engine DATSUN B110 1973 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 458 of 513

ENGINE

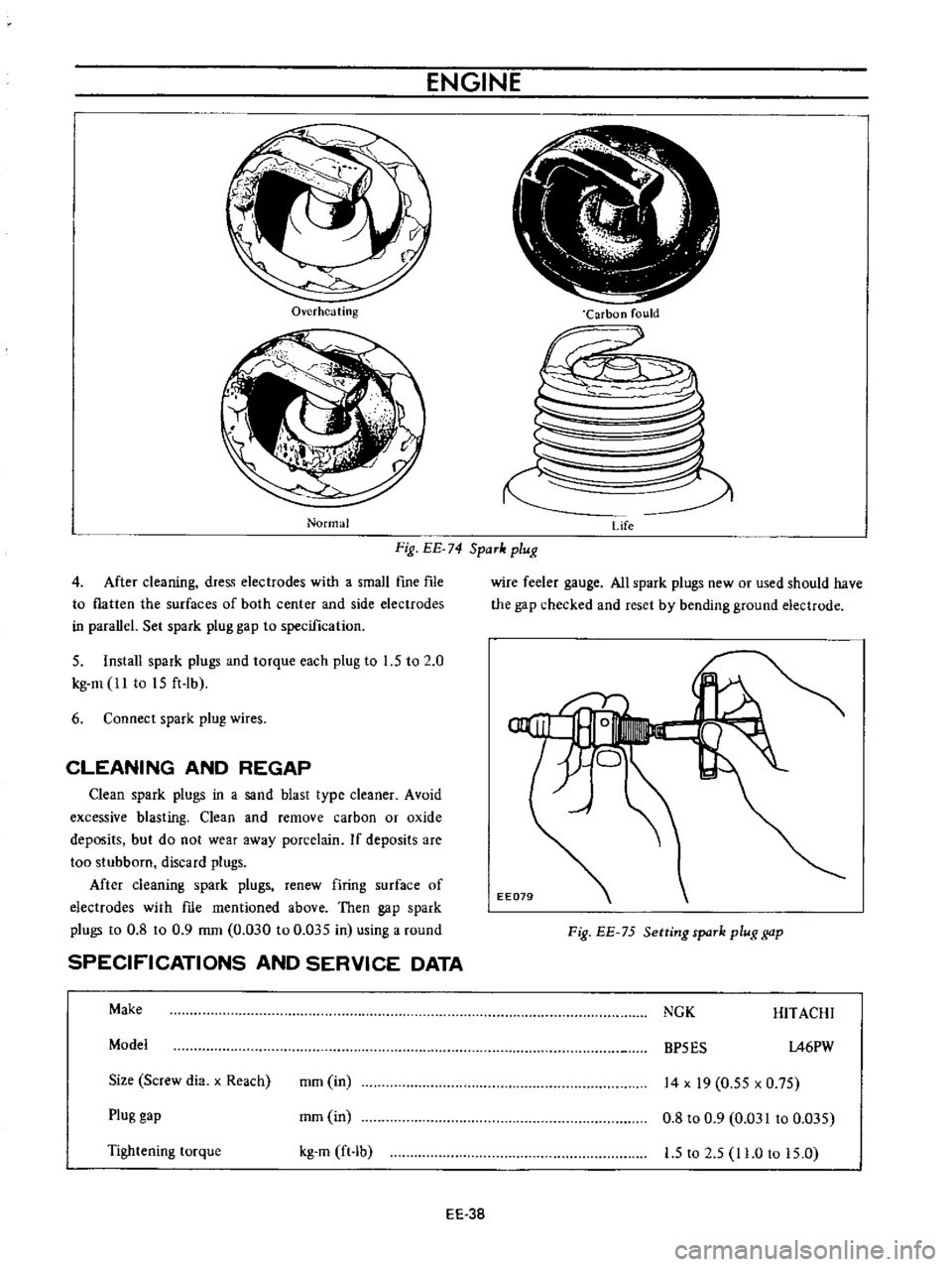

Overheating

Normal

Carbon

fould

Fig

EE

74

SpaTk

plug

Life

4

After

cleaning

dress

electrodes

with

a

small

fine

fIle

to

flatten

the

surfaces

of

both

center

and

side

electrodes

in

parallel

Set

spark

plug

gap

to

specification

5

Install

spark

plugs

and

torque

each

plug

to

1

5

to

2

0

kg

m

ll

to

15

ft

lb

6

Connect

spark

plug

wires

CLEANING

AND

REGAP

Clean

spark

plugs

in

a

sand

blast

type

cleaner

Avoid

excessive

blasting

Clean

and

remove

carbon

or

oxide

deposits

but

do

not

wear

away

porcelain

If

deposits

are

too

stubborn

discard

plugs

Mter

cleaning

spark

plugs

renew

firing

surface

of

electrodes

with

me

mentioned

above

Then

gap

spark

plugs

to

0

8

to

0

9

mm

0

030

to

0

035

in

using

a

round

SPECIFICATIONS

AND

SERVICE

DATA

Make

Model

Size

Screw

dia

x

Reach

mm

in

Plug

gap

mm

in

Tightening

torque

kg

m

ft

b

EE

38

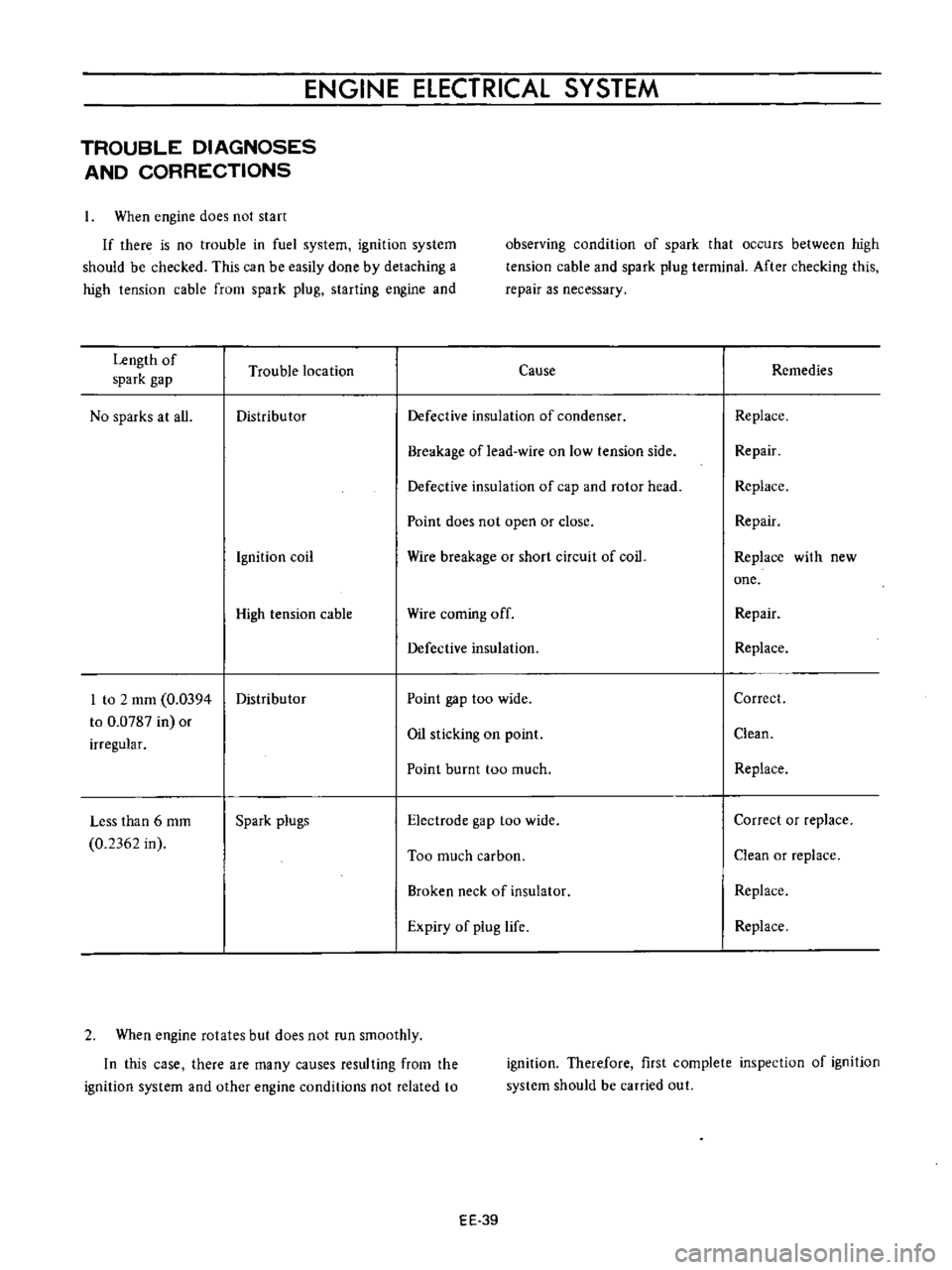

wire

feeler

gauge

All

spark

plugs

new

or

used

should

have

the

gap

checked

and

reset

by

bending

ground

electrode

Fig

EE

75

Setting

spaTk

plug

gap

NGK

HITACHI

BP5ES

1A6PW

14

x

19

0

55

x

0

75

0

8

to

0

9

0

031

to

0

035

1

5

to

2

5

11

0

to

15

0

Page 459 of 513

ENGINE

ELECTRICAL

SYSTEM

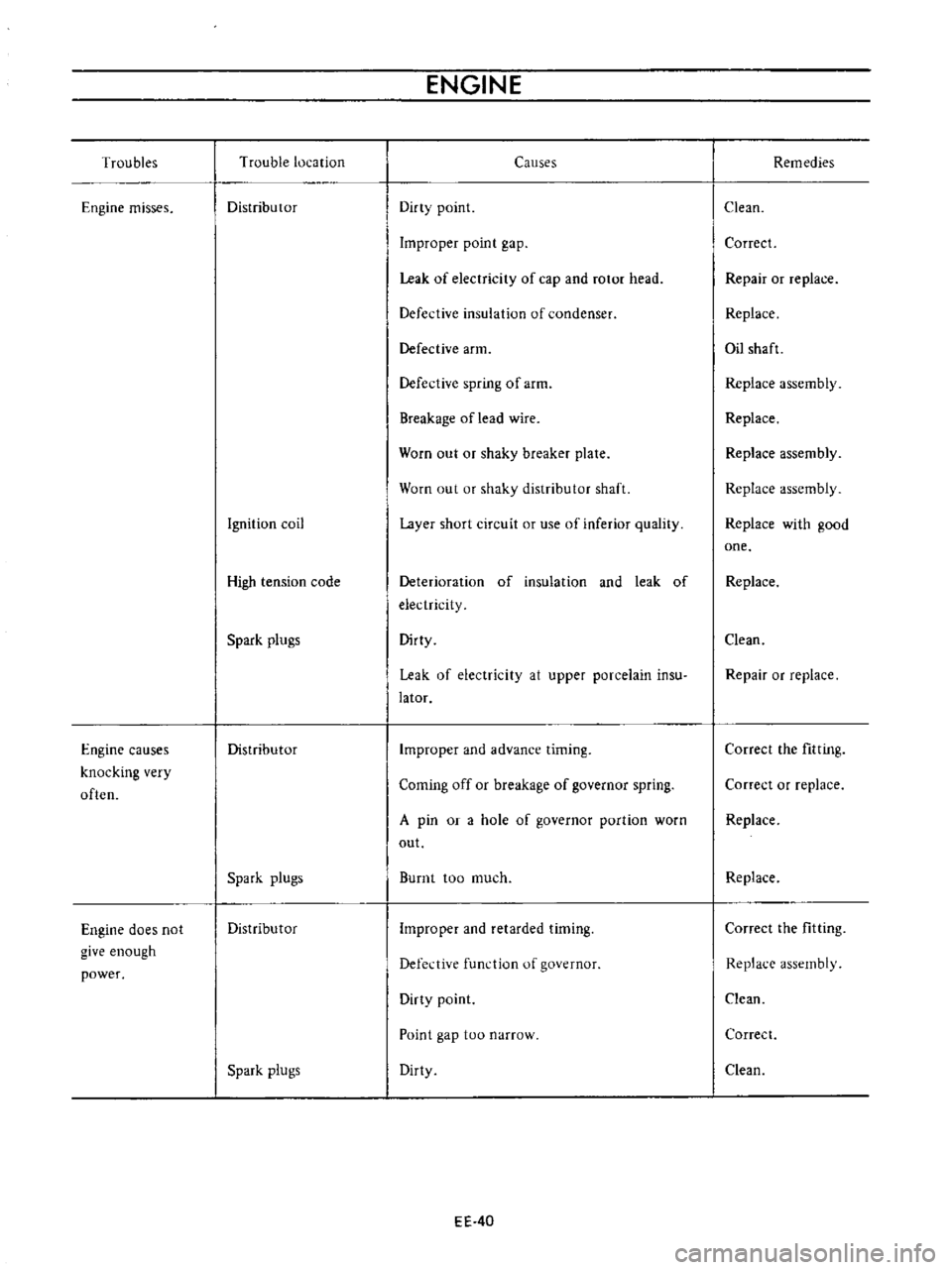

TROUBLE

DIAGNOSES

AND

CORRECTIONS

When

engine

does

not

start

If

there

is

no

trouble

in

fuel

system

ignition

system

should

be

checked

This

can

be

easily

done

by

detaching

a

high

tension

cable

from

spark

plug

starting

engine

and

observing

condition

of

spark

that

occurs

between

high

tension

cable

and

spark

plug

terminal

After

checking

this

repair

as

necessary

Length

of

Trouble

location

Cause

Remedies

spark

gap

No

sparks

at

all

Distributor

Defective

insulation

of

condenser

Replace

Breakage

of

lead

wire

on

low

tension

side

Repair

Defective

insulation

of

cap

and

rotor

head

Replace

Point

does

not

open

or

close

Repair

Ignition

coil

Wire

breakage

or

short

circuit

of

coil

Replace

with

new

one

High

tension

cable

Wire

coming

off

Repair

Defective

insulation

Replace

I

to

2

mm

0

0394

Distributor

Point

gap

too

wide

Correct

to

0

0787

in

or

Oil

sticking

on

point

Clean

irregular

Point

burnt

too

much

Replace

Less

than

6

mm

Spark

plugs

Electrode

gap

too

wide

Correct

or

replace

0

2362

in

Too

much

carbon

Clean

or

replace

Broken

neck

of

insulator

Replace

Expiry

of

plug

life

Replace

2

When

engine

rotates

but

does

not

run

smoothly

In

this

case

there

are

many

causes

resulting

from

the

ignition

system

and

other

engine

conditions

not

related

to

ignition

Therefore

first

complete

inspection

of

ignition

system

should

be

carried

out

EE

39

Page 460 of 513

Troubles

Engine

misses

Engine

causes

knocking

very

often

Engine

does

not

give

enough

power

Trouble

location

Distributor

Ignition

coil

High

tension

code

Spark

plugs

Distributor

Spark

plugs

Distributor

Spark

plugs

ENGINE

Causes

Dirty

point

Improper

point

gap

Leak

of

electricity

of

cap

and

rotor

head

Defective

insulation

of

condenser

Defective

arm

Defective

spring

of

arm

Breakage

oflead

wire

Worn

out

or

shaky

breaker

plate

Worn

out

or

shaky

distributor

shaft

Layer

short

circuit

or

use

of

inferior

quality

Deterioration

of

insulation

and

leak

of

electricity

Dirty

Leak

of

electricity

at

upper

porcelain

insu

lator

Improper

and

advance

timing

Coming

off

or

breakage

of

governor

spring

A

pin

or

a

hole

of

governor

portion

worn

out

Burnt

too

much

Improper

and

retarded

timing

Defedive

function

of

governor

Dirty

point

Point

gap

too

narrow

Dirty

EE

40

Remedies

Clean

Correct

Repair

or

replace

Replace

Oil

shaft

Replace

assembly

Replace

Replace

assembly

Replace

assembly

Replace

with

good

one

Replace

Clean

Repair

or

replace

Correct

the

fitting

Correct

or

replace

Replace

Replace

Correct

the

fitting

Replace

assembly

Clean

Correct

Clean

Page 461 of 513

DATE

ENGINE

ElECTRICAL

SYSTEM

SERVICE

JOURNAL

OR

BUl

LETIN

REFE

RENCE

JOURNAL

or

BULLETIN

No

PAGE

No

SUBJECT

EE

41

Page 462 of 513

ENGINE

i

1

H

t

RI

1

JOURNAL

or

DATE

BULLETIN

No

PAGE

No

SUBJECT

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

1

1111

1

EE

42

Page 463 of 513

DATSUN

1200

MODEL

B

110

SERIES

I

NISSAN

I

NISSAN

MOTOR

CO

LTD

TOKYO

JAPAN

SECTION

ER

ENGINE

REMOVAL

INSTAllATION

It

ENGINE

MOUNTING

ENGINE

REMOVAL

AND

INSTALLATION

ER

1

ER

4

Page 464 of 513

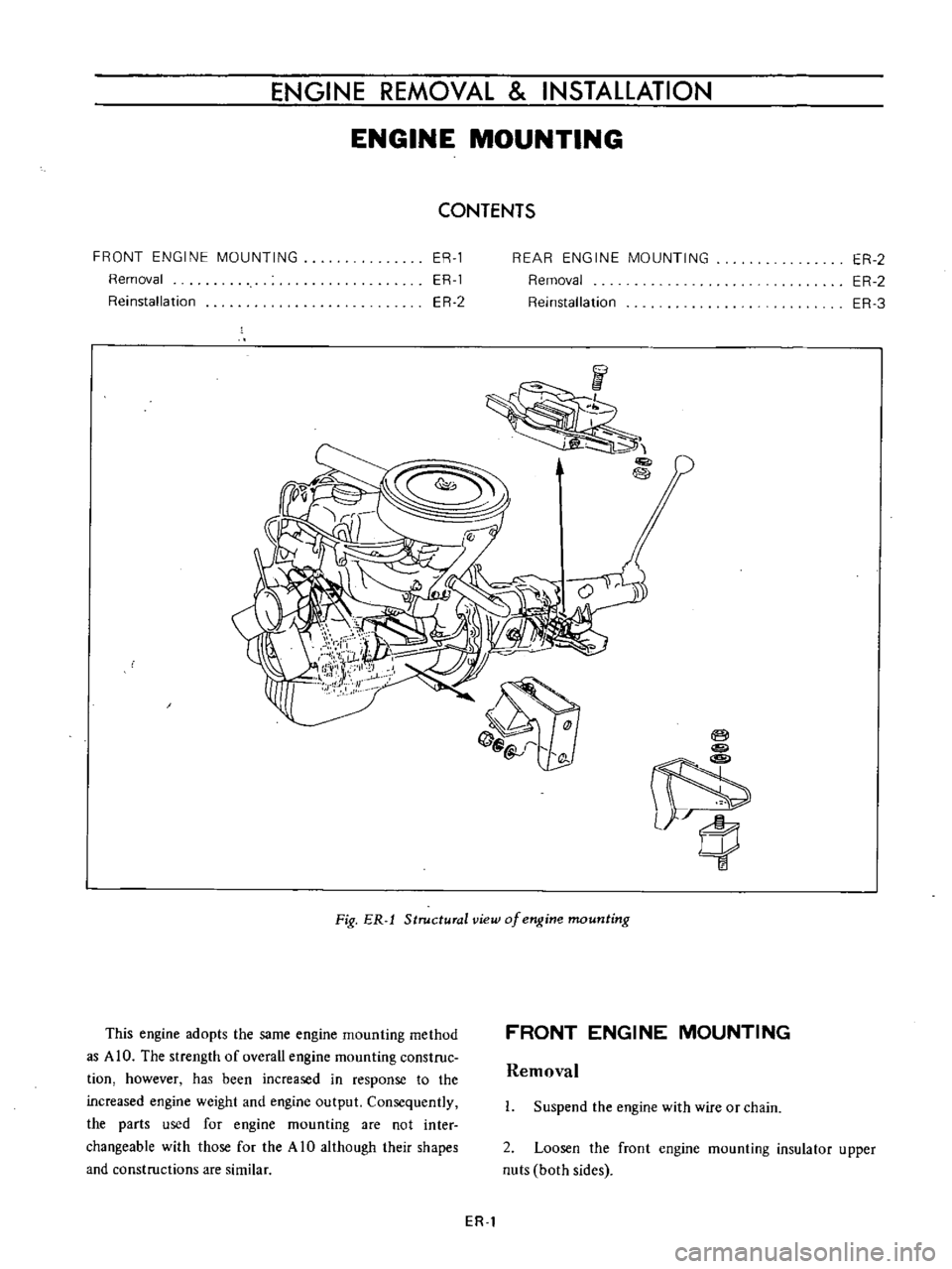

ENGINE

REMOVAL

INSTAllATION

ENGINE

MOUNTING

CONTENTS

FRONT

ENGINE

MOUNTING

Removal

Reinstallation

ER

1

ER

1

ER

2

REAR

ENGINE

MOUNTING

Removal

Reinstallation

ER

2

ER

2

ER

3

r

0

iQ

@

q

Fig

ER

1

Structural

view

of

engine

mounting

This

engine

adopts

the

same

engine

mounting

method

as

AIO

The

strength

of

overall

engine

mounting

construc

tion

however

has

been

increased

in

response

to

the

increased

engine

weight

and

engine

output

Consequently

the

parts

used

for

engine

mounting

arc

not

inter

changeable

with

those

for

the

A

10

although

their

shapes

and

constructions

are

similar

FRONT

ENGINE

MOUNTING

Removal

I

Suspend

the

engine

with

wire

or

chain

2

Loosen

the

front

engine

mounting

insulator

upper

nuts

both

sides

ER

1

Page 465 of 513

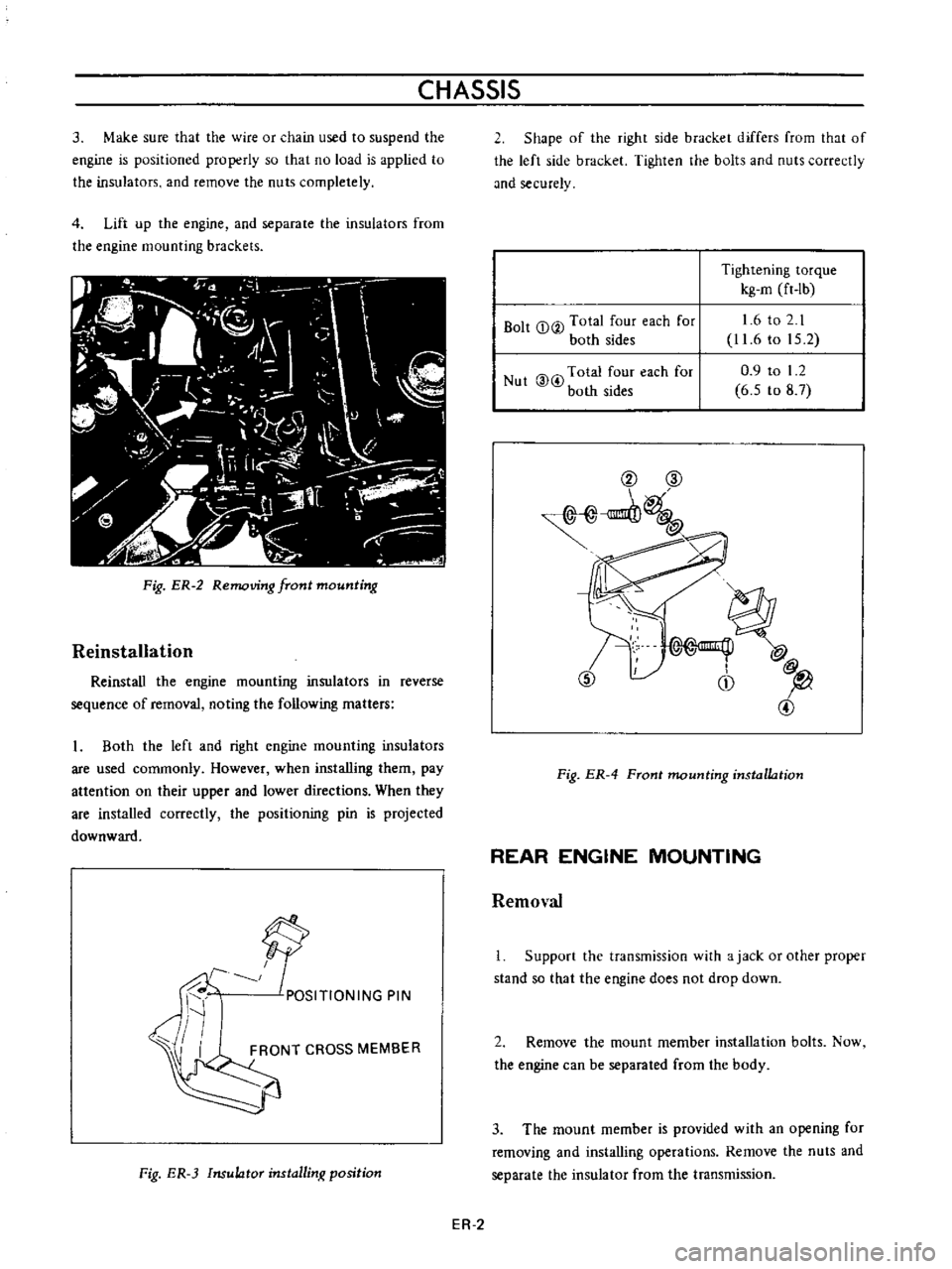

CHASSIS

3

Make

sure

that

the

wire

or

chain

used

to

suspend

the

engine

is

positioned

properly

so

that

no

load

is

applied

to

the

insulators

and

remove

the

nuts

completely

4

Lift

up

the

engine

and

separate

the

insulators

from

the

engine

mounting

brackets

l

J

o

II

f

T

io

I

t

i

1

A

t

t

I

21

u

I

1

Qj

1

It

I

j

fi

I

I

lt

y

Ii

Fig

ER

2

Removing

front

mounting

Reinstallation

Reinstall

the

engine

mounting

insulators

in

reverse

sequence

of

removal

noting

the

following

matters

Both

the

left

and

right

engine

mounting

insulators

are

used

commonly

However

when

installing

them

pay

attention

on

their

upper

and

lower

directions

When

they

are

installed

correctly

the

positioning

pin

is

projected

downward

f

9

POSITIONING

PIN

I

FRONT

CROSS

MEMBER

Fig

ER

3

Insulator

installinx

position

2

Shape

of

the

right

side

bracket

differs

from

that

of

the

left

side

bracket

Tighten

the

bolts

and

nuts

correctly

md

securely

Bolt

CD

V

Total

four

each

for

both

sides

Tightening

torque

kg

m

ft

Ib

1

6

to

2

1

11

6

to

15

2

0

9

to

I

2

6

5

to

8

7

Nut

@

i

Total

four

each

for

both

sides

@

CID

1

@

CD

l

Fig

ER

4

Front

mounting

installation

REAR

ENGINE

MOUNTING

Removal

Support

the

transmission

with

ajack

or

other

proper

stand

so

that

the

engine

does

not

drop

down

2

Remove

the

mount

member

installation

bolts

Now

the

engine

can

be

separated

from

the

body

3

The

mount

member

is

provided

with

an

opening

for

removing

and

installing

operations

Remove

the

nuts

and

separate

the

insulator

from

the

transmission

ER

2

Page 466 of 513

ENGINE

REMOVAL

INSTAllATION

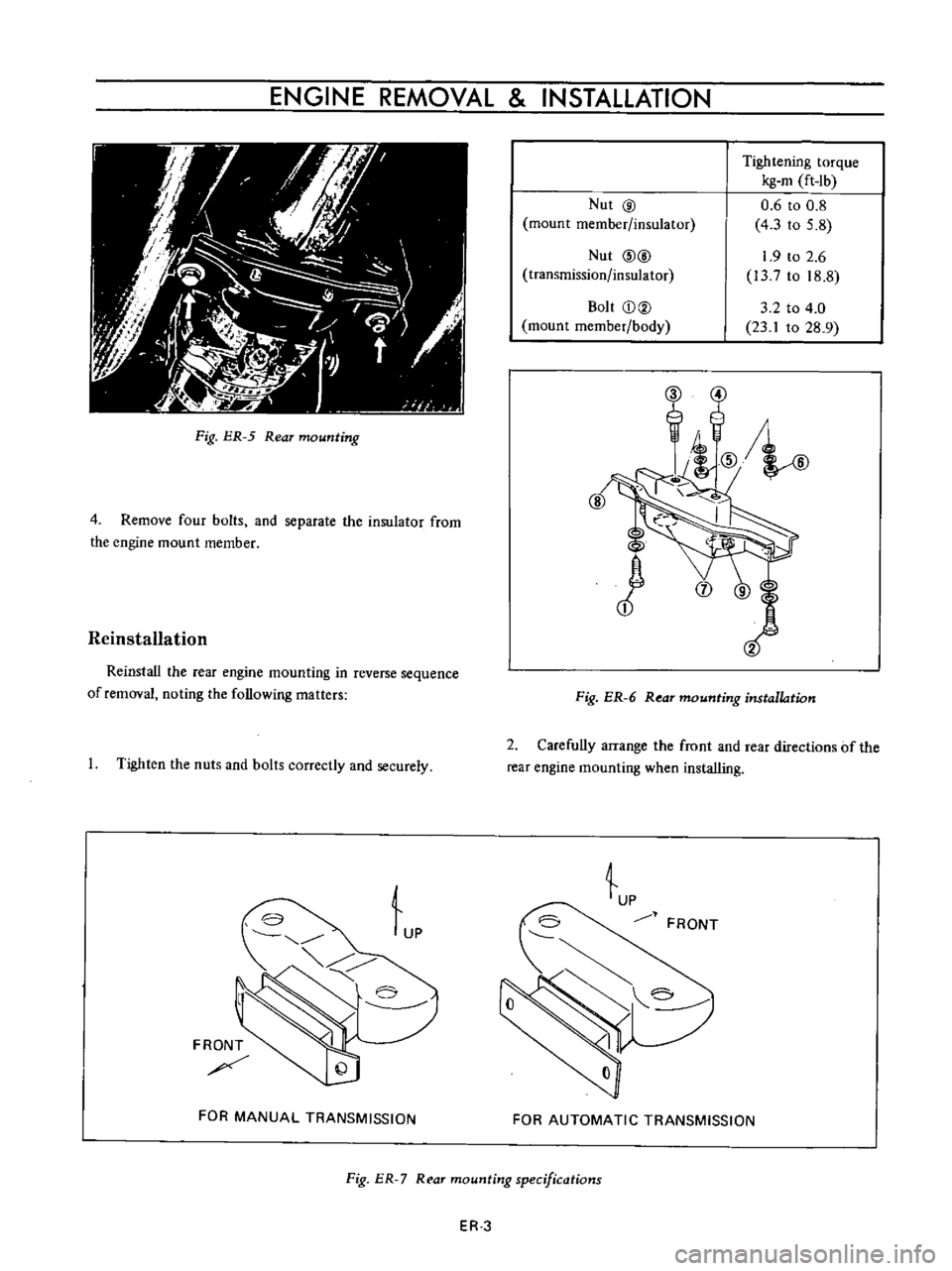

Fig

ER

5

Rear

mounting

4

Remove

four

bolts

and

separate

the

insulator

from

the

engine

mount

member

Reinstallation

Reinstall

the

rear

engine

mounting

in

reverse

sequence

of

removal

noting

the

following

matters

I

Tighten

the

nuts

and

bolts

correctly

and

securely

Lp

FRONT

FOR

MANUAL

TRANSMISSION

Nut

@

mount

member

insulator

Nut

@@

transmission

insulator

Bolt

CD@

mount

member

body

Tightening

torque

kg

m

ft

Ib

0

6

to

0

8

4

3

to

5

8

1

9

to

2

6

l3

to

18

8

3

2

to

4

0

23

1

to

28

9

Fig

ER

6

Rear

mounting

installation

2

Carefully

arrange

the

front

and

rear

directions

of

the

rear

engine

mounting

when

installing

tp

FRONT

FOR

AUTOMATIC

TRANSMISSION

Fig

ER

7

R

ar

mounting

specifications

ER

3

Page 467 of 513

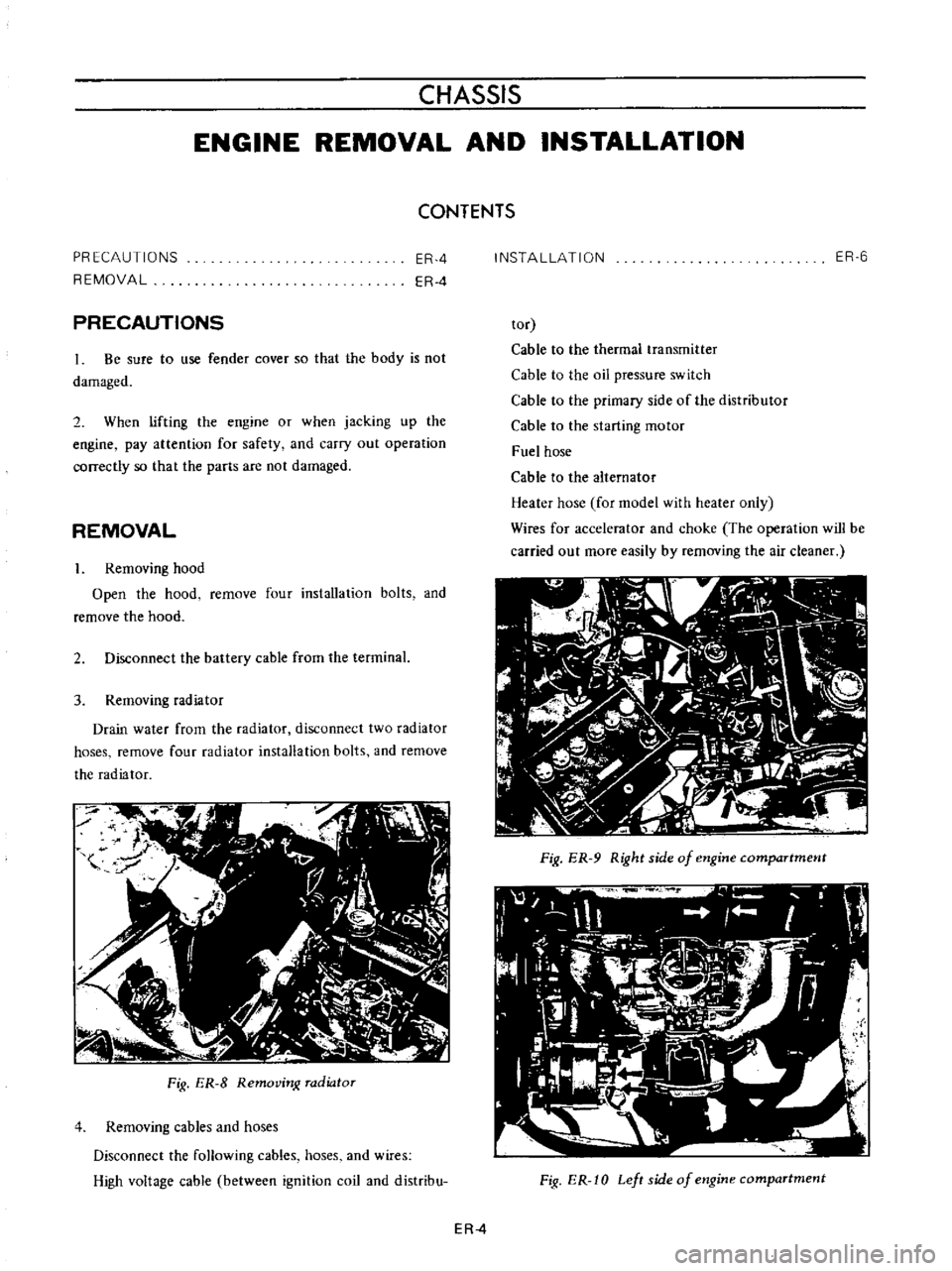

CHASSIS

ENGINE

REMOVAL

AND

INSTALLATION

CONTENTS

PR

ECAUTIONS

REMOVAL

ERA

ERA

PRECAUTIONS

Be

sure

to

use

fender

cover

so

that

the

body

is

not

damaged

2

When

lifting

the

engine

or

when

jacking

up

the

engine

pay

attention

for

safety

and

carry

out

operation

correctly

so

that

the

parts

are

not

damaged

REMOVAL

I

Removing

hood

Open

the

hood

remove

four

installation

bolts

and

remove

the

hood

2

Disconnect

the

battery

cable

from

the

terminal

3

Removing

radiator

Drain

water

from

the

radiator

disconnect

two

radiator

hoses

remove

four

radiator

installation

bolts

and

remove

the

radiator

Fig

ER

8

Removin

radiator

4

Removing

cables

and

hoses

Disconnect

the

following

cables

hoses

and

wires

High

voltage

cable

between

ignition

coil

and

distribu

INSTAllATION

ER

6

tor

Cable

to

the

thermal

transmitter

Cable

to

the

oil

pressure

switch

Cable

to

the

primary

side

of

the

distributor

Cable

to

the

starting

motor

Fuel

hose

Cable

to

the

alternator

Heater

hose

for

model

with

heater

only

Wires

for

accelerator

and

choke

The

operation

will

be

carried

out

more

easily

by

removing

the

air

cleaner

Fig

ER

9

Right

side

of

engine

compartment

Fig

ER

10

Left

side

of

engine

compartment

ERA