check engine DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 207 of 537

5

2

Checking

operation

of

duty

Procedure

Connect

anti

dieseling

solenoid

valve

connector

2

While

the

engine

is

idling

observe

the

wave

ronn

on

the

oscilloscope

in

the

same

way

as

stated

in

item

5

Figure

EE

83

Determine

the

ratio

tiT

as

shown

in

Figure

EE

85

I

T

x

100

20

to

401

1

at

idling

h

Lt

1

T

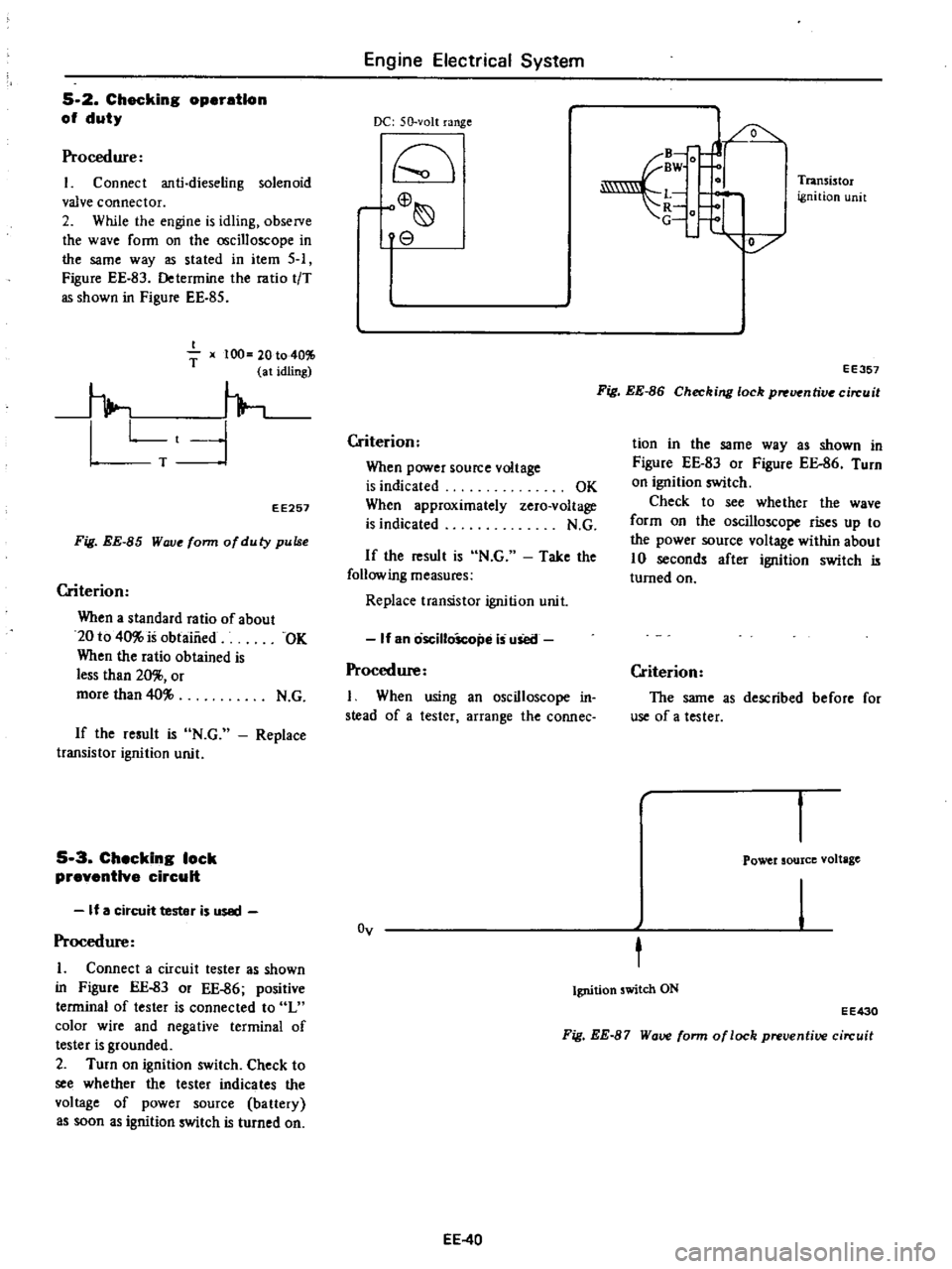

EE257

Fig

EE

85

Wove

form

ofduty

pulse

Criterion

When

a

standard

ratio

of

about

20

to

40

is

obtaiiied

OK

When

the

ratio

obtained

is

less

than

20

or

more

than

40

N

G

If

the

result

is

N

G

transistor

ignition

unit

Replace

5

3

Checking

lock

preventive

circuit

If

a

circuit

tester

is

used

Procedure

1

Connect

a

circuit

tester

as

shown

in

Figure

EE

83

or

EE

86

positive

terminal

of

tester

is

connected

to

L

color

wire

and

negative

terminal

of

tester

is

grounded

2

Turn

on

ignition

switch

Check

to

see

whether

the

tester

indicates

the

vol

age

of

power

source

ba

t1ery

as

soon

as

ignition

switch

is

turned

on

Engine

Electrical

System

DC

50

volt

range

rC

o

8

Criterion

When

power

source

voltage

is

indicated

When

approximately

is

indicated

OK

zero

voltage

N

G

If

the

result

is

N

G

Take

the

following

measures

Replace

transistor

ignition

unit

If

an

oscilloScope

is

uSetl

Procedure

I

When

using

an

oscilloscope

in

stead

of

a

tester

arrange

the

connec

Oy

EE

40

B

fJ

BW

O

L

t

1

V

Transi

tor

ignition

unit

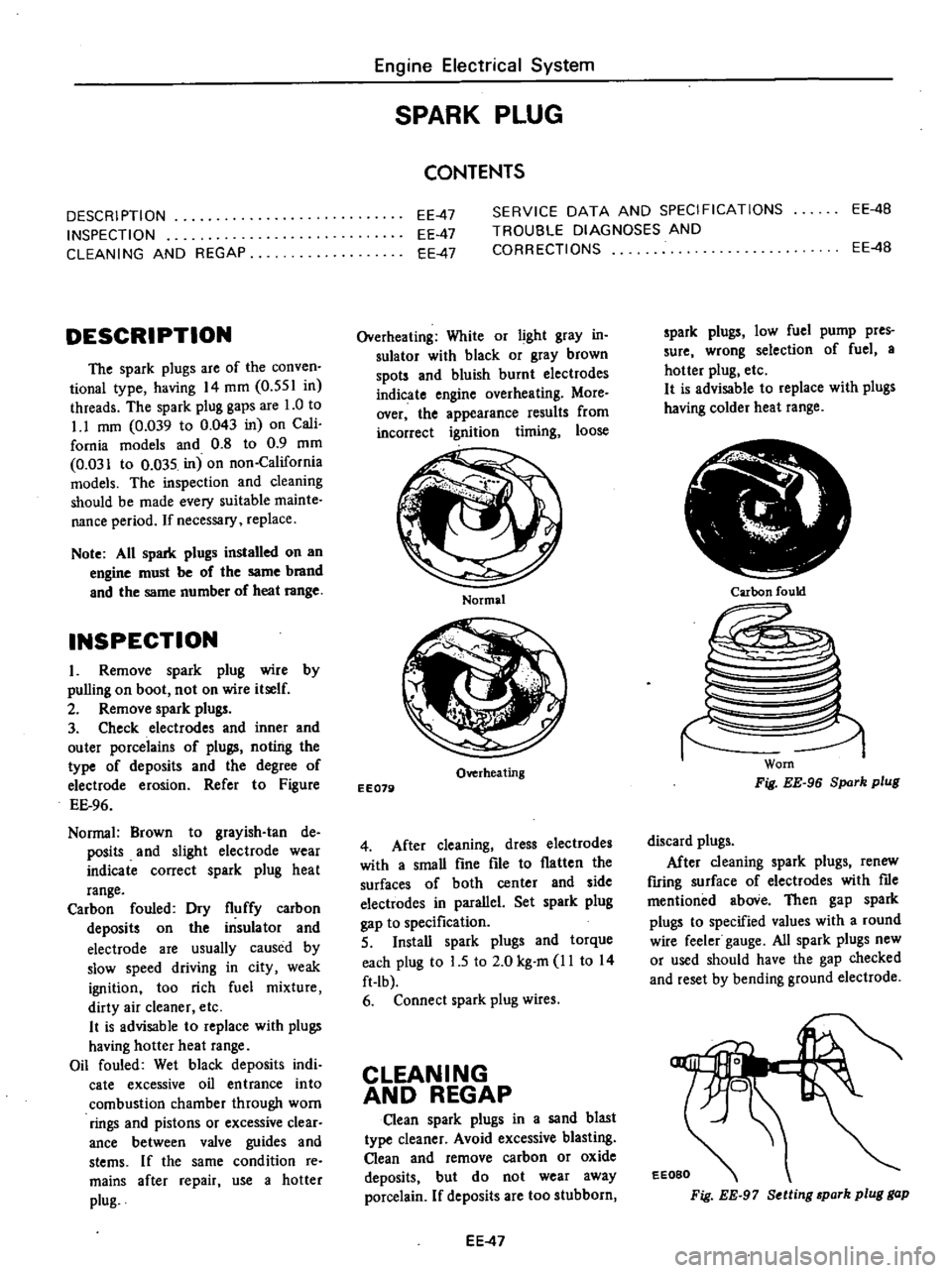

EE357

Fig

EE

86

Checking

lock

p

uentive

circuit

tion

in

the

same

way

as

shown

in

Figure

EE

83

or

Figure

EE

86

Turn

on

ignition

switch

Check

to

see

whether

the

wave

form

on

the

oscilloscope

rises

up

to

the

power

source

voltage

within

about

10

seconds

after

ignition

switch

is

turned

on

Criterion

The

same

as

described

before

for

use

of

a

tester

Power

source

voltage

t

Ignition

switch

ON

EE430

Fig

EE

87

Wave

form

of

lock

preventive

circuit

Page 214 of 537

DESCRIPTION

INSPECTION

CLEANING

AND

REGAP

DESCRIPTION

The

spark

plugs

are

of

the

conven

tional

type

having

14

mm

0

551

in

threads

The

spark

plug

gaps

are

1

0

to

1

1

mm

0

039

to

0

043

in

on

Cali

fomia

models

and

0

8

to

0

9

mm

0

031

to

0

035

in

on

non

California

models

The

inspection

and

cleaning

should

be

made

every

suitable

mainte

nance

period

If

necessary

replace

Note

All

spark

plugs

installed

on

an

engine

must

be

of

the

same

brand

and

the

same

number

of

heat

range

INSPECTION

L

Remove

spark

plug

wire

by

pulling

on

boot

not

on

wire

itself

2

Remove

spark

plugs

3

Check

electrodes

and

inner

and

outer

porcelains

of

plugs

noting

the

type

of

deposits

and

the

degree

of

electrode

erosion

Refer

to

Figure

EE

96

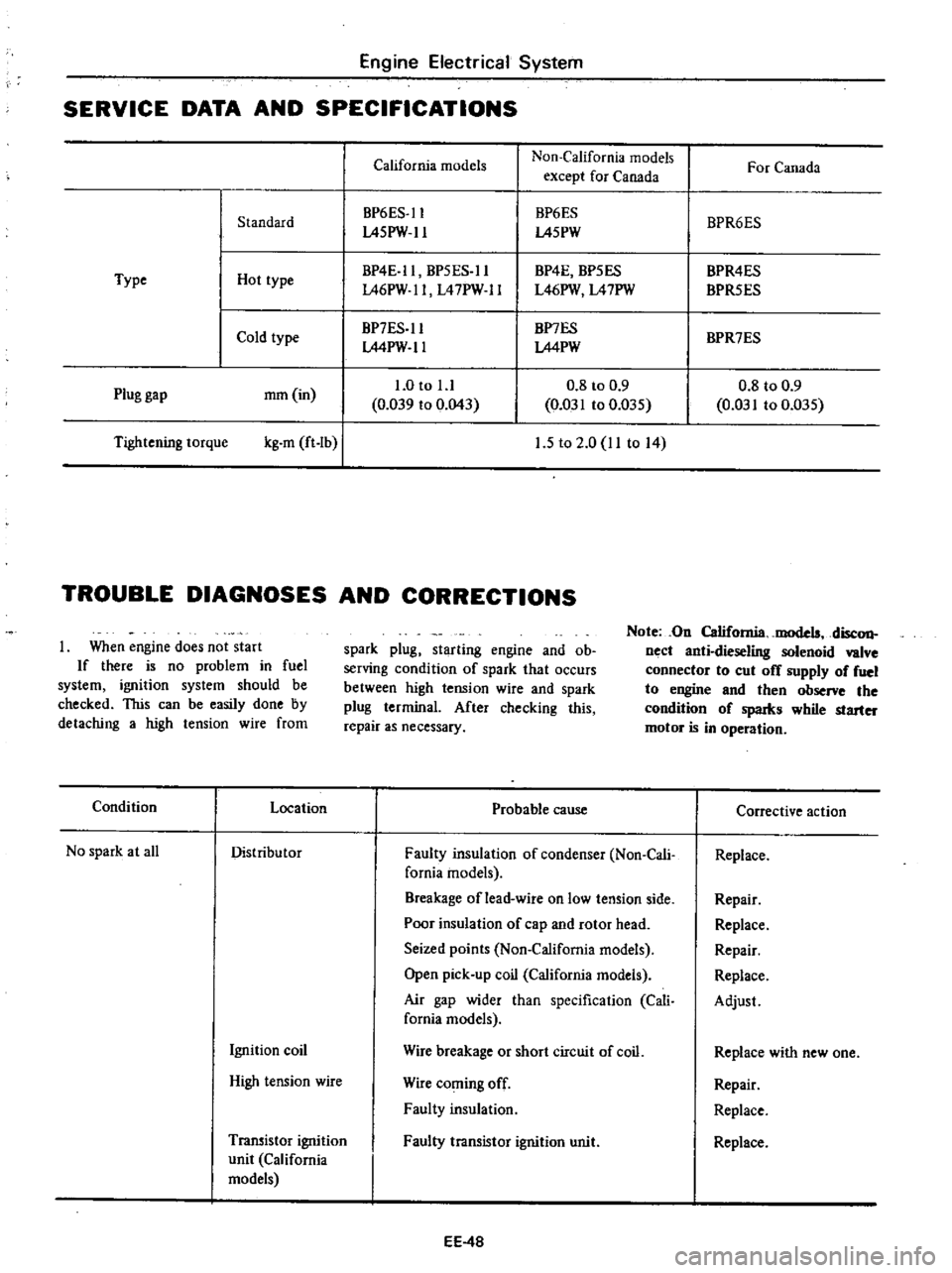

Normal

Brown

to

grayish

tan

de

posits

and

slight

electrode

wear

indicate

correct

spark

plug

heat

range

Carbon

fouled

Dry

fluffy

carbon

deposits

on

the

insulator

and

electrode

are

usually

caused

by

slow

speed

driving

in

city

weak

ignition

too

rich

fuel

mixture

dirty

air

cleaner

etc

It

is

advisable

to

replace

with

plugs

having

hotter

heat

range

Oil

fouled

Wet

black

deposits

indi

cate

excessive

oil

entrance

into

combustion

chamber

through

worn

rings

and

pistons

or

excessive

clear

ance

between

valve

guides

and

stems

If

the

same

condition

re

mains

after

repair

use

a

hotter

plug

Engine

Electrical

System

SPARK

PLUG

CONTENTS

EE

4B

EE

47

EE

47

EE

47

SERVICE

DATA

AND

SPECIFICATIONS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

EE

4B

Overheating

White

or

light

gray

in

sulator

with

black

or

gray

brown

spots

and

bluish

burnt

electrodes

indicate

engine

overheating

More

over

the

appearance

results

from

incorrect

ignition

timing

loose

Normal

Overheating

EE079

4

After

cleaning

dress

electrodes

with

a

smaU

fine

file

to

flatten

the

surfaces

of

both

center

and

side

electwdes

in

parallel

Set

spark

plug

gap

to

specification

5

InstaU

spark

plugs

and

torque

each

plug

to

L5

to

2

0

kg

m

11

to

14

ft

Ib

6

Connect

spark

plug

wires

CLEANING

AND

REGAP

Clean

spark

plugs

in

a

sand

blast

type

cleaner

Avoid

excessive

blasting

Clean

and

remove

carbon

or

oxide

deposits

but

do

not

wear

away

porcelain

If

deposits

are

too

stubborn

EE

47

spark

plugs

low

fuel

pump

pres

sure

wrong

selection

of

fuel

a

hotter

plug

etc

It

is

advisable

to

replace

with

plugs

having

colder

heat

range

Ir

i

Carbon

fould

Worn

Fig

EE

96

Spark

plug

discard

plugs

After

cleaning

spark

plugs

renew

firing

surface

of

electrodes

with

me

mentioned

aboVe

Then

gap

spark

plugs

to

specified

values

with

a

round

wire

feeler

gauge

All

spark

plugs

new

or

used

should

have

the

gap

checked

and

reset

by

bending

ground

electrode

EEOBO

Fig

EE

97

Setting

park

plug

gap

Page 215 of 537

Engine

Electrical

System

SERVICE

DATA

AND

SPECIFICATIONS

California

models

Non

California

models

For

Canada

except

for

Canada

BP6ES

ll

BP6ES

BPR6ES

Standard

L45PW

ll

L45PW

BP4E

ll

BP5ES

ll

BP4E

BP5ES

BPR4ES

Type

Hot

type

L46PW

ll

L47PW

ll

L46PW

L47PW

BPR5ES

Cold

type

BP7ES

ll

BP7ES

BPR7ES

LMPW

ll

LMPW

1

0

to

l

l

0

8

to

0

9

0

8

to

0

9

Plug

gap

mm

in

0

039

to

0

043

0

031

to

0

D35

0

031

to

0

035

Tightening

torque

kg

m

ft

Ib

I

1

5

to

2

0

11

to

14

TROUBLE

DIAGNOSES

AND

CORRECTIONS

When

engine

does

not

start

If

there

is

no

problem

in

fuel

system

ignition

system

should

be

checked

This

can

be

easily

done

by

detaching

a

high

tension

wire

from

spark

plug

starting

engine

and

ob

serving

condition

of

spark

that

occurs

between

high

tension

wire

and

spark

plug

terminal

After

checking

this

repair

as

necessary

Note

On

California

models

disc

on

nect

anti

dieseling

solenoid

valve

connector

to

cut

off

supply

of

fuel

to

engine

and

then

observe

the

condition

of

spaIks

while

starter

motor

is

in

operation

Condition

Location

Probable

cause

Corrective

action

No

spark

at

all

Distributor

Faulty

insulation

of

condenser

Non

Cali

Replace

fomia

models

Breakage

of

lead

wire

on

low

tension

side

Repair

Poor

insulation

of

cap

and

rotor

head

Replace

Seized

points

Non

California

models

Repair

Open

pick

up

coil

California

models

Replace

Air

gap

wider

than

specification

Cali

Adjust

fornia

models

Ignition

coil

Wire

breakage

or

short

circuit

of

coil

Replace

with

new

one

High

tension

wire

Wire

coming

off

Repair

Faulty

insulation

Replace

Transistor

ignition

Faulty

transistor

ignition

unit

Replace

unit

California

models

EE

4B

Page 225 of 537

l

t

tJ

I

P

o

CUll

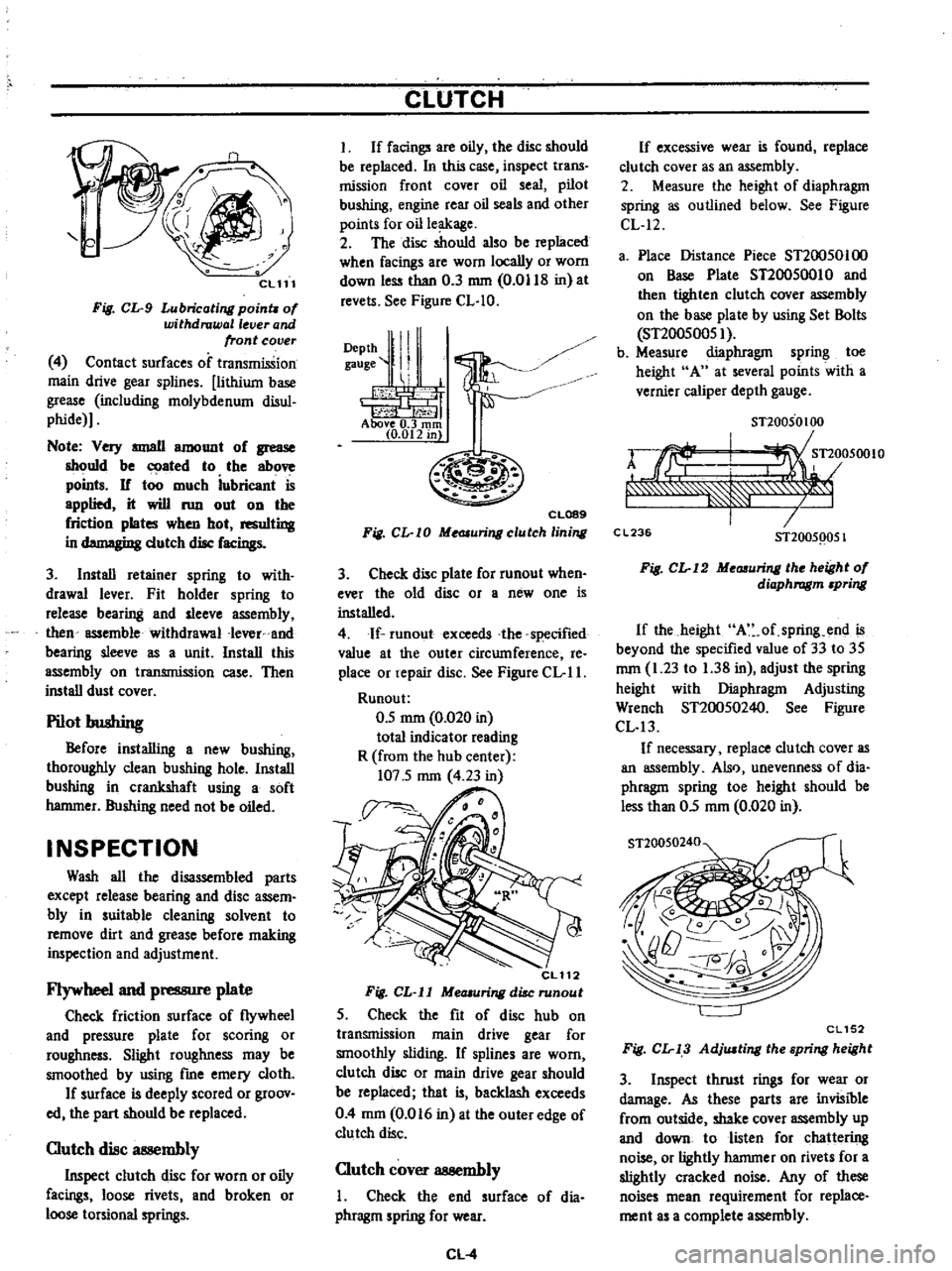

Fig

CL

9

Lubricating

poinu

of

withdrawal

lever

and

front

cover

4

Contact

surfaces

of

transmission

main

drive

gear

splines

lithium

base

grease

including

molybdenum

disul

phide

Note

Very

IIIIJllII

amount

of

grease

should

be

ated

to

the

above

points

If

too

much

iubricant

is

applied

it

will

run

out

on

the

friction

plates

when

hot

resulting

in

d

gi

dutch

disc

facings

3

Install

retainer

spring

to

with

drawal

lever

Fit

holder

spring

to

release

bearing

and

sleeve

assembly

then

assemble

withdrawal

Iever

and

bearing

sleeve

as

a

unit

Install

this

assembly

on

transmission

case

Then

install

dust

cover

Pilot

bushing

Before

installing

a

new

bushing

thoroughly

clean

bushing

hole

Install

bushing

in

crankshaft

using

a

soft

hammer

Bushing

need

not

be

oiled

INSPECTION

Wash

all

the

disassembled

parts

except

release

bearing

and

disc

assem

bly

in

suitable

cleaning

solvent

to

remove

dirt

and

grease

before

making

inspection

and

adjustment

Flywheel

and

pressure

plate

Check

friction

surface

of

flywheel

and

pressure

plate

for

scoring

or

roughness

Slight

roughness

may

be

smoothed

by

using

fme

emery

cloth

If

surface

is

deeply

scored

or

groov

ed

the

part

should

be

replaced

Clutch

disc

at

llembly

Inspect

clutch

disc

for

worn

or

oily

facings

loose

rivets

and

broken

or

loose

torsional

springs

CLUTCH

I

If

facings

are

oily

the

disc

should

be

replaced

In

this

case

inspect

trans

mission

front

cover

oil

seal

pilot

bushing

engine

rear

oil

seals

and

other

points

for

oil

leakage

2

The

disc

should

also

be

replaced

when

facings

are

worn

locally

or

worn

down

less

than

0

3

mm

0

0118

in

at

revels

See

Figure

CL

IO

DePth

ll

I

gauge

II

1

i

h

1

j1

t

f

Above

0

3

rom

10

012

in

CL089

Fig

CL

I0

Me

JIuringclutch

lining

3

Check

disc

plate

for

runout

when

ever

the

old

disc

or

a

new

one

is

installed

4

If

runoutexceeds

the

specified

value

at

the

outer

circumference

Ie

place

or

repair

disc

See

Figure

CL

II

Runou

t

0

5

mm

0

020

in

total

indicator

reading

R

from

the

hub

center

107

5

mm

4

23

in

CL112

Fig

CL

ll

MeOlUring

disc

runout

5

Check

the

fit

of

disc

hub

on

transmission

main

drive

gear

for

smoothly

sliding

If

splines

are

worn

clutch

disc

or

main

drive

gear

should

be

replaced

that

is

backlash

exceeds

0

4

mm

0

016

in

at

the

outer

edge

of

clutch

disc

Clutch

cover

assembly

I

Check

the

end

surface

of

dia

phragm

spring

for

wear

CL

4

If

excessive

wear

is

found

replace

clu

tch

cover

as

an

assembly

2

Measure

the

height

of

diaphragm

spring

as

outlined

below

See

Figure

CL

12

a

Place

Distance

Piece

ST20050100

on

Base

Plate

ST20050010

and

then

tighten

clutch

cover

assembly

on

the

base

plate

by

using

Set

Bolls

ST20050051

b

Measure

diaphragm

spring

toe

height

A

at

several

points

with

a

vernier

caliper

depth

gauge

STl0050100

rJrf

I

Tl

05001O

f

7

C

L23

STl005Q051

Fig

CL

12

Me

uring

the

height

of

diaphragm

pring

If

the

height

A

of

spring

end

is

beyond

the

specified

value

of

33

to

35

mm

1

23

to

1

38

in

adjust

the

spring

height

with

Diaphragm

Adjusting

Wrench

ST20050240

See

Figure

CL

13

If

necessary

replace

clutch

cover

as

an

assembly

Also

unevenness

of

dia

phragm

spring

toe

height

should

be

less

than

05

mm

0

020

in

ST20050240

CL152

Fig

CL

13

AdjlUting

the

spring

height

3

Inspect

thrust

rings

for

wear

or

damage

As

these

parts

are

invisible

from

outside

shake

cover

assembly

up

and

down

to

listen

for

chattering

noise

or

lightly

hammer

on

rivets

for

a

slightly

cracked

noise

Any

of

these

noises

mean

requirement

for

replace

ment

as

a

complete

assembly

Page 231 of 537

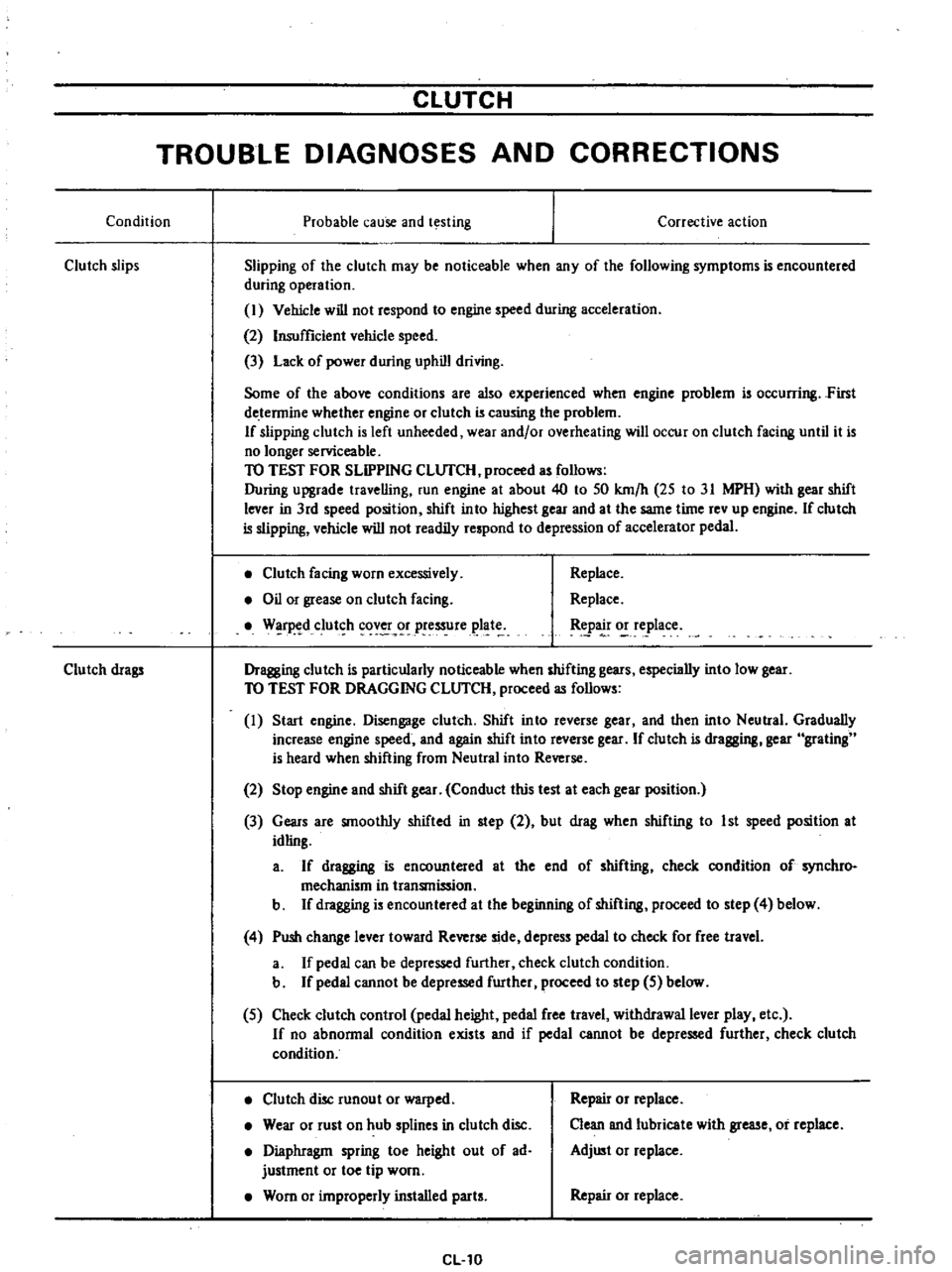

CLUTCH

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Probable

cause

and

testing

Clutch

slips

Corrective

action

Slipping

of

the

clutch

may

be

noticeable

when

any

of

the

following

symptoms

is

encountered

during

operation

I

Vehicle

will

not

respond

to

engine

speed

during

acceleration

2

Insufficient

vehicle

speed

3

Lack

of

power

during

uphill

driving

Some

of

the

above

conditions

are

also

experienced

when

engine

problem

is

oc

urring

First

de

tennine

whether

engine

or

clutch

is

causing

the

problem

If

slipping

clutch

is

left

unheeded

wear

and

or

overheating

will

occur

on

clutch

facing

until

it

is

no

longer

serviceable

TO

TEST

FOR

SLIPPING

CLlJfCH

proceed

as

follows

During

upgrade

travelling

run

engine

at

about

40

to

50

km

h

25

to

31

MPH

with

gear

shift

lever

in

3rd

speed

position

shift

into

highest

gear

and

at

the

same

time

rev

up

engine

If

clutch

is

slipping

vehicle

will

not

readily

respond

to

depression

of

accelerator

pedal

Clutch

facing

worn

excessively

Oil

or

grease

on

clutch

facing

W

r

d

clut

h

cov

r

pressure

plat

Replace

Replace

tpa

o

e

lace

Dragging

clutch

is

particularly

noticeable

when

shifting

gears

especially

into

low

gear

TO

TEST

FOR

DRAGGING

CLlJfCH

proceed

as

follows

I

Start

engine

Disengage

clutch

Shift

into

reverse

gear

and

then

into

Neutral

Gradually

increase

engine

speed

and

again

shift

into

reverse

gear

If

clutch

is

dragging

gear

grating

is

heard

when

shifting

from

Neutral

into

Reverse

Clutch

drags

2

Stop

engine

and

shift

gear

Conduct

this

test

at

each

gear

position

3

Gears

are

smoothly

shifted

in

step

2

but

drag

when

shifting

to

1st

speed

position

at

idling

a

If

dragging

is

encountered

at

the

end

of

shifting

check

condition

of

synchro

mechanism

in

transmission

b

If

dragging

is

encountered

at

the

beginning

of

shifting

proceed

to

step

4

below

4

Push

change

lever

toward

Reverse

side

depress

pedal

to

check

for

free

travel

a

If

pedal

can

be

depressed

further

check

clutch

condition

b

If

pedal

cannot

be

depressed

further

proceed

to

step

5

below

5

Check

clutch

control

pedal

height

pedal

free

travel

withdrawal

lever

play

etc

If

no

abnonnal

condition

exists

and

if

pedal

cannot

be

depressed

further

check

clutch

condition

Clutch

disc

runout

or

warped

Wear

or

rust

on

hub

splines

in

clutch

disc

Diaphragm

spring

toe

height

out

of

ad

justment

or

toe

tip

worn

Worn

or

improperly

installed

parts

CL10

Repair

or

replace

Clean

and

lubricate

with

grease

or

replace

Adjust

or

replace

Repair

or

replace

Page 242 of 537

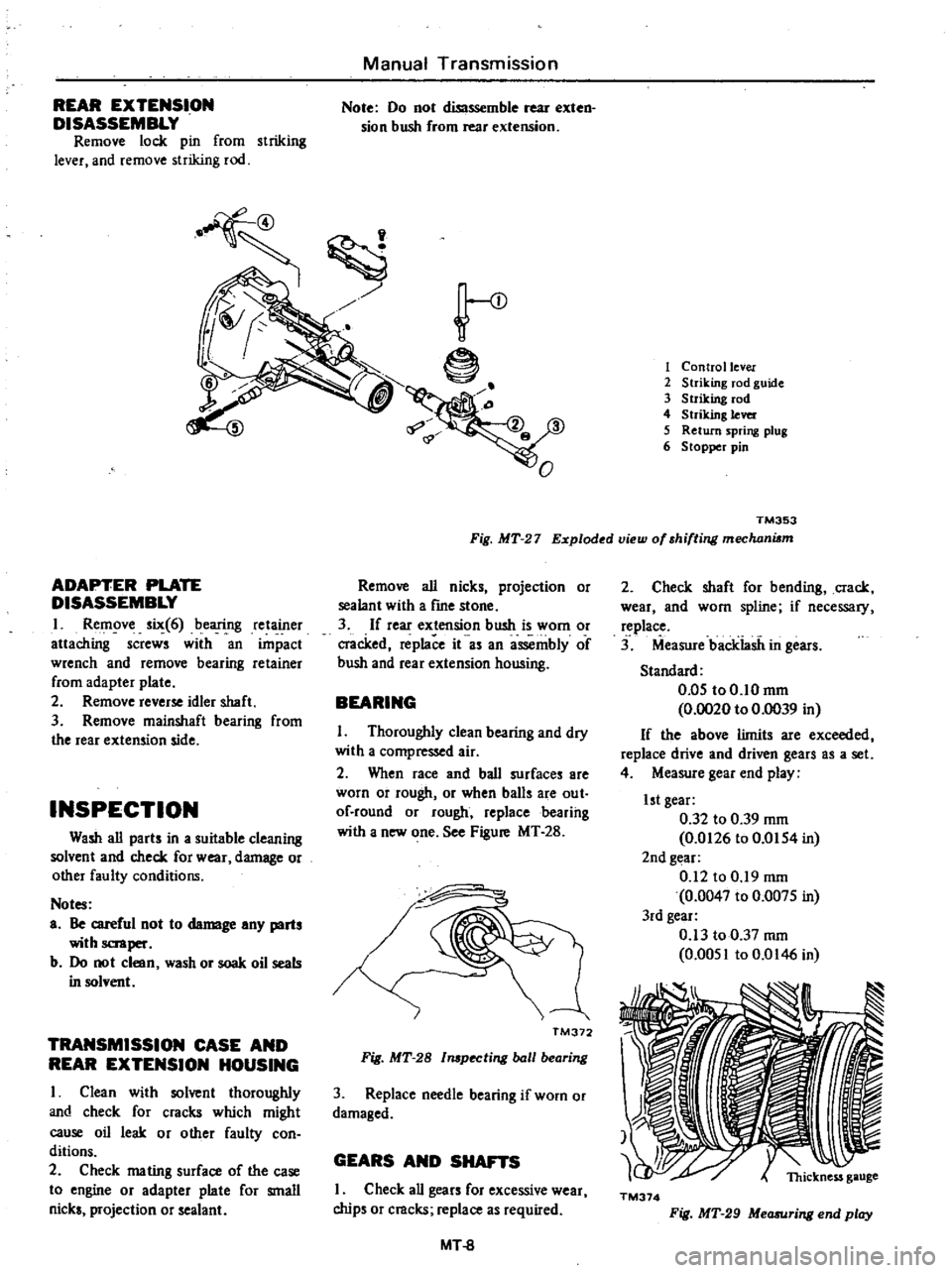

REAR

EXTENSION

DISASSEMBLY

Remove

lock

pin

from

striking

lever

and

remove

striking

rod

Manual

Transmission

Note

00

not

diSlssemble

rear

exten

sion

bush

from

rear

extension

ADAPTER

PLATE

DISASSEMBLY

I

Remove

six

6

bearing

retainer

attaching

screws

with

an

impact

wrench

and

remove

bearing

retainer

from

adapter

plate

2

Remove

reverse

idler

shaft

3

Remove

mainshaft

bearing

from

the

rear

extension

side

INSPECTION

Wash

all

parts

in

a

suitable

cleaning

solvent

and

check

for

wear

damage

or

other

faulty

conditions

Notes

a

Be

careful

not

to

damage

any

parts

with

scraper

b

00

not

clean

wash

or

soak

oil

seals

in

solvent

TRANSMISSION

CASE

AND

REAR

EXTENSION

HOUSING

I

Clean

with

solvent

thoroughly

and

check

for

cracks

which

might

cause

oil

leak

or

other

faulty

con

ditions

2

Check

mating

surface

of

the

case

to

engine

or

adapter

plate

for

small

nicks

projection

or

sealant

e

1

Control

lever

2

Striking

rod

guide

3

Striking

rod

4

Striking

lever

5

Return

spring

plug

6

Stopper

pin

TM353

Fig

MT

27

Exploded

view

of

shifting

mechani6m

Remove

all

nicks

projection

or

sealant

with

a

frne

stone

3

If

rear

extension

bush

is

worn

or

cracked

replace

it

as

an

assembly

of

bush

and

rear

extension

housing

BEARING

I

Thoroughly

clean

bearing

and

dry

with

a

compressed

air

2

When

race

and

ball

surfaces

are

worn

or

rough

or

when

balls

are

out

of

round

or

rough

replacebearihg

with

a

new

one

See

Figure

MT

28

I

TM372

Fig

MT

28

l

pecting

ball

bearing

3

Replace

needle

bearing

if

worn

or

damaged

GEARS

AND

SHAFTS

I

Check

all

gears

for

excessive

wear

chips

or

cracks

replace

as

required

MT

8

2

Check

shaft

for

bending

crack

wear

and

worn

spline

if

necessary

replace

3

Measure

backiasii

in

gears

Standard

0

05

to0

10mm

0

0020

to

0

0039

in

If

the

above

limits

are

exceeded

replace

drive

and

driven

gears

as

a

set

4

Measure

gear

end

play

1st

gear

0

32

to

0

39

mm

0

0126

to

0

0154

in

2nd

gear

0

12

to

0

19

mm

0

0047

to

0

0075

in

3rd

gear

0

13

to

0

37

mm

0

0051

to

0

0146

in

TM374

Fig

MT

29

Measuring

end

play

Page 256 of 537

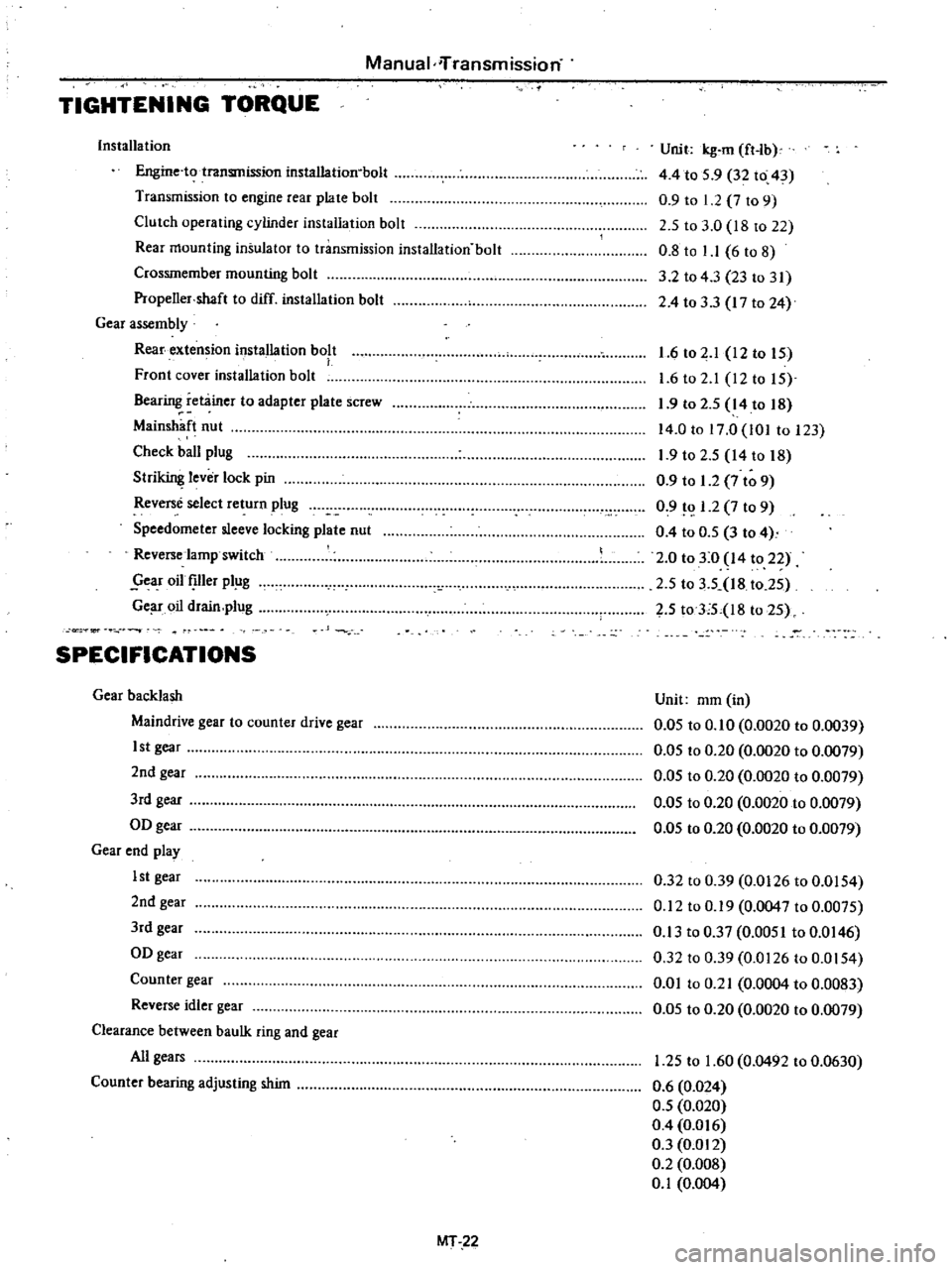

Manual

iTransmission

TIGHTENING

TORQUE

Installa

tion

Engine

to

transmission

installation

bolt

Transmission

to

engine

rear

plate

bolt

Clutch

operating

cylinder

installation

bolt

Rear

mounting

insulator

to

transmission

installation

bolt

Crossmember

mounting

bolt

Propeller

shaft

to

diff

installation

bolt

Gear

assembly

Rear

extension

installation

bolt

Front

cover

installation

bolt

Bearing

retainer

to

adapter

plate

screw

Main

haft

nut

Check

ball

plug

Stri

lever

lock

pin

Reverse

select

return

plug

Speedometer

sleeve

locking

plate

nut

Reverse

lamp

switch

year

oil

Ier

pl

g

Ge

r

oil

drain

plug

Unit

kg

m

ft

lb

4

4

to

5

9

32

to

43

0

9

to

1

2

7

to

9

2

5

to

3

0

18

to

22

0

8

to

1

1

6

to

8

3

2

to

43

23

to

31

2

4

to

33

17

to

24

1

6

to

2

1

12

to

IS

1

6

to

2

1

12to

IS

1

9

to

2

S

14

to

18

14

0

to

17

0

101

to

123

1

9

to

2

S

14

to

18

0

9

to

1

2

7

to

9

0

9

1

2

7

to

9

0

4

to

O

S

3

to

4

2

0

to

3

0

14

to

22

2

S

to

3

5

18

t02S

2

S

toTS

l8

to

2S

or

SPECIFICATIONS

Gear

backlash

Maindrive

gear

to

counter

drive

gear

1st

gear

2nd

gear

3rd

gear

OD

gear

Gear

end

play

1st

gear

2nd

gear

3rd

gear

OD

gear

Counter

gear

Reverse

idler

gear

Clearance

between

baulk

ring

and

gear

All

gears

Counter

bearing

adjusting

shim

Unit

mm

in

0

05

to

0

10

0

0020

to

0

0039

0

05

to

0

20

0

0020

to

0

0079

O

OS

to

0

20

0

0020

to

0

0079

0

05

to

0

20

0

0020

to

0

0079

0

05

to

0

20

0

0020

to

0

0079

0

32

to

0

39

0

0126

to

0

0154

0

12

to

0

19

0

0047

to

0

0075

0

13

to

0

37

0

0051

to

0

0146

0

32

to

0

39

0

0126

to

0

0154

0

01

to

0

21

0

0004

to

0

0083

0

05

to

0

20

0

0020

to

0

0079

1

25

to

1

60

0

0492

to

0

0630

0

6

0

024

0

5

0

020

0

4

0

016

0

3

0

012

0

2

0

008

0

1

0

004

MT

22

Page 257 of 537

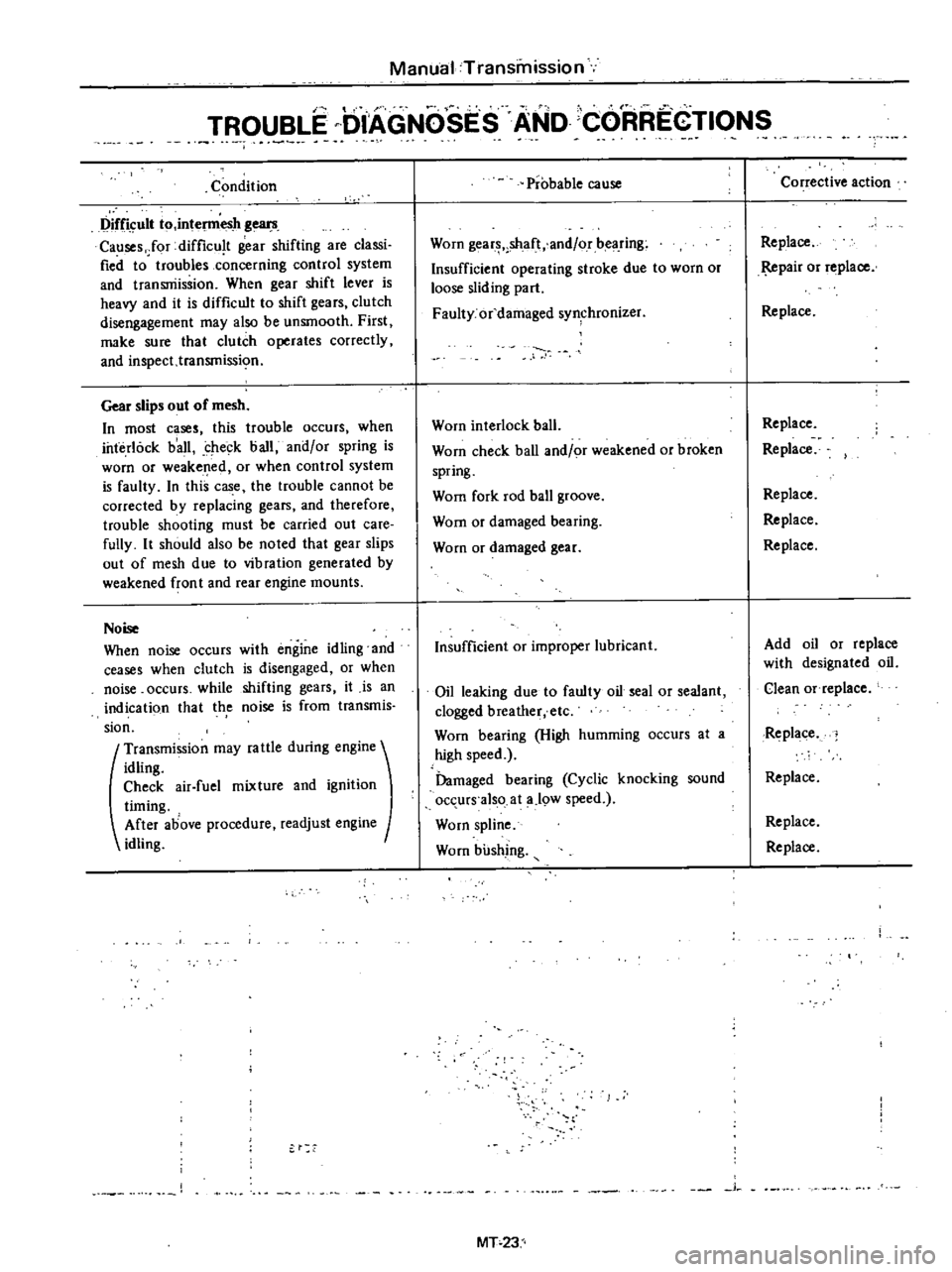

Manual

Transmission

I

TROUBLE

DIAGNOSES

AND

CORREGTIONS

Condition

Difficult

to

intel11lesh

gears

Causes

Jor

difficu

t

gear

shifting

are

classi

fied

to

troubles

concerning

control

system

and

transniissioo

When

gear

shift

lever

is

heavy

and

it

is

difficult

to

shift

gears

clutch

disengagement

may

also

be

unsmooth

First

make

sure

that

clutch

operates

correctly

and

inspect

transmissi

o

Gear

slips

out

of

mesh

In

most

cases

this

trouble

occurs

when

interlock

b

all

check

ball

and

or

spring

is

worn

or

weakened

or

when

control

system

is

faulty

In

this

case

the

trouble

cannot

be

corrected

by

replacing

gears

and

therefore

trouble

shooting

must

be

carried

out

care

fully

It

should

also

be

noted

that

gear

slips

out

of

mesh

due

to

vibration

generated

by

weakened

fron

t

and

rear

engine

mounts

Noise

When

noise

occurs

with

engine

idling

and

ceases

when

clutch

is

disengaged

or

when

noise

occurs

while

shifting

gears

it

is

an

indicati90

that

th

e

noise

is

from

transmis

sion

t

Transmission

may

fa

ule

during

engine

idling

Check

air

fuel

mixture

and

ignition

timing

After

above

procedure

readjust

engine

idling

Probable

cause

Worn

gear

shaft

and

or

bearing

Insufficient

operating

stroke

due

to

worn

or

loose

sliding

part

Faulty

or

damaged

synchronizer

Worn

interlock

ball

Worn

check

ball

and

or

weakened

or

broken

spring

Wom

fork

rod

ball

groove

Wom

or

damaged

bearing

Worn

or

damaged

gear

Insufficient

or

improper

lubricant

Oil

leaking

due

to

faulty

oil

seal

or

sealant

clogged

breather

etc

Worn

bearing

High

humming

occurs

at

a

high

speed

Damaged

bearing

Cyclic

knocking

sound

occurs

also

at

a

19W

speed

Worn

spline

Worn

bushing

j

MT

23

Corrective

action

Replace

pair

or

replace

Replace

Replace

Replace

Replace

Replace

Replace

Add

oil

or

replace

with

designated

oil

Clean

Of

replace

Replace

Replace

Replace

Replace

Page 298 of 537

Starter

should

be

brought

into

op

eration

only

when

selector

lever

is

in

P

and

N

positions

it

should

not

be

started

when

lever

is

in

D

2

I

and

R

positions

Back

up

lamp

should

also

light

when

selector

lever

is

placed

in

R

position

S

After

converter

is

installed

rotate

10

Check

level

of

oil

in

transmis

crankshaft

several

turns

and

check

to

be

sure

that

transmission

rotates

freely

sion

For

detailed

procedure

see

page

AT48

without

binding

6

Pour

recommended

automatic

II

Move

selector

lever

through

aU

positions

to

be

sure

that

transmission

transmission

fluid

up

to

correct

level

operates

correctly

through

oil

charge

pipe

verter

to

transmission

measure

dis

With

hand

brake

applied

rotate

tan

A

to

be

certain

that

they

are

7

Connect

manual

lever

to

shift

engine

at

idling

Without

disturbing

correctly

mbi

d

S

F

rod

Opeiationsliould

oecaTrie

f

bue

the

above

sclUng

ffiovTSelector

lever

AT

50

with

manual

and

selector

levers

in

through

N

to

D

to

2

to

I

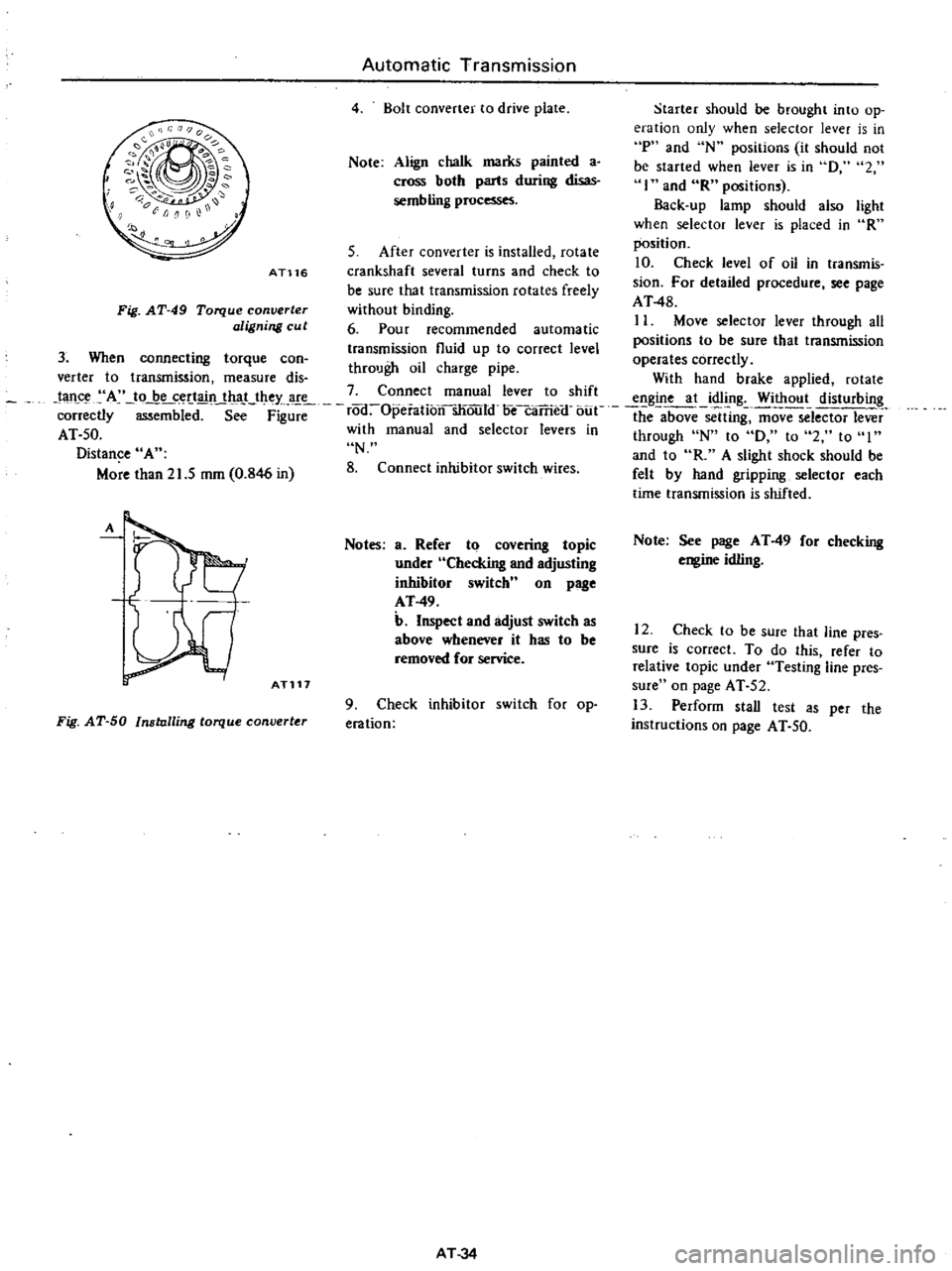

Distance

A

N

and

to

R

A

slight

shock

should

be

More

than

21

5

mm

0

846

in

8

Connect

inhibitor

switch

wires

felt

by

hand

gripping

selector

each

time

transmission

is

shifted

Automatic

Transmission

4

Bolt

converter

to

drive

plate

Note

Align

chalk

marks

painted

a

cross

both

parts

during

disas

sembling

processes

AT116

Fig

AT

49

Torque

converter

aligning

cu

t

3

When

connecting

torque

can

A

ATl17

Notes

a

Refer

to

covering

topic

under

Checking

and

adjusting

inhibitor

switch

n

on

page

AT

49

b

Inspect

and

adjust

switch

as

above

whenever

it

has

to

be

removed

for

service

Fig

AT

50

Installing

torque

converter

9

Check

inhibitor

switch

for

op

eration

AT

34

Note

See

page

AT

49

for

checking

engine

idling

12

Check

to

be

sure

that

line

pres

sure

is

correct

To

do

this

refer

to

relative

topic

under

Testing

line

pres

sure

on

page

AT

52

13

Perform

stall

test

as

per

the

instructions

on

page

AT

50

Page 300 of 537

Automatic

Transmission

MAJOR

REPAIR

OPERATION

SERVICE

NOTICE

FOR

DISASSEMBLY

AND

ASSEMBLY

TORQUE

CONVERTER

INSPECTION

TRANSMISSION

DISASSEMBL

Y

INSPECTION

ASSEMBL

Y

SERVICE

NOTICE

FOR

DISASSEMBLY

AND

ASSEMBLY

I

It

is

advisable

that

repair

opera

tions

be

carried

out

in

a

dust

proof

room

2

Due

to

the

differences

of

the

engine

capacities

the

specifications

of

component

parts

for

each

model

s

transmission

may

be

different

They

do

however

have

common

adjust

ment

and

repair

procedures

as

well

as

cleaning

and

inspection

procedures

outlined

hereinafter

3

During

repair

operations

refer

to

Service

Data

and

Specifications

see

tion

for

the

correct

parts

for

each

model

4

Before

removing

any

of

subas

semblies

thoroughly

clean

the

outside

of

the

transmission

to

prevent

dirt

from

entering

the

mechanical

parts

5

Do

not

use

a

waste

rag

Use

a

nylon

or

paper

cloth

6

After

disassembling

wash

all

dis

assembled

parts

and

examine

them

to

see

if

there

are

any

worn

damaged

or

defective

parts

and

how

they

are

affected

Refer

to

Service

Data

for

the

extent

of

damage

that

justifies

replacement

7

As

a

rule

packings

seals

and

similar

parts

once

disassembled

should

be

replaced

with

new

ones

TORQUE

CONVERTER

The

torque

converter

is

a

welded

construction

and

can

not

be

disas

sembled

CONTENTS

AT

36

AT

36

AT

36

AT

36

AT

36

AT

38

AT

38

COMPONENT

PARTS

FRONT

CLUTCH

REAR

CLUTCH

LOW

REVERSE

BRAKE

SERVO

PISTON

GOVERNOR

OIL

PUMP

PLANETARY

CARRIER

CONTROL

VALVE

AT

40

AT

40

AT

41

AT

42

AT

42

AT

43

AT

43

AT

44

AT

44

INSPECTION

2

Remove

bolts

securing

converter

1

Check

torque

convertf

for

any

housing

to

transmission

case

Remove

sign

of

damage

bending

oil

leak

or

torque

converter

deformation

If

necessary

replace

3

Remove

speedometer

pinion

2

Remove

rust

from

pilots

and

sleeve

bolt

Withdraw

pinion

bosses

completely

4

Remove

downshift

solenoid

and

If

torque

converter

oil

is

fouled

or

vacuum

diaphragm

Do

not

leave

dia

contaminated

due

to

burnt

clutch

phragm

rod

at

this

stage

of

disas

flush

the

torque

converter

as

follows

sembly

Rod

is

assembled

in

top

of

vacuum

diaphragm

See

Figure

I

Drain

oil

in

torque

converter

AT

53

2

Pour

non

lead

gasoline

or

kero

sene

into

torque

converter

approxi

mately

0

5

liter

I

U

S

pt

U

Imp

pt

3

Blow

air

into

torque

converter

and

flush

and

drain

out

gasoline

4

Fill

torque

converter

with

torque

converter

oil

approximately

0

5

liter

I

V

S

pt

U

Imp

pt

5

Again

blow

air

into

torque

con

verter

and

drain

torque

converter

oil

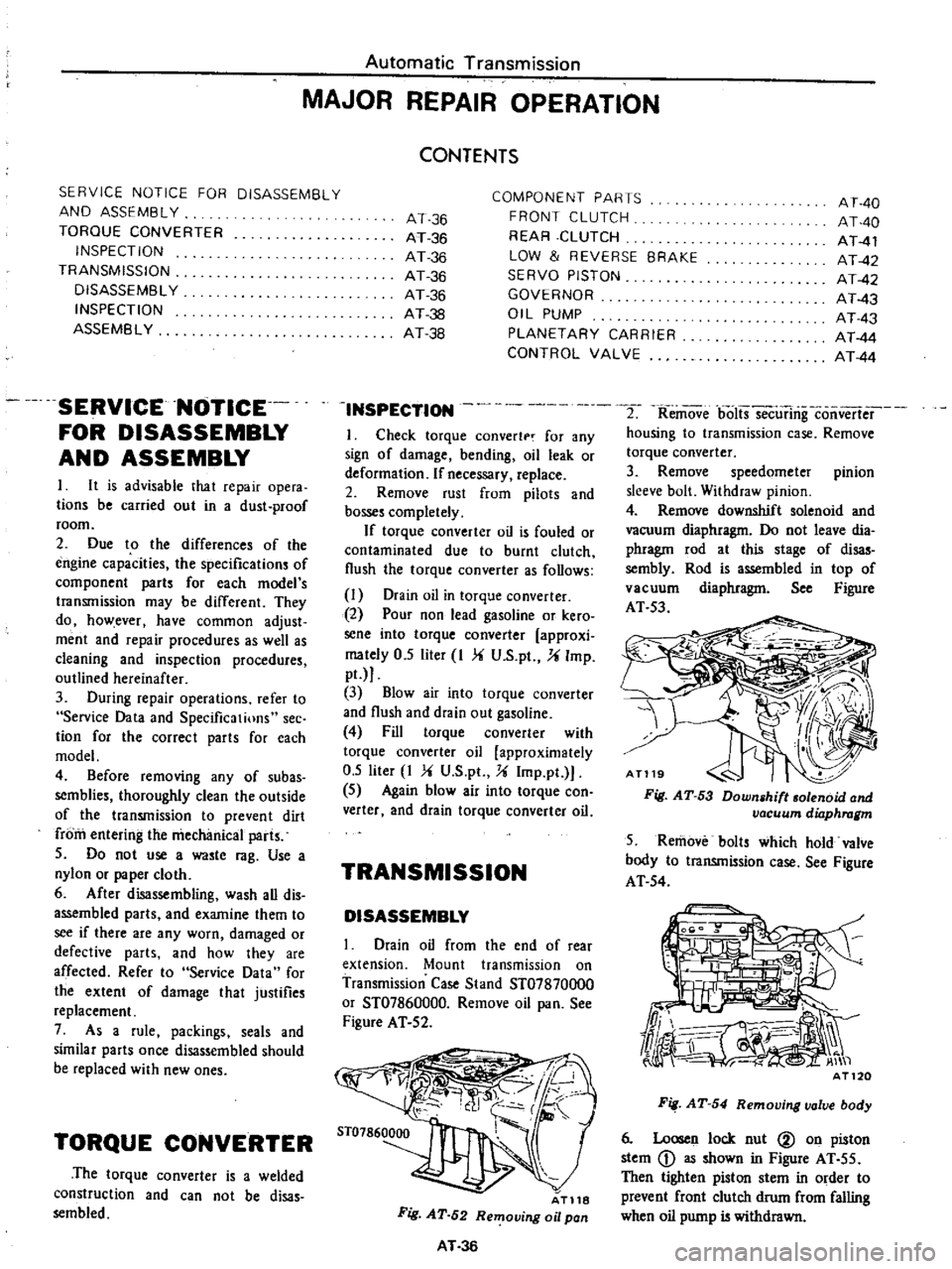

TRANSMISSION

DISASSEMBLY

I

Drain

oil

from

the

end

of

rear

extension

Mount

transmission

on

Transmission

Case

Stand

ST07870000

or

ST07860000

Remove

oil

pan

See

Figure

AT

52

AT118

Fig

AT

52

Removing

oil

pan

AT

36

Fig

AT

53

Down

hilt

olenoid

and

vacuum

dilJphragm

5

Remove

bolts

which

hold

valve

body

to

transmission

case

See

Figure

AT

54

Fig

AT

54

Removing

valve

body

6

Loosen

lock

nut

@

on

piston

stem

D

as

shown

in

Figure

AT

55

Then

tighten

piston

stem

in

order

to

prevent

front

clutch

drum

from

falling

when

oil

pump

is

withdrawn