clutch DATSUN PICK-UP 1977 Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 227 of 537

Stroke

30

mm

Jt

i

I

1

18

in

Sj

1

i

J

o

Fig

CL

15

Non

adj

table

operating

cylinder

CLUTCH

PEDAL

Removal

and

installation

Removal

See

Figure

CL

16

1

Pry

off

cotter

pin

and

take

out

clevis

pin

disconnect

push

rod

from

pedal

assembly

2

Unhook

return

spring

Loosen

off

fulcrum

pin

and

remove

pedal

as

sembly

CfJ

W5

6

3

ch

fD

ij

ll

i

A

1

aevis

pin

2

Cotter

pin

3

Return

spring

4

Pedal

boss

S

Pedal

assembly

6

Bush

7

Nut

8

Push

rod

9

Fulcrum

pin

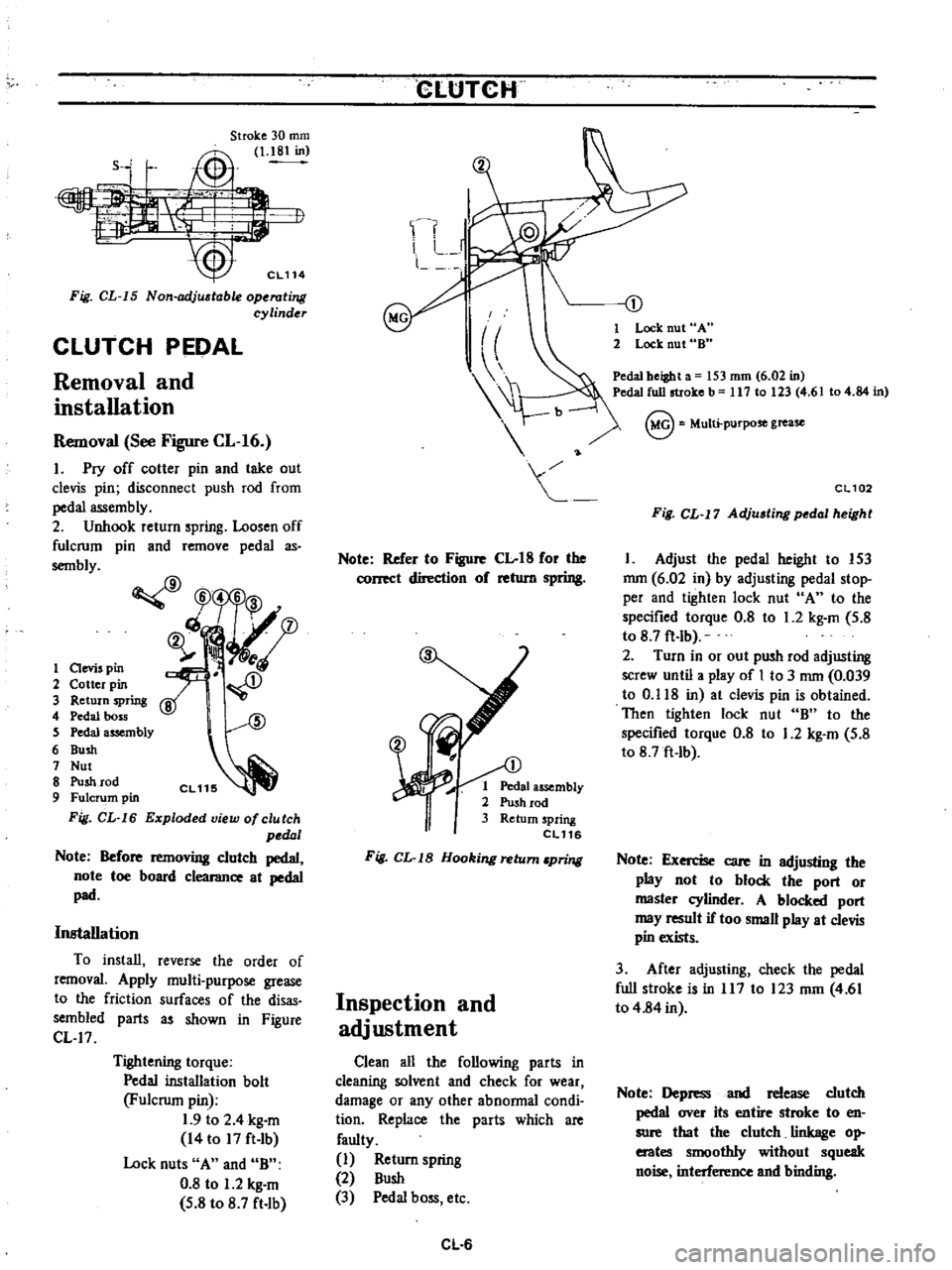

Fig

CL

16

Exploded

view

of

clutch

pedal

Note

Before

removing

clutch

pedal

note

toe

board

clearance

at

pedal

pad

Installation

To

install

reverse

the

order

of

removal

Apply

multi

purpose

grease

to

the

friction

surfaces

of

the

disas

sembled

parts

as

shown

in

Figure

CL

17

Tightening

torque

Pedal

installation

bolt

Fulcrum

pin

1

9

to

2

4

kg

m

14

to

17

ft

Ib

Lock

nuts

A

and

B

0

8

to

1

2

kg

m

5

8

to

8

7

ft

lb

CLtJTCH

Note

Refer

to

Figure

Clot8

for

the

correct

direction

of

return

spring

1

Pedal

assembly

2

Push

rod

3

Return

spring

eL116

Fig

CL

1B

Hooking

return

pring

Inspection

and

adjustment

Clean

all

the

following

parts

in

cleaning

solvent

and

check

for

wear

damage

or

any

other

abnormal

condi

tion

Replace

the

parts

which

are

faulty

1

Return

spring

2

Bush

3

Pedal

boss

etc

CL

6

1

Lock

nut

A

2

Lock

nut

8

Pedal

beiBht

a

53

mm

6

02

in

Pedal

full

stroke

b

117

10

23

4

6

104

84

in

@

Multi

purpose

grease

CL102

Fig

CL

17

Adju

ting

pedal

height

1

Adjust

the

pedal

height

to

153

mm

6

02

in

by

adjusting

pedal

stop

per

and

tighten

lock

nut

A

to

the

specified

torque

0

8

to

1

2

kg

m

5

8

to

8

7

ft

lb

2

Turn

in

or

out

push

rod

adjusting

screw

until

a

play

of

I

to

3

mm

0

039

to

0

118

in

at

clevis

pin

is

obtained

Then

tighten

lock

nut

B

to

the

specified

torque

0

8

to

1

2

kg

m

5

8

to

8

7ft

Ib

Note

Exercise

care

in

adjusting

the

play

not

to

block

the

port

or

master

cylinder

A

blocked

port

may

result

if

too

small

play

at

clevis

pin

exists

3

After

adjusting

check

the

pedal

full

stroke

is

in

117

to

123

mm

4

61

to

4

84

in

Note

Depress

and

release

clutch

pedal

over

its

entire

stroke

to

en

sure

that

the

clutch

linkage

op

erates

smoothly

without

squeak

noise

interference

and

binding

Page 228 of 537

CLUTCH

CYLINDER

MASTER

Removal

and

installation

Removal

I

Remove

clcvis

pin

at

push

rod

2

Disconnect

clutch

tube

from

master

cylinder

and

drain

clutch

fluid

3

Remove

bolts

securing

master

Disassembly

and

assembly

CLUTCH

cylinder

to

the

vehicle

and

dismount

master

cylinder

Note

Remove

dust

cover

from

master

cylinder

body

on

the

side

of

driv

er

s

seat

Installation

To

install

reverse

the

order

of

removal

Closely

observe

the

following

instructions

1

Adjust

pedal

height

by

changing

pedal

stopper

length

Disassembly

1

Remove

dust

cover

and

remove

stopper

ring

from

body

2

Remove

push

rod

and

piston

as

sembly

3

Take

off

piston

cups

4

Remove

spiing

seat

from

piston

and

take

off

supply

valve

if

necessary

See

Figure

CL

19

Note

Discard

piston

cup

supply

valve

and

spring

seat

after

removal

Assembly

To

assemble

reverse

the

order

of

disassembly

Closely

observe

the

fol

lowing

instructions

I

Dip

piston

cup

in

brake

fluid

before

installing

Make

sure

that

it

is

correctly

faced

in

position

2

Apply

a

coating

of

brake

fluid

to

cylinder

and

piston

when

assembling

3

Press

piston

into

spring

seat

when

assembling

CL

7

2

Bleed

air

out

of

hydraulic

system

Tightening

torque

Master

cylinder

to

dash

panel

0

8

to

1

2

kg

m

5

8

to

8

7

ft

lb

Clutch

tube

connector

Flare

nut

1

5

to

1

8

kg

m

II

to

13

ft

lb

3

Using

Flare

Nut

Torque

Wrench

GG94310000

tighten

each

connector

to

the

specified

torque

1

Reservoir

cap

2

Reservoir

3

Reservoir

band

4

Cylinder

body

5

Supply

valve

stopper

6

Return

spring

7

Spring

seat

8

Valve

spring

9

Supply

valve

rod

10

Supply

valve

11

Primary

cup

12

Piston

13

Push

rod

14

Secondary

cup

15

Stopper

16

Stopper

ring

17

DU5t

cover

18

Lock

nut

CL265

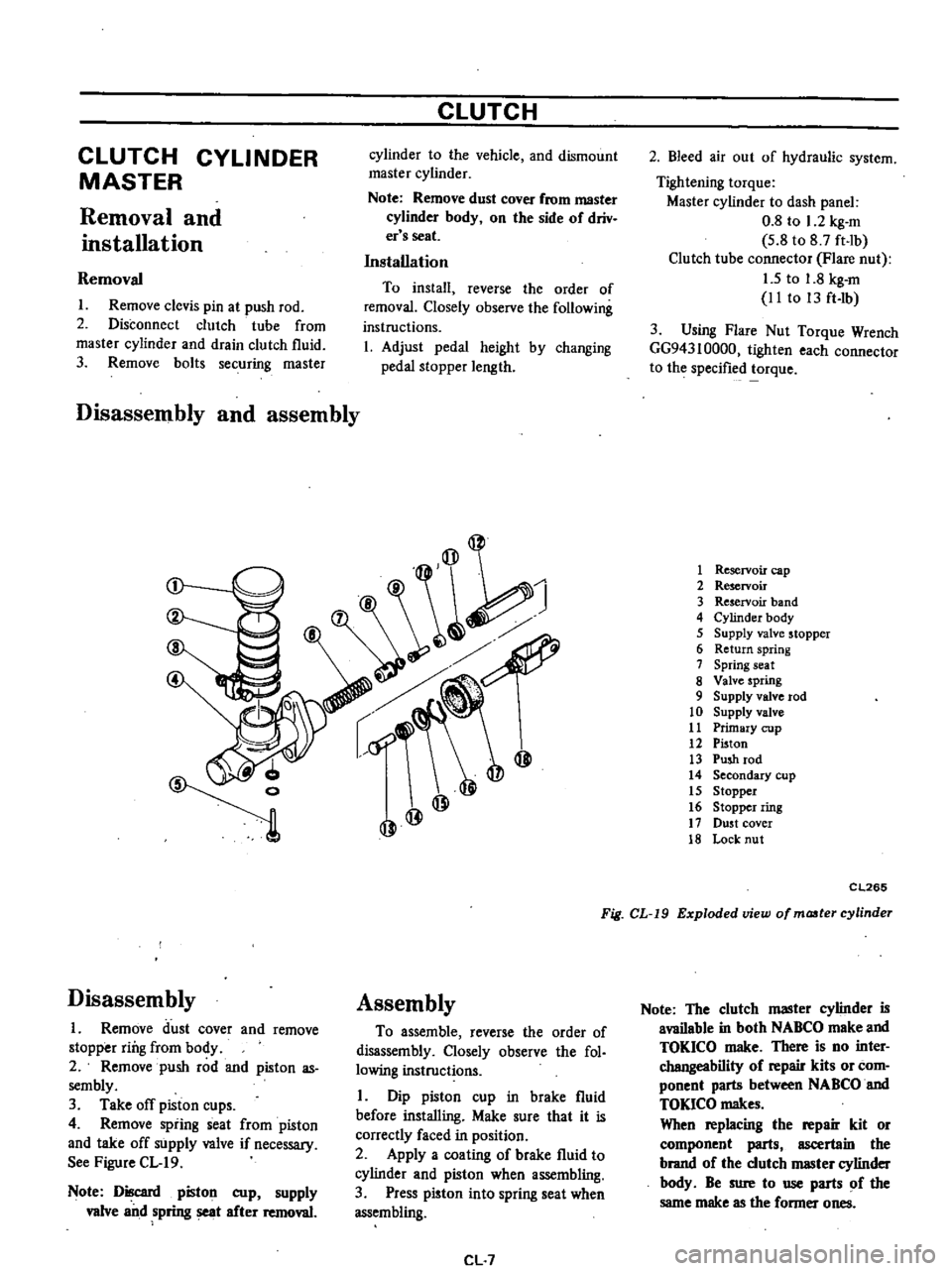

Fig

CL

19

Exploded

view

of

maater

cylinder

Note

The

clutch

master

cylinder

is

available

in

both

NABCO

make

and

TOKICO

make

There

is

no

inter

changeability

of

repair

kits

or

com

ponent

parts

between

NABCO

and

TOKlCO

makes

When

replacing

the

repair

kit

or

component

parts

ascertain

the

brand

of

the

clutch

IIIBSter

cylinder

body

Be

sure

to

use

parts

of

the

same

make

as

the

former

ones

Page 229 of 537

Inspection

Note

To

clean

or

wash

all

parts

of

master

cylinder

operating

cylinder

and

piping

clean

brake

fluid

must

be

used

Never

use

minera10ils

llUch

as

gasoline

and

kerosene

It

will

ruin

the

rubber

parts

of

the

hydrau

lic

system

I

Check

cylinder

and

piston

for

uneven

wear

or

damage

and

if

neces

sary

replace

2

If

the

clearance

between

cylinder

and

piston

is

more

than

0

15

mm

0

0059

in

replace

cylinder

3

Renew

piston

cup

when

dis

assembled

It

must

also

be

replaced

when

wear

or

deformation

due

to

fatigue

or

damage

is

found

4

Damaged

dust

cover

oil

reservoir

or

cap

should

be

replaced

Return

spring

and

valve

spring

must

also

be

replaced

when

they

are

broken

or

weak

5

Replace

clutch

hose

and

tube

if

any

abnormal

sign

of

damage

or

de

fro

ti

n

is

found

OPERATING

CYLINDER

Removal

and

installation

Removal

1

Detach

clutch

hose

from

operat

ing

cylinder

2

Remove

two

bolts

securing

op

erating

cylinder

to

clutch

housing

Installation

Install

in

the

reverse

order

of

re

moval

Observe

the

following

instructions

Bleed

air

thoroughly

from

clutch

hydraulic

system

2

Do

not

install

return

spring

or

clutch

will

not

be

disengaged

properly

Tightening

torque

Operating

cylinder

securing

bolt

2

5

to

3

5

kg

m

18

to

25

ft

lb

Bleeder

screw

0

7

to

0

9

kg

m

5

1

to

6

5

ft

Ib

Clutch

hose

connector

1

7

to

2

0

kg

m

12

to

14

ft

b

CLUTCH

Disassembly

and

assembly

Disassembly

1

Remove

push

rod

with

dust

cover

2

Remove

piston

assembly

and

pis

ton

spring

3

Remove

bleeder

screw

1

6

Cl11B

5

Piston

cup

6

Operating

cylinder

7

Bleeder

screw

1

Push

rod

2

Dust

cover

3

Piston

spring

4

Piston

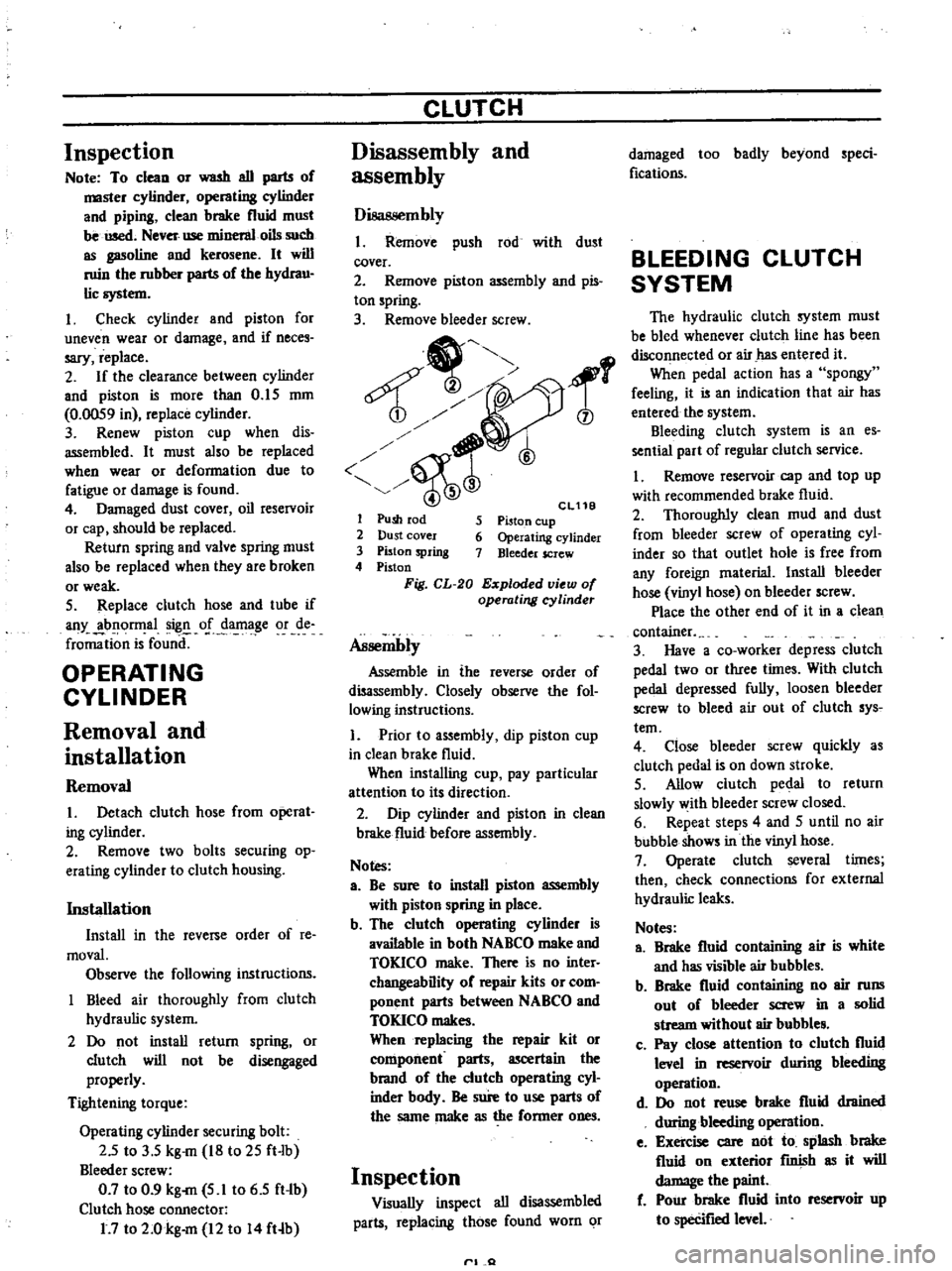

Fig

CL

20

Exploded

view

of

operating

cyUnder

Assembly

Assemble

in

the

reverse

order

of

disassembly

Closely

observe

the

fol

lowing

instructions

1

Prior

to

assembly

dip

piston

cup

in

clean

brake

fluid

When

installing

cup

pay

particular

attention

to

its

direction

2

Dip

cylinder

and

piston

in

clean

brake

fluid

before

assembly

Notes

a

Be

sure

to

install

piston

assembly

with

piston

spring

in

place

b

The

clutch

operating

cylinder

is

available

in

both

NABCO

make

and

TOKICO

make

There

is

no

inter

changeability

of

repair

kits

or

com

ponent

parts

between

NABCO

and

TOKICO

makes

When

replacing

the

repair

kit

or

component

parts

ascertain

the

brand

of

the

clutch

operating

cyl

inder

bndy

Be

sure

to

use

parts

of

the

same

make

as

the

former

ones

Inspection

Visually

inspect

all

disassembled

parts

replacing

those

found

worn

or

rl

Q

damaged

too

badly

beyond

speci

fications

BLEEDING

CLUTCH

SYSTEM

The

hydraulic

clutch

system

must

be

bled

whenever

clutch

line

has

been

disconnected

or

air

has

entered

it

When

pedal

action

has

a

spongy

feeling

it

is

an

indication

that

air

has

entered

the

system

Bleeding

clutch

system

is

an

es

sential

part

of

regular

clutch

service

I

Remove

reservoir

cap

and

top

up

with

recommended

brake

fluid

2

Thoroughly

clean

mud

and

dust

from

bleeder

screw

of

operating

cyl

inder

so

that

outlet

hole

is

free

from

any

foreign

rnaterial

Install

bleeder

hose

vinyl

hose

on

bleeder

screw

Place

the

other

end

of

it

in

a

clean

container

3

Have

a

co

worker

depress

clutch

pedal

two

or

three

times

With

clu

tch

pedal

depressed

fully

loosen

bleeder

screw

to

bleed

air

out

of

clutch

sys

tern

4

Close

bleeder

screw

quickly

as

clutch

pedal

is

on

down

stroke

5

Allow

clutch

pedal

to

return

slowly

with

bleeder

screw

closed

6

Repeat

steps

4

and

5

until

no

air

bubble

shows

in

the

vinyl

hose

7

Operate

clutch

several

times

then

check

connections

for

external

hydraulic

leaks

Notes

a

Brake

fluid

containing

air

is

white

and

has

visible

air

bubbles

b

Brake

fluid

containing

no

air

runs

out

of

bleeder

screw

in

a

solid

stream

without

air

bubble

c

Pay

close

attention

to

clutch

fluid

level

in

reservoir

during

bleeding

operation

d

Do

not

reuse

brake

fluid

drained

during

bleeding

operation

e

Exercise

care

not

to

splash

brake

fluid

on

exterior

fInish

as

it

will

damage

the

paint

f

Pour

brake

fluid

into

reservoir

up

to

specifIed

level

Page 230 of 537

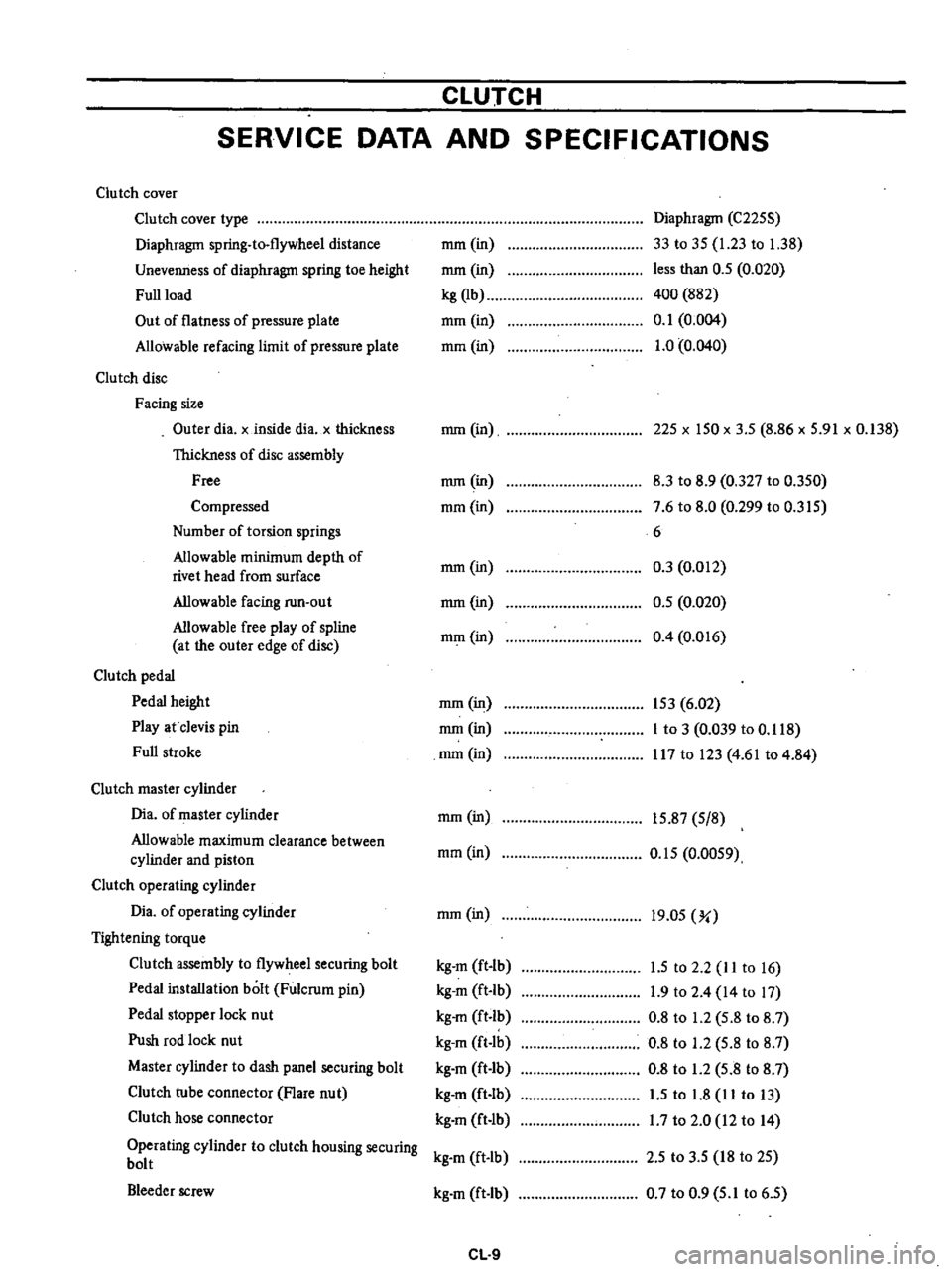

CLUTCH

SERVICE

DATA

AND

SPECIFICATIONS

Clutch

cover

Clu

tch

cover

type

Diaphragm

spring

to

flywheel

distance

Unevenness

of

diaphragm

spring

toe

height

Full

load

Out

of

flatness

of

pressure

plate

Allowable

refacing

limit

of

pressure

plate

Clutch

disc

Facing

size

Outer

dia

x

inside

dia

x

thickness

Thickness

of

disc

assembly

Free

Compressed

Number

of

torsion

springs

Allowable

minimum

depth

of

rivet

head

from

surface

Allowable

facing

run

out

Allowable

free

play

of

spline

at

the

outer

edge

of

disc

Clutch

pedal

Pedal

height

Play

at

clevis

pin

Full

stroke

Clutch

master

cylinder

Dia

of

master

cylinder

Allowable

maximum

clearance

between

cylinder

and

piston

Clutch

operating

cylinder

Dia

of

operating

cylinder

Tightening

torque

Clutch

assembly

to

flywheel

securing

bolt

Pedal

installation

bolt

Fulcrum

pin

Pedal

stopper

lock

nut

Push

rod

lock

nut

Master

cylinder

to

dash

panel

securing

bolt

Clutch

tube

connector

Flare

nut

Clutch

hose

connector

Operating

cylinder

to

clutch

housing

securing

bolt

Bleeder

screw

mm

in

mm

in

kg

Qb

mm

in

mm

in

Diaphragm

C225S

33

to

35

1

23

to

1

38

less

than

0

5

0

020

400

882

0

1

0

004

1

0

0

040

mm

in

225

x

150

x

3

5

8

86

x

5

91

x

0

138

mm

in

mm

in

8

3

to

8

9

0

327

to

0

350

7

6

to

8

0

0

299

to

0

315

6

0

3

0

012

0

5

0

020

0

4

0

016

mm

in

mm

in

mm

in

mm

in

153

6

02

mm

in

I

to

3

0

039

to

0

118

mm

in

117

to

123

4

61

to

4

84

mm

in

15

87

5

8

mm

in

0

15

0

0059

mm

in

19

05

Yo

kg

m

ft

lb

1

5

to

2

2

lito

16

kg

m

ft

Ib

1

9

to

2

4

14

to

17

kg

m

ft

b

0

8

to

1

2

5

8

to

8

7

kg

m

ft

lb

0

8

to

1

2

5

8

to

8

7

kg

m

ft

Ib

0

8

to

1

2

5

8

to

8

7

kg

m

ft

lb

1

5

to

1

8

11

to

13

kg

m

ft

lb

1

7

to

2

0

12

to

14

kg

m

ft

lb

2

5

to

3

5

18

to

25

kg

m

ft

Ib

0

7

to

0

9

5

1

to

6

5

CL

9

Page 231 of 537

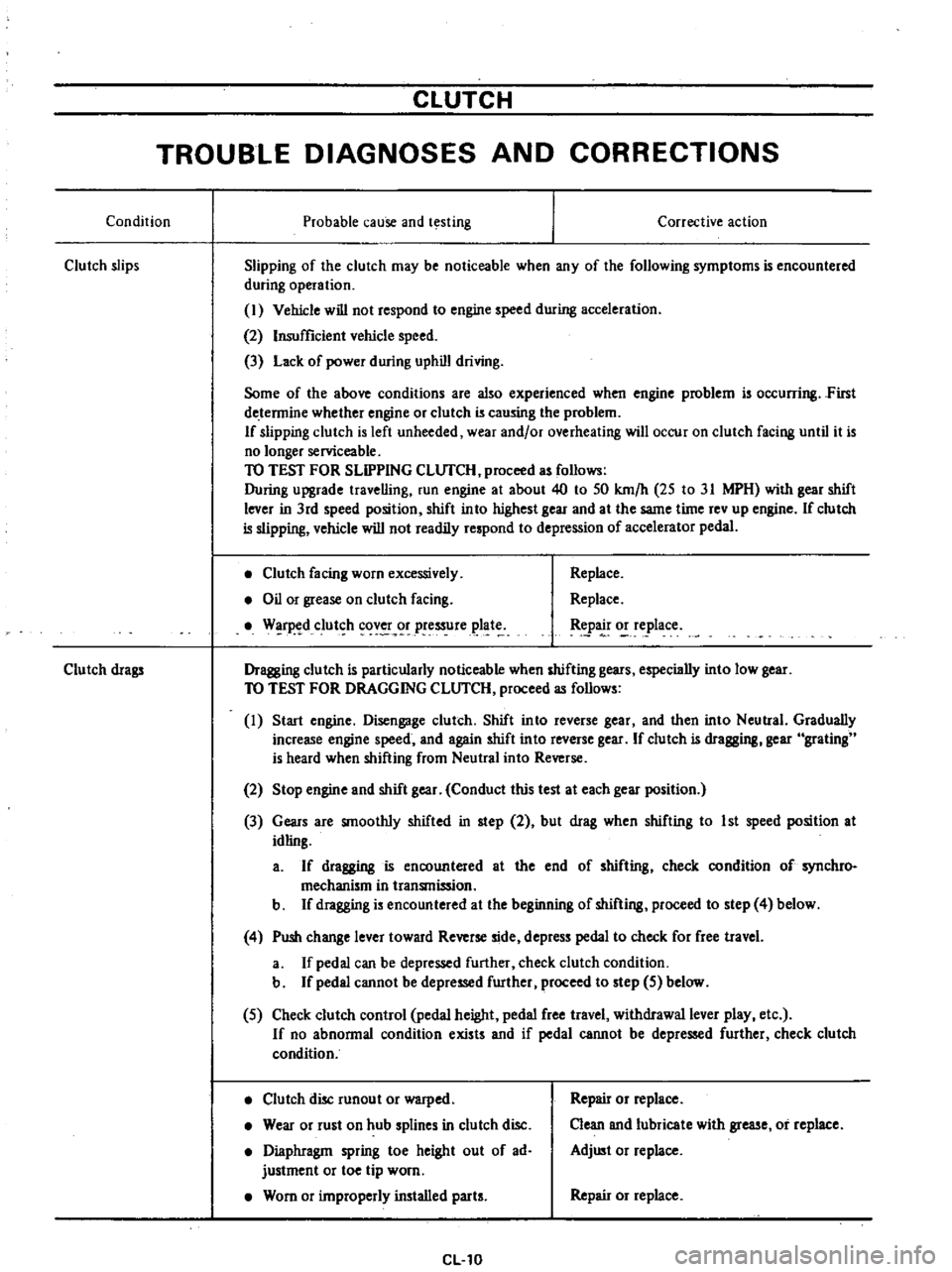

CLUTCH

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Probable

cause

and

testing

Clutch

slips

Corrective

action

Slipping

of

the

clutch

may

be

noticeable

when

any

of

the

following

symptoms

is

encountered

during

operation

I

Vehicle

will

not

respond

to

engine

speed

during

acceleration

2

Insufficient

vehicle

speed

3

Lack

of

power

during

uphill

driving

Some

of

the

above

conditions

are

also

experienced

when

engine

problem

is

oc

urring

First

de

tennine

whether

engine

or

clutch

is

causing

the

problem

If

slipping

clutch

is

left

unheeded

wear

and

or

overheating

will

occur

on

clutch

facing

until

it

is

no

longer

serviceable

TO

TEST

FOR

SLIPPING

CLlJfCH

proceed

as

follows

During

upgrade

travelling

run

engine

at

about

40

to

50

km

h

25

to

31

MPH

with

gear

shift

lever

in

3rd

speed

position

shift

into

highest

gear

and

at

the

same

time

rev

up

engine

If

clutch

is

slipping

vehicle

will

not

readily

respond

to

depression

of

accelerator

pedal

Clutch

facing

worn

excessively

Oil

or

grease

on

clutch

facing

W

r

d

clut

h

cov

r

pressure

plat

Replace

Replace

tpa

o

e

lace

Dragging

clutch

is

particularly

noticeable

when

shifting

gears

especially

into

low

gear

TO

TEST

FOR

DRAGGING

CLlJfCH

proceed

as

follows

I

Start

engine

Disengage

clutch

Shift

into

reverse

gear

and

then

into

Neutral

Gradually

increase

engine

speed

and

again

shift

into

reverse

gear

If

clutch

is

dragging

gear

grating

is

heard

when

shifting

from

Neutral

into

Reverse

Clutch

drags

2

Stop

engine

and

shift

gear

Conduct

this

test

at

each

gear

position

3

Gears

are

smoothly

shifted

in

step

2

but

drag

when

shifting

to

1st

speed

position

at

idling

a

If

dragging

is

encountered

at

the

end

of

shifting

check

condition

of

synchro

mechanism

in

transmission

b

If

dragging

is

encountered

at

the

beginning

of

shifting

proceed

to

step

4

below

4

Push

change

lever

toward

Reverse

side

depress

pedal

to

check

for

free

travel

a

If

pedal

can

be

depressed

further

check

clutch

condition

b

If

pedal

cannot

be

depressed

further

proceed

to

step

5

below

5

Check

clutch

control

pedal

height

pedal

free

travel

withdrawal

lever

play

etc

If

no

abnonnal

condition

exists

and

if

pedal

cannot

be

depressed

further

check

clutch

condition

Clutch

disc

runout

or

warped

Wear

or

rust

on

hub

splines

in

clutch

disc

Diaphragm

spring

toe

height

out

of

ad

justment

or

toe

tip

worn

Worn

or

improperly

installed

parts

CL10

Repair

or

replace

Clean

and

lubricate

with

grease

or

replace

Adjust

or

replace

Repair

or

replace

Page 232 of 537

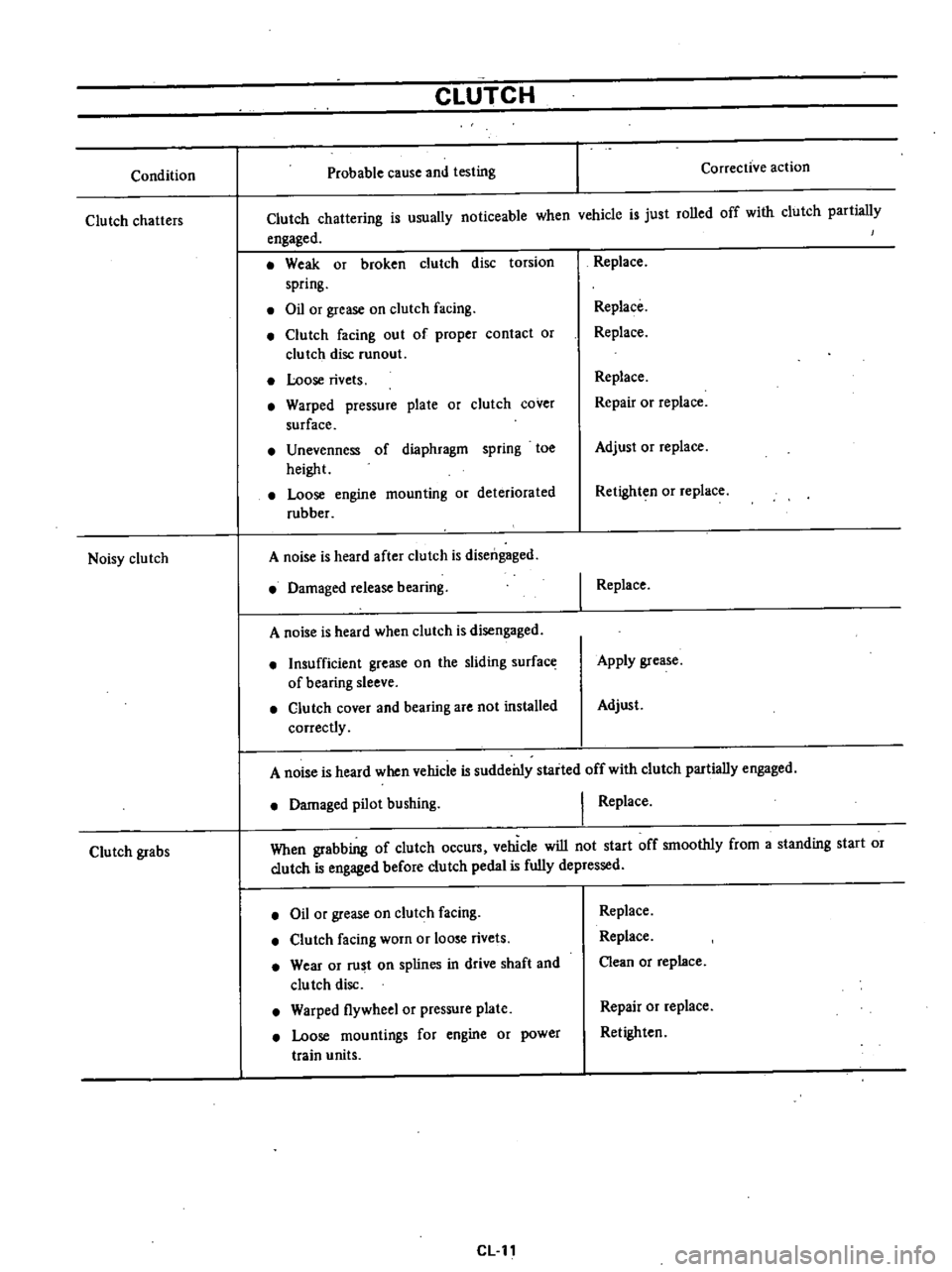

Condition

Clutch

chatters

Noisy

clutch

Clutch

grabs

CLUTCH

Probable

cause

and

testing

Corrective

action

Clutch

chattering

is

usually

noticeable

when

vchicle

is

just

rolled

off

with

clutch

partially

engaged

Weak

or

broken

clutch

disc

torsion

spring

Oil

or

grease

on

clutch

facing

Clutch

facing

out

of

proper

contact

or

clutch

disc

runout

Loose

rivets

Warped

pressure

plate

or

clutch

cover

surface

Unevenness

of

diaphragm

spring

toe

height

Loose

engine

mounting

or

deteriorated

rubber

A

noise

is

heard

after

clutch

is

disengaged

Damaged

release

bearing

A

noise

is

heard

when

clutch

is

disengaged

Insufficient

grease

on

the

sliding

surface

of

bearing

sleeve

Clutch

cover

and

bearing

are

not

installed

correctly

Replace

Replace

Replace

Replace

Repair

or

replace

Adjust

or

replace

Retighten

or

replace

I

Replace

Apply

grease

Adjust

A

noise

is

heard

when

vehicle

is

suddei11y

staited

off

with

clutch

partially

engaged

Damaged

pilot

bushing

I

Replace

When

grabbing

of

clutch

occurs

vehicle

will

not

start

off

smoothly

from

a

standing

start

or

clutch

is

engaged

before

clutch

pedal

is

fully

depressed

Oil

or

grease

on

clutch

facing

Clutch

facing

worn

or

loose

rivets

Wear

or

rust

on

splines

in

drive

shaft

and

clu

tch

disc

Warped

flywheel

or

pressure

plate

Loose

mountings

for

engine

or

power

train

units

CLll

Replace

Replace

Clean

or

replace

Repair

or

replace

Retighten

Page 233 of 537

Cl

Ul

CFf

SPECIAL

SERVICE

TOOLS

Tool

number

For

Reference

No

Description

use

page

or

tool

name

on

Figure

No

Unit

mm

in

ST20050010

620

Fig

CL

12

Base

plate

00

B210

710

610

y

S30

2

ST20050051

Set

bolt

SE002

q

3

ST20050

100

Distance

@

piece

7

8

mm

0

31

in

@1

@J

SEOQ3

4

ST20050240

620

Fig

CL

13

Diaphragm

B210

adjusting

710

wrench

610

S30

SE032

5

KV30100200

Clutch

aligning

bar

This

tool

is

used

to

conduct

disc

centeril

g

by

inserting

the

tool

into

pilot

bush

in

flywheel

when

installing

clutch

assembly

to

flywheel

620

710

610

S30

Fig

CL

2

Fig

CL

3

SEaOl

6

STl6610001

Pilot

bushing

puller

Fig

CL

6

620

710

610

S30

SE191

CL

12

Page 234 of 537

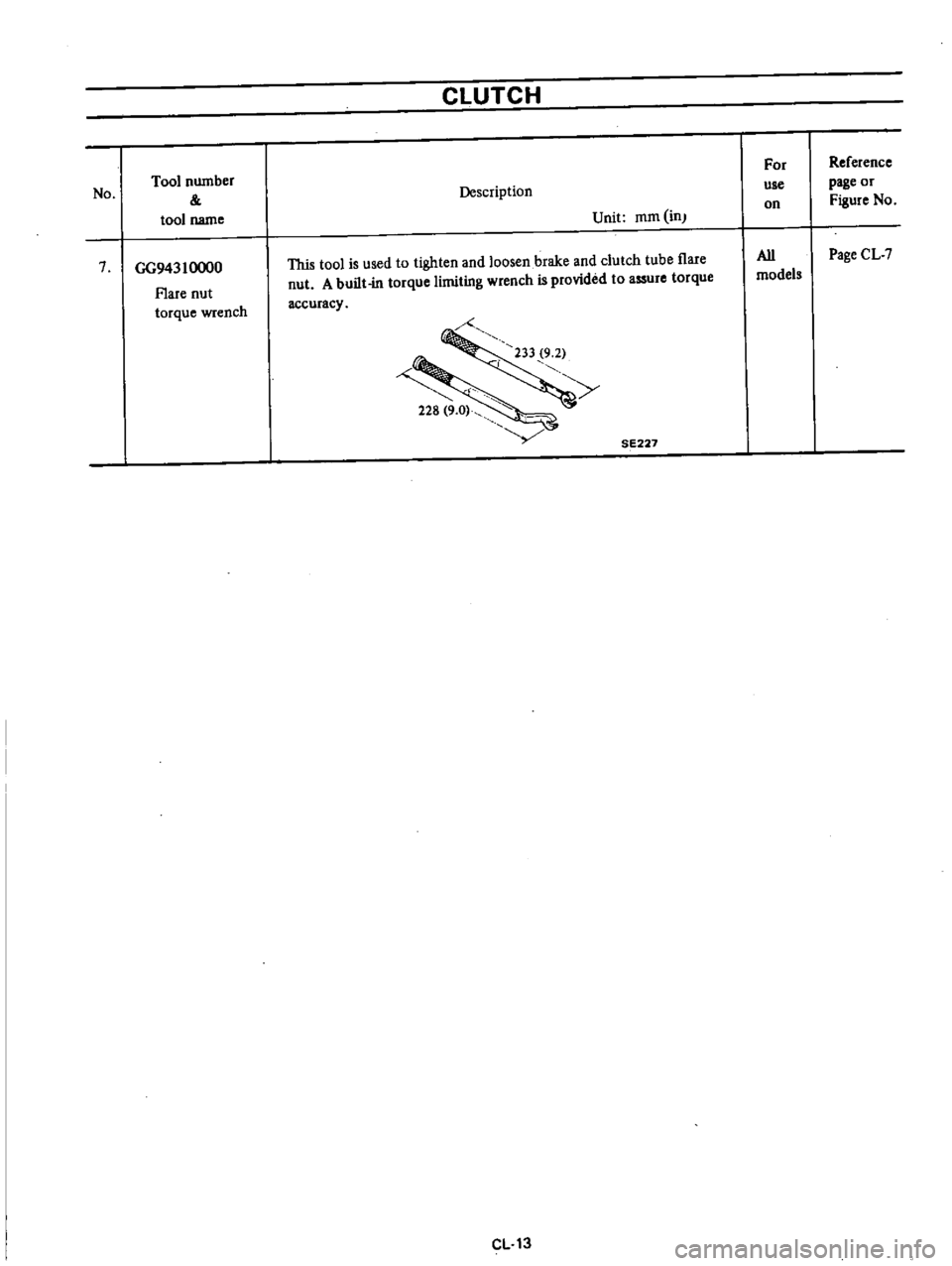

No

Tool

number

tool

name

7

GG94310000

Flare

nut

torque

wrench

CLUTCH

Description

Unit

mm

in

This

tool

is

used

to

tighten

and

loosen

brake

and

clutch

tube

flare

nut

A

built

in

torque

limiting

wrench

is

provided

to

assure

torque

accuracy

y

SE227

CL

13

For

use

on

All

models

Reference

page

or

Figure

No

Page

CL

7

Page 236 of 537

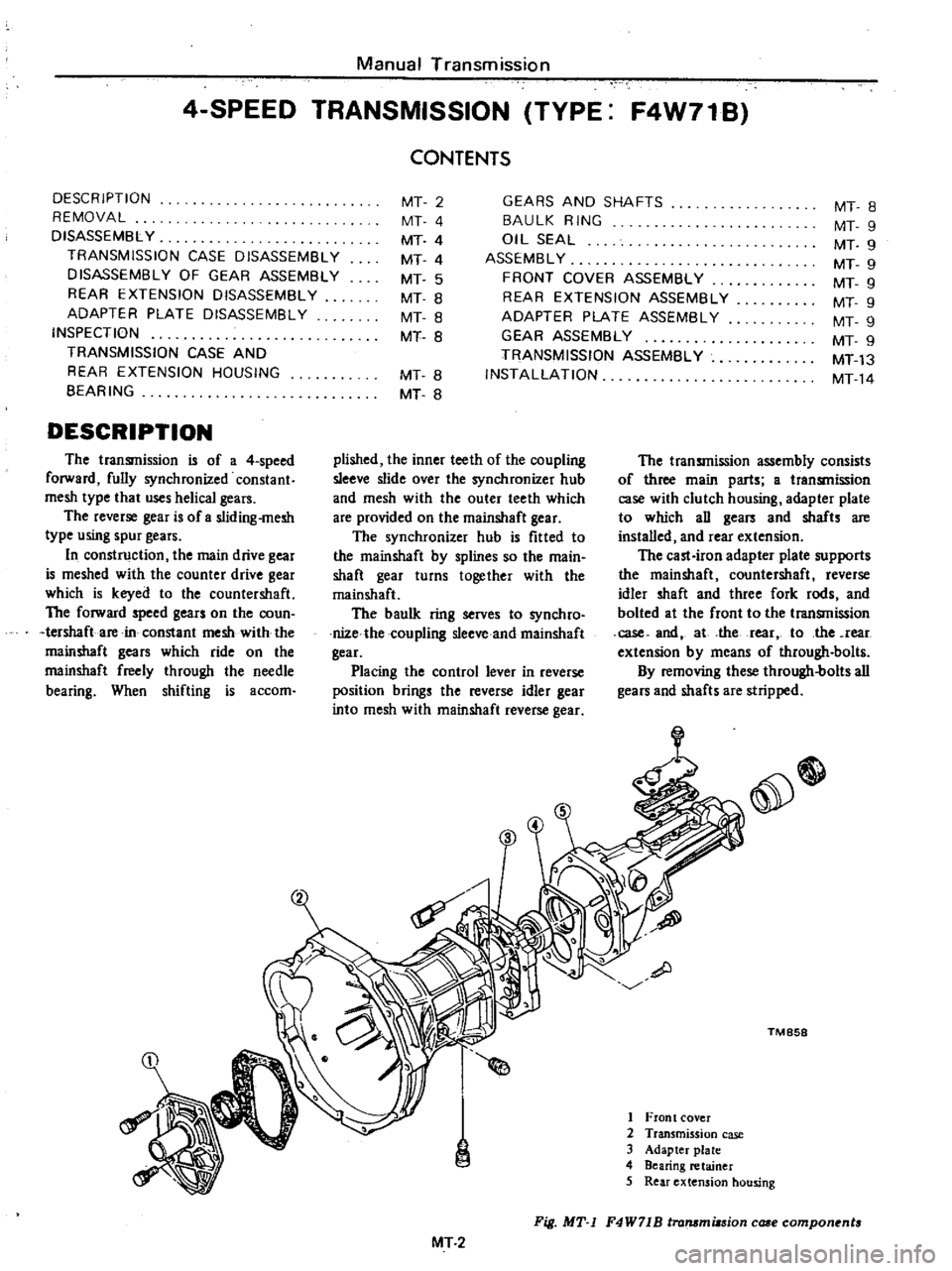

Manual

Transmission

4

SPEED

TRANSMISSION

TYPE

F4W71B

CONTENTS

DESCRIPTION

REMOVAL

DISASSEMBL

Y

TRANSMISSION

CASE

DISASSEMBLY

D

ISASSEMBL

Y

OF

GEAR

ASSEMBLY

REAR

EXTENSION

DISASSEMBLY

ADAPTER

PLATE

DISASSEMBLY

INSPECTION

TRANSMISSION

CASE

AND

REAR

EXTENSION

HOUSING

BEARING

GEARS

AND

SHAFTS

BAULK

RING

Oil

SEAL

ASSEMBL

Y

FRONT

COVER

ASSEMBLY

REAR

EXTENSION

ASSEMBLY

ADAPTER

PLATE

ASSEMBLY

GEAR

ASSEMBLY

TRANSMISSION

ASSEMBLY

INSTALLATION

MT

2

MT

4

MT

4

MT

4

MT

5

MT

B

MT

8

MT

8

MT

B

MT

8

MT

8

MT

9

MT

9

MT

9

MT

9

MT

9

MT

9

MT

9

MT13

MT14

DESCRIPTION

pUshed

the

inner

teeth

of

the

coupling

sleeve

slide

over

the

synchronizer

hub

and

mesh

with

the

outer

teeth

which

are

provided

on

the

mainshaft

gear

The

synchronizer

hub

is

fitted

to

the

mainshaft

by

splines

so

the

main

shaft

gear

turns

together

with

the

mainshaft

The

baulk

ring

serves

to

synchro

nile

the

coupling

sleeve

and

mainshaft

gear

Placing

the

control

lever

in

reverse

position

brings

the

reverse

idler

gear

into

mesh

with

mainshaft

reverse

gear

The

transmission

is

of

a

4

speed

forward

fully

synchronized

constant

mesh

type

that

uses

helical

gears

The

reverse

gear

is

ofa

sliding

mesh

type

using

spur

gears

In

construction

the

main

drive

gear

is

meshed

with

the

counter

drive

gear

which

is

keyed

to

the

countershaft

The

forward

speed

gears

on

the

coun

tershaft

are

in

constant

mesh

with

the

mainshaft

gears

which

ride

on

the

mainshaft

freely

through

the

needle

bearing

When

shifting

is

accom

The

transmission

assembly

consists

of

three

main

parts

a

transmission

case

with

clutch

housing

adapter

plate

to

which

an

gears

and

shafts

are

installed

and

rear

extension

The

cast

iron

adapter

plate

supports

the

mainshaft

countershaft

reverse

idler

shaft

and

three

fork

rods

and

bolted

at

the

front

to

the

transmission

case

and

at

the

rear

to

the

rear

extension

by

means

of

through

bolts

By

removing

these

through

bolts

all

gears

and

shafts

are

stripped

e

TM

858

1

Front

cover

2

Transmission

case

3

Adapter

plate

4

Bearing

retainer

5

Rear

extension

hOUsing

Fig

MT

1

F4W71B

lrammiasion

case

compon

nt

MT

2

Page 238 of 537

REMOVAL

In

dismounting

transmission

from

the

vehicle

proceed

as

follows

I

Disconnect

battery

ground

cable

from

terminal

2

Place

transmission

control

lever

in

neutIal

position

3

Remove

E

ring

and

control

lever

pin

from

transmission

striking

rod

guide

and

remove

control

lever

See

Figure

MT

4

TM335

Fig

MT

4

Remouing

controllelJ

r

4

Jack

up

the

vehicle

and

support

its

weight

on

safety

stands

Use

a

hydraulic

hoist

or

open

pit

if

avail

able

Confirm

that

safety

is

insured

5

Disconnect

exhaust

front

tube

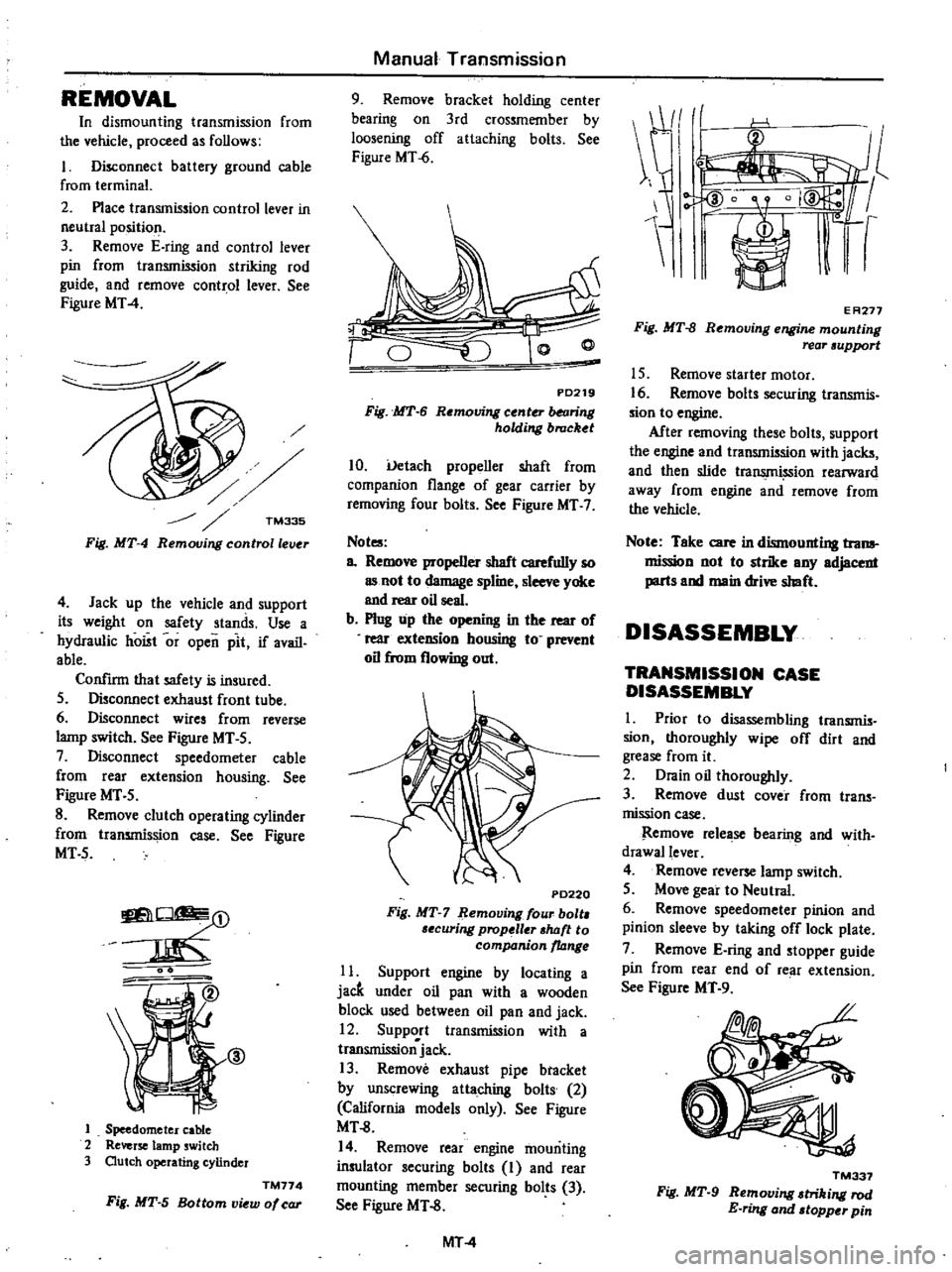

6

Disconnect

wires

from

reverse

lamp

switch

See

Figure

MT

5

7

Disconnect

speedometer

cable

from

rear

extension

housing

See

Figure

MT

5

8

Remove

clutch

operating

cylinder

from

transmission

case

See

Figure

MT5

O

m

J

@

1

Speedometer

cable

2

Reverse

lamp

switch

3

Outch

operating

cylinder

TM774

Fig

MT

5

Bottom

view

of

car

Manual

Transmission

9

Remove

bracket

holding

center

bearing

on

3rd

crossmember

by

loosening

off

attaching

bolts

See

Figure

MT

6

PD219

Fig

MT

6

Removing

center

balring

holding

brucket

10

Uetach

propeller

shaft

from

companion

flange

of

gear

carrier

by

removing

four

bolts

See

Figure

MT

7

Not

a

Remove

propeller

shaft

carefully

so

as

not

to

damage

spline

sleeve

yoke

and

rear

oil

seal

b

Plug

up

the

opening

in

the

rear

of

rear

exteDSion

housing

to

prevent

oil

from

flowing

out

P0220

Fig

MT

7

Remouing

four

bolt

6ecuring

prop

ller

shtJft

to

companion

ltJnge

11

Support

engine

by

locating

a

jacft

under

oil

pan

with

a

wooden

block

used

between

oil

pan

and

jack

12

Support

transmission

with

a

transmissionjack

13

Remove

exhaust

pipe

btacket

by

unscrewing

attaching

bolts

2

California

models

only

See

Figure

MT

8

14

Remove

rear

engine

mounting

insulator

securing

bolts

I

and

rear

mounting

member

securing

bolts

3

See

Figure

MT

8

MT

4

E

A277

Fig

MT

8

Removing

engine

mounting

rear

support

15

Remove

starter

motor

16

Remove

bolt

securing

transmis

sion

to

engine

After

removing

these

bolts

support

the

engine

and

transmission

with

jacks

and

then

slide

tra

ion

rearward

away

from

engine

and

remove

from

the

vehicle

Note

Take

care

in

dismounting

trona

mission

not

to

strike

any

adjacent

parts

and

main

drive

shaft

DISASSEMBLY

TRANSMISSION

CASE

DISASSEMBLY

I

Prior

to

disassembling

transmis

sion

thoroughly

wipe

off

dirt

and

grease

from

it

2

Drain

oil

thoroughly

3

Remove

dust

cover

from

trans

mission

case

Remove

release

bearing

and

with

drawallever

4

Remove

reverse

lamp

switch

5

Move

gear

to

Neutral

6

Remove

speedometer

pinion

and

pinion

sleeve

by

taking

off

lock

plate

7

Remove

E

ring

and

stopper

guide

pin

from

rear

end

of

re

ll

extension

See

Figure

MT

9

TM337

Fig

MT

9

Removing

triking

rod

E

ring

and

topper

pin