battery DATSUN PICK-UP 1977 Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 474 of 537

HEATER

UNIT

ASSEMBLY

Removal

L

Disconnect

battery

ground

cable

2

Drain

engine

coolant

3

Remove

defroster

hoses

4

Remove

three

cable

retaining

clips

and

disconnect

control

cables

from

valves

and

water

cock

5

Disconnect

two

fan

motor

lead

wires

from

each

connector

6

Disconnect

two

resistor

lead

wires

from

each

connector

7

Disconnect

water

hoses

from

core

and

water

cock

8

Remove

three

heater

housing

mounting

bolts

and

dismount

heater

unit

from

vehicle

Installation

1

Position

heater

unit

under

instru

ment

panel

and

install

three

heater

unit

securing

bolts

2

Install

water

hoses

3

Position

heater

control

cables

to

room

valve

air

intake

valve

and

water

cock

4

Adjust

control

cable

length

for

proper

operation

as

outlined

in

Adjust

ment

5

Connect

fan

motor

wires

and

resistance

wires

to

each

connector

plug

6

Install

defroster

hoses

7

Connect

battery

ground

cable

8

Fill

cooling

systeIT

9

Run

engine

at

2

000

rpm

with

AIR

lever

in

the

HOT

position

Make

sure

that

engine

coolant

is

fIlled

up

to

correct

level

HEATER

CORE

Removal

and

installation

L

Drain

engine

coolant

2

Remove

defroster

hoses

3

Disconnect

water

hoses

from

inlet

and

outlet

pipes

of

heater

core

4

Remove

four

clips

and

front

cover

Body

Electrical

System

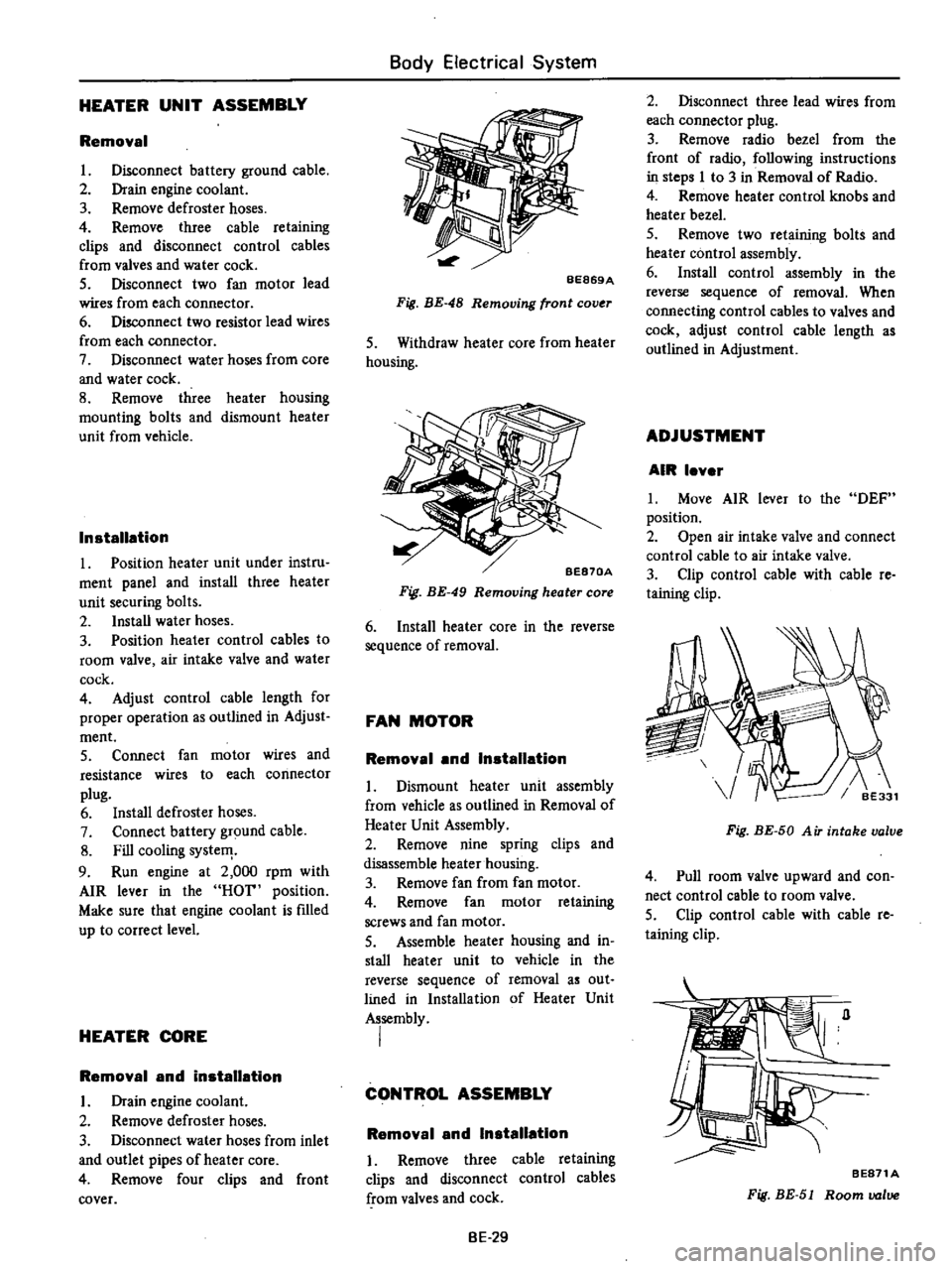

BE869A

Fig

BE

48

Removing

front

cov

r

S

Withdraw

heater

core

from

heater

housing

BE870A

Fig

BE

49

Removing

heater

core

6

Install

heater

core

in

the

reverse

sequence

of

removal

FAN

MOTOR

Removal

and

Installation

L

Dismount

heater

unit

assembly

from

vehicle

as

outlined

in

Removal

of

Heater

Unit

Assembly

2

Remove

nine

spring

clips

and

disassemble

heater

housing

3

Remove

fan

from

fan

motor

4

Remove

fan

motor

retaining

screws

and

fan

motor

S

Assemble

heater

housing

and

in

stall

heater

unit

to

vehicle

in

the

reverse

sequence

of

removal

as

out

lined

in

Installation

of

Heater

Unit

Assembly

I

CONTROL

ASSEMBLY

Removal

and

Installation

I

Remove

three

cable

retaining

clips

and

disconnect

control

cables

from

valves

and

cock

BE

29

2

Disconnect

three

lead

wires

from

each

connector

plug

3

Remove

radio

bezel

from

the

front

of

radio

following

instructions

in

steps

I

to

3

in

Removal

of

Radio

4

Remove

heater

control

knobs

and

heater

bezel

5

Remove

two

retaining

bolts

and

heater

control

assembly

6

Install

control

assembly

in

the

reverse

sequence

of

removal

When

connecting

control

cables

to

valves

and

cock

adjust

control

cable

length

as

outlined

in

Adjustment

ADJUSTMENT

AIR

lever

L

Move

AIR

lever

to

the

DEF

position

2

Open

air

intake

valve

and

connect

control

cable

to

air

intake

valve

3

Clip

control

cable

with

cable

re

taining

clip

Fig

BE

50

A

iT

intake

valve

4

Pull

room

valve

upward

and

con

nect

control

cable

to

room

valve

5

Clip

control

cable

with

cable

re

taining

clip

BE871A

Fig

BE

51

Room

valve

Page 475 of 537

TEMP

lever

1

Move

TEMP

lever

to

the

OFF

position

2

Connect

control

cable

to

the

lever

of

water

ock

when

water

cock

lever

is

pulled

forward

fully

closed

3

Install

control

cable

on

water

cock

bracket

with

cable

retaining

clip

SPECIFICATIONS

Item

FAN

MOTOR

Rated

power

consumption

Revolution

rpm

Fan

dia

mm

in

TACHOMETER

The

tachometer

is

optional

on

model

HL620

It

is

an

integral

part

of

the

ignition

system

It

counts

the

pulses

entering

the

ignition

coil

and

indicates

the

number

of

engine

revolu

tions

REPLACEMENT

I

Remove

battery

ground

cable

2

Remve

cluster

lid

following

instructions

iri

steps

I

to

4

of

Removal

in

Combination

Meter

Body

Electrical

System

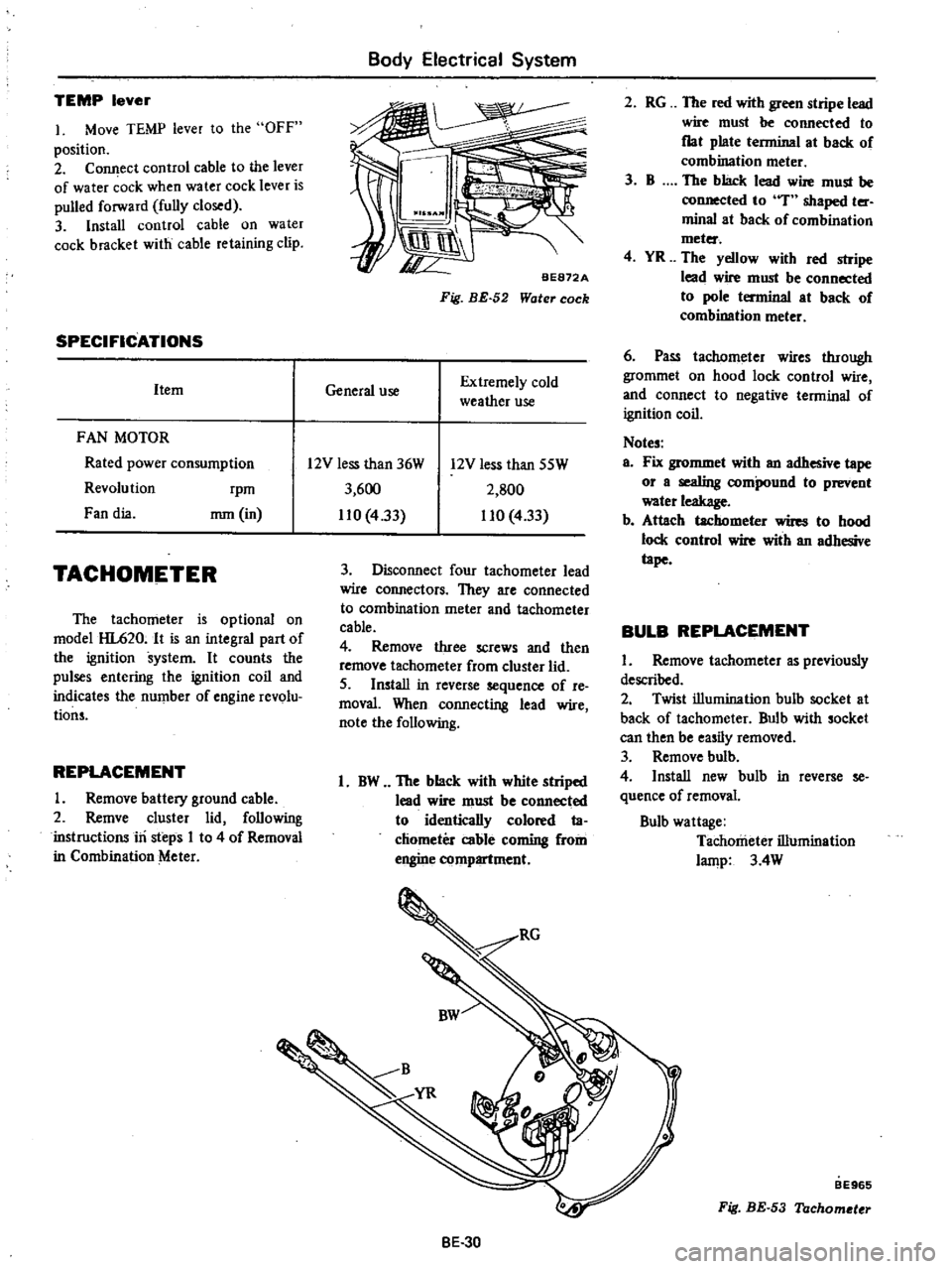

BE872A

Fig

BE

52

Water

cock

General

use

Extremely

cold

weather

use

2

RG

The

red

with

green

stripe

lead

wire

must

be

connected

to

flat

plate

terminal

at

back

of

combination

meter

3

B

The

black

lead

wire

must

be

connected

to

T

shaped

ter

minal

at

back

of

combination

meter

4

YR

The

yellow

with

red

stripe

lead

wire

must

be

connected

to

pole

terminal

at

back

of

combination

meter

6

Pass

tachllmeter

wires

through

grommet

on

hood

lock

control

wire

and

connect

to

negative

terminal

of

ignition

coil

Notes

a

Fix

grommet

with

an

adhesive

tape

or

a

sealing

compound

to

prevent

water

leakage

b

Attach

tachometer

wires

to

hood

lock

control

wire

with

an

adhesive

tape

BULB

REPLACEMENT

I

Remove

tachometer

as

previously

described

2

Twist

illumination

bulh

socket

at

back

of

tachometer

Bulb

with

socket

can

then

be

easily

removed

3

Remove

bulb

4

Install

new

bulb

in

reverse

se

quence

of

removal

Bulb

wattage

Tachometer

illumination

lamp

3

4W

12V

less

than

36W

3

600

110

433

12V

less

than

SSW

2

SOO

110

4

33

3

Disconnect

four

tachometer

lead

wire

connectors

They

are

connected

to

combination

meter

and

tachometer

cable

4

Remove

three

screws

and

then

remove

tachometer

from

cluster

lid

5

Install

in

reverse

sequence

of

re

moval

When

connecting

lead

wire

note

the

following

1

BW

The

black

with

white

striped

lead

wire

must

be

connected

to

identically

colored

ta

chometer

cable

coming

from

engine

compartment

BE

30

BE965

Fig

BE

53

Tachometer

Page 476 of 537

SEAT

BELT

WARNING

SYSTEM

DESCRIPTION

Except

Canada

When

the

ignition

switch

is

turned

to

the

ON

position

the

warning

lamp

comes

on

and

remains

on

for

4

to

8

seconds

The

warning

buzzer

sounds

for

4

to

8

seconds

intermittent

ly

if

the

driver

s

seat

belt

is

not

fastened

properly

The

seat

belt

warning

system

con

sists

of

a

driver

s

belt

switch

a

warning

buzzer

a

warning

lamp

a

timer

unit

and

an

ignition

switch

For

Canada

When

the

ignition

switch

is

turned

Body

Electrical

System

to

the

ON

position

the

warning

lamp

comes

on

and

the

warning

buz

zer

sounds

if

the

driver

s

seat

belt

is

not

fastened

properly

The

seat

belt

warning

system

con

sists

of

a

driver

s

belt

switch

a

warning

buzzer

a

warning

lamp

and

an

igni

tion

switch

REMOVAL

AND

INSTALLATION

Ignition

switch

Refer

to

page

BE

22

for

Removal

and

Installation

Timer

unit

Timer

unit

is

fIXed

on

a

reinforce

ment

behind

glove

box

BE688B

I

Disconnect

battery

ground

cable

2

Remove

glove

box

3

Disconnect

timer

unit

connector

4

Remove

two

screws

retaining

timer

unit

on

reinforcement

Timer

unit

can

then

be

taken

out

S

Installation

is

in

the

reverse

se

quence

of

removal

Warning

buzzer

Warning

buzzer

is

fIxed

on

a

re

inforcement

behind

glove

box

Refer

to

the

preceding

timer

unit

for

Removal

and

Installation

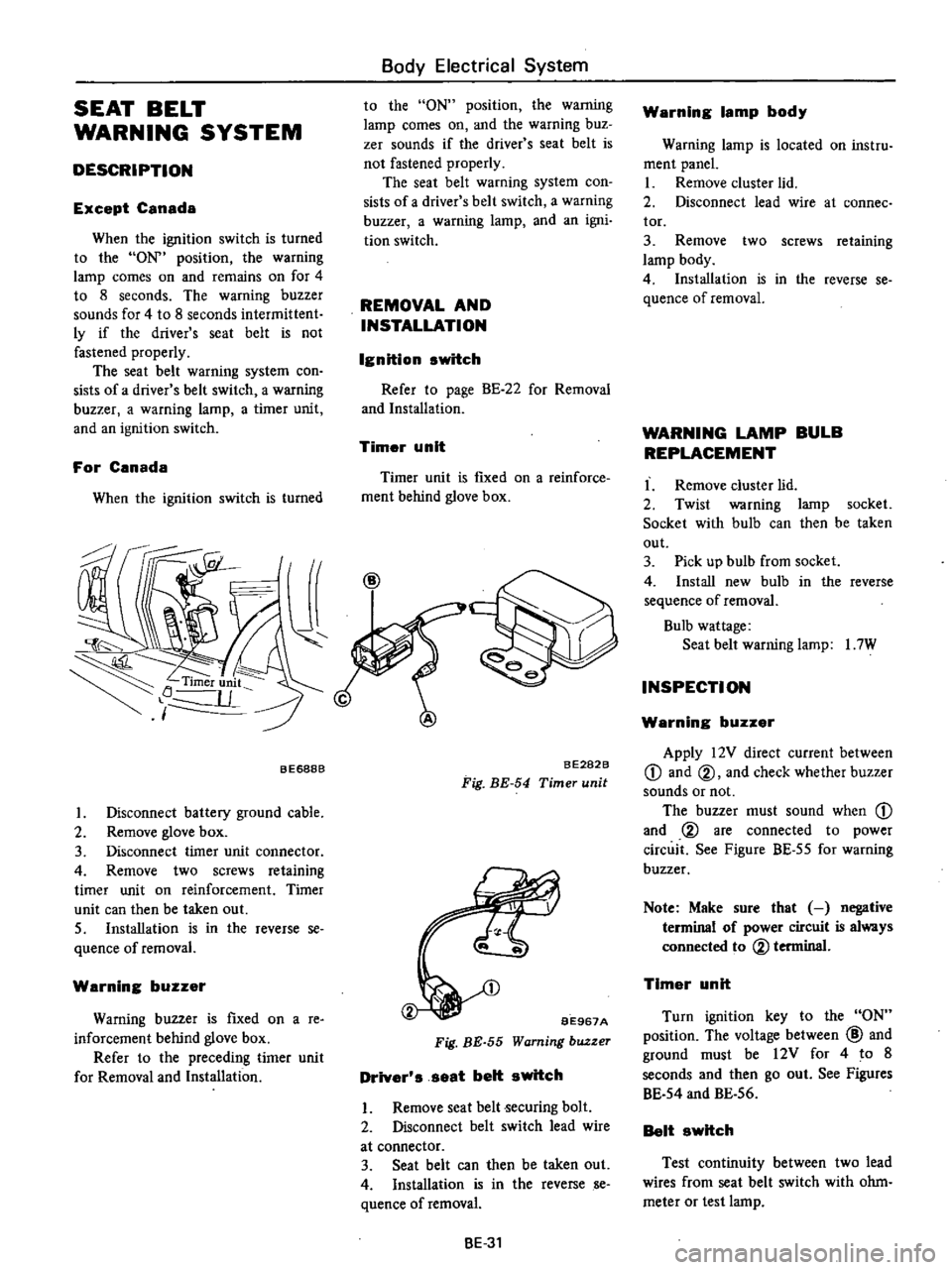

BE282B

Fig

BE

54

Timer

unit

BE967A

Fig

BE

55

Warning

buzzer

Driver

s

seat

belt

switch

I

Remove

seat

belt

ecuring

bolt

2

Disconnect

belt

switch

lead

wire

at

connector

3

Seat

belt

can

then

be

taken

out

4

Installation

is

in

the

reverse

se

quence

ofremoval

BE

31

Warning

lamp

body

Warning

lamp

is

located

on

instru

ment

panel

I

Remove

cluster

lid

2

Disconnect

lead

wire

at

connee

tor

3

Remove

two

screws

retaining

lamp

body

4

Installation

is

in

the

reverse

se

quence

of

removal

WARNING

LAMP

BULB

REPLACEMENT

I

Remove

cluster

lid

2

Twist

warning

lamp

socket

Socket

with

bulb

can

then

be

taken

out

3

Pick

up

bulb

from

socket

4

Install

new

bulb

in

the

reverse

sequence

of

removal

Bulb

wattage

Seat

belt

warning

lamp

I

7W

INSPECTION

Warning

buzzer

Apply

12V

direct

current

between

CD

and

@

and

check

whether

buzzer

sounds

or

not

The

buzzer

must

sound

when

CD

and

@

are

connected

to

power

circuit

See

Figure

BE

55

for

warning

buzzer

Note

Make

sure

that

negative

terminal

of

power

circuit

is

always

connected

to

@

terminal

Timer

unit

Turn

ignition

key

to

the

ON

position

The

voltage

between

@

and

ground

must

be

12V

for

4

to

8

seconds

and

then

go

out

See

Figures

BE

54

and

BE

56

Belt

switch

Test

continuity

between

two

lead

wires

from

seat

belt

switch

with

ohm

meter

or

test

lamp

Page 477 of 537

Body

Electrical

System

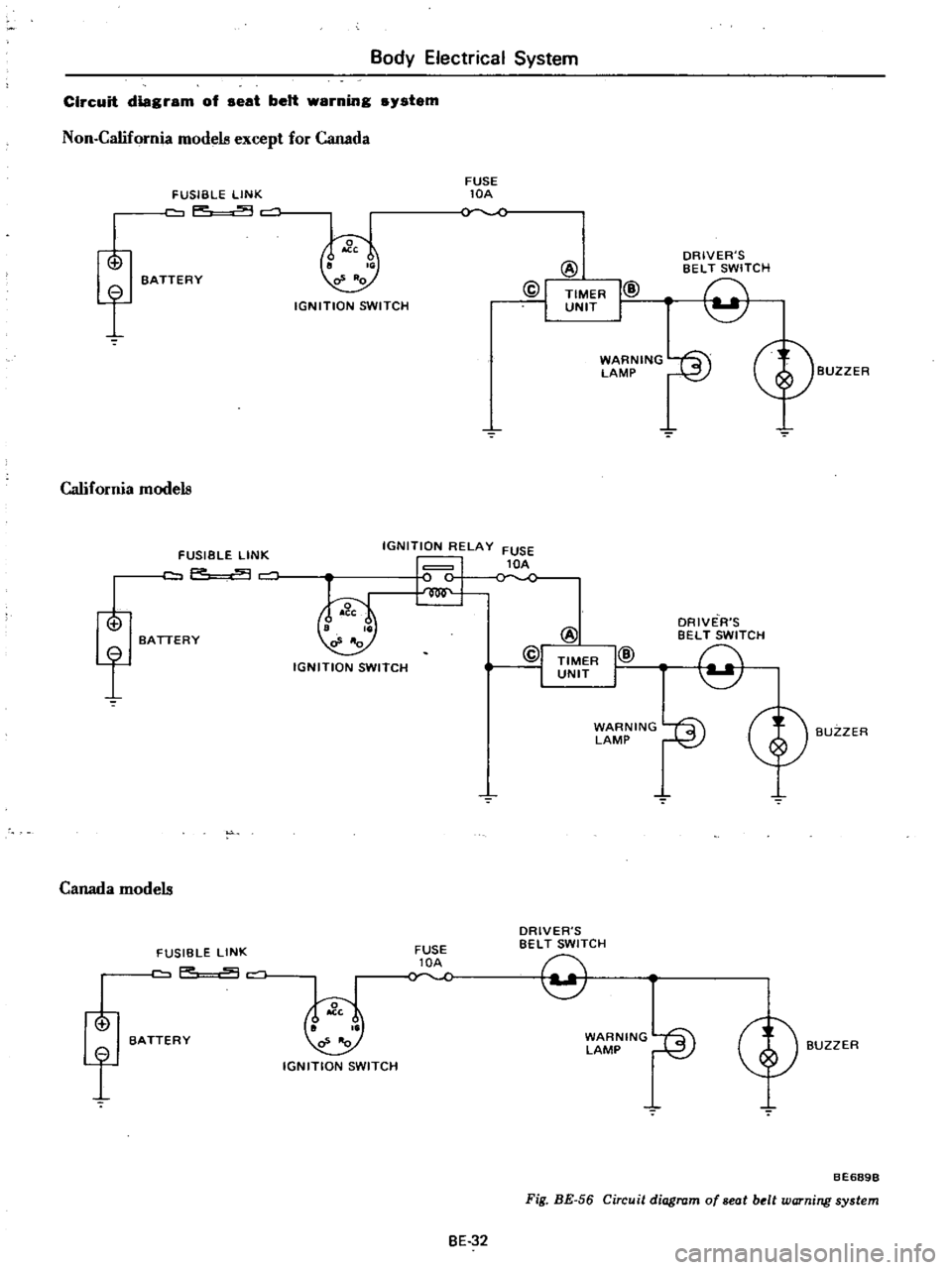

Circuit

diagram

of

seat

belt

warning

system

Non

California

modela

except

for

Canada

f

FUSIBLE

LINK

p

c

o

BATTERY

California

modela

f

Canada

modela

o

f

FUSIBLE

LINK

F

9

BATTERY

FUSIBLE

LINK

aP

c

BATTERY

IGNITION

SWITCH

FUSE

lOA

@

@I

TIMER

UNIT

I@

I

WARNING

fS

LAMP

l

2

IGNITION

RELAY

FUSE

1

lC

1

lOA

IGNITION

SWITCH

N

IGN

ITION

SWITCH

FUSE

lOA

BE

32

DRIVER

S

BELT

SWITCH

9

ORIVE

R

S

BELT

SWITCH

9

WARNING

r

i

LAMP

I

2

J

DRIVER

S

BELT

SWITCH

9

WARNING

fS

LAMP

I

2

J

Cf

BUZZER

BUZZER

BUZZER

BE689B

Fig

BE

56

Circuit

diagram

of

seat

belt

warning

system

Page 478 of 537

Body

Electrical

System

TROUBLE

DIAGNOSES

AND

CORRECTIONS

HORN

Condition

Horn

does

not

operate

Horn

sounds

continuously

Reduced

volume

and

or

tone

quality

Probable

cause

Discharged

battery

Measure

specific

gravity

of

electrolyte

Burnt

fuse

Faulty

horn

button

contact

Horn

sounds

when

horn

relay

terminal

s

is

grounded

Inoperative

horn

relay

Horn

sounds

when

B

and

H

horn

relay

tenninals

are

connected

with

a

test

lead

Damaged

horn

or

loose

horn

terminal

con

nection

Short

circuited

horn

button

and

or

horn

button

lead

wire

When

light

green

lead

wire

is

disconnected

from

horn

relay

terminal

s

horn

stops

to

sound

Inoperative

horn

relay

Loose

or

poor

connector

contact

Fuse

relay

horn

and

or

horn

button

Damaged

horn

BE

33

Corrective

action

Recharge

or

replace

battery

Correct

cause

and

replace

fuse

Repair

horn

button

Replace

horn

relay

Correct

horn

te

inal

onnection

or

replace

horn

Repair

horn

button

or

its

wiring

Replace

horn

relay

Repair

Replace

Page 481 of 537

CD

m

Cl

@

D

@

I

j

1

To

instrument

harness

IS

To

battery

30

To

check

connector

2

To

full

transistor

amplifier

16

To

fusible

link

3t

To

headlamp

L

U

type

2

California

models

only

17

To

engine

harness

No

2

32

To

sido

marker

lamp

L

B

3

To

hood

switch

18

To

alternator

33

To

front

combination

lamp

L

H

4

To

engine

compartment

lamp

1

9

To

front

combination

lamp

R

n

34

To

horn

Low

ll

l

S

To

washer

motor

20

To

headlamp

R

H

type

2

3S

To

horn

High

l

l

0

6

To

auto

choke

heater

relay

1

To

side

marker

lamp

R

n

36

To

B

C

D

D

cut

olenoid

California

models

7

To

detector

dri

e

counter

22

To

headlamp

R

B

type

1

only

Non

Califunia

model

except

for

Canada

23

To

ground

37

To

block

tcrminal

distributor

California

8

To

ignition

relay

California

models

only

i4

To

thermal

transmitter

models

only

9

To

floor

sensor

relay

California

modeb

only

is

To

distributor

Non

California

models

only

38

To

ignition

coil

Non

California

models

only

n

10

To

inhibitor

relay

A

T

only

26

To

8

C

D

D

cut

solenoid

Non

California

39

To

condenser

t

II

To

head

lamp

relay

models

only

40

To

ignition

coil

and

resistor

@

12

To

horn

relay

27

To

fuel

cut

solenoid

California

models

only

OJ

v

m

13

To

voltage

regulator

28

To

auto

choke

heater

g

e

14

To

cooler

cable

29

To

headlamp

L

R

type

1

OJ

to

o

Q

m

r0

C

1

i

Ql

CIl

Il

l

3

Page 483 of 537

m

ii

bl

l

l

l

if

3

i

m

1

Kickdown

solenoid

AlT

2

Oip

3

Inhibitor

switch

AfT

4

Oip

5

Engine

6

Battery

cable

7

Engine

slinger

8

Battery

cable

r

0

w

I

I

cf

n

L

J

TO

ENGtNE

ROOM

HARNESS

OJ

o

Q

m

O

Q

CIl

II

D

3

Page 488 of 537

Body

Electrical

System

EMISSION

WARNING

SYSTEM

California

models

CONTENTS

FLOOR

TEMPERATURE

WARNING

SYSTEM

California

models

DESCRIPTION

FLOOR

TEMPERATURE

WARNING

SYSTEM

California

models

DESCRIPTION

The

floor

temperature

warning

system

consists

of

a

floor

temperature

sensing

switch

installed

on

the

vehicle

floor

a

floor

temperature

relay

a

floor

temperature

warning

lamp

and

harnesses

When

the

floor

temperature

rises

to

an

abnormal

level

the

warning

lamp

will

come

on

to

call

the

attention

of

the

driver

i

f

FUSIBLE

LINK

P

BATTERY

IGNITION

SWITCH

BE

43

8E

43

WARNING

LAMP

TROUBLE

SHOOTING

GUIDE

BE

43

BE

44

The

warning

lamp

also

comes

on

during

operation

of

the

starter

motor

permitting

inspection

of

the

lamp

s

condition

The

lamp

goes

out

after

the

engine

starts

Refer

to

Section

EC

for

details

WARNING

LAMP

Bulb

replacement

I

Remove

cluster

lid

2

Twist

warni

ng

lamp

socket

Socket

with

bulb

can

then

be

taken

out

3

Pick

up

bulb

from

socket

IGNITION

RELAY

I

I

4

Installation

is

in

the

reverse

se

quence

of

removaL

Bulb

wattage

Floor

temperature

warning

lamp

17W

Lamp

body

replacement

I

Remove

cluster

lld

2

Disconnect

lead

wire

at

connee

tor

3

Remove

two

screws

retaining

lamp

body

4

Installation

is

in

the

reverse

se

quence

of

removal

FLOOR

I

l

I

SENSOR

RELAY

WARNING

I

LAMP

FLOOR

SENSOR

ON

FLOOR

TEMPERATURE

LOW

OFF

FLOOR

TEMPERATURE

HIGH

7

BE697B

Fig

BE

64

Circuit

diagram

of

floor

temperature

warning

system

BE

43

Page 494 of 537

The

refrigerant

within

the

thermo

bulb

changes

in

pressure

through

the

super

heat

condition

of

vaporized

re

frigerant

gas

which

comes

out

of

the

evaporator

causing

the

deflection

of

the

diaphragm

The

lift

of

the

ball

valve

attached

to

the

diaphragm

is

changed

by

the

deflection

of

the

dia

phragm

thus

controlling

the

amount

of

refrigerant

passing

the

orifice

ELECTRICAL

CIRCUIT

DESCRIPTION

The

electrical

circuit

of

the

air

conditioner

consists

of

four

switches

two

relays

a

solenoid

valve

a

fan

motor

and

a

compressor

magnetic

clutch

Air

Conditioning

Diaphragm

Orifice

Valve

ball

AC729

4

Sensing

bulb

Fig

A

C

6

Expansion

value

The

following

wiring

diagram

pro

vides

a

complete

description

of

the

whole

circuit

When

the

ignition

switch

and

the

fan

switch

are

ON

the

main

relay

is

activated

causing

battery

power

to

flow

through

the

fan

motor

and

the

magnetic

clutch

The

magnetic

clutch

is

activated

by

the

thermo

switch

AC

5

000

l

1

Motor

2

Fan

3

Lower

case

4

Cooler

duct

5

Evaporator

6

Expansion

valve

7

Upper

case

8

Resistor

9

Main

relay

10

Thermo

switch

II

Cable

clamp

12

Cable

13

Harness

AC725

Fig

AC

7

Cooling

unit

pressure

switch

and

compressor

relay

The

blower

motor

fan

speed

is

con

trolled

by

the

fan

switch

and

resistor

The

solenoid

valve

is

also

activated

This

in

turn

causes

the

fast

idle

control

device

F

l

C

D

to

increase

engine

speed

when

the

vehicle

is

at

rest

with

the

engine

ON

Page 496 of 537

MAIN

RELAY

The

main

relay

is

located

on

the

cooling

unit

When

the

ignition

switch

and

fan

switch

are

both

turned

on

the

COll

@

FAN

SWITCH

The

fan

switch

serving

as

a

control

unit

is

installed

on

the

center

console

This

switch

controls

the

blower

motor

speed

through

the

resistor

It

is

also

used

as

a

main

relay

switch

Fig

AC

I0

Fan

switch

THERMO

SWITCH

The

thermo

switch

is

located

on

the

upper

side

of

the

cooling

unit

and

is

controlled

by

the

cable

and

the

con

trollever

attached

to

the

console

box

It

is

so

designed

that

when

the

air

passing

through

the

evaporator

core

is

cooled

down

to

the

predetermined

Air

Conditioning

tacts

in

the

relay

are

closed

Then

electrical

power

from

the

battery

is

supplied

to

the

blower

motor

and

the

electrical

clutch

for

the

compressor

@

Dc

IDe

ID

1

1

l@

@

e

L

J

AC465

Fig

A

C

9

Main

relay

temperature

set

by

the

control

lever

it

automatically

turns

off

When

the

switch

is

turned

off

the

magnetic

clutch

is

turned

off

stopping

the

flow

of

refrigerant

inside

the

cooling

system

and

increasing

the

cooling

system

tem

perature

When

the

air

rises

to

the

pre

determined

temperature

the

thermo

switch

automatically

turns

on

In

this

way

the

temperature

of

the

air

dis

charged

from

the

cooling

unit

is

auto

matically

controlled

as

desired

PRESSURE

SWITCH

The

pressure

switch

is

turned

off

when

refrigerant

pressure

in

the

cooling

system

rises

to

an

abnormally

high

level

28

kg

cm2

398

psi

This

in

turn

turns

off

the

compressor

magnetic

clutch

actuating

the

com

pressor

relay

and

gradually

decreasing

pressure

in

the

cooling

system

When

the

pressure

drops

to

or

below

24

kg

cm2

341

psi

the

pressure

switch

again

turns

on

Thus

cooling

system

refrigerant

pressure

is

automatically

maintained

at

the

proper

value

a

t

all

times

AC

7

COMPRESSOR

RERAY

The

compressor

relay

is

attached

to

the

receiver

dryer

bracket

on

the

right

side

of

the

engine

compartment

This

relay

is

actuated

by

the

fan

switch

thermo

switch

and

pressure

switch

to

turn

on

and

off

the

compressor

magnetic

clutch

cv

1

2

AC731

Fig

A

C

11

Pressure

switch

and

compressor

relay

F

I

C

D

SOLENOID

VALVE

The

F

l

C

D

solenoid

valve

is

at

tached

to

the

dash

panel

in

the

engine

compartment

This

valve

supplies

vacu

um

to

the

F

I

C

D

diaphragm

through

the

vacuum

hose

connected

to

the

engine

intake

manifold

when

the

engine

is

at

idle

and

the

cooling

system

is

ON

thereby

raising

idle

speed

to

the

predetermined

rpm

800

IW

r

e

I

1

s

AC132

Fig

AC

12

F

l

C

D

solenoid

value