engine DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 466 of 537

Body

Electrical

System

ELECTRICAL

ACCESSORIES

CONTENTS

HORN

DESCRIPTION

REMOVAL

AND

INSTALLATION

IGNITION

SWITCH

REMOVAL

AND

INSTALLATION

INSPECTION

WINDSHIELD

WIPER

AND

WASHER

REMOVAL

AND

INSTALLATION

INSPECTION

RADIO

REMOVAL

AND

INSTALLATION

ADJUSTMENT

CLOCK

REMOVAL

I

NST

ALLA

TION

HEATER

DESCRIPTION

AIRFLOW

HEATER

UNIT

ASSEMBLY

BE

21

BE

21

BE

21

8E

n

BE

22

BE

22

BE

23

BE

23

BE

23

BE

25

BE

25

BE

25

BE

25

BE

25

BE

26

BE

26

BE

26

BE

28

BE

29

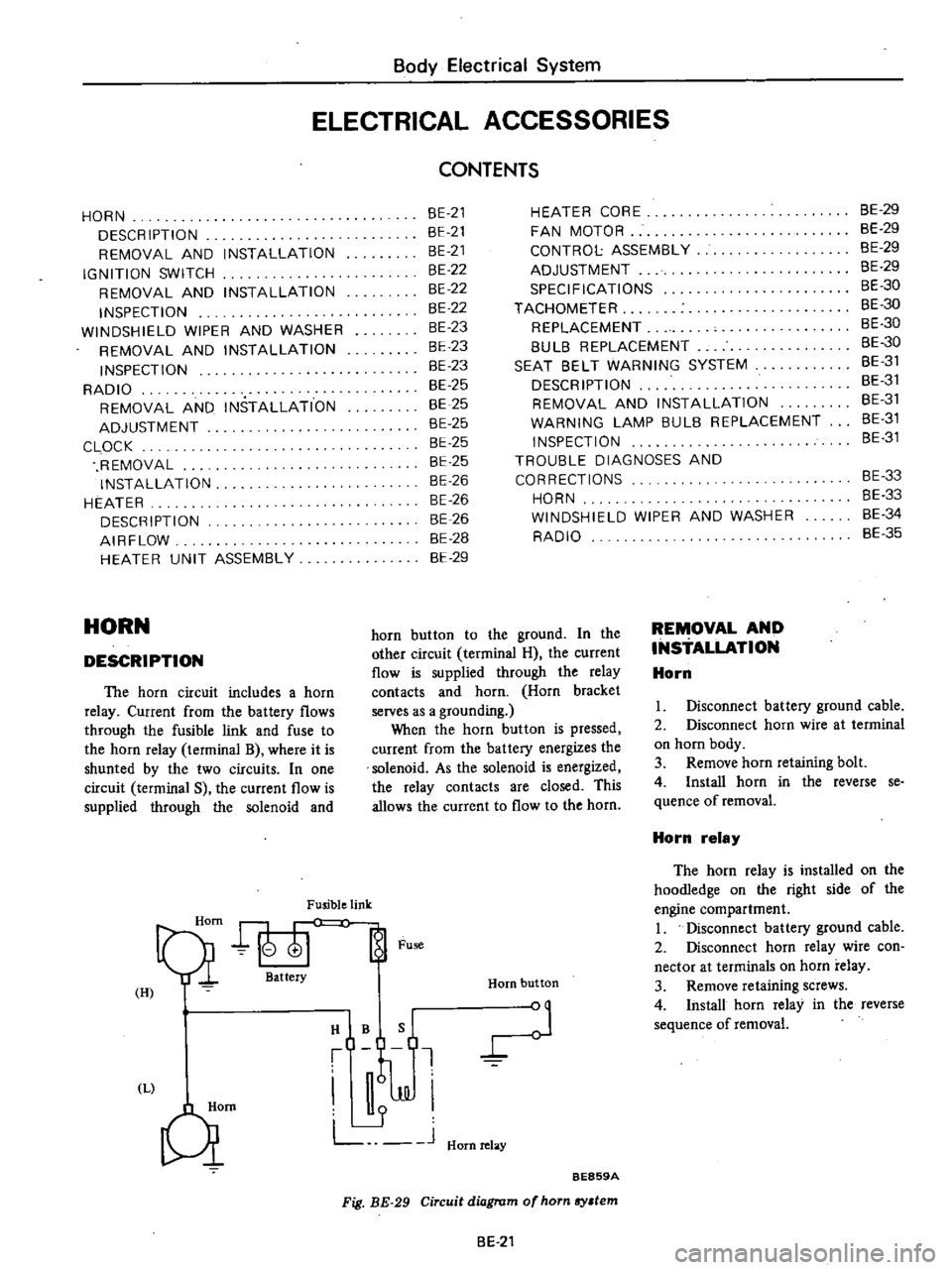

HORN

DESCRIPTION

The

horn

circuit

includes

a

horn

relay

Current

from

the

battery

flows

through

the

fusible

link

and

fuse

to

the

horn

relay

terminal

B

where

it

is

shunted

by

the

two

circuits

In

one

circuit

terminal

S

the

current

flow

is

supplied

through

the

solenoid

and

Fusible

link

Qi

att

Fu

H

I

HIBQ

t

J

JJI

L

J

Hornrelay

Qm

HEATER

CORE

FAN

MOTOR

CONTROL

ASSEMBLY

ADJUSTMENT

SPECIFICATIONS

TACHOMETER

REPLACEMENT

8UL8

REPLACEMENT

SEAT

8ELT

WARNING

SYSTEM

DESCRIPTION

REMOVAL

AND

INSTALLATION

WARNING

LAMP

BULB

REPLACEMENT

INSPECTION

TROUBLE

DIAGNOSES

AND

CORRECTIONS

HORN

WINDSHIELD

WIPER

AND

WASHER

RADIO

Horn

button

BE859A

Fig

BE

29

Circuit

diagram

of

horn

sy

tem

horn

button

to

the

ground

In

the

other

circuit

terminal

H

the

current

flow

is

supplied

through

the

relay

contacts

and

horn

Horn

bracket

serves

as

a

grounding

When

the

horn

button

is

pressed

current

from

the

battery

energizes

the

solenoid

As

the

solenoid

is

energized

the

relay

contacts

are

closed

This

allows

the

current

to

flow

to

the

horn

BE

21

REMOVAL

AND

INSTALLATION

Horn

8E

29

BE

29

BE

29

8E

29

BE

30

BE

30

BE

30

8E

30

8E

31

BE

31

BE

31

8E

31

8E

31

BE

33

8E

33

8E

34

BE

35

I

Disconnect

battery

ground

cable

2

Disconnect

horn

wire

at

terminal

on

horn

body

3

Remove

horn

retaining

bolt

4

Install

horn

in

the

reverse

se

quence

of

removal

Horn

relay

The

horn

relay

is

installed

on

the

hoodIedge

on

the

right

side

of

the

engine

compartment

I

Disconnect

battery

ground

cable

2

Disconnect

horn

relay

wire

con

nector

at

terminals

on

horn

relay

3

Remove

retaining

screws

4

Install

horn

relay

in

the

reverse

sequence

of

removal

Page 472 of 537

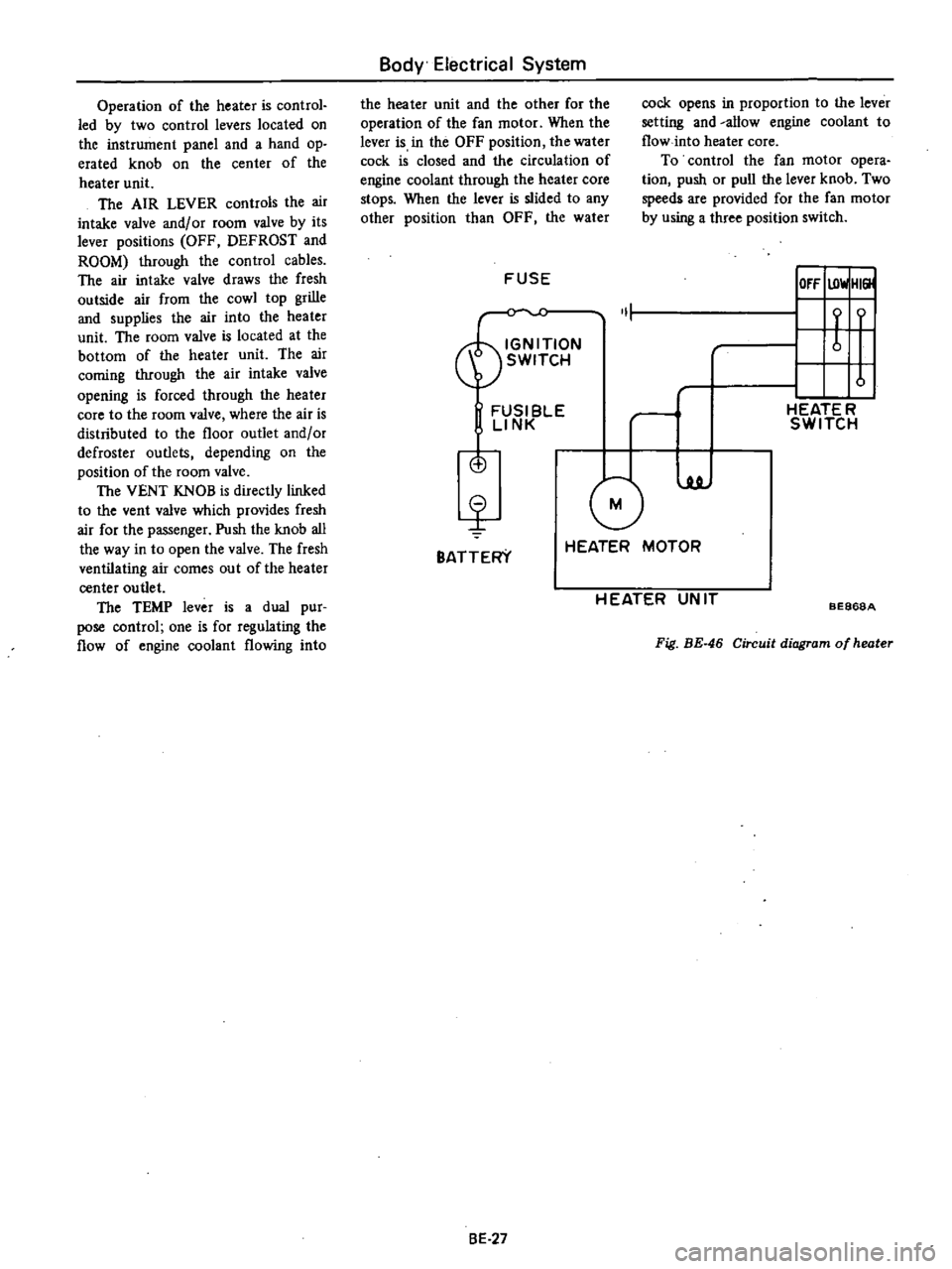

Operation

of

the

heater

is

control

led

by

two

control

levers

located

on

the

instrument

panel

and

a

hand

op

erated

knob

on

the

center

of

the

heater

unit

The

AIR

LEVER

controls

the

air

intake

valve

and

or

room

valve

by

its

lever

positions

OFF

DEFROST

and

ROOM

through

the

control

cables

The

air

intake

valve

draws

the

fresh

outside

air

from

the

cowl

top

grille

and

supplies

the

air

into

the

heater

unit

The

room

valve

is

located

at

the

bottom

of

the

heater

unit

The

air

coming

through

the

air

intake

valve

opening

is

forced

through

the

heater

core

to

the

room

valve

where

the

air

is

distributed

to

the

floor

outlet

and

or

defroster

outlets

depending

on

the

position

of

the

room

valve

The

VENT

KNOB

is

directly

linked

to

the

vent

valve

which

provides

fresh

air

for

the

passenger

Push

the

knob

all

the

way

in

to

open

the

valve

The

fresh

ventilating

air

comes

out

of

the

heater

center

outlet

The

TEMP

lever

is

a

dual

pur

pose

control

one

is

for

regulating

the

flow

of

engine

coolant

flowing

into

Body

Electrical

System

the

heater

unit

and

the

other

for

the

operation

of

the

fan

motor

When

the

lever

is

in

the

OFF

position

the

water

cock

is

closed

and

the

circulation

of

engine

coolant

through

the

heater

core

stops

When

the

lever

is

slided

to

any

other

position

than

OFF

the

water

cock

opens

in

proportion

to

the

lever

setting

and

allow

engine

coolant

to

flow

into

heater

core

To

control

the

fan

motor

opera

tion

push

or

pull

the

lever

knob

Two

speeds

are

provided

for

the

fan

motor

by

using

a

three

position

switch

FUSE

IOfF

UlwlHI

ON

1

t

f

SWITCH

u

FUSI

BlE

rl

HEATE

R

LINK

SWITCH

is

G

luJ

BATTERY

HEATER

MOTOR

H

EATER

UN

IT

BE868A

Fig

BE

46

Circuit

diagram

of

heater

8E

27

Page 474 of 537

HEATER

UNIT

ASSEMBLY

Removal

L

Disconnect

battery

ground

cable

2

Drain

engine

coolant

3

Remove

defroster

hoses

4

Remove

three

cable

retaining

clips

and

disconnect

control

cables

from

valves

and

water

cock

5

Disconnect

two

fan

motor

lead

wires

from

each

connector

6

Disconnect

two

resistor

lead

wires

from

each

connector

7

Disconnect

water

hoses

from

core

and

water

cock

8

Remove

three

heater

housing

mounting

bolts

and

dismount

heater

unit

from

vehicle

Installation

1

Position

heater

unit

under

instru

ment

panel

and

install

three

heater

unit

securing

bolts

2

Install

water

hoses

3

Position

heater

control

cables

to

room

valve

air

intake

valve

and

water

cock

4

Adjust

control

cable

length

for

proper

operation

as

outlined

in

Adjust

ment

5

Connect

fan

motor

wires

and

resistance

wires

to

each

connector

plug

6

Install

defroster

hoses

7

Connect

battery

ground

cable

8

Fill

cooling

systeIT

9

Run

engine

at

2

000

rpm

with

AIR

lever

in

the

HOT

position

Make

sure

that

engine

coolant

is

fIlled

up

to

correct

level

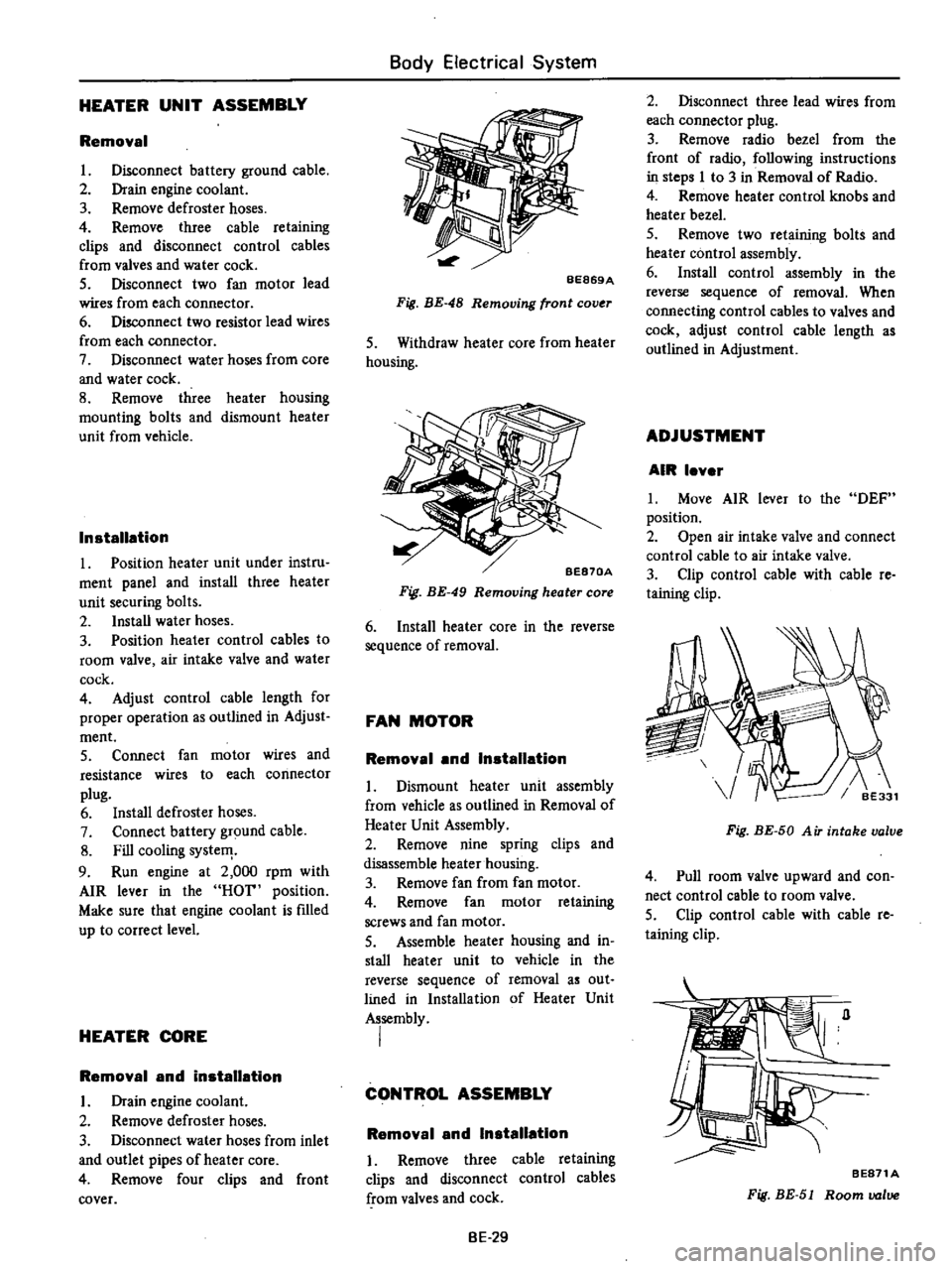

HEATER

CORE

Removal

and

installation

L

Drain

engine

coolant

2

Remove

defroster

hoses

3

Disconnect

water

hoses

from

inlet

and

outlet

pipes

of

heater

core

4

Remove

four

clips

and

front

cover

Body

Electrical

System

BE869A

Fig

BE

48

Removing

front

cov

r

S

Withdraw

heater

core

from

heater

housing

BE870A

Fig

BE

49

Removing

heater

core

6

Install

heater

core

in

the

reverse

sequence

of

removal

FAN

MOTOR

Removal

and

Installation

L

Dismount

heater

unit

assembly

from

vehicle

as

outlined

in

Removal

of

Heater

Unit

Assembly

2

Remove

nine

spring

clips

and

disassemble

heater

housing

3

Remove

fan

from

fan

motor

4

Remove

fan

motor

retaining

screws

and

fan

motor

S

Assemble

heater

housing

and

in

stall

heater

unit

to

vehicle

in

the

reverse

sequence

of

removal

as

out

lined

in

Installation

of

Heater

Unit

Assembly

I

CONTROL

ASSEMBLY

Removal

and

Installation

I

Remove

three

cable

retaining

clips

and

disconnect

control

cables

from

valves

and

cock

BE

29

2

Disconnect

three

lead

wires

from

each

connector

plug

3

Remove

radio

bezel

from

the

front

of

radio

following

instructions

in

steps

I

to

3

in

Removal

of

Radio

4

Remove

heater

control

knobs

and

heater

bezel

5

Remove

two

retaining

bolts

and

heater

control

assembly

6

Install

control

assembly

in

the

reverse

sequence

of

removal

When

connecting

control

cables

to

valves

and

cock

adjust

control

cable

length

as

outlined

in

Adjustment

ADJUSTMENT

AIR

lever

L

Move

AIR

lever

to

the

DEF

position

2

Open

air

intake

valve

and

connect

control

cable

to

air

intake

valve

3

Clip

control

cable

with

cable

re

taining

clip

Fig

BE

50

A

iT

intake

valve

4

Pull

room

valve

upward

and

con

nect

control

cable

to

room

valve

5

Clip

control

cable

with

cable

re

taining

clip

BE871A

Fig

BE

51

Room

valve

Page 475 of 537

TEMP

lever

1

Move

TEMP

lever

to

the

OFF

position

2

Connect

control

cable

to

the

lever

of

water

ock

when

water

cock

lever

is

pulled

forward

fully

closed

3

Install

control

cable

on

water

cock

bracket

with

cable

retaining

clip

SPECIFICATIONS

Item

FAN

MOTOR

Rated

power

consumption

Revolution

rpm

Fan

dia

mm

in

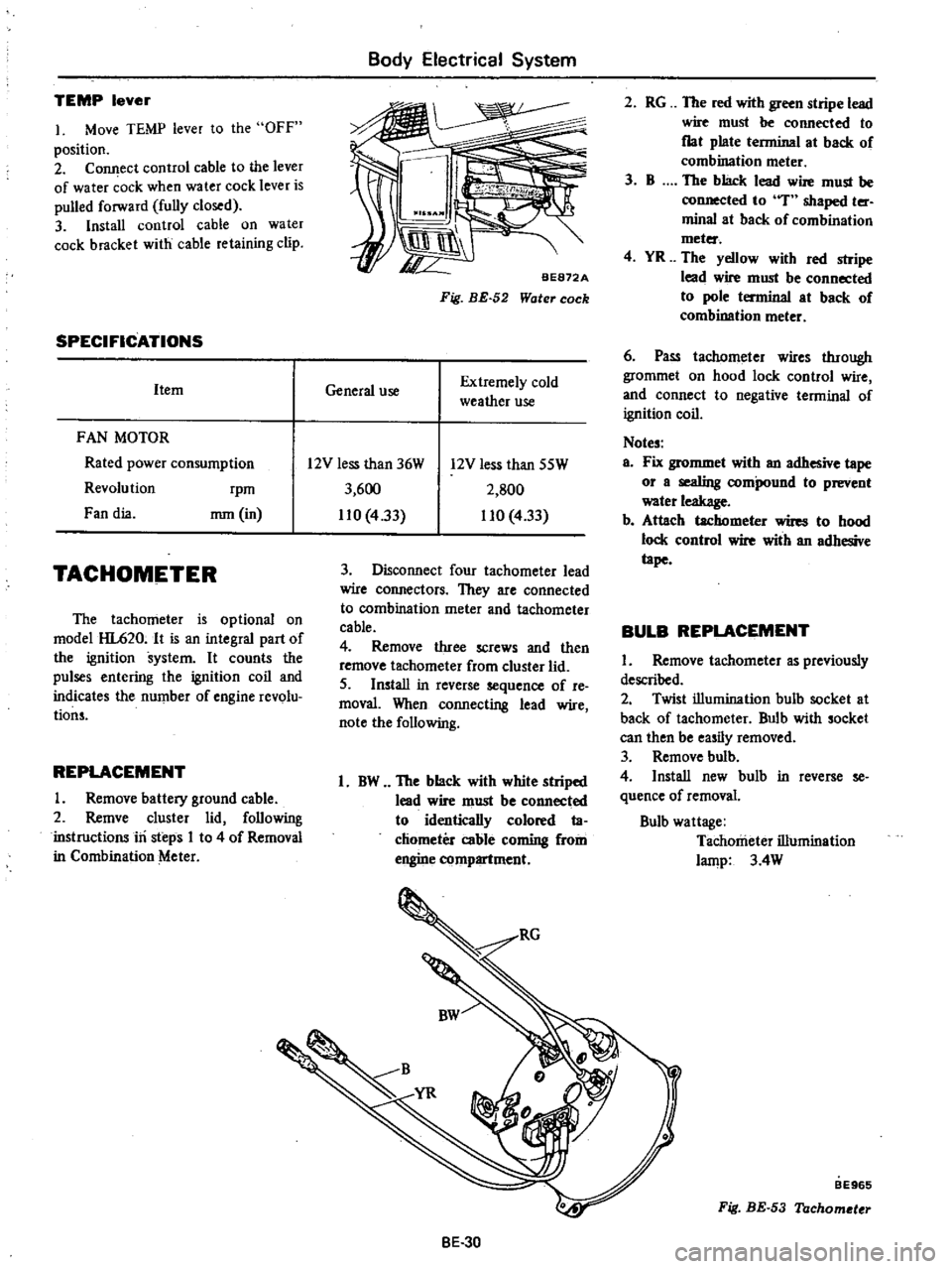

TACHOMETER

The

tachometer

is

optional

on

model

HL620

It

is

an

integral

part

of

the

ignition

system

It

counts

the

pulses

entering

the

ignition

coil

and

indicates

the

number

of

engine

revolu

tions

REPLACEMENT

I

Remove

battery

ground

cable

2

Remve

cluster

lid

following

instructions

iri

steps

I

to

4

of

Removal

in

Combination

Meter

Body

Electrical

System

BE872A

Fig

BE

52

Water

cock

General

use

Extremely

cold

weather

use

2

RG

The

red

with

green

stripe

lead

wire

must

be

connected

to

flat

plate

terminal

at

back

of

combination

meter

3

B

The

black

lead

wire

must

be

connected

to

T

shaped

ter

minal

at

back

of

combination

meter

4

YR

The

yellow

with

red

stripe

lead

wire

must

be

connected

to

pole

terminal

at

back

of

combination

meter

6

Pass

tachllmeter

wires

through

grommet

on

hood

lock

control

wire

and

connect

to

negative

terminal

of

ignition

coil

Notes

a

Fix

grommet

with

an

adhesive

tape

or

a

sealing

compound

to

prevent

water

leakage

b

Attach

tachometer

wires

to

hood

lock

control

wire

with

an

adhesive

tape

BULB

REPLACEMENT

I

Remove

tachometer

as

previously

described

2

Twist

illumination

bulh

socket

at

back

of

tachometer

Bulb

with

socket

can

then

be

easily

removed

3

Remove

bulb

4

Install

new

bulb

in

reverse

se

quence

of

removal

Bulb

wattage

Tachometer

illumination

lamp

3

4W

12V

less

than

36W

3

600

110

433

12V

less

than

SSW

2

SOO

110

4

33

3

Disconnect

four

tachometer

lead

wire

connectors

They

are

connected

to

combination

meter

and

tachometer

cable

4

Remove

three

screws

and

then

remove

tachometer

from

cluster

lid

5

Install

in

reverse

sequence

of

re

moval

When

connecting

lead

wire

note

the

following

1

BW

The

black

with

white

striped

lead

wire

must

be

connected

to

identically

colored

ta

chometer

cable

coming

from

engine

compartment

BE

30

BE965

Fig

BE

53

Tachometer

Page 480 of 537

Body

Electrical

System

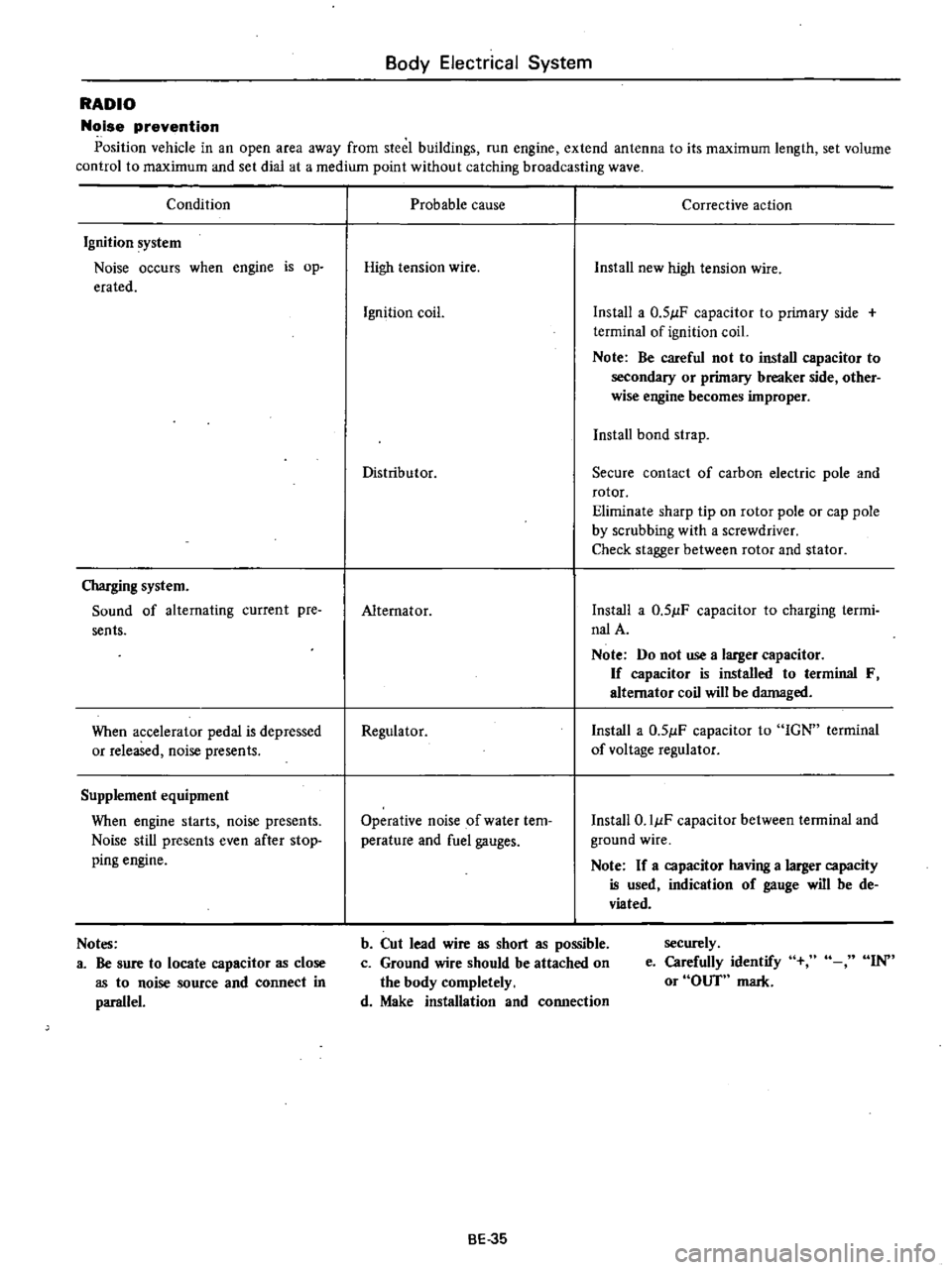

RADIO

Noise

prevention

Position

vehicle

in

an

open

area

away

from

steel

buildings

run

engine

extend

antenna

to

its

maximum

length

set

volume

control

to

maximum

and

set

dial

at

a

medium

point

without

catching

broadcasting

wave

Condition

Ignition

system

Noise

occurs

when

engine

is

op

erated

Charging

system

Sound

of

alternating

current

pre

sents

When

accelerator

pedal

is

depressed

or

released

noise

presents

Supplement

equipment

When

engine

starts

noise

presents

Noise

still

presents

even

after

stop

ping

engine

Notes

a

Be

sure

to

locate

capacitor

as

close

as

to

noise

source

and

connect

in

parallel

Probable

cause

Corrective

action

High

tension

wire

Install

new

high

tension

wire

Ignition

coil

Install

a

0

51lF

capacitor

to

primary

side

terminal

of

ignition

coil

Note

Be

careful

not

to

install

capacitor

to

secondary

or

primary

breaker

side

other

wise

engine

becomes

improper

Install

bond

strap

Distributor

Secure

contact

of

carbon

electric

pole

and

rotor

Eliminate

sharp

tip

on

rotor

pole

or

cap

pole

by

scrubbing

with

a

screwdriver

Check

stagger

between

rotor

and

stator

Alternator

Install

a

0

51lF

capacitor

to

charging

termi

nalA

Note

Do

not

use

a

larger

capacitor

If

capacitor

is

installed

to

terminal

F

alternator

coil

will

be

damaged

Regulator

Install

a

0

51lF

capacitor

to

IGN

terminal

of

voltage

regulator

Operative

noise

of

water

tem

perature

and

fuel

gauges

Install

O

IIlF

capacitor

between

terminal

and

ground

wire

Note

If

a

capacitor

having

a

larger

capacity

is

used

indication

of

gauge

will

be

de

viated

b

Cut

lead

wire

as

short

as

possible

c

Ground

wire

should

be

attached

on

the

body

completely

d

Make

installation

and

connection

securely

e

Carefully

identify

or

OUT

mark

IN

BE

35

Page 481 of 537

CD

m

Cl

@

D

@

I

j

1

To

instrument

harness

IS

To

battery

30

To

check

connector

2

To

full

transistor

amplifier

16

To

fusible

link

3t

To

headlamp

L

U

type

2

California

models

only

17

To

engine

harness

No

2

32

To

sido

marker

lamp

L

B

3

To

hood

switch

18

To

alternator

33

To

front

combination

lamp

L

H

4

To

engine

compartment

lamp

1

9

To

front

combination

lamp

R

n

34

To

horn

Low

ll

l

S

To

washer

motor

20

To

headlamp

R

H

type

2

3S

To

horn

High

l

l

0

6

To

auto

choke

heater

relay

1

To

side

marker

lamp

R

n

36

To

B

C

D

D

cut

olenoid

California

models

7

To

detector

dri

e

counter

22

To

headlamp

R

B

type

1

only

Non

Califunia

model

except

for

Canada

23

To

ground

37

To

block

tcrminal

distributor

California

8

To

ignition

relay

California

models

only

i4

To

thermal

transmitter

models

only

9

To

floor

sensor

relay

California

modeb

only

is

To

distributor

Non

California

models

only

38

To

ignition

coil

Non

California

models

only

n

10

To

inhibitor

relay

A

T

only

26

To

8

C

D

D

cut

solenoid

Non

California

39

To

condenser

t

II

To

head

lamp

relay

models

only

40

To

ignition

coil

and

resistor

@

12

To

horn

relay

27

To

fuel

cut

solenoid

California

models

only

OJ

v

m

13

To

voltage

regulator

28

To

auto

choke

heater

g

e

14

To

cooler

cable

29

To

headlamp

L

R

type

1

OJ

to

o

Q

m

r0

C

1

i

Ql

CIl

Il

l

3

Page 483 of 537

m

ii

bl

l

l

l

if

3

i

m

1

Kickdown

solenoid

AlT

2

Oip

3

Inhibitor

switch

AfT

4

Oip

5

Engine

6

Battery

cable

7

Engine

slinger

8

Battery

cable

r

0

w

I

I

cf

n

L

J

TO

ENGtNE

ROOM

HARNESS

OJ

o

Q

m

O

Q

CIl

II

D

3

Page 484 of 537

m

W

D

to

l

l

0

c

l

l

s

Q

3

For

Automatic

Transmission

LB

B

For

Manual

Transmission

m

For

Automatic

Transmission

COLOR

CODE

B

Black

BI

Brown

G

Green

L

Blue

Lg

Light

green

R

Red

W

White

Y

Yellow

BW

Black

with

white

stripe

LgR

Light

green

with

red

stripe

BY

RB

RB

B

WB

RB

YB

2

RB

I

B

1

BW

r

BY

LB

For

Automatic

Transmission

to

o

c

m

r0

O

O

Dl

For

Manual

Transmission

@

CJ

lti

3

RB

fB

BY

YB

RB@RB

YB

BY

1

To

kickdown

solenoid

fOT

Automatic

Transmission

2

To

reverse

switch

for

Manual

Tranmission

3

To

inhibitor

switch

for

Automatic

Transmission

4

To

oil

pressure

switch

5

To

starter

motor

6

To

engine

room

harness

for

Manual

Transmission

7

To

engine

room

harness

for

Automatic

Transmission

Page 485 of 537

m

J

c

@

@

r

1

I

I

I

II

U

j

J

r

U

I

IT

L

U

L

L

@

Qj

flll

I

1

I

I

1

lL

to

t

l

Q

1

To

room

Jamp

cable

2

To

light

switch

3

To

fuse

4

To

tachometer

or

clock

5

To

hazard

flasher

unit

6

To

stop

lamp

switch

7

To

ignition

switch

8

To

hazard

switch

9

To

tU

and

dimmer

switch

10

To

check

connector

11

To

AMP

M

T

only

11

To

combination

instrument

Non

California

mode15

except

for

Canada

13

To

combination

meter

14

To

flasher

unit

IS

To

kickdown

switch

AfT

only

16

To

hand

brake

switch

17

To

heater

motor

18

To

illumination

control

rheostat

19

To

wiper

switch

light

switch

illumination

lamp

20

To

wiper

switch

21

To

cigar

lighter

22

To

heater

control

illumination

lamp

23

To

radio

24

To

heater

control

25

To

belt

and

E

G

R

warning

lamp

Non

California

models

or

floor

te

peratuJe

California

models

26

To

heater

control

illumination

lamp

27

To

buzzer

28

To

belt

warning

timer

U

S

A

Olodels

29

To

indicator

lamp

AfT

only

30

To

cooler

harness

31

To

wiptr

motor

32

To

door

switch

R

H

33

To

engine

compartment

harness

34

To

floor

harness

E

m

S

@

o

J

o

Q

m

CD

n

Ql

en

I

i

3

Page 486 of 537

@

BG

B

LW

LW

B

L

AL

l

J

YA

CD

m

LW

4

ft

GL

LR

t4

B

t

R

LG

4D

It

GW

BW

GW

L

@

ii

b

l

l

l

lD

m

en

lD

A

A

G

Ri

G

L

Non

California

except

Canada

I

G

GR

13

L

R

j

M

T

only

GL

A

T

only

To

engine

compartment

harness

Non

california

except

Canada

G

r

wRfl

Lt

IIY

LIB

l

ll

RY

R

oIll

CD

o

c

m

o

O

II

fJl

1

3