steering wheel DATSUN PICK-UP 1977 User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 405 of 537

Condition

Wheel

wobbles

Unevenly

or

excessively

worn

tire

Tire

squeals

Wheel

and

Tire

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Probable

cause

Improper

tire

pressure

Damaged

tire

or

distorted

wheel

rim

Unbalanced

wheel

Loose

wheel

nuts

Worn

or

damaged

wheel

bearing

or

excessive

play

of

wheel

bearing

Improper

front

wheel

alignment

Worn

or

damaged

ball

joint

Excessive

steering

linkage

play

or

worn

steering

linkage

Loose

steering

linkage

connection

Broken

suspension

spring

Damaged

shock

absorber

Improper

tire

rotation

Improper

tire

pressure

Unbalanced

wheel

Improperly

adjusted

brake

Improper

wheel

alignment

Excessively

distorted

or

improperly

installed

suspension

link

High

speed

on

curves

Sudden

start

and

improper

speed

due

to

rapid

acceleration

or

improper

brake

ap

plication

Improper

tire

pressure

Improper

front

wheel

alignment

Distorted

knuckle

or

suspension

link

WT

5

Corrective

action

Measure

and

adjust

Repair

or

replace

Balance

Tighten

Correct

play

or

replace

wheel

bearing

Align

Replace

Adjust

Or

replace

Tighten

nuts

to

rated

torque

or

replace

worn

parts

if

any

Replace

Replace

Conduct

tire

rotation

periodically

Measure

and

adjust

Balance

or

replace

Adjust

Align

Repair

replace

or

if

necessary

reinstall

Reduce

speed

Follow

correct

and

proper

driving

manner

Measure

and

adjust

Align

Repair

or

replace

Page 407 of 537

STEERING

SYSTEM

STEERING

CONTENTS

DESCRIPTION

STEERING

GEAR

Remo

al

and

installation

Disassembly

and

assembly

ST

2

ST

3

ST

3

ST

4

Inspection

and

repair

STEERING

LINKAGE

Removal

and

installation

Inspection

and

repair

ST

5

ST

6

ST

6

ST

7

DESCRIPTION

The

other

end

of

the

cross

rod

is

linked

to

the

idler

arm

connecting

with

the

side

member

located

on

the

opposite

side

of

the

steering

gear

The

two

side

rods

serve

to

connect

the

steering

gear

arm

and

idler

arm

to

the

both

knuckle

arms

right

and

left

hand

sides

With

this

construction

even

if

the

left

andlor

right

wheel

moves

vertical

The

steering

gear

used

on

this

model

series

vehicles

is

e

same

re

circulating

type

This

steering

gear

is

designed

especially

for

easy

operation

and

high

durability

The

steering

linkage

is

of

a

relay

design

of

which

gear

arm

is

connected

to

one

end

of

the

adjustable

cross

rod

ly

and

independently

steering

can

be

safely

maintained

Steering

wheel

rotation

is

converted

to

gear

arm

motion

in

proportion

to

the

gear

ratio

by

the

steering

gear

The

gear

arm

motion

operates

the

side

rod

on

the

same

side

At

the

same

time

the

idler

arm

is

moved

through

the

cross

rod

and

the

opposite

side

rod

is

also

moved

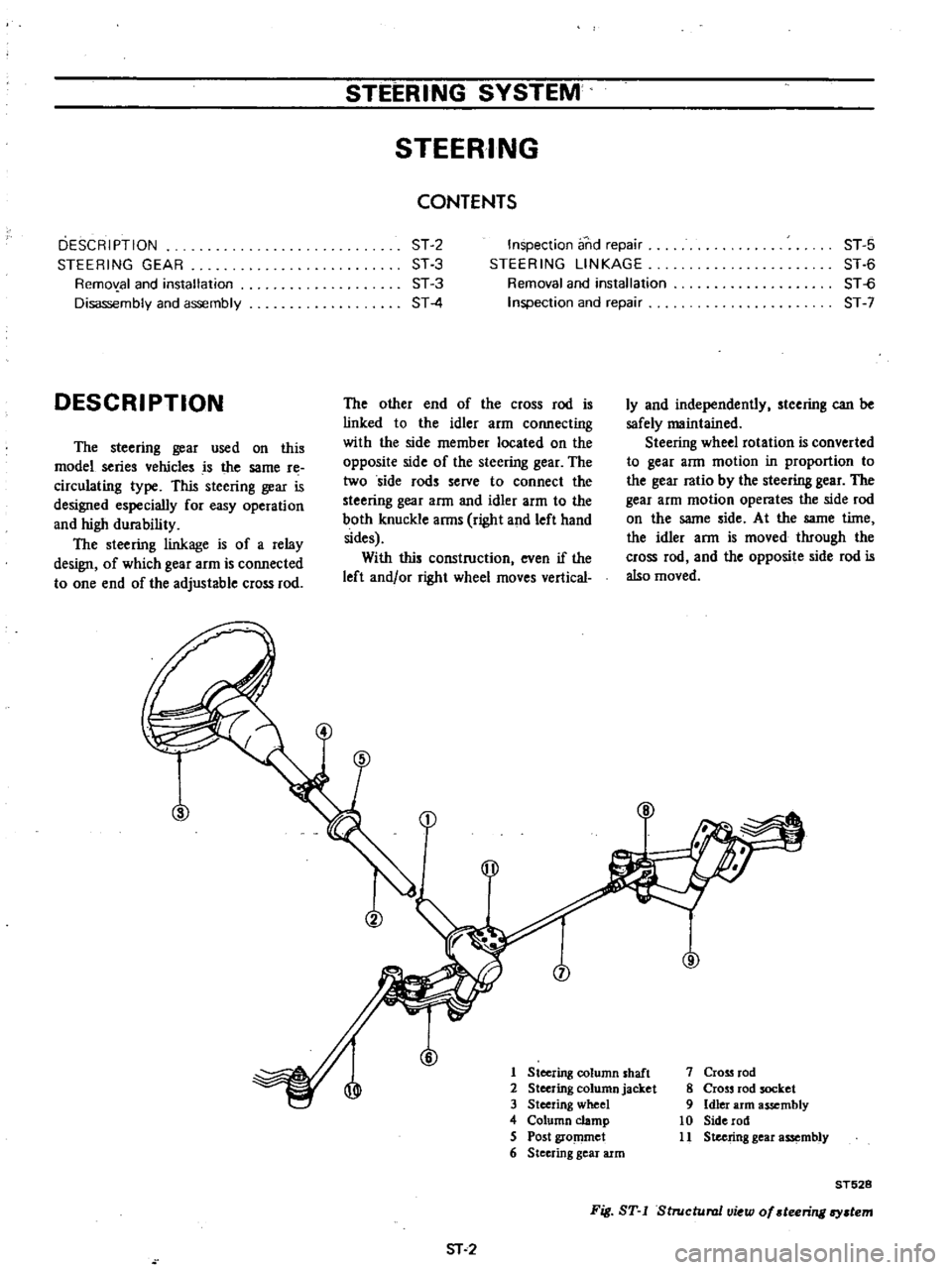

1

Steering

column

shaft

2

Steering

column

jacket

3

Steering

wheel

4

Column

clamp

S

Post

gro

llmet

6

Steering

gear

arm

sr

2

7

Cross

rod

8

Cross

rod

socket

9

Idler

arm

assembly

10

Side

rod

11

Steering

gear

assembly

ST528

Fig

ST

I

Structural

u

w

of

teeriTl

l

tem

Page 408 of 537

STEERING

GEAR

Removal

and

installation

Removal

I

Disconnect

battery

ground

cable

from

the

terminal

2

Remove

horn

pad

by

unscrewing

two

bolts

from

the

rear

side

of

steering

wheel

bar

Note

Be

sure

to

punch

mark

with

0

on

the

top

of

steering

column

shaft

Fig

ST

3

R

moving

horn

pad

STEERING

SYSTEM

A

@

@l

@

J

i

u

p

I

1

jj

ST199

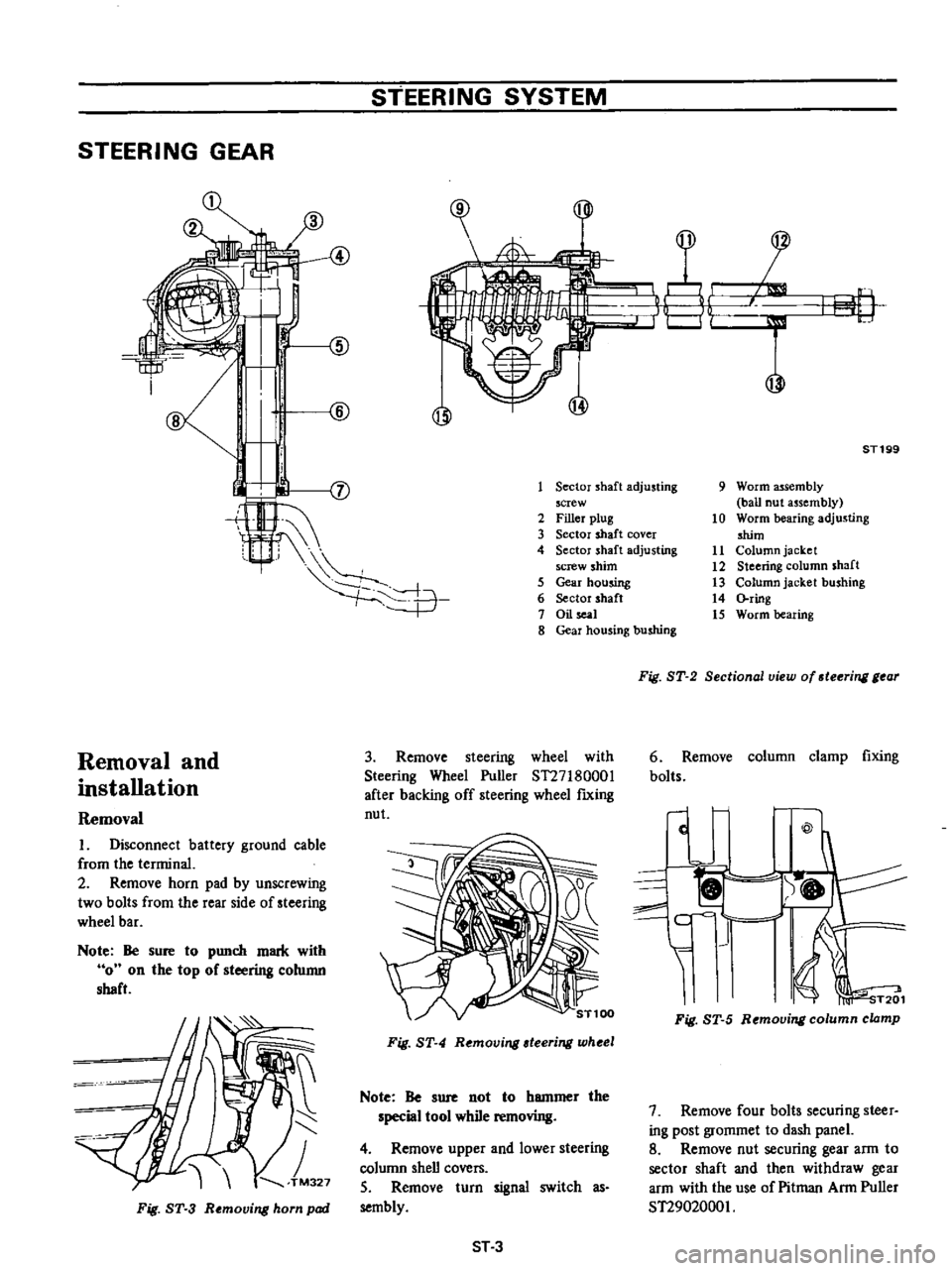

Sector

shaft

adjusting

screw

2

Filler

plug

3

Sector

shaft

cover

4

Sector

shaft

adjusting

screw

shim

5

Gear

housing

6

Sector

shaft

7

Oil

l

8

Gear

housing

bushing

3

Remove

steering

wheel

with

Steering

Wheel

Puller

ST27I80001

after

backing

off

steering

wheel

fIXing

nut

Fig

ST

4

Removing

teering

wheel

Note

Be

sure

not

to

hammer

the

special

tool

while

removing

4

Remove

upper

and

lower

steering

column

shell

covers

S

Remove

turn

signal

switch

as

sembly

ST3

9

Worm

assembly

ball

nut

assembly

10

Worm

bearing

adjusting

shim

11

Column

jacket

12

Steering

column

shaft

13

Column

jacket

bushing

14

ring

15

Worm

bearing

Fig

ST

2

Sectional

view

of

steering

gear

6

Remove

column

clamp

fixing

bolts

c

@

I

f

c

I

1

I

1

i

T201

Fig

ST

5

Removing

column

clamp

7

Remove

four

bolts

securing

steer

ing

post

grommet

to

dash

panel

8

Remove

nut

securing

gear

arm

to

sector

shaft

and

then

withdraw

gear

arm

with

the

use

of

Pitman

Arm

Puller

ST2902000I

Page 409 of 537

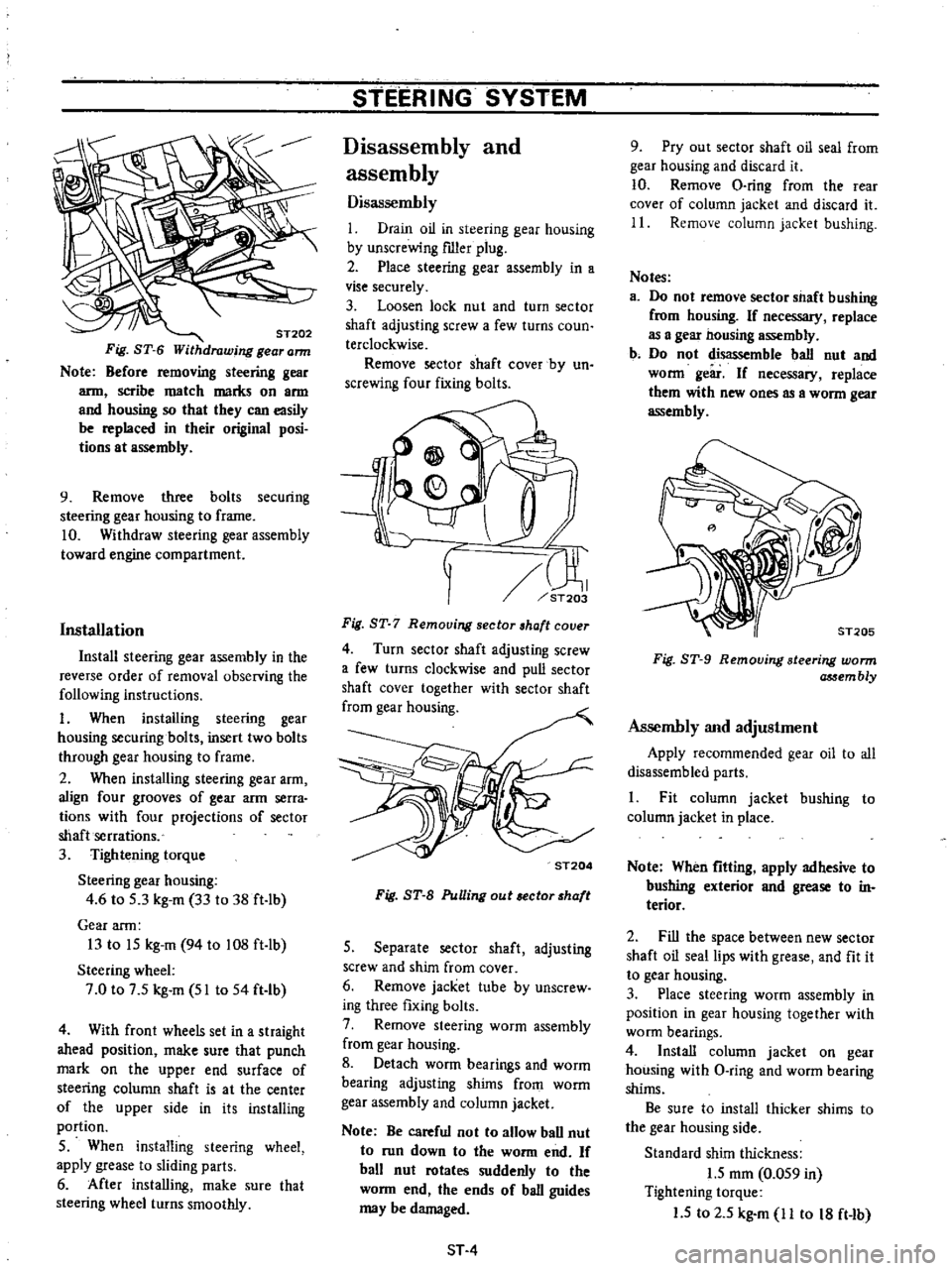

ST202

Fig

ST

6

Withdrawing

gear

ann

Note

Before

removing

steering

gear

arm

scribe

match

marks

on

arm

and

housing

so

that

they

can

easily

be

replaced

in

their

original

posi

tions

at

assembly

9

Remove

three

bolts

securing

steering

gear

housing

to

frame

10

Withdraw

steering

gear

assembly

toward

engine

compartment

Installation

Install

steering

gear

assembly

in

the

reverse

order

of

removal

observing

the

following

instructions

I

When

installing

steering

gear

housing

securing

bolts

insert

two

bolts

through

gear

housing

to

frame

2

When

installing

steering

gear

arm

align

four

grooves

of

gear

arm

serra

tions

with

four

projections

of

sector

shaft

serrations

3

Tightening

torque

Steering

gear

housing

4

6

to

S

3

kg

m

33

to

38

ft

lb

Gear

arm

13

to

IS

kg

m

94

to

108

ft

lb

Steering

wheel

7

0

to

7

S

kg

m

51

to

54

ft

Ib

4

With

front

wheels

set

in

a

straight

ahead

position

make

sure

that

punch

mark

on

the

upper

end

surface

of

steering

column

shaft

is

at

the

center

of

the

upper

side

in

its

installing

portion

S

When

installing

steering

wheel

apply

grease

to

sliding

parts

6

After

installing

make

sure

that

steering

wheel

turns

smoothly

STEERING

SYSTEM

Disassembly

and

assembly

Disassembly

I

Drain

oil

in

steering

gear

housing

by

unscrewing

fIller

plug

2

Place

steering

gear

assembly

in

a

vise

securely

3

Loosen

lock

nut

and

turn

sector

shaft

adjusting

screw

a

few

turns

coun

terclockwise

Remove

sector

shaft

cover

by

un

screwing

four

fixing

bolts

rn

ST203

Fig

ST

7

Remouing

sector

haft

couer

4

Turn

sector

shaft

adjusting

screw

a

few

turns

clockwise

and

pull

sector

shaft

cover

together

with

sector

shaft

from

gear

housing

ST204

Fig

ST

B

PuUing

out

ector

haft

S

Separate

sector

shaft

adjusting

screw

and

shim

from

cover

6

Remove

jacket

tube

by

unscrew

ing

three

fixing

bolts

7

Remove

steering

worm

assembly

from

gear

housing

8

Detach

worm

bearings

and

worm

bearing

adjusting

shims

from

worm

gear

assembly

and

column

jacket

Note

Be

careful

not

to

allow

ball

nut

to

run

down

to

the

worm

end

If

ball

nut

rotates

suddenly

to

the

worm

end

the

ends

of

ball

guides

may

be

damaged

ST

4

9

Pry

out

sector

shaft

oil

seal

from

gear

housing

and

discard

it

10

Remove

O

ring

from

the

rear

cover

of

column

jacket

and

discard

it

11

Remove

column

jacket

bushing

Notes

a

Do

not

remove

sector

shaft

bushing

from

housing

If

necessary

replace

as

a

gea2

nousing

assembly

b

Do

not

disassemble

ball

nut

and

worm

geir

If

necessary

replace

them

with

new

ones

as

a

worm

gear

assembly

Fig

ST

9

Removing

steering

worm

assem

bly

Assembly

and

adjustment

Apply

recommended

gear

oil

to

all

disassembled

parts

1

Fit

column

jacket

bushing

to

column

jacket

in

place

Note

When

fitting

apply

adhesive

to

bushing

exterior

and

grease

to

in

terior

2

Fill

the

space

between

new

sector

shaft

oil

seal

lips

with

grease

and

fit

it

to

gear

housing

3

Place

steering

worm

assembly

in

position

in

gear

housing

together

with

worm

bearings

4

Install

column

jacket

on

gear

housing

with

O

ring

and

worm

bearing

shims

Be

sure

to

install

thicker

shims

to

the

gear

housing

side

Standard

shim

thickness

1

5

mOl

0

OS9

in

Tightening

torque

1

5

to

2

S

kg

m

11

to

18

ft

Ib

Page 411 of 537

STEERING

LINKAGE

Removal

and

installation

Removal

I

Jack

up

the

front

of

vehicle

and

support

it

on

the

safety

stands

2

Remove

cotter

pins

and

nuts

fas

tening

side

rod

ball

stud

to

knuckle

arms

3

To

detach

side

rod

ball

studs

from

knuckle

arms

insert

Ball

Joint

Remover

HT72520000

between

them

and

separate

them

by

striking

the

top

of

this

tool

with

a

hammer

If

this

operation

must

be

done

without

this

tool

strike

the

knuckle

arm

boss

with

a

hammer

backing

up

the

opposite

side

of

it

with

a

large

hammer

and

bail

stud

is

freed

from

knuckle

arm

Must

not

strike

the

baIl

stud

head

the

ball

socket

of

side

rod

and

side

rod

with

a

hammer

and

so

on

in

this

operation

Fig

ST

11

Ball

joints

Ic

ann

side

4

Remove

riut

securing

gear

armOD

sector

shaft

and

remove

gear

arm

with

the

use

of

Pitman

Arm

Puller

ST29020001

See

Figure

ST

6

S

Remove

idler

arm

assembly

from

frame

by

backing

off

fixing

bolt

and

nut

Ffa

ST

12

Removing

idler

ann

STEERING

SYSTEM

6

Cross

rod

both

side

rods

and

the

adjacent

parts

can

then

be

freed

from

the

vehicle

as

an

assembly

7

Then

separate

the

ball

joints

of

steering

linkage

assembly

following

the

procedure

for

removal

of

the

side

rods

ball

joints

at

knuckle

arm

sides

Assembly

Install

steering

linkage

in

the

reo

verse

sequence

of

removal

observing

the

following

notes

Tightening

torque

Ball

stud

S

S

to

10

0

kg

m

40

to

72

ft

lb

Idler

arm

assembly

3

2

to

3

7

kg

m

23

to

27

ft

lb

Cross

rod

adjust

bar

lock

nut

8

to

10

kg

m

72

fL

2

f

2

When

cross

rod

sockets

and

cross

rod

are

separated

adjust

cross

rod

length

correctly

Adjustment

should

be

done

be

tween

the

centers

of

ball

joints

at

the

both

end

of

cross

rod

assembly

Standard

cross

rod

length

516

rom

20

31

in

3

Adjust

toe

in

and

steering

angle

The

procedures

of

toe

in

and

steer

ing

angle

adjustments

Ie

described

in

Section

F

A

Toe

in

1

to

5

mm

0

04

to

0

20

in

Steering

angle

Inner

wheel

3S030

to

36030

Outer

wheel

30030

to

31030

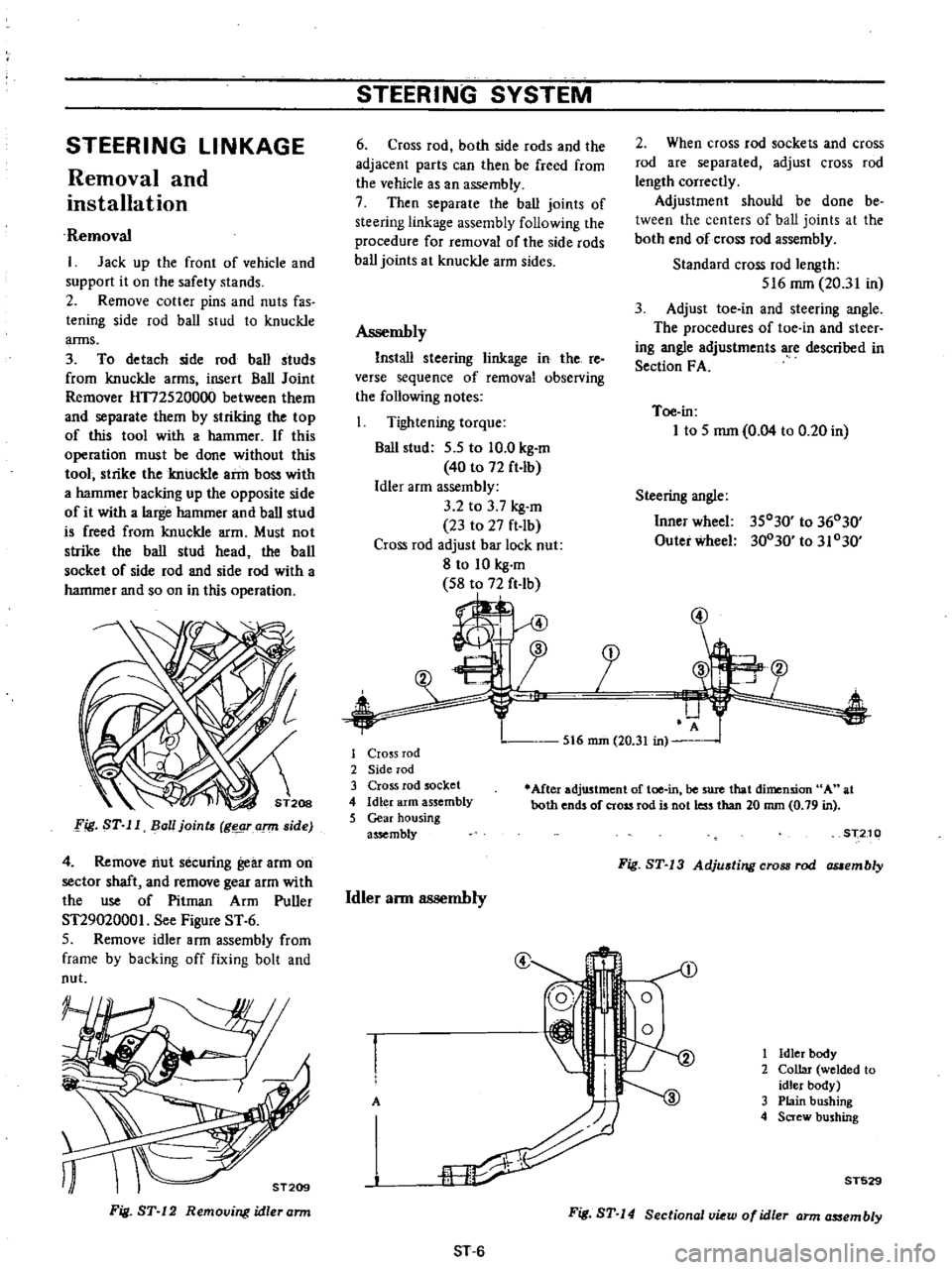

5t6

mm

20

31

in

1

Cro

s

rod

2

Side

rod

3

Cross

rod

socket

4

Idler

arm

assembly

5

Gear

housing

assembly

Mter

adjustment

of

toe

in

be

sure

that

dimension

A

at

both

ends

of

cross

rod

is

not

less

than

20

nun

0

79

in

Idler

ann

assembly

ST210

Fig

ST

13

Adjusting

cross

rod

assembly

@

1

Idler

body

2

Collar

welded

to

idler

body

A

3

Plain

bushing

4

Screw

bushing

T529

ST

6

Fig

ST

14

Sectional

W

of

idler

arm

as

sembly

Page 412 of 537

I

J

L6

3

4

5

1

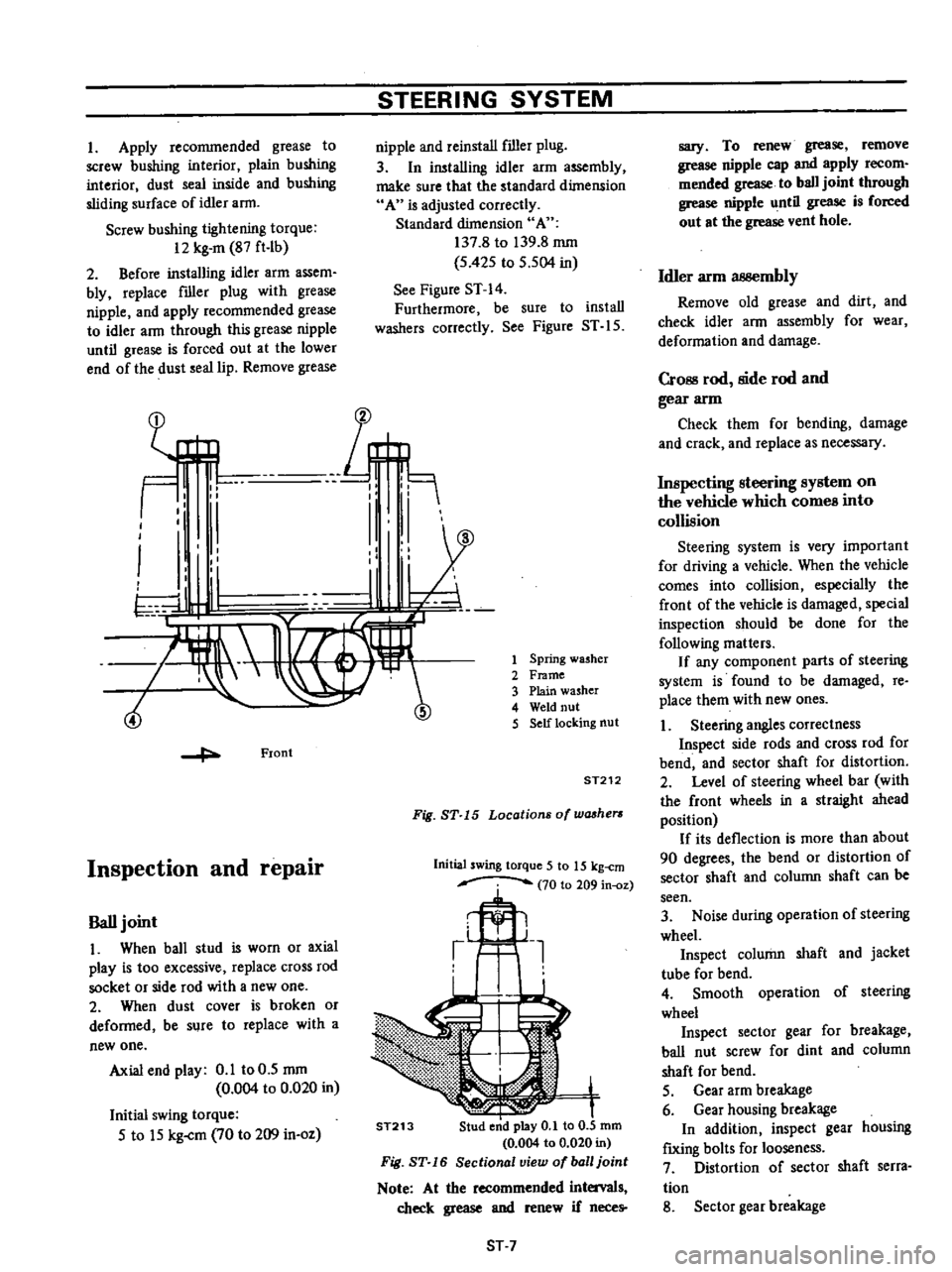

Apply

recommended

grease

to

screw

bushing

interior

plain

bushing

interior

dust

seal

inside

and

bushing

sliding

surface

of

idler

ann

Screw

bushing

tightening

torque

12

kg

m

87

ft

lb

2

Before

installing

idler

arm

assem

bly

replace

f

iller

plug

with

grease

nipple

and

apply

recommended

grease

to

idler

ann

through

this

grease

nipple

until

grease

is

forced

out

at

the

lower

end

of

the

dust

seal

lip

Remove

grease

I

8

I

II

I

I

FIODt

Inspection

and

repair

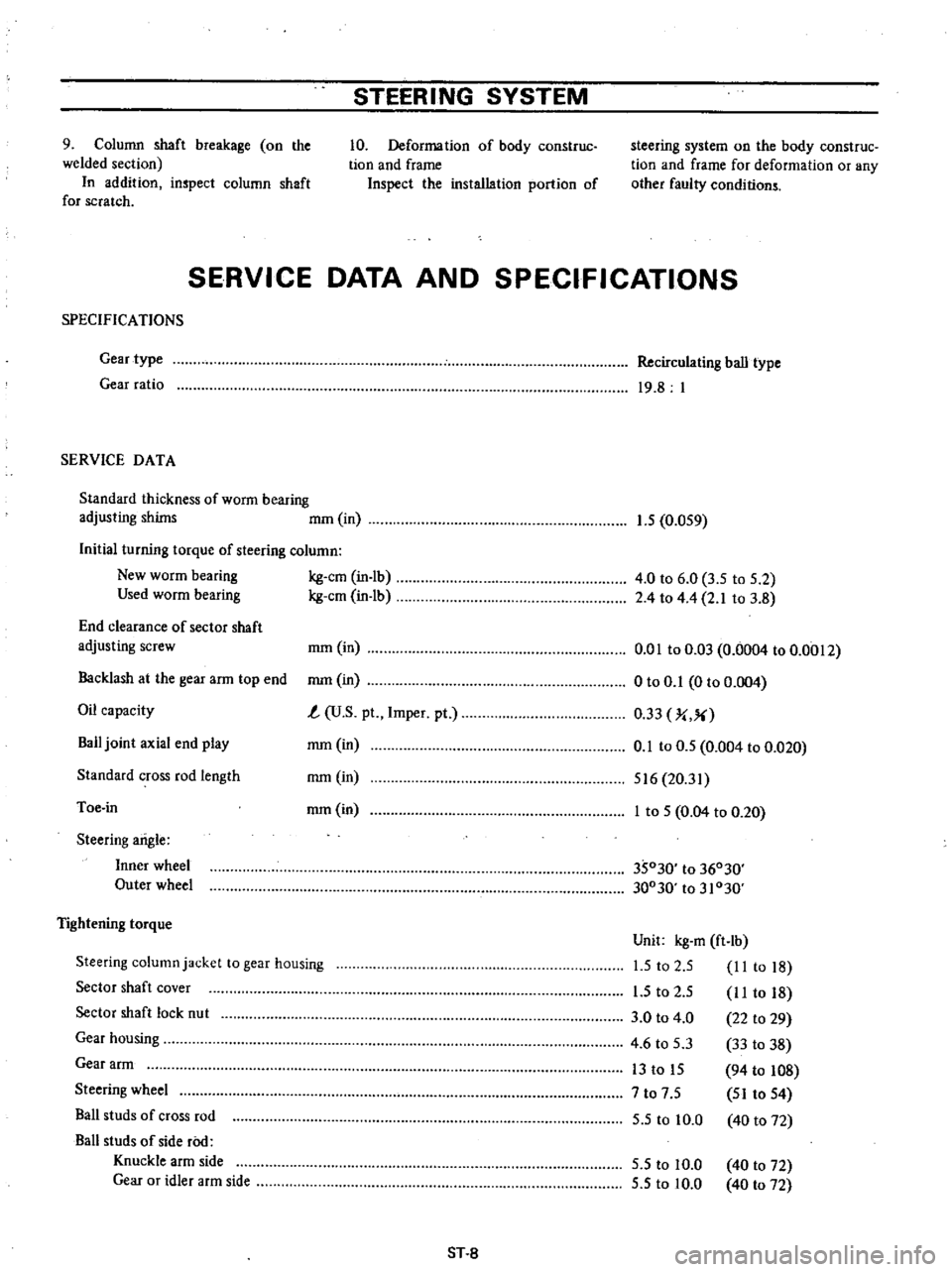

Ball

joint

1

When

ball

stud

is

worn

or

axial

play

is

too

excessive

replace

cross

rod

socket

or

side

rod

with

a

new

one

2

When

dust

cover

is

broken

or

defonned

be

sure

to

replace

with

a

new

one

Axial

end

play

0

1

to

0

5

mm

0

004

to

0

020

in

Initial

swing

torque

S

to

15

kg

cm

70

to

209

in

oz

STEERING

SYSTEM

nipple

and

reinstall

filler

plug

3

In

installing

idler

arm

assembly

make

sure

that

the

standard

dimension

A

is

adjusted

correctly

Standard

dimension

A

137

8

to

139

8

mm

S

42S

to

S

504

in

See

Figure

ST

14

Furthermore

be

sure

to

install

washers

correctly

See

Figure

ST

IS

Spring

washer

Frame

Plain

washer

Weld

nut

Self

locking

nut

ST212

Fig

ST

15

Locations

of

washers

Initial

swing

torque

5

to

15

kg

cm

70

to

209

in

oz

ST213

ST

7

sary

To

renew

grease

remove

grease

nipple

cap

and

apply

recom

mended

grease

to

ball

joint

through

grease

nipple

until

grease

is

forced

out

at

the

grease

vent

hole

Idler

arm

3B8embly

Remove

old

grease

and

dirt

and

check

idler

ann

assembly

for

wear

deformation

and

damage

CrOBS

rod

side

rod

and

gear

arm

Check

them

for

bending

damage

and

crack

and

replace

as

necessary

Inspecting

steering

system

on

the

vehicle

which

comes

into

collision

Steering

system

is

very

important

for

driving

a

vehicle

When

the

vehicle

comes

into

collision

especially

the

front

of

the

vehicle

is

damaged

special

inspection

should

be

done

for

the

following

matters

If

any

component

parts

of

steering

system

is

found

to

be

damaged

re

place

them

with

new

ones

1

Steering

angles

correctness

Inspect

side

rods

and

cross

rod

for

bend

and

sector

shaft

for

distortion

2

Level

of

steering

wheel

bar

with

the

front

wheels

in

a

straight

ahead

position

If

its

deflection

is

more

than

about

90

degrees

the

bend

or

distortion

of

sector

shaft

and

column

shaft

can

be

seen

3

Noise

during

operation

of

steering

wheel

Inspect

column

shaft

and

jacket

tube

for

bend

4

Smooth

operation

of

steering

wheel

Inspect

sector

gear

for

breakage

ball

nut

screw

for

dint

and

column

shaft

for

bend

S

Gear

arm

breakage

6

Gear

housing

breakage

In

addition

inspect

gear

housing

f

IXing

bolts

for

looseness

7

Distortion

of

sector

shaft

serra

tion

8

Sector

gear

breakage

Page 413 of 537

STEERING

SYSTEM

9

Column

shaft

breakage

on

the

welded

section

In

addition

inspect

column

shaft

for

scratch

10

Deformation

of

body

construc

tion

and

frame

Inspect

the

installation

portion

of

steering

system

on

the

body

construe

tion

and

frame

for

deformation

or

any

other

faulty

conditions

SERVICE

DATA

AND

SPECIFICATIONS

SPECIFICA

nONS

Gear

type

Gear

ratio

SERVICE

DATA

Standard

thickness

of

worm

bearing

adjusting

shims

mOl

in

Initial

turning

torque

of

steering

column

New

worm

bearing

kg

em

in

lb

Used

worm

bearing

kg

em

in

lb

End

clearance

of

sector

shaft

adjusting

screw

rom

in

Backlash

at

the

gear

arm

top

end

rom

in

Oil

capacity

t

U

S

pt

Impel

pt

Bail

joint

axial

end

play

rom

in

Standard

cross

rod

length

rom

in

Toe

in

rom

in

Steering

arigle

Inner

wheel

Outer

wheel

Tightening

torque

Steering

column

jacket

to

gear

housing

Sector

shaft

cover

Sector

shaft

lock

nut

Gear

housing

Gear

arm

Steering

wheel

Bail

studs

of

cross

rod

Ball

studs

of

side

roo

Knuckle

arm

side

Gear

or

idler

arm

side

ST

8

Recirculating

ball

type

19

8

I

1

5

0

OS9

4

0

to

6

0

3

5

to

S

2

2

4

to

4

4

2

1

to

3

8

om

to

0

03

0

0004

to

0

0012

o

to

0

1

0

to

0

004

0

33

J

X

0

1

to

0

5

0

004

to

0

020

516

20

31

I

to

S

0

04

to

0

20

35030

to

36030

30030

to

31030

Unit

kg

m

ft

lb

1

5

to

2

S

II

to

18

I

S

to

2

S

I

I

to

18

3

0

to

4

0

22

to

29

4

6

to

5

3

33

to

38

13

to

IS

94

to

108

7

to

7

S

SI

to

S4

S

S

to

10

0

40

to

72

S

S

to

10

0

S

5

to

10

0

40

to

72

40

to

72

Page 414 of 537

STEERING

SYSTEM

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Steering

wheel

moves

heavily

Steering

wheel

turns

but

sluggishly

Vehicle

pulls

to

one

side

Probable

cause

Wheel

alignment

out

of

specifications

or

air

pressure

in

tires

too

low

Steering

linkage

out

of

adjustment

Steering

column

out

of

alignment

Wheels

out

of

alignment

or

air

pressure

in

tires

too

low

Damaged

steering

linkage

Wheels

out

of

proper

alignment

Wheel

bearing

out

of

adjustment

Damaged

steering

linkage

ST

9

Corrective

action

Align

or

inflate

tires

to

correct

pressure

Adjust

and

see

relative

topic

under

Front

Suspension

Repair

Repair

or

inflate

tires

to

correct

air

pressure

Replace

and

see

relative

topic

under

Front

Suspension

Align

Adjust

Replace

and

see

relative

topic

under

Front

Suspension

Page 415 of 537

STEERING

SYSTEM

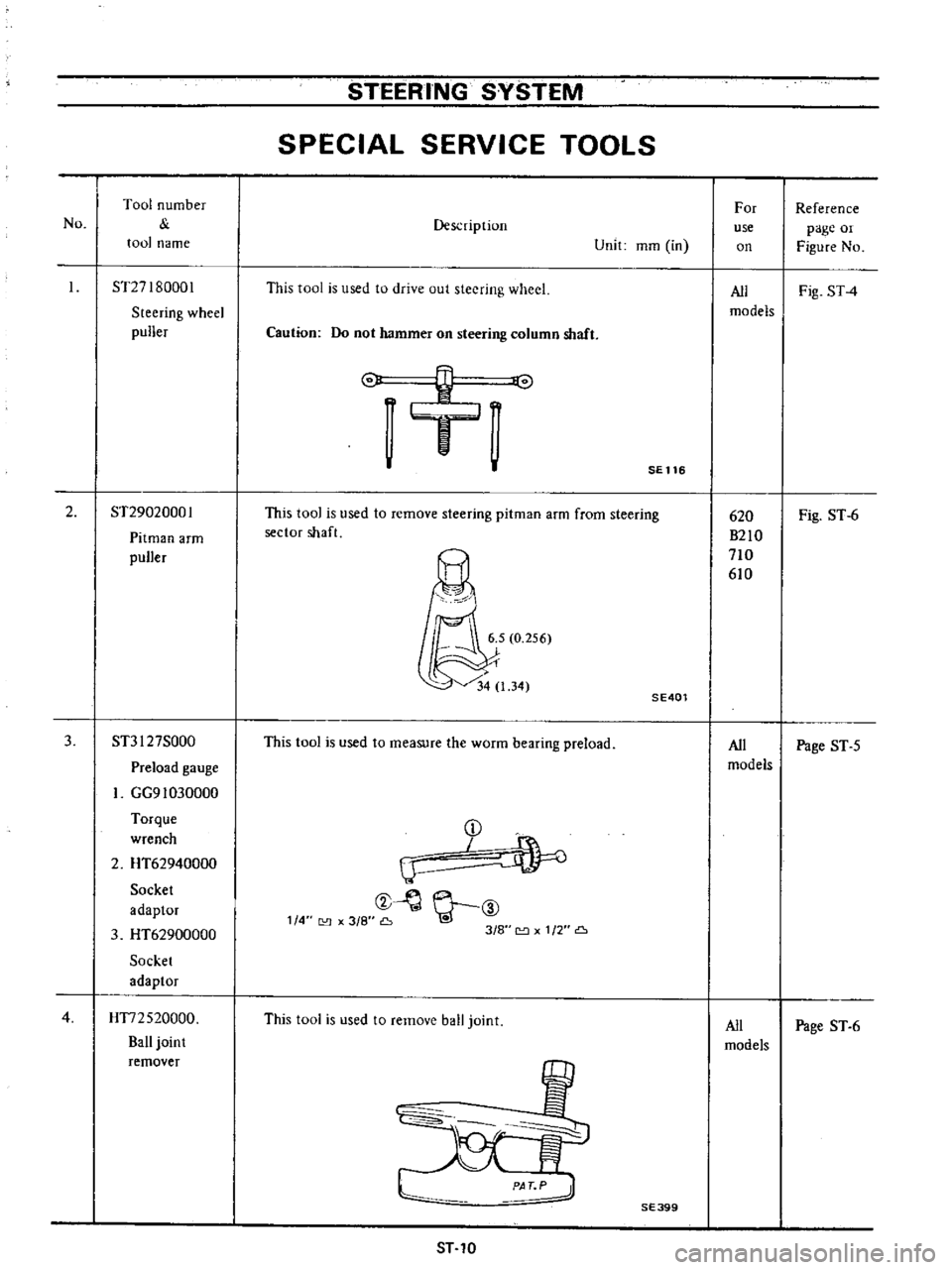

SPECIAL

SERVICE

TOOLS

No

Tool

number

tool

name

Description

Unit

mOl

in

For

use

on

Reference

page

or

Figure

No

ST27I80001

Steering

wheel

puller

This

tool

is

used

to

drive

out

steering

wheel

All

Fig

ST4

models

Caution

Do

not

hammer

on

steering

column

shaft

o

v

J

SE

116

2

ST29020001

Pitman

arm

puller

This

tool

is

used

to

remove

steering

pitman

arm

from

steering

sector

shaft

Fig

ST

6

SE401

3

ST3I

27S000

This

tool

is

used

to

measure

the

worm

bearing

preload

All

Page

ST

5

Preload

gauge

models

GG91030000

Torque

D

wrench

I

2

HT62940000

IJ

Socket

t

Y

ID

adaptor

114

3

8

Go

3

HT62900000

318

1

2

Socket

adaptor

4

HT72520000

This

tool

is

used

to

remove

ball

joint

All

Page

ST

6

Ball

joint

models

remover

620

B210

710

610

SE399

ST

10

Page 428 of 537

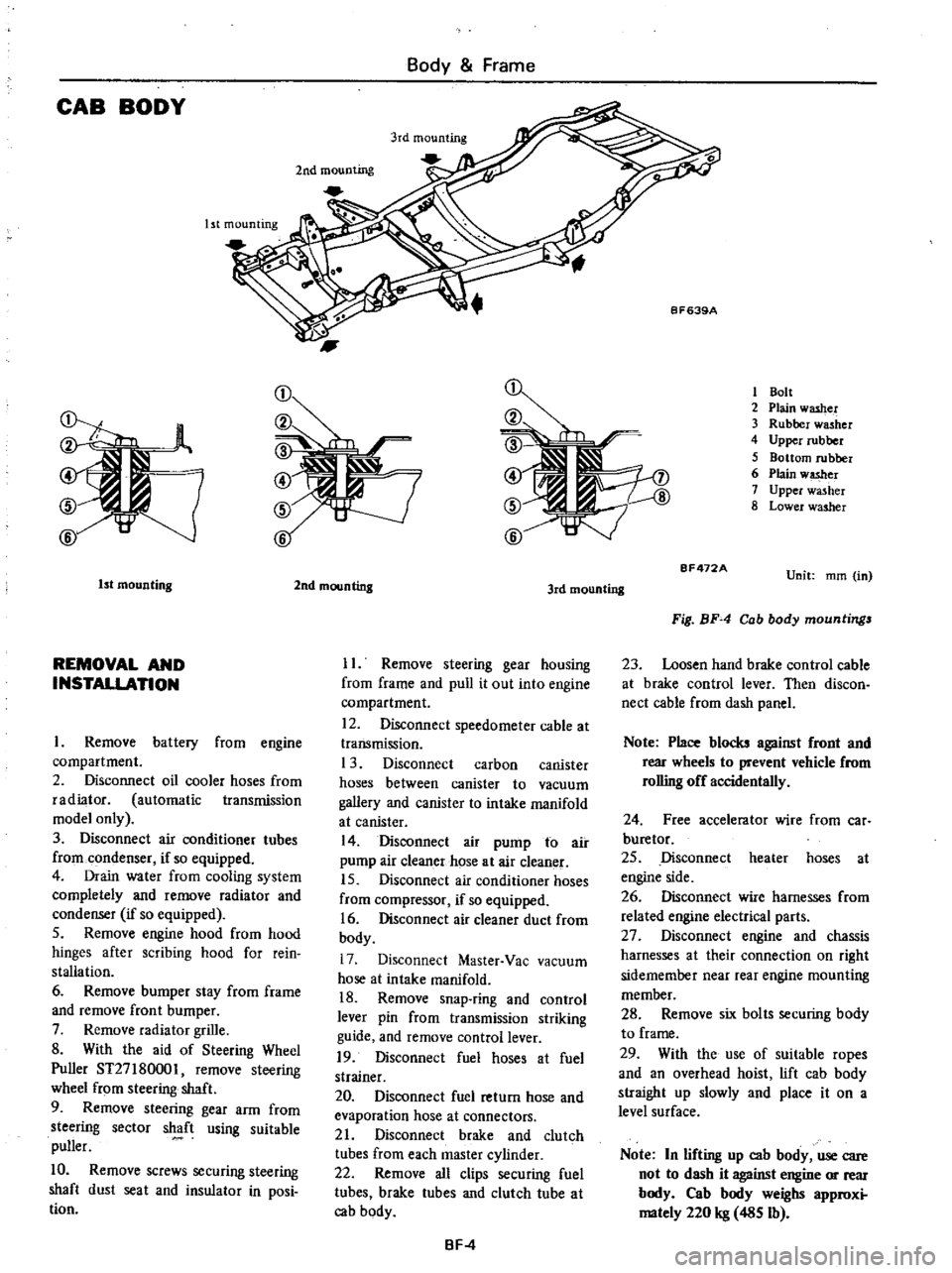

CAB

BODY

Body

Frame

Ist

mounting

2nd

mounting

1

Bolt

2

Plain

washer

3

Rubber

washer

4

Upper

rubber

5

Bottom

rubber

6

Plain

w

er

7

Upper

washer

8

Lower

washer

1st

mounting

REMOVAL

AND

INSTALLATION

Remove

battery

from

engine

compartment

2

Disconnect

oil

cooler

hoses

from

radiator

automatic

transmission

model

only

3

Disconnect

air

conditioner

tubes

from

condenser

if

so

equipped

4

Drain

water

from

cooling

system

completely

and

remove

radiator

and

condenser

if

so

equipped

5

Remove

engine

hood

from

hood

hinges

after

scribing

hood

for

rein

stallation

6

Remove

bumper

stay

from

frame

and

remove

front

bumper

7

Remove

radiator

grille

8

With

the

aid

of

Steering

Wheel

Puller

ST27

180001

remove

steering

wheel

from

steering

shaft

9

Remove

steering

gear

arm

from

steering

sector

shaft

using

suitable

puller

10

Remove

screws

securing

steering

shaft

dust

seat

and

insulator

in

posi

tion

2nd

mounting

3rd

mounting

II

Remove

steering

gear

housing

from

frame

and

pull

it

out

into

engine

compartment

12

Disconnect

speedometer

cable

at

transmission

1

3

Disconnect

carbon

canister

hoses

between

canister

to

vacuum

gallery

and

canister

to

intake

manifold

at

canister

14

Disconnect

air

pump

to

air

pump

air

cleaner

hose

at

air

cleaner

15

Disconnect

air

conditioner

hoses

from

compressor

if

so

equipped

16

Disconnect

air

cleaner

duct

from

body

17

Disconnect

Master

Vac

vacuum

hose

at

intake

manifold

18

Remove

snap

ring

and

control

lever

pin

from

transmission

striking

guide

and

remove

control

lever

19

Disconnect

fuel

hoses

at

fuel

strainer

20

Disconnect

fuel

return

hose

and

evaporation

hose

at

connectors

21

Disconnect

brake

and

clutch

tubes

from

each

master

cylinder

22

Remove

all

clips

securing

fuel

tubes

brake

tubes

and

clutch

tube

at

cab

body

BF

4

BF472A

Unit

mm

in

Fig

BF

4

Cab

body

mountings

23

Loosen

hand

brake

control

cable

at

brake

control

lever

Then

discon

nect

cable

from

dash

panel

Note

Place

blocks

against

front

and

rear

wheels

to

prevent

vehicle

from

rolling

off

accidentally

24

Free

accelerator

wire

from

car

buretor

25

Disconnect

heater

hoses

at

engine

side

26

Disconnect

wire

harnesses

from

related

engine

electrical

parts

27

Disconnect

engine

and

chassis

harnesses

at

their

connection

on

right

sidemember

near

rear

engine

mounting

member

28

Remove

six

bolts

securing

body

to

frame

29

With

the

use

of

suitable

ropes

and

an

overhead

hoist

lift

cab

body

straight

up

slowly

and

place

it

on

a

level

surface

Note

In

lifting

up

cab

body

use

care

not

to

dash

it

against

engine

or

rear

body

Cab

body

weighs

approxi

mately

220

kg

485

Ib