clutch DATSUN PICK-UP 1977 Owners Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 522 of 537

DESCR

IPTIDN

COMPRESSOR

CLUTCH

REMOVAL

INSTAllATION

DISASSEMBLY

ASSEMBLY

INSPECTION

DESCRIPTION

Model

CF206

is

a

crank

type

compressor

specially

designed

with

minimum

size

and

light

weight

for

use

on

compact

vehicles

The

compressor

crankshaft

is

driven

by

a

belt

from

the

crankshaft

pulley

through

the

electromagnetic

clutch

Two

pistons

positioned

in

line

are

actuated

by

connecting

rods

coo

nected

to

the

crankshaft

Discharge

and

suction

valves

are

mounted

in

the

valve

liner

between

the

crankcase

and

cylinder

head

As

a

lubricant

SUNlSO

NO

5

is

used

Simplified

positive

pressure

lubrication

utilizes

existing

pressure

differential

between

suction

intake

and

crankcase

to

provide

a

film

of

lubricating

oil

to

bearings

All

internal

components

have

been

designed

to

provide

more

than

adequate

lubrica

tion

to

cylinder

walls

connecting

rod

bearings

and

seal

assembly

The

result

is

improved

lubrication

lower

seal

temperatures

reduced

oil

pumping

and

a

reduction

in

the

number

of

moving

parts

Air

Conditioning

COMPRESSOR

AC33

AC34

AC34

AC34

AC35

AC

35

AC35

CONTENTS

SHAFT

SEAL

ASSEMBLY

REMOVAL

INSTAllATION

INSPECTION

CYLINDER

HEAD

AND

VALVES

REMOVAL

INSTAllATION

AC36

AC36

AC36

AC37

AC37

AC37

AC37

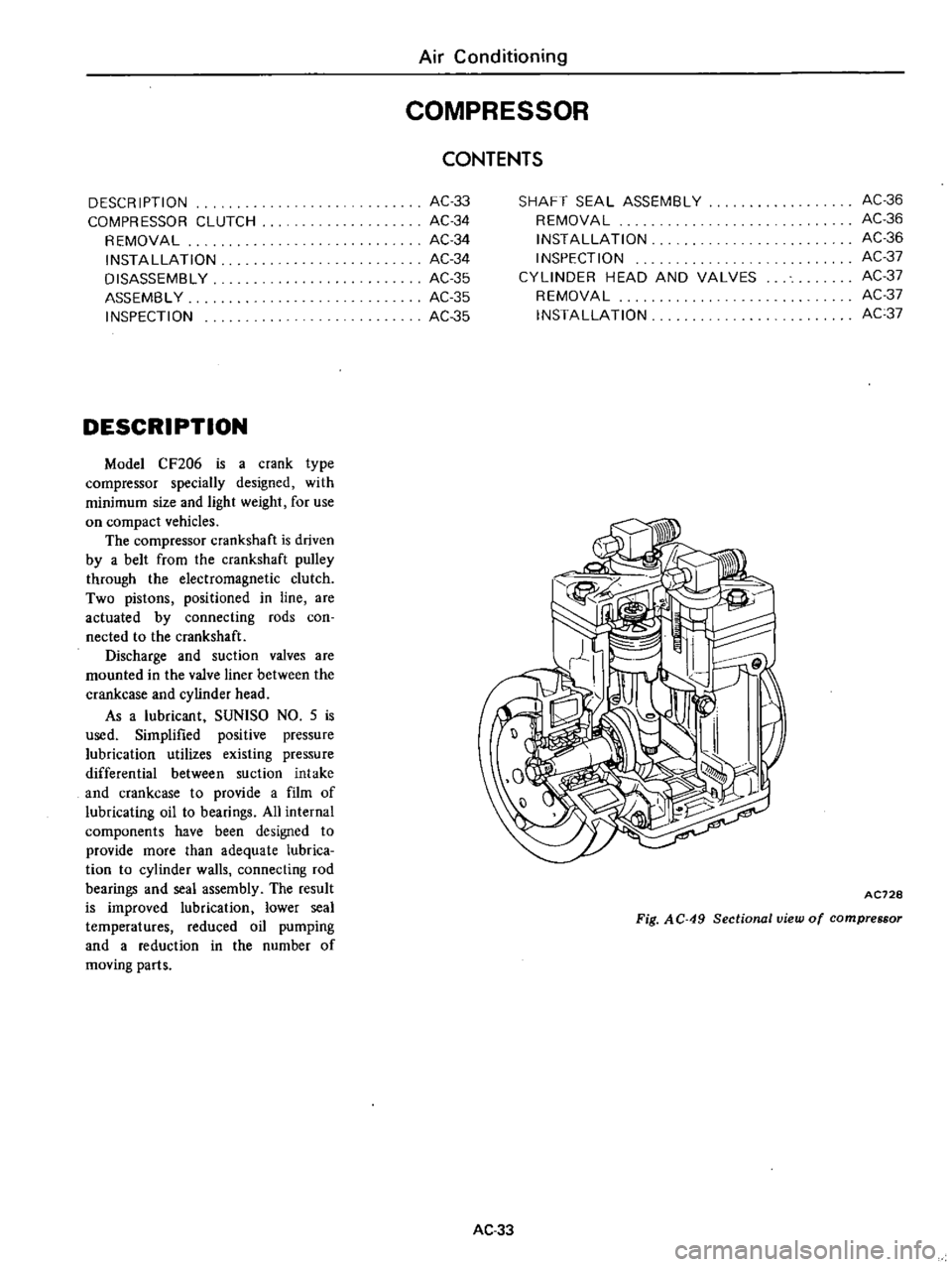

AC728

Fig

AC

49

Sectional

view

of

compressor

AC33

Page 523 of 537

Air

Conditioning

1foo

1t

1

t7

LV

I

1

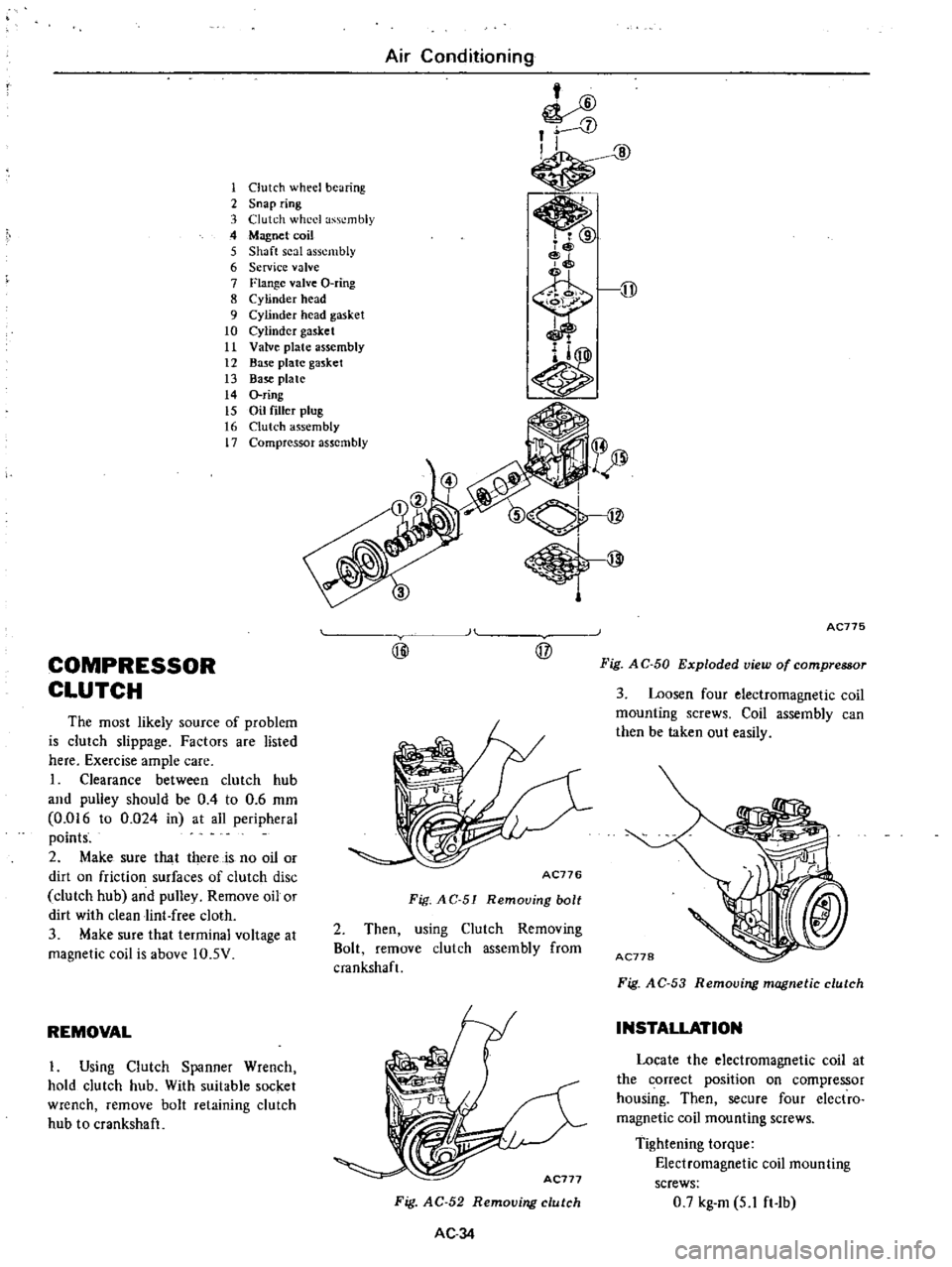

Clutch

wheel

bearing

2

Snap

ring

3

Clutch

wheel

assembly

4

Magnet

coil

5

Shaft

seal

assembly

6

Service

valve

7

Flange

valve

O

ring

8

Cylinder

head

9

Cylinder

head

gasket

10

Cylinder

gasket

11

Valve

plate

assembly

12

Base

plate

gasket

13

Base

plate

14

O

ring

15

Oil

filler

plug

16

Clutch

assembly

17

Compressor

assembly

COMPRESSOR

CLUTCH

The

most

likely

source

of

problem

is

clutch

slippage

Factors

are

listed

here

Exercise

ample

care

I

Clearance

between

clutch

hub

and

pulley

should

be

0

4

to

0

6

mm

0

016

to

0

024

in

at

all

peripheral

points

2

Make

sure

that

there

is

no

oil

or

dirt

on

friction

surfaces

of

clutch

disc

clutch

hub

and

pulley

Remove

oil

or

dirt

with

clean

lint

free

cloth

3

Make

sure

that

terminal

voltage

at

magnetic

coil

is

above

IO

5V

REMOVAL

I

Using

Clutch

Spanner

Wrench

hold

clutch

hub

With

suitable

socket

wrench

remove

bolt

retaining

clutch

hub

to

crankshaft

H

@

@

AC776

Fig

AC

51

Remouing

bolt

2

Then

using

Clutch

Removing

Bolt

remove

clutch

assembly

from

cmnkshaft

Fig

AC

52

Removing

clutch

AC34

AC775

Fig

A

C

50

Exploded

view

of

compressor

3

Loosen

four

electromagnetic

coil

mounting

screws

Coil

assembly

can

then

be

taken

out

easily

Fig

A

C

53

Removing

magnetic

clutch

INSTALLATION

Locate

the

electromagnetic

coil

at

the

correct

position

on

compressor

housing

Then

secure

four

electro

magnetic

coil

mounting

screws

Tightening

torque

Electromagnetic

coil

mounting

screws

0

7

kg

m

5

1

ft

Ib

Page 524 of 537

2

Install

the

clutch

assembly

on

the

crankshaft

Note

Key

should

be

set

on

crank

shaft

before

installing

clutch

assem

bly

3

Using

Clutch

Spanner

Wrench

hold

clutch

hub

With

socket

wrench

secure

clutch

hub

securing

bolt

Tightening

torque

Clutch

hub

securing

bolt

1

5

kg

m

II

ft

lb

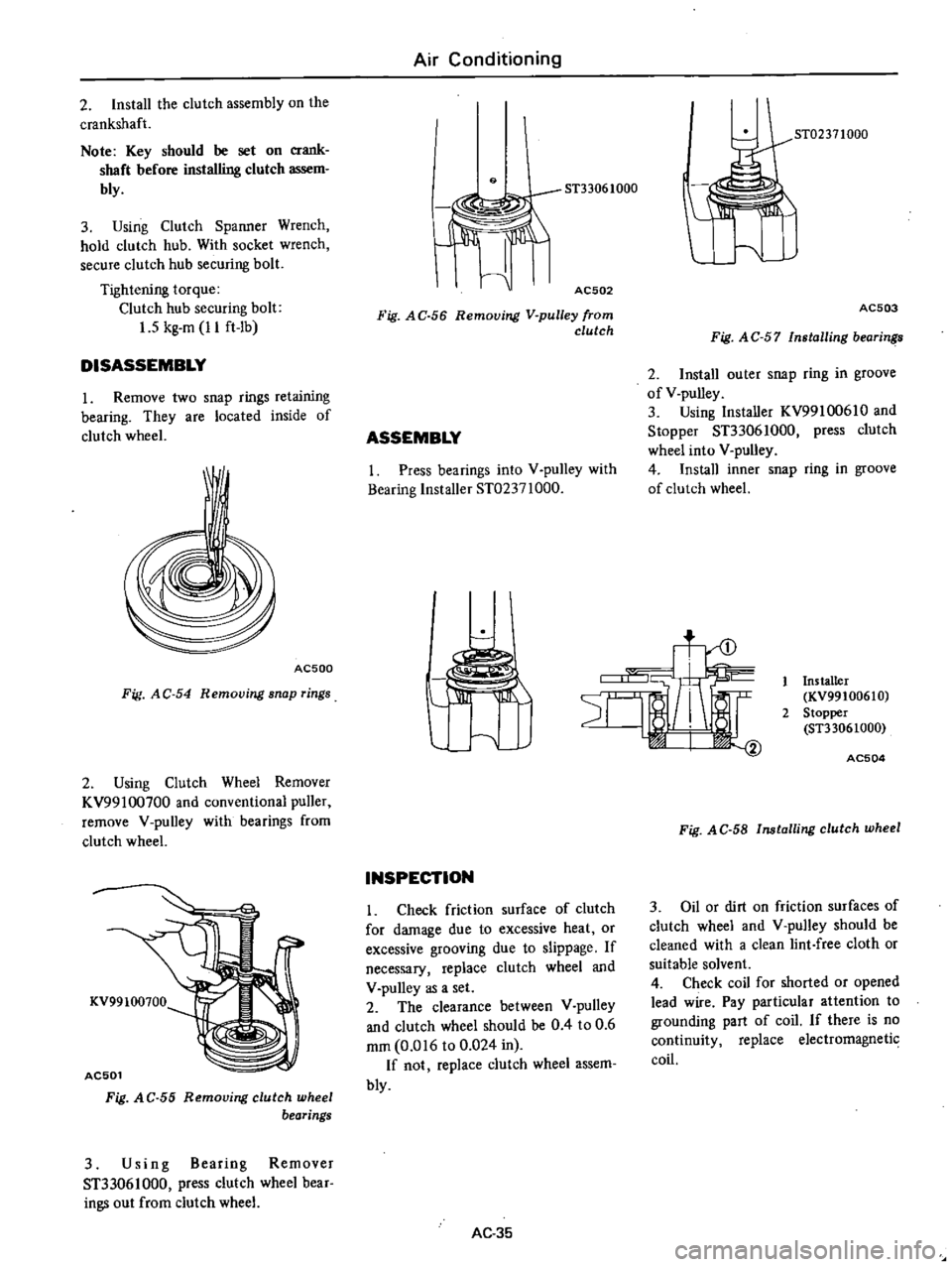

DISASSEMBLY

1

Remove

two

snap

rings

retaining

bearing

They

are

located

inside

of

clutch

wheel

AC500

Fig

AC

54

Removing

snap

rings

2

Using

Clutch

Wheel

Remover

KV99100700

and

conventional

puller

remove

V

pulley

with

bearings

from

clutch

wheel

KV99100700

AC501

Fig

A

C

55

Removing

clutch

wheel

bearings

3

Using

Bearing

Remover

ST33061000

press

clutch

wheel

bear

ings

out

from

clutch

wheel

Air

Conditioning

9

AC502

Fig

AC

56

Removing

V

pulley

from

clutch

ASSEMBLY

I

Press

bearings

into

V

pulley

with

Bearing

Installer

ST02371000

ST02371000

AC503

Fig

A

C

57

Installing

bearin

2

Install

outer

snap

ring

in

groove

of

V

pulley

3

Using

Installer

KV99100610

and

Stopper

ST33061000

press

clutch

wheel

into

V

pulley

4

Install

inner

snap

ring

in

groove

of

clutch

wheel

t

INSPECTION

Check

friction

surface

of

clutch

for

damage

due

to

excessive

heat

or

excessive

grooving

due

to

slippage

If

necessary

replace

clutch

wheel

and

V

pulley

as

a

set

2

The

clearance

between

V

pulley

and

clutch

wheel

should

be

0

4

to

0

6

mm

0

016

to

0

024

in

If

not

replace

clutch

wheel

assem

bly

AC

35

Installer

KV99100610

2

Stopper

ST33061000

AC504

Fig

AC

58

Installing

clutch

wheel

3

Oil

or

dirt

on

friction

surfaces

of

clutch

wheel

and

V

pulley

should

be

cleaned

with

a

clean

lint

free

cloth

or

suitable

solvent

4

Check

coil

for

shorted

or

opened

lead

wire

Pay

particular

attention

to

grounding

part

of

coil

If

there

is

no

continuity

replace

electromagnetic

coil

Page 525 of 537

AC506

Fig

AC

59

Grounding

point

of

coil

5

If

clutch

assembly

must

lie

re

placed

remember

that

break

in

opera

tion

is

necessary

The

break

in

opera

tion

consists

of

engaging

and

disengag

ing

the

clutch

some

tirty

times

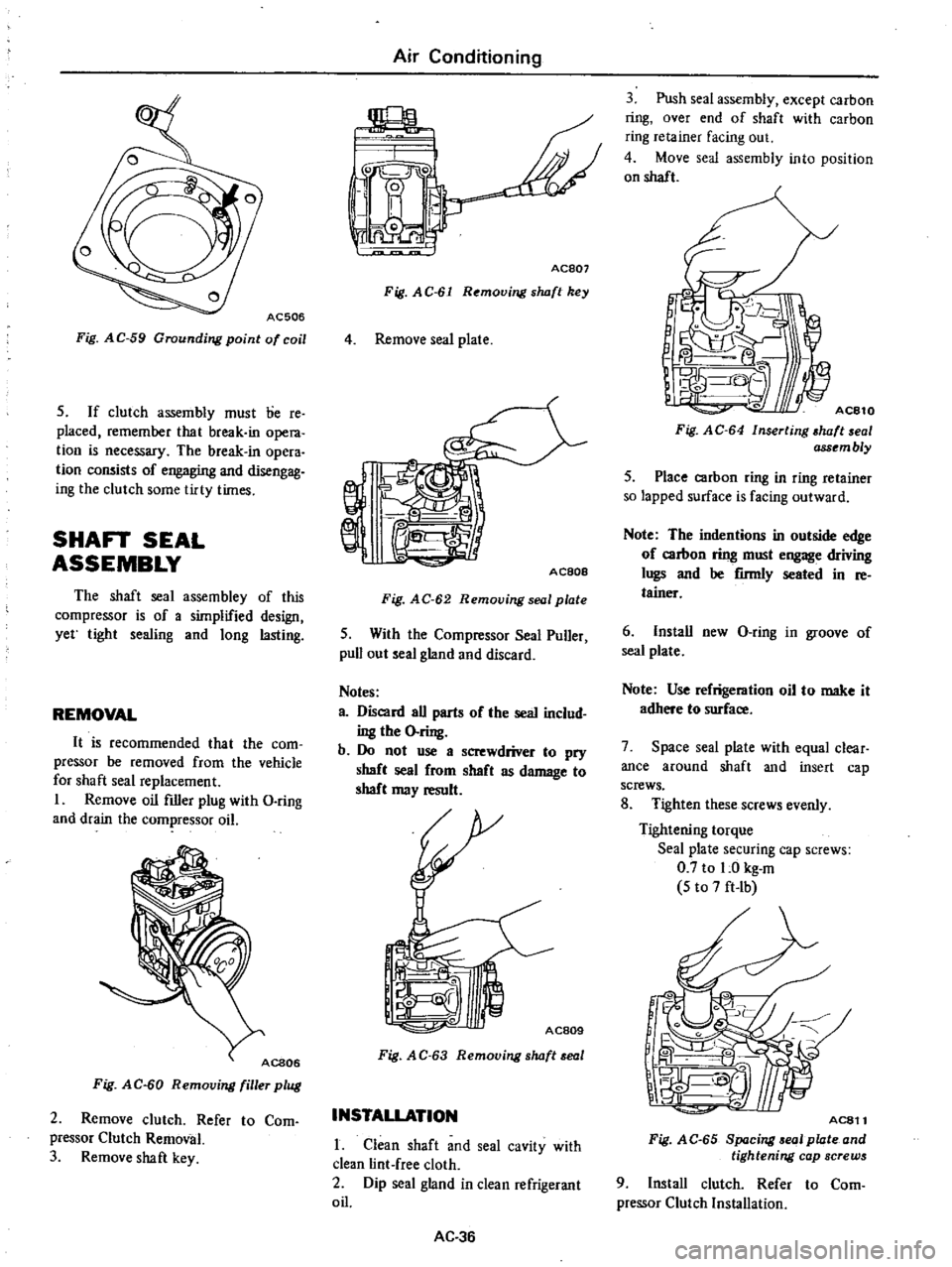

SHAFT

SEAL

ASSEMBLY

The

shaft

seal

assembley

of

this

compressor

is

of

a

simplified

design

yet

tight

sealing

and

long

lasting

REMOVAL

It

is

recommended

that

the

com

pressor

be

removed

from

the

vehicle

for

shaft

seal

replacement

I

Remove

oil

filler

plug

with

D

ring

and

drain

the

compressor

oil

Fig

AC

60

Removing

filler

plug

2

Remove

clutch

Refer

to

Com

pressor

Clutch

Removal

3

Remove

shaft

key

Air

Conditioning

jpL

Y

L

I

i

0

I

I

0

Ace07

Fig

AC

61

Removing

s

wft

key

4

Remove

seal

plate

AC80e

Fig

AC

62

Removing

seal

plate

5

With

the

Compressor

Seal

Puller

pull

out

seal

gland

and

discard

Notes

a

Discard

all

parts

of

the

seal

includ

ing

the

O

ring

b

Do

not

use

a

screwdriver

to

pry

shaft

seal

from

shaft

as

damage

to

shaft

may

result

AC809

Fig

A

C

63

Removing

s

wft

eal

INSTALLATION

1

Clean

shaft

and

seal

cavity

with

clean

lint

free

cloth

2

Dip

seal

gland

in

clean

refrigerant

oil

AC

36

3

Push

seal

assembly

except

carbon

ring

over

end

of

shaft

with

carbon

ring

retainer

facing

out

4

Move

seal

assembly

into

position

on

shaft

1

I

Fig

AC

64

Inserting

wft

al

ass

mbly

5

Place

carbon

ring

in

ring

retainer

so

lapped

surface

is

facing

outward

Note

The

indentions

in

outside

edge

of

carbon

ring

must

engage

driving

lugs

and

be

firmly

seated

in

re

tainer

6

Install

new

D

ring

in

groove

of

seal

plate

Note

Use

refrigeration

oil

to

make

it

adhere

to

surface

7

Space

seal

plate

with

equal

clear

ance

around

shaft

and

insert

cap

screws

8

Tighten

these

screws

evenly

Tightening

torque

Seal

plate

securing

cap

screws

0

7

to

1

0

kg

m

5

to

7

ft

Ib

AC811

Fig

AC

65

8p

cing

01

plate

and

tightening

cap

screws

9

Install

clutch

Refer

to

Com

pressor

Clutch

Installation

Page 528 of 537

Air

Conditioning

SPECIAL

SERVI

CE

TOOLS

Unit

mm

in

For

use

on

Reference

page

or

Figure

No

No

Tool

number

tool

name

Description

KV99100700

Clutch

wheel

remover

To

remove

clutch

wheel

from

V

pulley

620

Fig

AC

55

BE436

2

KV991006S0

To

install

clutch

wheel

into

V

pulley

620

Fig

AC

58

Clutch

wheel

38

1

50

1

installer

set

KV99100610

Installer

ST33061000

Stopper

BE437

3

ST33061000

To

remove

clutch

wheel

bearing

from

V

pulley

620

Fig

AC

56

Bearing

remover

38

1

50

BE438

4

ST02371000

To

install

clutch

wheel

bearing

into

V

pulley

620

Fig

AC

57

Bearing

installer

50

1

96

Co

tJ

BE439

AC

39

Page 529 of 537

Air

Conditioning

Tool

number

For

Reference

No

Description

use

page

or

Remarks

tool

name

Unit

mm

in

on

Figure

No

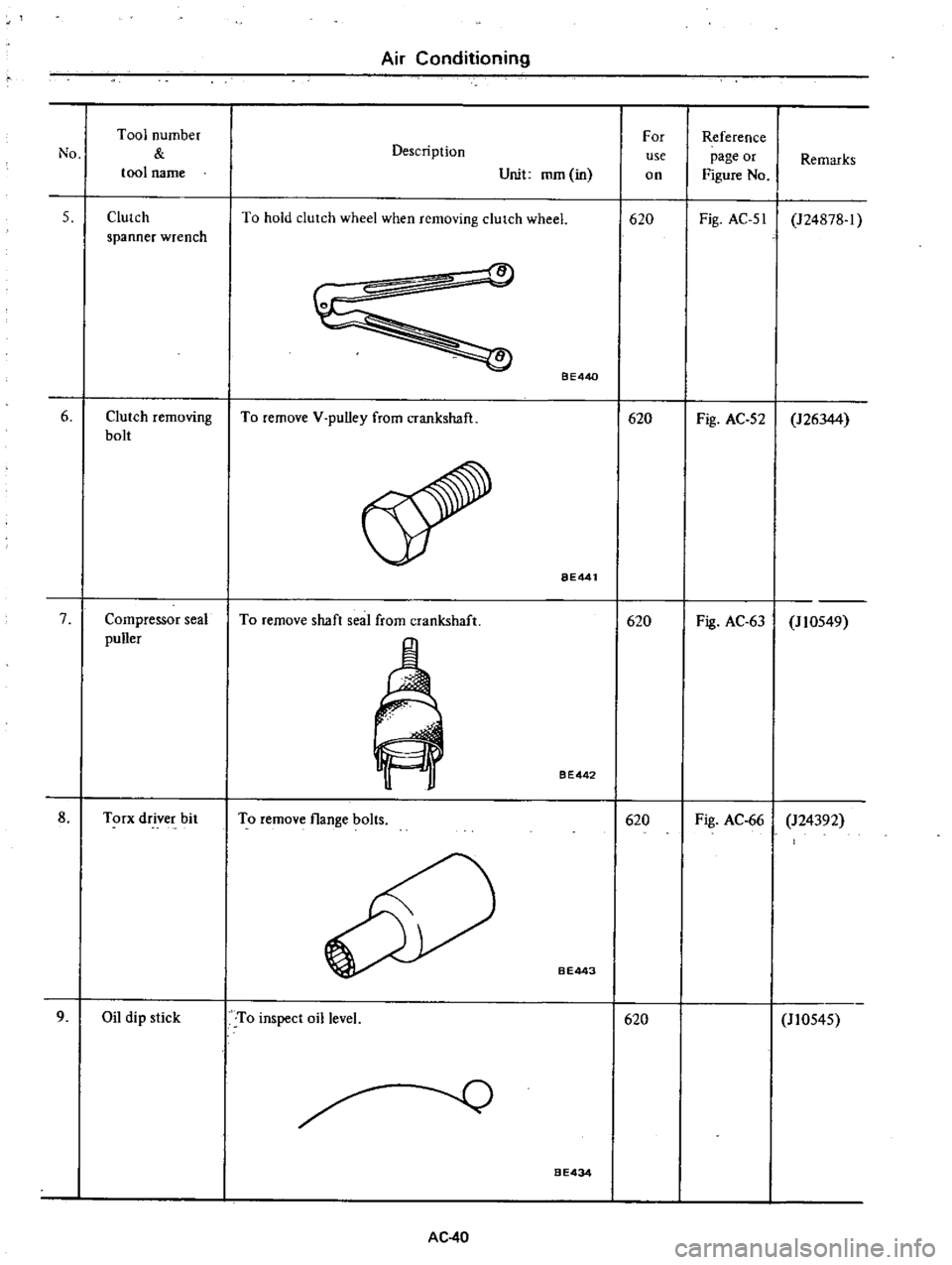

5

Clutch

To

hold

clutch

wheel

when

removing

clurch

wheel

620

Fig

AC

51

124878

1

spanner

wrench

6

Clutch

removing

bolt

7

Compressor

seal

puller

8

Torx

driver

bit

9

Oil

dip

stick

To

remove

V

pulley

from

crankshaft

To

remove

shaft

seal

from

crankshaft

To

remove

flange

bolts

To

inspect

oil

level

AC

40

BE440

BE441

BE442

B

E443

BE434

620

620

620

620

Fig

AC

52

126344

Fig

AC

63

J

10549

Fig

AC

66

124392

110545

Page 533 of 537

Service

Equipment

CHAssis

AND

BODY

TOOL

Applied

Ser

17

620NA

No

Tool

Number

Tool

Name

vehic

1e

Newly

Class

Remarks

added

or

unit

KYOO

1

02000

Clutch

5Tl

66

1000

I

Pilot

bushing

puller

All

X

3

610

710

530

KV30100200

Clutch

aligning

bar

All

X

2

610

710

530

5T200500

10

Base

plate

All

X

5

B210

610

710

530

5T20050100

Distance

piece

All

X

5

B210

610

710

530

5T20050051

5et

bolt

All

X

5

B210

610

710

530

5TZ0050240

Diaphragm

adjusting

wrench

All

X

5

B210

610

710

530

GG943

10000

Flare

nut

torque

wrench

All

X

2

FIO

B210

610

710

530

2

Manual

transmission

5TZ2360002

DriftC

All

X

2

B21O

530

5T23540000

Fork

rod

pin

punch

All

X

2

FIO

B210

610

710

530

5T23800000

Transmission

adapter

All

X

2

FIO

B210

610

710

530

5T23810001

5etting

plate

adapter

All

X

5

530

5T22520000

Wrench

All

X

2

B2iO

530

5T23860000

Counter

gear

drift

All

X

2

530

KV311

00400

Transmission

press

stand

All

X

5

530

5T30031000

Bearing

puller

All

X

2

FIO

B210

610

710

530

KV32101330

Bearing

puller

FSSW71B

X

X

2

B21O

530

3

Differential

ST063

I

0000

Diff

attachment

All

X

5

610

ST31530000

Drive

pinion

flange

wrench

All

X

2

B210

610

710

S30

ST3306S001

Diff

side

bearing

puller

All

X

2

610

S30

ST33051001

Puller

ST3306

I

000

Adapter

ST3090S000

Orive

pinion

rear

bearing

inner

race

All

X

2

610

S30

replacer

ST30031000

Puller

ST3090

1000

Base

ST33230000

Diff

side

bearing

drift

All

X

2

610

ST3194S000

Drive

pinion

setting

gauge

ass

y

All

X

2

610

ST3l941000

Height

gauge

5T3l942000

Dummy

shaft

SE

4

Page 535 of 537

Service

Equipment

AUTOMATIC

TRANSMISSION

TOOL

Applied

Set

3N71B

Newly

Tool

Number

Tool

Name

vehicle

Class

Remarks

added

or

unit

KVOOlO1OOO

ST07870000

Transmission

case

stand

All

X

3

ST2505S001

Oil

pressure

gauge

set

All

X

I

ST25

I

60000

Torque

driver

All

X

3

ST2532000l

Snap

ring

remover

All

X

3

ST25420001

Clutch

spring

compressor

All

X

3

ST25490000

Socket

extension

All

X

3

ST2557000l

Hex

head

extension

All

X

3

8210

610

710

S30

ST25580000

Oil

pump

assembling

gauge

All

X

3

ST25850000

Sliding

hammers

All

X

3

GG930

I

0000

Torque

wrench

All

X

3

HT6

I

000800

Hexagon

wrench

All

X

3

HT62350000

Spinner

handle

All

X

6

HT69860000

Snap

ring

remover

All

X

3

SE

6