder

the

oil

pan

drain

plug

I

i

l

TM

3

Page 491 of 513

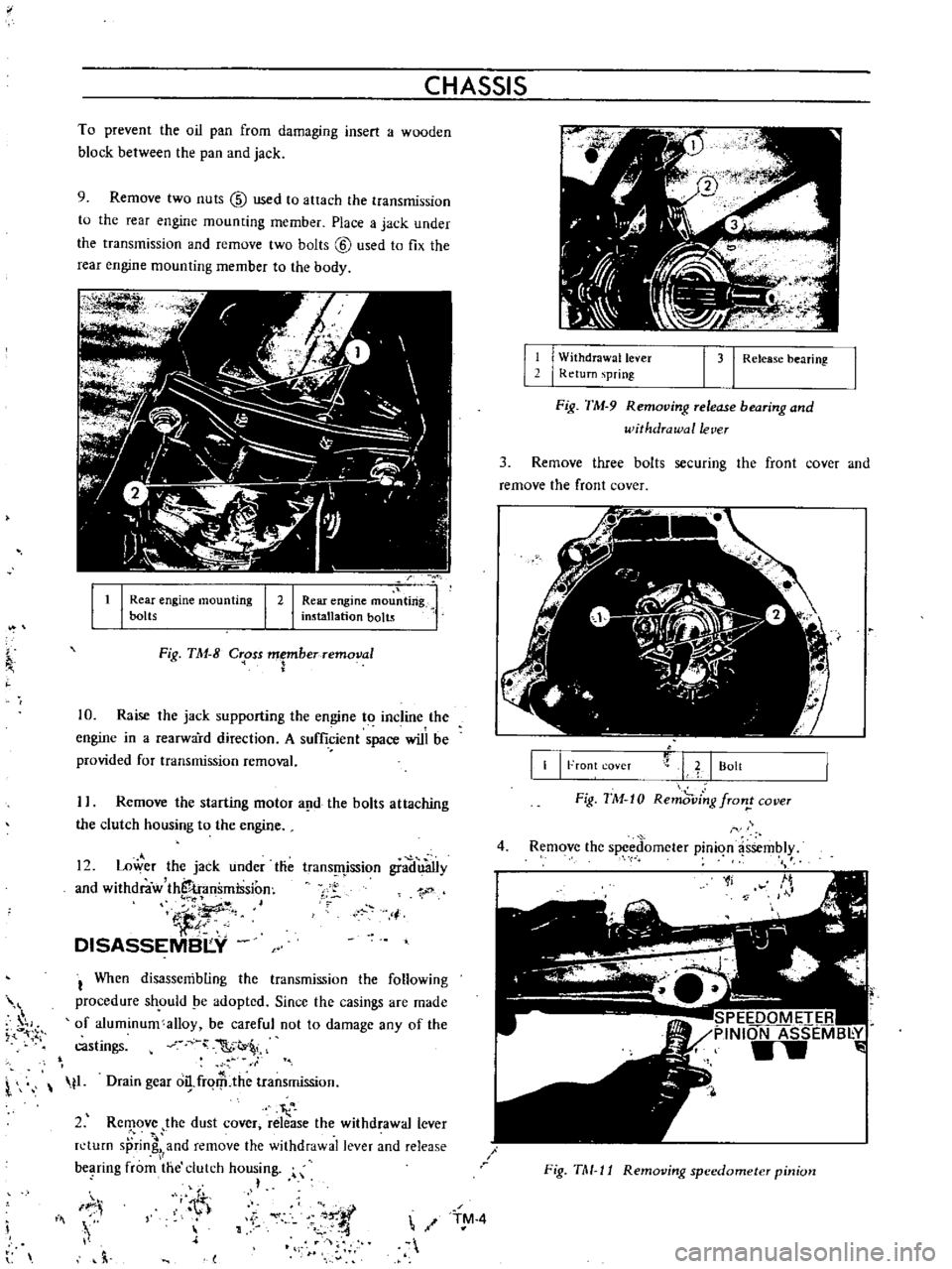

CHASSIS

To

prevent

the

oil

pan

from

damaging

insert

a

wooden

block

between

the

pan

and

jack

9

Remove

two

nuts

@

used

to

attach

the

transmission

to

the

rear

engine

mounting

member

Place

a

jack

under

the

transmission

and

remove

two

bolts

@

used

to

fix

the

rear

engine

mounting

member

to

the

body

It

I

Rear

engine

mou

ting

installation

bolts

I

Rear

engine

mounting

bolts

I

2

Fig

TM

8

C

oss

Fberremoval

10

Raise

the

jack

supporting

the

engine

to

incline

the

engine

in

a

rearward

direction

A

sufficient

space

will

be

provided

for

transmission

removal

I

Remove

the

starting

motor

a

d

the

bolts

attaching

the

clutch

housing

to

the

engine

12

Lower

the

jack

under

tlie

and

withdraw

thS

transmission

iJ

DISASSEMBI

Y

trans

fljssion

gradu3Ily

1

j

I

When

disassembling

the

transmission

the

following

procedure

sh

ould

pe

adopted

Since

the

casings

are

made

of

aluminum

alloy

be

careful

not

to

damage

any

of

the

castings

C

t

l

t1

Drain

gear

o

frqrP

the

transmission

I

2

Rc

ove

the

dust

cover

release

the

withdrawal

lever

n

turn

sprin

and

remove

the

withdrawal

lever

and

release

bC

lring

from

the

clutch

housing

h

IF

i

Iii

h

l

11

I

W

ithdrawallever

I

Return

spring

1

31

Release

bearing

Fig

TM

9

Removing

release

bearing

and

withdrawal

lever

3

Remove

three

bolts

securing

the

front

cover

and

remove

the

front

cover

II

I

Front

coveT

L

I

Bolt

Fig

TM

10

Remd

ving

fron

cover

4

Remove

the

spced

omcter

pinion

assembly

1f

SPEEDOMETER

PINION

ASSEMB

Y

w

Fig

TM

11

Removing

speedometer

pinion

TM

4

Page 496 of 513

TR

ANSMISSION

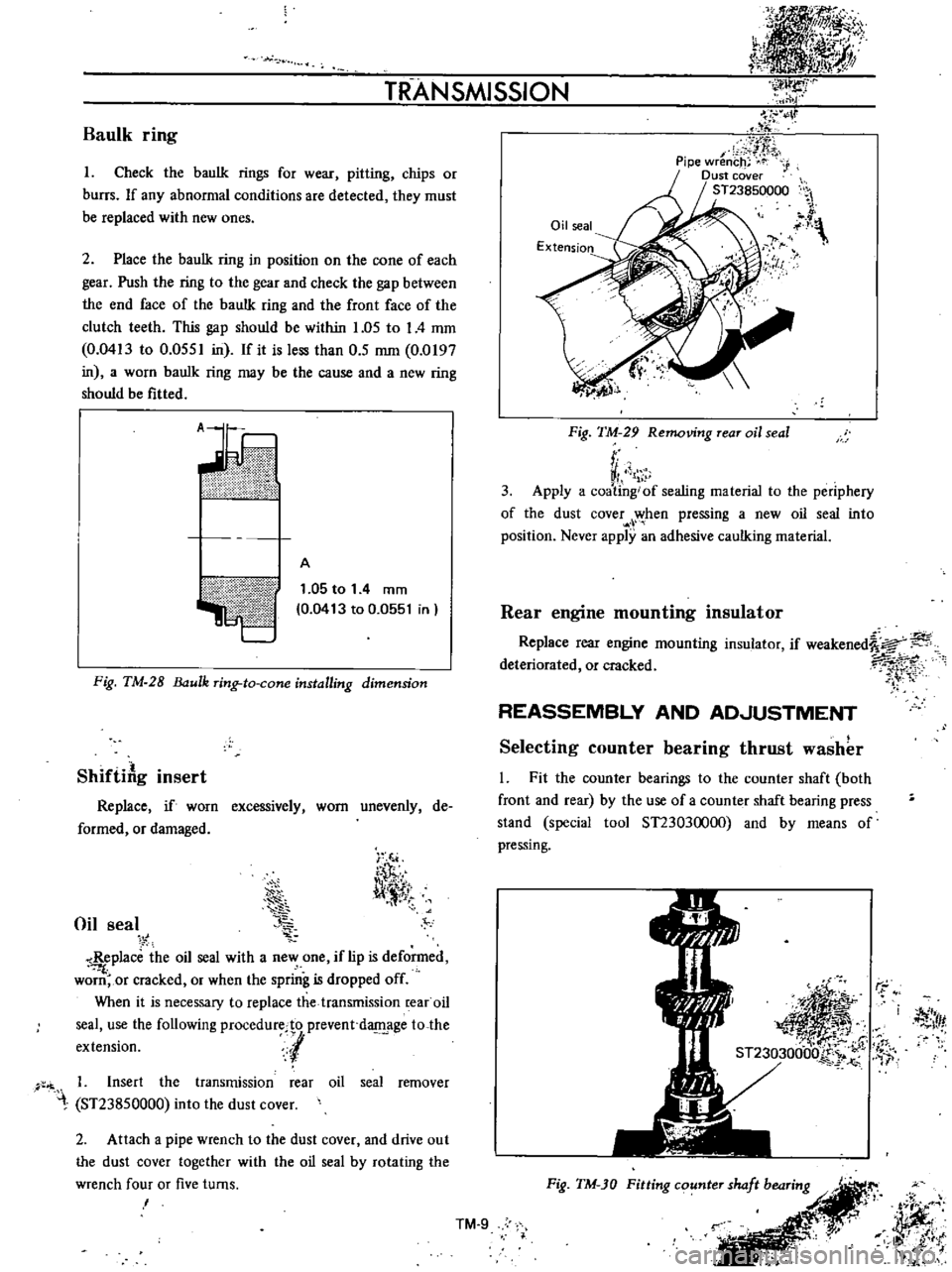

Baulk

ring

I

Check

the

baulk

rings

for

wear

pitting

chips

or

burrs

If

any

abnormal

conditions

are

detected

they

must

be

replaced

with

new

ones

2

Place

the

baulk

ring

in

position

on

the

cone

of

each

gear

Push

the

ring

to

the

gear

and

check

the

gap

between

the

end

face

of

the

bauIk

ring

and

the

front

face

of

the

clutch

teeth

This

gap

should

be

within

1

05

to

I

4

mm

0

0413

to

0

0551

in

If

it

is

less

than

0

5

mm

0

0197

in

a

worn

bauIk

ring

may

be

the

cause

and

a

new

ring

should

be

fitted

ii

V

ilillltII

l

A

1

05

to

1

4

mm

0

0413

to

0

0551

in

Fig

TM

28

ulk

ring

to

cone

installing

dimension

ShiftiAg

insert

Replace

if

worn

excessively

worn

unevenly

de

formed

or

damaged

Oil

seal

i

T

l

l

11

tT

Replace

the

oil

seal

with

a

new

one

if

lip

is

deformed

f

worn

or

cracked

or

when

the

spring

is

dropped

off

When

it

is

necessary

to

replace

the

transmission

rear

oil

seal

use

the

following

procedurecto

prevent

d

age

to

the

extension

l

1

Insert

the

transmission

rear

oil

seal

remover

ST23850000

into

the

dust

cover

2

Attach

a

pipe

wrench

to

the

dust

cover

and

drive

out

the

dust

cover

together

with

the

oil

seal

by

rotating

the

wrench

four

or

five

turns

I

Oil

seal

Extension

IJ

y

Fig

TM

29

Removing

rear

oil

seal

r

VI

1

3

Apply

a

coating

of

sealing

material

to

the

periphery

of

the

dust

cover

when

pressing

a

new

oil

seal

into

position

Never

apply

an

adhesive

caulking

material

Rear

engine

mounting

insulator

Replace

rear

engine

mounting

insulator

if

weakened

a

deteriorated

or

cracked

7i

1

rt

REASSEMBLY

AND

AD

JUSTMENT

Selecting

counter

bearing

thrust

washer

l

Fit

the

counter

bearings

to

the

counter

shaft

both

front

and

rear

by

the

use

of

a

counter

shaft

bearing

press

stand

special

tool

ST23030000

and

by

means

of

pressing

r

j

Itf

Fig

TM

JO

Fitting

counter

shaft

bearing

r

JJff

i

it

l

t

i

j

IlK

Ji

t

l

k

TM

9

Page 507 of 513

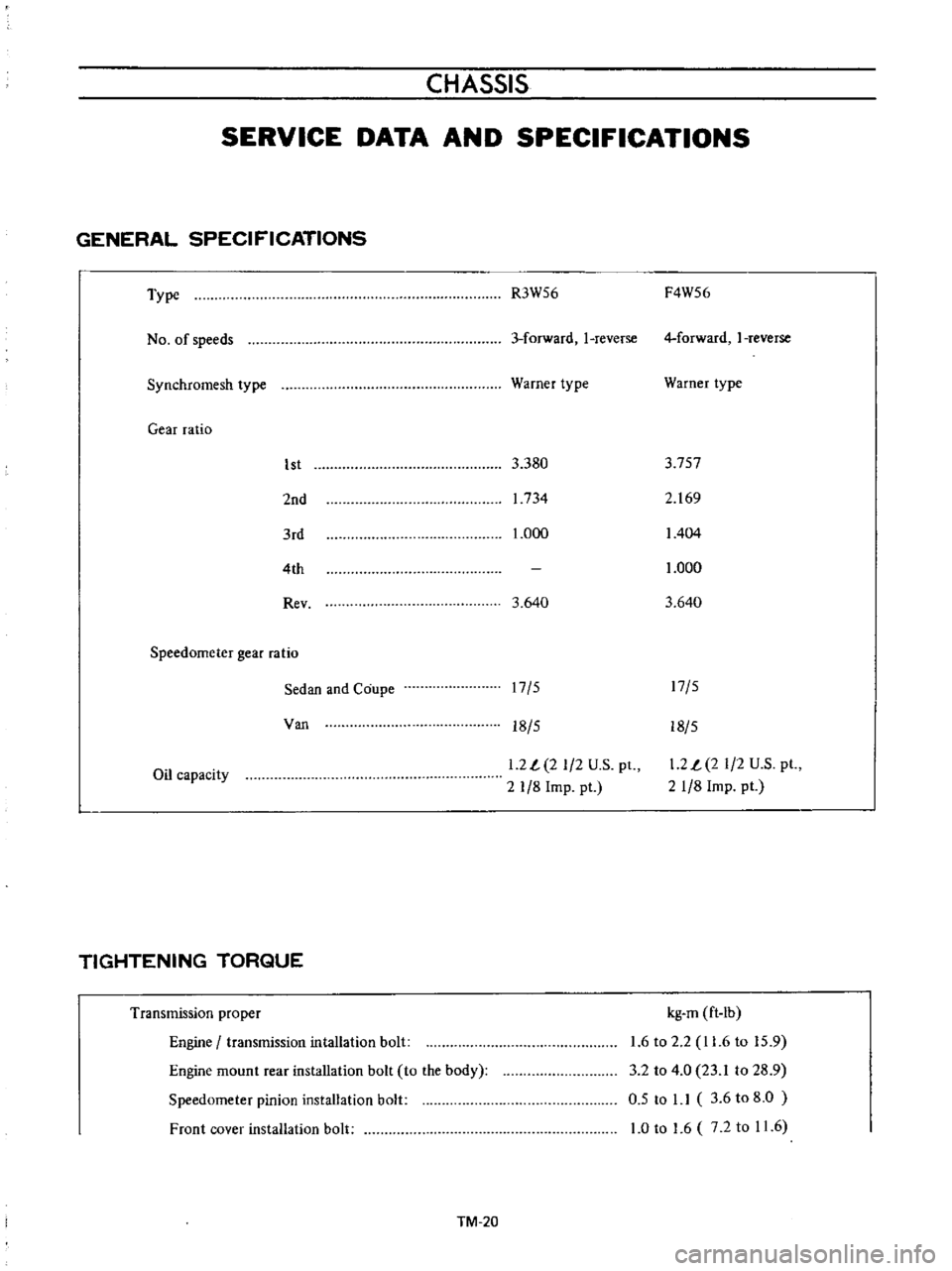

CHASSIS

SERVICE

DATA

AND

SPECIFICATIONS

GENERAL

SPECIFICATIONS

Type

No

of

speeds

Synchromesh

type

Gear

ratio

1st

2nd

3rd

4th

Rev

Speedometer

gear

ratio

Sedan

and

Coupe

Van

Oil

capacity

TIGHTENING

TORQUE

Transmission

proper

Engine

transmission

intallation

bolt

Engine

mount

rear

installation

bolt

to

the

body

Speedometer

pinion

installation

bolt

Front

cover

installation

bolt

TM

20

R3W56

F4W56

3

forward

I

reverse

4

forward

I

reverse

Warner

type

Warner

type

3

380

3

757

1734

2

169

1

000

1404

1

000

3

640

3

640

17

5

17

5

18

5

18

5

1

2

L

2

1

2

U

S

pt

2

1

8

Imp

pt

1

2

L

2

1

2

U

S

pt

21

8

Imp

pt

kg

m

ft

Ib

1

6

to

2

2

11

6

to

15

9

3

2

to

4

0

23

1

to

28

9

0

5

to

1

1

3

6

to

8

0

1

0

to

1

6

7

2

to

11

6