DATSUN PICK-UP 1977 Service Manual

Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 421 of 537

Engine

Control

Fuel

Exhaust

Systems

2

Remove

fuel

filter

INSPECTION

Fuel

tanle

Check

fuel

tank

for

cracks

or

deformation

If

necessary

replace

2

Fuel

hose

Inspect

all

hoses

for

cracks

fatigue

sweating

or

deterioration

Replace

any

hose

that

is

damaged

3

Fuel

tube

Replace

any

fuel

tube

that

is

crack

ed

rusted

collapsed

or

deformed

Note

Inspect

hoses

and

tubes

ac

cording

to

the

periodic

mainte

nance

schedule

4

Fuel

filter

Replace

fuel

filter

according

to

the

periodic

maintenance

schedule

or

when

it

is

clogged

or

restricted

DESCRIPTION

REMOVAL

DESCRIPTION

The

exhaust

systems

installed

on

the

non

California

models

differ

in

specifications

from

those

installed

on

the

California

models

Fuel

filter

is

of

a

cartridge

type

and

cannot

be

cleaned

Always

replace

with

a

new

one

5

Fuel

tank

gauge

unit

Check

gauge

unit

for

rust

deforma

tion

or

deterioration

If

necessary

replace

INSTALLATION

To

install

reverse

the

order

of

removal

Observe

the

following

I

Install

hose

clamps

securely

Do

not

tighten

excessively

to

avoid

damaging

hoses

2

Fasten

clips

holding

fuel

tube

on

under

body

securely

Failure

to

follow

this

caution

could

result

in

damage

to

the

surface

of

fuel

tube

3

Do

not

kink

or

twist

hose

and

tube

when

they

are

routed

EXHAUST

SYSTEM

CONTENTS

FE

6

FE

8

INSPECTION

INSTAllATION

Non

California

models

The

exhaust

system

consists

of

a

front

exhaust

tube

a

main

muffler

assembly

with

rear

tube

mounting

hangers

brackets

and

a

heat

insulator

FE

6

4

Install

fIller

hose

after

fuel

tank

has

been

mounted

in

place

Failure

to

follow

this

caution

could

result

in

leakage

from

around

hose

connections

5

When

installing

fuel

tank

gauge

unit

align

the

projection

of

tank

gauge

unit

with

the

notch

in

fuel

tank

and

tighten

it

securely

Be

sure

to

install

gauge

unit

with

O

ring

in

place

6

Run

engine

and

check

for

leaks

at

connections

Tightening

torque

Drain

plug

5

0

to

6

0

kg

m

36

to

43

ft

Ib

Fuel

tank

securing

bolt

0

8

to

1

I

kg

m

6

to

8

ft

Ib

Reservoir

tank

securing

bolt

032

to

0

44

kg

m

2

to

3

ft

Ib

FE

8

FE

8

California

models

The

exhaust

system

cOllsists

of

a

front

exhaust

tube

a

catalytic

conver

ter

assembly

a

center

tube

a

main

muffler

assembly

with

rear

tube

mounting

hangers

brackets

and

heat

insulators

The

catalytic

converter

is

COD

nected

to

the

front

tube

and

the

center

tube

with

bolts

and

nuts

Page 422 of 537

Engine

Control

Fuel

Exhaust

S

t

ys

ems

Non

Califomia

model

Qf

@

Si

tr

l

Qf

Si

tIJ

i

Qf

I

l

j

l

tr

l

r

Qf

Si

i

l

l

t

1

I

tr

l

9

r

8

1Bi

1

Front

tube

2

Exhaust

tube

clamp

3

Rear

tube

assembly

4

Muffler

assembly

5

Rear

tube

mounting

6

Front

tube

mounting

California

model

6

@@

8

Qf

@

fit

J

0

I

1

2

I

7

Front

tube

Catalytic

converter

Center

tube

Muffler

assembly

Diffuser

Rear

tube

mounting

Front

tube

mounting

FE390

Fig

FE

6

E

r

ha

t

system

FE

7

Page 423 of 537

Engine

Control

Fuel

Exhaust

Systems

REMOVAL

Non

California

models

I

Remove

exhaust

tube

U

bolt

clamp

2

Break

sealant

off

at

front

tube

to

main

muffler

connectio

n

3

Remove

rear

tube

mounting

bolt

and

remove

muffler

assembly

with

rear

tube

4

Remove

front

tube

heat

insulator

5

Remove

nuts

securing

front

tube

to

exhaust

manifold

and

remove

front

tube

mounting

bolts

Then

detach

front

tube

When

disconnecting

the

exhaust

tube

connections

pay

attention

to

the

following

point

I

Break

old

se

lant

off

at

t

1e

connection

by

lightly

tapping

around

the

tube

witlJ

a

hammer

and

twisting

muffler

See

Figures

FE

7

and

FE

8

2

Using

a

rubber

hammer

tap

on

the

front

end

of

muffler

while

pushing

it

toward

rear

The

mumer

assembly

can

then

be

taken

out

See

Figure

FE

9

FE187

Fig

FE

7

Breaking

Bealant

FEl88

Fig

FE

8

Twisting

muffler

ijl

4

FE189

Fig

FE

9

Tapping

muffler

with

Q

rubber

hammer

California

models

I

Remove

all

heat

insulators

2

Remove

exhaust

tube

U

bolt

clamp

3

Break

sealant

off

at

center

tube

to

main

muffler

connection

4

Remove

rear

tube

mounting

bolt

and

remove

muffler

assembly

with

rear

tube

5

Remove

bolts

securing

catalytic

converter

to

center

tube

and

remove

center

tube

mounting

bolts

Then

detach

center

tube

6

Remove

bolts

and

nuts

securing

catalytic

converter

to

front

tube

and

detach

catalytic

converter

7

Remove

nuts

securing

front

tube

to

exhaust

manifold

and

remove

front

tube

mounting

bolts

Then

detach

front

tube

INSPECTION

I

Check

muffler

and

tubes

for

cracks

Qr

damage

Replace

any

part

that

is

damaged

beyond

limits

2

Replace

bracket

and

mounting

insulator

that

are

cracked

fatigued

or

sweated

FE

8

INSTALLATION

Install

the

exhaust

system

assembly

in

reverse

order

of

removal

Observe

the

following

Notes

a

Insert

front

tube

until

it

touches

emboss

b

When

there

is

110

clearance

between

front

tube

and

floor

or

propeUer

shaft

turn

tube

along

center

line

of

tube

in

the

manifold

connecting

unit

and

obtain

proper

clearance

c

Check

all

tube

connections

for

ex

haust

gas

leaks

and

entire

system

for

unusual

noises

with

engine

running

d

After

installation

check

that

mounting

brackets

and

mounting

rubbers

are

free

from

undue

stress

If

any

of

the

above

parts

is

not

installed

properly

excessive

noises

or

vibrations

may

be

transmitted

to

the

vehicle

body

e

Tightening

torque

Exhaust

manifold

to

front

tube

nut

1

9

to

2

5

kg

m

14

to

18

ft

lb

U

bolt

securing

nut

1

9

to

2

1

kg

m

14

to

15

ft

lb

Mounting

bracket

bolt

1

0

to

1

2

kg

m

710

9

ft

lb

Front

tube

mounting

bracket

bolt

california

models

1

9

to

2

1

kg

m

14

to

15

ft

lb

Catalytic

converter

to

front

and

center

tube

bolt

California

models

3

2

to

4

3

kg

m

23

to

31

ft

Ib

If

exhaust

tubes

are

separated

at

connection

t

renew

muffler

assembly

etc

use

the

Genuine

Nissan

Sealant

Exhaust

Sealant

Kit

20720

N2225

or

equivalent

See

Figure

FE

IO

to

eliminate

gas

leakage

at

the

joint

Be

sure

to

observe

the

following

Page 424 of 537

Engine

Control

Fuel

Exhaust

Systems

I

Wipe

clean

all

the

contact

por

tions

of

tube

joints

allow

them

to

dry

thoroughly

2

Temporarily

mount

in

place

muffler

assembly

as

an

assembled

unit

on

the

vehicle

3

Insert

front

tube

until

it

touches

emboss

m

b

nlfrnnjj

mm

lJ

Ij

@L

J

FE263

Fig

FE

ll

Exhawt

tube

connection

4

Torque

nut

securing

the

male

and

female

tubes

at

the

connection

Tightening

torque

is

1

6

to

2

0

kg

m

12

to

14

ft

lb

5

Squeeze

approximately

5

CC

0

31

cu

in

of

sealant

into

injection

from

sealant

tube

See

Figure

FE

12

Sealant

tube

polyethylene

Injector

Fig

FE

IO

Exhaust

sealant

kit

Be

sure

to

place

cap

back

to

sealant

tube

since

sealant

will

dry

Approximately

5

cc

0

31

Cll

in

FE1l1

Fig

FE

12

Squeezing

sealant

to

injec

tor

6

Position

nozzle

of

injector

to

the

guide

and

press

it

there

firmly

Inject

sealant

slowly

until

sealant

begins

to

flow

out

of

the

slit

of

tube

This

indicates

that

the

bead

requires

no

further

sealant

Excessive

sealant

can

cause

a

clogged

tube

See

Figure

FE

13

After

injecting

wash

injector

thoroughly

in

clean

water

to

remove

all

traces

of

sealant

FE191

Fig

FE

13

Injecting

sealant

FE

9

7

Start

engine

and

let

it

idle

slowly

for

ten

minutes

minimum

to

hilfden

sealant

with

the

heat

of

exhaust

gas

8

Check

the

condition

of

sealant

before

driving

the

vehicle

It

is

also

essential

that

the

vehicle

should

not

be

accelerated

sharply

for

20

to

30

minutes

subsequent

to

this

operation

Noles

a

The

sealant

should

be

used

within

guaranty

term

indicated

on

the

kit

case

b

Exposure

of

sealant

to

the

skin

may

cause

a

rash

Wash

sealant

off

the

skin

with

water

c

Do

not

keep

the

sealant

tube

in

a

place

where

the

ambient

tempera

ture

is

above

400C

I040F

A

sealant

hardened

above

4QoC

I040F

cannot

be

used

The

most

suitable

storage

temperature

is

from

15

to

350C

59

to

950F

If

sealant

becomes

hardened

because

of

low

temperatures

wann

the

sealant

tube

with

lukewarm

water

until

the

sealant

is

softened

Do

not

warm

tube

at

a

temperature

over

400C

1040F

for

a

long

time

d

Thoroughly

read

the

instruction

sheet

furnished

with

the

kit

before

using

the

sealant

i

Page 425 of 537

DATSUN

PICK

UP

MODEL

620

SERIES

I

NISSAN

I

NISSAN

MOTOR

CO

LTD

TOKYO

JAPAN

SECTION

BF

BO

DY

FRAME

CAB

BODY

AND

FRAME

REAR

BODY

BODY

FRONT

END

HOOD

DOOR

WINDSHIELD

GLASS

INSTRUMENT

PANEL

INTERIOR

TRIM

AND

CENTER

CONSOLE

SEAT

BF

2

BF

5

BF

7

BF

8

BF

11

BF

16

BF

17

BF

18

BF

19

Page 426 of 537

Body

Frame

CAB

BODY

AND

FRAME

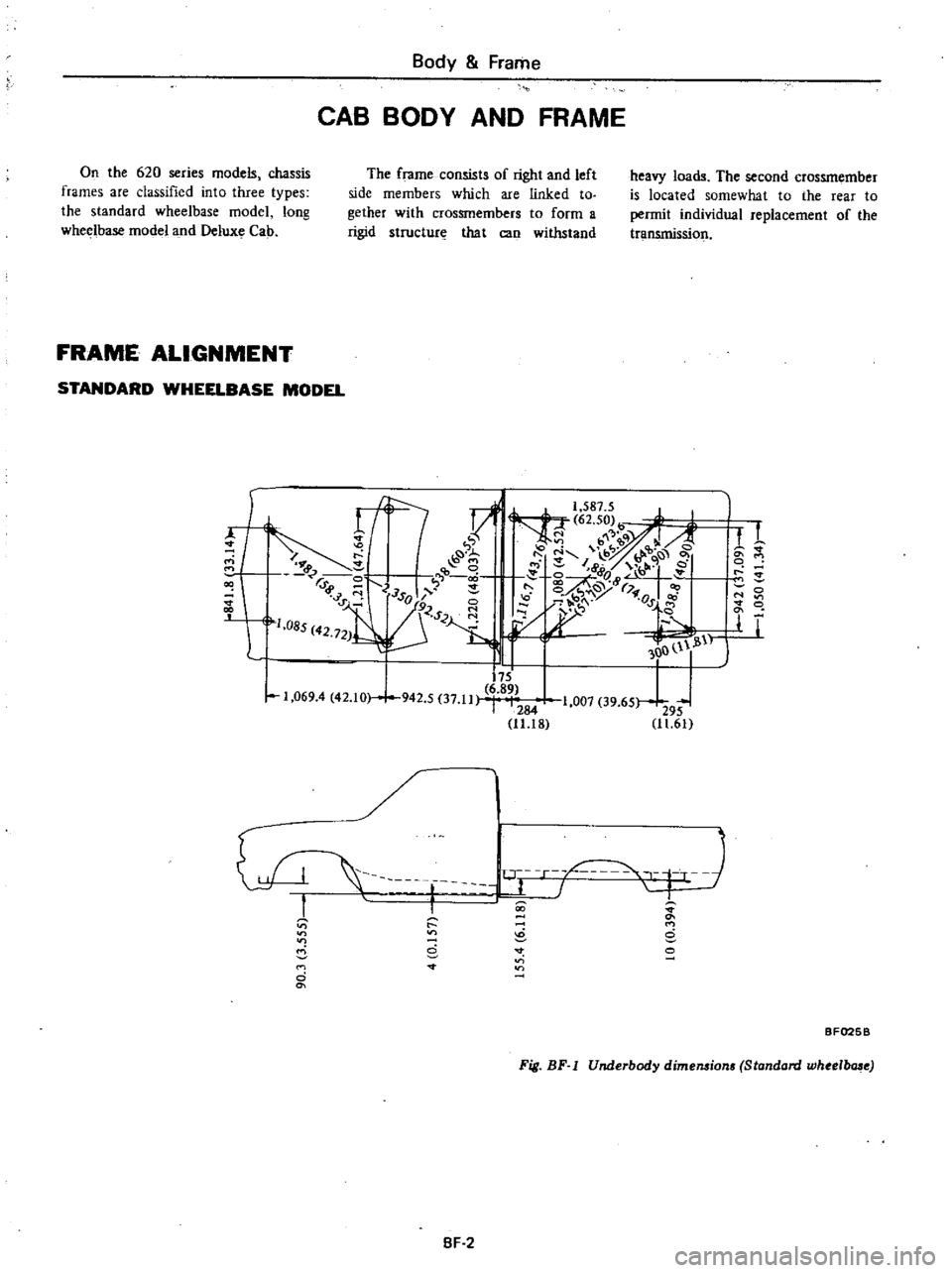

On

the

620

series

models

chassis

frames

are

classified

into

three

types

the

standard

wheelbase

model

long

wheelbase

model

and

Deluxe

Cab

The

frame

consists

of

right

and

left

side

members

which

are

linked

to

gether

with

crossmembers

to

form

a

rigid

structure

that

can

withstand

heavy

loads

The

second

crossmember

is

located

somewhat

to

the

rear

to

permit

individual

replacement

of

the

transmissiol

FRAME

ALIGNMENT

STANDARD

WHEELBASE

MODEL

f

r1

1

587

5

J

I

1

X

62

50

I

b

q

J

A

1

7

I

b

9

9

8

I

1

e

t

r

0

ij

e

6

rd

r

r

1sol

1

1

9ClS

1

085

42

721

Cl

H

1

I

11

OO

l

1

i11

175

6

89

1

069

4

42

10

942

5

37

11

1007

39

65

I

284

295

11

18

11

61

00

d

M

o

8

r

r

c

8

o

r

T

L

BF025B

Fig

BF

I

Underbody

dime1l8ion

Standard

whee

b

e

SF

2

Page 427 of 537

Body

Frame

LONG

WHEELBASE

MODEL

In

4

l1

1

873

8

Ir

mrn

0

IN

bi

1

b

v

p

v

M

r

y

M

t

c

I

f

G

0

v

D

c

IS

S

t

I

y

r

M

J

1

0

10

9

V

raj

p

N

78

1

085

42

72

1

350

Ii

I

1

20

63

d3

1

U

n

L

II

t

I

T

r

r

J

M

o

C

M

o

e

I

I

o

M

0

So

I

I

Fig

BF

2

Underbody

dimensions

Long

wheelbase

BF0268

DELUXE

CAB

17

1

C

y

0

l

r

r

M

2

V

d

J

JSO

r

S

1

085

42

72

I

I

I

li4

1

069

4

42

10

942

5

37

11

284

11

18

Jr

t

r

iO

u

b

P

tl

b

c

N

0

l

f

t

0

M

00

I

0

0

0

o

1

00

N

It

1

b

t

8Qa

3

o

OS

A

b

U

n

j

1

007

39

65

1

11

61

1

M

o

bu

c

r

I

T

I

I

M

8

R

It

o

BF

3

Fig

BR

3

Underbody

dimensiom

Delu

Cab

BF027B

Page 428 of 537

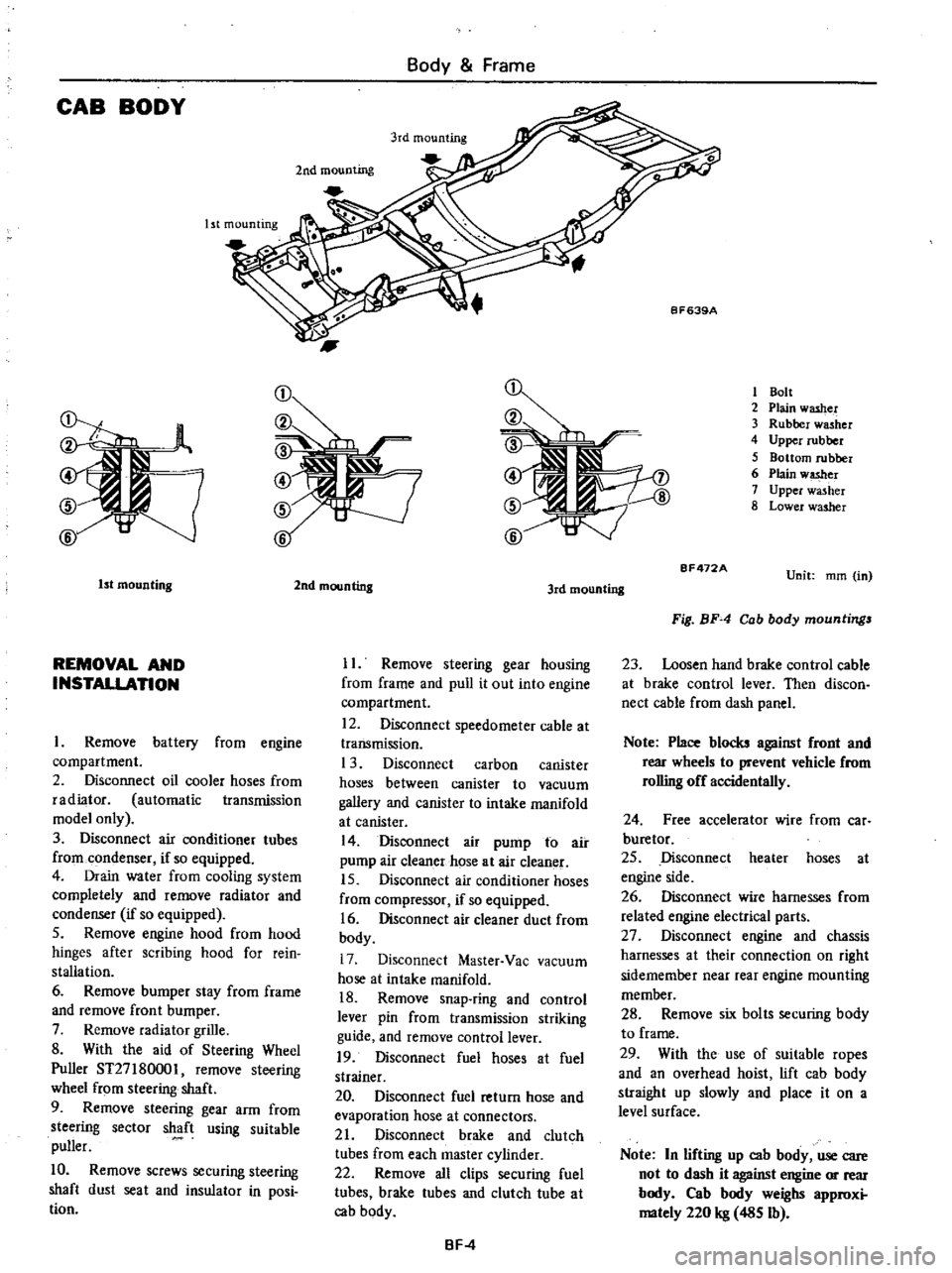

CAB

BODY

Body

Frame

Ist

mounting

2nd

mounting

1

Bolt

2

Plain

washer

3

Rubber

washer

4

Upper

rubber

5

Bottom

rubber

6

Plain

w

er

7

Upper

washer

8

Lower

washer

1st

mounting

REMOVAL

AND

INSTALLATION

Remove

battery

from

engine

compartment

2

Disconnect

oil

cooler

hoses

from

radiator

automatic

transmission

model

only

3

Disconnect

air

conditioner

tubes

from

condenser

if

so

equipped

4

Drain

water

from

cooling

system

completely

and

remove

radiator

and

condenser

if

so

equipped

5

Remove

engine

hood

from

hood

hinges

after

scribing

hood

for

rein

stallation

6

Remove

bumper

stay

from

frame

and

remove

front

bumper

7

Remove

radiator

grille

8

With

the

aid

of

Steering

Wheel

Puller

ST27

180001

remove

steering

wheel

from

steering

shaft

9

Remove

steering

gear

arm

from

steering

sector

shaft

using

suitable

puller

10

Remove

screws

securing

steering

shaft

dust

seat

and

insulator

in

posi

tion

2nd

mounting

3rd

mounting

II

Remove

steering

gear

housing

from

frame

and

pull

it

out

into

engine

compartment

12

Disconnect

speedometer

cable

at

transmission

1

3

Disconnect

carbon

canister

hoses

between

canister

to

vacuum

gallery

and

canister

to

intake

manifold

at

canister

14

Disconnect

air

pump

to

air

pump

air

cleaner

hose

at

air

cleaner

15

Disconnect

air

conditioner

hoses

from

compressor

if

so

equipped

16

Disconnect

air

cleaner

duct

from

body

17

Disconnect

Master

Vac

vacuum

hose

at

intake

manifold

18

Remove

snap

ring

and

control

lever

pin

from

transmission

striking

guide

and

remove

control

lever

19

Disconnect

fuel

hoses

at

fuel

strainer

20

Disconnect

fuel

return

hose

and

evaporation

hose

at

connectors

21

Disconnect

brake

and

clutch

tubes

from

each

master

cylinder

22

Remove

all

clips

securing

fuel

tubes

brake

tubes

and

clutch

tube

at

cab

body

BF

4

BF472A

Unit

mm

in

Fig

BF

4

Cab

body

mountings

23

Loosen

hand

brake

control

cable

at

brake

control

lever

Then

discon

nect

cable

from

dash

panel

Note

Place

blocks

against

front

and

rear

wheels

to

prevent

vehicle

from

rolling

off

accidentally

24

Free

accelerator

wire

from

car

buretor

25

Disconnect

heater

hoses

at

engine

side

26

Disconnect

wire

harnesses

from

related

engine

electrical

parts

27

Disconnect

engine

and

chassis

harnesses

at

their

connection

on

right

sidemember

near

rear

engine

mounting

member

28

Remove

six

bolts

securing

body

to

frame

29

With

the

use

of

suitable

ropes

and

an

overhead

hoist

lift

cab

body

straight

up

slowly

and

place

it

on

a

level

surface

Note

In

lifting

up

cab

body

use

care

not

to

dash

it

against

engine

or

rear

body

Cab

body

weighs

approxi

mately

220

kg

485

Ib

Page 429 of 537

Body

Frame

30

For

installation

reverse

above

steps

However

observe

the

following

instructions

i

If

the

cab

body

is

to

be

replaced

note

position

and

location

of

insula

tors

and

washers

used

See

Figure

BF

4

2

Adjust

hand

brake

stroke

pro

perly

3

Air

bleed

brake

and

clutch

system

thorougWy

Cab

body

to

frame

mounting

bolt

torque

1

6

to

2

2

kg

m

12

to

16

ft

Ib

o

i

k

q

1Q

j

b

crru

V

J

8F630

rr

1

4

n

Fig

BF

5

Lifting

up

cab

body

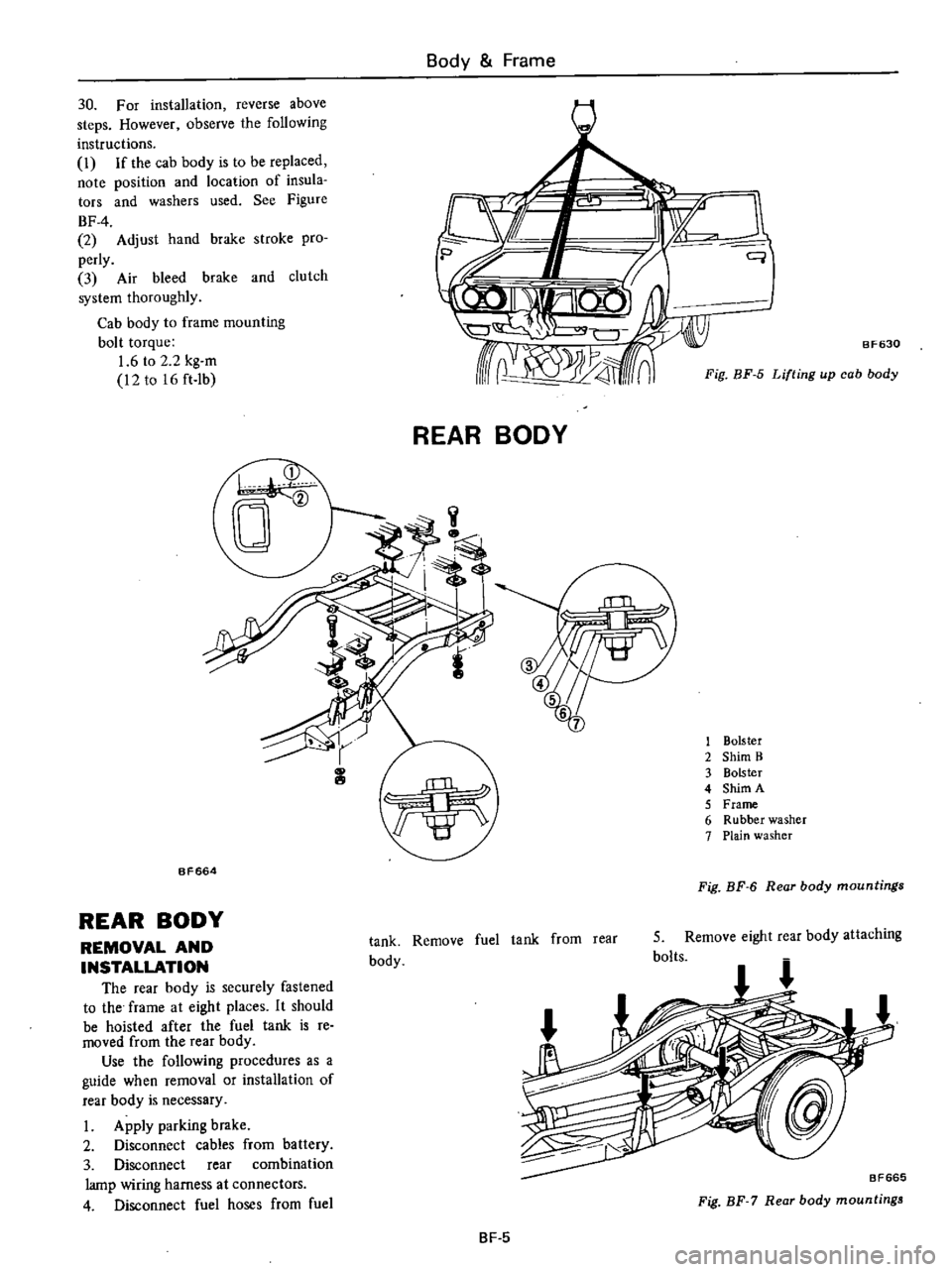

REAR

BODY

1

Bolster

2

Shim

B

3

Bolster

4

Shim

A

5

Frame

6

Rubber

washer

7

Plain

washer

BF664

Fig

BF

6

Rear

body

mountings

REAR

BODY

REMOVAL

AND

INSTALLATION

The

rear

body

is

securely

fastened

to

the

frame

at

eight

places

It

should

be

hoisted

after

the

fuel

tank

is

re

moved

from

the

rear

body

Use

the

following

procedures

as

a

guide

when

removal

or

installation

of

rear

body

is

necessary

I

Apply

parking

brake

2

Disconnect

cables

from

battery

3

Disconnect

rear

combination

lamp

wiring

harness

at

connectors

4

Disconnect

fuel

hoses

from

fuel

tank

Remove

fuel

tank

from

rear

body

5

Remove

eight

rear

body

attaching

bolts

BF665

Fig

BF

7

Rear

body

mountings

BF

5

Page 430 of 537

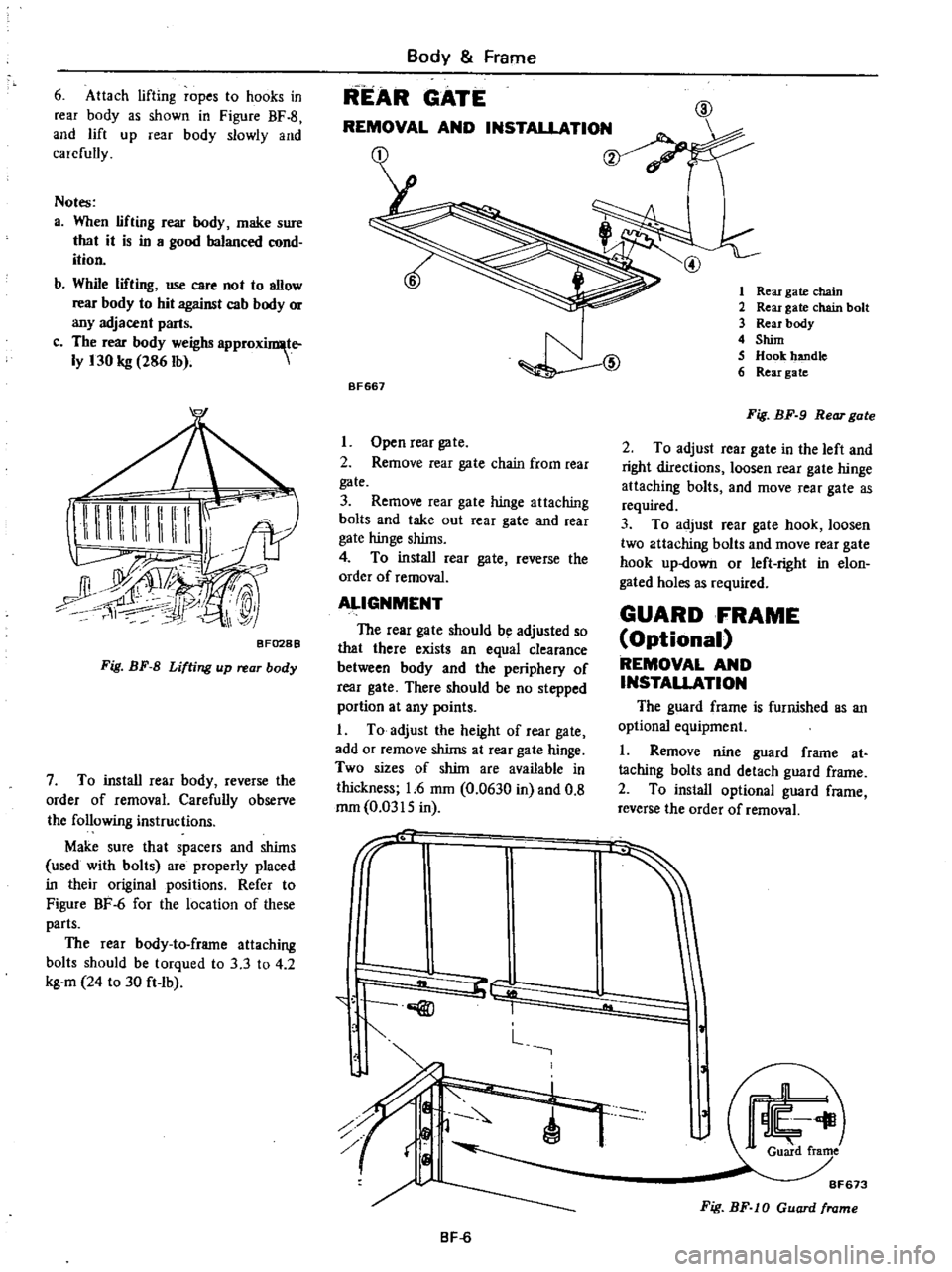

6

Attach

lifting

ropes

to

hooks

in

rear

body

as

shown

in

Figure

BF

8

and

lift

up

rear

body

slowly

and

carefully

Notes

a

When

lifting

rear

body

make

sure

that

it

is

in

a

good

balanced

cond

ition

b

While

lifting

use

care

not

to

allow

rear

body

to

hit

against

cab

body

or

any

adjacent

parts

c

The

rear

body

weighs

approxillll

te

Iy

130

kg

286

Ib

BF0288

Fig

BF

8

Lifting

up

rear

body

7

To

install

rear

body

reverse

the

order

of

removal

Carefully

observe

the

following

instructions

Make

sure

that

spacers

and

shims

used

with

bolts

are

properly

placed

in

their

original

positions

Refer

to

Figure

BF

6

for

the

location

of

these

parts

The

rear

body

to

frame

attaching

bolts

should

be

torqued

to

3

3

to

4

2

kg

m

24

to

30

ft

Ib

Body

Frame

REAR

GATE

00

REMOVAL

AND

INSTAllATION

1

W

@

BF661

I

Open

rear

gate

2

Remove

rear

gate

chain

from

ear

gate

3

Remove

rear

gate

hinge

attaching

bolts

and

take

out

rear

gate

and

rear

gate

hinge

shims

4

To

install

rear

gate

reverse

the

order

of

removal

ALIGNMENT

The

rear

gate

should

be

adjusted

so

that

there

exists

an

equal

clearance

between

body

and

the

periphery

of

rear

gate

There

should

be

no

stepped

portion

at

any

points

I

To

adjust

the

height

of

rear

gate

add

or

remove

shims

at

rear

gate

hinge

Two

sizes

of

shim

are

available

in

thickness

1

6

mm

0

0630

in

and

0

8

rom

0

0315

in

rr

r

f

r

@

C

L

i

BF

6

1

Rear

gate

chain

2

Rear

gate

chain

bolt

3

Rear

body

4

Shim

S

Hook

handle

6

Reargate

Fig

BF

9

Rear

gate

2

To

adjust

rear

gate

in

the

left

and

right

directions

loosen

rear

gate

hinge

attaching

bolts

and

move

rear

gate

as

required

3

To

adjust

rear

gate

hook

loosen

two

attaching

bolts

and

move

rear

gate

hook

up

down

or

left

right

in

elon

gated

holes

as

required

GUARD

FRAME

Optional

REMOVAL

AND

INSTAUATION

The

guard

frame

is

furnished

as

an

optional

equipment

I

Remove

nine

guard

frame

at

taching

bolts

and

detach

guard

frame

2

To

install

optional

guard

frame

reverse

the

order

of

removal

s

SF673

Fig

BF

lO

Guard

frame