ignition DATSUN PICK-UP 1977 Workshop Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 173 of 537

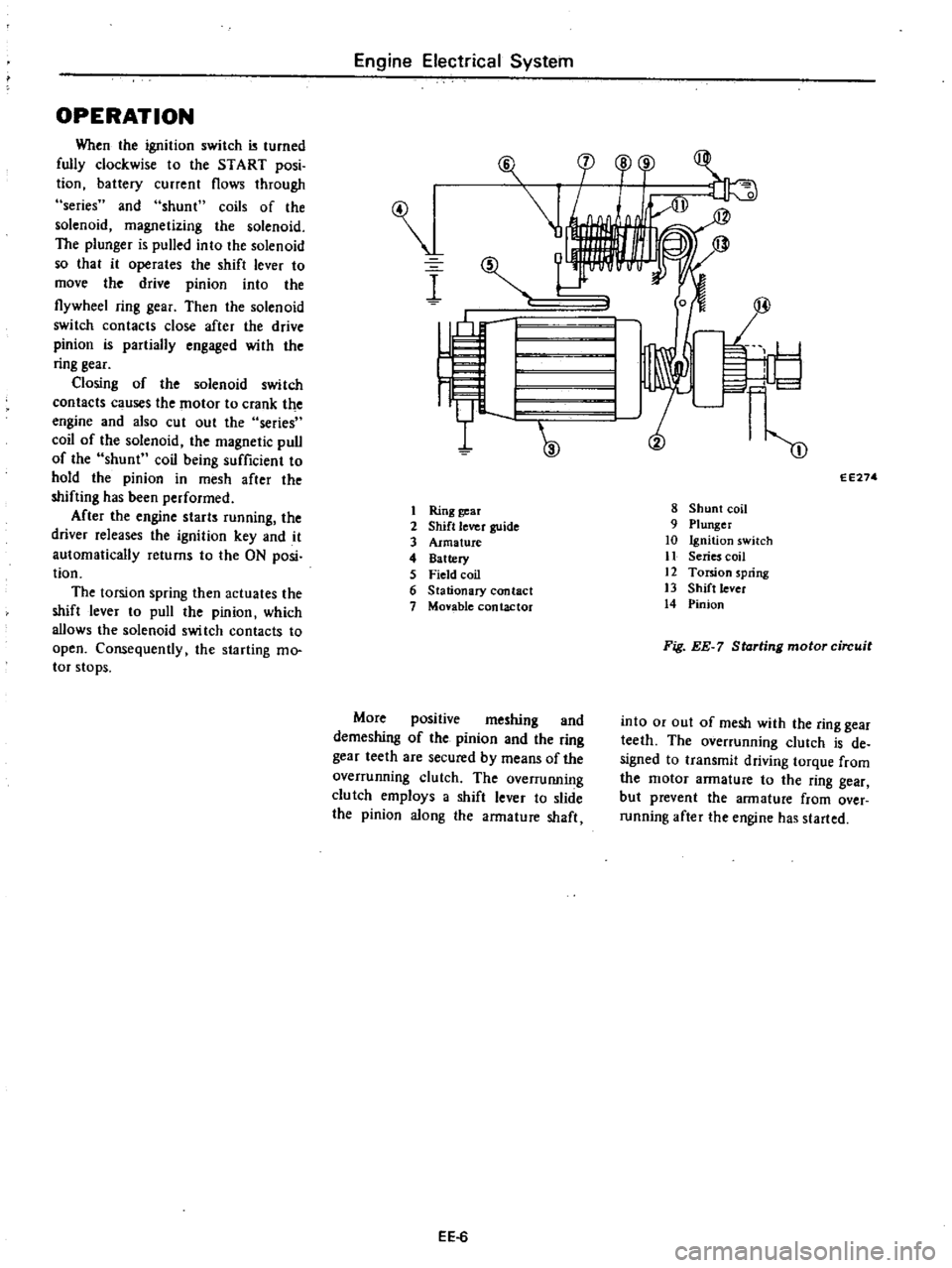

OPERATION

When

the

ignition

switch

turned

fully

clockwise

to

the

START

posi

tion

battery

current

flows

through

series

and

shunt

coils

of

the

solenoid

magnetizing

the

solenoid

The

plunger

is

pulled

into

the

solenoid

so

that

it

operates

the

shift

lever

to

move

the

drive

pinion

into

the

flywheel

ring

gear

Then

the

solenoid

switch

contacts

close

after

the

drive

pinion

is

partially

engaged

with

the

ring

gear

Closing

of

the

solenoid

switch

contacts

c

uses

the

motor

to

crank

the

engine

and

also

cut

out

the

series

coil

of

the

solenoid

the

magnetic

pull

of

the

shunt

coil

being

sufficient

to

hold

the

pinion

in

mesh

after

the

shifting

has

been

performed

After

the

engine

starts

running

the

driver

releases

the

ignition

key

and

it

automatically

returns

to

the

ON

posi

tion

The

torsion

spring

then

actuates

the

shift

lever

to

pull

the

pinion

which

allows

the

solenoid

swi

tch

contacts

to

open

Consequently

the

starting

mo

tor

stops

Engine

Electrical

System

I

I

Ring

gear

2

Shift

lever

guide

3

Armature

4

Battery

5

Field

coil

6

Stationary

contact

7

Monble

contactor

More

positive

meshing

and

demeshing

of

the

pinion

and

the

ring

gear

teeth

are

secured

by

means

of

the

overrunning

clutch

The

overruIUling

clutch

employs

a

shift

lever

to

slide

the

pinion

along

the

armature

shaft

EE

6

F

l

cp

o

r

1

I

I

W

m

EE274

8

Shunt

coil

9

Plunger

10

Ignition

switch

11

Series

coil

12

Torsion

spring

13

Shift

lever

14

Pinion

Fig

EE

7

Starting

motor

circuit

into

or

out

of

mesh

with

the

ring

gear

teeth

The

overrunning

clutch

is

de

signed

to

transmit

driving

torque

from

the

motor

armature

to

the

ring

gear

but

prevent

the

armature

from

over

running

after

the

engine

has

started

Page 179 of 537

Condition

Engine

Electrical

System

Probable

cause

Starting

motor

cranks

slowly

Dirty

or

worn

commutator

Armature

rubs

field

coil

Damaged

solenoid

switch

Starting

motor

operates

but

does

not

crank

engine

Worn

pinion

Locked

pinion

guide

Worn

ring

gear

Starting

motor

will

not

disengage

even

if

ignition

switch

is

turned

off

Damaged

solenoid

switch

Damaged

gear

teeth

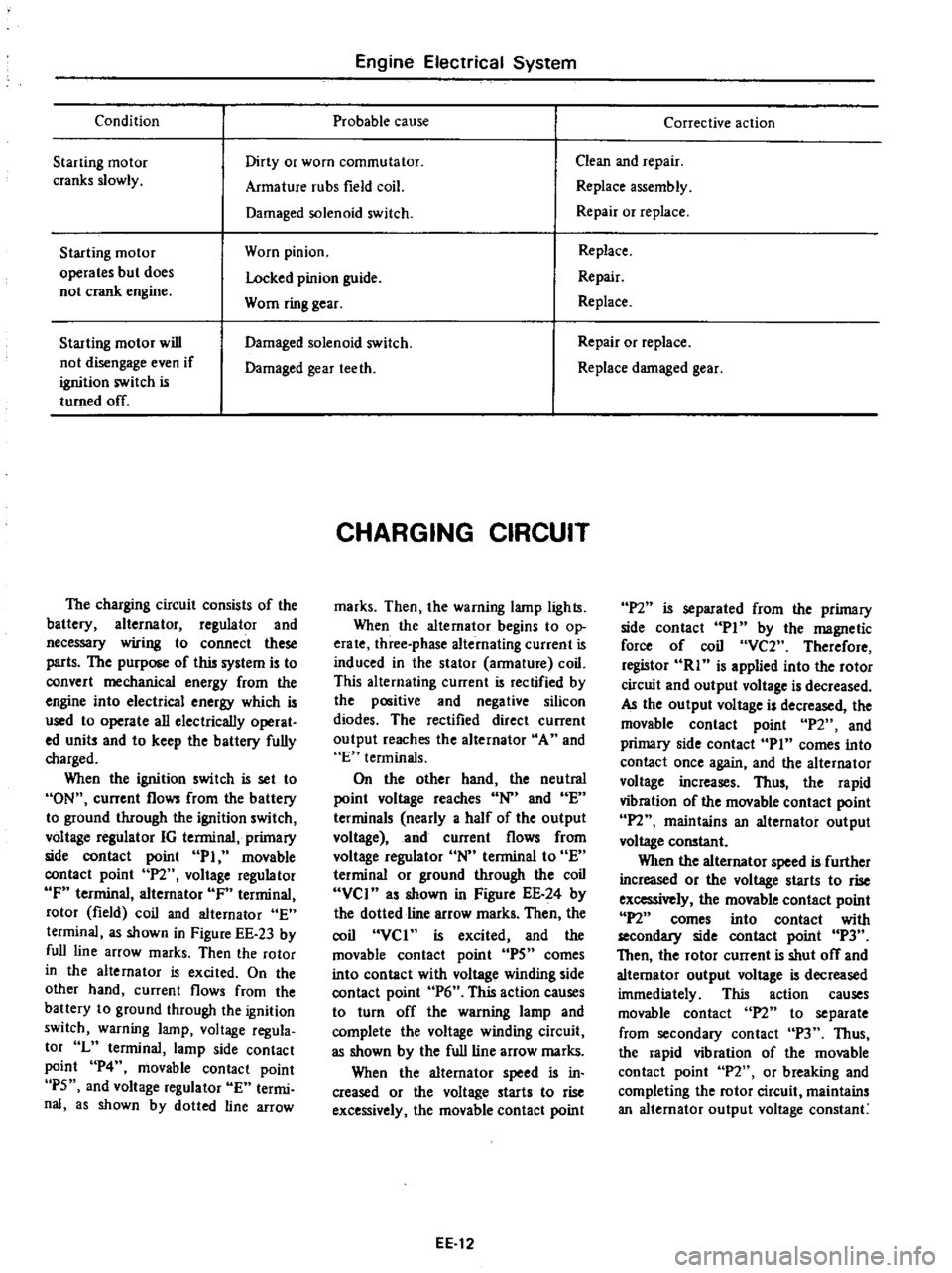

The

charging

circuit

consists

of

the

battery

alternator

regulator

and

necessary

wiring

to

connect

these

parts

The

purpose

of

this

system

is

to

convert

mechanical

energy

from

the

engine

into

electrical

energy

which

is

used

to

operate

all

electrically

operat

ed

units

and

to

keep

the

battery

fully

charged

When

the

ignition

switch

is

set

to

ON

current

flows

from

the

battery

to

ground

through

the

ignition

switch

voltage

regulator

IG

terminal

primary

side

contact

point

PI

movable

contact

point

P2

voltage

regulator

IF

terminal

alternator

IF

terminal

rotor

field

coil

and

alternator

E

terminal

as

shown

in

Figure

EE

23

by

full

line

arrow

marks

Then

the

rotor

in

the

alternator

is

excited

On

the

other

hand

current

flows

from

the

battery

to

ground

through

the

ignition

switch

warning

lamp

voltage

regula

tor

L

terminal

lamp

side

contact

point

P4

movable

contact

point

P5

and

voltage

regulator

E

termi

nal

as

shown

by

dotted

line

arrow

CHARGING

CIRCUIT

marks

Then

the

warning

lamp

lights

When

the

alternator

begins

to

op

erate

three

phase

alternating

current

is

induced

in

the

stator

armature

coil

This

alternating

current

is

rectified

by

the

positive

and

negative

silicon

diodes

The

rectified

direct

current

output

reaches

the

alternator

A

and

E

terminals

On

the

other

hand

the

neutral

point

voltage

reaches

N

and

E

terminals

nearly

a

half

of

the

output

voltage

and

current

flows

from

voltage

regulator

N

terminal

to

E

terminal

or

ground

through

the

coil

VCI

as

shown

in

Figure

EE

24

by

the

dotted

line

arrow

marks

Then

the

coil

VCI

is

excited

and

the

movable

contact

point

IPS

comes

into

contact

with

voltage

winding

side

contact

point

P6

This

action

causes

to

turn

off

the

warning

lamp

and

complete

the

voltage

winding

circuit

as

shown

by

the

full

line

arrow

marks

When

the

alternator

speed

is

in

creased

or

the

voltage

starts

to

rise

excessively

the

movable

contact

point

EE

12

Corrective

action

Clean

and

repair

Replace

assembly

Repair

or

replace

Replace

Repair

Replace

Repair

or

replace

Replace

damaged

gear

P2

is

separated

from

the

primary

side

contact

PI

by

the

magnetic

force

of

coil

VC2

Therefore

registor

RI

is

applied

into

the

rotor

circuit

and

output

voltage

is

decreased

AJ

the

output

voltage

is

decreased

the

movable

contact

point

P2

and

primary

side

contact

Pin

comes

into

contact

once

again

and

the

alternator

voltage

increases

Thus

the

rapid

vibration

of

the

movable

contact

point

IPl

maintains

an

alternator

output

voltage

constant

When

the

alternator

speed

is

further

increased

or

the

voltage

starts

to

rise

excessively

the

movable

contact

point

P2

comes

into

contact

with

secondllJ

side

contact

point

P3

Then

the

rotor

current

is

shut

off

and

alternator

output

voltage

is

decreased

immediately

This

action

causes

movable

contact

n

to

separate

from

secondary

contact

P3

Thus

the

rapid

vibration

of

the

movable

contact

point

P2

or

breaking

and

completing

the

rotor

circuit

maintains

an

alternator

output

voltage

constant

Page 181 of 537

Engine

Electrical

System

B

v

W

WR

WL

L2

VOLTAGE

REGULATOR

co

LW

I

P

B

r

FUSIBLE

LINK

m

I

WLI

LW

cJ

I

B

t

EARTH

POINT

m

WR

WR

CHARGE

g

00

WARNING

lAMP

00000

Equipped

with

cooler

I

I

I

I

TjT

m

CLB

W

WB

B

YWR

I

I

I

I

1

W

B

rn

ALTERNATOR

I

l

LW

BW

j

J

M

IG

I

W

BwtIl

IGNITION

SWITCH

COLOR

CODE

B

Black

OW

Black

with

white

stripe

W

White

WB

White

with

black

stripe

WR

White

with

red

stripe

WL

White

with

blue

stripe

LO

Blue

with

black

stripe

LW

Blue

with

white

stripe

Y

Yellow

lOA

C

o

0

0

0

o

0

0

FUSE

BLOCK

M

0

0

0

lOA

Ii

California

models

E

E492

Fig

EE

25

Circuit

diagram

of

charging

lfY

t

m

EE

14

Page 193 of 537

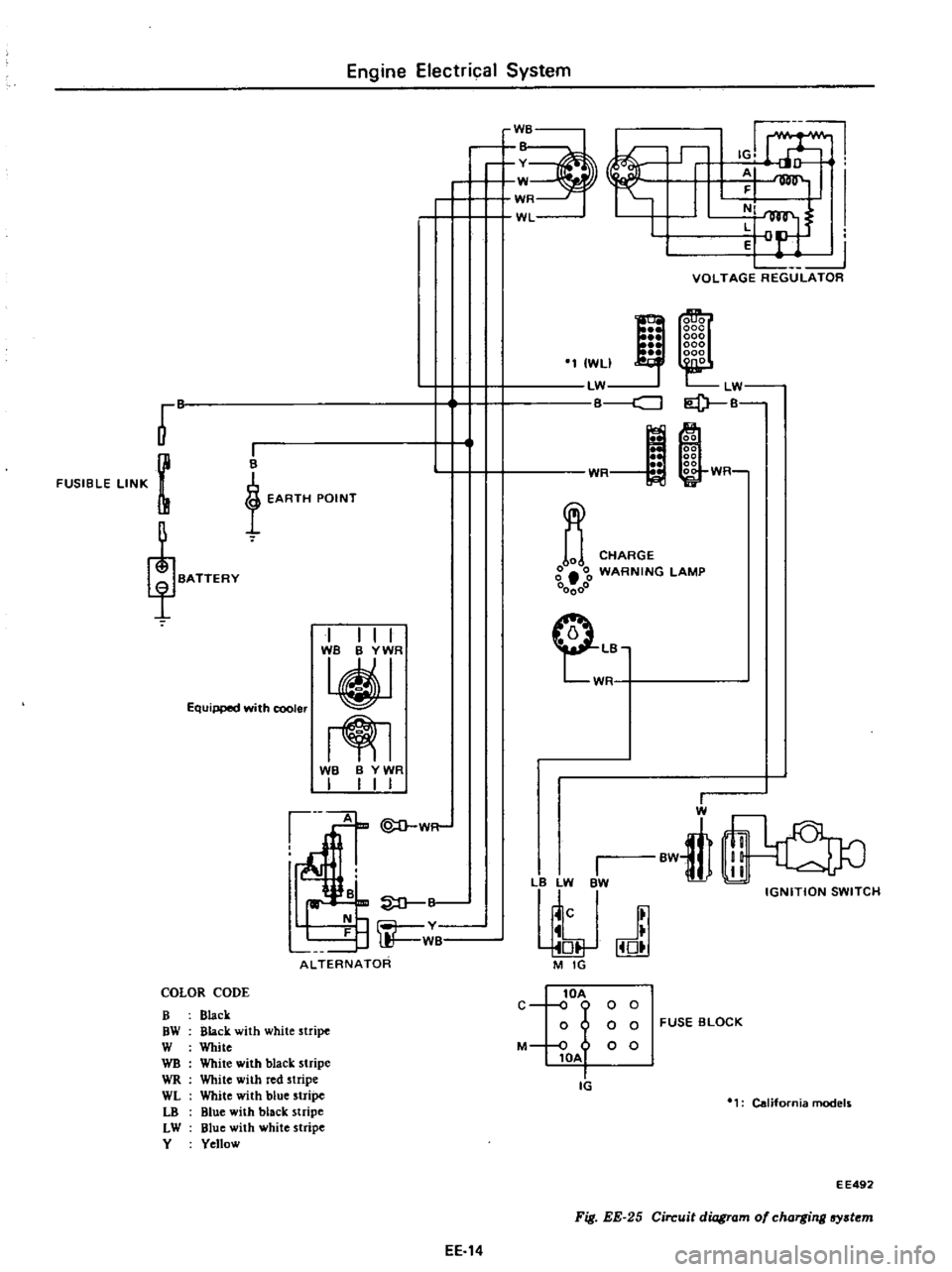

NON

CALIFORNIA

MODELS

Engine

Electrical

System

IGNITION

CIRCUIT

CONTENTS

EE

26

CALIFORNIA

MODELS

EE

2B

NON

CALIFORNIA

MODELS

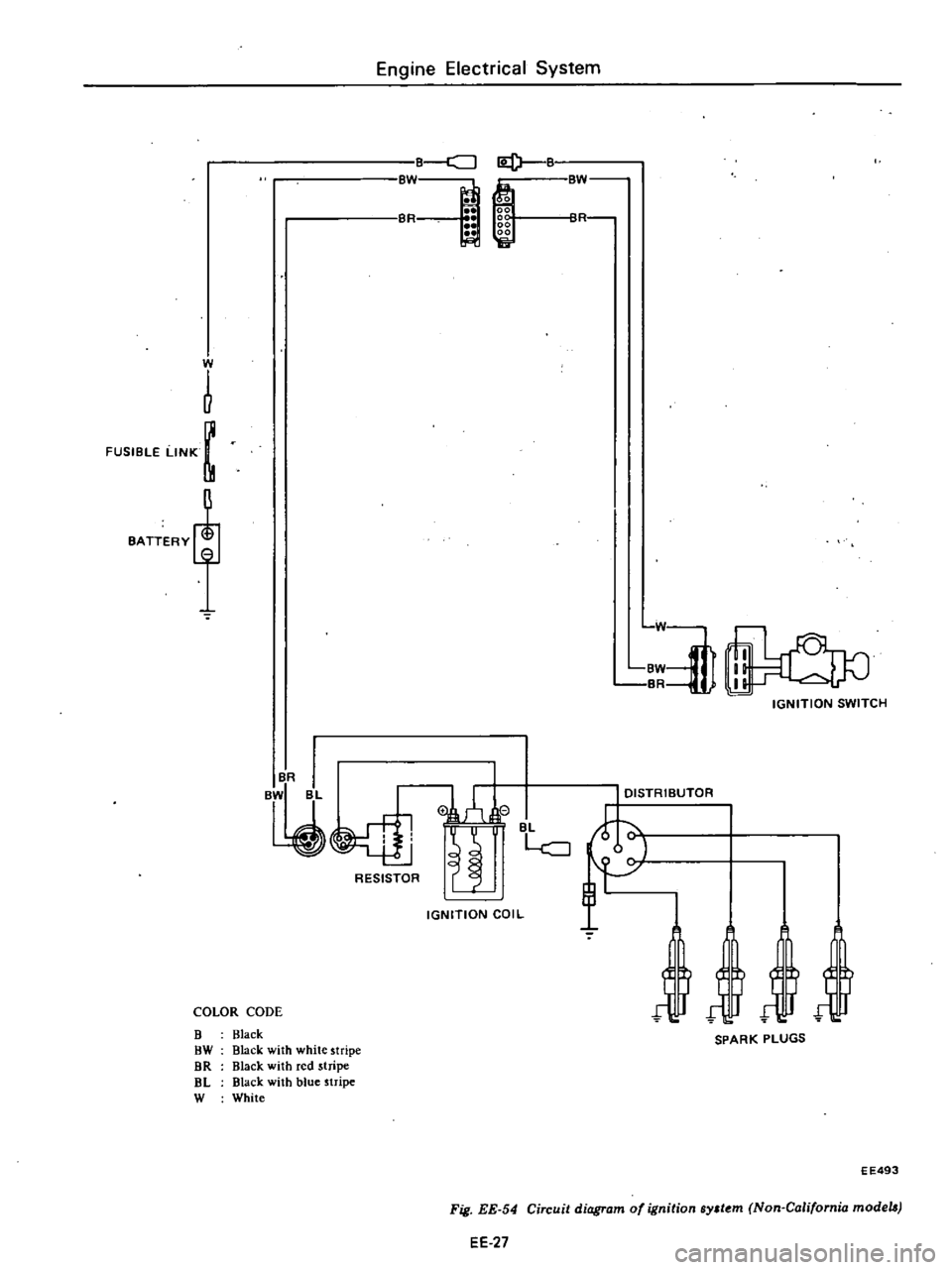

The

ignition

circuit

consists

of

the

ignition

switch

coil

distributor

wiring

spark

plugs

and

battery

The

circuit

is

equipped

with

a

resistor

During

cranking

electrical

current

bypasses

the

resistor

thereby

connecting

the

ignition

coil

directly

to

battery

This

provides

full

battery

voltage

available

at

coil

and

keeps

ignition

voltage

as

high

as

possible

The

low

voltage

current

is

supplied

by

the

battery

or

alternator

and

flows

through

the

primary

circuit

It

consists

of

the

ignition

switch

resistor

primary

winding

of

the

ignition

coil

distributor

contact

points

condenser

and

all

connecting

low

tension

wiring

The

high

voltage

current

is

pro

duced

by

the

ignition

coil

and

flows

through

the

secondary

circuit

result

ing

in

high

voltage

spark

between

the

electrodes

of

the

spark

plugs

in

engine

cylinders

This

circuit

contains

the

0

cl

Battery

Ignition

coil

secondary

winding

of

the

ignition

coil

high

tension

wiring

distributor

rotor

and

cap

When

the

ignition

switch

is

turned

on

and

the

distributor

contact

points

are

closed

the

primary

current

flows

through

the

primary

winding

of

the

coil

and

through

the

contact

points

to

ground

When

the

contact

points

are

opened

by

the

revolving

distributor

earn

the

magnetic

field

built

up

in

the

primary

winding

of

the

coil

moves

through

the

secondary

winding

of

the

coil

inducing

high

voltage

The

high

voltage

is

produced

every

time

the

contact

points

open

The

high

voltage

current

flows

through

the

high

tension

wire

to

the

distributor

cap

Then

the

rotor

distributes

the

current

to

one

of

the

spark

plug

terminals

in

the

distributor

Re5istor

To

starter

Secondary

winding

Cap

Breaker

point

f

Distributor

EE

26

cap

Then

the

spark

obtains

while

the

high

voltage

current

jumps

the

gap

between

the

insulated

electrode

and

the

ground

side

electrode

of

the

spark

plug

This

process

is

repeated

for

each

power

stroke

of

the

engine

The

distributor

contact

point

and

spark

plugs

should

be

inspected

clean

ed

and

regapped

at

tune

up

They

should

also

be

replaced

periodically

as

specified

in

the

Maintenance

Sched

ule

In

addition

apply

grease

NLGl

consistency

No

I

containing

MoS2

or

equivalent

to

distributor

shaft

and

grease

MIL

G

l0924B

containing

MoS2

or

equivalent

to

cam

as

reo

quired

The

remainder

of

the

ignition

component

parts

should

be

inspected

for

only

their

operation

tightness

of

electrical

terminals

and

wiring

con

dition

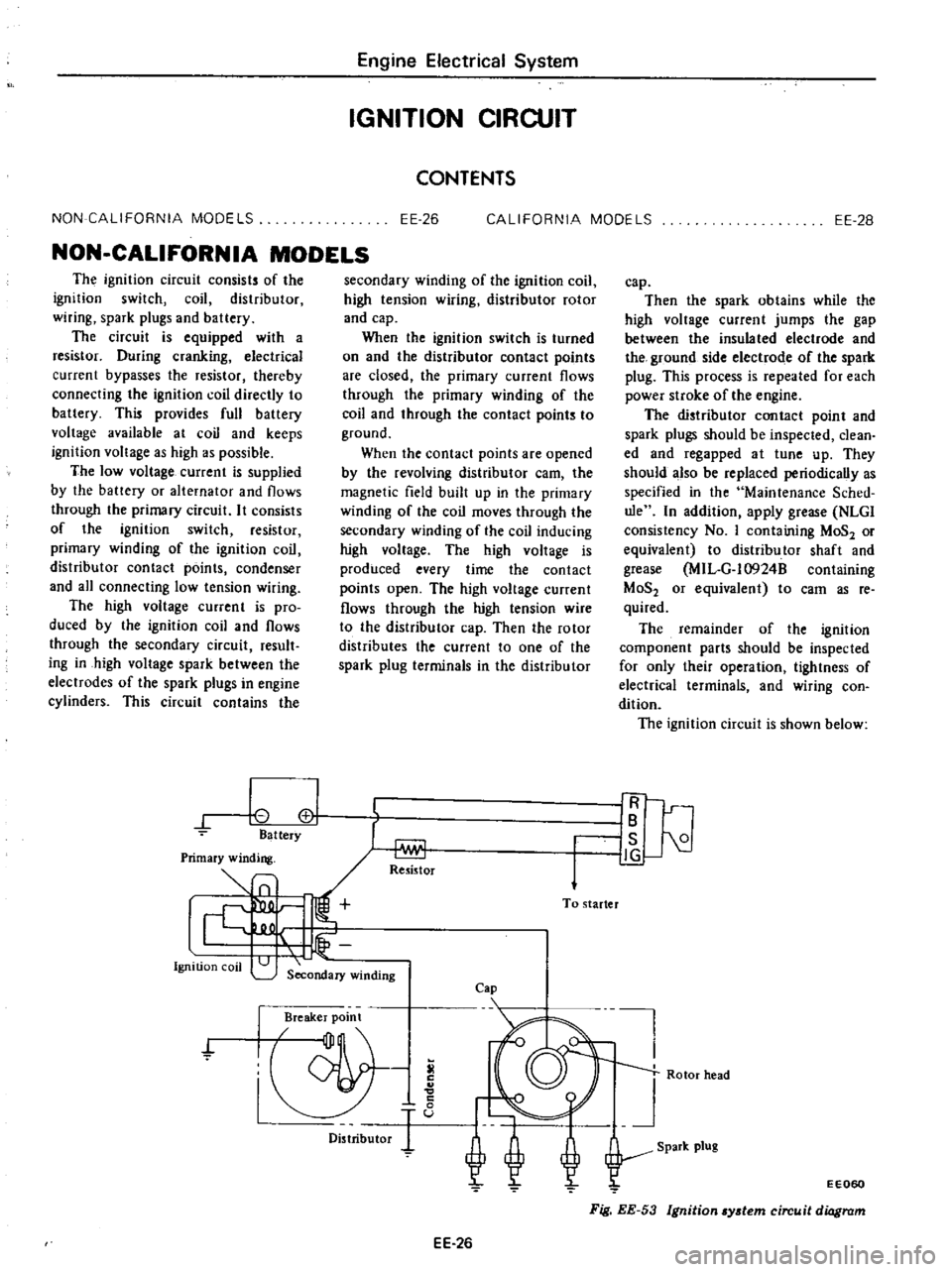

The

ignition

circuit

is

shown

below

IR

IB

I

is

21

J

g

Rotor

head

EE060

Fig

EE

53

Ignition

ydem

circuit

diagram

Page 194 of 537

FUSIBLE

LtNK

m

Engine

Electrical

System

E

CJI2t

Bf

o

00

00

fOl

R

BL

I

ti

L

oj

L

C

J

RESISTOR

IGNITION

COIL

COLOR

CODE

B

Black

OW

Black

with

white

stripe

DR

Black

with

red

stripe

aL

Black

with

blue

stripe

W

White

W

R

Wj

BW

BR

IGNITION

SWtTCH

DISTRtBUTOR

jjj

SPARK

PLUGS

EE493

EE

27

Fig

EE

54

Circuit

diagram

of

ignition

ByJt

m

Non

California

models

Page 195 of 537

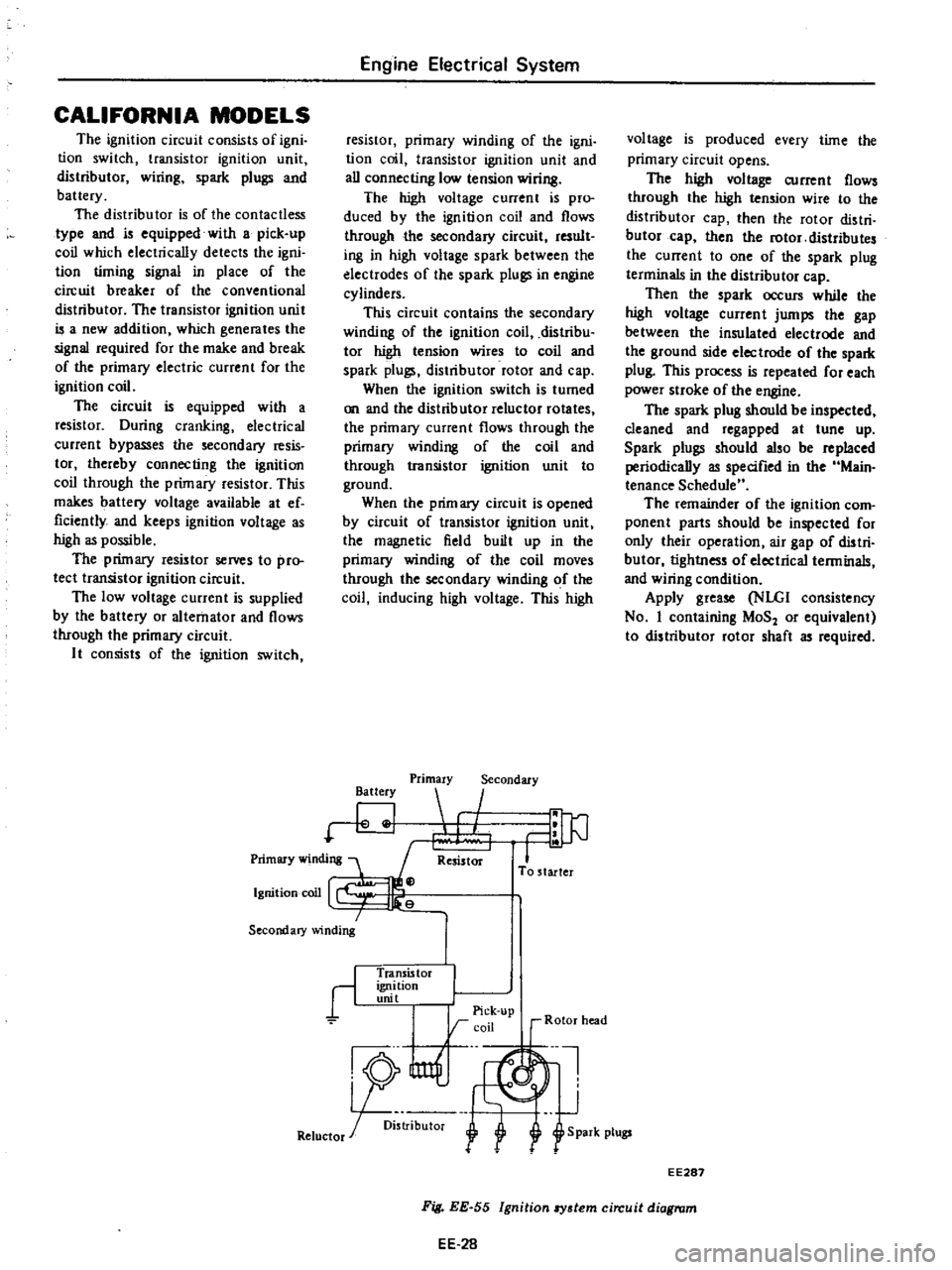

Primary

winding

1

Ignition

coo

I

Secondary

winding

CALIFORNIA

MODELS

The

ignition

circuit

consists

of

igni

tion

switch

transistor

ignition

unit

distributor

wiring

spark

plugs

and

battery

The

distributor

is

of

the

contactless

type

and

is

equipped

with

a

pick

up

coil

which

electrically

detects

the

igni

tion

timing

signal

in

place

of

the

circuit

breaker

of

the

conventional

distributor

The

transistor

ignition

unit

is

a

new

addition

which

generates

the

signal

required

for

the

make

and

break

of

the

primary

electric

current

for

the

ignition

coil

The

circuit

is

equipped

with

a

resistor

During

cranking

electrical

current

bypasses

the

secondary

resis

tor

thereby

connecting

the

ignition

coil

through

the

primary

resistor

This

makes

battery

voltage

available

at

ef

ficiently

and

keeps

ignition

voltage

as

high

as

possible

The

primary

resistor

selVeS

to

pro

tect

transistor

ignition

circuit

The

low

voltage

current

is

supplied

by

the

battery

or

alternator

and

flows

through

the

primary

circuit

It

consists

of

the

ignition

switch

Engine

Electrical

System

resistor

primary

winding

of

the

igni

tion

coil

transistor

ignition

unit

and

all

connecting

low

tension

wiring

The

high

voltage

current

is

pro

duced

by

the

ignition

coil

and

flows

through

the

secondary

circuit

result

ing

in

high

voltage

spark

between

the

electrodes

of

the

spark

plugs

in

engine

cylinders

This

circuit

contains

the

secondary

winding

of

the

ignition

coil

distribu

tor

high

tension

wires

to

coil

and

spark

plugs

distributor

rotor

and

cap

When

the

ignition

switch

is

turned

on

and

the

distributor

reluctor

rotates

the

primary

current

flows

through

the

primary

winding

of

the

coil

and

through

transistor

ignition

unit

to

ground

When

the

prim

ary

circuit

is

opened

by

circuit

of

transistor

ignition

unit

the

magnetic

field

built

up

in

the

primary

winding

of

the

coil

moves

through

the

secondary

winding

of

the

coil

inducing

high

voltage

This

high

Battery

Primary

Secondary

I

Resistor

To

starter

r

Transis

tor

ignition

unit

I

I

Pick

up

rcoil

r

Rotor

head

nl

J

R5

U1f

1

Retuctor

r

oi

l

f

S

park

plugs

voltage

is

produced

every

time

the

primary

circuit

opens

The

high

voltage

current

flows

through

the

high

tension

wire

to

the

distributor

cap

then

the

rotor

distri

butor

cap

then

the

rotor

distributes

the

current

to

one

of

the

spark

plug

terminals

in

the

distributor

cap

Then

the

spark

occurs

while

the

high

voltage

current

jumps

the

gap

between

the

insulated

electrode

and

the

ground

side

electrode

of

the

spark

plug

This

process

is

repeated

for

each

power

stroke

of

the

engine

The

spark

plug

should

be

inspected

cleaned

and

regapped

at

tune

up

Spark

plugs

should

also

be

replaced

periodically

as

specified

in

the

Main

tenance

Schedule

The

remainder

of

the

ignition

com

ponent

parts

should

be

inspected

for

only

their

operation

air

gap

of

distri

butor

tightness

of

electrical

terminals

and

wiring

condition

Apply

grease

NLGI

consistency

No

I

containing

MoS

or

equivalent

to

distributor

rotor

shaft

as

required

EE287

EE

28

Fig

EE

55

Ignition

8Y3tem

circuit

diagram

Page 196 of 537

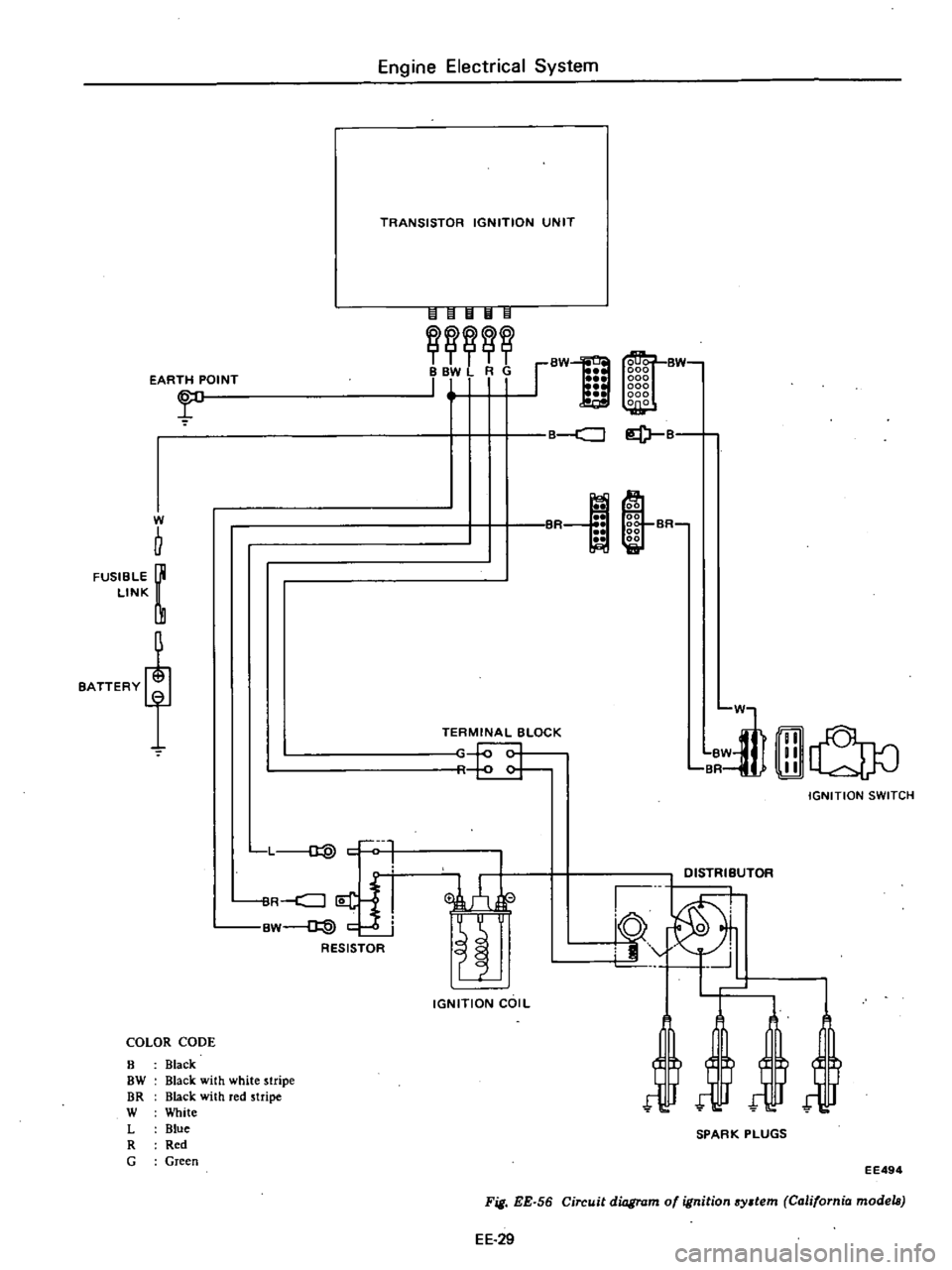

EARTH

POINT

r

W

b

FUSIBLE

LINK

BATTERY

L

d

l

ilR

j

i

BW

@

c

RESISTOR

COLOR

CODE

8

Black

OW

Black

with

white

stripe

DR

Black

with

red

stripe

W

White

L

Blue

R

Red

G

Green

Engine

Electrical

System

TRANSISTOR

IGNITION

UNIT

IHIIl

II

II

BW

BBV

RG

111

I

I

TERMINAL

BLOCK

r

c

IGNITION

COIL

BW

B

ml

BR

lliJ

LldJ0

IGNITION

SWITCH

EE

29

Fig

EE

56

Circuit

diagram

of

ignition

system

California

models

EE494

a

B

lof1

@

00

00

00

SR

00

00

Et

liiI

in

D1STRliUTOR

10

0

i9

J

SPARK

PLUGS

Page 199 of 537

DISASSEMBLY

To

disassemble

follow

the

below

proccd

ure

I

Take

off

cap

and

disconnect

rotor

head

2

Remove

vacuum

controller

EE291

Fig

EE

60

Removing

vacuum

controller

3

Remove

contact

set

Refer

to

Page

EE

31

when

contact

set

i

removed

EE323

Fig

EE

61

Removing

contact

tel

EE324

Fig

EE

62

Removing

breaker

plate

Engine

Electrical

System

4

When

breaker

plate

is

removed

be

careful

not

to

lose

steel

balls

between

breaker

spring

and

breaker

plate

5

Pul

roll

pin

out

and

siconnect

collar

to

remove

the

entire

rotating

parts

EE325

Fig

EE

63

Removing

roll

pin

EE326

Fig

EE

64

Removil1l

rotation

paTta

6

Remove

packing

from

the

top

of

cam

assembly

and

unscrew

earn

astern

bly

setscrew

Put

match

mark

across

earn

and

shaft

so

that

original

combi

nation

can

be

restored

at

assembly

EE

32

EE075

Fig

EE

65

Removing

cam

7

When

governor

weight

and

spring

are

disconnected

be

careful

not

to

stretch

or

deform

governor

spring

After

disassembling

apply

grease

to

governor

weights

ASSEMBLY

To

assemble

reverse

the

order

of

disassembly

Carefully

observe

the

fol

lowing

instructions

Align

match

marl

s

so

that

parts

are

assembled

to

their

original

posi

tions

2

Apply

grease

to

the

top

of

cam

assembly

as

required

3

Check

the

operation

of

governor

before

installing

distributor

on

engine

4

Adjust

ignition

timing

afteT

dis

tributor

is

installed

on

engine

Page 200 of 537

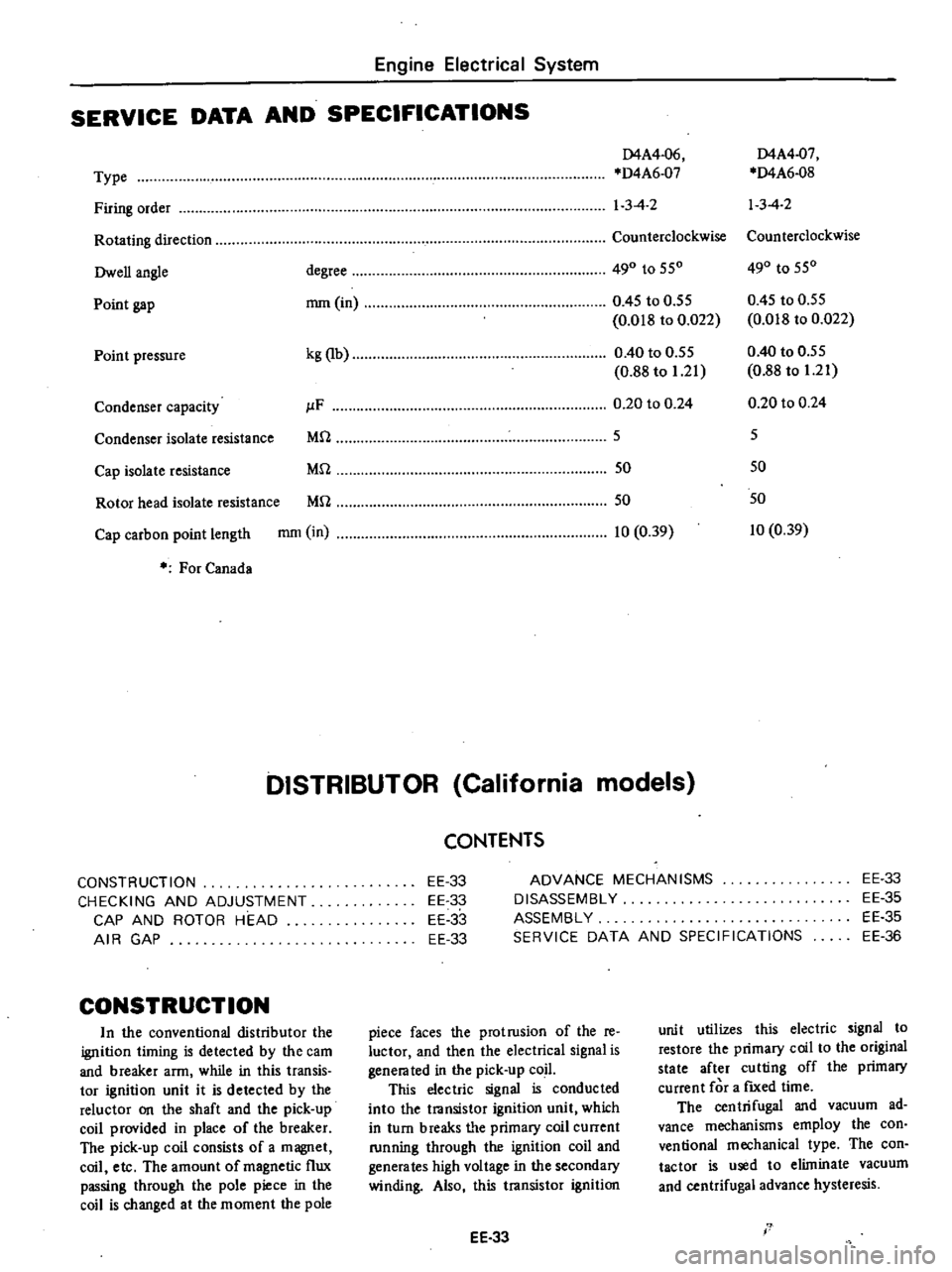

Engine

Electrical

System

SERVICE

DATA

AND

SPECIFICATIONS

D4A4

06

D4A4

07

Type

D4A6

07

D4A6

08

Firing

order

1

3

4

2

13

4

2

Rotating

direction

Counterclockwise

Counterclockwise

Owen

angle

degree

490

to

550

490

to

550

Point

gap

mm

in

0

45

to

0

55

0

45

to

0

55

0

018

to

0

022

0

018

to

0

022

Point

pressure

kg

lb

0

40

to

0

55

0

40

to

0

55

0

88

to

1

21

0

88

to

1

21

Condenser

capacity

JlF

0

20

to

0

24

0

20

to

0

24

Condenser

isolate

resistance

Mrl

5

5

Cap

isolate

resistance

Mrl

50

50

Rotor

head

isolate

resistance

Mrl

50

50

Cap

carbon

point

length

mm

in

10

0

39

10

0

39

For

Canada

DISTRIBUTOR

California

models

CONSTRUCTION

CHECKING

AND

ADJUSTMENT

CAP

AND

ROTOR

HEAD

AIR

GAP

CONSTRUCTION

In

the

conventional

distributor

the

ignition

liming

is

detected

by

the

cam

and

breaker

arm

while

in

this

transis

tor

ignition

unit

it

is

detected

by

the

reluctor

on

the

shaft

and

the

pick

up

coil

provided

in

place

of

the

breaker

The

pick

up

coil

consists

of

a

magnet

coil

etc

The

amount

of

magnetic

flux

passing

through

the

pole

piece

in

the

coil

is

changed

at

the

moment

the

pole

CONTENTS

EE

33

EE

33

EE

33

EE

33

ADVANCE

MECHANISMS

DISASSEMBLY

ASSEMBLY

SERVICE

DATA

AND

SPECIFICATIONS

EE

33

EE

35

EE

35

EE

36

piece

faces

the

protrusion

of

the

re

luctor

and

then

the

electrical

signal

is

genera

ted

in

the

pick

up

coil

This

electric

signal

is

conducted

into

the

transistor

ignition

unit

which

in

turn

breaks

tI

e

primary

coil

current

running

through

the

ignition

coil

and

generates

high

voltage

in

the

secondary

winding

Also

this

transistor

ignition

EE

33

unit

utilizes

this

electric

signal

to

restore

the

primary

coil

to

the

original

state

after

cutting

off

the

primary

current

for

a

fIXed

time

The

centrifugal

and

vacuum

ad

vance

mechanisms

employ

the

con

ventional

mechanical

type

The

con

tactor

is

used

to

eliminate

vacuum

and

centrifugal

advance

hysteresis

I

Page 203 of 537

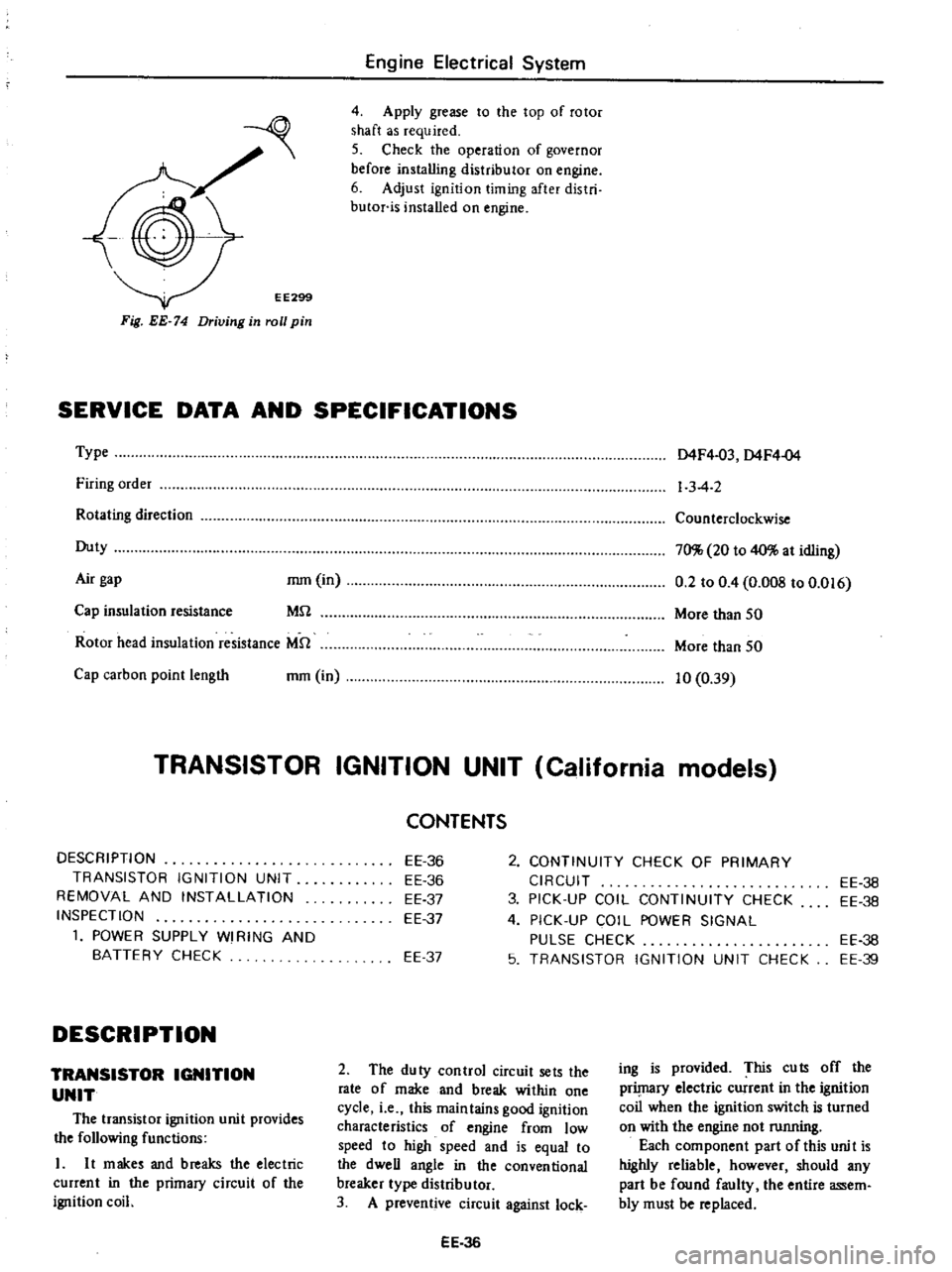

EE299

Fig

EE

74

Driving

in

roll

pin

Engine

Electrical

System

4

Apply

grease

to

the

top

of

rotor

shaft

as

required

5

Check

the

operation

of

governor

before

installing

distributor

on

engine

6

Adjust

ignition

timing

after

distri

butor

is

installed

on

engine

SERVICE

DATA

AND

SPECIFICATIONS

Type

Firing

order

Rotating

direction

Duty

Air

gap

mm

in

MU

Cap

insulation

resistance

Rotor

head

insulation

resistance

MU

Cap

carbon

point

length

mm

in

D4F4

03

D4F4

04

1

3

4

2

Counterclockwise

70

20

to

40

at

idling

0

2

to

0

4

O

OOS

to

0

016

More

than

50

More

than

50

10

0

39

TRANSISTOR

IGNITION

UNIT

California

models

DESCRIPTION

TRANSISTOR

IGNITION

UNIT

REMOVAL

AND

INSTALLATION

INSPECTION

1

POWER

SUPPLY

WI

RING

AND

BATTERY

CHECK

DESCRIPTION

TRANSISTOR

IGNITION

UNIT

The

transistor

ignition

unit

provides

the

following

functions

L

It

makes

and

breaks

the

electric

current

in

the

primacy

circuit

of

the

ignition

coil

2

CONTINUITY

CHECK

OF

PRIMARY

CIRCUIT

3

PICK

UP

COIL

CONTINUITY

CHECK

4

PICK

UP

COIL

POWER

SIGNAL

PULSE

CHECK

5

TRANSISTOR

IGNITION

UNIT

CHECK

CONTENTS

EE

36

EE

36

EE

37

EE

37

EE

37

2

The

duty

control

circuit

sets

the

rate

of

make

and

break

within

one

cycle

i

e

this

maintains

good

ignition

characteristics

of

engine

from

low

speed

to

high

speed

and

is

equal

to

the

dweU

angle

in

the

conventional

breaker

type

distributor

3

A

preventive

circuit

against

lock

EE

36

EE

36

EE

38

EE

38

EE

39

ing

is

provided

This

cuts

off

the

prilnaCY

electric

current

in

the

ignition

coil

when

the

ignition

switch

is

turned

on

with

the

engine

not

running

Each

component

part

of

this

unit

is

highly

reliable

however

should

any

part

be

found

faulty

the

entire

assem

bly

must

be

replaced