weight DATSUN PICK-UP 1977 User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 198 of 537

CHECKING

AND

ADJUSTMENT

CAP

AND

ROTOR

HEAD

Cap

and

rotor

head

should

be

in

spected

periodically

as

specified

in

the

Maintenance

Schedule

Remove

cap

and

clean

all

dust

and

carbon

deposits

from

cap

and

rotor

If

cap

is

cracked

or

is

leaking

replace

with

a

De

one

CONTACT

POINT

Contact

point

should

be

replaced

in

accordance

with

the

Maintenance

Schedule

Standard

point

gap

is

0

45

to

0

55

mm

O

OIS

to

0

022

in

In

case

size

is

off

the

standard

adjustment

is

made

by

loosening

point

screws

Gap

gauge

is

required

for

adjustment

When

point

surface

is

rough

take

off

any

irregularities

with

fine

sand

paper

of

No

500

or

600

or

with

oil

stone

When

wear

on

contact

points

is

noticeable

replace

points

together

with

contact

arm

To

replace

proceed

as

follows

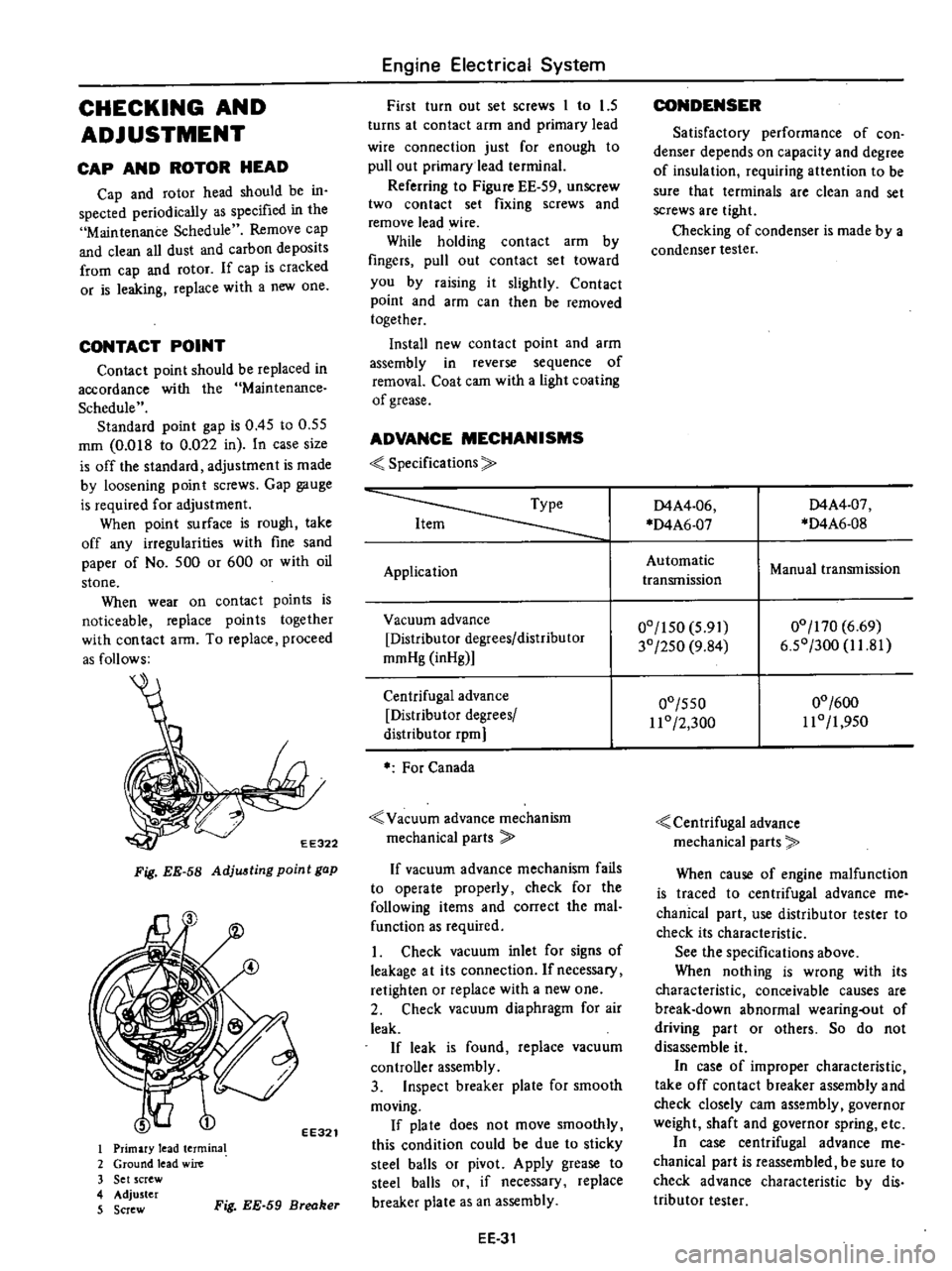

EE322

Fig

EE

58

Adju

ting

point

gap

EE321

I

Primary

lead

termina

2

Ground

lead

wire

3

Set

screw

4

Adjuster

5

Screw

Fig

EE

59

Breaker

Engine

Electrical

System

First

turn

out

set

screws

1

to

1

5

turns

at

contact

arm

and

primary

lead

wire

connection

just

for

enough

to

pull

out

primary

lead

terminal

Referring

to

Figure

EE

59

unSCrew

two

contact

set

fixing

screws

and

remove

lead

wire

While

holding

contact

arm

by

fingers

pull

out

contact

set

toward

you

by

raising

it

slightly

Contact

point

and

afm

can

then

be

removed

together

Install

new

contact

point

and

arm

assembly

in

reverse

sequence

of

removal

Coat

cam

with

a

light

coating

of

grease

ADVANCE

MECHANISMS

Specifications

Application

Vacuum

advance

Distributor

degrees

distributor

mmHg

inHg

Centrifugal

advance

Distributor

degrees

distribu

tor

rpm

For

Canada

Vacuum

advance

mechanism

mechanical

parts

If

vacuum

advance

mechanism

fails

to

operate

properly

check

for

the

following

items

and

correct

the

mal

function

as

required

1

Check

vacuum

inlet

for

signs

of

leakage

at

its

connection

Ifnecessacy

retighten

or

replace

with

a

new

one

2

Check

vacuum

diaphragm

for

air

leak

If

leak

is

found

replace

vacuum

controller

assembly

3

Inspect

breaker

plate

for

smooth

moving

If

pia

te

does

not

move

smoothly

this

condition

could

be

due

to

sticky

steel

balls

or

pivot

Apply

grease

to

steel

balls

or

if

necessary

replace

breaker

plate

as

an

assembly

EE

31

CONDENSER

Satisfactory

performance

of

con

denser

depends

on

capacity

and

degree

of

insulation

requiring

attention

to

be

sure

that

terminals

are

clean

and

set

screws

are

tight

Checking

of

condenser

is

made

by

a

condenser

tester

D4A4

06

D4A6

07

D4A4

07

D4A6

0S

Automatic

transmission

Manual

transmission

00

150

5

91

30

250

9

S4

00

170

6

69

6

50

300

1I

S1

00

550

11

0

2

300

00

600

110

1

950

Centrifugal

advance

mechanical

parts

When

cause

of

engine

malfunction

is

traced

to

centrifugal

advance

me

chanical

part

use

distributor

tester

to

check

its

characteristic

See

the

specifications

above

When

nothing

is

wrong

with

its

characteristic

conceivable

causes

are

break

down

abnormal

wearing

out

of

driving

part

or

others

So

do

not

disassemble

it

In

case

of

improper

characteristic

take

off

contact

breaker

assembly

and

check

closely

cam

assembly

governor

weight

shaft

and

governor

spring

etc

In

case

centrifugal

advance

me

chanical

part

is

reassembled

be

sure

to

check

advance

characteristic

by

dis

tributor

tester

Page 199 of 537

DISASSEMBLY

To

disassemble

follow

the

below

proccd

ure

I

Take

off

cap

and

disconnect

rotor

head

2

Remove

vacuum

controller

EE291

Fig

EE

60

Removing

vacuum

controller

3

Remove

contact

set

Refer

to

Page

EE

31

when

contact

set

i

removed

EE323

Fig

EE

61

Removing

contact

tel

EE324

Fig

EE

62

Removing

breaker

plate

Engine

Electrical

System

4

When

breaker

plate

is

removed

be

careful

not

to

lose

steel

balls

between

breaker

spring

and

breaker

plate

5

Pul

roll

pin

out

and

siconnect

collar

to

remove

the

entire

rotating

parts

EE325

Fig

EE

63

Removing

roll

pin

EE326

Fig

EE

64

Removil1l

rotation

paTta

6

Remove

packing

from

the

top

of

cam

assembly

and

unscrew

earn

astern

bly

setscrew

Put

match

mark

across

earn

and

shaft

so

that

original

combi

nation

can

be

restored

at

assembly

EE

32

EE075

Fig

EE

65

Removing

cam

7

When

governor

weight

and

spring

are

disconnected

be

careful

not

to

stretch

or

deform

governor

spring

After

disassembling

apply

grease

to

governor

weights

ASSEMBLY

To

assemble

reverse

the

order

of

disassembly

Carefully

observe

the

fol

lowing

instructions

Align

match

marl

s

so

that

parts

are

assembled

to

their

original

posi

tions

2

Apply

grease

to

the

top

of

cam

assembly

as

required

3

Check

the

operation

of

governor

before

installing

distributor

on

engine

4

Adjust

ignition

timing

afteT

dis

tributor

is

installed

on

engine

Page 202 of 537

Vacuum

advance

mechanism

mechanical

parts

If

vacuum

advance

mechanism

fails

to

operate

properly

check

for

the

following

items

and

correct

the

prob

lem

as

required

1

Check

vacuum

inlet

for

signs

of

leakage

at

its

connection

If

necessary

retighten

or

replace

with

a

new

one

2

Check

vacuum

diaphragm

for

air

leak

If

leak

is

found

replace

vacuum

controller

assembly

3

Inspect

breaker

plate

for

smooth

moving

If

plate

does

not

move

smoothly

this

condition

could

be

due

to

sticky

steel

balls

or

pivot

Apply

grease

to

steel

balls

or

if

necessary

replace

distributor

assembly

Centrifugal

advance

mechanical

parts

When

cause

of

engine

malfunction

is

traced

to

centrifugal

advance

mecha

nical

parts

use

distributor

tester

to

check

its

characteristics

See

to

the

specifications

above

If

nothing

is

wrong

with

its

charac

teristics

conceivable

causes

are

faulty

or

abnormal

wear

of

driving

part

or

others

So

do

not

disassemble

it

In

the

event

of

improper

character

istics

check

closely

rotor

shaft

assem

bly

governor

weight

and

shaft

If

any

of

above

parts

are

malfunc

tioning

replace

distributor

assembly

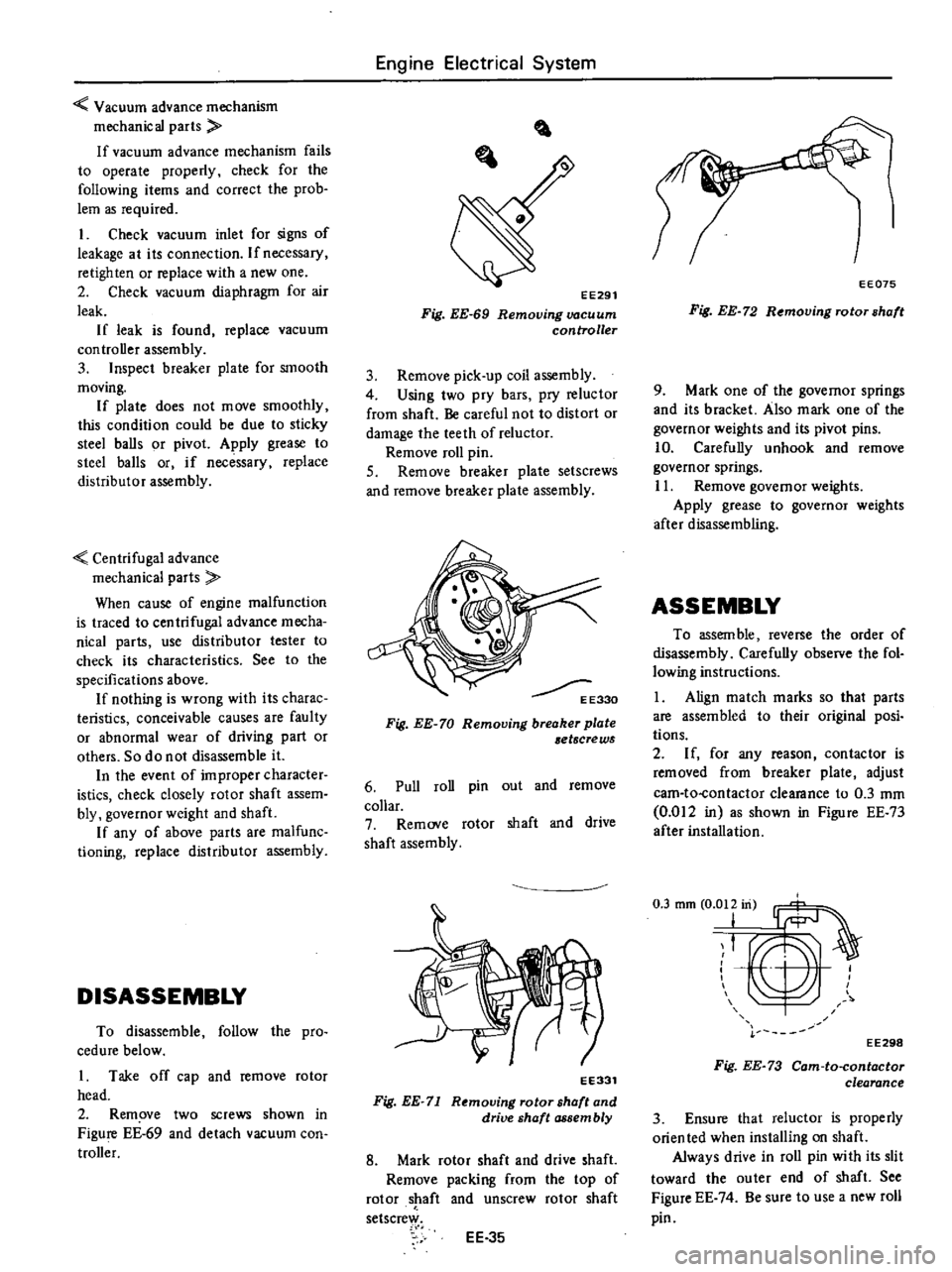

DISASSEMBLY

To

disassemble

follow

the

pro

cedure

below

1

Take

off

cap

and

remove

rotor

head

2

Remove

two

screws

shown

in

Figure

EE

69

and

detach

vacuum

con

troller

Engine

Electrical

System

EE291

Fig

EE

69

Removing

vacuum

controller

3

Remove

pick

up

coil

assembly

4

Using

two

pry

bars

pry

reluctor

from

shaft

Be

careful

not

to

distort

or

damage

the

teeth

of

reluctor

Remove

roll

pin

S

Remove

breaker

plate

setscrews

and

remove

breaker

plate

assembly

E330

Fig

EE

70

Removing

breaker

plate

etscrews

6

Pull

roll

pin

out

and

remove

collar

7

Remove

rotor

shaft

and

drive

shaft

assembly

EE331

Fig

EE

71

Removing

rotor

shaft

and

drive

shaft

assembly

8

Mark

rotor

shaft

and

drive

shaft

Remove

packing

from

the

top

of

rotor

shaft

and

unscrew

rotor

shaft

setscrew

EE

35

EE075

Fig

EE

72

Removing

rotor

shaft

9

Mark

one

of

the

governor

springs

and

its

bracket

Also

mark

one

of

the

governor

weights

and

its

pivot

pins

10

Carefully

unhook

and

remove

governor

springs

11

Remove

governor

weights

Apply

grease

to

governor

weights

after

disassembling

ASSEMBLY

To

assem

ble

reverse

the

order

of

disassembly

Carefully

observe

the

fol

lowing

instructions

1

Align

match

marks

so

that

parts

are

assembled

to

their

original

posi

tions

2

If

for

any

reason

contactor

is

removed

from

breaker

plate

adjust

cam

to

contactor

clearance

to

0

3

mm

0

012

in

as

shown

in

Figure

EE

73

after

installation

T

EE298

Fig

EE

73

Cam

to

contactor

clearance

3

Ensure

that

reluctor

is

properly

orien

ted

when

installing

on

shaft

Always

drive

in

roll

pin

with

its

slit

toward

the

outer

end

of

shaft

See

Figure

EE

74

Be

sure

to

use

a

new

roll

pin

Page 223 of 537

DESCRIPTION

REMOVAL

AND

INSTAllATION

Removal

Installation

DESCRIPTION

The

clutch

is

a

single

dry

disc

type

CLUTCH

CLUTCH

CONTENTS

CL

2

Cl2

CL

2

CL

3

DISASSEMBLY

AND

ASSEMBLY

D

isassemb

I

y

Assembly

INSPECTION

CL

3

Cl3

CL

3

CL

4

using

a

diaphragm

spring

It

consists

of

the

clutch

disc

pressure

plate

dia

phragm

spring

thrust

rings

clutch

cover

I

and

clutch

release

bearing

e

M

0

s

8

o

8

l150

5

91

dia

225

8

86

dia

REMOVAL

AND

I

NSTALLATIO

Removal

1

Remove

transmission

from

ve

hicle

For

details

of

transmission

removal

refer

to

Transmission

Section

2

Insert

Clutch

Aligning

Bar

KV30100200

into

clutch

disc

hub

until

it

will

no

longer

go

It

is

im

A

u

o

6

o

C

62

2

44

dia

I

260

10

2

dia

CL231

Fig

CL

l

Construction

of

clutch

disc

and

COller

assembly

Unit

mm

in

portant

to

support

weight

of

clutch

disc

during

further

steps

See

Figure

CL

2

3

Loosen

six

screws

attaching

clutch

cover

to

flywheel

one

turn

at

a

time

each

un

til

spring

pressure

is

re

leased

Be

sure

to

turn

them

out

in

a

crisscross

fashion

Note

Exercise

special

care

to

avoid

grease

or

on

getting

on

clutch

linings

CL2

Fig

CL

2

Supporting

clutch

assembly

Page 238 of 537

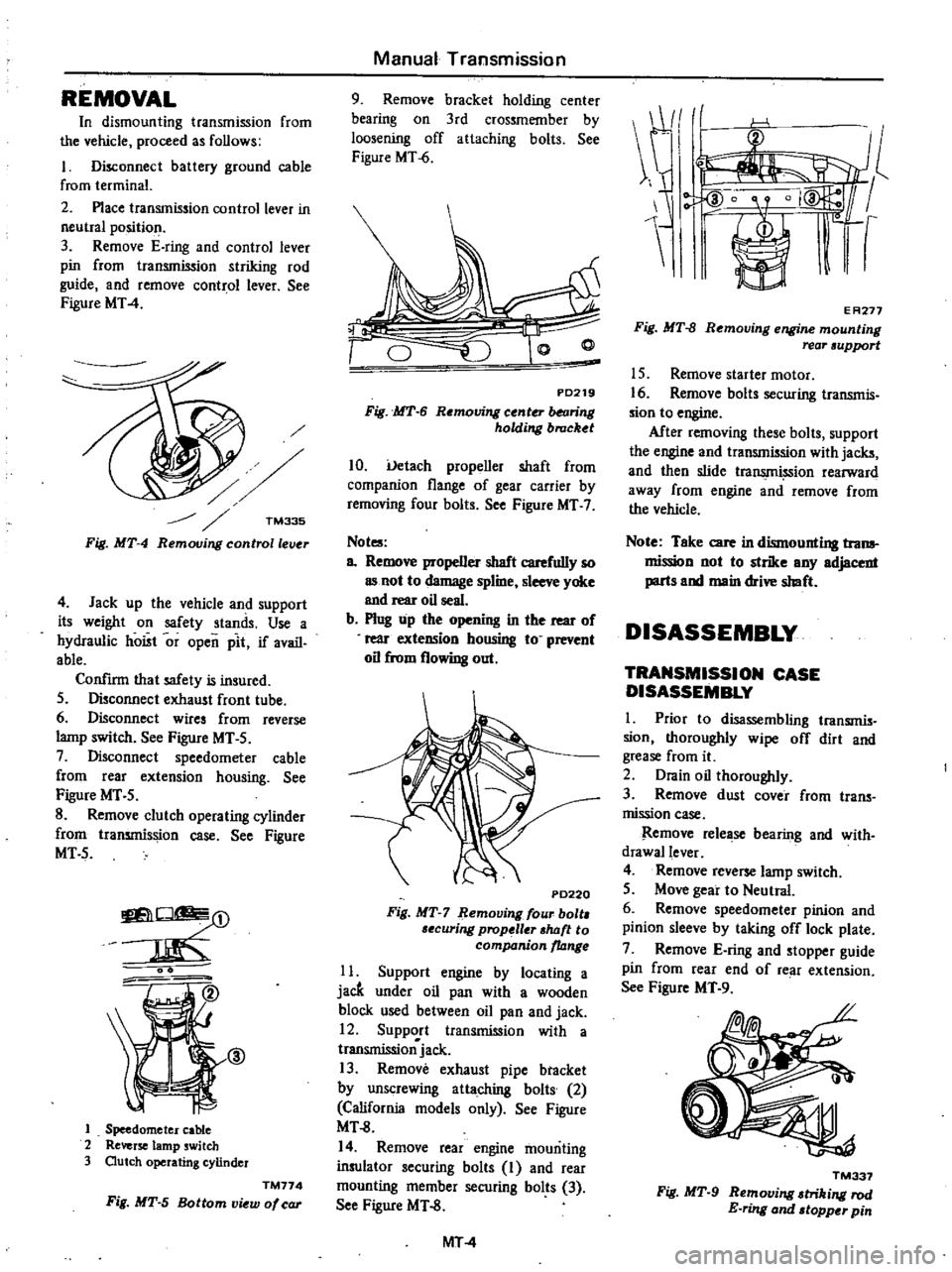

REMOVAL

In

dismounting

transmission

from

the

vehicle

proceed

as

follows

I

Disconnect

battery

ground

cable

from

terminal

2

Place

transmission

control

lever

in

neutIal

position

3

Remove

E

ring

and

control

lever

pin

from

transmission

striking

rod

guide

and

remove

control

lever

See

Figure

MT

4

TM335

Fig

MT

4

Remouing

controllelJ

r

4

Jack

up

the

vehicle

and

support

its

weight

on

safety

stands

Use

a

hydraulic

hoist

or

open

pit

if

avail

able

Confirm

that

safety

is

insured

5

Disconnect

exhaust

front

tube

6

Disconnect

wires

from

reverse

lamp

switch

See

Figure

MT

5

7

Disconnect

speedometer

cable

from

rear

extension

housing

See

Figure

MT

5

8

Remove

clutch

operating

cylinder

from

transmission

case

See

Figure

MT5

O

m

J

@

1

Speedometer

cable

2

Reverse

lamp

switch

3

Outch

operating

cylinder

TM774

Fig

MT

5

Bottom

view

of

car

Manual

Transmission

9

Remove

bracket

holding

center

bearing

on

3rd

crossmember

by

loosening

off

attaching

bolts

See

Figure

MT

6

PD219

Fig

MT

6

Removing

center

balring

holding

brucket

10

Uetach

propeller

shaft

from

companion

flange

of

gear

carrier

by

removing

four

bolts

See

Figure

MT

7

Not

a

Remove

propeller

shaft

carefully

so

as

not

to

damage

spline

sleeve

yoke

and

rear

oil

seal

b

Plug

up

the

opening

in

the

rear

of

rear

exteDSion

housing

to

prevent

oil

from

flowing

out

P0220

Fig

MT

7

Remouing

four

bolt

6ecuring

prop

ller

shtJft

to

companion

ltJnge

11

Support

engine

by

locating

a

jacft

under

oil

pan

with

a

wooden

block

used

between

oil

pan

and

jack

12

Support

transmission

with

a

transmissionjack

13

Remove

exhaust

pipe

btacket

by

unscrewing

attaching

bolts

2

California

models

only

See

Figure

MT

8

14

Remove

rear

engine

mounting

insulator

securing

bolts

I

and

rear

mounting

member

securing

bolts

3

See

Figure

MT

8

MT

4

E

A277

Fig

MT

8

Removing

engine

mounting

rear

support

15

Remove

starter

motor

16

Remove

bolt

securing

transmis

sion

to

engine

After

removing

these

bolts

support

the

engine

and

transmission

with

jacks

and

then

slide

tra

ion

rearward

away

from

engine

and

remove

from

the

vehicle

Note

Take

care

in

dismounting

trona

mission

not

to

strike

any

adjacent

parts

and

main

drive

shaft

DISASSEMBLY

TRANSMISSION

CASE

DISASSEMBLY

I

Prior

to

disassembling

transmis

sion

thoroughly

wipe

off

dirt

and

grease

from

it

2

Drain

oil

thoroughly

3

Remove

dust

cover

from

trans

mission

case

Remove

release

bearing

and

with

drawallever

4

Remove

reverse

lamp

switch

5

Move

gear

to

Neutral

6

Remove

speedometer

pinion

and

pinion

sleeve

by

taking

off

lock

plate

7

Remove

E

ring

and

stopper

guide

pin

from

rear

end

of

re

ll

extension

See

Figure

MT

9

TM337

Fig

MT

9

Removing

triking

rod

E

ring

and

topper

pin

Page 297 of 537

Automatic

Transmission

REMOVAL

AND

INSTALLATION

TRANSMISSION

ASSEMBLY

REMOVAL

INSTALLATION

TRANSMISSION

ASSEMBLY

When

dismounting

the

automatic

transmission

from

a

vehicle

pay

at

tention

to

the

following

points

1

Before

dismounting

the

trans

mission

rigidly

inspecl

it

by

aid

of

the

Troubleshooting

Chart

and

dis

mount

it

only

when

considered

to

be

necessary

2

Dismount

the

transmission

with

utmost

care

and

when

mounting

observe

the

tightening

torque

indi

cated

on

another

table

not

to

exert

excessive

force

REMOVAL

In

dismounting

automatic

transmis

sion

from

vehicle

proceed

as

follows

I

Disconnect

battery

ground

cable

from

terminal

2

Disengage

torsion

shaft

from

ac

celerator

linkage

3

Jack

up

vehicle

and

support

its

weight

on

safety

stands

Recommend

a

hydraulic

hoist

or

open

pit

be

utilized

if

available

Make

sure

that

safety

is

insured

4

Remove

propeller

shaft

Note

Plug

up

the

opening

in

the

rear

extension

to

prevent

oil

from

flowing

out

5

Disconnect

front

exhaust

tube

6

Disconnect

selector

range

lever

from

manual

shaft

7

Disconnect

wire

connections

at

inhibitor

switch

CONTENTS

AT

33

AT

33

AT

33

TRANSMISSION

CONTROL

LINKAGE

REMOVAL

AND

INSTALLATION

ADJUSTMENT

AT

35

AT

35

AT

35

8

Disconnect

vacuum

tube

from

vacuum

diaphragm

and

wire

connee

lions

at

downshift

solenoid

9

Disconnect

speedometer

cable

from

rear

extension

10

Disconnect

oil

charging

pipe

II

Disconnect

oil

cooler

inlet

and

outlet

tubes

at

transmission

case

12

Support

engine

by

locating

a

jack

under

oil

pan

with

a

wooden

block

used

between

oil

pan

and

jack

Support

transmission

by

means

of

a

transmission

jack

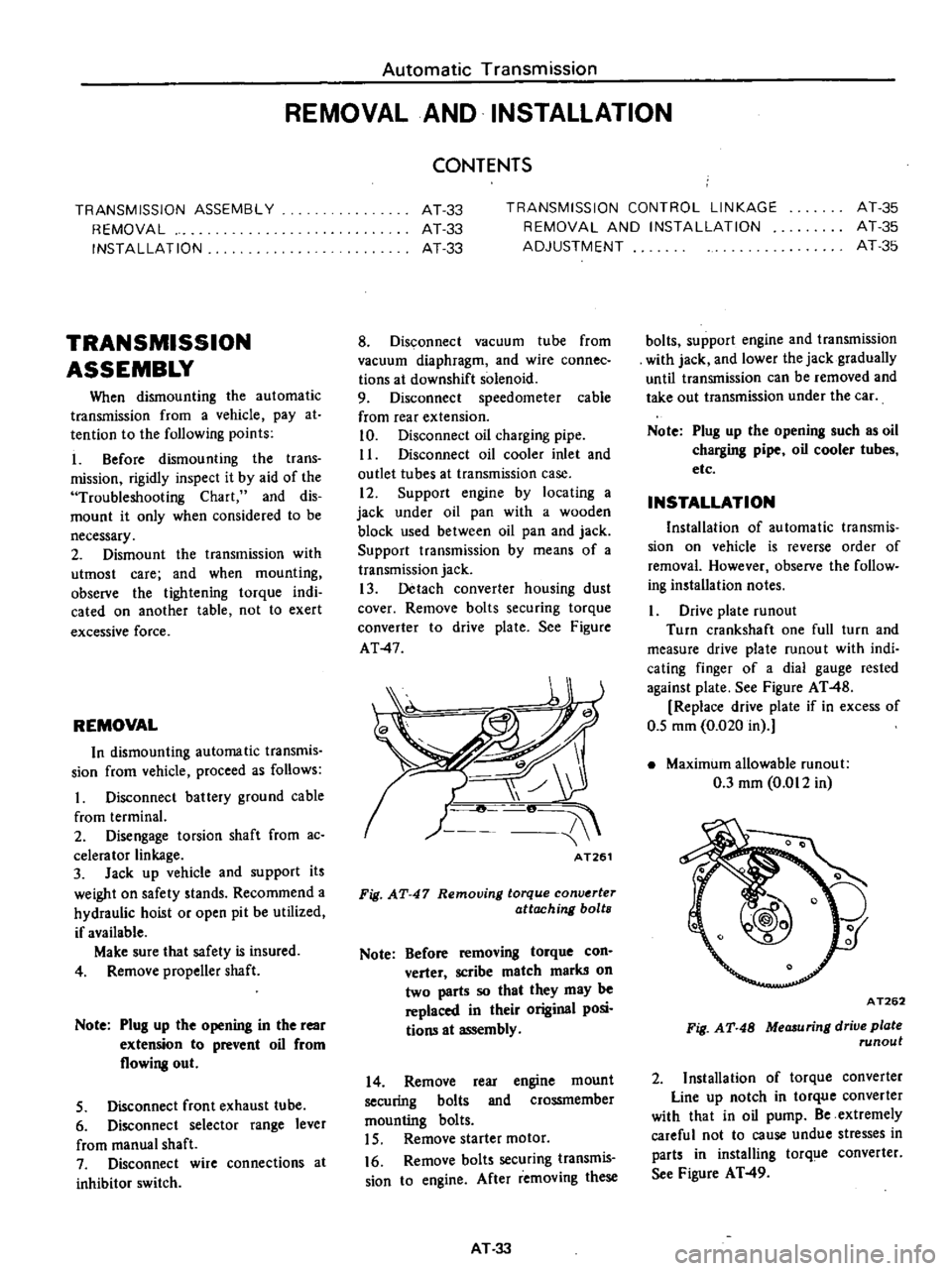

13

Detach

converter

housing

dust

cover

Remove

bolts

securing

torque

converter

to

drive

plate

See

Figure

AT

4

AT261

Fig

AT

47

Removing

torque

conv

rter

attaching

bolts

Note

Before

removing

torque

con

verter

scribe

match

marks

on

two

parts

so

that

they

may

be

replaced

in

their

original

posi

tions

at

assembly

14

Remove

rear

engine

mount

securing

bolts

and

crossmember

mounting

bolts

15

Remove

starter

motor

16

Remove

bolts

securing

transmis

sion

to

engine

After

removing

these

AT

33

bolts

support

engine

and

transmission

with

jack

and

lower

the

jack

gradually

until

transmission

can

be

removed

and

take

out

transmission

under

the

car

Note

Plug

up

the

opening

such

as

oil

charging

pipe

oil

cooler

tubes

etc

INSTALLATION

Installation

of

automatic

transmis

sion

on

vehicle

is

reverse

order

of

removal

However

observe

the

follow

ing

installation

notes

Drive

plate

runout

Turn

crankshaft

one

full

turn

and

measure

drive

plate

mnou

t

with

indi

cating

finger

of

a

dial

gauge

rested

against

plate

See

Figure

AT

48

Replace

drive

plate

if

in

excess

of

0

5

mm

0

020

in

Maximum

allowable

mnout

0

3

mm

0

012

in

A

T262

Fig

AT

48

MeCJ

uring

drive

plate

runout

2

Installation

of

torque

converter

Line

up

notch

in

torque

converter

with

that

in

oil

pump

Be

extremely

careful

not

to

cause

undue

stresses

in

parts

in

installing

torq

e

converter

See

Figure

AT

49

Page 332 of 537

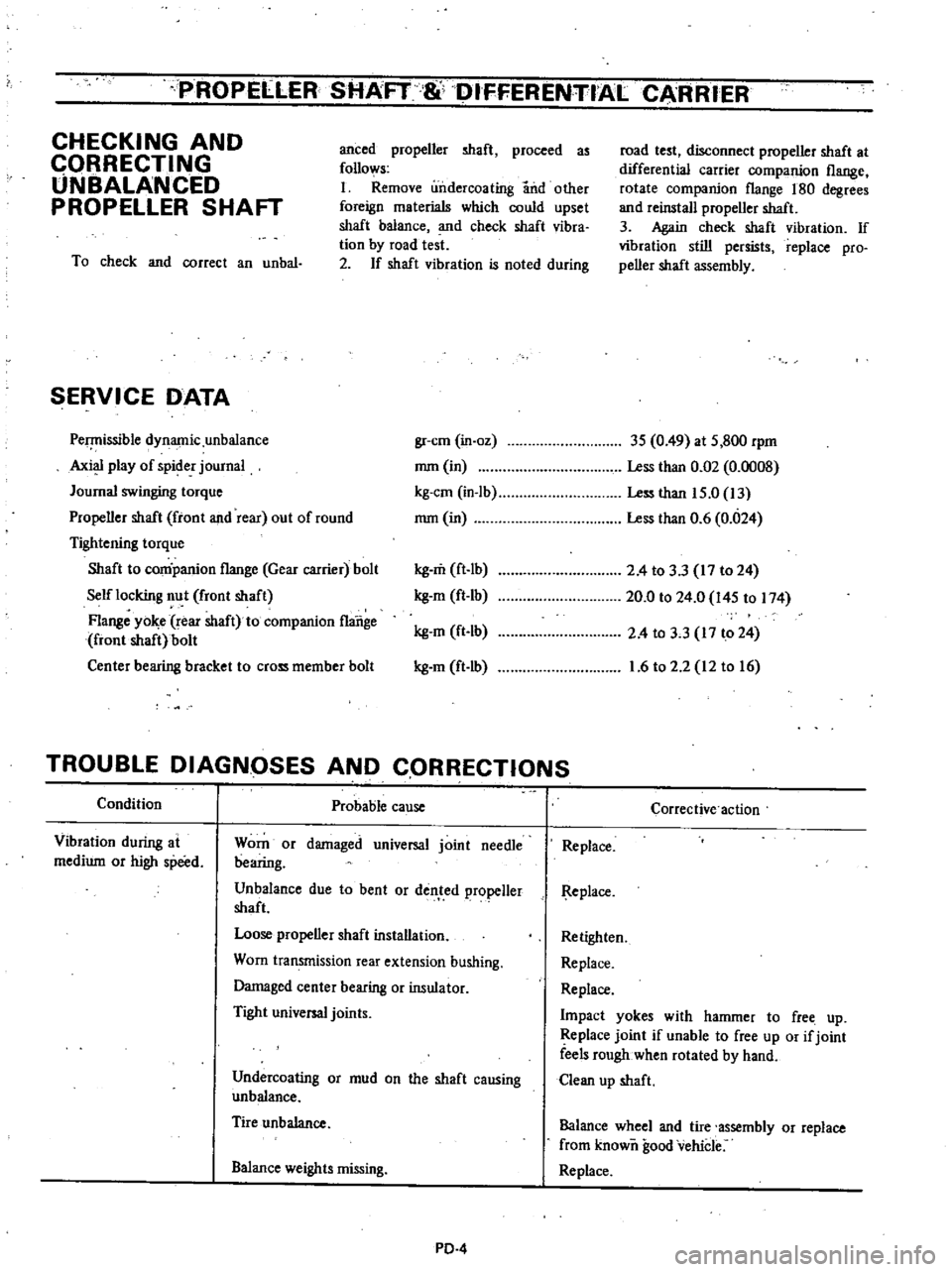

PROPELLER

SHAFT

8l

DIFFERENTIALCAAR

ER

CHECKING

AND

CQRRECTING

UNBALANCED

PROPELLER

SHAFT

anced

propeller

shaft

proceed

as

follows

I

Remove

undercoating

and

other

foreign

materials

which

could

upset

shaft

balance

and

check

shaft

vibra

tion

by

road

test

2

If

shaft

vibration

is

noted

during

To

check

and

correct

an

unbal

SERVICE

DATA

Pe

issible

dynamic

unbalance

Axi

play

of

spider

journal

Journal

swinging

torque

Propeller

shaft

front

and

rear

out

of

round

Tightening

torque

Shaft

to

conipanion

flange

Gear

carrier

bolt

Self

locking

nut

front

shaft

Flange

yo

e

rear

shaft

to

companion

flange

front

shaft

bolt

Center

bearing

bracket

to

cross

member

bolt

road

test

disconnect

propeller

shaft

at

differential

carrier

companion

flange

rotate

companion

flange

180

degrees

and

reinstall

propeller

shaft

3

Again

check

shaft

vibration

If

vibration

still

persists

replace

pro

peller

shaft

assembly

gr

cm

in

oz

3S

0

49

at

S

800

rpm

mm

in

Less

than

0

02

0

0008

kg

em

in

Ib

Less

than

IS

O

13

mm

in

Less

than

0

6

0

024

kg

m

ft

lb

kg

m

ft

Ib

kg

m

ft

lb

kg

m

ft

lb

2

4

to

3

3

17

to

24

20

0

to

24

0

l4S

to

174

2

4

to

3

3

17

to

24

1

6

to

2

2

12

to

16

TROUBLE

DIAGNOSES

AND

CQRRECTIONS

Condition

Probable

cause

Vibration

during

at

medium

or

high

speed

Worn

or

damaged

universal

joint

needle

bearing

Unbalance

due

to

bent

or

dented

propeller

shaft

Loose

propeller

shaft

installation

Worn

transmission

rear

extension

bushing

Damaged

center

bearing

or

insulator

Tight

universal

joints

Undercoating

or

mud

on

the

shaft

causing

unbalance

Tire

unbalance

Balance

weights

missing

PD

4

Corrective

action

Replace

I

l

eplace

Retighten

Replace

Replace

Impact

yokes

with

hammer

to

free

up

Replace

joint

if

unable

to

free

up

or

if

joint

feels

rough

when

rotated

by

hand

Clean

up

shaft

Balance

wheel

and

tire

assembly

or

replace

from

known

good

vehicle

Replace

Page 336 of 537

PROPElli

ER

SHAfT

DIFFERENTIAL

G

ARRIERf

Notes

a

PUller

should

be

handled

with

care

in

catchins

the

edge

of

bearing

inner

race

b

Be

careful

not

to

confuse

left

and

right

hand

parts

2

Remove

ring

gear

by

spreading

out

lock

strap

and

loosening

ring

gear

bolts

in

diagonally

3

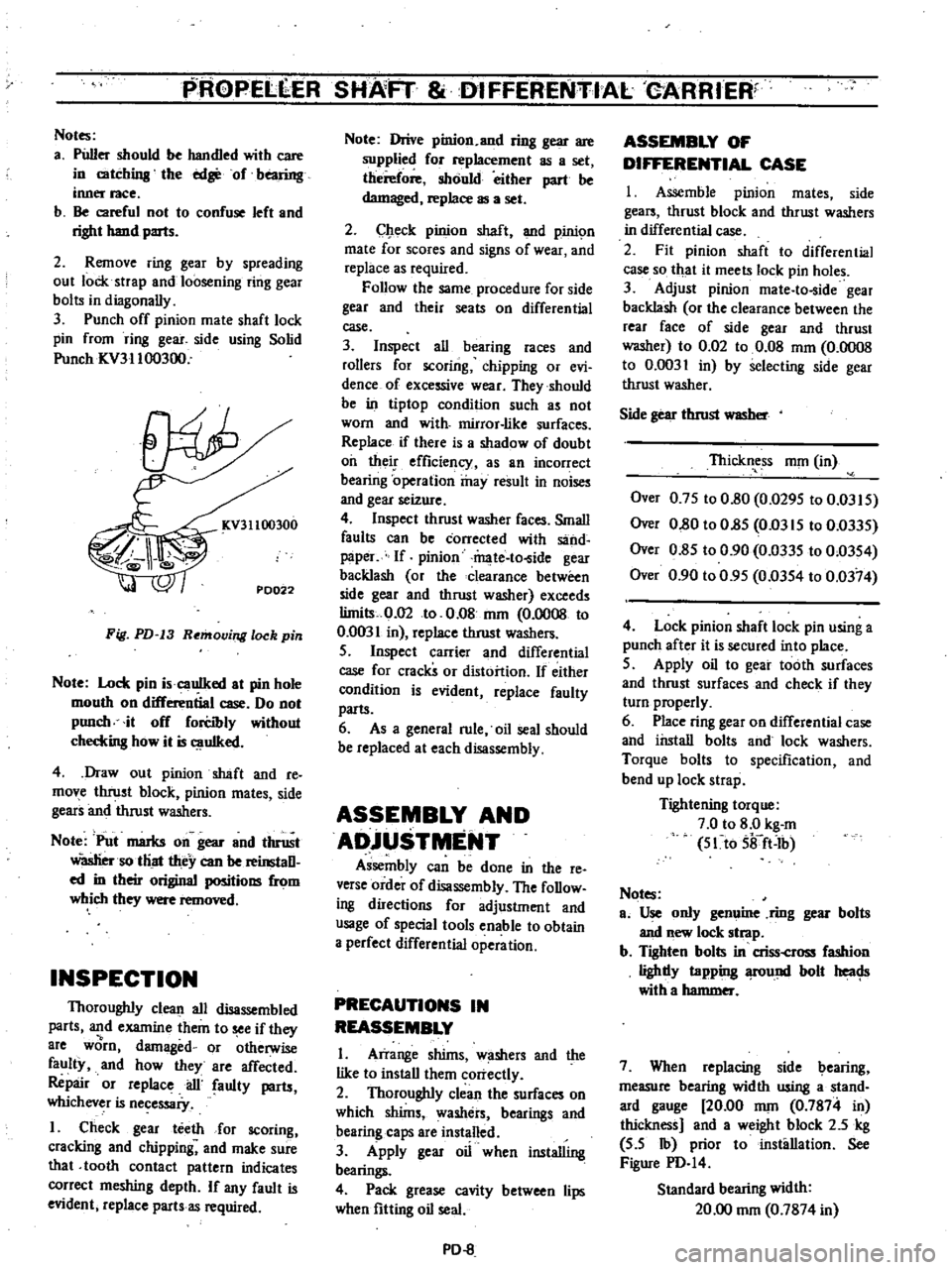

Punch

off

pinion

mate

shaft

lock

pin

from

ring

gear

side

using

Solid

Punch

ICV31100300

KV31100300

PD022

Fig

PD

13

Removing

lock

pin

Note

Lock

pin

i

cauIked

at

pin

hole

mouth

on

differential

case

Do

not

punch

it

off

forCibly

without

checkins

how

it

is

uIked

4

Draw

out

pinion

shaft

and

re

move

thrust

block

pinion

mates

side

gears

and

thrust

washers

Note

Put

marks

on

gear

and

thrust

Wasliersotliat

they

can

be

reinstaD

ed

in

their

original

positions

from

which

they

were

removed

INSPECTION

Thoroughly

clean

all

disassembled

parts

and

examine

them

to

see

if

they

8re

worn

damaged

or

otherwise

faulty

and

how

they

are

affected

Repair

or

replace

ail

faulty

parts

whichever

is

necessaiy

I

Check

gear

teeth

for

scoring

cracking

and

chipping

and

make

sure

that

tooth

contact

pattern

indicates

correct

meshing

depth

If

any

fault

is

evident

replace

parts

as

required

Note

Drive

pinion

and

ring

gear

are

supplied

for

replacement

as

a

set

therefore

should

either

part

be

damaged

replace

as

a

set

2

Check

pinion

shaft

and

pinic

m

mate

for

scores

and

signs

of

wear

and

replace

as

required

Follow

the

same

procedure

for

side

gear

and

their

seats

on

differential

case

3

Inspect

all

bearing

races

and

rollers

for

scoring

chipping

or

evi

dence

of

excessive

wear

They

should

be

in

tiptop

condition

such

as

not

worn

and

with

mirror

like

surfaces

Replace

if

there

is

a

shadow

of

doubt

oil

their

efficiency

as

an

incorrect

bearing

operation

may

result

in

noises

and

gear

seizure

4

Inspect

thrust

washer

faces

Small

faults

can

be

corrected

with

sand

paper

If

pinion

mate

to

ide

gear

backlash

or

the

clearance

between

side

gear

and

thrust

washer

exceeds

limits

0

02

to

0

08

nun

0

0008

to

0

0031

in

replace

thrust

washers

S

Inspect

carrier

and

differential

case

for

cracks

or

distortion

If

either

condition

is

evident

replace

faulty

parts

6

As

a

general

rule

oil

seal

should

be

replaced

at

each

disassembly

ASSEMBLY

AND

ADjUSTMENT

Assembly

can

be

done

in

the

reo

verse

order

of

disassembly

The

foDow

ing

directions

for

adjustment

and

usage

of

special

tools

enable

to

obtain

a

perfect

differential

operation

PRECAUTIONS

IN

REASSEMBLY

I

Arrange

shims

w

shers

and

the

like

to

install

them

correctly

2

Thoroughly

clean

the

surfaces

on

which

shims

washers

bearings

and

bearing

caps

are

installed

3

Apply

gear

oil

when

installing

bearings

4

Pack

grease

cavity

between

lips

when

fitting

oil

seal

PD

8

ASSEMBLY

OF

DIFFERENTIAL

CASE

I

Assemble

pinion

mates

side

gears

thrust

block

and

thrust

washers

in

differential

case

2

Fit

pinion

shaft

to

differential

case

so

that

it

meets

lock

pin

holes

3

Adjust

pinion

mate

to

ide

gear

backlash

or

the

clearance

between

the

rear

face

of

side

gear

and

thrust

washer

to

0

02

to

0

08

mOl

0

0008

to

0

0031

in

by

selecting

side

gear

thrust

washer

Side

gear

thrust

WlISber

Thickness

nun

in

Over

0

7S

to

0

80

0

029S

to

0

03IS

Over

0

80

to

O

8S

Om

IS

to

0

033S

Over

0

8S

to

0

90

0

033S

to

0

03S4

Over

0

90

to

0

9S

0

03S4

to

0

0374

4

Lock

pinion

shaft

lock

pin

using

a

punch

after

it

is

secured

into

place

S

Apply

oil

to

gear

tooth

surfaces

and

thrust

surfaces

and

check

if

they

turn

properly

6

Place

ring

gear

on

differential

case

and

install

bolts

and

lock

washers

Torque

bolts

to

specification

and

bend

up

lock

strap

Tightening

torque

7

0

to

8

0

kg

m

S1to

Sifft

Ib

Notes

ao

Use

only

genuine

ring

gear

bolts

and

new

lock

strap

b

Tighten

bolts

in

criss

cross

fashion

lighdy

tapping

fOund

bolt

heac

Js

with

a

hammer

7

When

replacing

side

bearing

measure

bearing

width

using

a

stand

ard

gauge

20

00

nun

0

7874

in

thickness

and

a

weight

block

2

5

kg

S

S

Ib

prior

to

installation

See

Figure

PD

I4

Standard

bearing

width

20

00

nun

0

7874

in

Page 358 of 537

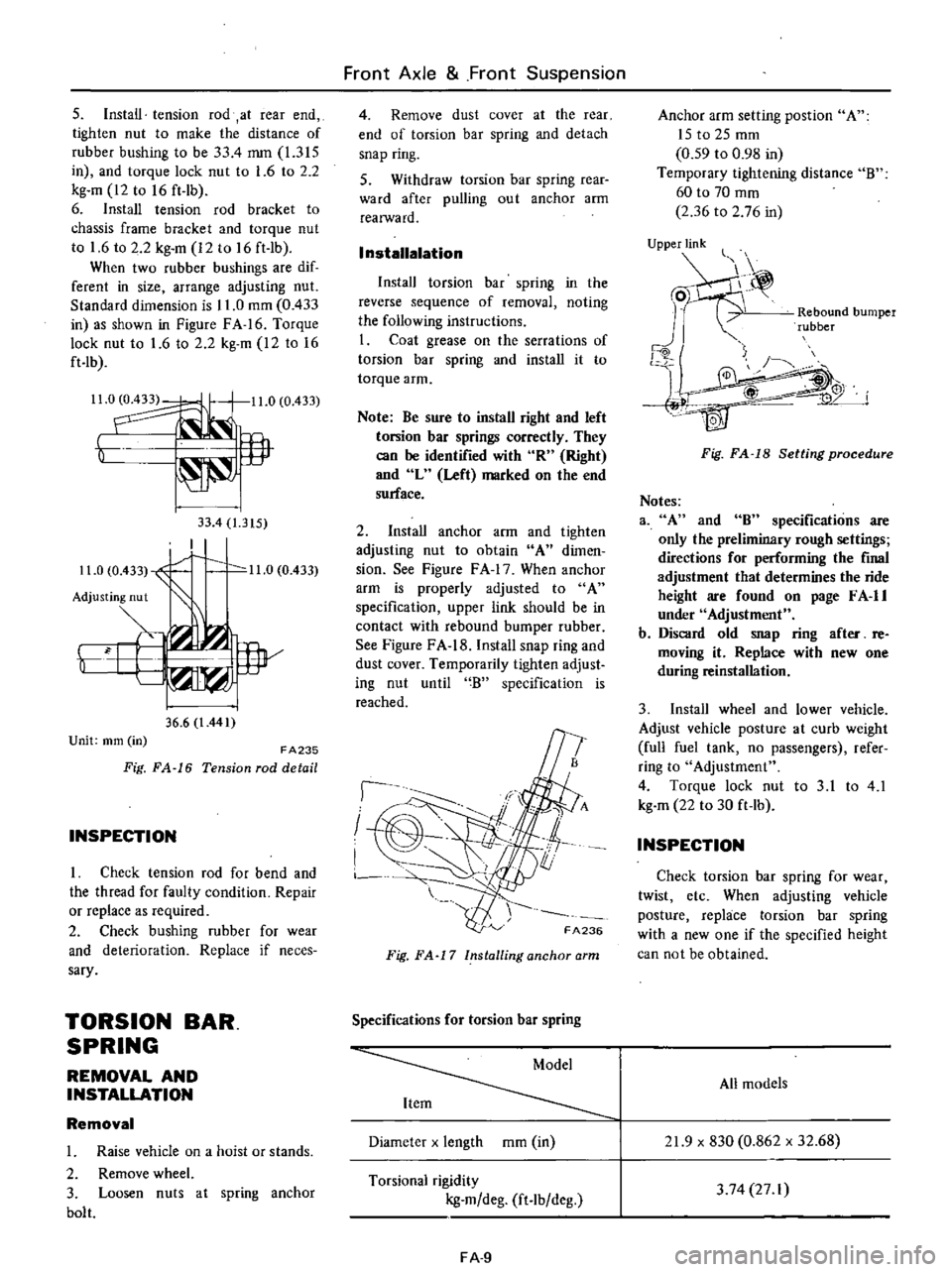

s

Install

tension

rod

at

rear

end

tighten

nut

to

make

the

distance

of

rubber

bushing

to

be

33

4

mm

1

315

in

and

torque

lock

nut

to

1

6

to

2

2

kg

m

12

to

16

ft

lb

6

Install

tension

rod

bracket

to

chassis

frame

bracket

and

torque

nut

to

1

6

to

2

2

kg

m

12

to

16

ft

lb

When

two

rubber

bushings

are

dif

ferent

in

size

arrange

adjusting

nut

Standard

dimension

is

11

0

mOl

0

433

in

as

shown

in

Figure

FA

16

Torque

lock

nut

to

1

6

to

2

2

kg

m

12

to

16

ft

lb

Il

0

11

0

0

433

t

lP

33

4

1

315

I

11

0

0

433

1

0

11

0

0

433

Adjusting

nut

Y

i

w

36

6

l

441

Unit

mm

in

FA235

Fig

FA

16

Tension

rod

detail

INSPECTION

I

Check

tension

rod

for

bend

and

the

thread

for

faulty

condition

Repair

or

replace

as

required

2

Check

bushing

rubber

for

wear

and

deterioration

Replace

if

neces

sary

TORSION

BAR

SPRING

REMOVAL

AND

INSTALLATION

Removal

1

Raise

vehicle

on

a

hoist

or

stands

2

Remove

wheel

3

Loosen

nuts

at

spring

anchor

bolt

Front

Axle

Front

Suspension

4

Remove

dust

cover

at

the

rear

end

of

torsion

bar

spring

and

detach

snap

ring

S

Withdraw

torsion

bar

spring

rear

ward

after

pulling

ou

t

anchor

arm

realWard

I

nstallalation

Install

torsion

bar

spring

in

the

reverse

sequence

of

removal

noting

the

following

instructions

I

Coat

grease

on

the

serrations

of

torsion

bar

spring

and

install

it

to

torque

arm

Note

Be

sure

to

install

right

and

left

torsion

bar

springs

correctly

They

can

be

identified

with

R

Right

and

L

Left

marked

on

the

end

surface

2

Install

anchor

arm

and

tighten

adjusting

nut

to

obtain

A

dimen

sion

See

Figure

F

A

17

When

anchor

arm

is

properly

adjusted

to

A

specification

upper

link

should

be

in

contact

with

rebound

bumper

rubber

See

Figure

FA

18

Install

snap

ring

and

dust

cover

Temporarily

tighten

adjust

ing

nut

until

B

specification

is

reached

I

I

I

FA236

Fig

FA

17

Installing

anchor

arm

Specifications

for

torsion

bar

spring

Diameter

x

length

mOl

in

Torsional

rigidity

kg

m

deg

ft

lb

deg

FA

9

Anchor

arm

setting

post

ion

A

ISt02Smm

0

59

to

0

98

in

Temporary

tightening

distance

B

60

to

70

mOl

2

36

to

2

76

in

UjPPje

Rebound

bumper

rubber

j

4W

Fig

FA

18

Setting

procedure

Notes

3

A

and

8

specifications

are

only

the

preliminary

rough

settings

directions

for

performing

the

final

adjustment

that

determines

the

ride

height

are

found

on

page

F

A

II

under

Adjustment

b

Discard

old

snap

ring

after

re

moving

it

Replace

with

new

one

during

reinstallation

3

Install

wheel

and

lower

vehicle

Adjust

vehicle

posture

at

curb

weight

full

fuel

tank

no

passengers

refer

ring

to

Adjustment

4

Torque

lock

nut

to

3

1

to

4

1

kg

m

22

to

30

ft

lb

INSPECTION

Check

torsion

bar

spring

for

wear

twist

etc

When

adjusting

vehicle

posture

replace

torsion

bar

spring

with

a

new

one

if

the

specified

height

can

not

be

obtained

All

models

21

9

x

830

0

862

x

32

68

3

74

27

I

Page 361 of 537

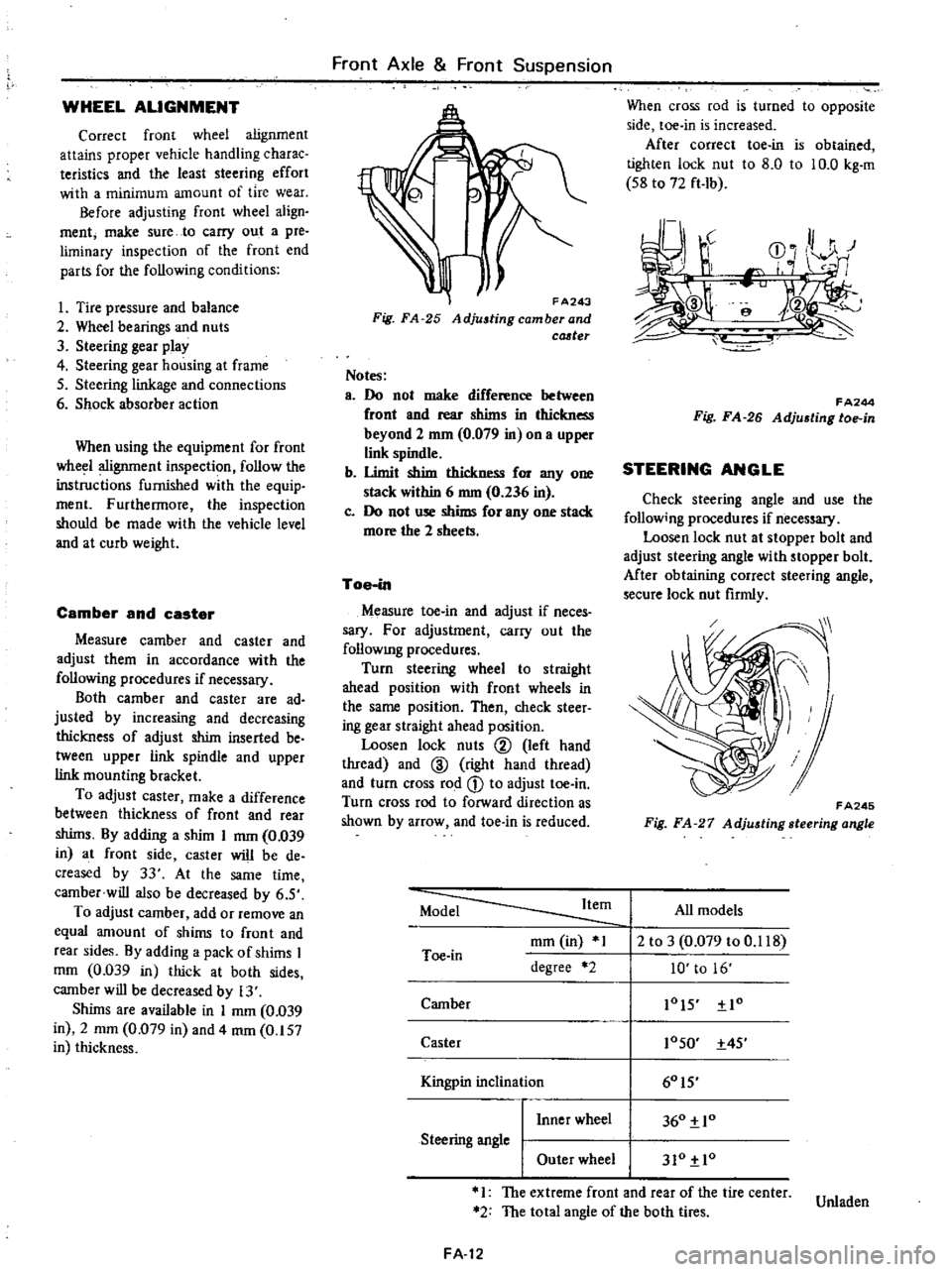

WHEEL

ALIGNMENT

Correct

front

wheel

alignment

attains

proper

vehicle

handling

charac

teristics

and

the

least

steering

effort

with

a

minimum

amount

of

tire

wear

Before

adjusting

front

wheel

align

ment

make

sure

to

carry

out

a

pre

liminary

inspection

of

the

front

end

parts

for

the

following

conditions

1

Tire

pressure

and

balance

2

Wheel

bearings

and

nuts

3

Steering

gear

play

4

Steering

gear

housing

at

frame

S

Steering

linkage

and

connections

6

Shock

absorber

action

When

using

the

equipment

for

front

wheel

alignment

inspection

follow

the

inst

c

tions

furnished

with

the

equip

ment

Furthennore

the

inspection

should

be

made

with

the

vehicle

level

and

at

curb

weight

Camber

and

caster

Measure

camber

and

caster

and

adjust

them

in

accordance

with

the

following

procedures

if

necessary

Both

camber

and

caster

are

ad

justed

by

increasing

and

decreasing

thickness

of

adjust

shim

inserted

be

tween

upper

link

spindle

and

upper

link

mounting

bracket

To

adjust

caster

make

a

difference

between

thickness

of

front

and

rear

shims

By

adding

a

shim

I

mm

0

039

in

at

front

side

caster

will

be

de

creased

by

33

At

the

same

time

camber

will

also

be

decreased

by

6

S

To

adjust

camber

add

or

remove

an

equal

amount

of

shims

to

front

and

rear

sides

By

adding

a

pack

of

shims

I

mOl

0

039

in

thick

at

both

sides

camber

will

be

decreased

by

13

Shims

are

available

in

I

mm

0

039

in

2

mOl

0

079

in

and

4

mOl

0

157

in

thickness

Front

Axle

Front

Suspension

FA243

Fig

FA

25

Adjustingcamberand

cCJ

ter

Notes

a

Do

not

make

difference

between

front

and

rear

shims

in

thickness

beyond

2

mm

0

079

in

on

a

upper

link

spindle

b

Umit

shim

thickness

for

anyone

stack

within

6

nun

0

236

in

c

Do

not

use

shims

for

anyone

stack

more

the

2

sheets

Toe

in

Measure

toe

in

and

adjust

if

neces

sary

For

adjustment

carry

out

the

follOWIng

procedures

Turn

steering

wheel

to

straight

ahead

position

with

front

wheels

in

the

same

position

Then

check

steer

ing

gear

straight

ahead

position

Loosen

lock

nuts

@

left

hand

thread

and

ID

right

hand

thread

and

turn

cross

rod

CD

to

adjust

toe

in

Turn

cross

rod

to

forward

direction

as

shown

by

arrow

and

toe

in

is

reduced

When

cross

rod

is

turned

to

opposite

side

toe

in

is

increased

After

correct

toe

in

is

obtained

tighten

lock

nut

to

8

0

to

10

0

kg

m

S8

to

72

ft

Ib

r

J

r

CD

0

HI

r

I

e

f

FA244

Fig

FA

26

Adju6ting

toe

in

STEERING

ANGLE

Check

steering

angle

and

use

the

follow

ng

procedures

if

necessary

Loosen

lock

nut

at

stopper

bolt

and

adjust

steering

angle

with

stopper

bolt

Mter

obtaining

correct

steering

angle

secure

lock

nut

firmly

FA245

Fig

FA

27

Adjusting

steering

angle

Model

Item

All

models

mOl

in

1

2

to

3

0

079

to

0

118

Toe

in

degree

2

10

to

16

Camber

lOIS

Io

Caster

10SO

4S

I

60IS

Kingpin

inc

inal10n

I

Inner

wheel

360

10

Steering

angle

I

Outer

wheel

310

10

1

The

extreme

front

and

rear

of

the

tire

center

Unladen

2

The

total

angle

of

the

both

tires

FA

12