engine oil capacity DATSUN PICK-UP 1977 User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 480 of 537

Body

Electrical

System

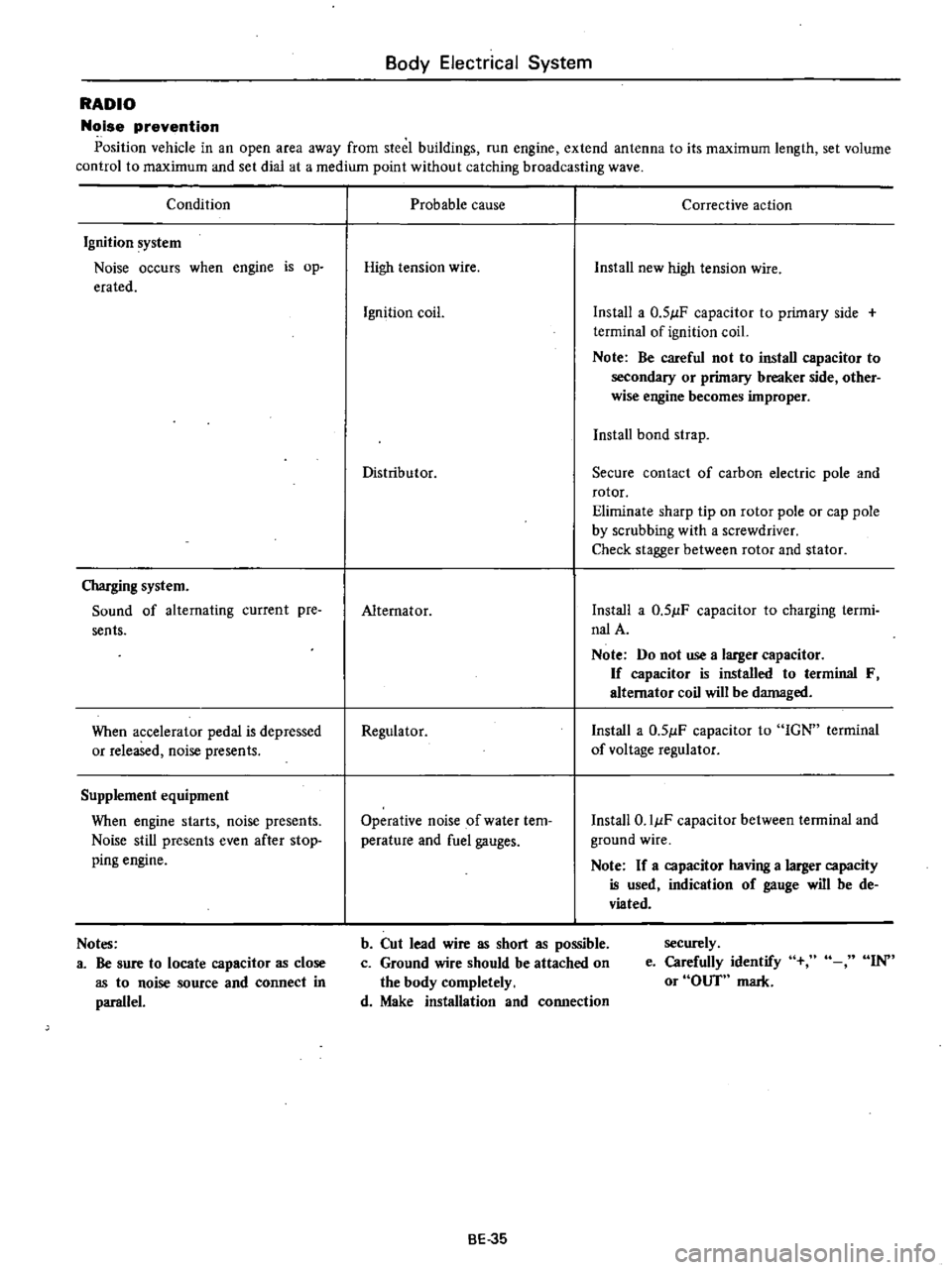

RADIO

Noise

prevention

Position

vehicle

in

an

open

area

away

from

steel

buildings

run

engine

extend

antenna

to

its

maximum

length

set

volume

control

to

maximum

and

set

dial

at

a

medium

point

without

catching

broadcasting

wave

Condition

Ignition

system

Noise

occurs

when

engine

is

op

erated

Charging

system

Sound

of

alternating

current

pre

sents

When

accelerator

pedal

is

depressed

or

released

noise

presents

Supplement

equipment

When

engine

starts

noise

presents

Noise

still

presents

even

after

stop

ping

engine

Notes

a

Be

sure

to

locate

capacitor

as

close

as

to

noise

source

and

connect

in

parallel

Probable

cause

Corrective

action

High

tension

wire

Install

new

high

tension

wire

Ignition

coil

Install

a

0

51lF

capacitor

to

primary

side

terminal

of

ignition

coil

Note

Be

careful

not

to

install

capacitor

to

secondary

or

primary

breaker

side

other

wise

engine

becomes

improper

Install

bond

strap

Distributor

Secure

contact

of

carbon

electric

pole

and

rotor

Eliminate

sharp

tip

on

rotor

pole

or

cap

pole

by

scrubbing

with

a

screwdriver

Check

stagger

between

rotor

and

stator

Alternator

Install

a

0

51lF

capacitor

to

charging

termi

nalA

Note

Do

not

use

a

larger

capacitor

If

capacitor

is

installed

to

terminal

F

alternator

coil

will

be

damaged

Regulator

Install

a

0

51lF

capacitor

to

IGN

terminal

of

voltage

regulator

Operative

noise

of

water

tem

perature

and

fuel

gauges

Install

O

IIlF

capacitor

between

terminal

and

ground

wire

Note

If

a

capacitor

having

a

larger

capacity

is

used

indication

of

gauge

will

be

de

viated

b

Cut

lead

wire

as

short

as

possible

c

Ground

wire

should

be

attached

on

the

body

completely

d

Make

installation

and

connection

securely

e

Carefully

identify

or

OUT

mark

IN

BE

35

Page 515 of 537

2

R

C7

c

L

PJJ

I

8

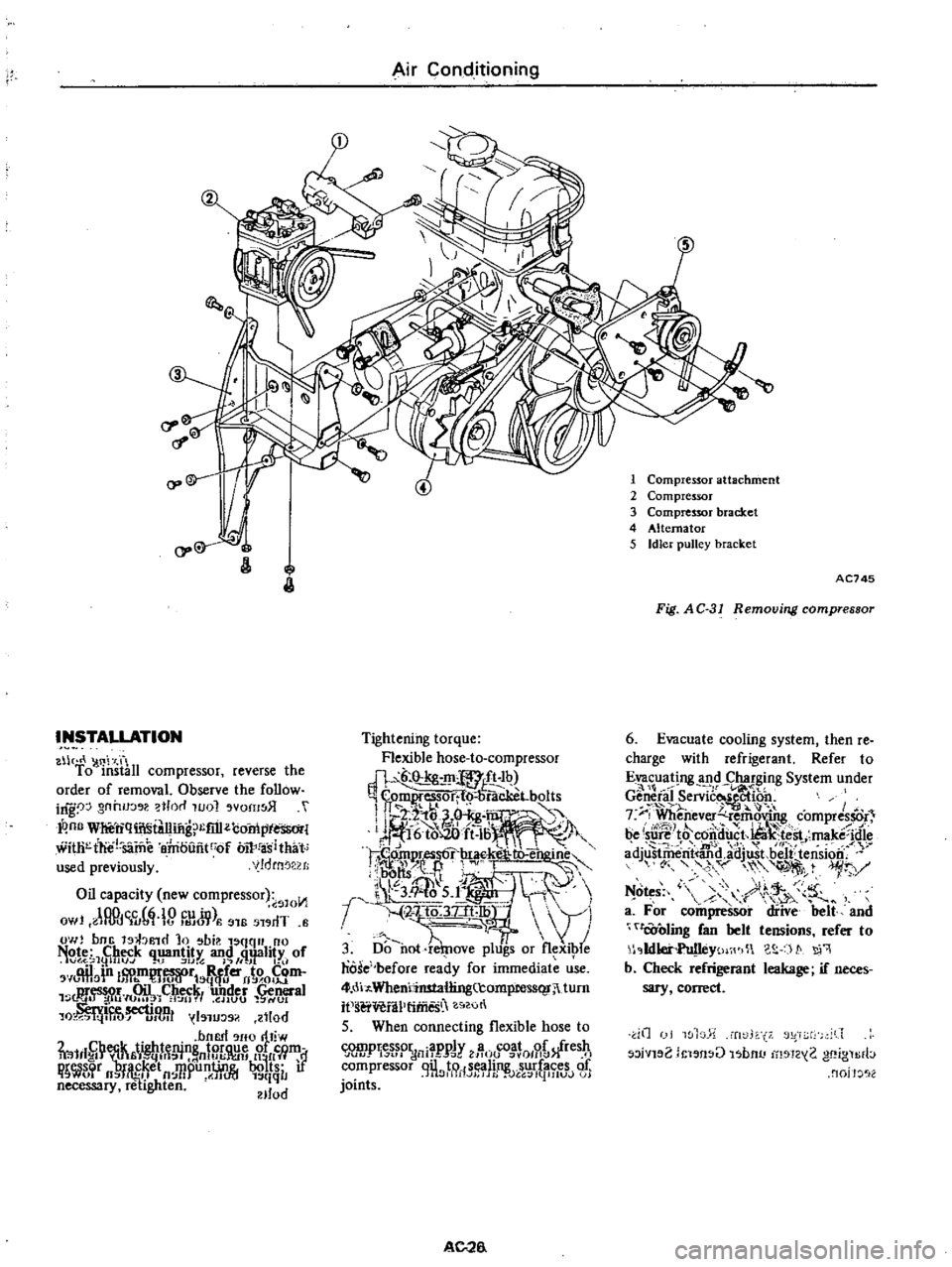

INSTALLATION

a

c

J

l

i

rp

To

install

compressor

reverse

the

order

of

removal

Observe

the

follow

ing

nhlJo

e

trorf

1001

vom

R

i

n3

Wheliqli

liiAniitg

fiil

l

in

pt

l

witlil

tiiel

sam

efuouiitITof

b11

1fasitlult

used

previously

v

d

rnl

2

Oil

capacity

new

compressor

O

910

1

owt

llllt

blj

f

H

w

s

013

5

rlT

s

0

111

boc

19

bB1rllo

bi2

qqll

no

e

l

bffik

kuanM

mpdi

x

of

Jli

oln

L

il

m

1IlffiiOrb

fler

ot

oldm

F

n

Cheo

f

undeF

r

n

al

1

aQ

r1tIU

Jt

t31

HClJI1

t

JIVU

i

rlUI

1o

ifm

ft

q

t

VI

31U

S

ltlod

bnM

UfO

l

W

kldf

CJiJi

ti

WIf

nl

L

llil

g

ncn

d

oressor

M

et

illpuntinl

botts

if

l9Wul

fb

i

l

fI

I

l

1Ttio

l

qqlJ

necessary

re

Ighten

I

d

210

Air

Conditioning

Tightening

torque

Flexible

hose

to

compressor

dl

t

kg

J

l

IQ

1

Tf

es

oriti

ra

Lbolts

IbP

fo

o15g

m

J

r

f6i

o

20

i

il

f

J

rt

I

r

aGket

engine

Dons

1

1

0

1

1

3

16

5

l11fd

1l

V

f

42

3

3U

llif

Yl

I

u

y

j

3

D

not

remove

IJgs

orflexibie

1i6

e

before

ready

for

immediate

use

4l

di

Wheniiinstallingccomptess

i

turn

it

serWfiPtiffies

SlOt

5

When

connecting

flexible

hose

to

9mPr

ssor

apD

v

a

coat

of

Hfresh

JU

UI

l1Il

t

2

JIUU

uOHltl

r

fl

compressor

0

1

to

fs

aHn

lurfaces

of

1n

1l11

JJ

J

f

PJU

Ht

UlUJ

jJ

joints

AC

26

5

1

Compressor

attachment

2

Compressor

3

Compressor

bracket

4

AHernator

5

Idler

pulley

bracket

AC745

Fig

AC

31

Removing

compressor

6

Evacuate

cooling

system

then

re

charge

with

refrigerant

Refer

to

Evacuating

and

Charging

System

under

l

r

Gen

efal

Servic

ectioo

f

iI

t

7

F

Whenever

remoV

J

compres

r

be

su

J

t8

C6itiu

t

Ua

t

st

make

idie

mV

i

1rJ

adjustril

rit

and

adjwt

beJf

tension

yv

1

r

Y

N

o

s

9

r

h

v

a

For

compressor

diive

belt

and

tOoling

fan

belt

tensions

refer

to

1

Ildlet

Yt

j

WI

c

S

t

q

b

Cheok

refrigerant

leakage

if

neces

sary

correct

dO

I

wl

Tw

l

rt

f

r2

iVl

2

i

l

n

U

l

bnu

1

1Z

2

gf

ign

rb

nojJ

2