clutch DATSUN PICK-UP 1977 Manual PDF

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 315 of 537

values

it

indicates

that

the

engine

is

in

abnormal

condition

or

the

torque

con

verter

s

one

way

clutch

is

slipping

4

Others

1

If

the

accelerating

performance

is

poor

until

vehicle

speed

of

approxi

mately

50

km

h

30

MPH

is

attained

and

then

normal

beyond

that

speed

it

can

be

judged

that

the

torque

con

verter

s

one

way

clutch

is

slipping

Automatic

Transmission

2

If

the

torque

converter

s

one

way

clutch

sticks

vehicle

speed

can

not

exceed

approximately

80

km

h

50

MPH

in

the

road

test

In

such

a

case

the

torque

converter

oil

tem

perature

rises

abnormally

and

so

special

care

is

required

3

If

the

transmission

does

not

op

erate

properly

at

all

vehicle

speeds

it

indicates

poor

engine

performance

VEHICLE

SPEED

AT

GEAR

SHIFT

Throttle

opening

mmHg

Kickdown

0

Half

throttle

200

Fuol

throttle

0

Minimum

throttle

450

ROAD

TEST

An

accurate

knowledge

of

the

auto

JT

l

ltic

transmission

is

required

for

an

exact

diagnosis

It

is

recommended

that

a

diagnosis

guide

chart

with

the

standard

vehicle

speeds

for

each

stage

of

the

up

and

down

shiftings

be

prepared

Measured

vehicle

speeds

are

to

be

filled

in

the

adjoining

column

after

each

testing

Also

it

is

advisable

to

mount

a

stopper

for

positioning

the

throttle

opening

Gear

shift

Vehicle

speed

km

h

MPH

Propeller

shaft

rpm

Dl

D2

51

to

65

32

to

40

1

840

to

2

340

D2

D3

92

to

106

57

to

66

3

340

to

3

840

D3

D2

96

to

82

60

to

51

3

460

to

2

960

D2

Dl

49

to

36

30

to

22

1

790

to

1

290

Dl

D2

9t023

6toI4

330to

830

D2

D3

48

to

61

30

to

38

1

720

to

2

220

D3

D2

or

D3

Dl

37

to

24

23

to

15

1

350

to

850

D2

Dl

19

12

700

Max

12

I

51

to

38

32

to

24

1

860

to

1

360

1

12

I

51

to

38

32

to

24

1

860

to

1

360

1

Reduce

the

speed

by

shifting

to

I

range

from

D

range

output

shaft

2

000

rpm

Vehicle

speed

can

be

calculated

by

the

following

formula

V

2

x

1f

x

r

x

Np

x

60

RF

x

1

000

V

Vehicle

speed

km

h

Np

Propeller

shaft

revolution

rpm

R

Final

gear

ratio

r

Tire

effective

radius

m

TT

The

ratio

of

circumference

of

a

circle

to

its

diameter

3

14

Note

where

RF

4

375

r

0

321

6

00

14

AT

51

Page 316 of 537

CHECKING

SPEED

CHANGING

CONDITION

The

driver

s

feeling

during

gear

changes

should

also

be

checkedatten

tively

I

A

sharp

shock

or

unSffioothness

is

felt

during

a

gear

change

2

A

gear

change

is

made

with

a

long

and

dragging

feeling

These

indicate

that

the

tIuottle

pressure

is

too

low

or

some

valve

connected

to

the

throttle

is

faulty

h

k

100

1

1

2

I

2

J

I

1

2

I

I

I

2

3

oo

I

c

I

E

I

I

300

I

Z

5

L

mmHg

t

1

400

I

I

1

Output

shaft

speed

rpm

20

30

40

50

60

70

80

90100

00

io

3

0

40

0

60

Vehicle

speed

R

4

315

r

0

321

6

00

14

ATll0

Fig

AT

111

Shift

IChedule

Automatic

Transmission

SHI

SCHEDULE

500

CHECKING

ITEMS

DURING

km

hO

1O

SPEED

CHANGE

I

In

D

range

gear

changes

DI

D2

D3

are

effected

In

R

range

the

speed

does

not

increase

2

The

kickdown

operates

properly

3

By

moving

the

lever

from

D

to

I

gear

changes

D

2

1

2

1

are

effected

In

the

ranges

12

and

I

the

engine

braking

works

prop

erly

4

In

I

the

speed

does

not

in

crease

5

Should

be

quickly

fixed

at

2

range

6

In

P

vehicle

can

he

parked

properly

If

any

malfunction

occurs

in

second

gear

during

the

road

test

that

is

if

vehicle

shakes

drags

or

slings

while

shifting

up

from

D

directly

to

D

or

in

shifting

up

from

D

to

D2

the

brake

band

should

be

ad

justed

If

these

troubles

remain

after

the

brake

band

is

adjusted

check

the

servo

piston

seal

for

oil

leakage

MPH

Ii

io

LINE

PRESSURE

TEST

When

any

slipping

occurs

in

clutch

or

brake

or

the

feeling

during

a

speed

change

is

not

correct

the

line

pressure

must

be

checked

Measuring

line

pressure

is

done

by

a

pressure

gauge

attached

to

two

pres

sure

measuring

holes

after

removing

blind

plugs

located

at

transmission

case

See

Figure

AT

112

The

line

pressure

measurement

is

begun

at

idling

and

taken

step

by

step

by

enlarging

the

throttle

opening

I

A

sharp

shock

in

up

shifting

or

too

high

changing

speeds

are

caused

mostly

by

too

high

throttle

pressure

2

Slipping

or

incapability

of

opera

tion

is

mostly

due

to

oil

pressure

leakage

within

the

gear

trains

or

spool

valve

AT

S2

3

3SA

000

t

I

1

I

c

l

1

c

7

D

jf

o

CV

ATl13

1

Lige

pressure

2

Governor

feed

3

SerVo

release

pressure

Fig

AT

112

MeCJ

uring

line

preuure

Page 317 of 537

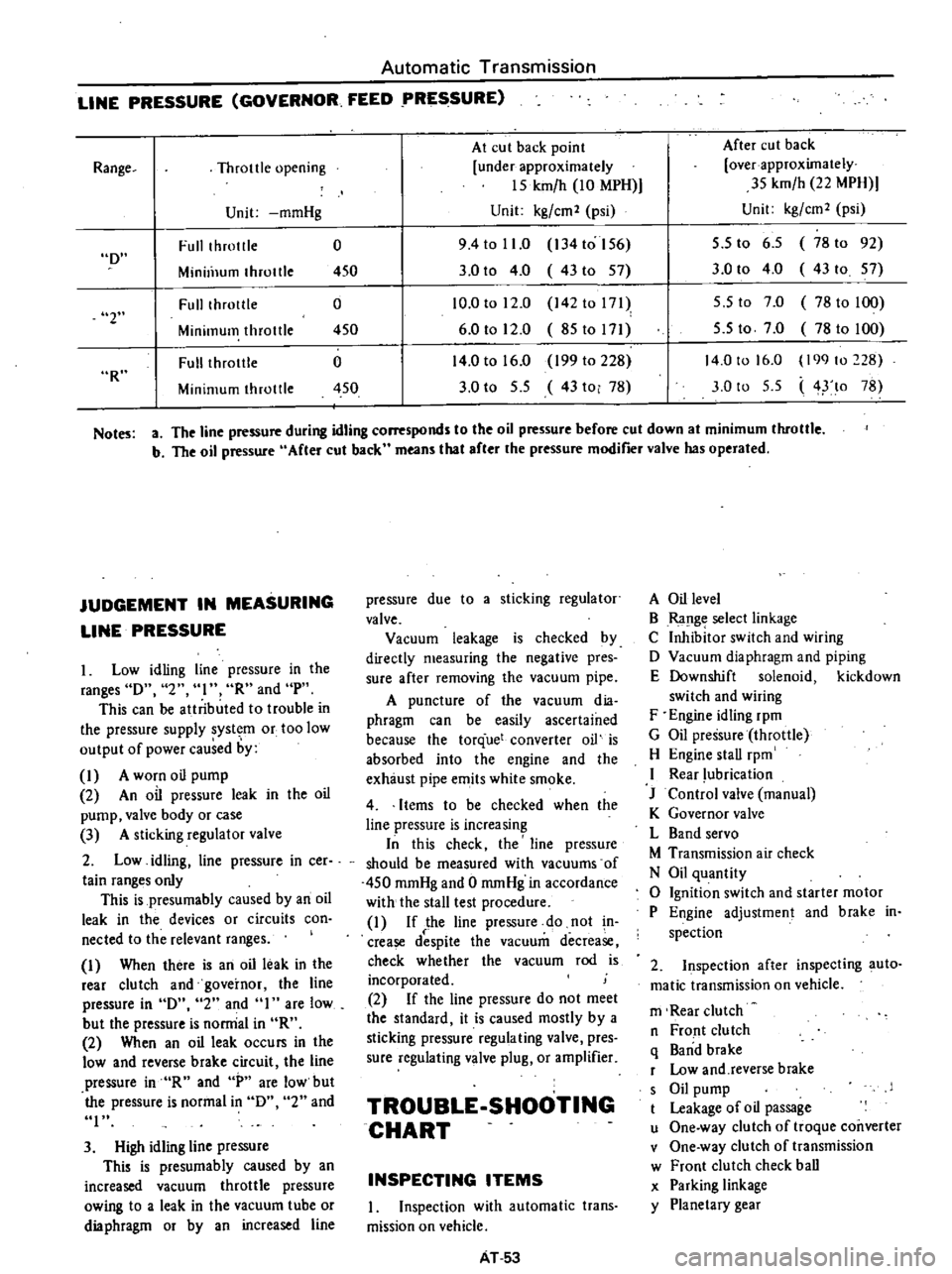

Automatic

Transmission

LINE

PRESSURE

GOVERNOR

FEED

PRESSURE

At

cut

back

point

After

cut

back

Throttle

opening

under

approximately

over

approximately

15

kmfh

10

MPH

35

kmfh

22

MPH

Unit

mmHg

Unit

kgfcm2

psi

Unit

kgfcm2

psi

Full

throtlle

0

9

4

to

11

0

134

to

156

5

5

to

6

5

78

to

92

Minill1um

throttle

450

3

0

to

4

0

43to

57

3

0

to

4

0

43

to

57

Fulllhrotlle

0

10

0

to

12

0

142

to

171

5

5

to

7

0

78

to

100

Minimum

throttle

450

6

0

to

12

0

85to171

5

5

to

7

0

78

to

100

Full

throtlle

0

14

0

to

16

0

199

to

228

14

0

to

16

0

199

to

228

Minimum

throttle

450

3

0

to

5

5

43

to

78

3

0

to

5

5

4

lo

78

Range

D

2

R

Notes

a

The

line

pressure

during

idling

corresponds

to

the

oil

pressure

before

cut

down

at

minimum

throttle

b

The

oil

pressure

After

cut

back

means

that

after

the

pressure

modifier

valve

has

operated

JUDGEMENT

IN

MEASURING

LINE

PRESSURE

Low

idling

line

pressure

in

the

ranges

D

2

I

R

and

pH

This

can

be

atlributed

to

trouble

in

the

pressure

supply

system

or

too

low

output

of

power

caused

by

I

A

worn

oil

pump

2

An

oil

pressure

leak

in

the

oil

pump

valve

body

or

case

3

A

sticking

regulator

valve

2

Low

idling

line

pressure

in

cer

tain

ranges

only

This

is

presumably

caused

by

an

oil

leak

in

the

devices

or

circuits

con

nected

to

the

relevant

ranges

I

When

there

is

an

oil

leak

in

the

rear

clutch

and

governor

the

line

pressure

in

D

2

and

I

are

low

but

the

pressure

is

norrrial

in

R

2

When

an

oil

leak

occurs

in

the

low

and

reverse

brake

circuit

the

line

pressure

in

R

and

P

are

low

but

the

pressure

is

normal

in

D

2

and

I

3

High

idling

line

pressure

This

is

presumably

caused

by

an

increased

vacuum

throttle

pressure

owing

to

a

leak

in

the

vacuum

tube

or

dia

phragm

or

by

an

increased

line

pressure

due

to

a

sticking

regulator

valve

Vacuum

leakage

is

checked

by

directly

measuring

the

negative

pres

sure

after

removing

the

vacuum

pipe

A

puncture

of

the

vacuum

dia

phragm

can

be

easily

ascertained

because

the

torque

converter

oil

is

absorbed

into

the

engine

and

the

exhaust

pipe

emits

white

smoke

4

Items

to

be

checked

when

the

line

pressure

is

increasing

In

this

check

the

line

pressure

should

be

measured

with

vacuums

of

450

mmHg

and

0

mmHg

in

accordance

with

the

stall

test

procedure

I

If

the

line

pressure

do

not

n

crease

despite

the

vacuum

decrease

check

whether

the

vacuum

rod

is

incorporated

2

If

the

line

pressure

do

not

meet

the

standard

it

is

caused

mostly

by

a

sticking

pressure

regulating

valve

pres

sure

regulating

valve

plug

or

amplifier

TROUBLE

SHOOTING

CHART

INSPECTING

ITEMS

1

Inspection

with

automatic

trans

mission

on

vehicle

AT

53

A

Oil

level

B

Ra

lge

select

linkage

C

Inhibitor

switch

and

wiring

D

Vacuum

diaphragm

and

piping

E

Downshift

solenoid

kickdown

switch

and

wiring

F

Engine

idling

rpm

G

Oil

pressure

throttle

H

Engine

stall

rpm

I

Rear

lubrication

J

Control

valve

manual

K

Governor

valve

L

Band

servo

M

Transmission

air

check

N

Oil

quantity

o

Ignition

switch

and

starter

motor

P

Engine

adjustment

and

brake

in

spection

2

Inspection

after

inspecting

auto

matic

transmission

on

vehicle

m

Rear

clutch

n

Front

clutch

q

Band

brake

r

Low

and

reverse

brake

s

Oil

pump

t

Leakage

of

oil

passage

u

One

way

clutch

of

troque

coilVerter

v

One

way

clutch

of

transmission

w

Front

clutch

check

ball

x

Parking

linkage

y

Planetary

gear

Page 318 of 537

Automatic

Transmission

TROUBLE

SHOOTING

CHART

FOR

3N718

AUTOMATIC

TRANSMISSION

The

number

shown

beluw

indicates

the

sequence

in

which

the

checks

should

be

taken

up

Trouble

ABeD

EFGHIIJKL

MNOP

tnnqr

stuv

wxy

ngine

does

not

start

in

N

P

ranges

2

3

1

Engine

starts

in

other

range

than

N

and

P

1

2

Sharp

shock

in

shifting

from

N

to

0

range

Vehicle

will

not

run

in

D

range

bul

I

TUns

in

2u

l

and

R

ranges

2

4

@

3

5

6

3

7

@

@

2

1

3

Vehicle

will

not

run

in

0

1

2

ranges

bul

runs

in

R

range

1

2

Clutch

slips

Very

poor

acceleration

4

Vehicle

will

nol

run

in

R

range

bul

runs

in

0

2

and

I

r

nges

1

2

Iukh

slips

Very

poor

acceleration

3

5

6

4

@@

1

@

@

Vehicle

will

not

run

in

any

range

1

2

3

5

6

4

1

@

@

Clutches

or

brakes

slip

somewhat

1

2

6

I

3

5

7

4

@@

in

starting

Vehicle

runs

in

N

range

I

3

2

Maximum

speed

not

allained

1

2

4

5

7

6

3

8

OO

I@

Acceleration

poor

Vehicle

braked

by

Ihrowing

Icver

inlo

3

2

1

@

I

@

R

range

I

Excessive

creep

1

No

creep

al

all

I

2

3

5

4

@@

@

1

Failure

10

dumge

gear

from

2nd

I

2

3

5

6

8

7

4

@

@

to

3rd

Failure

tllchJllgC

gear

from

1

1

1

2

3

5

6

8

7

4

@

@

@

to

2ud

Too

high

a

gear

change

poinl

from

I

sC

to

2nd

from

2nd

to

1

2

3

5

6

4

1

3rd

Gear

change

directly

from

lsl

to

2

4

3

1

@

@

rd

occurs

AT

54

Page 319 of 537

Automatic

Transmission

Trouble

ABCD

EFGH

I

J

KL

MNOP

mnqr

s

t

u

v

w

x

y

Too

sharp

a

shock

in

change

from

1

2

4

5

3

@

l1st

to

2nd

Too

sharp

a

shock

in

change

from

1

2

3

3

5

4

@

2nd

to

3rd

Almost

no

shock

or

clutches

slipping

in

change

from

1st

to

1

2

3

4

6

8

7

5

@

@

2nd

Almost

no

shock

or

slipping

in

@

@

@

change

from

2nd

to

3rd

1

2

3

4

6

8

7

5

Engine

races

extremely

Vehicle

braked

by

gear

change

from

2

1

V

@

1st

to

2nd

Vehicle

braked

by

gear

change

from

3

2

1

2nd

to

3rd

Failure

to

change

gear

from

1

3

4

6

5

2

1

@

@

3rd

to

2nd

Failure

10

change

gear

from

2nd

I

3

4

6

5

2

1

@

to

1st

or

from

3rd

to

lIst

Gear

change

shock

felt

during

f

deceleration

by

releasing

1

2

3

4

5

6

accelerator

pedal

Too

high

a

change

point

from

f

3rd

to

2nd

from

2nd

to

I

2

3

4

5

6

1st

Kickdown

does

not

operate

when

depressing

pedal

in

3rd

within

2

1

4

5

3

@

f

kickdown

vehicle

speed

Kickdown

operates

or

engine

over

runs

when

depressing

pedal

in

1

2

3

5

6

7

4

@

@

3rd

beyond

kickdown

vehicle

speed

limit

Races

extremely

or

slips

in

changing

I

from

Jrd

to

2nd

when

1

2

4

6

5

3

f

@

@

@

depressing

pedal

Failure

to

change

from

3rd

to

nd

I

2

4

51

3

@

j

when

changing

lever

into

2

range

Gear

change

from

2nd

10

1st

or

from

2nd

to

3rd

in

2

I

2

3

range

AT

55

Page 322 of 537

Automatic

Transmission

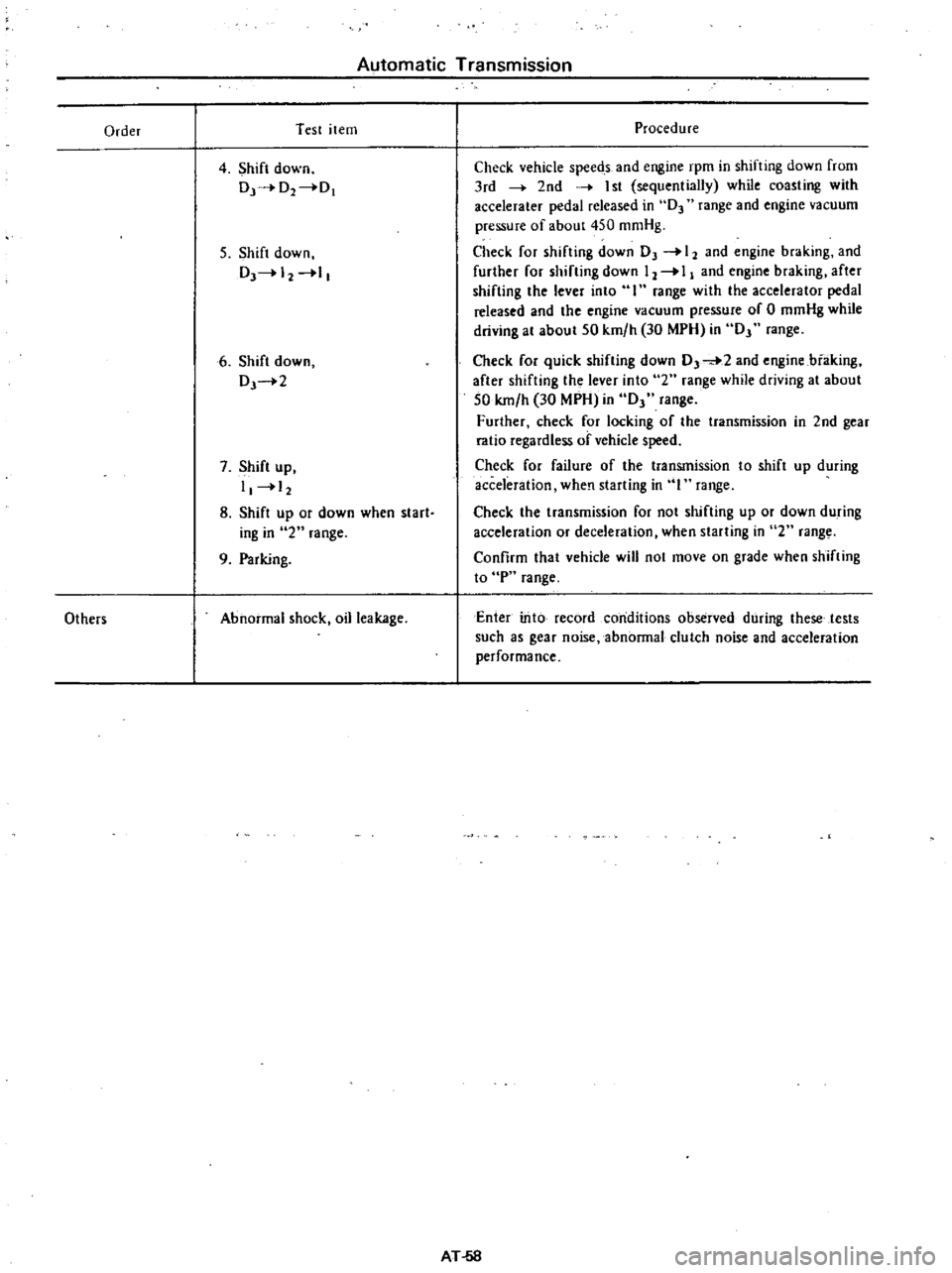

Order

Test

item

4

Shift

down

Dr

O2

0

5

Shift

down

DJ

12

1

6

Shift

down

DJ

2

7

Shift

up

I

12

8

Shift

up

or

down

when

start

iog

in

2

range

9

Parking

Others

Abnormal

shock

oil

leakage

Procedure

Check

vehicle

speeds

and

engine

rpm

in

shifting

down

from

3rd

2nd

I

st

sequentially

while

coasting

with

accelerater

pedal

released

in

D3

range

and

engine

vacuum

pressure

of

about

450

mmHg

Check

for

shifting

down

OJ

12

and

engine

braking

and

further

for

shifting

down

12

I

and

engine

braking

after

shifting

the

lever

into

I

range

with

the

accelerator

pedal

released

and

the

engine

vacuum

pressure

of

0

mmHg

while

driving

at

about

50

km

h

30

MPH

in

OJ

range

Check

for

quick

shifting

down

0

2

and

engine

biaking

after

shifting

the

lever

into

2

range

while

driving

at

about

50

km

h

30

MPH

in

OJ

range

Further

check

for

locking

of

the

transmission

in

2nd

gear

ratio

regardless

of

vehicle

speed

Check

for

failure

of

the

transmission

to

shift

up

during

acceleration

when

starting

in

I

range

Check

the

transmission

for

not

shifting

up

or

down

during

acceleration

or

deceleration

when

starting

in

2

rang

Confirm

that

vehicle

will

not

move

on

grade

when

shifting

to

P

range

Enter

into

record

conditions

observed

during

these

tests

such

as

gear

noise

abnormal

clutch

noise

and

acceleration

performance

AT

58

Page 323 of 537

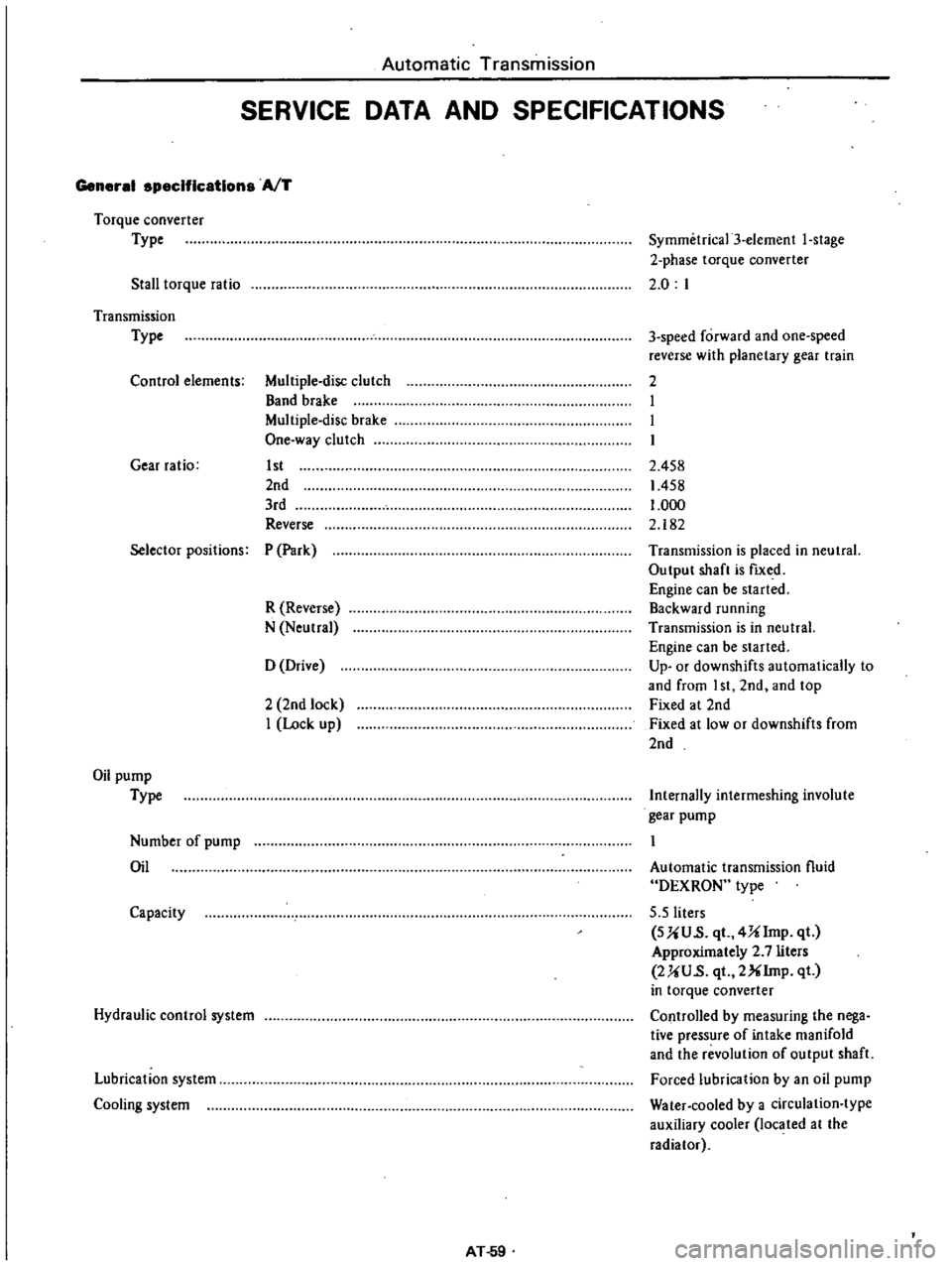

Automatic

Transmission

SERVICE

DATA

AND

SPECIFICATIONS

General

specifications

AfT

Torque

converter

Type

Stall

torque

ratio

Symmetrica13

element

I

stage

2

phase

torque

converter

2

0

I

Transmission

Type

Control

elements

Multiple

disc

clutch

Band

brake

Multiple

disc

brake

One

way

clutch

Gear

ratio

1st

2nd

3rd

Reverse

3

speed

forward

and

one

speed

reverse

with

planetary

gear

train

2

I

I

I

2

458

1458

1

000

2

182

Selector

positions

P

Park

R

Reverse

N

Neutral

Transmission

is

placed

in

neutral

Output

shaft

is

fIXed

Engine

can

be

started

Backward

running

Transmission

is

in

neutral

Engine

can

be

started

Up

or

downshifts

automatically

to

and

from

I

st

2nd

and

top

Fixed

at

2nd

Fixed

at

low

or

downshifts

from

2nd

o

Drive

2

2nd

lock

I

Lock

up

Oil

pump

Type

Internally

intermeshing

involute

gear

pump

Number

of

pump

Oil

Automatic

transmission

fluid

DEXRON

type

5

5

liters

SUU

s

qt

4Ulmp

qt

Approximately

2

7

liters

2UU

s

qt

2XIrnp

qt

in

torque

converter

Controlled

by

measuring

the

nega

tive

pressure

of

intake

manifold

and

the

revolution

of

output

shaft

Forced

lubrication

by

an

oil

pump

Water

cooled

by

a

circulation

type

auxiliary

cooler

located

at

the

radiator

Capacity

Hydraulic

control

system

Lubrication

system

Cooling

system

AT

59

Page 324 of 537

Specifications

and

adjustment

AfT

Automatic

transmission

assembly

Model

code

number

Torque

converter

assembly

Stamped

mark

on

th

e

TiC

Front

clutch

Number

of

drive

plate

Number

of

driven

plates

Clearance

Thickness

of

retainin

g

plate

Rear

clutch

Number

of

drive

plates

Number

of

driven

plates

Clearance

Thickness

of

retaining

plate

Low

reverse

brake

Number

of

drive

plates

Number

f

driven

pla

es

Clearance

Thickness

of

retaining

plaie

Brake

band

Piston

size

Big

dia

S

all

dia

Control

valve

assembly

Stamped

mark

on

slraine

Governor

assembly

Stamped

mark

on

governor

body

Automatic

Transmission

mOl

in

mm

in

mOl

inJ

mOl

in

mOl

in

mOl

in

mOl

in

AT

60

X2402

16

B

3

3

1

6

to

1

8

0

063

to

0

071

10

6

0

417

10

8

0

42S

11

0

0

433

11

2

0

441

11

4

0

449

11

6

0

4S7

4

4

1

0

to

1

5

0

039

to

0

OS9

4

8

0

189

4

4

0

80

to

1

0S

0

0315

to

0

0413

11

8

0

46S

12

0

0

472

12

2

0

480

12

4

0

488

12

6

0

496

12

8

O

S04

64

2

S2

40

1

57

E

35

Page 325 of 537

Automatic

Transmission

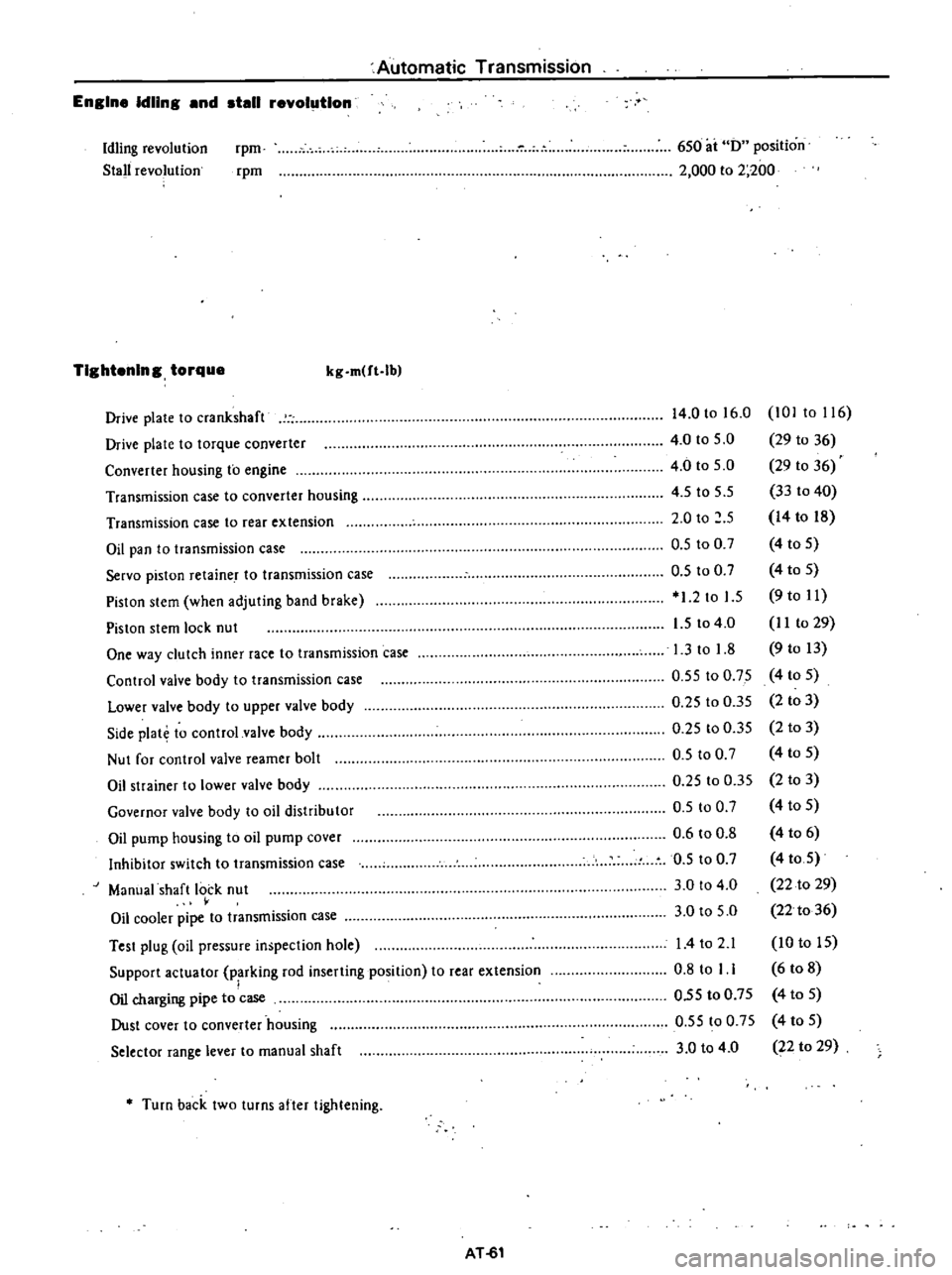

Engine

Idling

and

stall

revolution

Idling

revolution

Stall

revolution

rpm

rpm

6S0

ai

0

position

2

000

to

2

200

TIghtening

torque

kg

m

ft

lb

Drive

plate

to

crankshaft

Drive

plate

to

torque

converter

Converter

housing

to

engine

Transmission

case

to

converter

housing

Transmission

case

to

rear

extension

Oil

pan

to

transmission

case

Servo

piston

retaine

T

to

transmission

case

Pislon

slem

when

adjuting

band

brake

Piston

stem

lock

nut

One

way

clutch

inner

race

to

transmission

case

Control

valve

body

to

transmission

case

Lower

valve

body

to

upper

valve

body

Side

plat

to

control

valve

body

Nut

for

control

valve

reamer

bolt

Oil

strainer

to

lower

valve

body

Governor

valve

body

to

oil

distribu

tor

Oil

pump

housing

to

oil

pump

cover

Inhibitor

switch

to

transmission

case

Manual

shaft

lock

nut

Oil

cooler

pipe

to

transmission

case

Test

plug

oil

pressure

inspection

hole

Support

actuator

parking

rod

inserting

position

to

rear

extension

I

Oil

charging

pipe

to

case

Dust

cover

to

converter

housing

Selector

range

lever

to

manual

shaft

14

0

to

16

0

101

to

116

4

0

to

5

0

29

to

36

4

0

to

S

O

29

10

36

4

S

to

5

5

33

to

40

2

0

to

S

14

to

18

O

S

to

0

7

4

to

S

O

S

to

0

7

4

to

S

1

2

to

1

5

9

to

11

1

5

to

4

0

I

I

to

29

1

3

to

1

8

9

to

13

0

5S

to

0

75

4

to

S

0

25

to

O

3S

2

to

3

0

25

to

0

35

2

to

3

O

S

to

0

7

4

to

S

0

25

to

0

35

2

to

3

D

S

100

7

4

to

5

0

6

to

0

8

4

to

6

0

5

to

0

7

4

toS

3

0

to

4

0

22

to

29

3

0

to

S

O

22

to

36

I

4to

2

1

10

to

IS

0

8

to

I

1

6

to

8

O

5S

to

0

7S

4

to

S

O

5S

to

0

75

4

to

S

3

0

to

4

0

22

to

29

Turn

back

two

turns

after

tightening

AT

61

Page 326 of 537

Automatic

Transmission

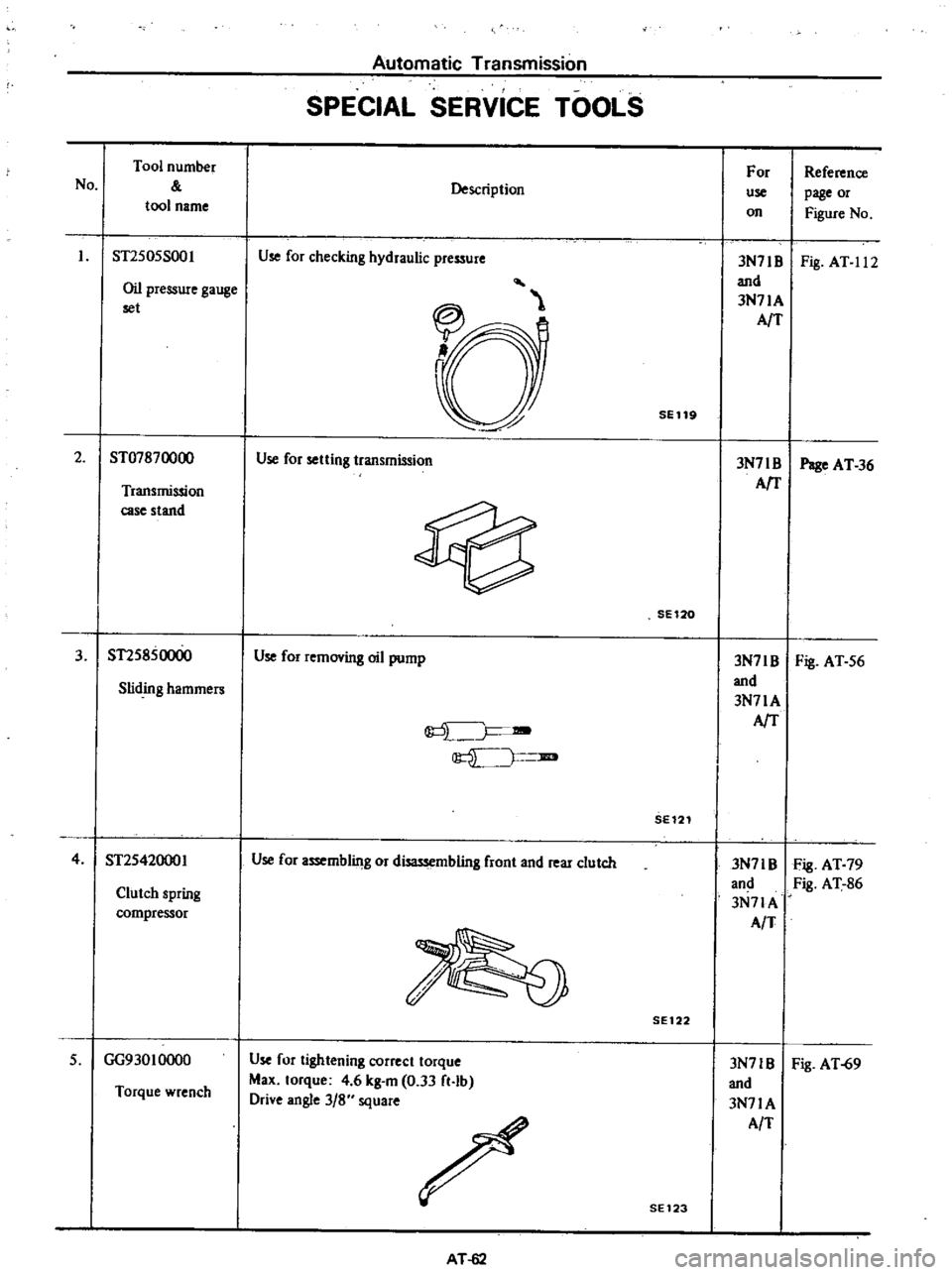

SPECIAL

SERVICE

TOOLS

No

Tool

number

tool

name

Description

For

use

on

Reference

page

or

Figure

No

Oil

pressure

gauge

set

3N71B

Fig

AT

11

2

and

3N71A

AfT

ST2S0SS001

Use

for

checking

hydraulic

pressure

SE119

2

ST07870000

Use

for

setting

transmission

3N71

B

Page

AT

36

AfT

Transmission

case

stand

SE120

3

ST2S850000

Use

for

removing

oil

pump

3N7IB

Fig

AT

S6

and

Sliding

hammers

3N71A

J

AfT

JIB

SE121

4

ST2S42000I

Use

for

assemblilJg

or

disassembling

front

and

rear

clutch

3N71B

Fig

AT

79

and

Fig

AT

86

Clutch

spring

3N7lA

compressor

AIT

SE

122

3N71B

Fig

AT

69

and

3N71A

AlT

Torque

wrench

Use

for

tightening

correct

torque

Max

torque

4

6

kg

m

0

33

ft

lb

Drive

angle

3

8

square

S

GG93010000

SE123

AT

62