clock DATSUN PICK-UP 1977 User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 200 of 537

Engine

Electrical

System

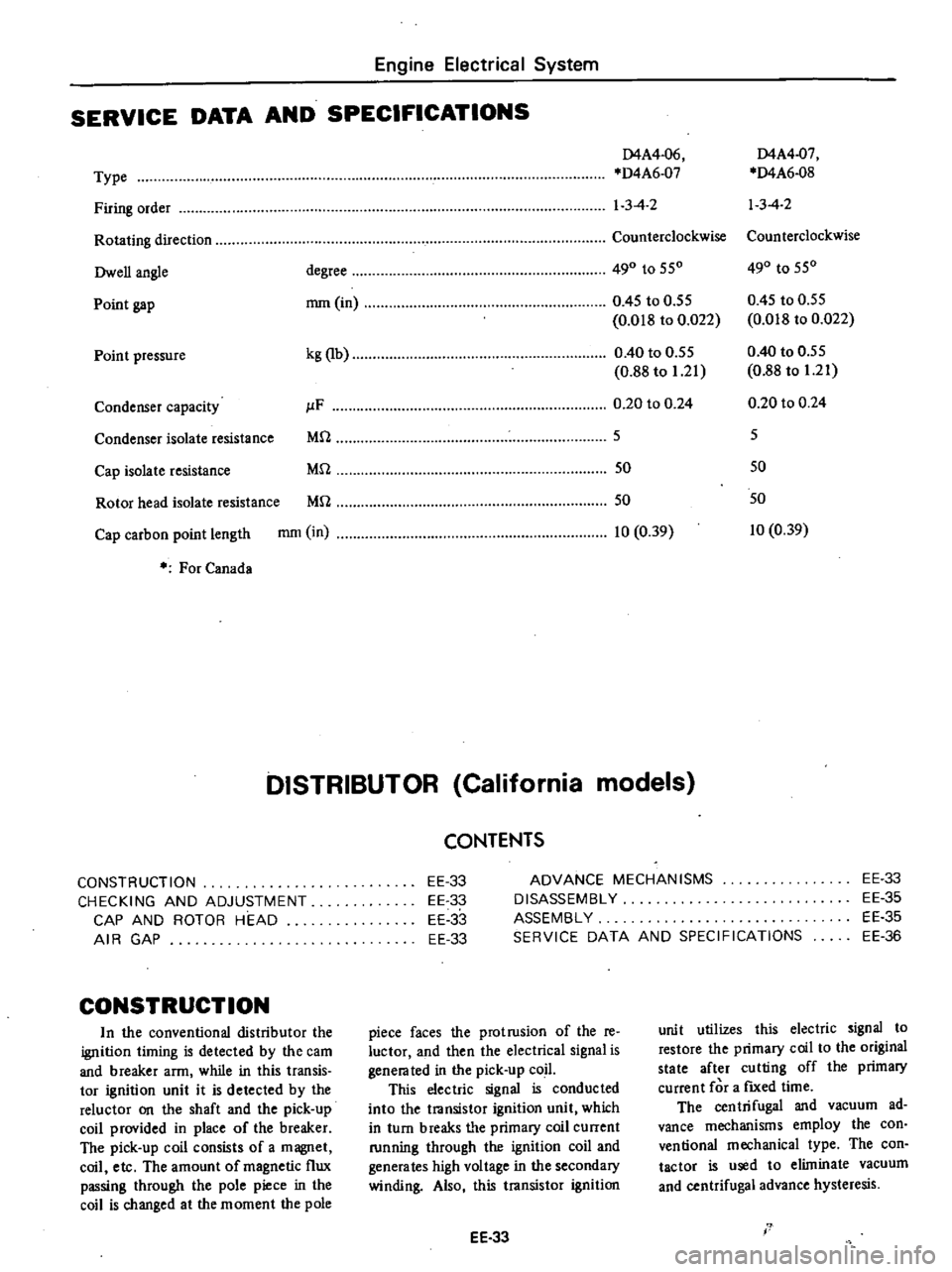

SERVICE

DATA

AND

SPECIFICATIONS

D4A4

06

D4A4

07

Type

D4A6

07

D4A6

08

Firing

order

1

3

4

2

13

4

2

Rotating

direction

Counterclockwise

Counterclockwise

Owen

angle

degree

490

to

550

490

to

550

Point

gap

mm

in

0

45

to

0

55

0

45

to

0

55

0

018

to

0

022

0

018

to

0

022

Point

pressure

kg

lb

0

40

to

0

55

0

40

to

0

55

0

88

to

1

21

0

88

to

1

21

Condenser

capacity

JlF

0

20

to

0

24

0

20

to

0

24

Condenser

isolate

resistance

Mrl

5

5

Cap

isolate

resistance

Mrl

50

50

Rotor

head

isolate

resistance

Mrl

50

50

Cap

carbon

point

length

mm

in

10

0

39

10

0

39

For

Canada

DISTRIBUTOR

California

models

CONSTRUCTION

CHECKING

AND

ADJUSTMENT

CAP

AND

ROTOR

HEAD

AIR

GAP

CONSTRUCTION

In

the

conventional

distributor

the

ignition

liming

is

detected

by

the

cam

and

breaker

arm

while

in

this

transis

tor

ignition

unit

it

is

detected

by

the

reluctor

on

the

shaft

and

the

pick

up

coil

provided

in

place

of

the

breaker

The

pick

up

coil

consists

of

a

magnet

coil

etc

The

amount

of

magnetic

flux

passing

through

the

pole

piece

in

the

coil

is

changed

at

the

moment

the

pole

CONTENTS

EE

33

EE

33

EE

33

EE

33

ADVANCE

MECHANISMS

DISASSEMBLY

ASSEMBLY

SERVICE

DATA

AND

SPECIFICATIONS

EE

33

EE

35

EE

35

EE

36

piece

faces

the

protrusion

of

the

re

luctor

and

then

the

electrical

signal

is

genera

ted

in

the

pick

up

coil

This

electric

signal

is

conducted

into

the

transistor

ignition

unit

which

in

turn

breaks

tI

e

primary

coil

current

running

through

the

ignition

coil

and

generates

high

voltage

in

the

secondary

winding

Also

this

transistor

ignition

EE

33

unit

utilizes

this

electric

signal

to

restore

the

primary

coil

to

the

original

state

after

cutting

off

the

primary

current

for

a

fIXed

time

The

centrifugal

and

vacuum

ad

vance

mechanisms

employ

the

con

ventional

mechanical

type

The

con

tactor

is

used

to

eliminate

vacuum

and

centrifugal

advance

hysteresis

I

Page 203 of 537

EE299

Fig

EE

74

Driving

in

roll

pin

Engine

Electrical

System

4

Apply

grease

to

the

top

of

rotor

shaft

as

required

5

Check

the

operation

of

governor

before

installing

distributor

on

engine

6

Adjust

ignition

timing

after

distri

butor

is

installed

on

engine

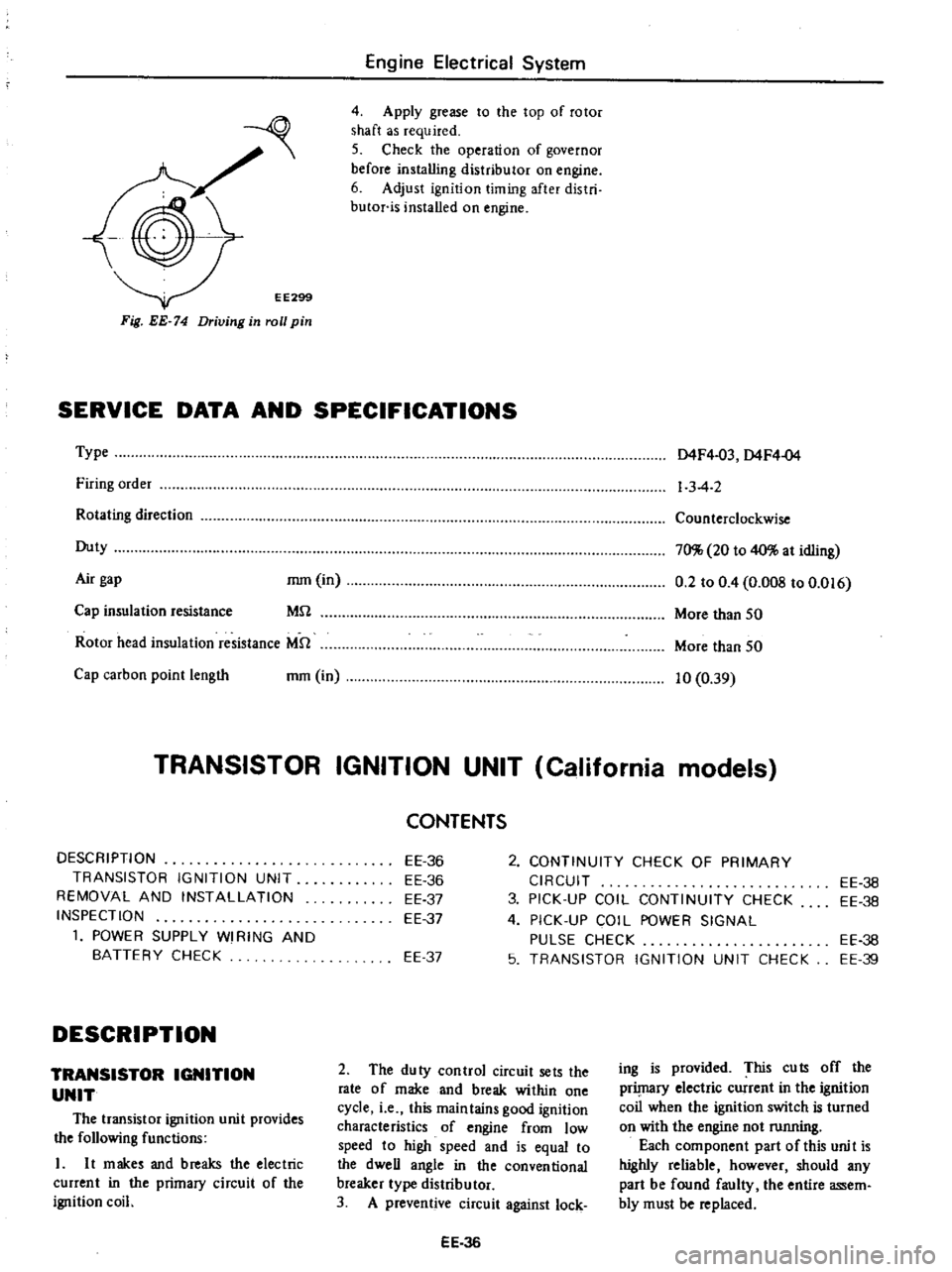

SERVICE

DATA

AND

SPECIFICATIONS

Type

Firing

order

Rotating

direction

Duty

Air

gap

mm

in

MU

Cap

insulation

resistance

Rotor

head

insulation

resistance

MU

Cap

carbon

point

length

mm

in

D4F4

03

D4F4

04

1

3

4

2

Counterclockwise

70

20

to

40

at

idling

0

2

to

0

4

O

OOS

to

0

016

More

than

50

More

than

50

10

0

39

TRANSISTOR

IGNITION

UNIT

California

models

DESCRIPTION

TRANSISTOR

IGNITION

UNIT

REMOVAL

AND

INSTALLATION

INSPECTION

1

POWER

SUPPLY

WI

RING

AND

BATTERY

CHECK

DESCRIPTION

TRANSISTOR

IGNITION

UNIT

The

transistor

ignition

unit

provides

the

following

functions

L

It

makes

and

breaks

the

electric

current

in

the

primacy

circuit

of

the

ignition

coil

2

CONTINUITY

CHECK

OF

PRIMARY

CIRCUIT

3

PICK

UP

COIL

CONTINUITY

CHECK

4

PICK

UP

COIL

POWER

SIGNAL

PULSE

CHECK

5

TRANSISTOR

IGNITION

UNIT

CHECK

CONTENTS

EE

36

EE

36

EE

37

EE

37

EE

37

2

The

duty

control

circuit

sets

the

rate

of

make

and

break

within

one

cycle

i

e

this

maintains

good

ignition

characteristics

of

engine

from

low

speed

to

high

speed

and

is

equal

to

the

dweU

angle

in

the

conventional

breaker

type

distributor

3

A

preventive

circuit

against

lock

EE

36

EE

36

EE

38

EE

38

EE

39

ing

is

provided

This

cuts

off

the

prilnaCY

electric

current

in

the

ignition

coil

when

the

ignition

switch

is

turned

on

with

the

engine

not

running

Each

component

part

of

this

unit

is

highly

reliable

however

should

any

part

be

found

faulty

the

entire

assem

bly

must

be

replaced

Page 276 of 537

R

RANGE

REVERSE

In

R

range

the

front

clutch

and

the

low

and

reverse

brake

are

applied

The

power

flow

is

through

the

input

shaft

front

clutch

and

connecting

shell

to

the

sun

gear

Clockwise

rota

tion

of

the

sun

gear

causes

counter

clockwise

rotation

of

the

rear

planeta

ry

gears

With

the

connecting

drum

held

stationary

by

the

low

and

reverse

brake

the

rear

planetary

gears

rotate

the

rear

internal

gear

and

drive

the

flange

counterclockwise

The

rear

drive

flange

splined

to

the

output

shaft

rotates

the

output

shaft

counterclock

wise

at

a

reduced

speed

with

an

increase

in

torque

for

reverse

gear

Automatic

Transmission

R

Fig

AT

26

Power

tranamis

ion

during

R

range

m

i

1

A

TOBS

Fig

A

T

21

Optrationof

each

mechanism

during

R

range

When

the

manual

valve

V

is

posi

Clutch

Low

Band

servo

One

tioned

at

R

range

the

oil

having

the

Gear

Partina

Ranae

re

ne

way

line

pressure

7

is

directed

to

line

ralio

Front

Rear

brake

Openlion

Relulie

clutch

plwl

pressure

circuits

5

and

6

The

pressure

in

the

circuit

5

actuates

the

Park

on

on

low

and

reverse

brake

after

being

Ruene

2

182

on

on

on

introduced

into

line

pressure

circuit

Neutral

12

through

the

I

st

2nd

shift

valve

ID

The

pressure

in

the

circuit

op

DI

Low

2

458

on

on

erates

the

release

side

of

the

band

servo

and

the

front

c1u

tch

after

being

Driowe

D2

Second

1

458

on

on

led

to

line

pressure

circuit

0

D3

Top

1

000

on

on

on

through

the

2nd

3rd

shift

valve

@

2

Second

1

458

The

throttle

pressure

I

6

and

the

line

on

on

pressure

6

which

vary

with

the

12

Second

S8

on

on

degree

of

accelerator

pedal

depression

II

Low

2

458

both

act

the

pressure

regulator

on

on

on

valve

CD

and

press

against

its

valve

CD

increasing

line

pressure

7

In

Rn

range

the

governor

pressure

is

absent

making

all

such

valves

as

the

1st

2nd

shift

valve

ID

lnd

3rd

shift

valvc

@

and

pressurc

modifier

valve

inoperative

AT16

Page 280 of 537

Automatic

Transmission

R

RANGE

REVERSE

R

In

R

range

the

front

dutch

and

the

low

and

reverse

brake

are

applied

The

power

flow

is

through

the

input

shaft

front

clutch

and

connecting

shell

to

the

sun

gear

Clockwise

rota

tion

of

the

sun

gear

causes

counter

clockwise

rotation

of

the

rear

planeta

ry

gears

With

the

connecting

drum

held

Slationary

by

the

low

and

reverse

brake

the

rear

planetary

gears

rotate

the

rear

internal

gear

and

drive

the

flange

counterclockwise

The

rear

drive

flange

splined

to

the

output

shaft

rotates

the

output

shaft

counterclock

wise

at

a

reduced

speed

with

an

increase

in

torque

for

reverse

gear

f

When

Ihe

manual

valve

CV

is

posi

tioned

at

R

range

Ihe

oil

having

Ihe

line

pressure

7

is

directed

to

line

pressure

circuits

5

and

6

The

pressure

in

the

circuit

5

actuates

the

low

and

reverse

brake

after

being

introduced

into

line

pressure

circuit

12

through

the

I

st

2nd

shift

valve

@

The

pressure

in

Ihe

circuit

op

erates

the

release

side

of

the

band

servo

and

the

front

clutch

after

being

led

to

line

pressure

circuit

10

through

the

2nd

3rd

shift

valve

@

The

throtlle

pressure

16

and

the

line

pressure

6

which

vary

with

the

degree

of

acceJerator

pedal

depression

both

act

on

the

prcssure

regulator

valve

CD

and

press

against

its

valve

CD

increasing

line

pressure

7

In

R

range

the

governor

pressure

is

absent

making

all

slldl

valves

as

the

J

SI

2nd

shift

valve

@

2nd

3rd

shift

valvc

@

and

pressure

modifier

valve

j

inoperative

C

Fig

AT

26

Power

transmi

ion

during

R

range

A

TOS5

Fig

AT

27

Operation

attach

mechanism

during

R

range

G

Clutch

Low

A

Band

servo

One

Parkin

Ran

no

wa

plwl

ratio

Front

Rear

brake

Operllioo

Rdr

ue

clutch

k

on

on

Revctte

1

181

on

on

on

Neutnl

DI

Low

1

418

on

on

Driw

D2

Second

1

458

on

on

DJ

Top

1

000

on

on

on

on

2

Second

1

458

on

on

12

Second

1

458

on

on

I

II

Low

2

458

on

on

AT

16

Page 284 of 537

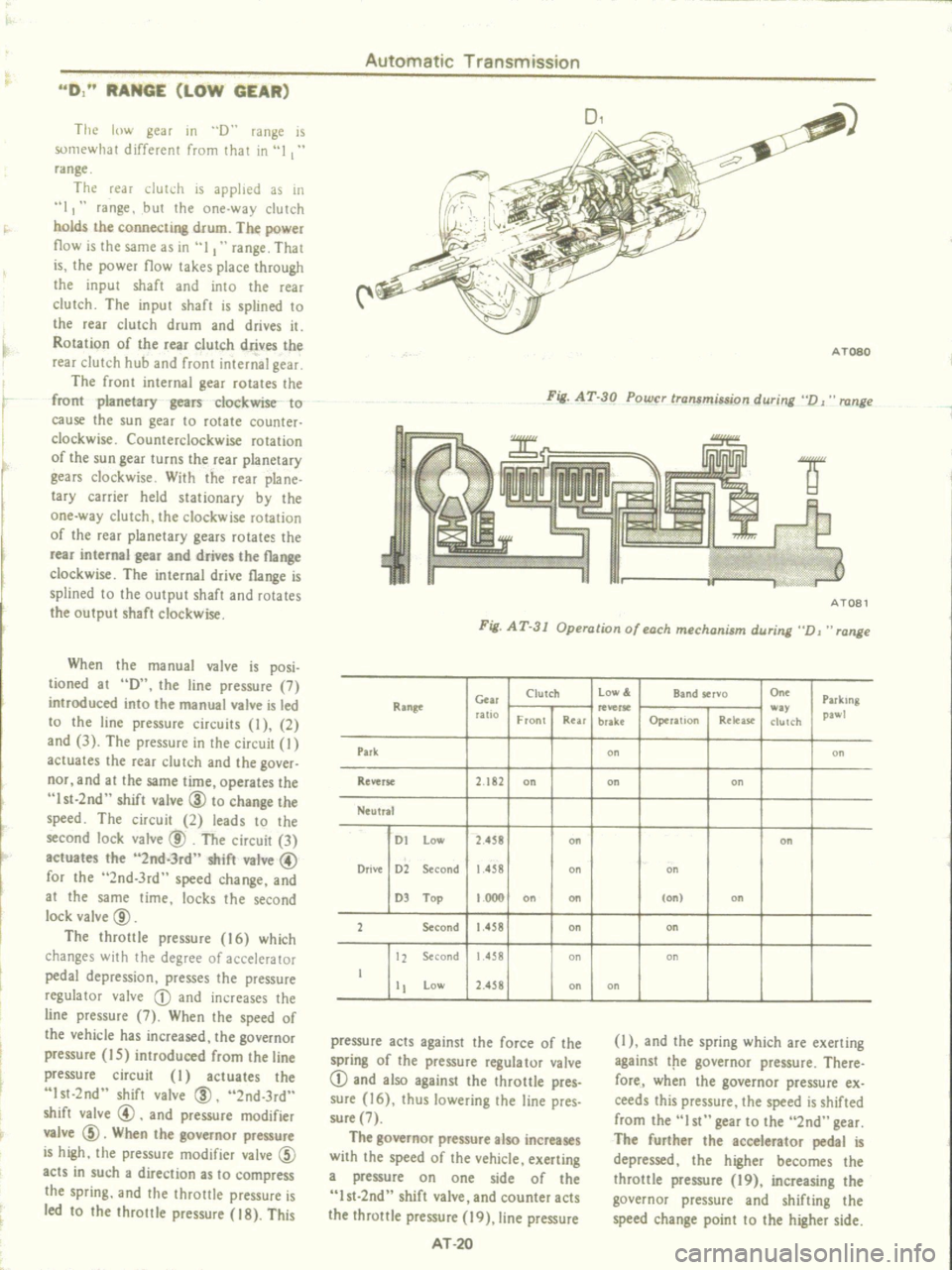

D

RANGE

LOW

GEAR

Automatic

Transmission

The

low

gear

in

D

range

is

somewhat

different

from

that

in

I

range

The

rear

c1utdl

is

applied

as

III

I

range

but

the

one

way

clutch

holds

the

connecting

drum

The

power

now

is

the

same

as

in

1

J

range

That

is

the

power

now

takes

place

through

Ihe

input

shaft

and

into

the

rear

clutch

The

input

shaft

is

splined

to

the

rear

clutch

drum

and

drives

it

Rotation

of

Ihe

rear

clutch

drives

the

rear

clutch

hub

and

front

internal

gear

The

front

internal

gear

rotales

the

front

planetary

gears

clockwise

to

cause

the

sun

gear

to

rotate

counter

clockwise

Counterclockwise

rotation

of

the

sun

gear

turns

the

rear

planetary

gears

clockwise

With

the

rear

plane

tary

carrier

held

stationary

by

the

one

way

clutch

the

clockwise

rotation

of

the

rear

planetary

gears

rotates

the

rear

internal

gear

and

drives

the

flange

clockwise

The

internal

drive

flange

is

splined

to

the

outpul

shaft

and

rotates

the

output

shaft

clockwise

When

the

manual

valve

is

posi

tioned

at

D

the

line

pressure

7

introduced

into

the

manual

valve

is

led

to

the

line

pressure

circuits

l

2

and

3

The

pressure

in

the

circuit

I

acluates

the

rear

clutch

and

the

gover

nor

and

al

the

same

time

operates

the

1st

2nd

shift

valve

CID

to

change

the

speed

The

circuit

2

leads

to

the

second

lock

valve

@

The

circuit

3

actuates

the

2nd

3rd

shift

valve

@

for

the

2nd

3rd

speed

change

and

at

the

same

lime

locks

the

second

lock

valve

@

The

throttle

pressure

16

which

changes

with

the

degree

of

accelerator

pedal

depression

presses

Ihe

pressure

regulator

valve

CD

and

increases

the

line

pressure

7

When

Ihe

speed

of

the

vehicle

has

increased

the

governor

pressure

15

introduced

from

the

line

pressure

circuit

I

actuates

the

I

SI

2nd

shift

valve

CID

2nd

3rd

shift

valve

@

and

pressure

modifier

valve

ID

When

the

governor

pressure

is

high

the

pressure

modifier

valve

ID

acls

in

such

a

direction

as

to

compress

the

spring

and

the

throttle

pressure

is

led

to

the

throttle

pressure

18

This

ATOSO

Fig

AT

30

Power

transmission

during

D

J

range

liIIl

I

IW

L

AT08l

Fig

AT

31

Operation

of

each

mechanism

during

VJ

range

Clutch

low

Band

servo

On

Parking

Cur

Ran

Rllelle

way

pawl

ratio

Front

Rur

brake

Operation

Rekase

ch

lch

Park

on

on

RellerK

2

t82

on

on

on

Neutral

01

low

2

S8

on

on

Orivt

02

Second

1

458

on

on

OJ

Top

1000

on

on

on

on

2

Second

1

458

on

00

t2

Second

1

458

on

on

t

tt

low

2

458

on

on

pressure

acts

against

the

force

of

the

spring

of

the

pressure

regulator

valve

CD

and

also

against

the

throttle

pres

sure

16

thus

lowering

the

line

pres

sure

7

The

governor

pressure

also

increases

with

the

speed

of

Ihe

vehicle

exerting

a

pressure

on

one

side

of

the

lst

2nd

shift

valve

and

counter

acts

the

Ihrottle

pressure

19

line

pressure

AT

20

l

and

the

spring

which

are

exerting

against

t

1e

governor

pressure

There

fore

when

the

governor

pressure

ex

ceeds

Ihis

pressure

the

speed

is

shifted

from

the

I

st

gear

to

the

2nd

gear

The

further

the

accelerator

pedal

is

depressed

the

higher

becomes

the

throttle

pressure

19

increasing

the

governor

pressure

and

shifting

the

speed

change

point

to

the

higher

side

Page 286 of 537

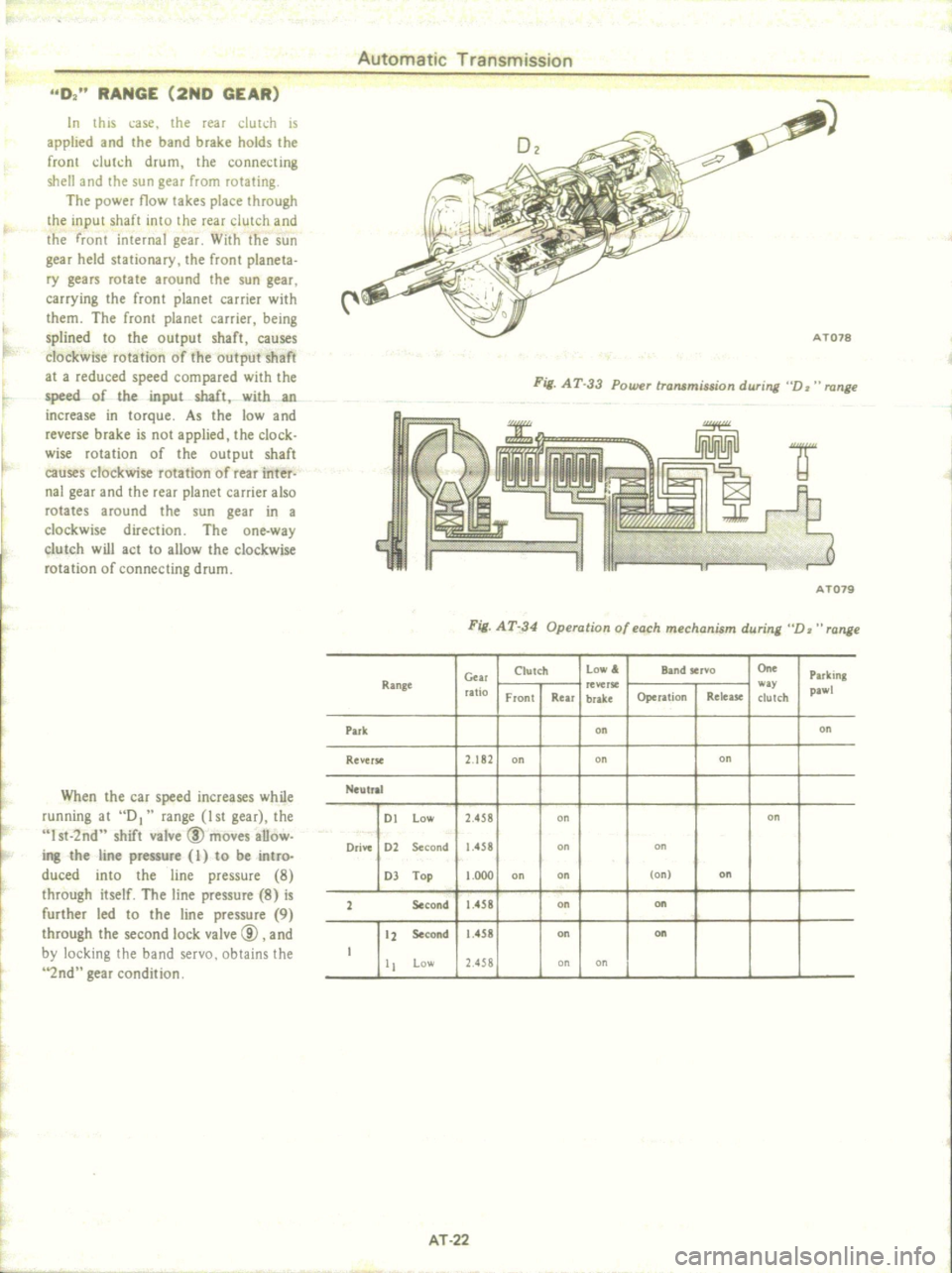

D

RANGE

2ND

GEAR

Automatic

Transmission

t

In

this

case

the

rear

c1ut

h

IS

applied

and

the

band

brake

holds

the

fronl

dUh

h

drum

the

connecting

shell

and

the

sun

gear

from

rotating

The

power

flow

lakes

place

through

the

input

shaft

into

the

rear

clutch

and

the

front

internal

gear

With

the

sun

gear

held

stationary

the

front

planeta

ry

gears

rotate

around

the

sun

gear

carrying

the

front

planet

carrier

with

them

The

fronl

planet

carrier

being

splined

to

the

output

shaft

causes

clockwise

rotation

of

the

output

shaft

at

a

reduced

speed

compared

with

the

speed

of

the

input

shaft

with

an

increase

in

torque

As

the

low

and

reverse

brake

is

not

applied

the

clock

wise

rotation

of

the

output

shaft

causes

clockwise

rotation

of

rear

inter

nal

gear

and

the

rear

planet

carrier

also

rotates

around

the

sun

gear

in

a

clockwise

direction

The

one

way

clutch

will

act

to

allow

the

clockwise

rotation

of

connecting

drum

When

the

car

speed

increases

while

running

at

D

range

I

st

gear

the

st

2nd

shift

valve

ID

moves

allow

ing

the

line

pressure

I

to

be

intro

duced

into

the

line

pressure

8

Ihrough

itself

The

line

pressure

8

is

further

led

to

the

line

pressure

9

through

the

second

lock

valve

@

and

by

locking

the

band

servo

obtains

the

2nd

gear

condition

Fig

AT

33

Power

transmission

during

Dz

range

A

T079

Fig

AT

34

Operation

of

each

mechanism

during

D

range

Clutch

Low

Band

servo

On

Patking

G

Range

reverse

w

pawl

ratio

Fronl

Rur

brake

Optrltion

Release

clutch

PlIk

on

on

Revtne

2

182

on

on

on

Neutral

01

Low

2

4S8

on

on

Drive

02

Second

1

4S8

on

on

OJ

Top

1

000

on

on

on

on

2

Second

1

4S8

on

on

12

Second

1

4S8

on

on

1

II

Low

2

4S8

on

on

AT

22

Page 292 of 537

2

RANGE

2ND

GEAR

Automatic

Transmission

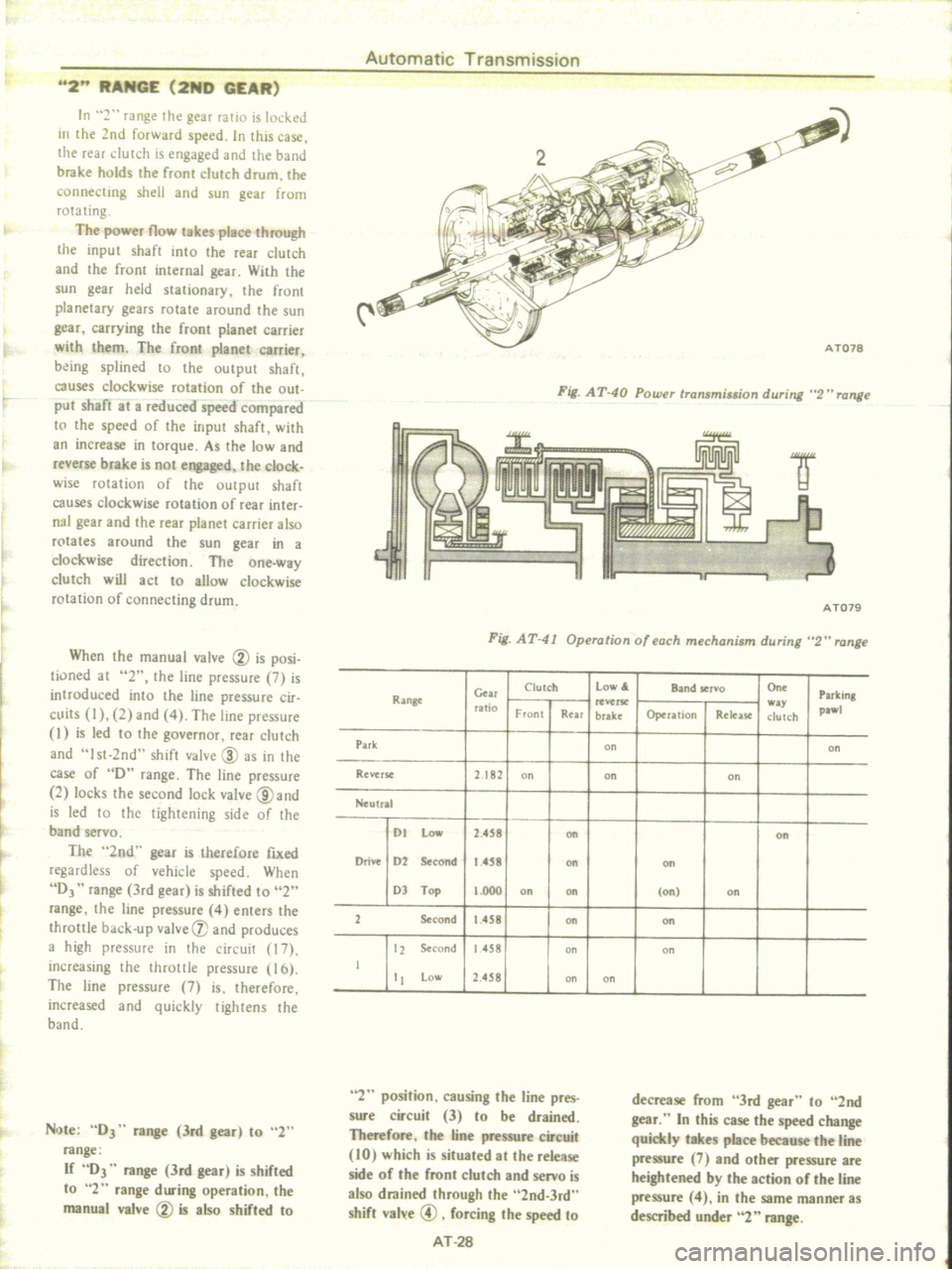

In

2

range

the

gear

rario

is

IOI

keJ

III

the

2nd

forward

speed

In

this

case

the

rear

dutch

is

engaged

and

the

band

brake

holds

the

front

clutch

drum

the

connecting

shell

and

sun

gear

from

rotating

The

power

flow

takes

place

through

the

input

shaft

inlo

the

rear

clutch

and

the

front

internal

gear

With

Ihe

sun

gear

held

stationary

the

front

planetary

gears

rotate

around

the

sun

gear

carrying

the

front

planet

carrier

with

them

The

front

planet

carrier

being

splined

to

the

output

shaft

causes

clockwise

rotation

of

the

OUI

put

shaft

at

a

reduced

speed

compared

to

the

speed

of

the

input

shaft

with

an

increase

in

torque

As

the

low

and

reverse

brake

is

not

engaged

the

clock

wise

rotation

of

the

output

shaft

causes

clockwise

rotation

of

fear

inter

nal

gear

and

the

rear

planet

carrier

also

rotates

around

the

sun

gear

in

a

clockwise

direction

The

one

way

clutch

will

act

to

allow

clockwise

rotation

of

connecting

drum

When

the

manual

valve

V

is

posi

tioned

at

2

the

line

pressure

7

is

introduced

into

the

line

pressure

cir

cuits

I

2

and

4

The

line

pressure

I

is

led

to

the

governor

rear

clutch

and

I

st

2nd

shift

valve

CID

as

in

the

case

of

D

range

The

line

pressure

2

locks

the

second

lock

valve

@and

is

led

to

thc

tightening

side

of

Ihe

band

servo

The

2nd

gear

is

therefore

fixed

regardless

of

vehicle

speed

When

DJ

range

3rd

gear

is

shifted

to

2

range

the

line

pressure

4

enters

Ihe

throttle

back

up

valve

V

and

produces

a

high

pressure

in

the

circuit

17

increasing

thc

throttle

pressure

li

6

The

line

pressure

7

is

therefore

increased

and

quickly

tightens

the

band

N

e

DJ

range

3rd

gear

to

2

range

If

DJ

range

3rd

gear

is

shifled

to

2

range

during

operation

the

manual

valve

V

is

also

shifted

to

A

T078

Fig

AT

40

Powu

tTansminion

during

2

H

range

A

1079

Fig

AT

41

Operation

of

each

mechanism

during

2

range

Clutch

Low

Band

ser

o

On

Parking

Gw

Ran8t

utio

w

pa

Front

Rear

brake

Operalion

Release

dutch

Pui

on

on

Revtrs

e

2

182

on

on

on

Neutral

01

Low

2

458

on

on

Drive

02

Second

1

458

Oft

Oft

OJ

Top

1

000

on

on

on

on

1

Second

1

458

on

Oft

12

tocond

1458

on

on

J

tt

Low

2

458

on

on

2

position

causing

the

line

pres

sure

circuit

3

to

be

drained

Therefore

the

line

pressure

circuit

10

which

is

situated

at

the

release

side

of

the

front

clutch

and

servo

is

also

drained

through

the

2nd

3rd

shift

val

e

@

forcing

the

speed

to

AT

28

decrease

from

3rd

gear

to

2nd

gear

In

this

case

the

speed

change

quickly

takes

place

because

the

line

pressure

7

and

other

pressure

are

heightened

by

the

action

of

the

line

pressure

4

in

the

same

manner

as

described

under

2

range

Page 294 of 537

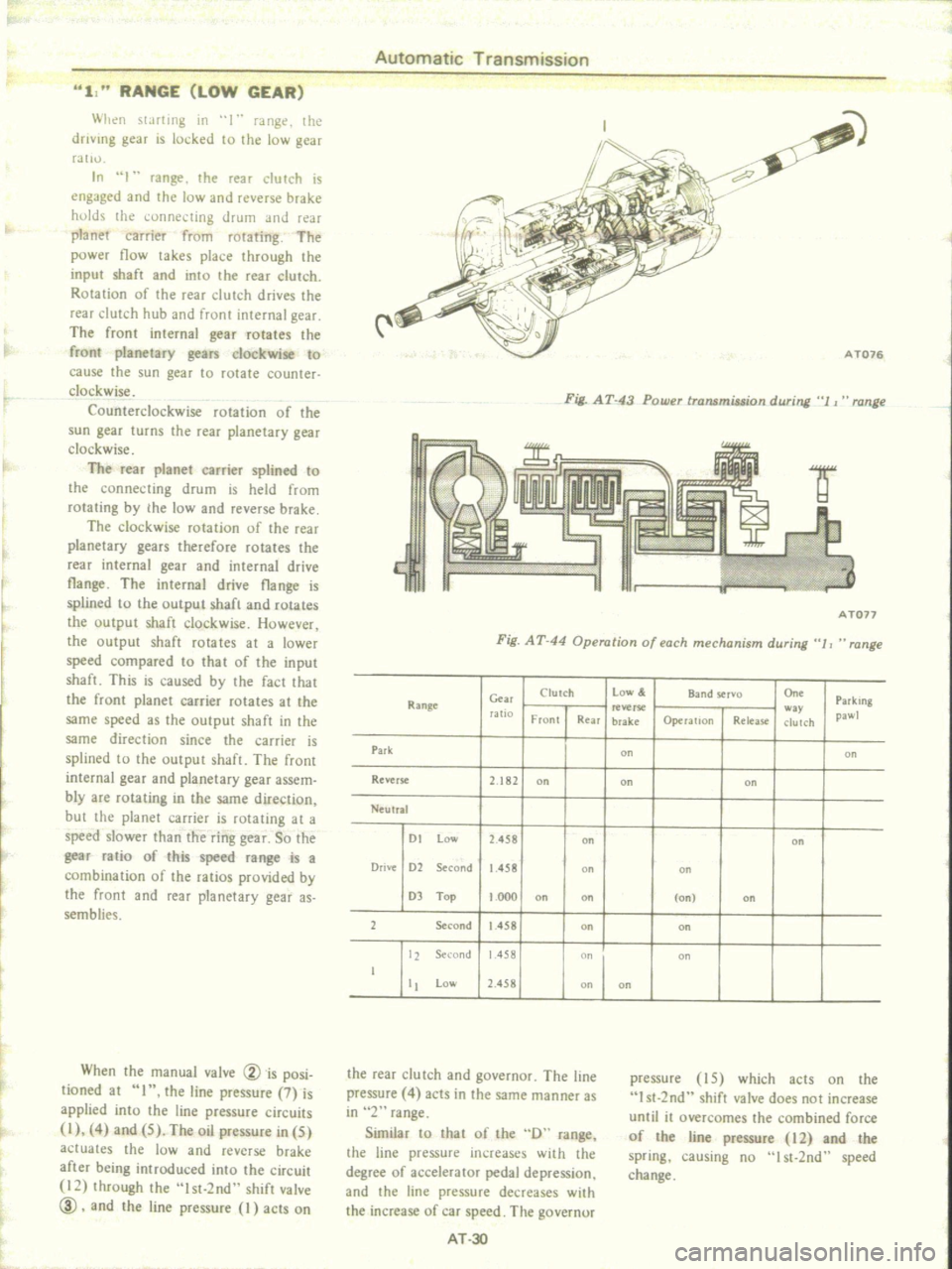

1

RANGE

LOW

GEAR

Automatic

Transmission

f

Wilen

slJrting

in

I

range

the

drlvlIlg

gear

is

IOl

ked

to

the

low

gear

fJIIIJ

In

H

range

the

rear

clutch

is

engJged

and

the

low

and

reverse

brake

hulds

he

onnecting

drum

and

feac

planet

carrier

from

rotating

The

power

tlow

lakes

place

through

the

input

shaft

and

into

lhe

rear

clutch

ROlalion

of

the

rear

clutch

drives

lhe

rear

dutch

hub

and

front

internal

gear

The

front

internal

gear

rotates

the

front

planetary

gears

clockwise

to

cause

the

sun

gear

to

rotate

counter

clockwise

Counterclockwise

rotation

of

the

sun

gear

turns

the

rear

planetary

gear

clockwise

The

rear

planet

carrier

splined

to

the

connecting

drum

is

held

from

rotating

by

the

low

and

reverse

brake

The

clockwise

rotation

of

the

rear

planetary

gears

therefore

rotates

the

rear

internal

gear

and

internal

drive

tlange

The

internal

drive

tlange

is

splined

to

the

output

shaft

and

rotates

the

uutput

shaft

clockwise

However

the

output

shaft

rotates

at

a

lower

speed

compared

to

that

of

the

input

shaft

This

is

caused

by

the

fact

Ihat

the

front

planet

carrier

rotates

at

the

same

speed

as

Ihe

OUlput

shaft

in

the

same

direction

since

the

carrier

is

splined

to

the

output

shaft

The

front

internal

gear

and

planetary

gear

assem

bly

are

rotating

in

the

same

direction

but

the

planet

carrier

is

rotating

at

a

speed

slower

than

the

ring

gear

So

the

gear

ralio

of

this

speed

range

is

a

combination

of

the

ratios

provided

by

the

front

and

rear

planetary

gear

as

semblies

When

the

manual

valve

Vis

posi

tioned

at

I

the

line

pressure

7

is

applied

into

the

line

pressure

circuits

I

4

and

5

The

oil

pressure

in

5

actuates

the

luw

and

reverse

brake

after

being

introduced

into

the

circuit

12

through

Ihe

1st

2nd

shift

valve

ID

and

the

line

pressure

I

acts

on

C

A

T076

Fig

AT

43

Power

transmission

during

1

J

range

Fai1

A

TOn

Fig

AT

44

Operation

of

each

mechanism

during

JJ

range

Clutch

Low

Band

servo

On

Parking

Gm

Range

reverse

w

pawl

ratIO

Front

Rur

brake

Operatlon

Release

clulCh

Park

on

on

Reverse

2

182

on

on

on

Neutral

01

low

2

458

on

on

Drive

02

Second

1

458

on

on

03

Top

1000

on

on

on

on

2

Second

1

458

on

on

2

Second

IAS8

on

on

I

1

low

2

458

on

on

the

rear

clutch

and

governor

The

line

pressure

4

acts

in

the

same

manner

as

in

2

range

Similar

to

that

of

the

D

range

the

line

pressure

inr

reases

with

the

degree

of

accelerator

pedal

depression

and

the

line

pressure

decreases

with

the

increase

of

car

speed

The

governor

pressure

15

which

acts

on

the

I

st

2nd

shift

valve

does

not

increase

until

it

overcomes

the

combined

force

of

the

line

pressure

12

and

the

spring

causing

no

st

2nd

speed

cha

nge

AT

30

Page 303 of 537

Fig

AT

70

Measuring

ring

to

plate

clearance

Available

retaining

plate

Thickness

mm

in

1l

8

0

465

12

0

0472

12

2

0480

124

0488

12

6

0496

12

8

0

504

For

inspection

procedure

for

low

and

reverse

brake

see

page

AT

42

for

Assembly

3

Install

one

way

clutch

so

that

the

arrow

mark

is

toward

front

of

vehicle

It

should

be

free

to

rotate

only

in

clockwise

direction

See

Figure

AT

71

mITIJ

o

oml

AT137

Fig

AT

71

One

way

clutch

4

After

installing

rear

extension

torque

attaching

bolts

to

2

0

to

2

5

kg

m

14

to

18

ft

lb

Place

manual

lever

in

P

range

and

check

to

be

sure

that

rear

output

shaft

is

securely

blocked

5

Tighten

servo

retainer

temporari

ly

at

this

stage

of

assembly

6

Place

rear

clutch

assembly

with

needle

bearing

on

front

assembly

Automatic

Transmission

7

Install

rear

clutch

hub

and

front

planetary

carrier

as

shown

in

Figure

AT

72

AT142

Fig

AT

72

Installing

planetary

carrier

8

Assemble

connecting

shell

and

other

parts

up

to

front

Clutch

in

reverse

order

of

disassembly

AT143

Fig

AT

73

Installing

connecting

shell

9

Adjust

total

end

play

and

front

end

playas

follows

Front

end

play

L

r

L

CD

I

r

L

11

I

J

Total

end

play

@

Front

clutch

thrust

washer

2

Oil

pump

cover

3

Front

clutch

4

Rear

clutch

AT138

5

Trammission

case

6

Oil

pump

gasket

7

Oil

pump

cover

bearing

race

Fig

AT

74

End

play

1

Measure

the

distance

A

and

C

by

vernier

calipers

as

shown

in

Figure

AT

75

AT

39

i

Rear

c

clutch

N

edle

bearing

Bearing

race

I

Fig

AT

75

AT139

Measuring

the

distance

A

and

C

2

Measure

the

distance

B

and

D

of

oil

pump

cover

as

shown

in

Figure

AT

76

I

L

I

Oiipi

mp

AT140

Fig

AT

76

Measuring

the

distance

B

and

D

Adjustment

of

total

end

play

Select

oil

pump

cover

bearing

race

by

calculating

the

following

formula

TT

A

B

W

where

T

T

Required

thickness

of

oil

pump

cover

bearing

race

mm

in

A

Measured

distance

A

mm

in

B

Measured

distance

B

mm

in

W

Thickness

of

bearing

race

temporarily

inserted

mm

in

Available

oil

pump

cover

bearing

race

Thickness

mm

in

1

2

0

047

I

4

0

055

1

6

0

063

1

8

0

071

2

0

0

079

2

2

0

087

Specified

total

end

play

0

25100

50

mm

0

0098

to

0

0197

in

Page 353 of 537

spindle

and

torque

bolt

to

10

3

to

12

1

kg

m

75

to

88

ft

lb

Bend

lock

plate

to

engaged

flats

on

boll

head

Note

When

disassembled

discard

used

lock

plate

5

Pack

grea

to

the

upP

r

and

lower

bushings

on

knuckle

spindle

until

grease

c

omes

out

from

gr

ease

seal

6

Fill

wheel

hub

and

cap

with

grease

up

to

the

described

level

See

Figure

F

A

4

FA141

Fig

FA

4

Gre

ing

wheel

hub

7

Pack

roller

and

cone

assembly

and

the

cavity

of

grease

seal

lip

with

grease

8

Coat

grease

to

the

thread

of

knuckle

spindle

bearing

washer

and

bearing

lock

nul

9

Secure

wheel

hub

bearings

bear

ing

washer

and

spindle

nut

on

knuckle

spindle

and

adju

t

bearing

preload

referring

to

the

paragraph

Wheel

bearing

adjustment

Note

Be

sure

to

obtain

correct

pre

load

on

wheel

bearings

for

the

pu

rpose

of

ving

their

long

life

taking

care

to

keep

wheel

be8rlngs

grease

seal

bearing

washer

and

spin

dle

nut

clean

when

installing

them

WHEEL

BEARING

D

TM

NT

Wrong

adjustment

of

wheel

bear

ing

causes

abnonnal

wear

and

score

on

the

bearings

and

knuckle

spindle

Front

Axle

Front

Suspension

To

attain

proper

preload

on

wheel

bearings

proceed

the

following

opera

tions

I

Torque

spindle

nut

to

3

0

to

3

S

kg

m

22

to

25

ft

lb

using

torque

wrench

FA227

Fig

FA

5

Tightening

apindle

nut

2

Rotate

wheel

hub

a

few

turns

clockwise

and

counterclockwise

to

seat

bearings

Then

retighten

spindle

nut

to

the

same

tightening

torque

Be

certain

to

rotate

hub

smoothly

3

Back

off

spindle

nut

in

range

from

40

to

70

degrees

Locate

adjust

ing

cap

on

spindle

nut

so

as

to

align

the

castellation

on

the

cap

with

the

cotter

pin

hole

in

the

spindle

4

Check

the

hub

rotation

If

hub

rotates

properly

measure

bearing

rota

tion

starting

torque

If

measured

torque

is

deviated

from

the

specified

value

r

place

beari

gs

r

re

dju

st

The

starting

torque

can

be

mea

sured

by

a

spring

balance

as

shown

in

Figure

F

A

6

Spring

balance

indication

at

hub

bolt

New

bearing

2

1

kg

4

Ib

o

ess

Used

bearing

1

0

kg

2

2

lb

or

less

Notes

a

When

measuring

the

starting

force

pull

the

spring

balance

toward

tan

gential

direction

against

normal

line

connected

between

hub

boll

and

spindle

center

b

Axial

play

is

permissible

to

exist

in

0

1

mm

0

004

in

or

less

FA

4

fA22S

Fig

FA

6

Mea

uring

bearing

rotation

atarting

torque

S

Install

a

new

cotter

pin

Bend

the

ends

of

coller

pin

around

the

castel

lated

flange

of

adjusting

cap

Then

install

hub

cap

DISASSEMBLY

AND

ASSEMBLY

Knuckle

spindle

I

Drive

spindle

bushing

and

grease

seal

out

of

knuckle

spindle

with

KiTlg

Pin

Bush

Drift

ST3S380000

Discard

bushing

and

grease

seal

when

disas

sembled

2

After

cleaning

king

pin

bores

thoroughly

install

bushing

carefully

by

using

the

above

special

tpol

Posi

tion

bushing

in

accordance

With

the

instructions

fIlled

in

Figure

F

A

7

and

FA

8

34

mm

1

34

in

Upper

side

in

lower

boss

I

I

1

II

I

Pla

ce

this

position

in

line

with

grease

nipple

hole

Upper

side

in

upper

boss

FA229

Fig

FA

7

King

pin

bu

hing