checking oil DATSUN PICK-UP 1977 Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 200 of 537

Engine

Electrical

System

SERVICE

DATA

AND

SPECIFICATIONS

D4A4

06

D4A4

07

Type

D4A6

07

D4A6

08

Firing

order

1

3

4

2

13

4

2

Rotating

direction

Counterclockwise

Counterclockwise

Owen

angle

degree

490

to

550

490

to

550

Point

gap

mm

in

0

45

to

0

55

0

45

to

0

55

0

018

to

0

022

0

018

to

0

022

Point

pressure

kg

lb

0

40

to

0

55

0

40

to

0

55

0

88

to

1

21

0

88

to

1

21

Condenser

capacity

JlF

0

20

to

0

24

0

20

to

0

24

Condenser

isolate

resistance

Mrl

5

5

Cap

isolate

resistance

Mrl

50

50

Rotor

head

isolate

resistance

Mrl

50

50

Cap

carbon

point

length

mm

in

10

0

39

10

0

39

For

Canada

DISTRIBUTOR

California

models

CONSTRUCTION

CHECKING

AND

ADJUSTMENT

CAP

AND

ROTOR

HEAD

AIR

GAP

CONSTRUCTION

In

the

conventional

distributor

the

ignition

liming

is

detected

by

the

cam

and

breaker

arm

while

in

this

transis

tor

ignition

unit

it

is

detected

by

the

reluctor

on

the

shaft

and

the

pick

up

coil

provided

in

place

of

the

breaker

The

pick

up

coil

consists

of

a

magnet

coil

etc

The

amount

of

magnetic

flux

passing

through

the

pole

piece

in

the

coil

is

changed

at

the

moment

the

pole

CONTENTS

EE

33

EE

33

EE

33

EE

33

ADVANCE

MECHANISMS

DISASSEMBLY

ASSEMBLY

SERVICE

DATA

AND

SPECIFICATIONS

EE

33

EE

35

EE

35

EE

36

piece

faces

the

protrusion

of

the

re

luctor

and

then

the

electrical

signal

is

genera

ted

in

the

pick

up

coil

This

electric

signal

is

conducted

into

the

transistor

ignition

unit

which

in

turn

breaks

tI

e

primary

coil

current

running

through

the

ignition

coil

and

generates

high

voltage

in

the

secondary

winding

Also

this

transistor

ignition

EE

33

unit

utilizes

this

electric

signal

to

restore

the

primary

coil

to

the

original

state

after

cutting

off

the

primary

current

for

a

fIXed

time

The

centrifugal

and

vacuum

ad

vance

mechanisms

employ

the

con

ventional

mechanical

type

The

con

tactor

is

used

to

eliminate

vacuum

and

centrifugal

advance

hysteresis

I

Page 201 of 537

t3

l

l

J

@

r

9

V

fW

@

@

CHECKING

AND

ADJUSTMENT

CAP

AND

ROTOR

HEAD

Cap

and

rotor

head

must

be

in

spected

periodically

as

specified

in

the

Maintenance

Schedule

Remove

cap

and

clean

all

dust

and

carbon

deposits

from

cap

and

rotor

from

time

to

time

If

cap

is

cracked

or

is

leaking

replace

with

a

new

one

AIR

GAP

Standard

air

gap

is

0

2

to

0

4

mm

0

008

to

0

016

in

If

the

gap

is

off

the

standard

adjustment

mould

be

made

by

loos

ening

pick

up

coil

screws

Gap

gauge

is

required

for

adjust

ment

Air

gaps

must

be

checked

from

time

to

time

Air

gap

0

2

to

0

4

mm

0

008

to

0

016

in

Engine

Electrical

System

tl

@

9

EE328

Fig

EE

67

Checking

oir

gap

To

remove

pick

up

cail

disconnect

distributor

harness

at

terminal

block

and

remove

screw

securing

pick

up

coil

ADVANCE

MECHANISMS

Specifications

Type

Item

Vacuum

advance

Distributor

degrees

Distributor

mmHg

inHg

Centrifugal

advance

Distributor

degrees

Distributor

cpm

EE34

1

Cap

assembly

2

Rotor

head

a55embly

3

Roll

pin

4

ReJuctor

S

Pick

up

coil

6

Contactoi

7

Breaker

plate

assembly

8

Packing

9

Rotor

shaft

10

Governor

spring

11

Governor

weigh

t

12

Shaft

a

Jscmbly

13

Cap

setter

14

Vacuum

controller

15

Housing

16

Fixing

plate

17

O

ring

18

Collar

EE327

Fig

EE

66

Exploded

view

of

di3tributor

assembly

and

distributor

harness

to

their

positions

EE329

Fig

EE

68

Remouing

pick

up

coil

D4F4

04

D4F4

Q3

Manual

Automatic

00

150

5

91

30

250

9

84

00

550

110

2

300

00

600

110

1

950

Page 204 of 537

Engine

Electrical

System

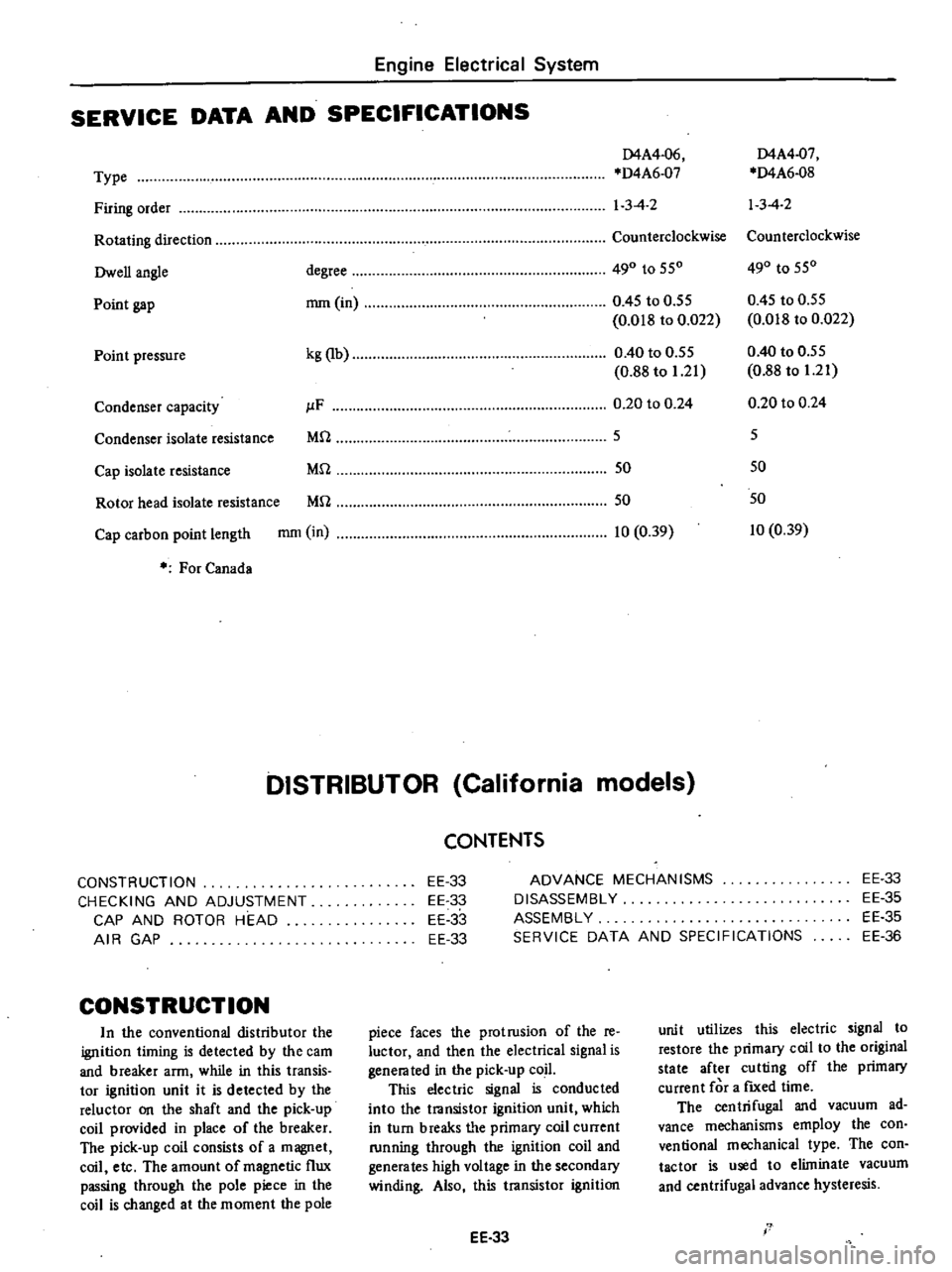

Transistor

ignition

unit

r

1

Power

switching

circuit

Duty

control

circuit

To

starter

To

distributor

Ba

ttery

Ignition

coil

1

Spark

timing

1

Signal

mom

toring

circuit

Lock

j

preven

ling

circuit

nm

Distributor

EE437

Fig

EE

75

Transistor

ignition

unit

circuit

diagram

REMOVAL

AND

INSTALLATION

Transistor

ignition

unit

is

located

on

the

right

hand

dash

side

panel

in

passenger

compartment

Disconnect

battery

negative

cable

2

Disconnect

wiring

harness

from

unit

3

Remove

two

setscrews

and

te

move

unit

4

To

install

reverse

the

order

of

removal

Note

Be

sure

to

connect

wiring

har

nesses

to

their

proper

positio

Failure

to

do

so

will

damage

the

unit

Refer

to

Figure

EE

76

Fig

EE

76

External

view

of

ignition

unit

INSPECTION

If

the

engine

does

not

run

due

to

faulty

ignition

system

check

the

igni

tion

system

as

follows

Check

for

a

cracked

distributor

rotor

or

cap

and

corroded

tenninals

Visually

inspect

high

tension

wires

for

condition

and

if

necessary

use

an

ignition

oscilloscope

or

a

circuit

tester

to

make

performance

checks

Check

spark

plugs

and

adjust

gaps

as

neces

sary

Replace

a

spark

plug

which

is

not

suitable

for

further

use

If

the

above

checks

cannot

correct

the

problem

check

the

entire

ignition

system

with

an

oscilloscope

or

a

circuit

tester

L

CHECKING

WITH

AN

OSCILLOSCOPE

An

oscilloscope

can

be

used

for

checking

almost

all

the

items

in

a

transistor

ignition

system

CHECKING

WITH

A

CIRCUIT

TESTER

A

circuit

tester

can

not

be

used

for

the

duty

control

circuit

and

power

t18nsistor

performance

tests

Both

methods

use

of

an

oscilloscope

and

a

circuit

tester

are

described

in

this

section

EE

37

The

items

are

classified

by

numerals

in

accordance

with

the

objective

of

checks

to

be

performed

Several

wiring

diagrams

are

found

on

pages

EE

41

to

EE

45

The

thick

lines

indicate

the

objective

of

each

individual

item

check

When

checking

a

circuit

with

an

oscilloscope

or

a

circuit

tester

be

careful

not

to

confuse

the

polarity

of

the

lead

wires

if

potential

difference

exists

between

the

check

points

at

which

the

lead

wires

are

to

be

con

tacted

Also

do

not

attempt

to

con

nect

the

lead

wires

to

any

points

in

the

circuit

other

than

those

designated

Careless

handling

of

the

lead

wires

will

result

in

damage

to

the

transistor

ignition

unit

as

well

as

to

the

oscillo

scope

or

circuit

tester

The

connection

of

a

tachometer

or

a

timing

light

in

parallel

with

an

oscilloscope

or

a

circuit

tester

is

al

lowable

provided

that

such

a

connec

tion

is

made

with

due

consideration

to

wiring

connections

1

POWER

SUPPLY

WIRING

AND

BAnERY

CHECK

See

wIrIng

diagram

In

FIgure

EE

88

Procedure

I

Turn

on

ignition

switch

2

Connect

a

circuit

tester

or

an

oscilloscope

as

shown

in

the

figure

below

DC

50

volt

range

EE302

Fig

EE

77

Checking

power

supply

wiring

and

batt

ry

Criterion

When

power

source

battery

voltage

is

indicated

OK

Lower

or

no

indication

N

G

Page 205 of 537

If

the

result

is

N

C

Take

the

following

measures

I

Check

BW

and

B

color

wire

harness

respectively

for

proper

con

ductance

2

Check

battery

terminals

for

proper

connection

3

Check

charge

condition

of

bat

tery

if

an

excessively

low

voltage

is

indicated

2

CONTINUITY

CHECK

OF

PRIMARY

CIRCUIT

2

1

CheckIng

prImary

circuit

See

wiring

diagram

In

Fig

EE

89

Proced

ure

I

Disconnect

L

color

wire

from

ignition

unit

2

Turn

on

ignition

switch

3

C

ooneet

a

cireui

t

tester

or

an

oscilloscope

as

shown

in

Figure

EE

78

DC

50

volt

range

tf

S

EE303

Fig

EE

78

Checking

primary

circuit

Criterion

When

Donnal

power

Source

battery

voltage

is

indicated

OK

Lower

or

no

indication

N

G

If

the

result

is

N

C

Take

the

following

measures

1

Check

BW

and

L

color

wire

Engine

Electrical

System

harness

respectively

for

proper

con

ductance

2

Check

resistor

and

ignition

coil

terminals

for

loose

contact

3

Check

resistor

and

ignition

coil

for

discontinuity

4

Check

WB

color

wire

harness

of

ignition

coil

assembly

for

proper

continuity

2

2

Chacklng

IgnitIon

coil

auembly

See

wiring

diagram

In

Fig

EE

90

Procedure

I

Disconnect

ignition

coil

and

dis

tributor

harness

from

ignition

coil

external

resistor

2

Connect

a

circuit

tester

as

shown

in

the

figure

below

Resistance

1

range

Q

o

fD

ro

EE336

Fig

EE

79

Checking

ignition

coil

assembly

Criterion

When

approximately

1

6

to

2

0

ohm

is

indicated

OK

More

than

2

0

ohm

N

C

If

the

result

is

N

C

Replace

ignition

coil

assembly

3

PICK

UP

COIL

CONTINUITY

CHECK

See

wirIng

dIagram

In

Figure

EE

91

Procedure

Disconnect

R

and

G

color

wires

from

ignition

unit

2

Connect

a

circuit

tester

as

shown

in

the

figure

below

EE

3B

Resistance

10

range

fp

EE305

Fig

EE

BO

Checking

pick

up

coil

Criterion

When

approximately

720

ohm

is

indicated

OK

Far

less

than

or

more

than

720

ohm

N

C

If

the

result

is

N

C

Replace

pick

up

coil

assembly

4

PICK

UP

COIL

POWER

SIGNAL

PULSE

CHECK

Procedure

I

Disconnect

anti

dieseling

solenoid

valve

connector

2

Connect

a

circuit

tester

as

shown

in

the

figure

below

3

Rotate

starter

motor

4

Read

the

tester

indication

AC

2

S

volt

range

EE306

Fig

EE

81

Checking

pick

up

coil

power

aignal

pulse

Criterion

When

pointer

deflects

slightly

OK

When

pointer

does

not

deflect

at

all

N

C

If

the

result

is

N

C

Replace

pick

up

coil

assembly

Page 206 of 537

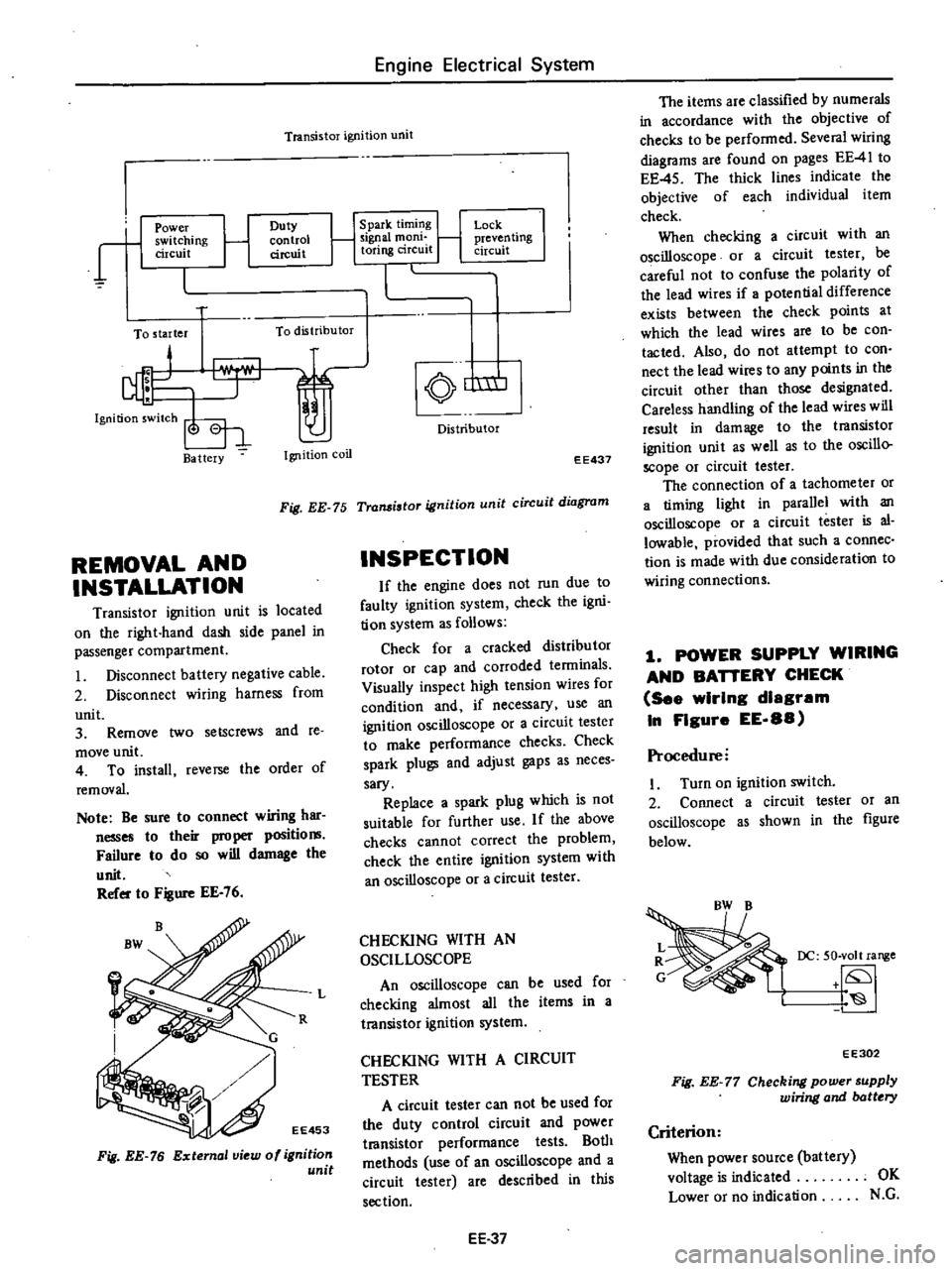

Procedure

with

an

oscilloscope

1

Disconnect

anti

dieseling

solenoid

valve

connector

2

Connect

a

positive

lead

of

an

oscilloscope

to

R

olor

wire

and

a

negative

lead

of

an

oscilloscope

to

G

color

wire

3

Set

a

SLOPE

select

switch

of

an

oscilloscope

to

the

positive

side

If

so

equipped

4

Rotate

starter

motor

5

Check

the

wave

form

as

shown

in

the

figure

below

EE268

Fig

EE

82

Wave

form

of

pick

up

coil

Criterion

When

the

wave

form

takes

the

shape

of

a

full

line

OK

When

the

wave

form

takes

the

shape

of

a

dashed

line

or

when

there

is

no

wave

form

N

G

If

the

result

is

N

G

Replace

pick

up

coil

assembly

5

TRANSISTOR

IGNITION

UNIT

CHECK

See

wiring

diagram

In

Figure

EE

92

Check

items

5

1

and

5

2

with

an

oscilloscope

Where

an

oscilloscope

is

not

availa

ble

check

to

make

sure

that

all

previ

ous

tests

are

satisfactory

and

that

no

spark

is

issuing

from

the

secondary

high

tension

wire

If

everything

else

is

satisfactory

then

the

transistor

ignition

unit

is

faulty

or

there

is

discontinuity

in

the

secondary

high

tension

wire

Replace

the

faulty

part

After

replacement

check

the

sparks

from

the

secondary

cord

5

1

Checking

operatIon

of

transIstor

Ignition

unit

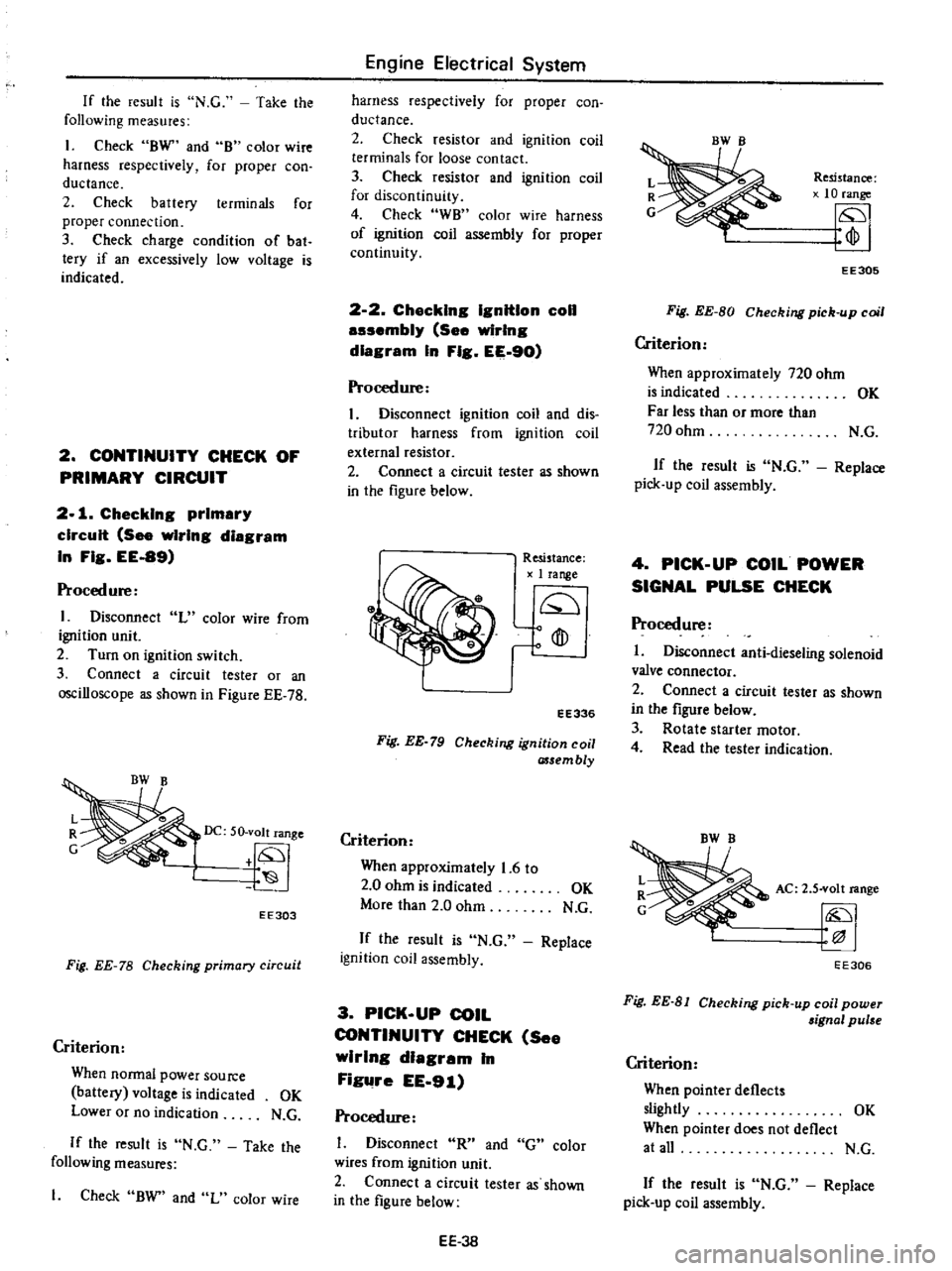

Procedure

I

Connect

ignition

coil

and

dis

tributor

harness

to

ignition

coil

exter

nal

resistor

Engine

Electrical

System

Oscilloscope

o

EB

80

To

body

metal

Ignition

coil

terminal

8W

r

8

0

C

0

EB

Fig

EE

83

Checking

operation

of

transistor

ignition

unit

EE307

@

@

2

Connect

wiring

harness

to

the

ignition

unit

3

Disconnect

anti

dieseling

solenoid

valve

connector

4

Connect

oscilloscope

as

shown

in

Figure

EE

83

rotate

the

starter

motor

and

observe

the

wave

form

on

the

oscilloscope

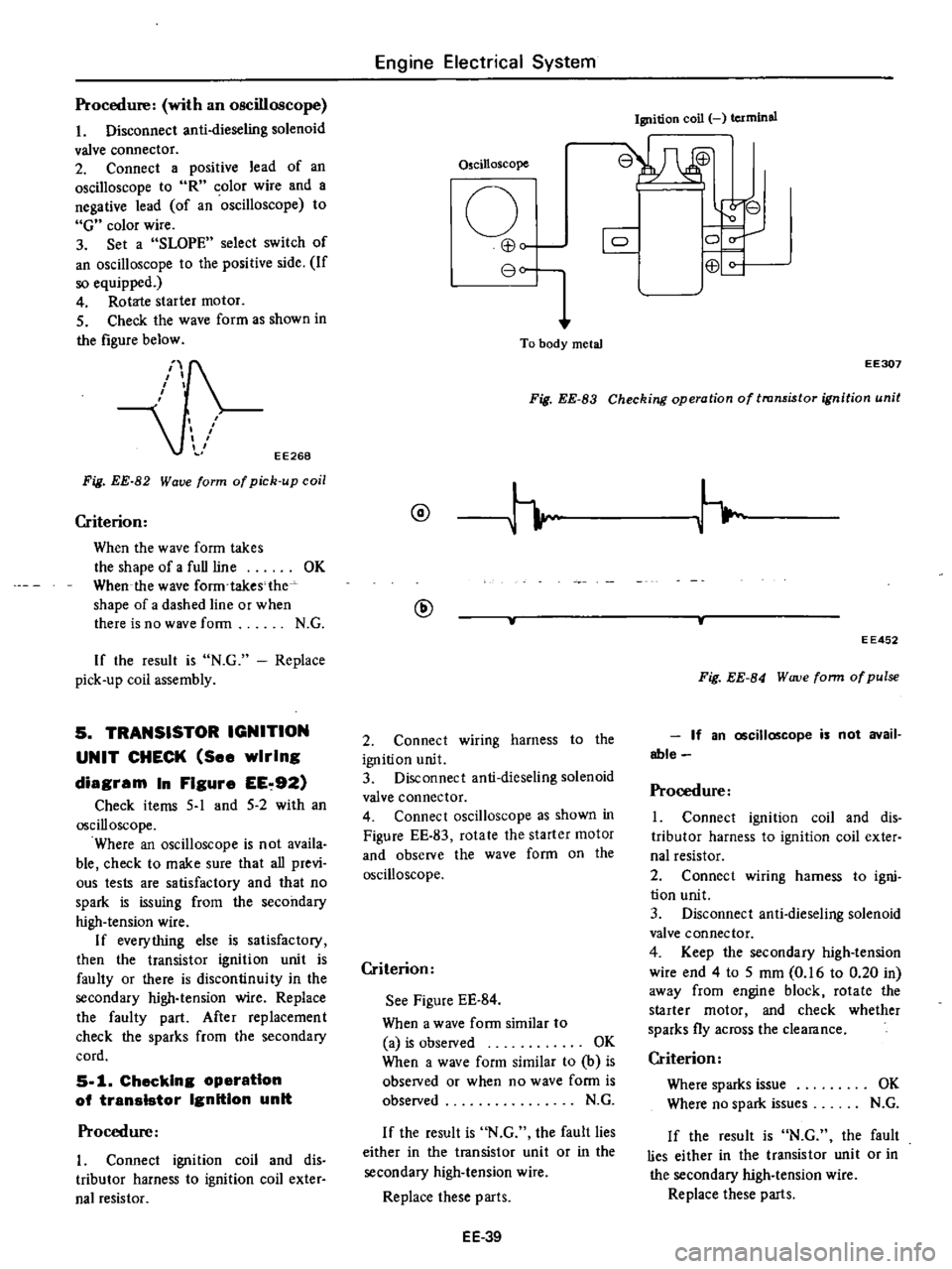

Criterion

See

Figure

EE

84

When

a

wave

form

similar

to

a

is

observed

OK

When

a

wave

form

similar

to

b

is

obseIVed

or

when

no

wave

form

is

observed

N

G

If

the

result

is

N

G

the

fault

lies

either

in

the

transistor

unit

or

in

the

secondary

high

tension

wire

Replace

these

parts

EE

39

EE452

Fig

EE

84

W

uve

form

of

pulse

If

an

oscilloscope

is

not

avail

able

Procedure

1

Connect

ignition

coil

and

dis

tributor

harness

to

ignition

coil

exter

nal

resistor

2

Connect

wiring

harness

to

igni

tion

unit

3

Disconnect

anti

dieseling

solenoid

valve

connector

4

Keep

the

secondary

high

tension

wire

end

4

to

5

mm

0

16

to

0

20

in

away

from

engine

block

rotate

the

starter

motor

and

check

whether

sparks

fly

across

the

clearance

Criterion

Where

sparks

issue

OK

Where

no

spark

issues

N

G

If

the

result

is

N

G

the

fault

lies

either

in

the

transistor

unit

or

in

the

secondary

high

tension

wire

Replace

these

paris

Page 215 of 537

Engine

Electrical

System

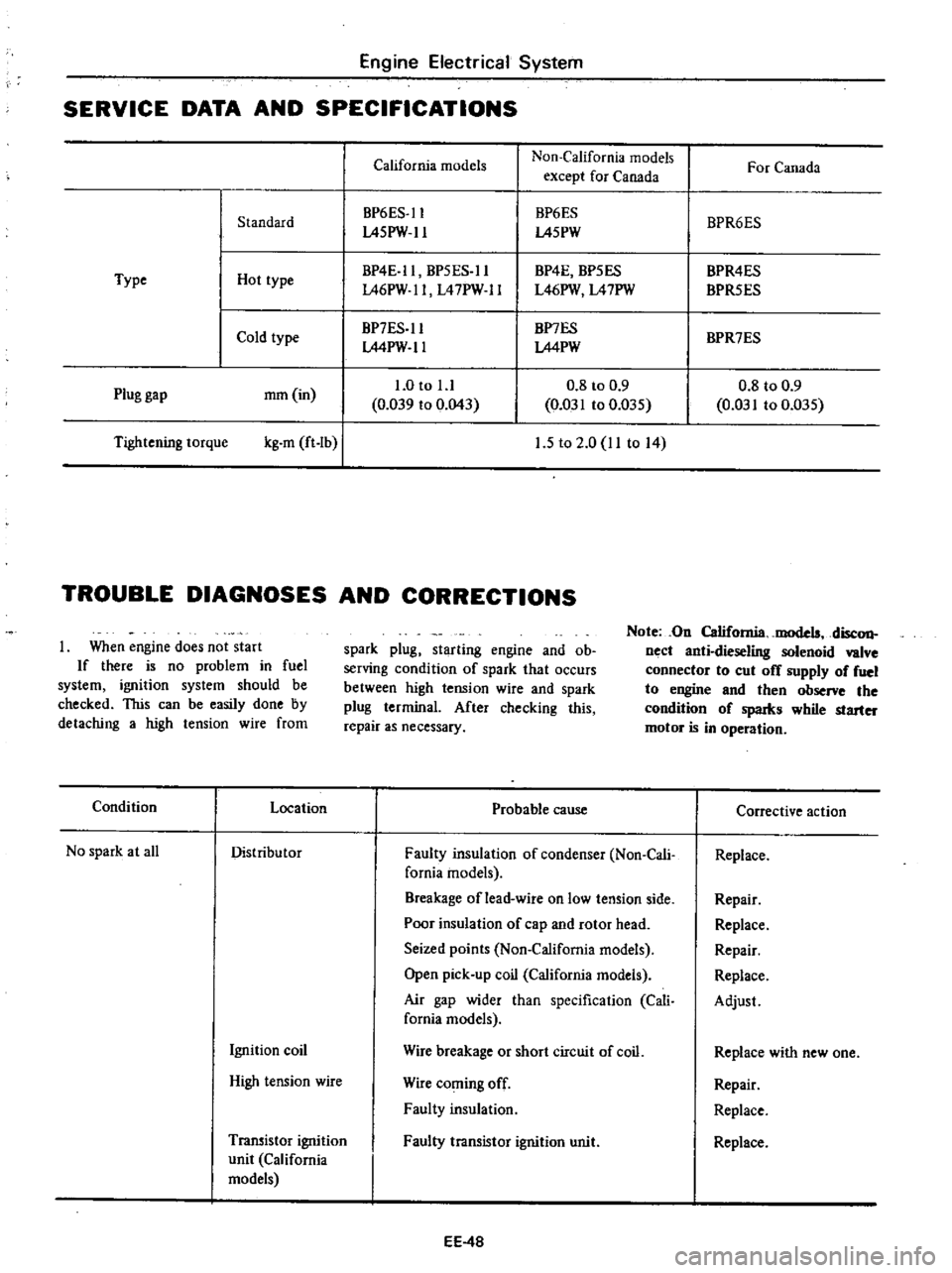

SERVICE

DATA

AND

SPECIFICATIONS

California

models

Non

California

models

For

Canada

except

for

Canada

BP6ES

ll

BP6ES

BPR6ES

Standard

L45PW

ll

L45PW

BP4E

ll

BP5ES

ll

BP4E

BP5ES

BPR4ES

Type

Hot

type

L46PW

ll

L47PW

ll

L46PW

L47PW

BPR5ES

Cold

type

BP7ES

ll

BP7ES

BPR7ES

LMPW

ll

LMPW

1

0

to

l

l

0

8

to

0

9

0

8

to

0

9

Plug

gap

mm

in

0

039

to

0

043

0

031

to

0

D35

0

031

to

0

035

Tightening

torque

kg

m

ft

Ib

I

1

5

to

2

0

11

to

14

TROUBLE

DIAGNOSES

AND

CORRECTIONS

When

engine

does

not

start

If

there

is

no

problem

in

fuel

system

ignition

system

should

be

checked

This

can

be

easily

done

by

detaching

a

high

tension

wire

from

spark

plug

starting

engine

and

ob

serving

condition

of

spark

that

occurs

between

high

tension

wire

and

spark

plug

terminal

After

checking

this

repair

as

necessary

Note

On

California

models

disc

on

nect

anti

dieseling

solenoid

valve

connector

to

cut

off

supply

of

fuel

to

engine

and

then

observe

the

condition

of

spaIks

while

starter

motor

is

in

operation

Condition

Location

Probable

cause

Corrective

action

No

spark

at

all

Distributor

Faulty

insulation

of

condenser

Non

Cali

Replace

fomia

models

Breakage

of

lead

wire

on

low

tension

side

Repair

Poor

insulation

of

cap

and

rotor

head

Replace

Seized

points

Non

California

models

Repair

Open

pick

up

coil

California

models

Replace

Air

gap

wider

than

specification

Cali

Adjust

fornia

models

Ignition

coil

Wire

breakage

or

short

circuit

of

coil

Replace

with

new

one

High

tension

wire

Wire

coming

off

Repair

Faulty

insulation

Replace

Transistor

ignition

Faulty

transistor

ignition

unit

Replace

unit

California

models

EE

4B

Page 268 of 537

1st

2nd

shift

valve

FSV

The

FSV

is

a

transfer

valve

which

shifts

gears

from

low

to

second

When

Ihe

vehicle

is

stopped

the

FSV

is

depressed

to

the

right

side

by

force

of

a

spring

located

on

the

left

side

putting

the

FSV

is

in

the

low

position

When

vehicle

speed

increases

the

governor

pressure

15

is

applied

to

Ihe

right

side

of

the

FSV

and

the

FSV

is

forced

toward

the

left

Contrarily

the

line

pressure

I

togelher

with

the

spring

force

force

the

FSV

toward

the

right

opposing

the

governor

pressure

15

When

the

vehide

speed

exceeds

a

certain

level

the

governor

pressure

15

exceeds

the

sum

of

the

throttle

pressure

and

Ihe

spring

force

and

the

FSV

is

forced

toward

the

left

When

the

FSV

is

depressed

10

a

certain

position

the

lire

pressure

I

is

closed

and

only

the

spring

depresses

the

FSV

toward

the

right

and

it

is

depressed

to

the

end

for

a

moment

As

a

resull

the

line

p

ressure

lJ

is

for

warded

to

8

the

band

servo

is

engaged

through

the

SLY

and

the

speed

is

shifted

to

2nd

With

the

accelerator

pedal

depressed

the

FSV

remains

iIi

the

Low

position

unless

the

governor

pressure

IS

increases

to

a

high

leVel

corresponding

to

the

line

pressure

I

since

the

line

pressure

I

increase

when

the

accelerator

pedal

is

depresse9

Contrarily

when

vehicle

speed

de

creases

the

governor

pressure

15

decrease

Howeve

f

the

gear

is

not

shifted

to

Low

nless

the

governor

pressure

15

becomes

zero

since

the

force

depressing

the

FSV

toward

the

right

is

being

delivered

only

by

the

spring

Low

in

range

I

is

led

to

the

low

and

reverse

clutch

from

line

pres

sure

5

through

line

prbssure

12

2nd

is

simultaneousi

y

led

to

the

ieft

end

spring

unit

Consequently

al

thougp

the

goverflor

pressure

in

creases

the

valve

is

still

forced

toward

the

right

and

the

SFV

is

fixedjn

the

Low

position

When

kicked

down

to

the

2nd

speed

the

SDV

operates

and

the

line

pressure

13

forces

the

FSV

toward

the

right

Although

the

Automatic

Transmission

governor

pressure

15

is

considerably

high

the

valve

is

forced

completely

toward

the

right

and

the

FSV

is

returned

to

the

Low

position

This

operation

is

alled

Kickdown

shift

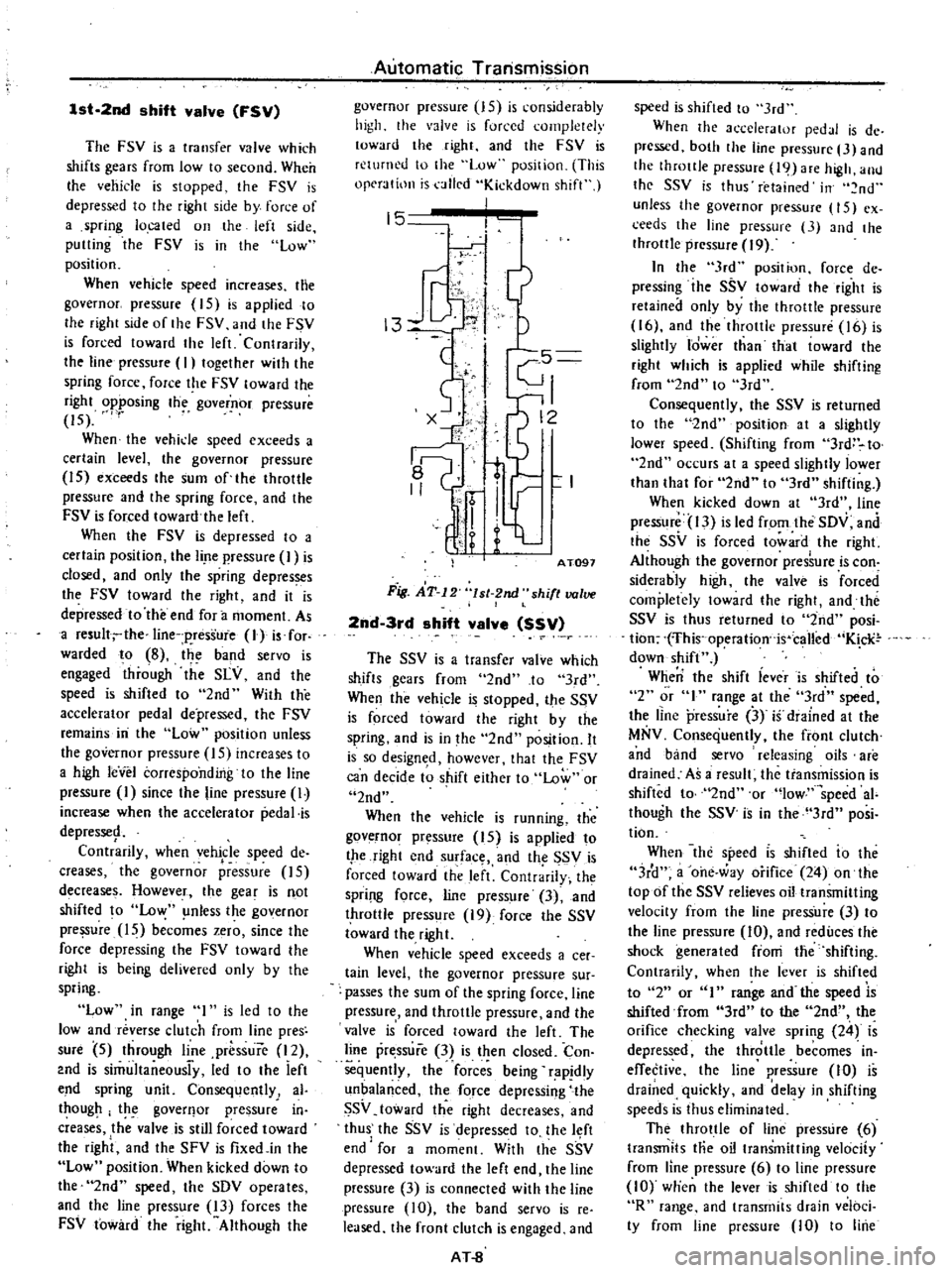

15

j

13

1

c5

I

0

t

r

I

I

q

1

AT091

Fig

AT

12

lsl

2nd

shift

valve

2nd

3rd

shift

valve

SSV

The

SSV

is

a

transfer

valve

which

shifts

gears

from

2nd

to

3rd

When

the

vehicle

is

stopped

the

SSV

is

forced

toward

the

right

by

the

spring

and

is

in

the

2nd

position

It

is

so

design

d

however

that

the

FSV

can

decide

to

shift

either

to

Low

or

2nd

When

the

vehicle

is

running

the

governor

pressure

15

is

applied

to

the

right

end

surface

and

th

SSV

is

forced

toward

the

left

Contrarily

the

Spri

l

force

line

pressure

3

and

throttle

press

re

19

force

the

SSV

toward

the

right

When

vehicle

speed

exceeds

a

cee

tain

level

the

governor

pressure

sur

passes

the

sum

of

the

spring

force

line

pressure

and

throttle

pressure

and

the

valve

is

forced

toward

the

left

The

line

pressure

3

is

then

closed

Con

sequently

the

forces

being

rapjdly

unbalanced

the

force

depressing

the

SSV

toward

the

right

decreases

and

thus

the

SSV

is

depressed

to

the

l

ft

end

for

a

moment

With

Ihe

SSV

depressed

toward

the

left

end

lhe

line

pressure

3

is

connected

with

the

line

pressure

10

the

band

servo

is

re

leased

the

front

clutch

is

engaged

and

AT

8

speed

is

shifted

to

3rd

When

the

accelerator

pedJI

is

de

prcssed

both

the

line

pressure

3

and

the

throttle

pressure

19

are

high

allll

the

SSV

is

thus

retained

in

nd

unless

the

governor

pressure

15

ex

ceeds

the

line

pressure

3

and

the

throttle

pressure

19

In

the

3rd

position

force

de

pressing

ihe

SSV

toward

the

right

is

retained

only

by

the

throttle

pressure

16

and

the

throttle

pressure

16

is

slightly

Idwer

than

that

toward

the

right

which

is

applied

while

shifting

from

2nd

to

3rd

Consequently

the

SSV

is

returned

to

the

2nd

position

at

a

slightly

lower

speed

Shifting

from

3rd

to

2nd

occurs

at

a

speed

slightly

lower

than

that

for

2nd

to

3rd

shifting

When

kicked

down

at

3rd

line

pressure

13

is

led

from

the

SDV

and

the

SSV

is

forced

toward

the

right

Although

the

governor

pres

ure

is

con

siderably

high

the

valve

is

forced

completely

loward

the

right

and

tht

SSV

is

thus

returned

to

2nd

posi

tion

fhis

operation

is

called

K

cli

down

shift

When

the

shift

iever

is

shifted

to

2

or

I

range

at

the

3rd

speed

the

line

pressure

3

if

diained

at

the

MNV

Consequently

the

front

clutch

and

band

servo

releasing

oils

are

drained

As

a

result

the

transmission

is

shifted

to

2nd

or

low

speed

ai

though

the

SSV

is

in

the

3rd

posi

tion

When

the

specd

IS

shifted

io

the

3r

1

a

one

way

orifice

24

on

the

topof

the

SSV

relieves

oil

transmitting

velocity

from

the

line

pressure

3

to

the

line

pressure

10

and

reduces

the

shock

generated

fioni

the

shifting

Contrarily

when

the

lever

is

shifted

to

2

or

I

range

and

the

speed

is

shifted

from

3rd

to

the

2nd

the

orifice

checking

valve

spring

24

is

depressed

the

throttle

becomes

in

effective

the

line

pressure

10

is

drained

quickly

and

delay

in

shifting

speeds

is

thus

eliminated

The

throttle

of

line

pressure

6

transmits

Hie

oil

transmitting

velocity

from

line

pressure

6

to

line

pressurc

10

wtien

the

lever

is

shifted

to

the

R

range

and

transmits

drain

veloci

ty

from

line

pressure

10

to

line

Page 298 of 537

Starter

should

be

brought

into

op

eration

only

when

selector

lever

is

in

P

and

N

positions

it

should

not

be

started

when

lever

is

in

D

2

I

and

R

positions

Back

up

lamp

should

also

light

when

selector

lever

is

placed

in

R

position

S

After

converter

is

installed

rotate

10

Check

level

of

oil

in

transmis

crankshaft

several

turns

and

check

to

be

sure

that

transmission

rotates

freely

sion

For

detailed

procedure

see

page

AT48

without

binding

6

Pour

recommended

automatic

II

Move

selector

lever

through

aU

positions

to

be

sure

that

transmission

transmission

fluid

up

to

correct

level

operates

correctly

through

oil

charge

pipe

verter

to

transmission

measure

dis

With

hand

brake

applied

rotate

tan

A

to

be

certain

that

they

are

7

Connect

manual

lever

to

shift

engine

at

idling

Without

disturbing

correctly

mbi

d

S

F

rod

Opeiationsliould

oecaTrie

f

bue

the

above

sclUng

ffiovTSelector

lever

AT

50

with

manual

and

selector

levers

in

through

N

to

D

to

2

to

I

Distance

A

N

and

to

R

A

slight

shock

should

be

More

than

21

5

mm

0

846

in

8

Connect

inhibitor

switch

wires

felt

by

hand

gripping

selector

each

time

transmission

is

shifted

Automatic

Transmission

4

Bolt

converter

to

drive

plate

Note

Align

chalk

marks

painted

a

cross

both

parts

during

disas

sembling

processes

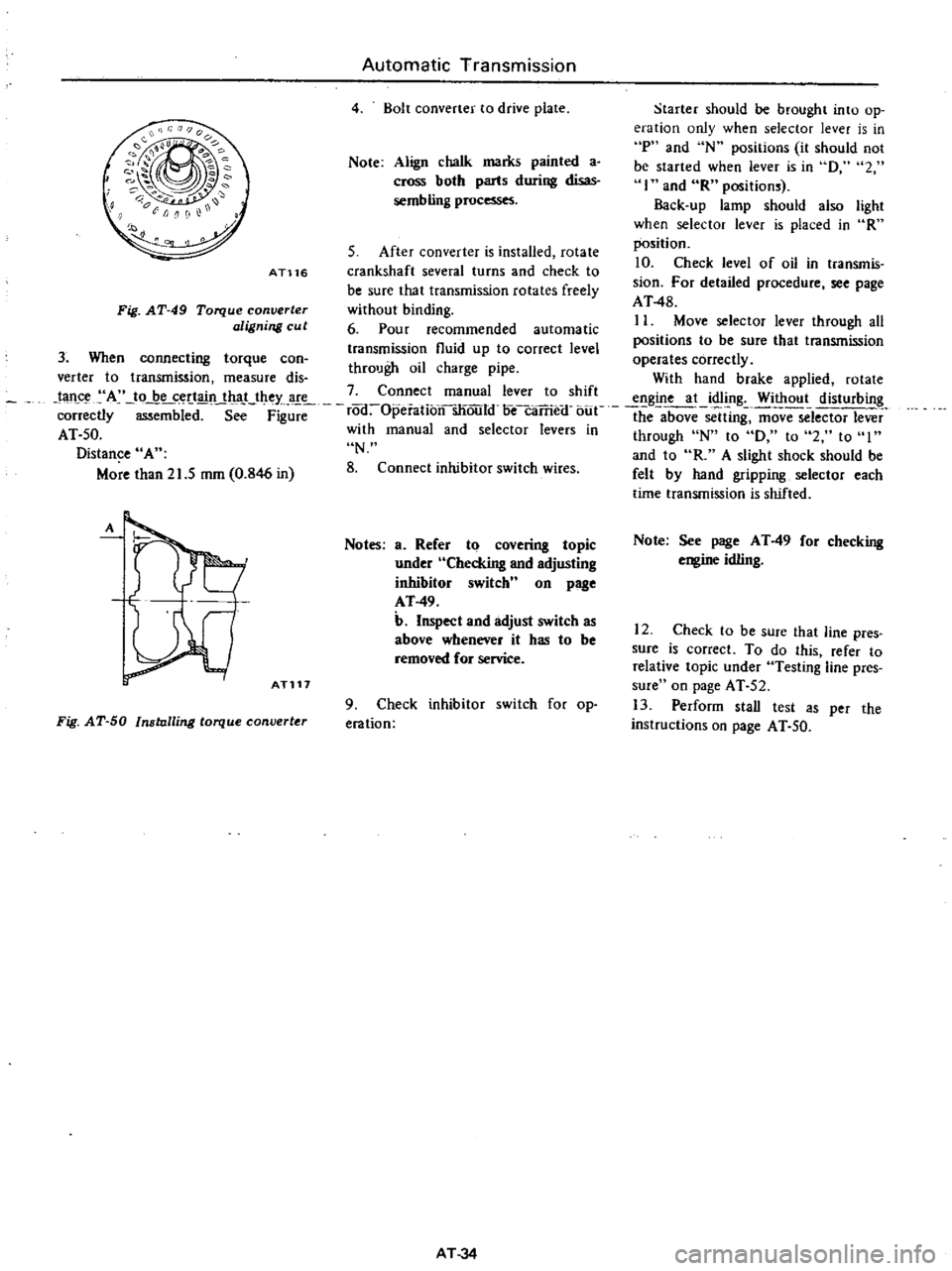

AT116

Fig

AT

49

Torque

converter

aligning

cu

t

3

When

connecting

torque

can

A

ATl17

Notes

a

Refer

to

covering

topic

under

Checking

and

adjusting

inhibitor

switch

n

on

page

AT

49

b

Inspect

and

adjust

switch

as

above

whenever

it

has

to

be

removed

for

service

Fig

AT

50

Installing

torque

converter

9

Check

inhibitor

switch

for

op

eration

AT

34

Note

See

page

AT

49

for

checking

engine

idling

12

Check

to

be

sure

that

line

pres

sure

is

correct

To

do

this

refer

to

relative

topic

under

Testing

line

pres

sure

on

page

AT

52

13

Perform

stall

test

as

per

the

instructions

on

page

AT

50

Page 312 of 537

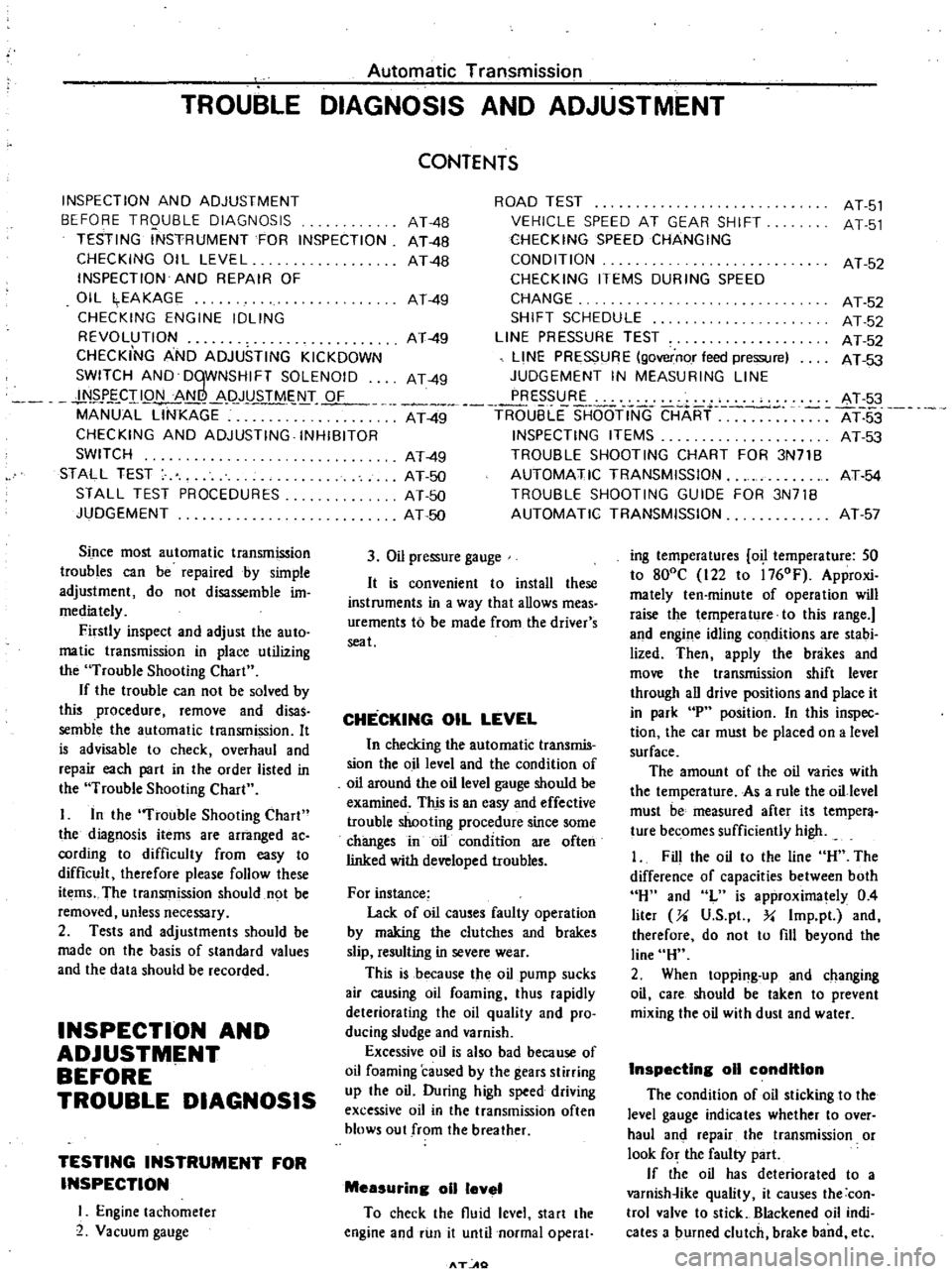

Automatic

Transmission

TROUBLE

DIAGNOSIS

AND

ADJUSTMENT

INSPECTION

AND

ADJUSTMENT

BEFORE

TRQUBLE

DIAGNOSIS

TESTING

INSTRUMENT

FOR

INSPECTION

CHECKING

OIL

LEVEL

INSPECTION

AND

REPAIR

OF

OIL

EAKAGE

CHECKING

ENGINE

IDLING

REVOLUTION

CHECKING

AND

ADJUSTING

KICKDOWN

SWITCH

AND

DqWNSHIFT

SOLENOID

N

J

J

CII

Q

t

L

8li

p

JYSTMs

T

OF

MANUAL

LINKAGE

CHECKING

AND

ADJUSTING

INHIBITOR

SWITCH

STALL

TEST

STALL

TEST

PROCEDURES

JUDGEMENT

Since

most

automatic

transmission

troubles

can

be

repaired

by

simple

adjustment

do

not

disassemble

im

mediately

Firstly

inspect

and

adjust

the

auto

matic

transmission

in

place

utilizing

the

Trouble

Shooting

Chart

If

the

trouble

can

not

be

solved

by

this

procedure

remove

and

disas

semble

the

automatic

transmission

It

is

advisable

to

check

overhaul

and

repair

each

part

in

the

order

listed

in

the

Trouble

Shooting

Chart

I

In

the

Trouble

Shooting

Chart

the

diagnosis

items

are

arranged

ac

cording

to

difficulty

from

easy

to

difficult

therefore

please

follow

these

items

The

transmission

should

not

be

removed

unless

necessary

2

Tests

and

adjustments

should

be

made

on

the

basis

of

standard

values

and

the

data

should

be

recorded

INSPECTION

AND

ADJUSTMENT

BEFORE

TROUBLE

DIAGNOSIS

TESTING

INSTRUMENT

FOR

INSPECTION

I

Engine

tachometer

2

Vacuum

gauge

ROAD

TEST

VEHICLE

SPEED

AT

GEAR

SHIFT

CHECKING

SPEED

CHANGING

CONDITION

CHECKING

ITEMS

DURING

SPEED

CHANGE

SHIFT

SCHEDULE

LINE

PRESSURE

TEST

LINE

PRESSURE

governor

feed

pressure

JUDGEMENT

IN

MEASURING

LINE

PRESSURE

At

49

TR6

uBLE

SHOOTINC

CHART

INSPECTING

ITEMS

TROUBLE

SHOOTING

CHART

FOR

3N71B

AUTOMATIC

TRANSMISSION

TROUBLE

SHOOTING

GUIDE

FOR

3N71B

AUTOMATIC

TRANSMISSION

CONTENTS

AT

4B

AT

48

AT

4B

AT

49

AT

49

AT

49

AT

49

AT

50

AT

50

AT

50

3

Oil

pressure

gauge

It

is

convenient

to

install

these

instruments

in

a

way

that

allows

meas

urements

to

be

made

from

the

driver

s

seat

CHECKING

OIL

LEVEL

In

checking

the

automatic

transmis

sion

the

o

illevel

and

the

condition

of

oil

around

the

oil

level

gauge

should

be

examined

This

is

an

easy

and

effective

trouble

shooting

procedure

since

some

changes

in

oil

condition

are

often

linked

with

developed

troubles

For

instance

Lack

of

oil

causes

faulty

operation

by

making

the

clutches

and

brakes

slip

resulting

in

severe

wear

This

is

because

the

oil

pump

sucks

air

causing

oil

foaming

thus

rapidly

deteriorating

the

oil

quality

and

pro

ducing

sludge

and

varnish

Excessive

oil

is

also

bad

because

of

oil

foaming

caused

by

the

gears

stirring

up

the

oil

During

high

speed

driving

excessive

oil

in

the

transmission

often

blows

out

from

the

breather

Measuring

011

level

To

check

the

fluid

level

start

the

engine

and

run

it

until

normal

operat

T

AO

AT

51

AT

51

AT

52

AT

52

AT

52

AT

52

AT

53

AT

3

AT

53

AT

53

AT

54

AT

57

ing

temperatures

o

temperature

SO

to

800C

122

to

l760F

Approxi

mately

ten

minute

of

operation

will

raise

the

temperature

to

this

range

and

engine

idling

conditions

are

stabi

lized

Then

apply

the

brakes

and

move

the

transmission

shift

lever

through

all

drive

positions

and

place

it

in

park

P

position

In

this

inspec

tion

the

car

must

be

placed

on

a

level

surface

The

amount

of

the

oil

varies

with

the

temperature

As

a

rule

the

oil

level

must

be

measured

after

its

temper

ture

becomes

sufficiently

high

1

Fill

the

oil

to

the

line

H

The

difference

of

capacities

between

both

H

and

L

is

approximately

0

4

liter

Ji

V

S

p

Y

Imp

pl

and

therefore

do

not

to

fill

beyond

the

line

H

2

When

topping

up

and

changing

oil

care

should

be

taken

to

prevent

mixing

the

oil

with

dust

and

water

InspectIng

011

condition

The

condition

of

oil

sticking

to

the

level

gauge

indicates

whether

to

over

haul

and

repair

the

transmission

or

look

for

the

faulty

part

If

the

oil

has

deteriorated

to

a

varnish

ike

quality

it

causes

the

con

trol

valve

to

stick

Blackened

oil

indi

cates

a

burned

clutch

brake

band

etc

Page 313 of 537

In

these

cases

the

transmission

must

be

repaired

Notes

a

In

checking

oil

level

use

special

paper

cloth

to

handle

the

level

gauge

and

be

careful

not

to

let

the

scraps

of

paper

and

cloth

stick

to

the

gauge

b

Insert

the

gauge

fully

and

take

it

out

quickly

before

splashing

oil

adheres

to

the

gauge

Then

observe

the

level

c

Use

automatic

transmission

fluid

having

DEXRON

identifications

only

in

the

3N71B

automatic

trans

mission

d

Pay

attention

because

the

oil

to

be

used

differs

from

that

used

in

the

Nissan

Full

Automatic

TranSJTIis

sion

3N71A

Never

mix

the

oils

INSPECTION

AND

REPAIR

OF

OIL

LEAKAGE

When

oil

leakage

takes

place

the

portion

near

the

leakage

is

covered

with

oil

presenting

difficulty

in

detecting

the

spot

Therefore

the

places

where

oil

seals

and

gaskets

are

equipped

are

enumerated

below

11

Converter

housing

Rubber

ring

of

oil

pump

housing

Oil

seal

of

oil

pump

housing

Oil

seal

of

engine

crankshaft

Bolts

of

converter

housing

to

case

2

Trarismission

and

rear

extension

Junction

of

transm

ss

ion

and

rear

extension

J

Oil

cooler

tube

connectors

Oil

pan

Oil

pressure

inspection

holes

Refer

to

Figure

AT

il2

Mounting

portion

of

vacuum

dia

phragm

and

downshift

solenoid

Breather

and

oil

charging

pipe

Speedometer

pinion

sleeve

Oil

se

l

of

rear

extension

To

exactly

locate

the

place

of

oil

leaka

le

proceed

as

follows

Place

the

vehicle

in

a

pit

and

by

sampling

the

leaked

oil

determine

if

it

is

the

torque

converter

oil

The

torque

converter

oil

has

a

color

like

r

d

wine

So

it

is

easily

distinguished

from

engine

oil

or

gear

oil

Automatic

rransmission

Wipe

off

the

leaking

oil

and

dust

and

deiecl

the

spol

of

oil

eakage

l

se

nonflammable

organic

solve

t

s

ch

as

carbon

tetrachloride

for

wiping

Raise

the

oil

tcmperalure

by

op

erating

the

engine

and

shift

the

lever

to

D

to

increase

the

oil

pressure

The

spot

of

oil

lcakage

will

then

be

found

more

easily

Note

As

oil

leakage

from

the

breaih

er

does

not

take

place

except

when

running

at

high

speed

it

is

impos

sible

to

locate

this

leakage

with

vehicle

stationary

CHECKING

ENGINE

IDLING

REVOLUTION

The

engine

idling

revolution

should

be

properly

adjusted

If

the

engine

revolution

is

too

low

the

engine

does

not

operate

smoothly

and

if

too

high

a

strong

shock

or

creep

develops

when

changing

over

from

N

to

D

or

R

CHECKING

AND

ADJUSTING

KICK

DOWN

SWITCH

AND

DOWNSHIFT

SOLENOID

When

the

kickdown

operation

is

not

made

properly

or

the

speed

chang

ing

point

s

too

high

check

the

kick

down

switch

downshift

solenoid

and

wiring

between

them

When

the

igni

li

n

key

is

pqsitioned

a

t

the

I

st

stage

nd

the

accelerator

pedal

is

depressed

deeply

the

switch

contact

should

be

closed

and

the

solenoid

should

click

If

it

does

not

click

it

indicates

a

defect

Then

check

each

part

with

the

testing

instruments

See

Figure

ATl09

d

I

t

AT10S

Fig

AT

109

Downshift

solenoid

Note

Watch

for

oil

leakage

from

transmission

case

AT

4Q

INSPECTION

AND

ADJUSTMENT

OF

MANUAL

LINKAGE

The

adjustmcnt

of

manual

linkage

is

equaUy

important

as

Inspection

of

Oil

Level

for

the

automatic

transmis

sion

Thereforc

great

care

should

be

exercised

because

incorrect

adjustment

will

rcsult

in

the

brcakdown

of

the

transmission

Inspection

Pull

the

selector

lever

toward

you

and

turn

it

as

far

as

P

to

I

range

wherc

clicks

will

be

felt

by

the

hand

This

is

the

detcnt

of

manual

valve

in

the

valve

body

and

indicates

th

correct

position

of

the

lever

Inspect

whether

the

pointer

of

selector

dial

corresponds

to

this

point

and

also

whether

the

lever

comes

in

alignment

with

the

stepping

of

posi

tion

plate

when

it

is

released

Adjustment

This

procedure

can

be

accomplish

ed

by

refcrring

to

page

AT

35

for

Removal

and

Installa

tion

CHECKING

AND

ADJUSTING

INHIBITOR

SWITCH

The

inhibitor

switch

lights

the

re

verse

lamp

in

the

range

R

of

the

transmission

operatio

l

and

also

rotates

the

starter

motor

in

the

ranges

N

and

P

CD

@

b

ell

If

L

t

7

4l

@

1l

j7

@

@

@

dl

AT109

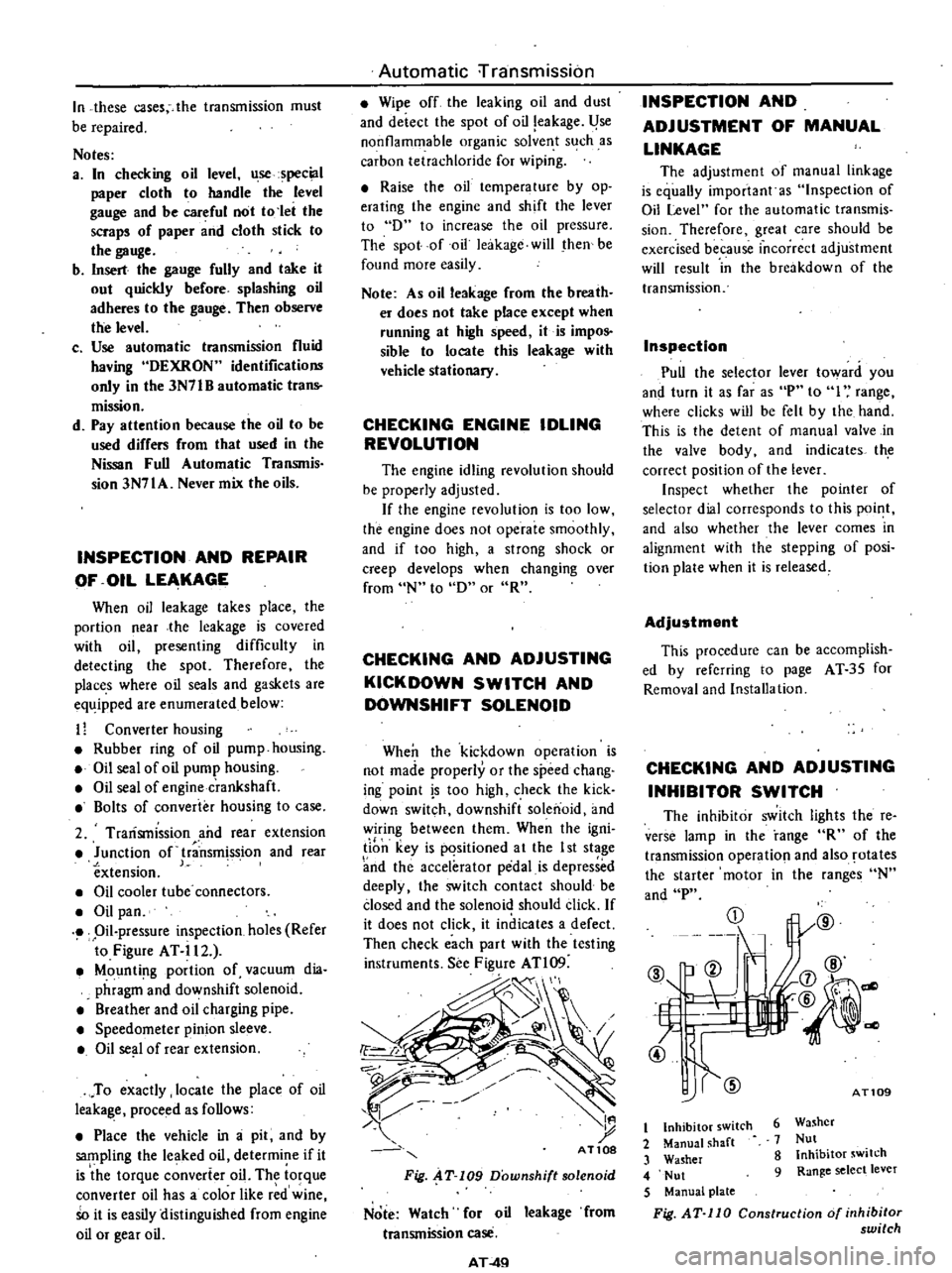

6

Washer

7

Nut

8

Inhibitor

switch

9

Range

select

lever

t

Inhibitor

switch

2

Manual

shaft

3

Washer

4

Nut

5

Manual

plate

Fig

AT

110

Construction

of

inhibitor

switch