check engine DATSUN PICK-UP 1977 Manual PDF

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 130 of 537

CLEANING

AND

INSPECTION

Dirt

gum

wuler

or

l

arbon

con

taminatiun

in

or

on

exterior

moving

parts

of

a

arburctor

arc

often

respon

sihk

for

unsatisfactory

performance

For

this

reason

efficient

carbutetioll

dcpends

upon

careful

cleaning

and

inspection

while

servicing

I

Blow

all

passages

and

castings

with

compressed

air

and

blow

off

all

parts

until

dry

Note

Do

not

pass

drills

or

wires

through

calibrated

jet

or

passaaa

as

this

may

enlarge

orirlce

and

seriously

affect

carburetor

calibrs

lion

2

Check

all

parts

for

wear

If

wear

is

noted

damaged

parts

must

be

re

placed

Note

especially

the

following

Engine

Fuel

I

Check

float

needle

and

seat

for

wear

If

wear

is

noted

assembly

must

be

replaced

2

Check

throule

and

choke

shaft

bores

in

throtlle

chamber

and

choice

chamber

for

wear

or

out

of

roundness

3

Inspect

idle

adjusting

needle

for

burrs

or

ridges

Such

a

condition

re

quires

replacemen

1

3

Inspect

gaskets

0

see

if

they

appear

hard

or

briUle

or

if

edges

are

torn

or

distorted

If

any

such

condi

tion

i

noted

they

must

be

replaced

4

Check

filter

screen

for

dirt

or

lint

Clean

and

if

screen

is

distorted

or

remain

plugged

replace

5

Check

linkage

for

operating

condition

6

Inspect

operation

of

accelerating

pump

Pour

f

el

into

jloat

chamber

and

make

throtlle

lever

operate

Check

condition

of

fuel

injection

from

the

EF

34

accelerating

nowe

7

Push

connecting

rod

of

dia

phragm

chamber

and

block

passage

of

vacuum

with

finger

When

connecting

rod

becomes

free

check

for

leakage

of

air

or

damage

to

diaphragm

Jets

Carburetor

performance

depends

on

jet

and

air

bleed

That

is

why

these

components

must

be

fabricated

with

utmost

care

To

clean

them

use

cleaning

solvent

and

blow

air

on

them

Larger

inner

numbers

tamped

on

the

jet

indicate

larger

diameters

Ac

cordingly

main

and

slow

jets

with

lalger

nUmbers

provide

richer

mixture

the

smaller

the

numbers

the

leaner

the

mixture

Conversely

the

main

and

slow

air

bleeds

through

which

air

to

passes

through

make

the

fueLleaner

if

they

bear

larger

numbers

the

smaller

the

numbers

the

richer

the

fuel

Page 132 of 537

Engine

Fuel

toms

and

causes

of

carburetor

troubles

and

remedies

for

them

are

listed

to

facilitate

quick

repairs

There

are

various

causes

of

engine

malfunctions

It

sometimes

happens

that

a

carburetor

which

has

no

fault

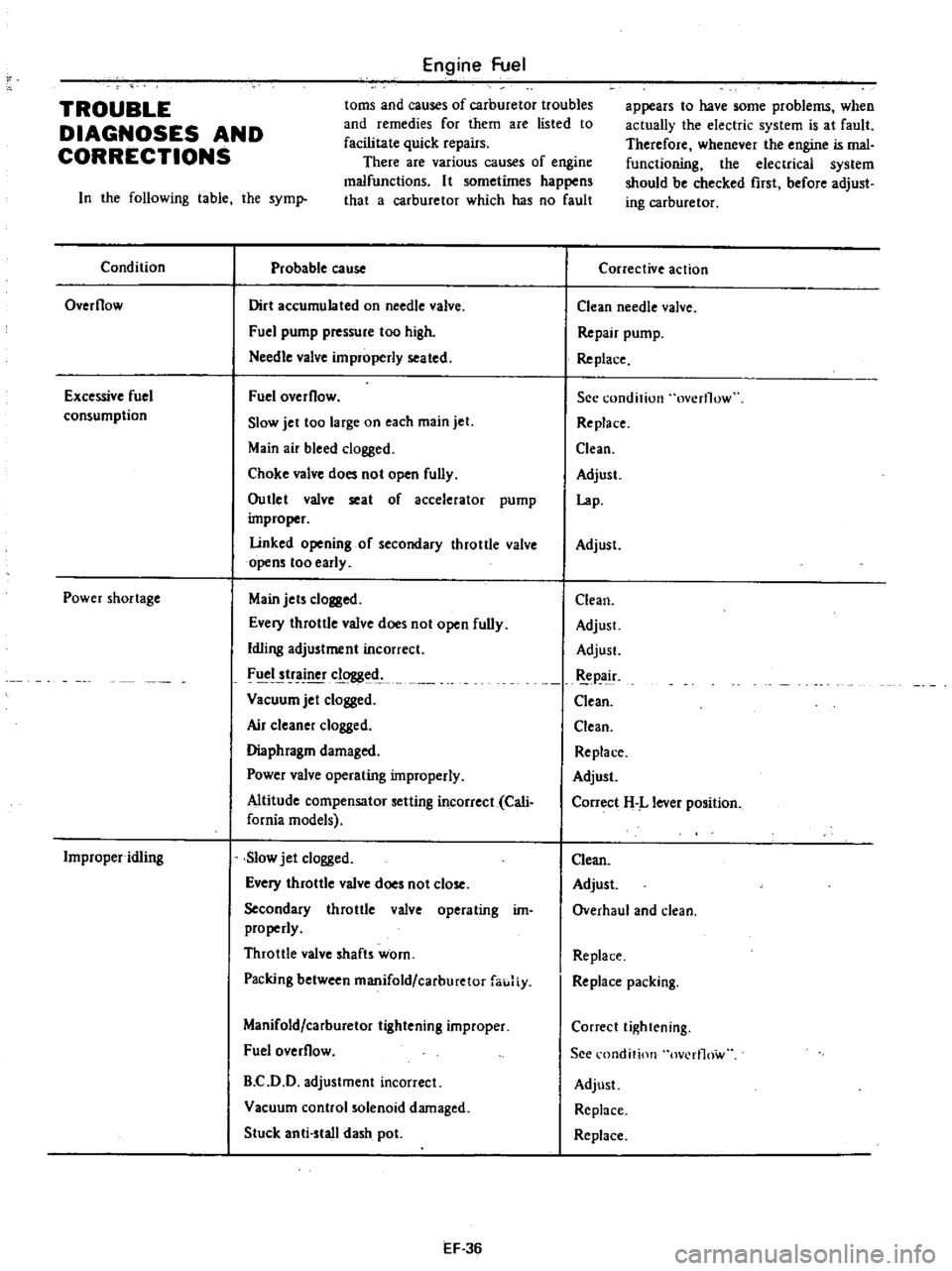

TROUBLE

DIAGNOSES

AND

CORRECTIONS

In

the

following

table

the

syml

Condition

Probable

cause

Overflow

Dirt

accumulated

on

needle

valve

Fuel

pump

pressure

too

high

Needle

valve

improperly

seated

Excessive

fuel

consumption

Fuel

overflow

Slow

jet

too

large

on

each

main

jet

Main

air

bleed

clogged

Choke

valve

does

not

open

fully

Outlet

valve

seat

of

accelerator

pump

improper

Linked

opening

of

secondary

throttle

valve

opens

too

early

Power

shortage

Main

jets

clogged

Every

throttle

valve

does

not

open

fully

Idling

adjustment

incorrect

FIICI

tr

clogged

Vacuum

jet

clogged

Air

c1eane

clogged

Diaphragm

damaged

Power

valve

operating

improperly

Altitude

compensator

setting

incorrect

Cali

fornia

models

Improper

idling

Slow

jet

clogged

Every

throttle

valve

does

not

close

Secondary

throttle

valve

operating

im

properly

Throttle

valve

shafts

worn

Packing

between

manifold

carburetor

fauJiy

Manifold

carburetor

tightening

improper

Fuel

overflow

B

C

D

D

adjustment

incorrect

Vacuum

control

solenoid

damaged

Stuck

anti

stall

dash

pot

EF

36

appears

to

have

some

problems

when

actually

the

electric

system

is

at

fault

Therefore

whenever

the

engine

is

mal

functioning

the

electrical

system

should

be

checked

rust

before

adjust

ing

carburetor

Corrective

action

Clean

needle

valve

Repair

pump

Re

place

See

condition

overflow

Replace

Clean

Adjust

Lap

Adjust

Clean

Adjust

AdjusL

pa

ir

Clean

Clean

Replace

Adjust

Correct

H

L

lever

position

Clean

Adjust

Overhaul

and

clean

Replace

Replace

packing

Correct

tightening

See

l

ondition

ov

rl1ow

Adjust

Replace

Replace

Page 133 of 537

Condition

Engine

hesitation

Engine

does

not

start

Engine

Fuel

Probable

cause

Main

jet

or

slow

jet

clogged

By

pass

hole

idle

passage

dogged

Emulsion

tube

dogged

Idling

adjustment

incorrect

Secondary

throttle

valve

operating

im

properly

Altitude

compensator

setting

incorrect

Cali

fornia

models

Fuel

overflows

No

fuel

Idling

adjustment

incorrect

Fast

idle

adjustment

incorrect

Damaged

anti

dieseling

solenoid

EF

37

Corrective

action

Clean

Clean

tube

Clean

Adjust

Overhaul

and

clean

Correct

H

L

lever

position

See

condition

overflow

Check

pump

fuel

pipe

and

needle

valve

Adjust

Adjust

Replace

Page 135 of 537

There

are

three

types

of

control

system

These

are

J

Closed

type

CIllnkcase

emission

control

system

Emission

Control

System

of

GENERAL

DESCRIPTION

2

Exhaust

emission

control

system

3

Evaporative

ell

lhsion

control

sys

tem

Pericxiic

inspection

and

required

seCV1Clng

of

these

systems

should

be

carried

out

to

reduce

harmful

emis

sions

to

a

minimum

CRANKCASE

EMISSION

CONTROL

SYSTEM

c

01

Lkf

If

1

TIL

II

tll

1

j

GUuuu

DESCRIPTION

This

system

returns

blow

by

gas

to

both

the

intake

manifold

and

carbure

tor

air

cleaner

The

positive

crankcase

ventilation

p

C

V

valve

is

provided

to

conduct

crankcase

blow

by

gas

to

the

intake

manifold

During

partial

throttle

operation

of

the

engine

the

intake

manifold

sucks

the

blow

by

gas

through

the

P

C

V

valve

Normally

the

capacity

of

the

valve

is

sufficient

to

handle

any

blow

by

and

a

small

amount

of

ventilating

air

4

c

Fresh

air

Blow

by

gas

The

ventilating

air

is

then

drawn

from

the

dust

side

of

the

cadlUretor

air

cleaner

tluough

the

tube

con

necting

carburetor

air

cleaner

to

rock

er

cover

into

the

crankcase

Under

full

tluottle

condition

the

manifold

vacuwn

is

insufficient

to

draw

the

blow

by

flow

tluough

the

valve

and

its

flow

goes

through

the

tube

connection

in

the

reverse

diree

tion

On

vehicles

with

an

excessively

high

blow

by

some

of

the

flow

will

go

through

the

tube

connection

to

carbu

retor

air

cleaner

under

all

conditions

1

Sealtypc

oil

level

gauge

2

Bame

plate

3

Flame

arrester

4

Filler

5

P

C

Y

valve

6

Steel

net

7

Bame

plate

EC716

Fig

EC

l

Crankcase

miaion

control

ay

tem

EC

2

INSPECTION

P

c

V

VALVE

AND

FILTER

Checking

P

C

V

valve

in

accord

ance

with

the

following

method

With

engine

running

at

idle

remove

the

ventilator

hose

from

P

C

V

valve

if

the

valve

is

working

a

hissing

noise

will

be

heard

as

air

passes

through

the

valve

and

a

strong

vacuwn

should

be

felt

immediately

when

a

fmger

is

placed

over

valve

inlet

Replace

P

C

V

valve

and

filter

in

accordance

with

the

maintenance

schedule

VENTILATION

HOSE

1

Check

hoses

and

hose

connec

tions

for

leaks

2

Disconnect

all

hoses

and

clean

with

compressed

air

If

any

hose

cannot

be

free

of

obstructions

replace

Ensure

that

flame

arrester

is

surely

inserted

in

hose

between

air

cleaner

and

rocker

cover

Page 140 of 537

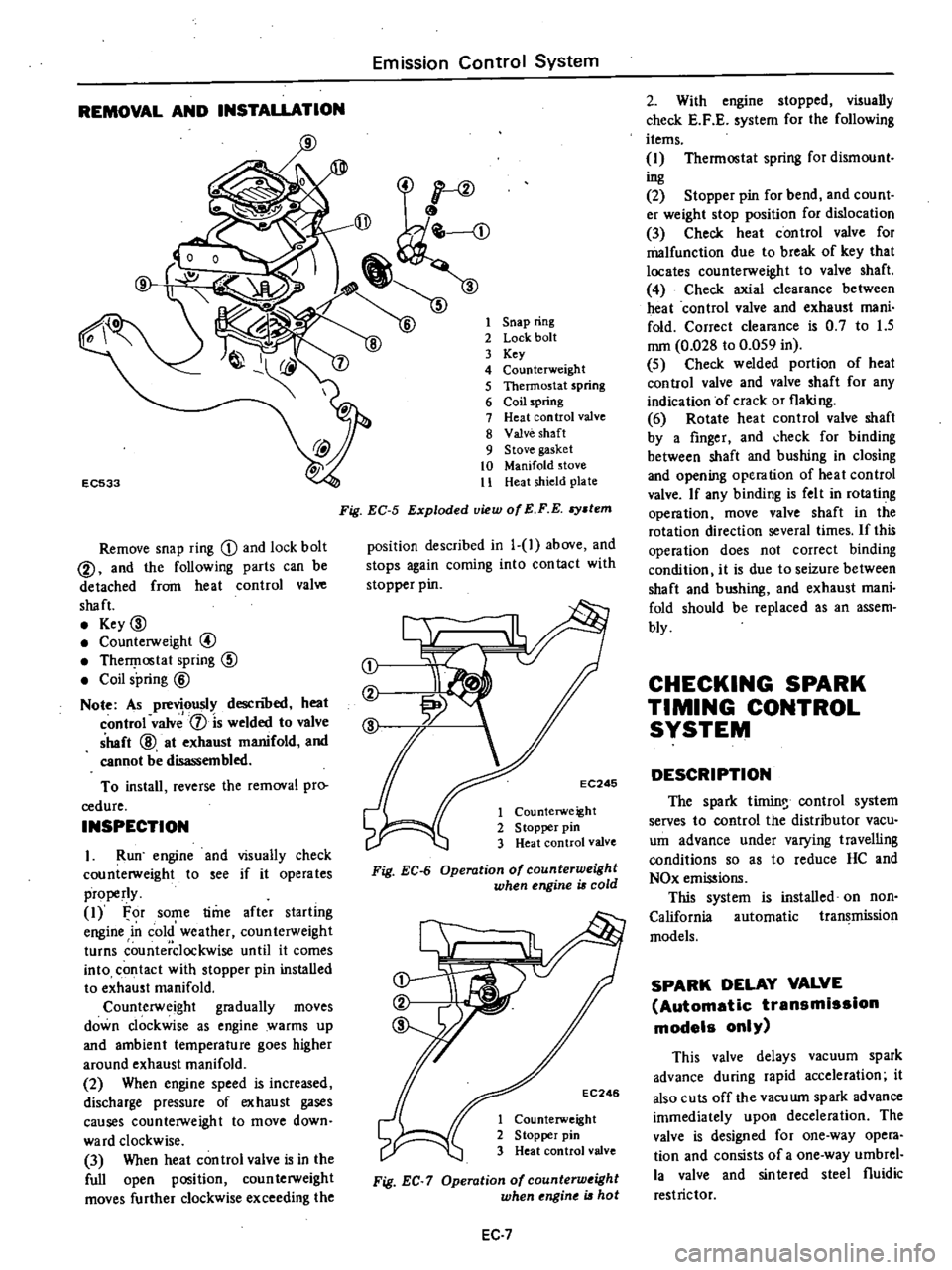

REMOVAL

AND

INSTAUATION

Emission

Control

System

EC533

Remove

snap

ring

D

and

lock

bolt

@

and

the

following

parts

can

be

detached

from

heat

control

valve

shaft

Key

00

Counterweight

@

TherI

lostat

spring

CID

Coil

spring

@

Note

As

previously

descnoed

heat

control

valv

1

is

welded

to

valve

shaft

@

at

exhaust

manifold

and

cannot

be

disassembled

To

install

reverse

the

removal

pro

cedure

INSPECTION

I

Run

engine

and

visually

check

counterweight

to

see

if

it

operates

properly

1

For

some

time

after

starling

engine

in

cold

weather

counterweight

turns

counterclockwise

until

it

comes

into

contact

with

stopper

pin

installed

to

exhaust

manifold

Counterweight

gradually

moves

down

clockwise

as

engine

warms

up

and

ambient

temperature

goes

higher

around

exhaust

manifold

2

When

engine

speed

is

increased

discharge

pressure

of

exhaust

gases

causes

counterweight

to

move

down

ward

clockwise

3

When

heat

con

trol

valve

is

in

the

full

open

position

coun

terweight

moves

further

clockwise

exceeding

the

1

Snap

ring

2

Lock

bolt

3

Key

4

Counterweight

5

Thermostat

spring

6

Coil

spring

7

Heat

control

valve

8

Valve

shaft

9

Stove

gasket

10

Manifold

stove

11

Heat

shield

plate

Fig

EC

5

Exploded

view

of

E

F

E

stem

position

described

in

1

1

above

and

stops

again

coming

into

con

tact

with

stopper

pin

j

EC246

1

Counterweight

2

S

topper

pin

3

Heat

control

valve

Fig

EC

6

Operation

of

counterweight

when

engine

is

cold

EC246

1

Counterweight

2

Stopper

pin

3

Heat

control

valve

Fig

EC

7

Operation

of

counterw

ight

when

ngine

is

hot

EC

7

2

With

engine

stopped

visually

check

E

F

E

system

for

the

following

items

1

Thermostat

spring

for

dismount

ing

2

Stopper

pin

for

bend

and

count

er

weight

stop

position

for

dislocation

3

Check

heat

control

valve

for

malfunction

due

to

break

of

key

that

locates

counterweight

to

valve

shaft

4

Check

axial

clearance

between

heat

control

valve

and

exhaust

mani

fold

Correct

clearance

is

0

7

to

1

5

mm

0

028

to

0

059

in

5

Check

welded

portion

of

heat

control

valve

and

valve

shaft

for

any

indication

of

crack

or

flaking

6

Rotate

heat

control

valve

shaft

by

a

finger

and

check

for

binding

between

shaft

and

bushing

in

closing

and

opening

operation

of

heat

control

valve

If

any

binding

is

felt

in

rotating

operation

move

valve

shaft

in

the

rotation

direction

several

times

If

this

operation

does

not

correct

binding

condition

it

is

due

to

seizure

between

shaft

and

bushing

and

exhaust

mani

fold

should

be

replaced

as

an

assem

bly

CHECKING

SPARK

TIMING

CONTROL

SYSTEM

DESCRIPTION

The

spark

tirnin

control

system

serves

to

control

the

distributor

vacu

um

advance

under

varying

travelling

conditions

so

as

to

reduce

HC

and

NOx

emissions

This

system

is

installed

on

non

California

automatic

transmission

models

SPARK

DELAY

VALVE

Automatic

transmission

models

only

This

valve

delays

vacuum

spark

advance

during

rapid

acceleration

it

also

cuts

off

the

vacuwn

spark

advance

immediately

upon

deceleration

The

valve

is

designed

for

one

way

opera

tion

and

consists

of

a

one

way

umbrel

la

valve

and

sinlered

steel

fluidic

restrictor

Page 144 of 537

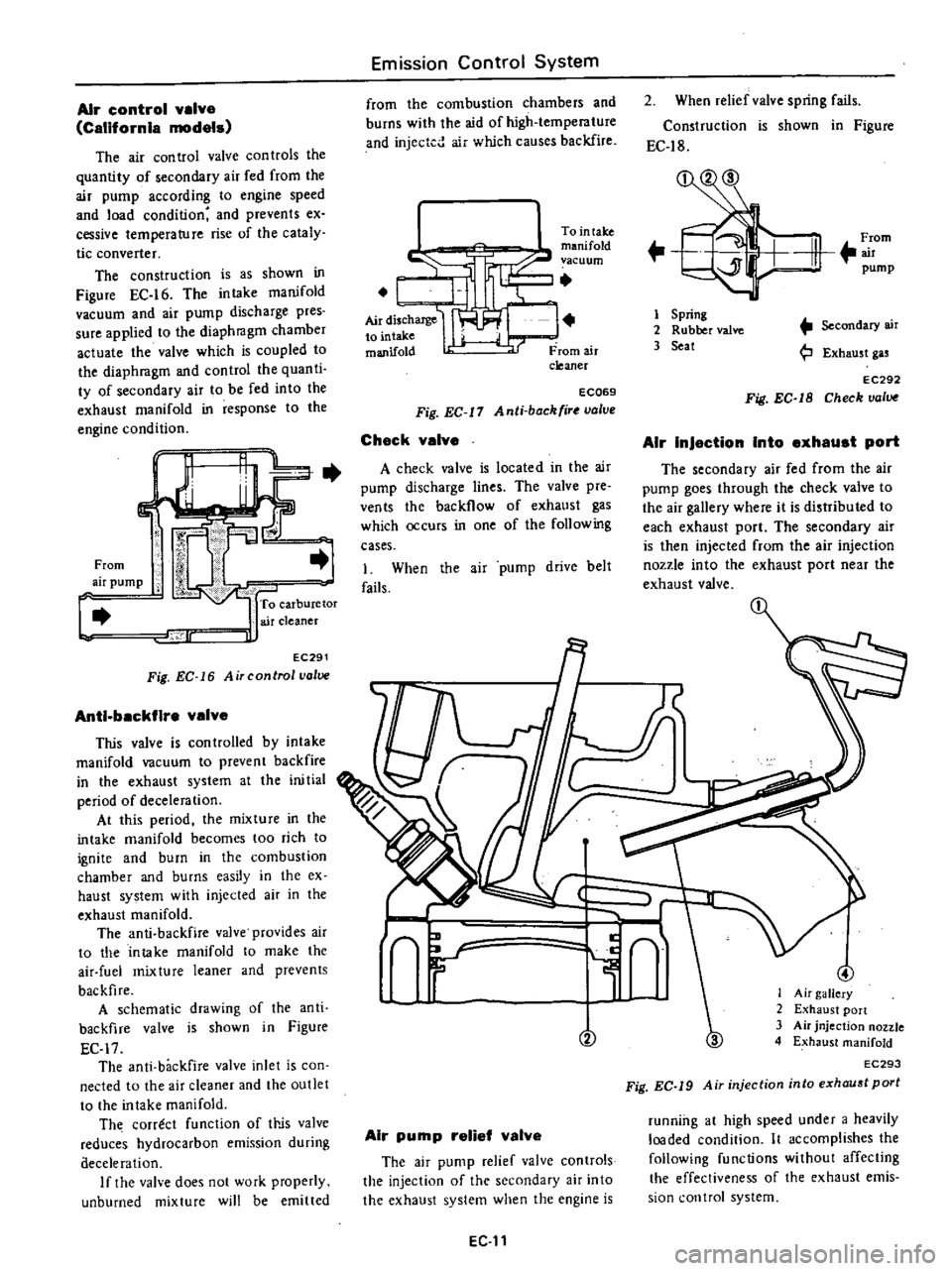

Air

control

valve

CalifornIa

models

The

air

control

valve

con

troIs

the

quantity

of

secondary

air

fed

from

the

air

pump

according

to

engine

speed

and

load

condition

and

prevents

ex

cessive

temperature

rise

of

the

cataly

tic

converter

The

construction

is

as

shown

in

Figure

EC

16

The

intake

manifold

vacuum

and

air

pump

discharge

pres

sure

applied

to

the

diaphragm

chamber

actuate

the

valve

which

is

coupled

to

the

diaphragm

and

control

the

quanti

ty

of

secondary

air

to

be

fed

into

the

exhaust

manifold

in

response

to

the

engine

condition

c

From

air

pump

To

carburetor

air

cleaner

lr

J

EC291

Fig

EC

16

Air

control

valve

Anti

backfire

valve

This

valve

is

con

trolled

by

intake

manifold

vacuum

to

prevent

backfire

in

the

exhaust

system

at

the

ini

tial

period

of

deceleration

At

this

period

the

mixture

in

the

intake

manifold

becomes

too

rich

to

ignite

and

burn

in

the

combustion

chamber

and

burns

easily

in

the

ex

haust

system

with

injected

air

in

the

exhaust

manifold

The

anti

backfire

valve

provides

air

to

the

intake

manifold

to

make

the

air

fuel

mixture

leaner

and

prevents

backfire

A

schematic

drawing

of

the

anti

backfire

valve

is

shown

in

Figure

EC

17

The

anti

backfire

valve

inlet

is

con

nected

to

the

air

cleaner

and

the

outlet

to

the

intake

manifold

Th

correct

function

of

It

jS

valve

reduces

hydrocarbon

emission

during

aeceleration

If

the

valve

does

not

work

properly

unburned

mixture

will

be

emitted

Emission

Control

System

from

the

combustion

chambers

and

burns

with

the

aid

of

high

temperature

and

injected

air

which

causes

backfire

I

Tointake

c

manifold

vacuum

I

L

AirdisChaJ1le

I

to

mtake

manifold

From

air

cleaner

ECQ69

Fig

EC

11

Anti

back

ir

valve

Check

valve

A

check

valve

is

located

in

the

air

pump

discharge

lines

The

valve

pre

ven

ts

the

backflow

of

exhaust

gas

which

occurs

in

one

of

the

following

cases

1

When

the

air

pump

drive

belt

fails

2

When

relief

valve

spring

fails

Construction

is

shown

in

Figure

EC

18

F

rom

m

pump

1

Spring

2

Rubber

valve

3

Seat

Secondary

air

Exhaust

gas

EC292

Fig

EC

1B

Check

valve

AIr

InJaction

Into

axhaust

port

The

secondary

air

fed

from

the

air

pump

goes

through

the

check

valve

to

the

air

gallery

where

it

is

distributed

to

each

exhaust

port

The

secondary

air

is

then

injected

from

the

air

injection

nozzle

into

the

exhaust

port

near

the

exhaust

valve

n

L

y

r

V

Air

pump

relief

valve

The

air

pump

relief

valve

controls

the

injection

of

the

secondary

air

into

the

exhaust

system

when

the

engine

is

EG

11

3

I

Air

gallery

2

Exhaust

port

3

Air

jnjection

nozzle

4

Exhaust

manifold

EC293

Fig

EC

19

Air

injection

into

exhaust

port

running

at

high

speed

under

a

heavily

loaded

condition

It

accomplishes

the

following

functions

without

affecting

the

effectiveness

of

the

exhaust

emis

sion

control

system

Page 145 of 537

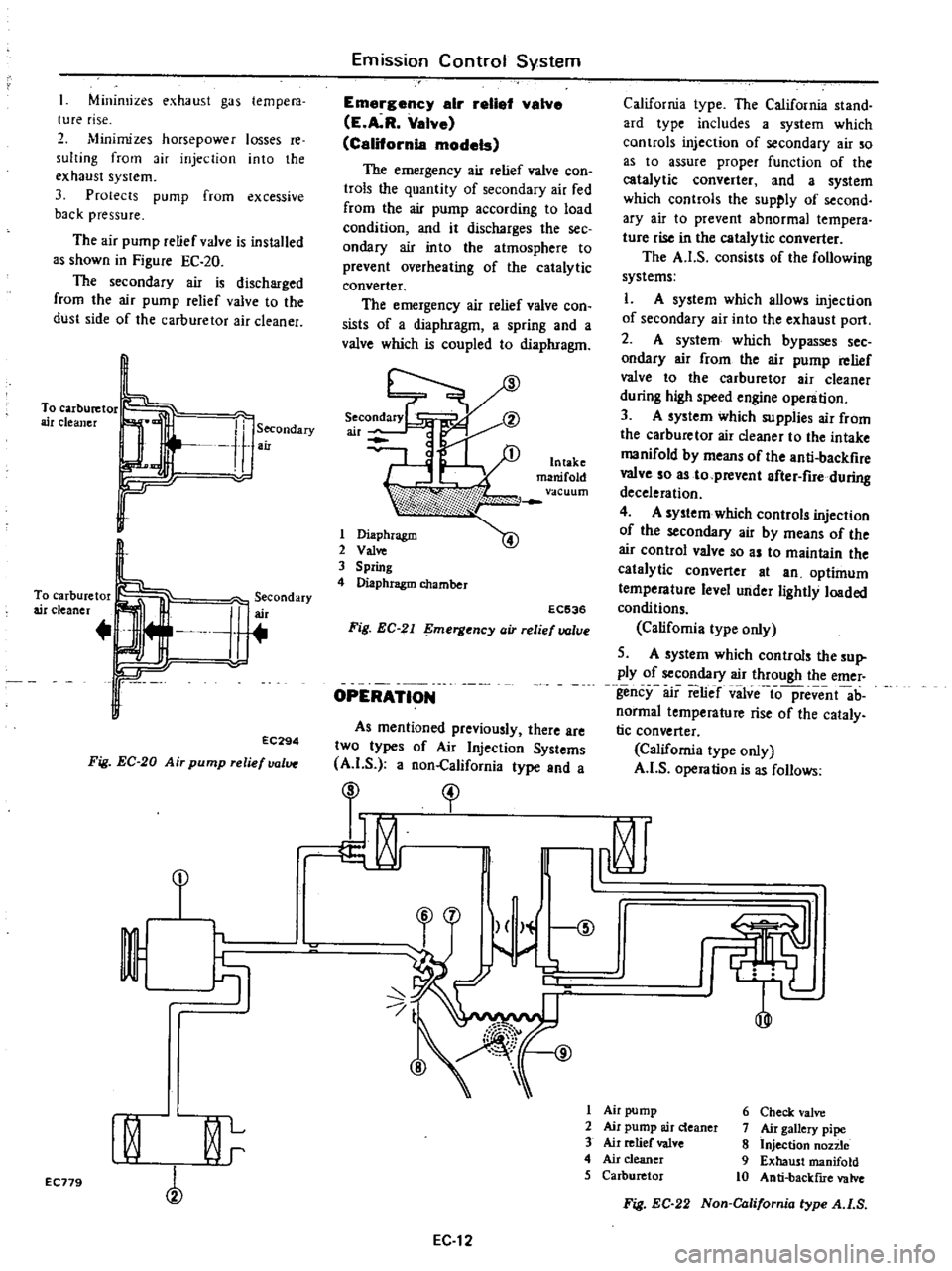

Minimizes

exhaust

gas

tempera

lure

rise

2

Minimizes

horsepower

losses

re

suiting

from

air

injection

into

the

exhaust

system

3

Protects

pump

from

excessive

back

pressure

The

air

pump

relief

valve

is

installed

as

shown

in

Figure

EC

20

The

secondary

air

is

discharged

from

the

air

pump

relief

valve

to

the

dust

side

of

the

carburetor

air

cleaner

To

carburetor

air

cleaner

Secondary

air

To

carburetor

air

cleaner

J

erCOndary

r

r

EC294

Fig

EC

20

Air

pump

relief

valve

Emission

Control

System

Emargency

air

retial

valve

E

A

R

Valve

California

models

The

emergency

air

relief

valve

con

trols

the

quantity

of

secondary

air

fed

from

the

air

pump

according

to

load

condition

and

it

discharges

the

see

ondary

air

into

the

atmosphere

to

prevent

overheating

of

the

catalytic

converter

The

emergency

air

relief

valve

con

sists

of

a

diaphragm

a

spring

and

a

valve

which

is

coupled

to

diaphragm

1

Diaphragm

2

Val

3

Spring

4

Diaphragm

chamber

EC536

Fig

EC

21

mergency

air

relief

valve

OPERATION

As

mentioned

previously

there

are

two

types

of

Air

Injection

Systems

A

I

S

a

non

California

type

and

a

California

type

The

California

stand

ard

type

includes

a

system

which

controls

injection

of

secondary

air

so

as

to

assure

proper

function

of

the

catalytic

converter

and

a

system

which

controls

the

supply

of

second

ary

air

to

prevent

abnormal

tempera

tUfe

rise

in

the

catalytic

converter

The

A

I

S

consists

of

the

following

systems

L

A

system

which

allows

injection

of

secondary

air

into

the

exhaust

port

2

A

system

which

bypasses

sec

ondary

air

from

the

air

pump

relief

valve

to

the

carburetor

air

cleaner

during

high

speed

engine

operation

3

A

system

which

supplies

air

from

the

carburetor

air

cleaner

to

the

intake

manifold

by

means

of

the

anti

backfire

valve

so

as

to

prevent

after

fire

during

deceleration

4

A

system

which

controls

injection

of

the

secondary

air

by

means

of

the

air

control

valve

so

as

to

maintain

the

catalytic

converter

at

an

optimum

temperature

level

under

lightly

loaded

condi

tions

Califomia

type

only

5

A

system

which

controls

the

sup

ply

of

secondary

air

through

the

emer

gency

air

relief

vilve

io

pfevent

ab

normal

temperature

rise

of

the

cataly

tic

converter

California

type

only

A

I

S

operation

is

as

follows

I

I

t

1

r

9

I

Air

pump

6

Check

valve

I

0

L

2

Air

pump

air

deaner

7

Air

gallery

pipe

3

Air

relief

valve

8

Injection

non

e

r

4

Air

cleaner

9

Exhaust

manifold

5

Carburetor

10

Anti

backflIe

valve

EC179

Fig

EC

22

Non

California

type

A

I

S

EC

12

Page 147 of 537

9

From

air

pump

l

h

1

Not

actuated

REMOVAL

AND

INSTALLATION

Air

p

mp

sir

cleaner

Remove

air

hose

then

detach

air

cleaner

from

hoodledge

Air

cleaner

element

and

Ii

r

deancr

lower

body

are

built

into

a

unit

construction

Replace

air

cleaner

clcl

nen

and

lower

body

as

an

assembly

J

J

tt

c

t

o

J

EC

323

Fig

EC

26

Replacing

oir

cleaner

element

Air

pum

Remove

air

hoses

from

air

pump

2

Loosen

air

pump

adjusting

bar

mounting

bolts

and

air

pump

mount

ing

bolts

then

remove

air

pump

drive

bell

3

Remove

air

pump

pulley

4

Remove

air

pump

from

bracket

Air

control

valve

California

models

l

Disconnect

air

hoses

and

a

vacu

um

hose

from

air

control

valve

2

Remove

air

con

trol

valve

from

bracket

E

A

R

valve

California

modela

Remove

vacuum

pipe

and

air

hose

and

dismount

E

A

R

valve

Emission

Control

System

o

jJ

To

Intake

mamfold

rF

vacuum

r

To

air

cleaner

From

air

pump

EC781

Fig

EC

27

Locotion

of

E

A

R

wive

Antl

backflravalve

Disconnect

air

hose

and

vacuum

hose

from

anti

backfire

valve

Check

valve

Disconnect

hose

and

remove

check

valve

from

air

gallery

pipe

Air

ganery

pIpe

andinJactlon

nozzles

It

is

very

difficult

to

remove

the

air

gallery

from

the

exhaust

manifold

without

bending

the

pipe

which

could

result

in

fractures

or

leakage

There

fore

removal

of

the

air

gallery

pipe

and

injection

nozzles

should

be

under

taken

only

when

they

are

damaged

I

Lubricate

around

the

connecting

portion

of

air

injection

nozzle

and

air

gallery

with

engine

oil

2

Hold

air

injection

nozzle

hexagon

head

with

a

wrench

and

unfasten

flare

screw

connecting

ait

gallery

to

injec

tion

nozzle

Remove

air

gallery

EC

14

To

intake

manifold

vaCUl

lm

r

Y

4

9

Gf

T

I

To

air

cleaner

I

Actuated

EC299

Fig

EC

25

Operation

of

air

control

value

Notes

a

Apply

engine

011

to

rews

several

times

during

above

work

b

Be

atreful

not

to

damage

other

parts

3

Unfasten

air

injection

nozzle

from

cylinder

head

applying

engine

oil

to

screwed

portion

several

times

4

Check

air

gallery

and

nozzle

for

fractures

or

leakage

Clean

air

injection

nozzle

with

a

wire

brush

5

At

time

of

installation

hold

air

injection

nozzle

hexagon

head

with

a

wrench

and

tighten

air

gallery

flange

screw

to

a

torque

of

5

0

to

5

9

kg

m

36

to

43

ft

lb

6

Check

cylinder

head

air

injection

nozzle

and

air

gallery

for

leaks

with

engine

running

Air

pump

relief

vslve

Loosen

carburetor

air

cleaner

mounting

sc

ews

and

remove

air

pump

relief

valve

InstallatIon

Install

in

the

reverse

order

of

reo

moval

DISASSEMBLY

AND

ASSEMBLY

Disassembly

of

air

pump

1

Remove

four

pulley

drive

bolts

and

remove

pulley

from

hub

2

Secure

air

pump

drive

hub

in

a

vise

as

shewn

in

Figure

EC

28

and

remove

four

end

cover

bolts

Page 151 of 537

Air

pump

I

Operate

engine

until

it

reaches

normal

operating

temperature

2

Inspect

all

hose

hose

connec

tions

and

air

gallery

for

leaks

and

correct

if

necessary

before

checking

air

injection

pump

3

Check

air

injection

pump

belt

tension

and

adjust

to

specifications

if

necessary

4

Disconnect

air

supply

hose

at

check

valve

5

Disconnect

vacuum

hose

from

the

air

control

valve

California

type

only

6

Insert

open

pipe

end

of

Air

Pump

Test

Gauge

Adapter

STl9870000

in

air

supply

hose

Clamp

hose

securely

to

adapter

to

prevent

it

from

blowing

out

Position

adapter

and

test

lli

uge

so

that

air

blast

emitted

through

drilled

pipe

plug

will

be

harmlessly

dissipated

7

Install

a

tachometer

on

engine

With

engine

speed

at

2

600

rpm

ob

serve

pressure

produced

at

test

gauge

Air

pressure

should

be

100

mmHg

3

94

inHg

or

more

8

If

air

pressure

does

not

meet

above

specifications

proceed

as

fol

lows

I

Repeat

2

and

3

above

2

Disconnect

air

supply

hose

at

anti

backfire

valve

Plug

air

hose

open

ing

and

screw

with

a

clamp

Repeat

pressure

test

3

With

engine

speed

at

1

500

rpm

close

hole

of

test

gauge

with

finger

If

a

leaking

sound

is

heard

or

leaking

air

is

felt

by

ftnger

at

relief

valve

relief

valve

is

malfunctioning

Relief

valve

should

be

replaced

or

repaired

4

If

air

injection

pump

does

not

meet

minimum

requirement

of

pres

sure

test

it

should

be

replaced

Control

valve

The

following

procedures

are

reo

commended

for

checking

and

or

as

certaining

that

the

various

components

of

the

exhaust

emission

con

Irol

system

are

operating

properly

The

engine

and

all

components

must

be

at

normal

operating

tempera

tures

when

the

tests

are

performed

Prior

to

performing

any

extensive

diag

nosis

of

the

exhaust

control

system

it

Emission

Control

System

must

be

determined

that

the

engine

as

a

unit

is

functioning

properly

Check

valva

Warm

up

engine

thoroughly

2

Disconnect

hose

leading

to

check

valve

from

air

hose

COJUlector

3

Check

hose

opening

for

any

indi

cation

of

exhaust

gas

leaks

Ifleaks

are

detected

replace

check

valve

4

Race

the

engine

lightly

at

about

2

000

cpm

and

then

return

it

to

idling

VisuaDy

check

the

hose

for

any

indication

of

exhaust

gas

leaks

before

the

engine

returns

to

idling

speed

If

leaks

are

detected

replace

check

valve

EC310

Fig

EC

43

Checking

check

valve

Air

pump

raIle

valve

After

completing

inspection

of

air

pump

check

air

pump

relief

valve

in

the

following

steps

J

Disconnect

hoses

leading

to

check

valve

and

air

control

valve

from

air

hose

connector

and

install

blind

cap

to

the

connector

2

With

engine

running

at

about

3

000

rpm

under

no

load

place

your

hand

on

the

air

outlet

of

air

pump

relief

valve

to

check

for

discharged

air

If

no

air

is

felt

replace

the

air

pump

relief

valve

EC311

Fig

EC

44

Checking

air

pump

relief

valve

EC

18

Air

control

valve

C

U

ornla

models

I

Warm

up

engine

thoroughly

2

Before

checking

air

control

valve

check

all

hoses

for

loose

connection

leaks

etc

and

repair

or

correct

if

necessary

3

With

engine

idling

disconnect

the

outlet

side

hose

of

the

air

control

valve

and

place

your

hand

on

the

air

hose

outlet

to

check

for

air

If

no

air

is

felt

replace

the

air

control

valve

4

Pull

vacuum

hose

off

from

air

con

trol

valve

If

discharge

of

air

from

air

hose

stops

the

air

con

trol

valve

is

normaL

If

discharge

is

still

felt

replace

the

valve

Plug

up

the

removed

vacuum

hose

to

stabilize

engine

running

EC312

Fig

EC

45

Checking

air

control

valve

Emarsancy

air

rella

valve

E

A

R

Valve

lCalHornla

models

L

Warm

up

engine

thoroughly

2

Before

checking

air

control

valve

check

all

hoses

for

loose

connection

leaks

etc

and

repair

or

correct

if

necessary

3

Race

engine

approximately

2

000

rpm

under

no

load

Place

your

hand

on

air

outlet

of

E

A

R

valve

to

check

for

presence

of

discharged

air

If

no

air

is

felt

E

A

R

valve

is

normal

4

Disconnect

vacuum

hose

from

B

A

R

valve

as

shown

in

Figure

EC

46

Page 152 of 537

Race

engine

approximately

2

000

rpm

under

no

load

Place

your

hand

on

air

outlet

of

E

A

R

valve

to

check

for

presence

of

discharged

air

If

air

is

felt

E

A

R

valve

is

normaL

5

If

E

A

R

valve

does

not

function

properly

at

above

steps

replace

E

A

R

valve

To

air

pump

I

ET267

Fig

EC

46

Cheeking

E

A

R

volve

Anti

backfire

valve

A

valve

Warm

up

engine

thoroughly

2

Disconnect

hose

from

air

cleaner

and

place

a

finger

near

the

outlet

3

Run

engine

at

about

3

000

rpin

under

no

load

then

quickly

cetum

it

to

idling

If

you

feel

a

pull

or

suction

force

on

your

finger

the

anti

backfire

valve

is

functioning

normally

If

no

suction

is

felt

replace

the

anti

backflre

valve

Fig

EC

47

Checking

anti

backfire

valve

1

t

D

I

Y1

VI

I

ID

4

JO

0

2

E

C

R

control

valve

3

E

C

R

passage

4

Intake

manifold

5

Thermal

vacuum

valve

6

E

C

R

tube

7

Exhaust

manifold

Emission

Control

System

tXHAUST

GAS

RECIRCULATION

CONTROL

SYSTEM

E

G

R

DESCRIPTION

In

the

exhaust

gas

recirculation

system

a

part

of

the

exhaust

gas

is

returned

to

the

combustion

chamber

to

lower

the

spark

flame

temperature

during

combustion

This

results

in

a

reduction

of

the

nitrogen

oxide

con

ten

t

in

the

exhaust

gas

The

exhaust

gas

recirculation

sys

tem

consists

of

an

E

G

R

passage

E

G

R

con

trol

valve

thermal

vacuum

volve

E

G

R

tube

and

hose

A

warn

@

I

ing

system

which

indicates

when

the

E

G

R

control

system

must

be

in

spected

is

also

installed

in

all

620

models

except

those

bound

for

Coli

fornia

and

Canada

When

the

E

G

R

con

trol

valve

is

open

some

of

the

exhaust

gas

is

led

from

the

exhaust

manifold

to

the

E

G

R

chamber

through

the

E

G

R

passage

The

exhaust

gas

is

then

con

trolled

in

quantity

by

the

E

G

R

valve

and

is

introduced

into

the

intake

manifold

Open

c1ose

operation

of

the

E

G

R

control

valve

is

controlled

by

the

thermal

vacuum

valve

which

opera

tes

on

carburetor

vacuum

and

engine

cool

ant

temperature

EC349

Fig

EC

4

Exhaust

Gas

Recirculation

system

E

G

R

E

G

R

system

operating

Thermal

Intake

manifold

E

G

R

Remarks

E

G

R

water

temperature

oC

OF

vacuum

valve

vacuum

control

valve

Below

570C

135OF

Close

Close

Non

california

Above

MfT

models

only

Idling

Not

Above

57

to

630C

Open

70

mmHg

Close

actuated

135

to

145OF

76

inHg

California

models

Below

and

N

on

Fullthrollle

f

alifomia

AfT

Above

57

to

6

oC

models

Actua

ted

Open

Above

50

mmHg

Open

135

to

145OF

1

97

inHg

EC

19

OPERATION

Operation

of

E

G

R

system

is

as

shown

below