torque DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 19 of 537

Engine

Tune

up

BASIC

MECHANICAL

SYSTEM

ADJUSTING

INTAKE

AND

EXHAUST

VALVE

CLEARANCE

CHECKING

AND

ADJUSTING

DRIVE

BELT

RETIGHTENING

CYLINDER

HEAD

BOLTS

MANIFOLD

NUTS

AND

CARBURETOR

SECURING

NUTS

CHECKING

ENGINE

OIL

REPLACING

OIL

FILTER

CHANGING

ENGINE

COOLANT

ADJUSTING

INTAKE

AND

EXHAUST

VALVE

CLEARANCE

Note

After

tightening

cylinder

head

bolts

adjust

intake

and

exhaust

valve

clearances

Valve

clearance

adjustment

is

impossible

when

the

engine

is

in

oper

ation

1

Loosen

pivot

locking

nu

t

and

turn

pivot

screw

until

the

specified

clearance

is

obtained

while

cold

Using

service

tool

tighten

pivot

locking

nut

securely

after

adjustment

and

recheck

the

clearance

2

Warm

up

engine

for

at

least

several

minutes

and

stop

it

Measure

valve

clearance

while

hot

If

out

of

specifications

adjust

Unit

mm

in

Intake

0

20

0

008

Cold

Exhaust

0

25

0

010

Intake

0

25

OmO

Wann

I

Exhaust

0

30

0

012

STl

064000

I

ET009

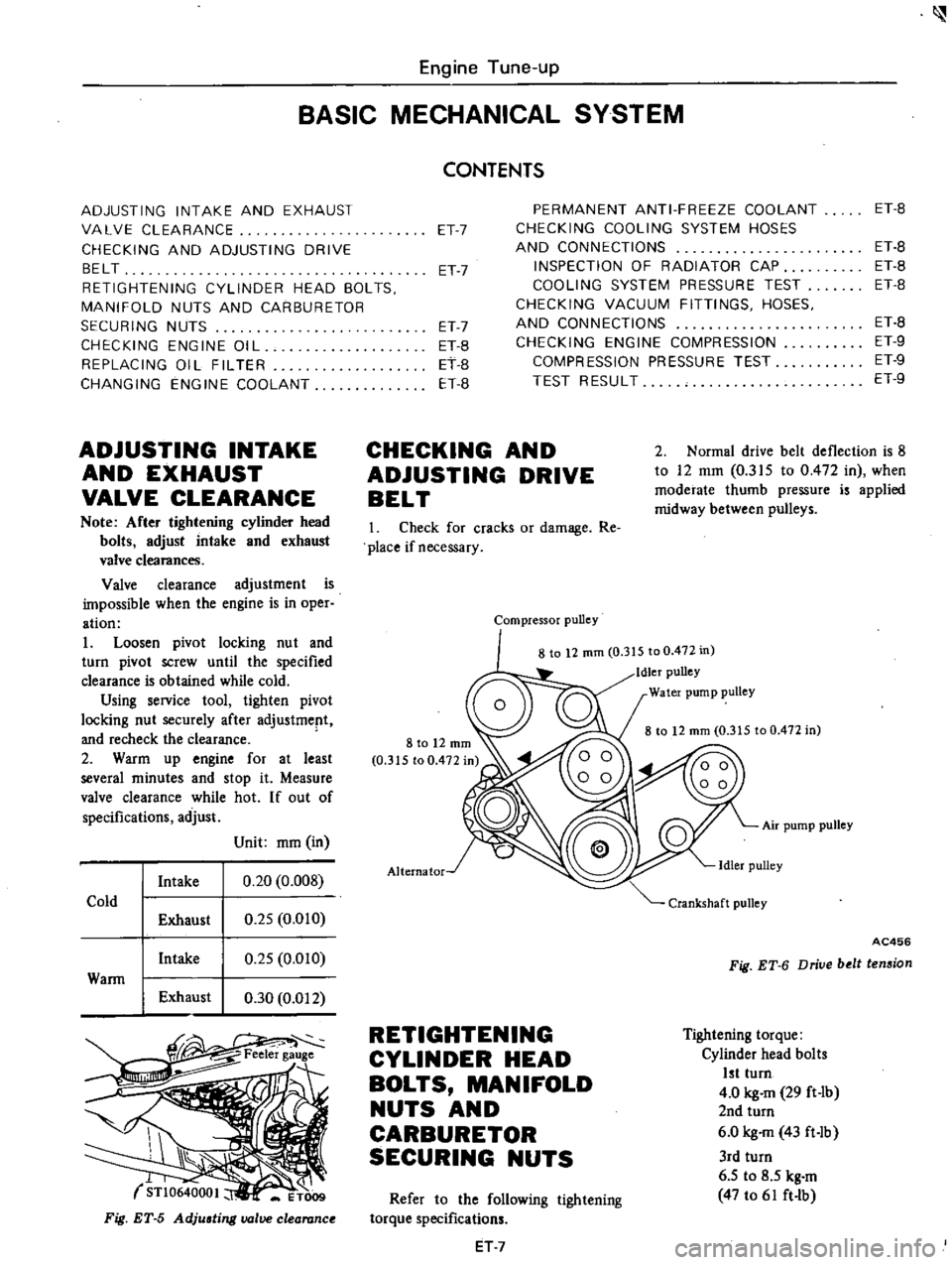

Fig

ET

5

Adjusting

valve

clearance

CONTENTS

ET

7

PERMANENT

ANTI

FREEZE

COOLANT

CHECKING

COOLING

SYSTEM

HOSES

AND

CONNECTIONS

INSPECTION

OF

RADIATOR

CAP

COOLING

SYSTEM

PRESSURE

TEST

CHECKING

VACUUM

FITTINGS

HOSES

AND

CONNECTIONS

CHECKING

ENGINE

COMPRESSION

COMPRESSION

PRESSURE

TEST

TEST

RESULT

ET

7

ET7

ET

B

ET

B

ET

B

CHECKING

AND

ADJUSTING

DRIVE

BELT

ET

B

ET

B

ET

B

ET

B

ET

B

ET

9

ET

9

ET

9

2

Normal

drive

belt

deflection

is

8

to

12

mm

0

315

to

0

472

in

when

moderate

thumb

pressure

is

applied

midway

between

pulleys

1

Check

for

cracks

or

damage

Re

place

if

necessary

Compressor

pulley

8

to

12

mm

0

315

to

0

472

in

Idler

pulley

Water

pump

pulley

8

to

12

mm

0

315

to

0

472

in

Air

pump

pulley

Alternator

AC456

Fig

ET

6

Driue

belt

tension

RETIGHTENING

CYLINDER

HEAD

BOLTS

MANIFOLD

NUTS

AND

CARBURETOR

SECURING

NUTS

Tightening

torque

Cylinder

head

bolts

1st

turn

4

0

kg

m

29

ft

Ib

2nd

turn

6

0

kg

m

43

ft

Ib

3rd

turn

6

5

to

8

5

kg

m

47

to

61

ft

lb

Refer

to

the

following

tightening

torque

specifications

ET

7

Page 38 of 537

r

Engine

Tune

up

A

T

C

air

cleaner

Operating

temperature

OC

OF

30

to

54

86

to

129

Tightening

torque

Cylinder

head

bolts

1st

turn

2nd

turn

3rd

turn

Spark

plugs

kg

m

ft

b

kg

lll

ft

lb

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

4

0

29

6

0

43

6

5

to

8

5

47

to

61

1

2

to

1

6

8

7

to

11

6

0

5

to

1

0

3

6

to

7

2

1

5

to

2

0

II

to

14

Manifold

nuts

Carburetor

nuts

ET

26

Page 40 of 537

Engine

Tune

up

Condition

Probable

cause

Low

or

no

current

Ign

tion

system

out

of

order

Burned

distributor

point

Improper

point

gap

Faulty

condenser

Leak

at

rotor

cap

and

rotor

Faulty

spark

plug

Improper

ignition

timing

Faulty

ignition

coil

Disconnection

of

high

tension

cable

Loose

connection

or

disconnection

in

primary

circuit

Fuel

system

out

of

order

Lack

offuel

Dirty

fuel

strainer

Dirty

or

clogged

fuel

pipe

Fuel

pump

will

not

work

properly

Carburetor

choke

will

not

work

properly

Improper

adjustment

of

float

level

Improper

idling

Dirty

or

clogged

carburetor

Clogged

breather

pip

of

fuel

tank

Malfunctioning

an

ti

dieseling

solenoid

valve

Incorrect

sparle

plug

tightening

or

faulty

gasket

Improper

grade

engine

oil

or

low

viscosity

Incorrect

valve

clearance

Compression

leak

from

valve

seat

Sticky

valve

stem

Weak

or

damaged

valve

springs

Compression

leak

at

cylinder

head

gasket

Sticking

or

damaged

piston

ring

Worn

piston

ring

or

cylinder

Trouble

ooting

procedure

Pour

the

engine

oil

from

plug

hole

and

then

measure

cylinder

compression

Compression

increases

Compression

does

not

change

Low

comp

ion

ET

28

Corrective

action

Check

for

loose

terminal

or

disconnection

in

primary

circuit

Check

for

burned

points

Repair

or

replace

Adjust

Replace

Clean

or

replace

aean

adjust

plug

gap

or

replace

Adjust

Replace

Replace

Repair

or

replace

Supply

Replace

Clean

Repair

or

replace

Check

and

adjust

Correct

Adjust

Disassemble

and

clean

Repair

and

clean

Check

for

loose

terminal

or

wire

harness

Tighten

to

normal

torque

or

replace

gasket

Replace

with

proper

grade

oil

Adjust

Remove

cyljnder

head

and

lap

valves

Correct

or

replace

valve

and

valve

guide

Replace

valve

springs

Replace

gasket

Replace

piston

rings

Overhaul

engine

Malfunctiong

cylinder

or

piston

ring

Compression

leaks

from

valve

cylinder

head

or

head

gasket

Except

transistor

ignition

system

Page 44 of 537

Condition

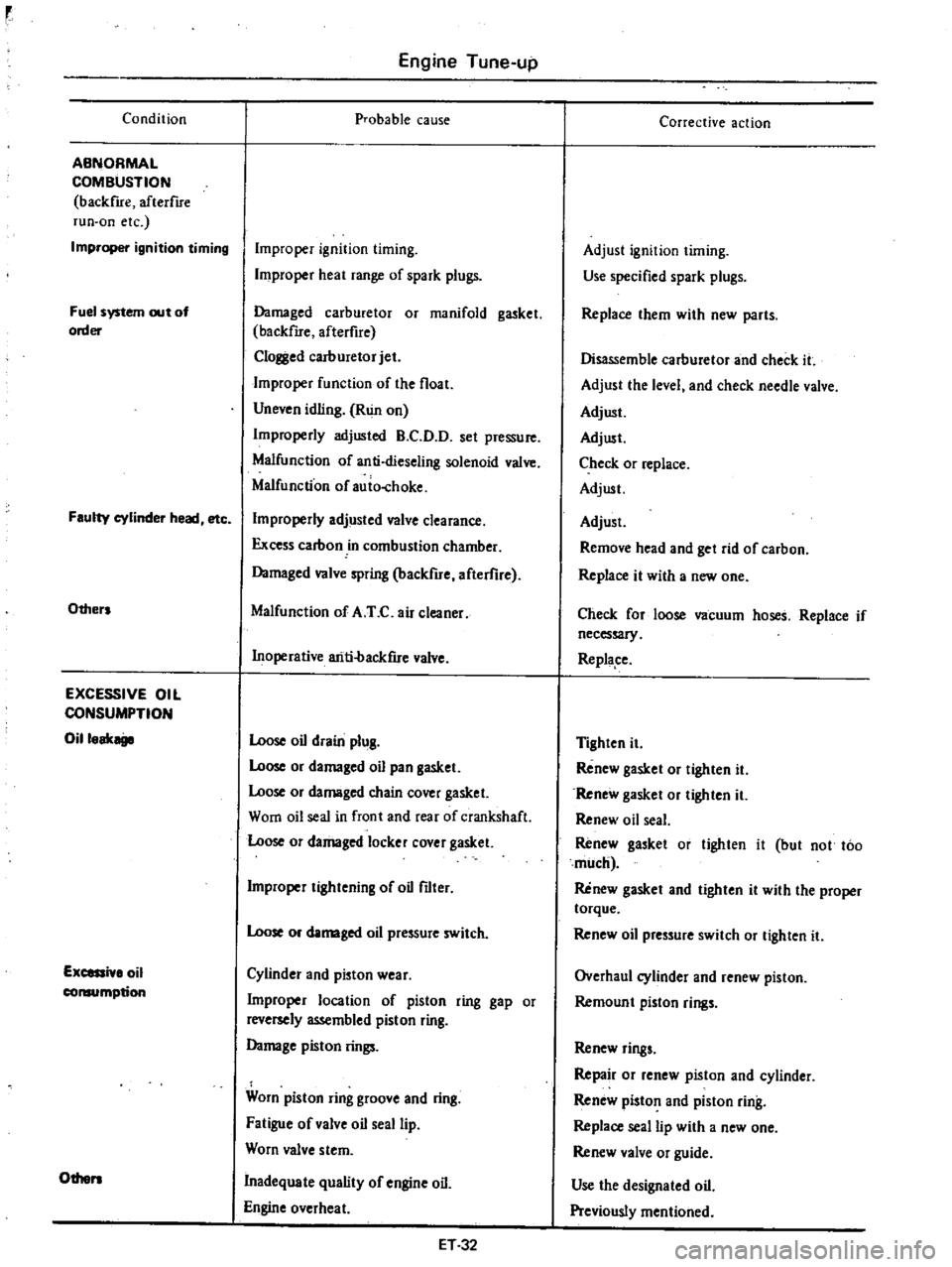

ABNORMAL

COMBUSTION

backfue

afterflre

run

on

etc

Improper

ignition

timing

Fuel

system

out

of

order

Faulty

cylinder

head

etc

Others

EXCESSIVE

OIL

CONSUMPTION

Oilloak

Excessi

lo

oil

consumption

Others

Engine

Tune

up

probable

cause

Improper

ignition

timing

Improper

heat

range

of

spark

plugs

Damaged

carburetor

or

manifold

gasket

backfue

afterfire

Clol

l

ed

carburetor

jet

Improper

function

of

the

float

Uneven

idling

Run

on

Improperly

adjusted

B

C

D

D

set

pressure

Malfunction

of

anti

dieseling

solenoid

valve

Malfunction

of

auio

choke

Improperly

adjusted

valve

clearance

Excess

carbon

in

combustion

chamber

Damaged

valve

spring

backfire

afterflre

Malfunction

of

A

T

C

air

cleaner

Inoperative

ariti

backfue

valve

Loose

oil

drain

plug

Loose

or

damaged

oil

pan

gasket

Loose

or

damaged

chain

cover

gasket

Worn

oil

seal

in

front

and

rear

of

crankshaft

Loose

or

damaged

locker

cover

gasket

Improper

tightening

of

oil

filter

Loose

or

damaged

oil

pressure

switch

Cylinder

and

pioton

wear

Improper

location

of

piston

ring

gap

or

reversely

assembled

piston

ring

Damage

piston

rings

Worn

piston

ring

groove

and

ring

Fatigue

of

valve

oil

seal

lip

Worn

valve

stem

Inadequate

quality

of

engine

oil

Engine

overheat

ET32

Corrective

action

Adjust

ignition

timing

Use

specified

spark

plugs

Replace

them

with

new

parts

Disassemble

carburetor

and

check

it

Adjust

the

level

and

check

needle

valve

Adjust

Adjust

Check

or

replace

Adjust

Adjust

Remove

head

and

get

rid

of

carbon

Replace

it

with

a

new

one

Check

for

loose

vacuum

hoses

Replace

if

necessary

Replape

Tighten

it

Renew

gasket

or

tighten

it

Renew

gasket

or

tighten

it

Renew

oil

seal

Renew

gasket

or

tighten

it

but

not

too

much

Renew

gasket

and

tighten

it

with

the

proper

torque

Renew

oil

pressure

switch

or

tighten

it

Overhaul

cylinder

and

renew

piston

Remoun

t

piston

rings

Renew

rings

Repair

or

renew

piston

and

cylinder

Renew

piston

and

piston

ring

Replace

seal

lip

with

a

new

one

Renew

valve

or

guide

Use

the

designated

oil

Previously

mentioned

Page 62 of 537

Standard

Taper

and

out

of

round

of

journal

and

crank

pin

mm

in

less

than

0

01

0

0004

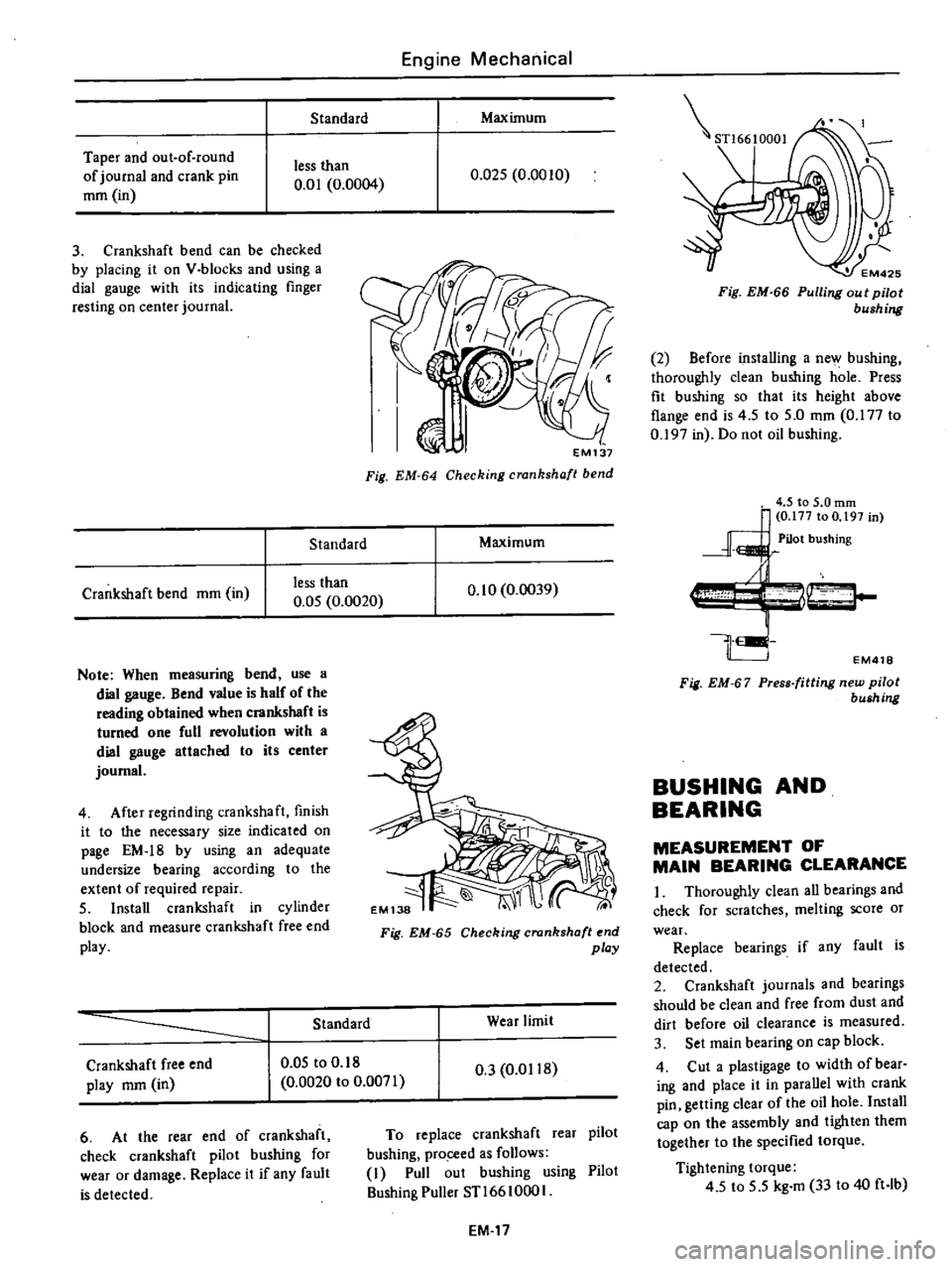

3

Crankshaft

bend

can

be

checked

by

placing

it

on

V

blocks

and

using

a

dial

gauge

with

its

indicating

finger

resting

on

center

journal

Standard

Crankshaft

bend

mm

in

less

than

0

05

0

0020

Note

When

measuring

bend

use

a

dial

gauge

Bend

value

is

half

of

the

reading

obtained

when

crankshaft

is

turned

one

full

revolution

with

a

dial

gauge

attached

to

its

center

journal

4

After

regrinding

crankshaft

finish

it

to

the

necessary

size

indicated

on

page

EM

18

by

using

an

adequate

undersize

bearing

according

to

the

extent

of

required

repair

5

Install

crankshaft

in

cylinder

block

and

measure

crankshaft

free

end

play

Engine

Mechanical

Maximum

0

Q25

0

0010

EM137

Fig

EM

64

Checking

crankshaft

bend

Maximum

0

10

0

0039

Fig

EM

65

Checking

crankshaft

end

play

Standard

Wear

limit

Crankshaft

free

end

play

mm

in

0

05

to

0

18

0

0020

to

0

0071

0

3

0

0118

6

At

the

rear

end

of

crankshaft

check

crankshaft

pilot

bushing

for

wear

or

damage

Replace

it

if

any

fault

is

detected

To

replace

crankshaft

rear

pilot

bushing

pro

ceed

as

follows

I

Pull

out

bushing

using

Pilot

Bushing

Puller

STl66

1000

I

EM

17

STl6610001

EM425

Fig

EM

66

Pulling

out

pilot

bushing

2

Before

installing

a

new

bushing

thoroughly

clean

bushing

hole

Press

fit

bushing

so

that

its

height

above

flange

end

is

4

5

to

5

0

mm

0

177

to

0

197

in

Do

not

oil

bushing

EM418

Fig

EM

67

Press

fitting

new

pilot

bush

ng

BUSHING

AND

BEARING

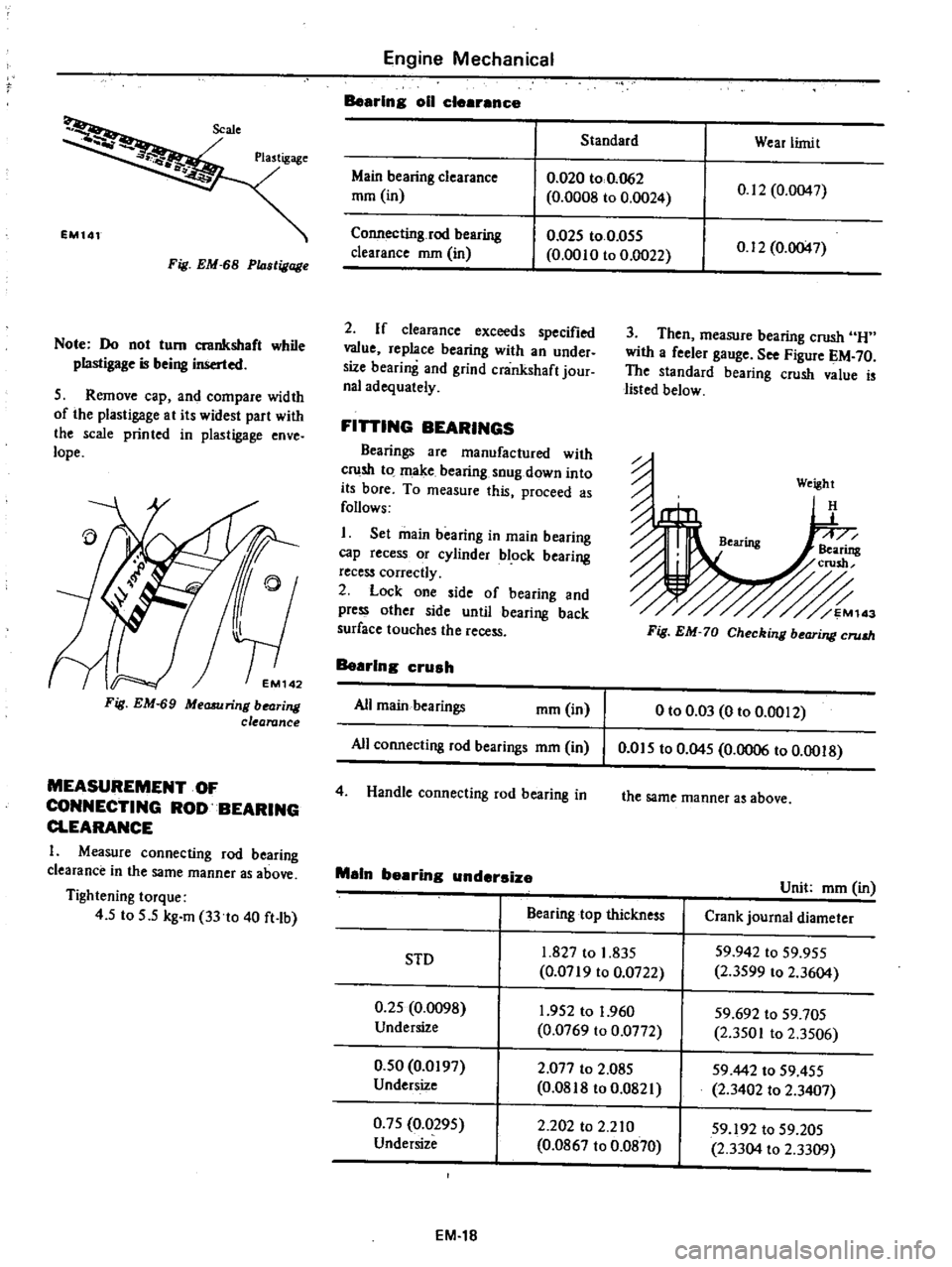

MEASUREMENT

OF

MAIN

BEARING

CLEARANCE

I

Thoroughly

clean

all

bearings

and

check

for

scratches

melting

score

or

wear

Replace

bearings

if

any

fault

is

detected

2

Crankshaft

journals

and

bearings

should

be

clean

and

free

from

dust

and

dirt

before

oil

clearance

is

measured

3

Set

main

bearing

on

cap

block

4

Cut

a

plastigage

to

width

of

bear

ing

and

place

it

in

parallel

with

crank

pin

getting

clear

of

the

oil

hole

Install

cap

on

the

assembly

and

tighten

them

together

to

the

specified

torque

Tightening

torque

4

5

to

5

5

kg

m

33

to

40

ft

lb

Page 63 of 537

Fig

EM

68

P14stigage

Note

Do

not

tum

crankshaft

while

plastigage

is

being

inserted

5

Remove

cap

and

compare

width

of

the

plastigage

at

its

widest

part

with

the

scale

printed

in

plastigage

enve

lope

Fig

EM

69

Measuring

bearing

clearance

MEASUREMENT

OF

CONNECTING

ROD

BEARING

CLEARANCE

I

Measure

connecting

rod

bearing

clearance

in

the

same

manner

as

above

Tightening

torque

4

5

to

5

5

kg

m

33

to

40

ft

lb

Engine

Mechanical

Bearing

011

clearance

Standard

Wear

limit

Main

bearing

clearance

mm

in

0

020

to

0

062

0

0008

to

0

0024

0

12

0

0047

Connecting

rod

bearing

clearance

mm

in

0

025

to

0

055

0

0010

to

0

0022

0

12

0

0047

2

If

clearance

exceeds

specified

value

replace

bearing

with

an

under

size

bearing

and

grind

crankshaft

jour

nal

adequately

FiniNG

BEARINGS

Bearings

are

manufactured

with

crush

to

make

bearing

snug

down

into

its

bore

To

measure

this

proceed

as

follows

I

Set

main

bearing

in

main

bearing

cap

recess

or

cylinder

block

bearing

recess

correctly

2

Lock

one

side

of

bearing

and

press

other

side

until

bearing

back

surface

touches

the

recess

Bearing

crush

All

main

bearings

mm

in

All

connecting

rod

bearings

mm

in

4

Handle

connecting

rod

bearing

in

3

Then

measure

bearing

crush

H

with

a

feeler

gauge

See

Figure

EM

70

The

standard

bearing

crush

value

is

listed

below

Weight

H

Fig

EM

70

Checking

bearing

crum

o

to

0

03

0

to

0

0012

0

015

to

0

045

0

0006

to

0

0018

the

same

manner

as

above

Main

bearing

undersize

Unit

mm

in

Bearing

top

thickness

Crank

journal

diameter

1

827

to

1

835

59

942

to

59

955

SID

0

0719

to

0

0722

2

3599

to

2

3604

0

25

0

0098

1

952

to

1

960

59

692

to

59

705

Undersize

0

0769

to

0

0772

2

3501

to

2

3506

0

50

0

0197

2

077

to

2

085

59442

to

59

455

Undersize

0

0818

to

0

0821

2

3402

to

2

3407

0

75

0

0295

2

202

to

2

210

59

192

to

59

205

Undersize

0

0867

to

0

0870

2

3304

to

2

3309

EM

18

Page 66 of 537

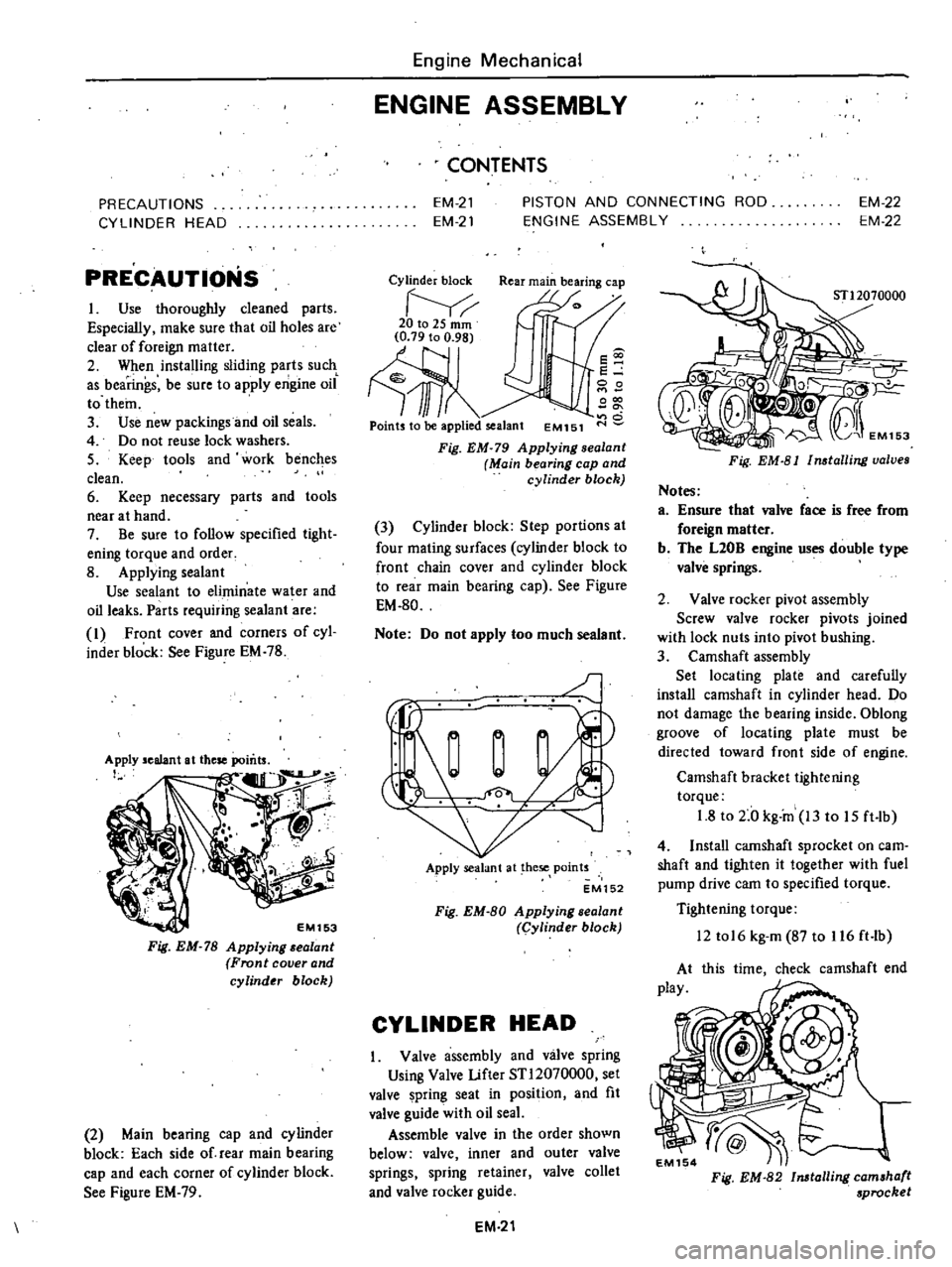

PRECAUTIONS

CYLINDER

HEAD

PRECAUTIONS

I

Use

thoroughly

cleaned

parts

Especially

make

sure

that

oil

holes

are

clear

of

foreign

matter

2

When

installing

sliding

parts

such

as

bearings

be

s

uIe

to

apply

engine

oil

to

them

3

Use

new

packing

and

oil

seals

4

Do

not

reuse

lock

washers

5

Keep

tools

and

work

benches

clean

6

Keep

necessary

parts

and

tools

near

at

hand

7

Be

sure

to

follow

specified

tight

ening

torque

and

order

8

Applying

sealant

Use

sealant

to

eliminate

water

and

oil

leaks

Parts

requiring

sealant

are

I

Front

cover

and

corners

of

cyl

inder

block

See

Figure

EM

78

EM153

Fig

EM

78

Applying

alant

Front

cover

and

cylinder

block

2

Main

bearing

cap

and

cylinder

block

Each

side

of

rear

main

bearing

cap

and

each

corner

of

cylinder

block

See

Figure

EM

79

Engine

Mechanical

ENGINE

ASSEMBLY

CONTENTS

EM

21

EM

21

PISTON

AND

CONNECTING

ROD

ENGINE

ASSEMBLY

EM

22

EM

22

Cylinder

block

Rear

main

bearing

cap

20to2Smm

Ill

Points

to

be

applied

sealant

EM151

s

e

00

000

o

Fig

EM

79

Applying

sealanl

Main

bearing

cap

and

cylinder

block

3

Cylinder

block

Step

portions

at

four

mating

surfaces

cylinder

block

to

front

chain

cover

and

cylinder

block

to

rear

main

bearing

cap

See

Figure

EM

80

Note

Do

not

apply

too

much

sealant

J

Apply

sealant

at

hese

points

EM152

Fig

EM

80

Applying

sealant

Cylinder

block

CYLINDER

HEAD

Valve

assembly

and

valve

spring

Using

Valve

Lifter

STl2070000

set

valve

pring

seat

in

position

and

fit

valve

guide

with

oil

seaL

Assemble

valve

in

the

order

shown

below

valve

inner

and

outer

valve

springs

spring

retainer

valve

collet

and

valve

rocker

guide

EM

21

Fig

EM

81

Installing

valves

Notes

a

Ensure

that

valve

face

is

free

from

foreign

matter

b

The

L20B

engine

uses

double

type

valve

springs

2

Valve

rocker

pivot

assembly

Screw

valve

rocker

pivots

joined

with

lock

nuts

into

pivot

hushing

3

Camshaft

assembly

Set

locating

plate

and

carefully

install

camshaft

in

cylinder

head

Do

not

damage

the

bearing

inside

Oblong

groove

of

locating

plate

must

be

directed

toward

front

side

of

engine

Camshaft

bracket

tightening

torque

1

8

to

2

0

kg

in

13

to

15

ft

lb

4

Install

camshaft

sprocket

on

earn

shaft

and

tighten

it

together

with

fuel

pump

drive

cam

to

specified

torque

Tightening

torque

12

tol6

kg

m

87

to

116

ft

lb

this

time

check

camshaft

end

Fig

EM

82

Installing

camshaft

sprocket

Page 67 of 537

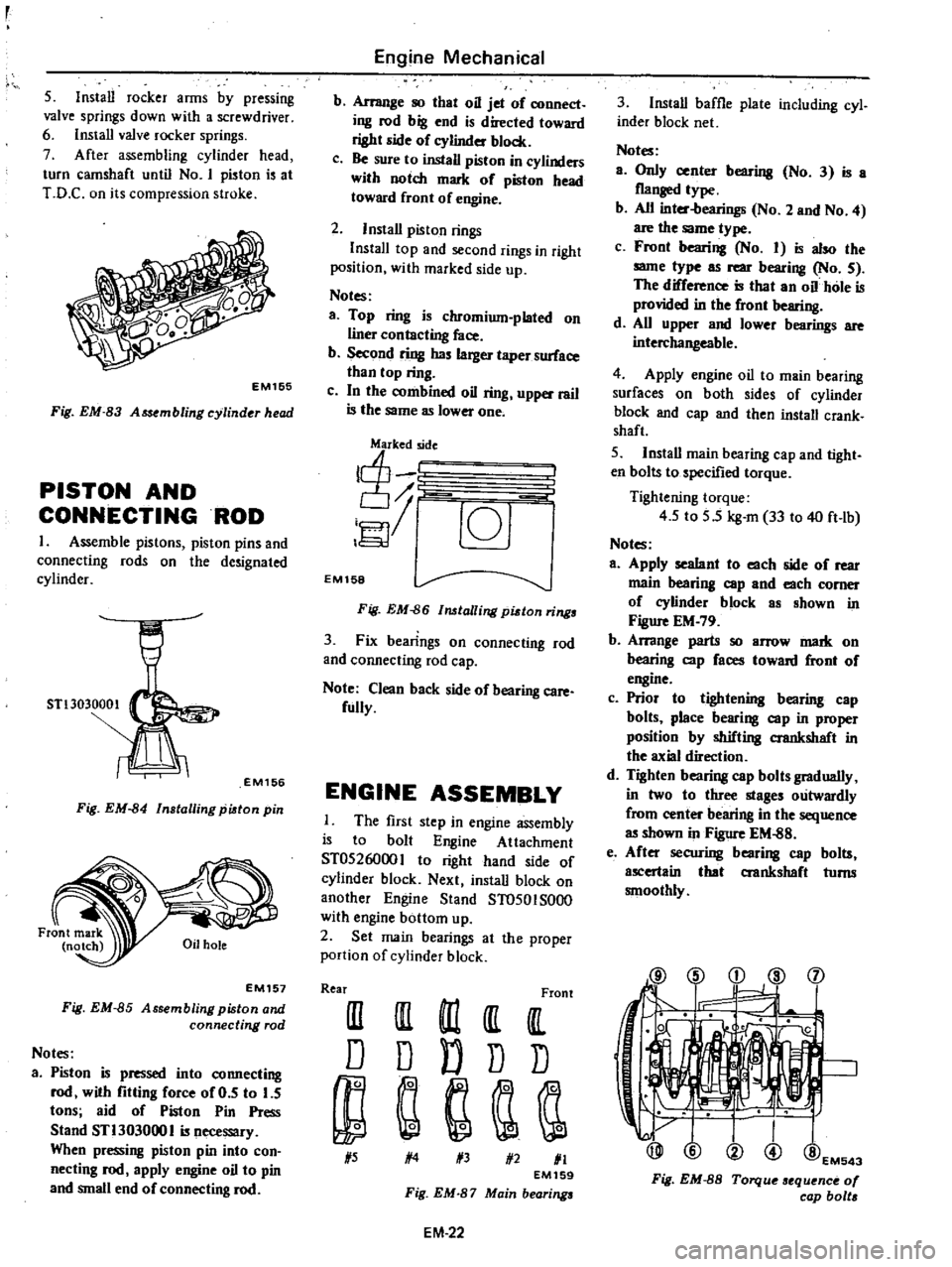

5

Install

rocker

arms

by

pressing

valve

springs

down

with

a

screwdriver

6

Install

valve

rocker

springs

7

After

assembling

cylinder

head

turn

camshaft

until

No

I

piston

is

at

T

D

C

on

its

compression

stroke

EM1S5

Fig

EM

83

A

embling

cylinder

head

PISTON

AND

CONNECTINGROD

1

Assemble

pistons

piston

pins

and

connecting

rods

on

the

de

ignated

cylinder

STl3030001

EM156

Fig

EM

84

Installing

piston

pin

EM157

Fig

EM

85

Assembling

piston

and

connecting

rod

Notes

a

Piston

is

pressed

into

connecting

rod

with

fitting

force

of

0

5

to

5

tons

aid

of

Piston

Pin

Press

Stand

STl303000

I

is

necessary

When

pressing

piston

pin

into

con

necting

rod

apply

engine

oil

to

pin

and

small

end

of

connecting

rod

Engine

Mechanical

b

Arrange

so

that

oil

jet

of

connect

ing

rod

big

end

is

directed

toward

right

side

of

eylinder

block

c

Be

sure

to

install

piston

in

cylinders

with

notch

mark

of

piston

head

toward

front

of

engine

2

Install

piston

rings

InstalI

top

and

second

rings

in

right

position

with

marked

side

up

Notes

a

Top

ring

is

chromium

plated

on

liner

contacting

face

b

Second

ring

has

larger

taper

surface

than

top

ring

c

In

the

combined

oil

ring

upper

rail

is

the

same

as

lower

one

j

c6J

EM158

Fig

EM

86

lalling

pidon

rings

3

Fix

bearings

on

connecting

rod

and

connecting

rod

cap

Note

Clean

back

side

of

bearing

care

fully

ENGINE

ASSEMBLY

The

first

step

in

engine

assembly

is

to

bolt

Engine

Attachment

ST0526000

I

to

right

hand

ide

of

cylinder

block

Next

install

block

on

another

Engine

Stand

ST0501S000

with

engine

bottom

up

2

Set

main

bearings

at

the

proper

portion

of

cylinder

block

Rear

Front

III

III

m

It

IlL

D

D

D

D

D

1

5

1

4

1

3

1

2

1

1

EM159

Fig

EM

87

Main

bearings

EM

22

3

Install

baffle

plate

including

cyl

inder

block

net

Notes

a

Only

center

bearing

No

3

is

a

flanged

type

b

All

inter

bearings

No

2

and

No

4

are

the

same

type

c

Front

bearing

No

I

is

also

the

same

type

as

rear

bearing

No

5

The

difference

is

that

an

oil

hole

is

provided

in

the

front

bearing

d

All

upper

and

lower

bearings

are

interchangeable

4

Apply

engine

oil

to

main

bearing

surfaces

on

both

sides

of

cylinder

block

and

cap

and

then

install

crank

shaft

5

Install

main

bearing

cap

and

tight

en

bolts

to

specified

torque

Tightening

torque

4

5

to

5

5

kg

m

33

to

40

ft

lb

Notes

a

Apply

sealant

to

each

side

of

rear

main

bearing

cap

and

each

comer

of

eylinder

block

as

shown

in

Figure

EM

79

b

Arrange

parts

so

arrow

mark

on

bearing

cap

faces

toward

front

of

engine

c

Prior

to

tightening

bearing

cap

bolts

place

bearing

cap

in

proper

position

by

shifting

crankshaft

in

the

axial

direction

d

Tighten

bearing

cap

bolts

gradually

in

two

to

three

stages

outwardly

from

center

bearing

in

the

sequence

as

shown

in

Figure

EM

88

e

After

securing

bearing

cap

bolts

ascertain

that

aankshaft

turns

smoothly

@

i

d

l

j

1

@EM543

Fig

EM

8S

Torque

sequence

0

cap

bolt

Page 68 of 537

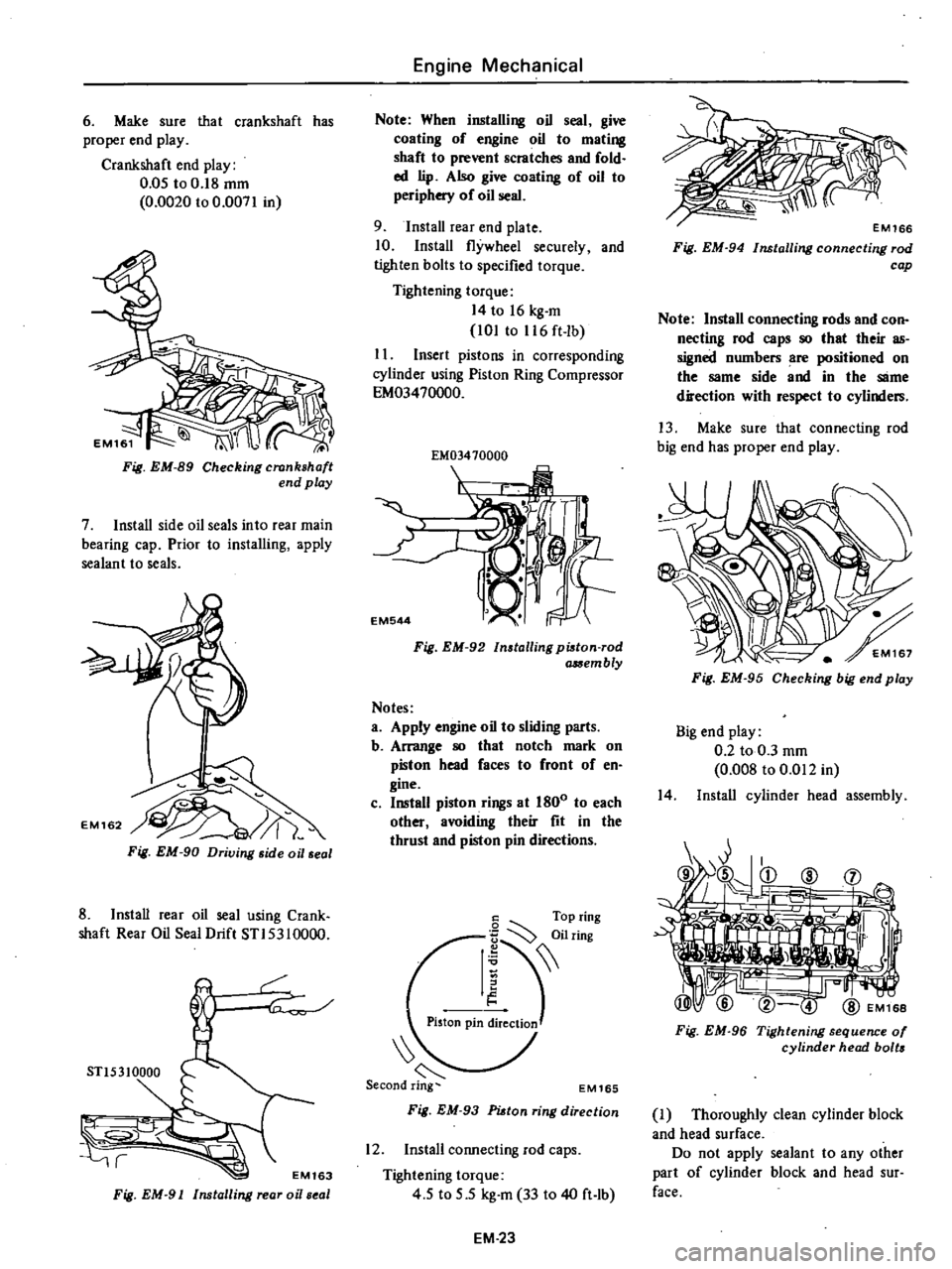

6

Make

sure

that

crankshaft

has

proper

end

play

Crankshaft

end

play

0

05

to

0

18

mm

0

0020

to

0

0071

in

Fig

EM

89

Checking

crankshaft

end

play

7

Install

side

oil

seals

into

rear

main

bearing

cap

Prior

to

installing

apply

sealant

to

seals

Fig

EM

90

Driving

side

oil

seal

8

Install

rear

oil

seal

using

Crank

shaft

Rear

Oil

Seal

Drift

STI5310000

r

STl5310000

r

EM163

Fig

EM

91

Installing

rear

oi

seal

Engine

Mechanical

Note

When

installing

oil

seal

give

coating

of

engine

oil

to

mating

shaft

to

prevent

scratches

and

fold

ed

lip

Also

give

coating

of

oil

to

periphery

of

oil

seal

9

Install

rear

end

plate

10

Install

flywheel

securely

and

tighten

bolts

to

specified

torque

Tightening

torque

14

to

16

kg

m

101

to

116

ft

lb

I

I

Insert

pistons

in

corresponding

cylinder

using

Piston

Ring

Compressor

EM03470000

EM03410000

I

EM544

Fig

EM

92

Installing

pi8ton

rod

a

Sembly

Notes

a

Apply

engine

oil

to

sliding

parts

b

Arrange

80

that

notch

mark

on

piston

head

faces

to

front

of

en

gine

c

Install

piston

rings

at

1800

to

each

other

avoiding

their

fit

in

the

thrust

and

piston

pin

directions

6

Top

ring

I

iilring

Piston

pin

ireClioJ

EM165

Fig

EM

93

PUtan

ring

direction

12

Install

connecting

rod

caps

Tightening

torque

4

5

to

5

5

kg

m

33

to

40

ft

lb

EM

23

Fig

EM

94

Installing

connecting

rod

cap

Note

Install

connecting

rods

and

con

necting

rod

caps

80

that

their

as

signed

numbers

are

positioned

on

the

same

side

and

in

the

SlIme

direction

with

respect

to

cylinders

13

Make

sure

that

connecting

rod

big

end

has

proper

end

play

Fig

EM

95

Checking

big

end

play

Big

end

play

0

2

to

0

3

mm

0

008

to

0

Ql2

in

14

Install

cylinder

head

assembly

Fig

EM

96

Tightening

sequence

01

cylinder

head

bolts

J

Thoroughly

clean

cylinder

block

and

head

surface

Do

not

apply

sealant

to

any

other

part

of

cylinder

block

and

head

sur

face

Page 69 of 537

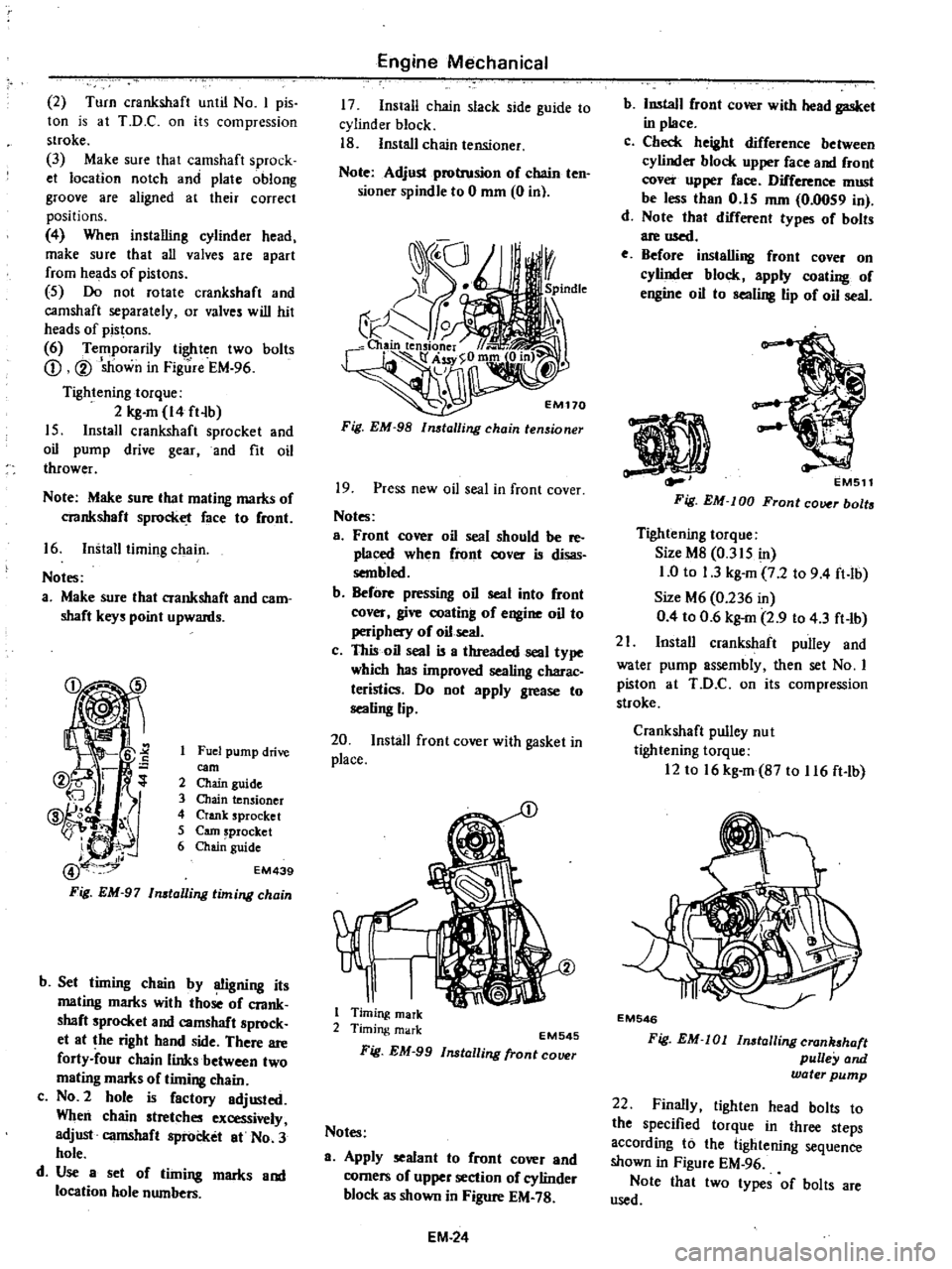

2

Turn

crankshaft

until

No

I

pis

ton

is

at

T

D

C

on

its

compression

stroke

3

Make

sure

thai

camshaft

sprock

et

location

notch

and

plate

oblong

groove

are

aligned

at

their

correct

positions

4

When

installing

cylinder

head

make

sure

that

all

valves

are

apart

from

heads

of

pistons

5

Do

not

rotate

crankshaft

and

camshaft

separately

or

valves

will

hit

heads

of

pistons

6

Temporarily

tighten

two

bolts

CD

V

sJiown

in

Fig

re

EM

96

Tightening

torque

2

kg

m

14

ft

b

15

Install

crankshaft

sprocket

and

oil

pump

drive

gear

and

fit

oil

thrower

Note

Make

sure

lhat

maling

marks

of

crankshaft

sprocket

face

10

Cront

16

Install

timing

chain

Noles

a

Make

sure

that

crankshaft

and

cam

shaft

keys

point

upwards

Fuel

pump

drive

earn

2

Chain

guide

3

Chain

tensioner

4

Crank

sprocket

5

earn

sprocket

6

Chai

guide

EM439

b

Set

timing

chain

by

OOgning

its

mating

marks

with

those

oC

crank

shaft

sprocket

and

camshaft

sprock

et

at

the

right

hand

side

There

are

forty

four

chain

links

between

two

mating

marks

of

timing

chain

c

NO

2

hole

is

Cactory

adjusted

When

chain

stretches

excessively

adjust

camshaft

sprocket

at

No

3

hole

d

Use

a

set

of

timing

marks

and

location

hole

numbers

Engine

Mechanical

17

Install

chain

slack

side

guide

to

cylinder

block

18

Install

chain

tensioner

Note

Adjust

protrusion

oC

chain

ten

sioner

spindle

to

0

mm

0

in

Fig

EM

98

lmtalling

chain

tensioner

19

Press

new

oil

seal

in

front

cover

Notes

a

Front

cover

oil

seal

should

be

reo

placed

when

Cront

cover

is

disas

sembled

b

BeCore

pressing

oil

seal

into

Cront

cover

give

coating

of

engine

oil

to

periphery

of

oil

seal

c

This

oil

seal

is

a

threaded

seal

type

which

has

improved

sealing

charac

teristics

Do

not

apply

grease

to

sealing

lip

20

Install

front

cover

with

gasket

in

place

1

Timing

mark

2

Timing

mark

EM545

Fig

EM

99

Installing

fronl

COlHlr

Notes

a

Apply

sealant

to

Cront

cover

and

corners

oC

upper

section

of

cylinder

block

as

shown

in

Figure

EM

78

EM

24

b

Install

Cront

cover

with

head

gasket

in

place

c

Check

height

diCCerence

between

cylinder

block

upper

Cace

and

Cront

cover

upper

Cace

DifCerence

must

be

less

than

0

15

mm

0

0059

in

d

Note

that

difCerent

types

oC

bolts

are

used

e

Before

installing

front

cover

on

cylinder

block

apply

coating

oC

engine

oil

10

sealing

lip

of

oil

seal

EMS11

Fig

EM

lOD

Front

cover

bolts

Tightening

torque

Size

M8

0

315

in

1

0

to

1

3

kg

m

7

2

to

9

4

ft

lb

Size

M6

0

236

in

0

4

to

0

6

kg

m

2

9

to

4

3

ft

lb

21

Install

crankshaft

pulley

and

water

pump

assembly

then

set

No

I

piston

at

ToO

C

on

its

compression

stloke

Crankshaft

pulley

nu

I

tightening

torque

12

to

16

kg

m

B7

to

116

ft

lb

EM546

Fig

EM

Ol

lnstallingcran

haft

pulley

and

water

pump

22

Finally

tighten

head

bolts

to

the

specified

torque

in

three

steps

according

to

the

lightening

sequence

shown

in

Figure

EM

96

Note

thai

Iwo

types

of

bolts

are

used