air condition DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 511 of 537

Air

Conditioning

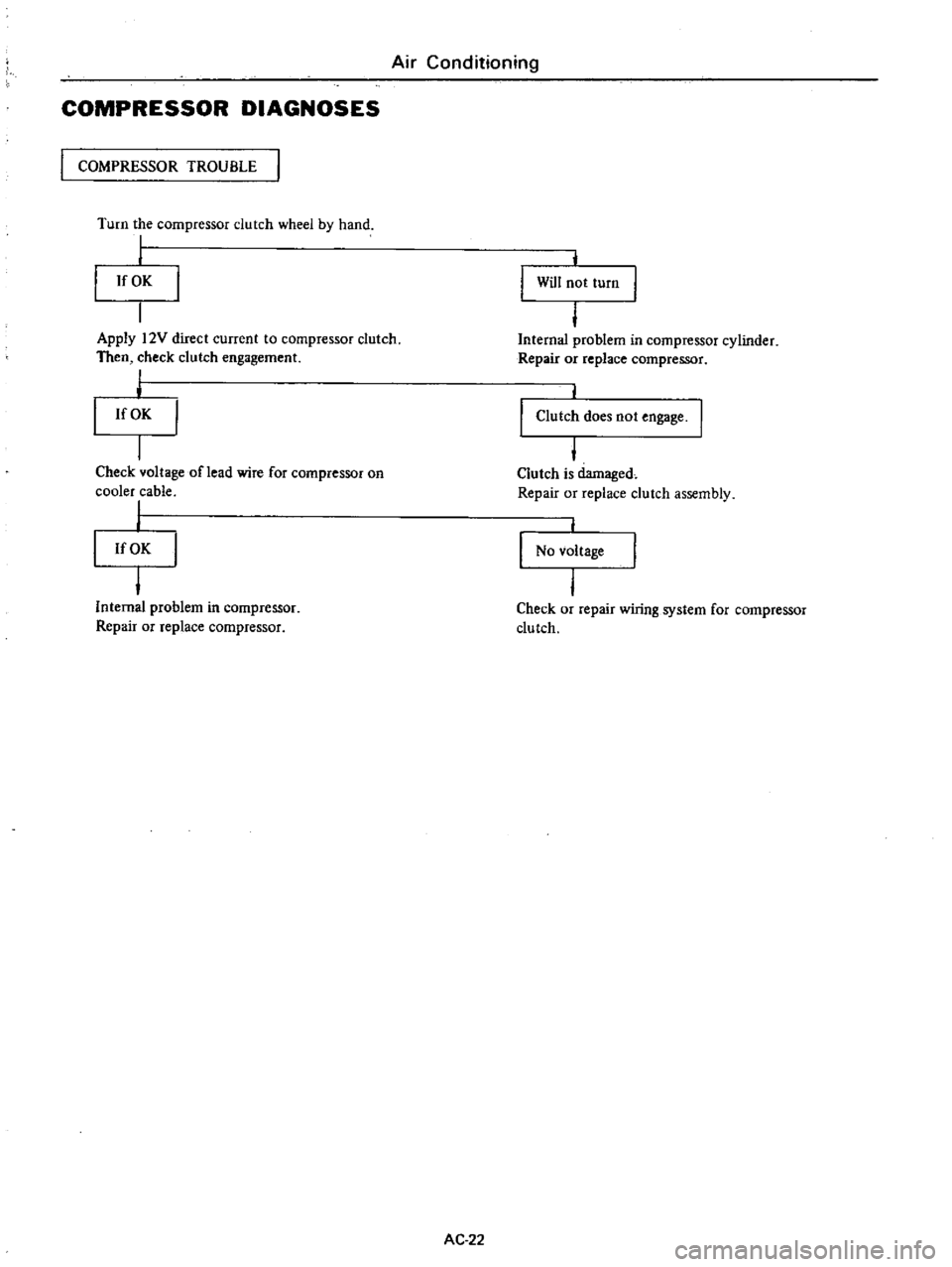

COMPRESSOR

DIAGNOSES

I

COMPRESSOR

TROUBLE

Turn

the

compressor

dutch

wheel

by

hand

I

I

If

OK

j

Will

not

turn

Apply

12V

direct

current

to

compressor

clutch

Then

check

clutch

engagement

I

j

If

OK

I

Internal

problem

in

compressor

cylinder

Repair

or

replace

compressor

Check

voltage

oflead

wire

for

compressor

on

cooler

cable

I

I

If

OK

I

Clutch

does

not

engage

I

Clutch

is

damaged

Repair

or

replace

dutch

assembly

No

voltage

I

Internal

problem

in

compressor

Repair

or

replace

compressor

Check

or

repair

wiring

system

for

compressor

clutch

AC

22

Page 512 of 537

Air

Conditioning

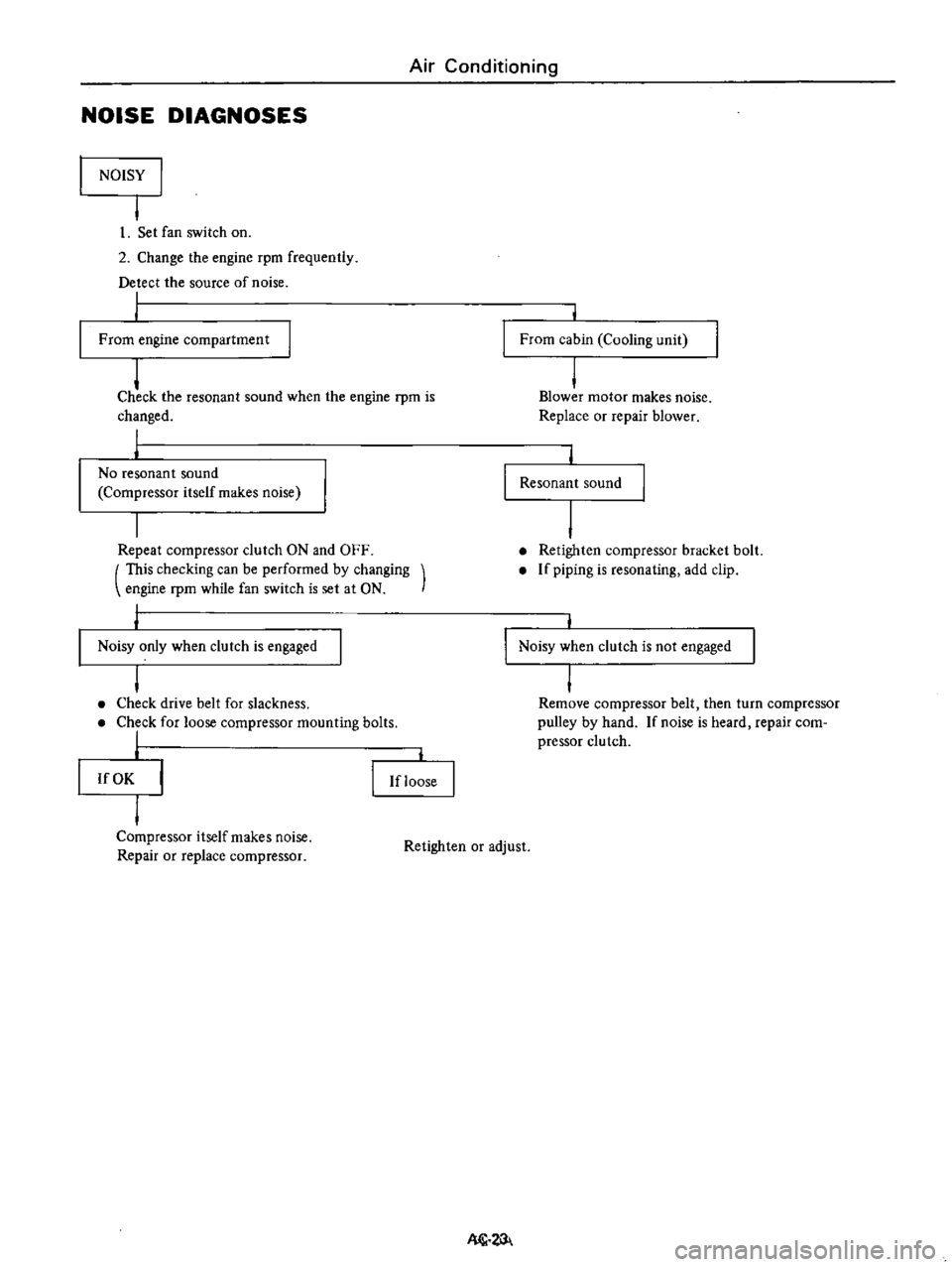

NOISE

DIAGNOSES

NOISY

I

I

I

Set

fan

switch

on

2

Change

the

engine

rpm

frequently

Detect

the

source

of

noise

I

From

engine

compartment

From

cabin

Cooling

unit

j

Check

the

resonant

sound

when

the

engine

rpm

is

changed

I

I

No

resonant

sound

Compressor

itself

makes

noise

j

Blower

motor

makes

noise

Replace

or

repair

blower

Resonant

sound

Repeat

compressor

clutch

ON

and

OFF

This

checking

can

be

performed

by

changing

engine

rpm

while

fan

switch

is

set

at

ON

Retighten

compressor

bracket

bolt

If

piping

is

resonating

add

clip

Noisy

only

when

clutch

is

engaged

Noisy

when

clutch

is

not

engaged

I

Check

drive

belt

for

slackness

Check

for

loose

compressor

mounting

bolts

I

I

Remove

compressor

belt

then

turn

compressor

pulley

by

hand

If

noise

is

heard

repair

com

pressor

clutch

If

OK

If

loose

Compressor

itself

makes

noise

Repair

or

replace

compressor

Retighten

or

adjust

Nl1

Page 513 of 537

Air

Conditioning

BLOWER

MOTOR

DIAGNOSES

Blower

motor

inoperative

Check

fuse

In

fuse

block

15A

W

Single

fuse

15A

at

cooling

unit

I

j

If

OK

Check

the

continuity

and

fitting

of

fan

switch

I

I

If

OK

I

I

Connect

fan

switch

to

wiring

harness

2

Turn

the

ignition

switch

ON

IG

3

Set

fan

switch

at

ON

1

2

or

3

position

Check

the

voltage

for

blower

motor

Blue

lead

wire

is

poweI

source

Blue

wire

with

white

stripe

is

for

grounding

I

I

Voltage

I

I

Check

the

continuity

and

fitting

of

resistance

on

cooling

unit

I

I

If

OK

If

damaged

I

I

Replace

blower

motor

Replace

resistance

AC

24

mown

fuse

Replace

fuse

j

If

damaged

I

I

Replace

fan

switch

No

voltage

Replace

main

relay

Page 514 of 537

Air

Conditioning

REMOVAL

AND

INSTALLATION

COMPRESSOR

REMOVAL

INSTALLATION

IDLER

PULLEY

FAN

BELT

TENSION

ADJUSTMENT

REMOVAL

AND

INSTALLATION

INSPECTION

COOLING

UNIT

REMOVAL

AND

INSTALLATION

DISASSEMBLY

AND

ASSEMBLY

INSPECTION

RECEIVER

DRYER

AND

PIPING

COMPRESSOR

REMOVAL

I

Remove

battery

2

Disconnect

compressor

lead

wire

at

connector

3

Loosen

idler

pulley

lock

nut

then

adjusting

bolt

Remove

compressor

drive

belt

from

compressor

pulley

AC477

Fig

AC

28

Removing

drive

belt

4

Discharge

system

Refer

to

Dis

charging

System

under

General

Service

section

CONTENTS

AC

25

AC25

AC26

AC

27

AC

27

AC27

AC

27

AC27

AC

27

AC

2B

AC

29

AC

29

REMOVAL

AND

INSTALLATION

INSPECTION

WIRING

HARNESS

AND

COMPONENTS

WIRING

DIAGRAM

MAINTENANCE

MAIN

RELAY

COMPRESSOR

RELAY

FAN

SWITCH

RESISTOR

FOR

FAN

SWITCH

THERMO

SWITCH

F

I

C

D

SOLENOID

VALVE

AC29

AC29

AC30

AC30

AC31

AC31

AC31

AC31

AC32

AC32

AC

32

5

Remove

flexible

hose

fixing

plate

and

disconnect

low

and

high

pressure

flexible

hoses

from

compressor

Notes

a

Use

two

wrenches

when

disconnect

ing

pipe

joints

b

Plug

flexible

hose

and

compressor

joint

openings

immediately

after

disconnection

to

prevent

entry

of

dust

moisture

laden

air

etc

Fig

AC

29

Disconnecting

ftexible

hoses

from

compressor

6

Remove

bolts

securing

fuel

tube

to

compressor

attachment

AC

25

Y

1

L

AC744

7

Remove

four

bolts

securing

com

pressor

to

its

bracket

Compressor

and

attachment

can

now

be

detached

as

an

assembly

Notes

a

There

are

a

total

of

four

bolts

two

on

upper

side

of

bracket

and

two

on

lower

side

of

compreSsor

Loosen

upper

bolts

and

remove

lower

bolts

When

removing

upper

bolts

securely

hold

compressor

with

one

hand

b

When

installing

temporarily

tighten

upper

bolts

then

tighten

lower

bolts

Page 515 of 537

2

R

C7

c

L

PJJ

I

8

INSTALLATION

a

c

J

l

i

rp

To

install

compressor

reverse

the

order

of

removal

Observe

the

follow

ing

nhlJo

e

trorf

1001

vom

R

i

n3

Wheliqli

liiAniitg

fiil

l

in

pt

l

witlil

tiiel

sam

efuouiitITof

b11

1fasitlult

used

previously

v

d

rnl

2

Oil

capacity

new

compressor

O

910

1

owt

llllt

blj

f

H

w

s

013

5

rlT

s

0

111

boc

19

bB1rllo

bi2

qqll

no

e

l

bffik

kuanM

mpdi

x

of

Jli

oln

L

il

m

1IlffiiOrb

fler

ot

oldm

F

n

Cheo

f

undeF

r

n

al

1

aQ

r1tIU

Jt

t31

HClJI1

t

JIVU

i

rlUI

1o

ifm

ft

q

t

VI

31U

S

ltlod

bnM

UfO

l

W

kldf

CJiJi

ti

WIf

nl

L

llil

g

ncn

d

oressor

M

et

illpuntinl

botts

if

l9Wul

fb

i

l

fI

I

l

1Ttio

l

qqlJ

necessary

re

Ighten

I

d

210

Air

Conditioning

Tightening

torque

Flexible

hose

to

compressor

dl

t

kg

J

l

IQ

1

Tf

es

oriti

ra

Lbolts

IbP

fo

o15g

m

J

r

f6i

o

20

i

il

f

J

rt

I

r

aGket

engine

Dons

1

1

0

1

1

3

16

5

l11fd

1l

V

f

42

3

3U

llif

Yl

I

u

y

j

3

D

not

remove

IJgs

orflexibie

1i6

e

before

ready

for

immediate

use

4l

di

Wheniiinstallingccomptess

i

turn

it

serWfiPtiffies

SlOt

5

When

connecting

flexible

hose

to

9mPr

ssor

apD

v

a

coat

of

Hfresh

JU

UI

l1Il

t

2

JIUU

uOHltl

r

fl

compressor

0

1

to

fs

aHn

lurfaces

of

1n

1l11

JJ

J

f

PJU

Ht

UlUJ

jJ

joints

AC

26

5

1

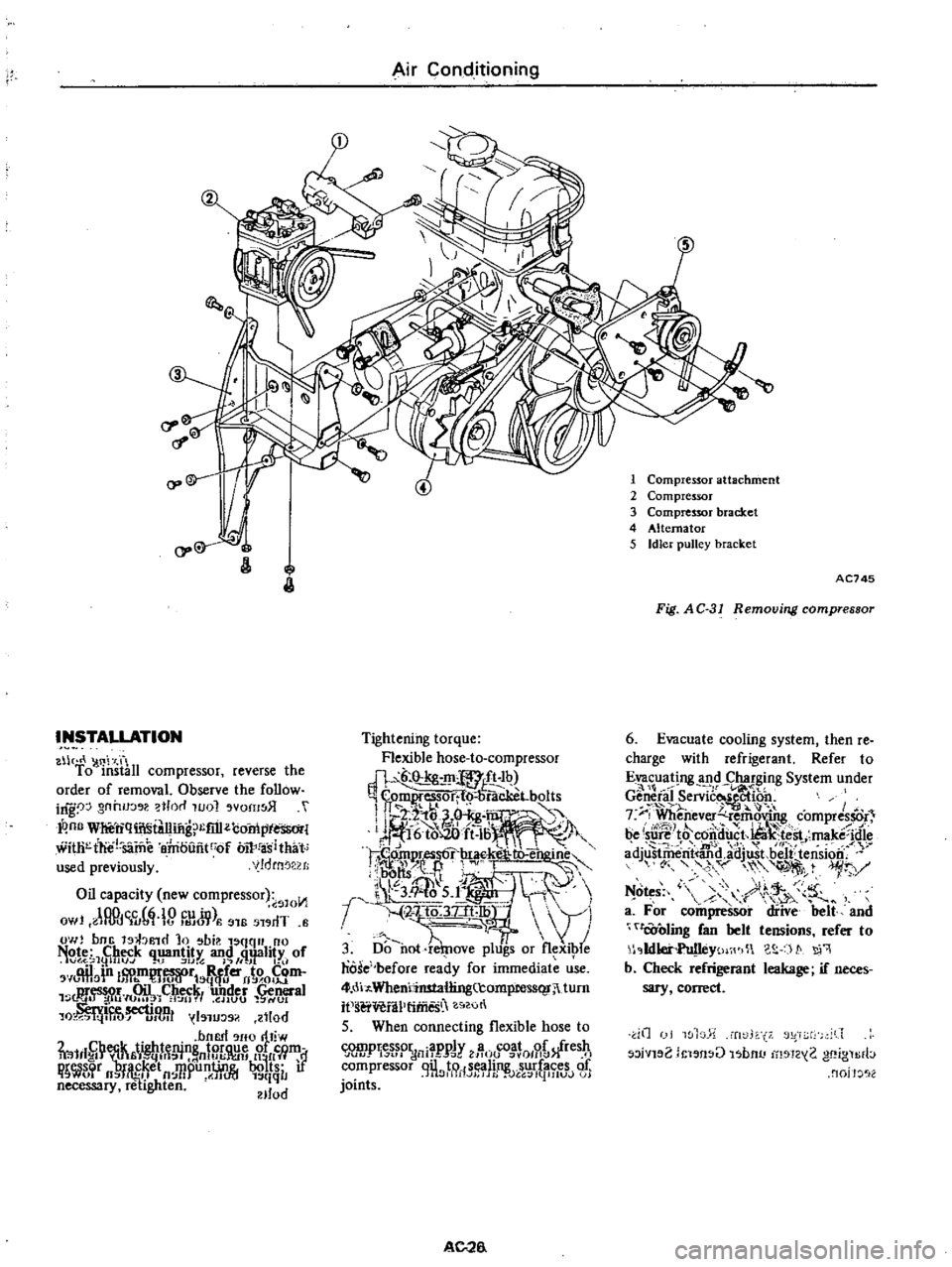

Compressor

attachment

2

Compressor

3

Compressor

bracket

4

AHernator

5

Idler

pulley

bracket

AC745

Fig

AC

31

Removing

compressor

6

Evacuate

cooling

system

then

re

charge

with

refrigerant

Refer

to

Evacuating

and

Charging

System

under

l

r

Gen

efal

Servic

ectioo

f

iI

t

7

F

Whenever

remoV

J

compres

r

be

su

J

t8

C6itiu

t

Ua

t

st

make

idie

mV

i

1rJ

adjustril

rit

and

adjwt

beJf

tension

yv

1

r

Y

N

o

s

9

r

h

v

a

For

compressor

diive

belt

and

tOoling

fan

belt

tensions

refer

to

1

Ildlet

Yt

j

WI

c

S

t

q

b

Cheok

refrigerant

leakage

if

neces

sary

correct

dO

I

wl

Tw

l

rt

f

r2

iVl

2

i

l

n

U

l

bnu

1

1Z

2

gf

ign

rb

nojJ

2

Page 516 of 537

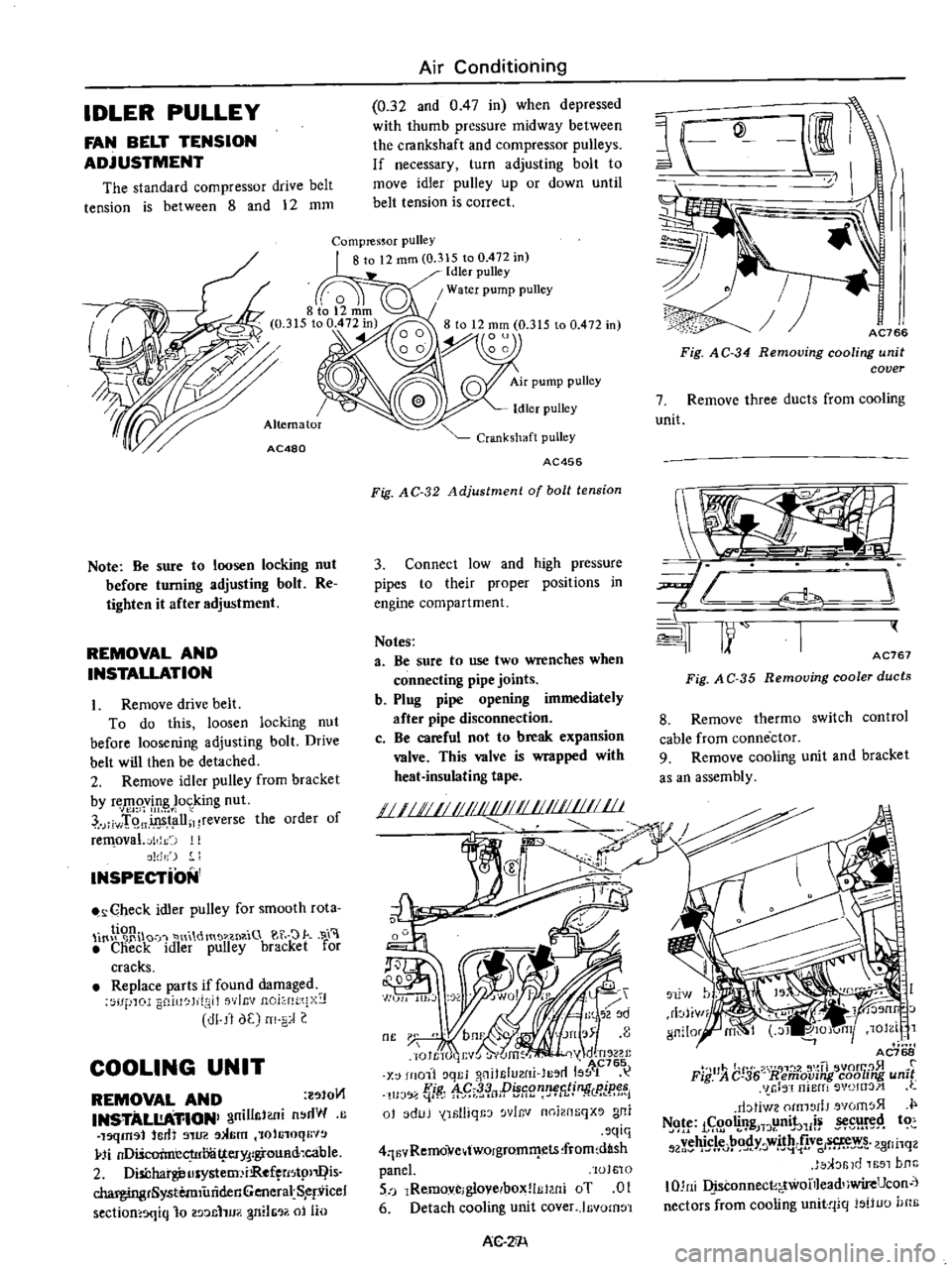

IDLER

PULLEY

FAN

BELT

TENSION

ADJUSTMENT

The

standard

compressor

drive

belt

tension

is

between

8

and

12

mm

AC480

Note

Be

sure

to

loosen

locking

nut

before

turning

adjusting

bolt

Re

tighten

it

after

adjustment

REMOVAL

AND

INSTALLATION

Remove

drive

belt

To

do

this

loosen

locking

nut

before

loosening

adjusting

bolt

Drive

belt

will

then

be

detached

2

Remove

idler

pulley

from

bracket

by

r

J1e

vM

or

king

nut

jiwT

9ff

t

llil

reverse

the

order

of

rerr

oval

jldJ

1

t

Jldr

J

I

INSPECTiON

Oheck

idler

pulley

for

smooth

rota

tion

G

0

llfHt

H

Y

d

H

u

t

1

W

n

l

ot

Jrk

H

l

Check

i

ler

pulley

bracket

for

cracks

Replace

arts

iffound

damaged

c

f

lOJ

gD

IlI

J

l

gtt

flvlnv

nOj

IH

q

g

cll

dE

m

J

COOLING

UNIT

REMOVAL

AND

oM1

INSTALl

A

1lIONI

gnillslUli

n

dW

C

19qm91

crft

llU2

3

6rn

f01

Gl0ql

pj

nDiScoimecprlY

i

ferY

lgroUR

hable

2

Disbhargiou

y

tem

iRefrflsll

Qis

chargingrSystemiillidenGeneral

S

ervicel

sectiom5qiq

10

2

9

fl

1U

n

1Ii

2

oj

liD

Air

Conditioning

0

32

and

0

47

in

when

depressed

with

thumb

pressure

midway

between

the

crankshaft

and

compressor

pulleys

If

necessary

turn

adjusting

bolt

to

move

idler

pulley

up

or

down

until

belt

tension

is

correct

Idler

pulley

Crankshaft

pulley

AC456

Fig

AC

32

Adjustment

of

bolt

tension

3

Connect

low

and

high

pressure

pipes

to

their

proper

positions

in

engine

compartment

Notes

3

Be

sure

to

use

two

wrenches

when

connecting

pipe

joints

b

Plug

pipe

opening

immediately

after

pipe

disconnection

c

Be

careful

not

to

break

expansion

valve

This

valve

is

wrapped

with

heat

insulating

tape

0

J

JWu

J

1

2

ld

m

bm

Ufl

J51

8

I

1

lEldgJ

v

Jwm

j

y

d

n

l2u

1

C765

X

fIlO

1i

qJ

j

gnjlcfu2fIJ

lc

rf

1551

1UJ

flip

1h

tqnPfffi2n

Wfi

i

V1c

ip

j

at

3duJ

lsIliqr

J

wlr

v

n

irWfiqX

ani

qiq

4q

v

Remo

e

tworgromll

ets

from

dash

panel

lots

n

5

lRemove

glovelbox

lBl

n1

oT

0

6

Detach

cooling

unit

cover

Icyom

n

AC

ZA

AC766

Fig

AC

34

Removing

cooling

unit

cover

7

Remove

three

ducts

from

cooling

unit

i

j

l

I

11

AC767

Fig

A

C

35

Removing

cooler

ducts

8

Remove

thermo

switch

control

cable

from

conne

ctor

9

Remove

cooling

unit

and

bracket

as

an

assembly

J

t

AC768

F

lIJAh

Cr

P

3

6

R

1

7

fi

vorr

l

l51

r

Ig

emo

vmg

coo

mg

um

r

n

I1iBITJ

0HJ

Jl

t

rbtivl2

Ofm

IIfj

wom

51

f

H

f

L

ol

IJgjjJpn

1I

SH

tc

vehicle

bn

y

with

five

rews

q

2tl

G

i

O

r

Jv

a8f1l1

J

a

I

ld

1

51

b

nc

IOJni

QisconnecEf

twonleadliwif

eUcon

1

nectars

from

cooling

unitqiq

s

iuo

UHf

Page 517 of 537

I

o

Fig

AC

37

Disconnectirt

connector

3

DISASSEMBLY

AND

ASSEMBLY

I

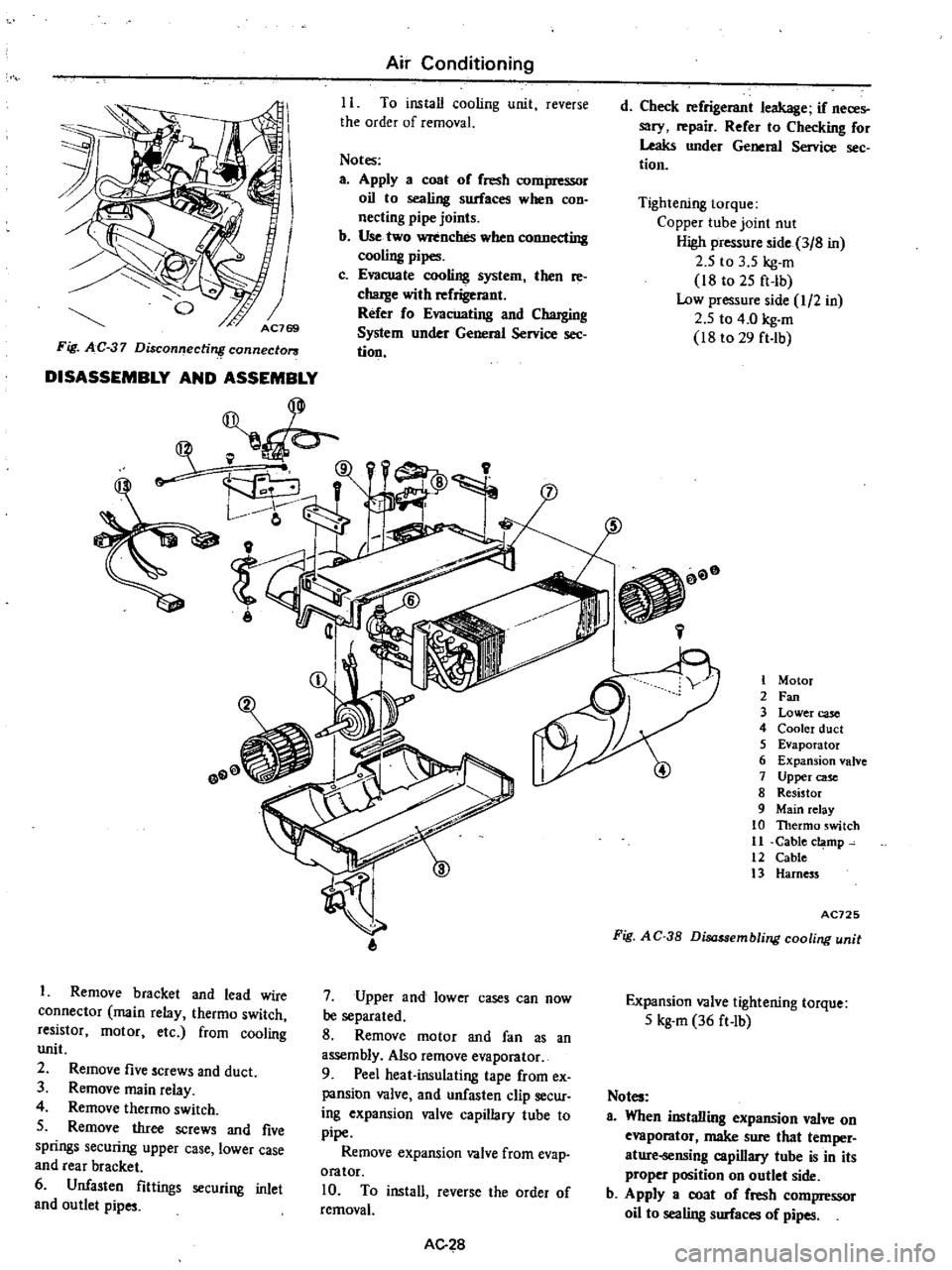

Remove

bracket

and

lead

wire

connector

main

relay

thermo

switch

resistor

motor

etc

from

cooling

unit

2

Remove

five

screws

and

duct

3

Remove

main

relay

4

Remove

thermo

switch

5

Remove

three

screws

and

five

springs

securing

upper

case

lower

case

and

rear

bracket

6

Unfasten

fittings

securing

inlet

and

outlet

pipes

Air

Conditioning

11

To

install

cooling

unit

reverse

the

order

of

removal

Notes

a

Apply

a

coat

of

fresh

compressor

oil

to

sealing

surfaces

when

COD

necting

pipe

joints

b

Use

two

wrenches

when

connecting

cooling

pipes

c

Evacuate

cooling

system

then

re

chaJge

with

refrigerant

Refer

fo

Evacuating

and

Charging

System

under

General

Service

see

tion

9

7

Upper

and

lower

cases

can

now

be

separated

8

Remove

motor

and

fan

as

an

assembly

Also

remove

evaporator

9

Peel

heat

insulating

tape

from

ex

pansion

valve

and

unfasten

clip

secur

ing

expansion

valve

capillary

tube

to

pipe

Remove

expansion

valve

from

evap

orator

10

To

install

reverse

the

order

of

removal

AG

28

d

Check

refrigerant

leakage

if

neces

sary

repair

Refer

to

Checking

for

Leaks

under

General

Service

sec

tion

Tightening

torque

Copper

tube

joint

nut

High

pressure

side

3

8

in

2

5

to

3

5

kg

m

18

to

25

ft

lb

Low

pressure

side

I

2

in

2

5

to

4

0

kg

m

18

to

29

ft

lb

00

L

1

Motor

2

Fan

3

Lower

case

4

Cooler

duct

5

Evaporator

6

Expansion

valve

7

Upper

case

8

Resistor

9

Main

relay

10

Thermo

switch

11

Cable

c

mp

12

Cable

3

Harness

AC725

Fig

A

C

38

Disassembling

cooling

unit

Expansion

valve

tightening

torque

5

kg

m

36

ft

Ib

Notes

a

When

installing

expansion

valve

on

evaporator

make

sure

that

temper

ature

oensing

capillary

tube

is

in

its

proper

position

on

outlet

side

b

Apply

a

coat

of

fresh

compressor

oil

to

sealing

surfaces

of

pipes

Page 518 of 537

INSPECTION

Evaporator

Check

evaporator

for

leakage

or

damage

If

damaged

replace

Expansion

valve

Check

expansion

valve

for

leakage

or

clogging

If

clogged

clean

filter

in

expansion

valve

If

damaged

replace

RECEIVER

DRYER

AND

PIPING

REMOVAL

AND

INSTAUATION

Receiver

dryer

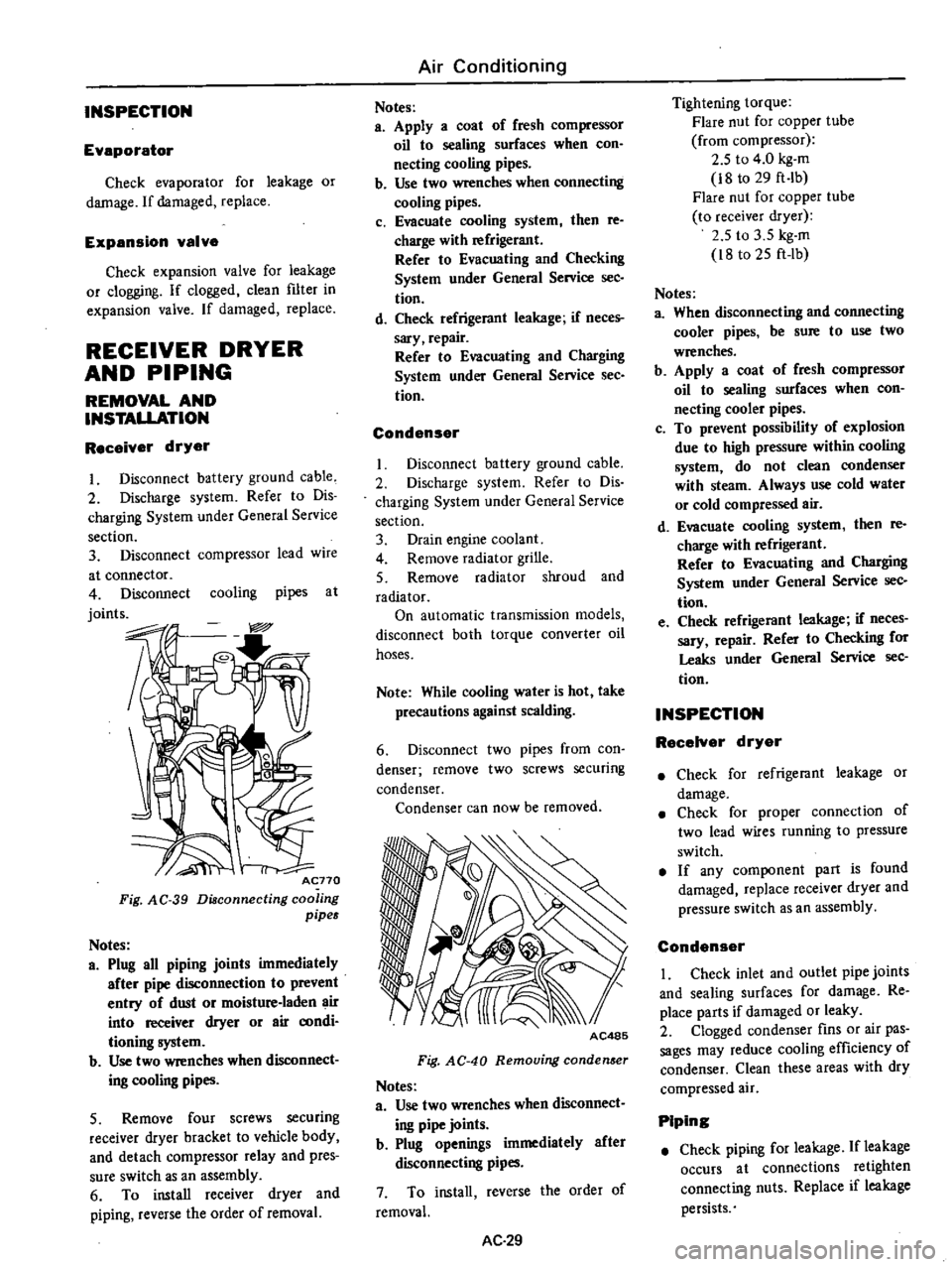

I

Disconnect

battery

ground

cable

2

Discharge

system

Refer

to

Dis

charging

System

under

General

Service

section

3

Disconnect

compressor

lead

wire

at

connector

4

Disconnect

cooling

pipes

at

joints

Acno

Fig

AC

39

Diaconnecting

coo

ing

pipes

Notes

a

Plug

all

piping

joints

immediately

after

pipe

disconnection

to

prevent

entry

of

dust

or

moisture

laden

air

into

receiver

dryer

or

air

aJOdi

tioning

system

b

Use

two

wrenches

when

dIsconnect

ing

cooling

pipes

5

Remove

four

screws

securing

receiver

dryer

bracket

to

vehicle

body

and

detach

compressor

relay

and

pres

sure

switch

as

an

assembly

6

To

install

receiver

dryer

and

piping

reverse

the

order

of

removal

Air

Conditioning

Notes

a

Apply

a

coat

of

fresh

compressor

oil

to

sealing

surfaces

when

con

necting

cooling

pipes

b

Use

two

wrenches

when

connecting

cooling

pipes

c

Evacuate

cooling

system

then

re

charge

with

refrigerant

Refer

to

Evacuating

and

Checking

System

under

General

Service

sec

tion

d

Check

refrigerant

leakage

if

neces

sary

repair

Refer

to

Evacuating

and

Charging

System

under

General

Service

See

tion

Condenser

Disconnect

battery

ground

cable

2

Discharge

system

Refer

to

Dis

charging

System

under

General

Service

section

3

Drain

engine

coolant

4

Remove

radiator

grille

5

Remove

radiator

shroud

and

radiator

On

automatic

transmission

models

disconnect

both

torque

converter

oil

hoses

Note

While

cooling

water

is

hot

take

precautions

against

scalding

6

Disconnect

two

pipes

from

con

denser

remove

two

screws

securing

condenser

Condenser

can

now

be

removed

AC485

Fig

AC

40

Removing

conden

er

Notes

a

Use

two

wrenches

when

disconnect

ing

pipe

joints

b

Plug

openings

immediately

after

disconnecting

pipes

7

To

install

reverse

the

order

of

removal

AC

29

Tightening

torque

Flare

nut

for

copper

tube

from

compressor

2

5

to

4

0

kg

m

i8

to

29

ft

Ib

Flare

nut

for

copper

tube

to

receiver

dryer

2

5

to

3

5

kg

m

i8

to

25

ft

lb

Notes

a

When

disconnecting

and

connecting

cooler

pipes

be

sure

to

use

two

wrenches

b

Apply

a

coat

of

fresh

compressor

oil

to

sealing

surfaces

when

con

necting

cooler

pipes

c

To

prevent

possibility

of

explosion

due

to

high

pressure

within

cooling

system

do

not

clean

condenser

with

steam

Always

use

cold

water

or

cold

compressed

air

d

Evacuate

cooling

system

then

re

charge

with

refrigerant

Refer

to

Evacuating

and

Charging

System

under

General

Service

sec

tion

e

Check

refrigerant

leakage

if

neces

sary

repair

Refer

to

Checking

for

Leaks

under

General

Service

sec

tion

INSPECTION

RecelYer

dryer

Check

for

refrigerant

leakage

or

damage

Check

for

proper

connection

of

two

lead

wires

running

to

pressure

switch

If

any

component

part

is

found

damaged

replace

receiver

dryer

and

pressure

switch

as

an

assembly

Condenser

I

Check

inlet

and

outlet

pipe

joints

and

sealing

surfaces

for

damage

Re

place

parts

if

damaged

or

leaky

2

Clogged

condenser

fins

or

air

pas

sages

may

reduce

cooling

efficiency

of

condenser

Clean

these

areas

with

dry

compressed

air

Piping

Check

piping

for

leakage

If

leakage

occurs

at

connections

retighten

connecting

nuts

Replace

if

leakage

persists

Page 519 of 537

Ll1

1t

W

l

THERMO

SWITCH

I

I

Air

Conditioning

WIRING

HARNESS

AND

COMPONENTS

WIRING

DIAGRAM

BW

c

J

ii

1

l

BW

La

GL

FROM

LIGHT

SWITCH

CJ

Id

lW

f

8

L

rRl

@

W

I

FUSE

15A

1

J

D

CJ

B

B

o

J

I

B

y

i

jqt

0

noc

I

no

vi

1

J

mcl

y

yldru

ao

11

jblr

J

H

WJ1

q

2f

br

r

t

lH

iot

f1

tH

o

hm

I

l

i

I

1

rf

l

t

f

r

dt

ll

II

h

J

IiJ

l

I

d

hi

s

n

Jq

DDj

G

w

TG

r

i

i

It

U

JI1

GH

Jdf

J

t

ggo

J

10

lHohfth

gniJuo

lUb

Jl

VUlt

l0

H

2

1

19

i

tl

b

wt

IO

t

l

lo

J

I

l

l

to

tJ

b

YR

lStO

Y1

1

t

J

I

FUSE

I

II

nlWI

I

bn

f

w

1

U

QI

llnio

fiq

ni

I

tsH

W

tflt

fli

htTin

lnl

O

J

11

IJ

i

Ji

fjI

i

i

11

i

ltll

ii

A

jll

I

I

I

gm

J

lIno

tl

Jl

JIIgiJ

l

1I0U

mflu

J

l

tllU

lJU

8

f

r

j

d

j

J

l1

Jlt

d

HInO

IG

to

l

VFJ

r1

rjJ

1

J

h

nI

0

i

IEvUID

l

il

1

i2

1

MN

k

B

gg

liii

gg

1

B

J

Ii

i

ELECTRIC

FUEL

PUMP

@

ILLUMINATION

CONTROL

RHEOSTAT

COLOR

CODE

B

Black

BW

Black

with

white

stripe

L

Blue

LW

Blue

with

white

stripe

LR

Blue

with

red

stripe

W

White

tll

G

GreeMnQ

r

iC

O

1

r

J

l

GL

Green

with

blue

stripe

R

L

Red

ith

blue

stripe

201011

lIt

J

m

I

W

tfli

I

o

lUll

IJ

Ub

OW

If

U

d

l

Q

I

ni

IGNITION

SWITCH

WIJIJJOO

W

l

Iuul

vomo

C

held

l

Jlb

vi

ia

1

1

tnd

15

W

le

llt

J

l

nq

LnJ

J

I

1

luil

mpHO

ibGt

L

D

lb

tldmoGl

nG

III

rbliw7

tHO

b

b

1

AC727

ns

1

j

fJ

l

YI

l

mtl

m

0

I

lfi

IO

fI

l

jg

h5

4

MjVj

IJC

p

i

W

i

1q

Page 520 of 537

MAINTENANCE

Replace

any

wiring

harness

which

is

cracked

deteriorated

or

poorly

in

sulated

Always

replace

wire

with

those

of

the

same

diameter

Do

not

use

wire

of

smaller

diameter

Where

necessary

securely

retain

wire

harnesses

with

clips

or

tapes

so

that

they

will

not

be

frayed

or

worn

by

vibration

Notes

a

Repair

or

replace

any

electrical

part

which

is

questionable

or

likely

to

cause

a

short

circuit

When

disconnecting

battery

cables

always

disconnect

ground

cable

be

fore

positive

cable

Clean

battery

and

terminals

before

connecting

cables

then

connect

positive

cable

and

ground

cable

in

that

order

Apply

a

coat

of

grease

to

terminals

to

prevent

rust

formation

b

Do

not

attempt

to

conduct

a

con

tinuity

test

with

a

screwdriver

or

service

tools

always

use

test

lead

wires

c

Do

not

ground

terminals

when

circuits

are

open

or

unloaded

always

use

a

test

lamp

12V

3W

or

circuit

tester

as

a

load

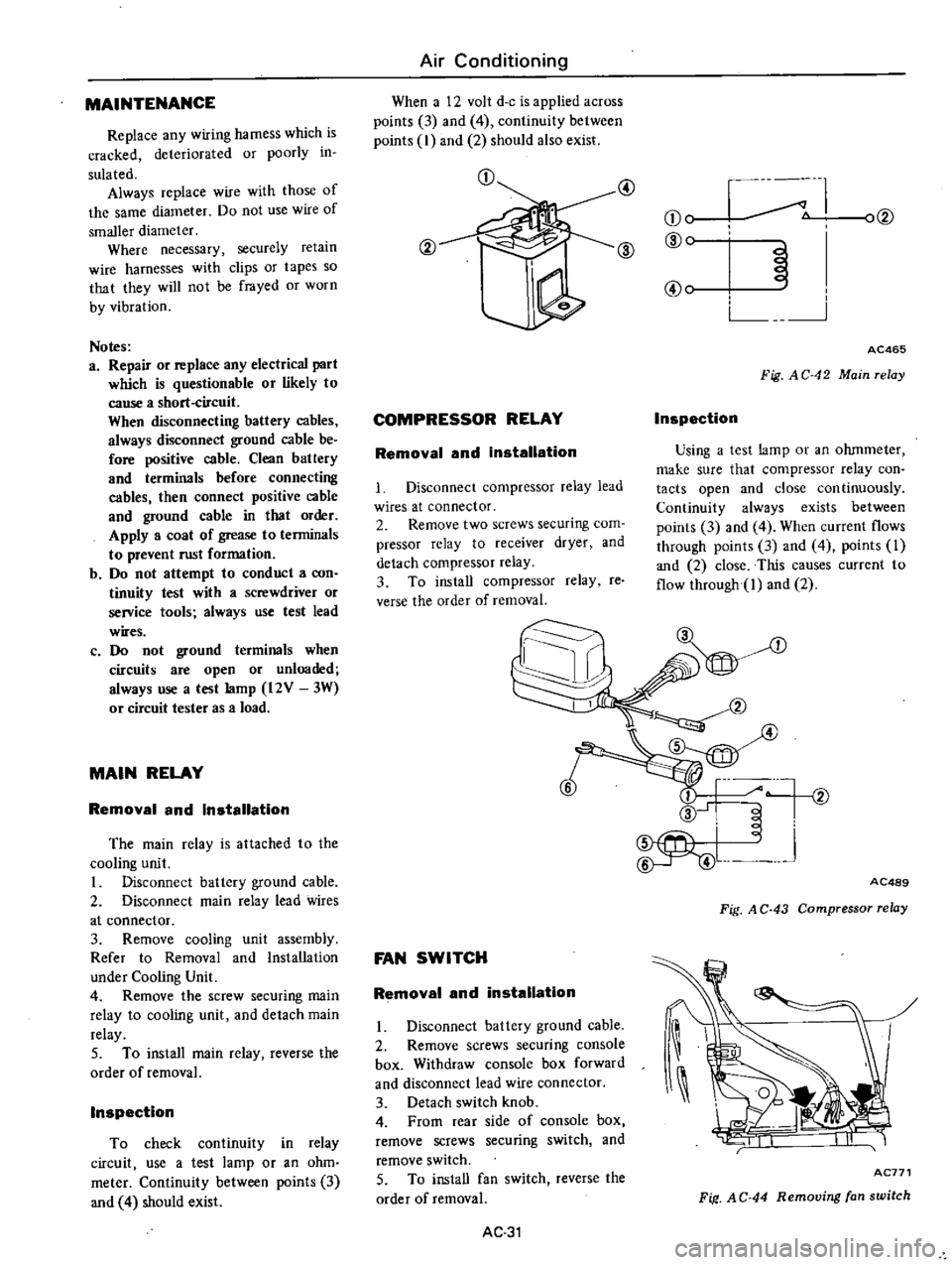

MAIN

RELAY

Removal

and

Installation

The

main

relay

is

attached

to

the

cooling

unit

I

Disconnect

battery

ground

cable

2

Disconnect

main

relay

lead

wires

at

connector

3

Remove

cooling

unit

assembly

Refer

to

Removal

and

Installation

under

Cooling

Unit

4

Remove

the

screw

securing

main

relay

to

cooling

unit

and

detach

main

relay

5

To

install

main

relay

reverse

the

order

of

removal

Inspection

To

check

continuity

in

relay

circuit

use

a

test

lamp

or

an

ohm

meter

Continuity

between

points

3

and

4

should

exist

Air

Conditioning

When

a

12

volt

d

c

is

applied

across

points

3

and

4

continuity

between

points

I

and

2

should

also

exist

CD

00

COMPRESSOR

RELAY

Removal

and

installation

Disconnect

compressor

relay

lead

wires

at

connector

2

Remove

two

screws

securing

com

pressor

relay

to

receiver

dryer

and

detach

compressor

relay

3

To

install

compressor

relay

reo

verse

the

order

of

removal

@

I

ul

CDe

JOO

ID

IDe

@e

L

AC465

Fig

AC

42

Main

relay

Inspection

Using

a

test

lamp

or

an

ohmmeter

make

sure

that

compressor

relay

con

tacts

open

and

close

con

tinuously

Continuity

always

exists

between

points

3

and

4

When

current

flows

through

points

3

and

4

points

1

and

2

close

This

causes

current

to

flow

through

1

and

2

FAN

SWITCH

Removal

and

installation

1

Disconnect

battery

ground

cable

2

Remove

screws

securing

console

box

Withdraw

console

box

forward

and

disconnect

lead

wire

connector

3

Detach

switch

knob

4

From

rear

side

of

console

box

remove

screws

securing

switch

and

remove

switch

5

To

install

fan

switch

reverse

the

order

of

removal

AC

31

i

t

v

J

AC489

Fig

A

C

43

Compressor

relay

AC771

Fif

AC

44

Removing

fan

switch