ECU DATSUN PICK-UP 1977 Manual Online

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 424 of 537

Engine

Control

Fuel

Exhaust

Systems

I

Wipe

clean

all

the

contact

por

tions

of

tube

joints

allow

them

to

dry

thoroughly

2

Temporarily

mount

in

place

muffler

assembly

as

an

assembled

unit

on

the

vehicle

3

Insert

front

tube

until

it

touches

emboss

m

b

nlfrnnjj

mm

lJ

Ij

@L

J

FE263

Fig

FE

ll

Exhawt

tube

connection

4

Torque

nut

securing

the

male

and

female

tubes

at

the

connection

Tightening

torque

is

1

6

to

2

0

kg

m

12

to

14

ft

lb

5

Squeeze

approximately

5

CC

0

31

cu

in

of

sealant

into

injection

from

sealant

tube

See

Figure

FE

12

Sealant

tube

polyethylene

Injector

Fig

FE

IO

Exhaust

sealant

kit

Be

sure

to

place

cap

back

to

sealant

tube

since

sealant

will

dry

Approximately

5

cc

0

31

Cll

in

FE1l1

Fig

FE

12

Squeezing

sealant

to

injec

tor

6

Position

nozzle

of

injector

to

the

guide

and

press

it

there

firmly

Inject

sealant

slowly

until

sealant

begins

to

flow

out

of

the

slit

of

tube

This

indicates

that

the

bead

requires

no

further

sealant

Excessive

sealant

can

cause

a

clogged

tube

See

Figure

FE

13

After

injecting

wash

injector

thoroughly

in

clean

water

to

remove

all

traces

of

sealant

FE191

Fig

FE

13

Injecting

sealant

FE

9

7

Start

engine

and

let

it

idle

slowly

for

ten

minutes

minimum

to

hilfden

sealant

with

the

heat

of

exhaust

gas

8

Check

the

condition

of

sealant

before

driving

the

vehicle

It

is

also

essential

that

the

vehicle

should

not

be

accelerated

sharply

for

20

to

30

minutes

subsequent

to

this

operation

Noles

a

The

sealant

should

be

used

within

guaranty

term

indicated

on

the

kit

case

b

Exposure

of

sealant

to

the

skin

may

cause

a

rash

Wash

sealant

off

the

skin

with

water

c

Do

not

keep

the

sealant

tube

in

a

place

where

the

ambient

tempera

ture

is

above

400C

I040F

A

sealant

hardened

above

4QoC

I040F

cannot

be

used

The

most

suitable

storage

temperature

is

from

15

to

350C

59

to

950F

If

sealant

becomes

hardened

because

of

low

temperatures

wann

the

sealant

tube

with

lukewarm

water

until

the

sealant

is

softened

Do

not

warm

tube

at

a

temperature

over

400C

1040F

for

a

long

time

d

Thoroughly

read

the

instruction

sheet

furnished

with

the

kit

before

using

the

sealant

i

Page 428 of 537

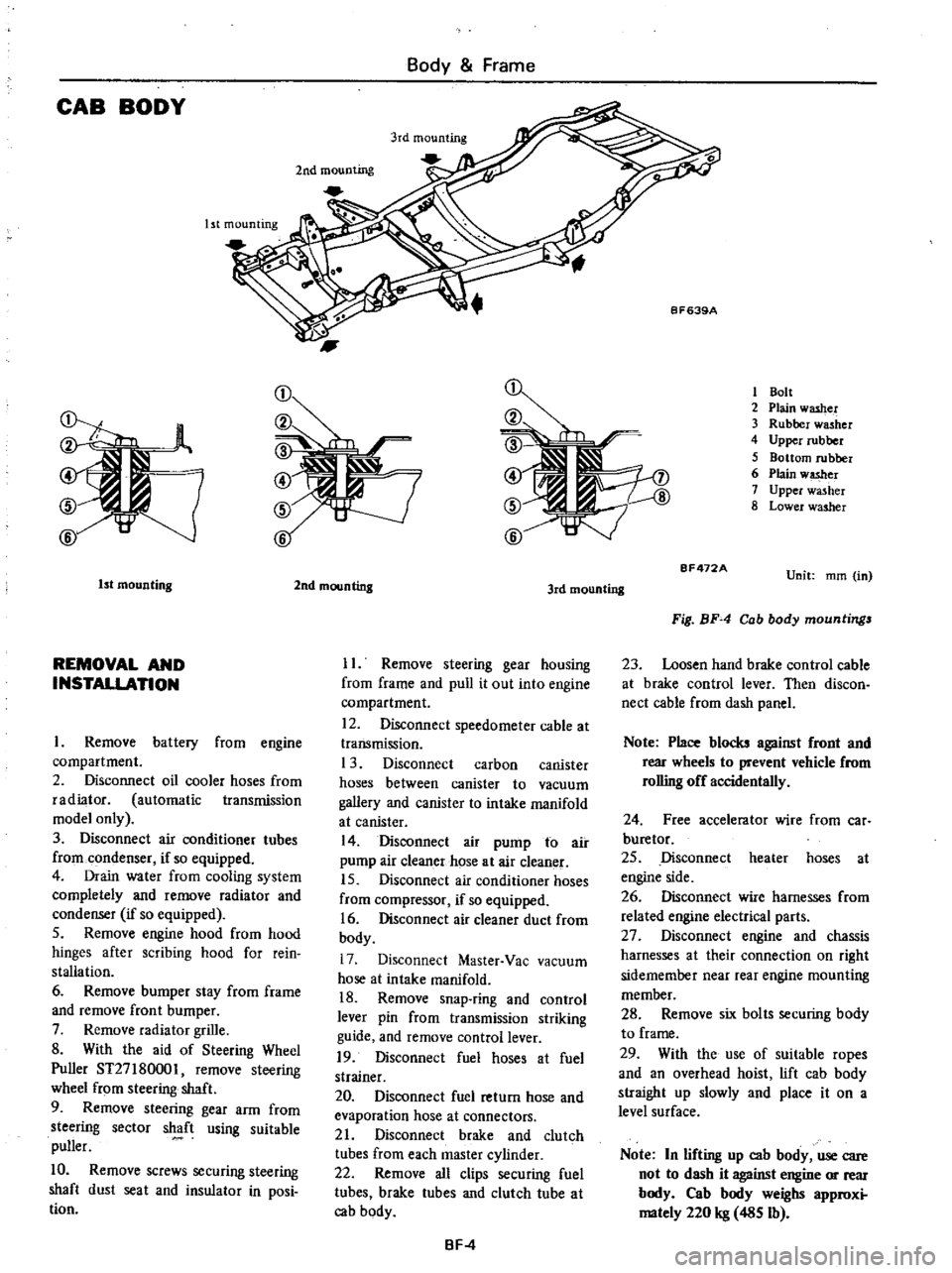

CAB

BODY

Body

Frame

Ist

mounting

2nd

mounting

1

Bolt

2

Plain

washer

3

Rubber

washer

4

Upper

rubber

5

Bottom

rubber

6

Plain

w

er

7

Upper

washer

8

Lower

washer

1st

mounting

REMOVAL

AND

INSTALLATION

Remove

battery

from

engine

compartment

2

Disconnect

oil

cooler

hoses

from

radiator

automatic

transmission

model

only

3

Disconnect

air

conditioner

tubes

from

condenser

if

so

equipped

4

Drain

water

from

cooling

system

completely

and

remove

radiator

and

condenser

if

so

equipped

5

Remove

engine

hood

from

hood

hinges

after

scribing

hood

for

rein

stallation

6

Remove

bumper

stay

from

frame

and

remove

front

bumper

7

Remove

radiator

grille

8

With

the

aid

of

Steering

Wheel

Puller

ST27

180001

remove

steering

wheel

from

steering

shaft

9

Remove

steering

gear

arm

from

steering

sector

shaft

using

suitable

puller

10

Remove

screws

securing

steering

shaft

dust

seat

and

insulator

in

posi

tion

2nd

mounting

3rd

mounting

II

Remove

steering

gear

housing

from

frame

and

pull

it

out

into

engine

compartment

12

Disconnect

speedometer

cable

at

transmission

1

3

Disconnect

carbon

canister

hoses

between

canister

to

vacuum

gallery

and

canister

to

intake

manifold

at

canister

14

Disconnect

air

pump

to

air

pump

air

cleaner

hose

at

air

cleaner

15

Disconnect

air

conditioner

hoses

from

compressor

if

so

equipped

16

Disconnect

air

cleaner

duct

from

body

17

Disconnect

Master

Vac

vacuum

hose

at

intake

manifold

18

Remove

snap

ring

and

control

lever

pin

from

transmission

striking

guide

and

remove

control

lever

19

Disconnect

fuel

hoses

at

fuel

strainer

20

Disconnect

fuel

return

hose

and

evaporation

hose

at

connectors

21

Disconnect

brake

and

clutch

tubes

from

each

master

cylinder

22

Remove

all

clips

securing

fuel

tubes

brake

tubes

and

clutch

tube

at

cab

body

BF

4

BF472A

Unit

mm

in

Fig

BF

4

Cab

body

mountings

23

Loosen

hand

brake

control

cable

at

brake

control

lever

Then

discon

nect

cable

from

dash

panel

Note

Place

blocks

against

front

and

rear

wheels

to

prevent

vehicle

from

rolling

off

accidentally

24

Free

accelerator

wire

from

car

buretor

25

Disconnect

heater

hoses

at

engine

side

26

Disconnect

wire

harnesses

from

related

engine

electrical

parts

27

Disconnect

engine

and

chassis

harnesses

at

their

connection

on

right

sidemember

near

rear

engine

mounting

member

28

Remove

six

bolts

securing

body

to

frame

29

With

the

use

of

suitable

ropes

and

an

overhead

hoist

lift

cab

body

straight

up

slowly

and

place

it

on

a

level

surface

Note

In

lifting

up

cab

body

use

care

not

to

dash

it

against

engine

or

rear

body

Cab

body

weighs

approxi

mately

220

kg

485

Ib

Page 429 of 537

Body

Frame

30

For

installation

reverse

above

steps

However

observe

the

following

instructions

i

If

the

cab

body

is

to

be

replaced

note

position

and

location

of

insula

tors

and

washers

used

See

Figure

BF

4

2

Adjust

hand

brake

stroke

pro

perly

3

Air

bleed

brake

and

clutch

system

thorougWy

Cab

body

to

frame

mounting

bolt

torque

1

6

to

2

2

kg

m

12

to

16

ft

Ib

o

i

k

q

1Q

j

b

crru

V

J

8F630

rr

1

4

n

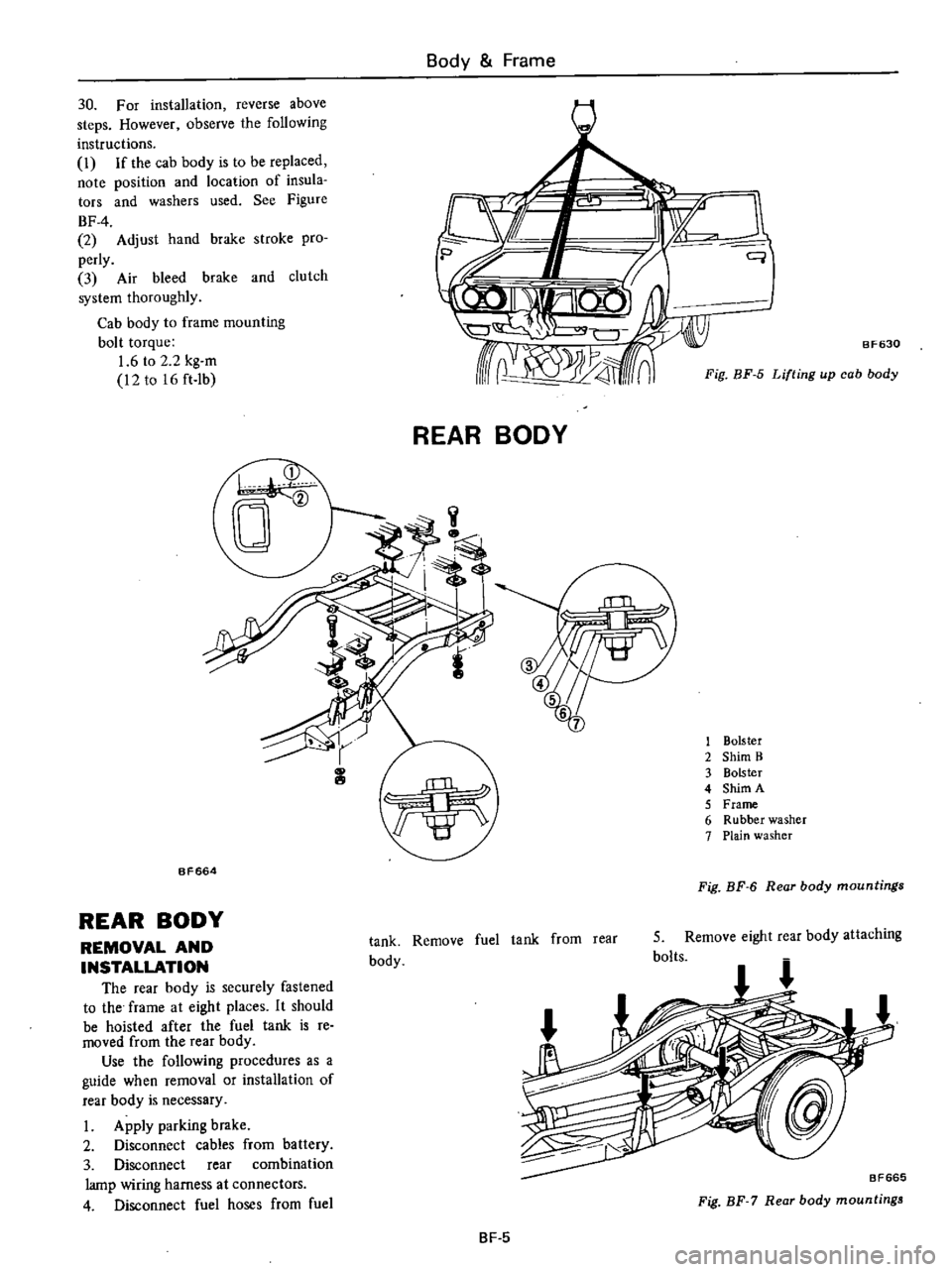

Fig

BF

5

Lifting

up

cab

body

REAR

BODY

1

Bolster

2

Shim

B

3

Bolster

4

Shim

A

5

Frame

6

Rubber

washer

7

Plain

washer

BF664

Fig

BF

6

Rear

body

mountings

REAR

BODY

REMOVAL

AND

INSTALLATION

The

rear

body

is

securely

fastened

to

the

frame

at

eight

places

It

should

be

hoisted

after

the

fuel

tank

is

re

moved

from

the

rear

body

Use

the

following

procedures

as

a

guide

when

removal

or

installation

of

rear

body

is

necessary

I

Apply

parking

brake

2

Disconnect

cables

from

battery

3

Disconnect

rear

combination

lamp

wiring

harness

at

connectors

4

Disconnect

fuel

hoses

from

fuel

tank

Remove

fuel

tank

from

rear

body

5

Remove

eight

rear

body

attaching

bolts

BF665

Fig

BF

7

Rear

body

mountings

BF

5

Page 432 of 537

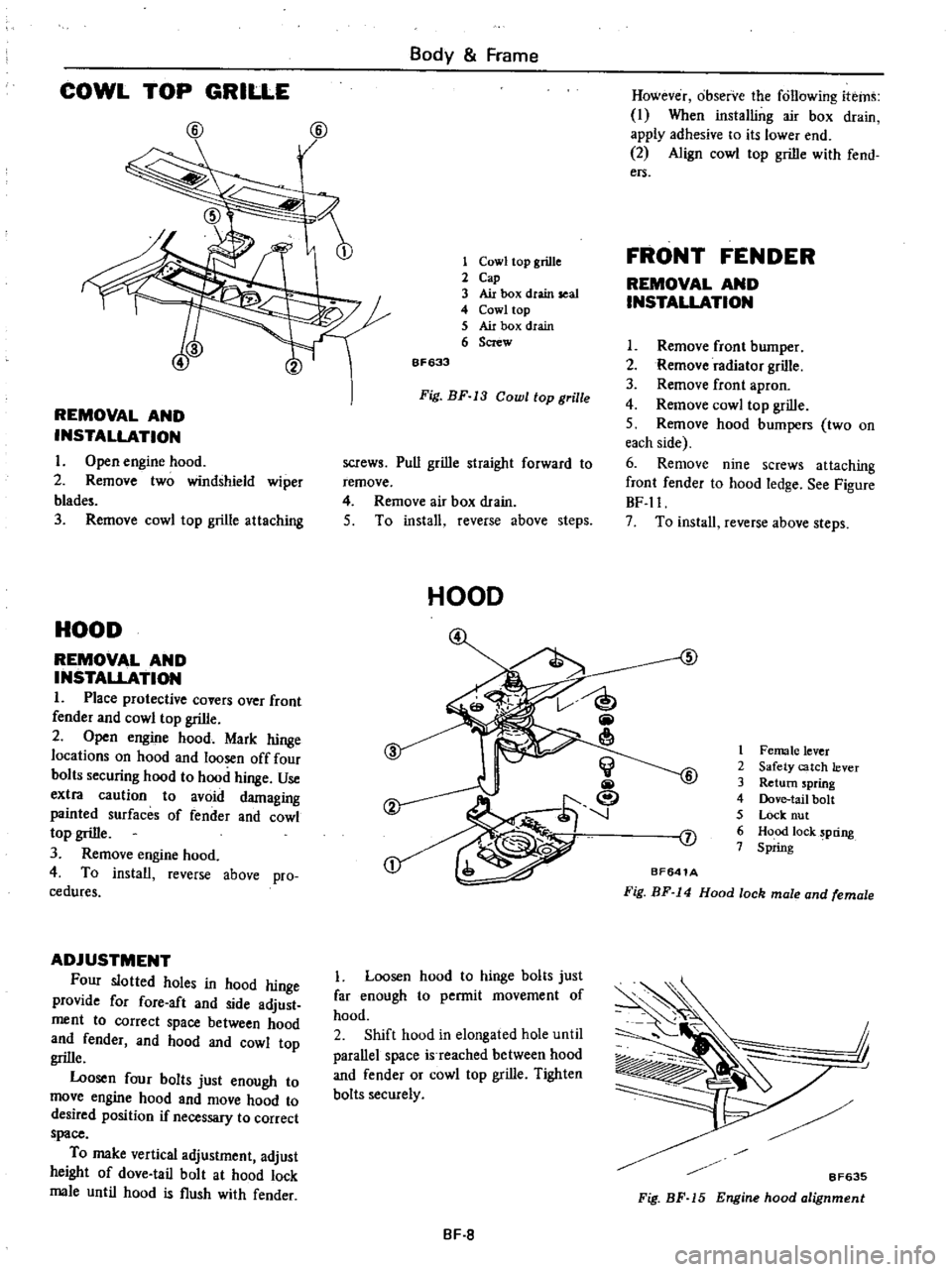

COWL

TOP

GRILLE

@

@

REMOVAL

AND

INSTALLATION

I

Open

engine

hood

2

Remove

two

windshield

wiper

blad

3

Remove

cowl

top

grille

attaching

HOOD

REMOVAL

AND

INSTALLATION

1

Place

protective

covers

over

front

fender

and

cowl

top

grille

2

Open

engine

hood

Mark

hinge

locations

on

hood

and

loosen

off

four

bolts

securing

hood

to

hood

hinge

Use

extra

caution

to

avoid

damaging

painted

surfaces

of

fender

and

cowl

top

grille

3

Remove

engine

hood

4

To

install

reverse

above

pro

cedures

ADJUSTMENT

Four

slotted

holes

in

hood

hinge

provide

for

fore

aft

and

side

adjust

ment

to

correct

space

between

hood

and

fender

and

hood

and

cowl

top

grille

Loosen

four

bolts

just

enough

to

move

engine

hood

and

move

hood

to

desired

position

if

necessary

to

correct

space

To

make

vertical

adjustment

adjust

height

of

dove

tail

bolt

at

hood

lock

male

until

hood

is

flush

with

fender

Body

Frame

1

Cowl

top

grille

2

Cap

3

Air

box

dtain

seal

4

Cowl

top

5

Air

box

drain

6

Screw

6F633

Fig

BF

13

Cowl

top

grille

screws

Pull

grille

straight

forward

to

remove

4

Remove

air

box

drain

5

To

install

reverse

above

steps

HOOD

Loosen

hood

to

hinge

bolts

just

far

enough

to

permit

movement

of

hood

2

Shift

hood

in

elongated

hole

until

parallel

space

is

reached

between

hood

and

fender

or

cowl

top

grille

Tighten

bolts

securely

BF

8

However

observe

the

following

items

I

When

installing

air

box

drain

apply

adhesive

to

its

lower

end

2

Align

cowl

top

grille

with

fend

ers

FRONT

FENDER

REMOVAL

AND

INSTALLATION

I

Remove

front

bumper

2

Remove

radiator

grille

3

Remove

front

apron

4

Remove

cowl

top

grille

S

Remove

hood

bumpers

two

on

each

side

6

Remove

nine

screws

attaching

front

fender

to

hood

ledge

See

Figure

BF

ll

7

To

install

reverse

above

steps

5

1

Female

lever

2

Safety

catch

lever

3

Return

spring

4

Dove

tail

bolt

S

Lock

nut

6

Hood

lock

pring

7

Spring

J

BF641A

Fig

BF

14

Hood

lock

male

and

female

j

I

8F635

Fig

BF

15

Engine

hood

alignment

Page 433 of 537

Body

Frame

Note

Vertical

adjustment

should

be

carried

out

after

hood

lock

male

and

female

adjustment

has

been

completed

3

To

correct

hood

lock

alignment

loosen

two

hood

lock

male

attaching

bolts

and

move

hood

lock

male

and

female

in

the

lateral

and

fore

and

aft

directions

as

required

D

1r

r

BF642A

Fig

BF

16

Adjusting

hood

lock

male

Tightening

torque

Male

and

female

attaching

bolts

0

45

to

0

60

kg

m

3

3

to

4

3

ft

Ib

4

Dove

tail

bolt

at

hood

lock

male

provides

for

vertical

adjustment

in

aligning

hood

to

make

it

flush

with

fender

To

correct

loosen

lock

nut

on

dove

tail

bolt

and

turn

dove

tail

bolt

in

or

out

as

necessary

to

obtain

a

correct

height

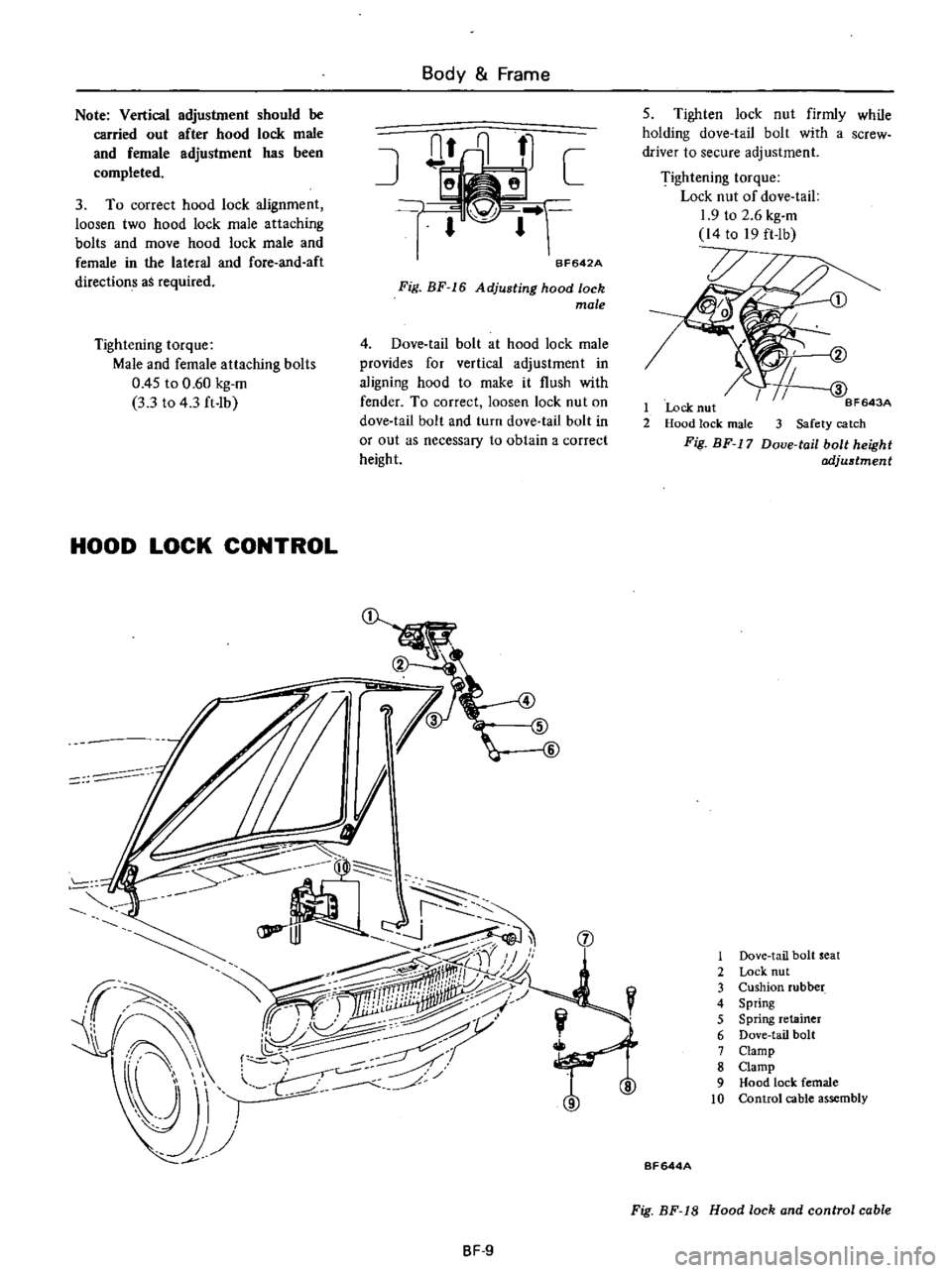

HOOD

LOCK

CONTROL

JI

I

i

I

r

lPP

J

jJ

J

Sr

aj

I

I

I

J

f

ifry

ff

I

ii1iiilliii

j

iW

r

U

I

j

Y

f

7

j

1

JJ

J

8F

9

5

Tighten

lock

nut

firmly

while

holding

dove

tail

bolt

with

a

screw

driver

to

secure

adjustment

Tightening

torque

Lock

nut

of

dove

tail

1

9

to

2

6

kg

m

14

to

19

ft

lb

BF643A

1

Lock

nut

2

Hood

lock

male

3

Safety

catch

Fig

BF

17

Doue

tail

bolt

height

adjustment

1

Dove

tail

bolt

seat

2

Lock

nut

3

Cushion

rubber

4

Spring

5

Spring

retainer

6

Dove

tail

bolt

7

Clamp

8

Clamp

9

Hood

lock

female

10

Control

cable

assembly

BF644A

Fig

BF

18

Hood

lock

and

control

cable

Page 434 of 537

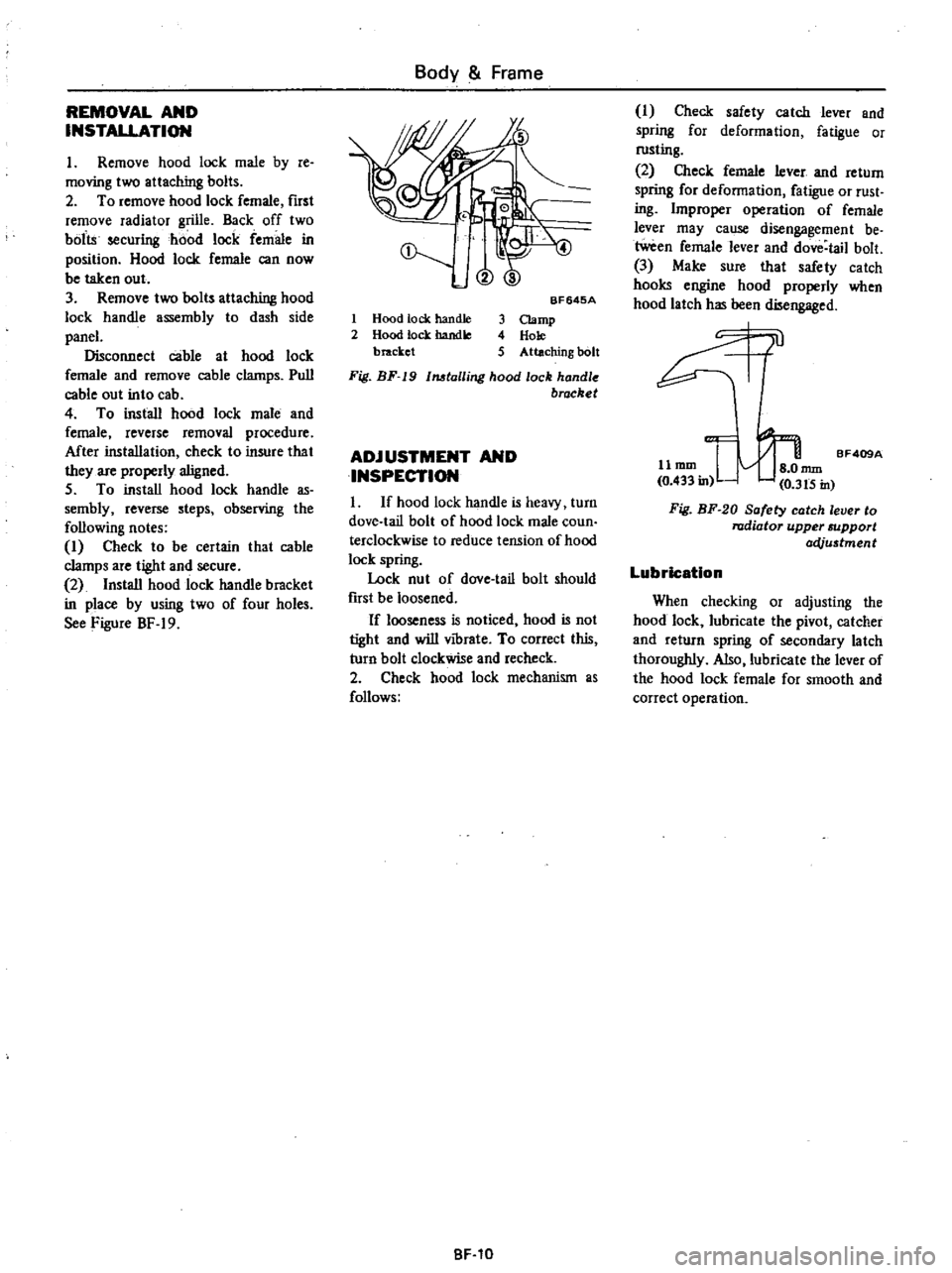

REMOVAL

AND

INSTALLATION

I

Remove

hood

lock

male

by

re

moving

two

attaching

bolts

2

To

remove

hood

lock

female

first

remove

radiator

grille

Back

off

two

bolts

securing

hood

lock

female

in

position

Hood

lock

female

can

now

be

taken

out

3

Remove

two

bolts

attaching

hood

lock

handle

assembly

to

dash

side

paneL

Disconnect

cable

at

hood

lock

female

and

remove

cable

clamps

Pull

cable

out

into

cab

4

To

install

hood

lock

male

and

female

reverse

removal

procedure

Mter

installation

check

to

insure

that

they

are

properly

aligned

5

To

install

hood

lock

handle

as

sembly

reverse

steps

observing

the

following

notes

I

Check

to

be

certain

that

cable

clamps

are

tight

and

secure

2

Install

hood

lock

handle

bracket

in

place

by

using

two

of

four

holes

See

Figure

BF

19

Body

Frame

@

1

Hood

tock

handle

2

Hood

lock

handle

bracket

BF645A

3

Clamp

4

Hole

5

Attaching

bolt

Fig

BF

19

1MtalIing

hood

lock

handle

brocket

ADJUSTMENT

AND

INSPECTION

I

If

hood

lock

handle

is

heavy

turn

dove

tail

bolt

of

hood

lock

male

coun

terclockwise

to

reduce

tension

of

hood

lock

spring

Lock

nut

of

dove

tail

bolt

should

fust

be

loosened

If

looseness

is

noticed

hood

is

not

tight

and

will

vibrate

To

correct

this

turn

bolt

clockwise

and

recheck

2

Check

hood

lock

mechanism

as

follows

BF

10

I

Check

safety

catch

lever

and

spring

for

deformation

fatigue

or

rusting

2

Check

female

lever

and

return

spring

for

deformation

fatigue

or

rust

ing

Improper

operation

of

female

lever

may

cause

disengagement

be

tween

female

lever

and

dove

tail

bolt

3

Make

sure

that

safety

catch

hooks

engine

hood

properly

when

hood

latch

has

been

disengaged

0l

11

mm

I

nun

BF409A

0

433

in

0

3t5

in

Fig

BF

20

Safety

catch

lever

to

radiator

upper

support

acVu5tment

Lubrication

When

checking

or

adjusting

the

hood

lock

lubricate

the

pivot

catcher

and

return

spring

of

secondary

latch

thoroughly

Also

lubricate

the

lever

of

the

hood

lock

female

for

smooth

and

correct

operation

Page 436 of 537

@

I

r

L

c

@

DESCRIPTION

The

door

consists

of

inner

and

outer

panels

welded

together

to

form

a

rigid

structure

The

curved

glass

provides

greater

shoulder

room

A

door

that

incorporates

a

ventila

tor

window

is

also

available

as

an

option

The

weatherstrip

is

inserted

into

the

groove

on

the

door

sash

side

and

is

attached

by

clips

on

the

door

side

DOOR

REMOVAL

AND

INSTALLATION

I

With

door

in

full

open

position

place

a

garage

jack

or

stand

beneath

door

to

support

its

weight

when

bolts

are

removed

Place

rag

between

door

and

jack

or

stand

to

avoid

damaging

painted

surface

Body

Frame

CD

1

@

@

ID

@

AJ

@

@

@

1

Door

sash

2

Window

outside

weatherstrip

3

Window

inside

weatherstrip

4

Door

atherstrip

5

Rear

glass

run

rubber

6

Door

finish

holder

7

Rear

lower

sash

8

Seal

screen

9

Door

weatherstrip

clip

10

Front

glass

run

rubber

11

Lower

door

hinge

12

Upper

door

hinge

13

Front

lower

sash

14

Door

glass

15

Glazing

rubber

16

Door

glass

bottom

channel

11

Lower

support

18

Upper

support

19

Door

ventilator

assembly

BF031B

Fig

BF

22

Door

with

ntilator

window

Optional

BF023

Fig

BF

23

Supporting

door

2

Separate

lower

door

hinge

hole

cover

from

dash

side

trim

3

While

supporting

door

as

above

back

off

body

to

upper

and

lower

hinge

attaching

bolts

accessible

from

inside

cab

three

each

Door

can

now

be

taken

out

from

cab

body

I

t

I

l

f

p1

1

W

JJ

i

Sl

j

Fig

BF

24

Removing

door

hinge

bolt

8F

12

4

To

install

reverse

removal

pro

cedure

ALIGNMENT

Elongated

holes

three

each

in

door

hinge

and

door

lock

striker

pro

vide

for

up

and

down

forward

and

backward

and

or

sideways

adjustment

to

assure

proper

door

fit

to

door

opening

To

adjust

door

alignment

loosen

bolts

and

move

door

to

desired

posi

lion

to

obtain

a

parallel

space

between

door

sides

and

door

opening

Also

check

to

be

certain

that

weatherstrip

contacts

body

opening

evenly

to

pre

vent

entry

of

mud

and

water

DOOR

TRIM

AND

SEAL

REMOVAL

AND

INSTALLATION

1

Remove

screw

securing

inside

door

handle

escutcheon

remove

es

cutcheon

2

Remove

screws

which

hold

pull

handle

and

arm

rest

in

position

Pull

handle

and

arm

rest

can

then

be

taken

out

3

Pull

retaining

spring

off

regulator

handle

Take

out

regulator

handle

and

seat

washer

Page 437 of 537

BF640

4

When

removing

door

finish

it

is

important

that

inside

door

panel

and

door

finish

are

not

damaged

With

a

screwdriver

pry

off

re

taining

clips

exercising

care

not

to

damage

clips

I

a

I

II

I

L

jl

ld

II

Fig

BF

26

Removing

door

finish

5

Separate

water

seal

screen

from

inside

door

panel

6

To

install

reverse

removal

pro

cedure

However

observe

the

follow

ing

instalJation

notes

i

When

water

seal

screen

is

to

be

replaced

be

Sure

to

cement

it

back

into

position

securely

to

ensure

a

water

sealed

door

This

can

be

done

by

evenly

applying

adhesive

to

grooves

in

inside

door

panel

Broken

screen

Or

one

suspected

to

be

leaking

must

be

replaced

with

a

new

one

Body

Frame

1

3

Seat

washer

Regulator

handle

Retaining

spring

Fig

BF

25

Removing

regulator

handle

Adhesive

I

i

f

f

nil

Section

A

A

Ii

ir

coil

IIIII

I

J

J

iif

J

lUJ

A

A

J

J

BF641

Fig

BF

27

Adhesive

for

seal

screen

2

With

door

glass

up

set

regulator

handle

at

an

angle

shown

in

Figure

BF

28

d

1

J

900

Spring

l

BF462

Fig

BF

28

Installation

angle

of

regulator

handle

GLASS

RUN

REMOVAL

AND

INSTALLATION

I

With

door

in

full

out

position

lower

glass

all

the

way

2

Remove

pull

handle

arm

rest

and

regulator

handle

3

Remove

door

fmish

and

water

seal

screen

4

Remove

outer

and

inner

weather

strips

from

door

BF

13

5

Remove

door

glass

6

Remove

glass

run

rubbers

from

front

and

rear

lower

sashes

and

from

those

of

fixed

door

Use

caution

to

avoid

damaging

rubbers

during

removal

operation

7

Remove

front

and

rear

lower

door

sashes

when

ventilator

window

is

not

provided

8

On

vehicles

equipped

with

venti

lator

window

remove

ventilator

window

frame

and

rear

lower

door

sash

9

To

install

reverse

removal

pro

cedure

However

observe

the

follow

ing

notes

I

Before

applying

adhesive

clean

the

inside

of

door

sash

2

Apply

adhesive

to

glass

run

rubber

on

door

sash

contacting

face

and

fit

it

correctly

Particularly

care

should

be

taken

at

corners

and

contact

face

to

assure

a

good

fit

CD

CID

BF641

1

Door

sash

2

Glass

run

rubber

3

Adhesive

Fig

BF

29

Applying

adhesive

to

glass

run

ru

bber

DOOR

VENTILATOR

WINDOW

Optional

REMOVAL

AND

INSTALLATION

I

Remove

five

ventilator

window

frame

attaching

bolts

Lift

frame

out

of

door

For

detailed

procedure

refer

to

relative

topic

under

Door

Glass

and

Regulator

2

Remove

nuts

and

spring

securing

lower

end

of

ventilator

window

to

frame

3

Work

off

rivets

which

hold

upper

end

of

ventilator

window

to

frame

take

out

window

4

To

install

reverse

removal

pro

cedure

Page 438 of 537

Body

Frame

DOOR

GLASS

AND

REGULATOR

CD

REMOVAL

AND

INSTALLATION

L

Open

door

lower

glass

all

the

way

2

Remove

iflllide

door

handle

es

cutcheon

3

Remove

pull

handle

4

Remove

arm

rest

5

Remove

regulator

handle

6

Remove

door

finish

7

Peel

off

water

seal

screen

8

Work

off

outer

and

inner

weath

erstrips

from

door

being

sure

not

to

scratch

door

paint

during

operation

Use

a

suitable

plain

screwdriver

or

similar

flat

bladed

tool

io

remove

and

place

a

piece

of

rag

between

screw

driver

and

door

panel

BF643

1

Outet

weatherstrip

2

Screwdriver

3

Piece

of

rag

Fig

BF

31

Removing

outer

weather

trip

9

Remove

three

door

glass

bottom

channel

attaching

bolts

Remove

door

glass

by

lifting

it

straight

up

Fig

BF

30

Door

gl

and

regulator

10

On

door

equipped

with

venti

lator

remove

three

bolts

securing

door

glass

bottom

channel

then

let

glass

go

to

the

bottom

of

door

Remove

ventilator

frame

attaching

bolts

and

lift

frame

straight

up

out

of

door

Remove

door

glass

by

lifting

it

straight

up

11

Back

off

the

five

guide

channel

to

regulator

base

attaching

screws

Take

out

regulator

assembly

through

large

access

hole

in

inside

door

panel

DOOR

LOCK

1

Escutcheon

2

Inside

handle

3

Spring

4

Door

lock

knob

5

Knob

grommet

6

Outside

handle

7

Outside

handle

rod

j

f

ffi

I

Fig

BF

32

BF035

Removing

door

glass

12

To

install

reverse

removal

pro

cedure

ADJUSTMENT

I

In

and

out

and

fore

and

aft

ad

justment

can

be

made

by

moving

front

or

rear

sash

and

guide

channel

as

required

The

ease

with

which

window

assem

bly

raises

and

lowers

depends

on

ad

justment

of

rear

lower

sash

Rear

lower

sash

should

be

parallel

with

front

lower

sash

2

Fore

and

aft

adjustment

is

deter

mined

by

position

of

guide

channel

and

front

lower

sash

Moving

front

lower

sash

backward

reduces

play

in

window

assembly

j

CID

@

8

Nylon

nut

9

Locking

plate

ring

10

LOcking

plate

11

Door

lock

cylinder

12

Door

lock

13

Stopper

BF

14

BF410A

Fig

BF

33

Door

lock

mechonillm

Page 442 of 537

Body

Frame

INTERIOR

TRIM

AND

CENTER

CONSOLE

HEADLINING

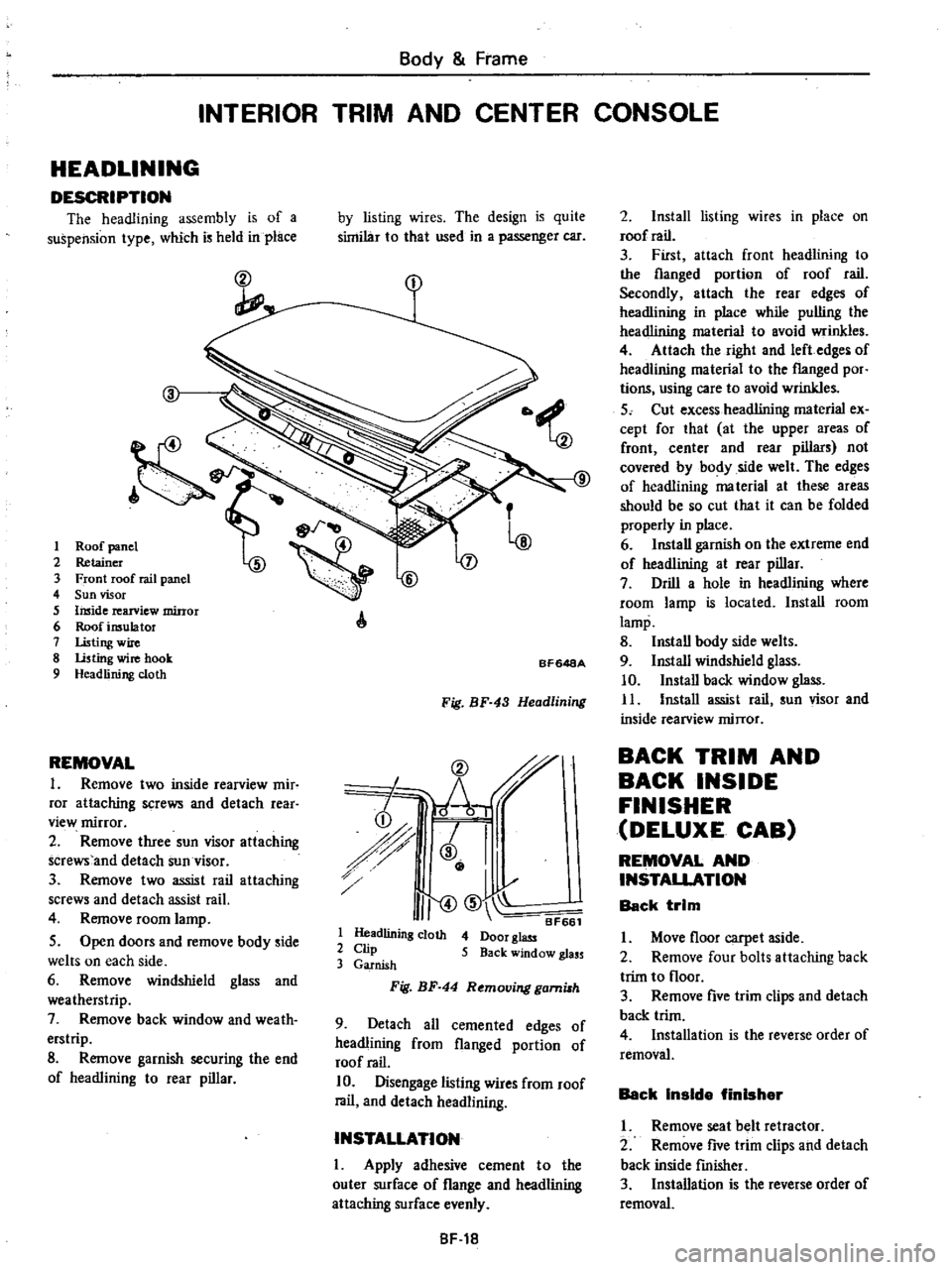

DESCRIPTION

The

headlining

assembly

is

of

a

suspension

type

which

is

held

in

place

ct

I

2

3

4

5

6

7

8

9

REMOVAL

1

Remove

two

inside

rearview

mir

ror

attaching

screws

and

detach

rear

view

mirror

2

Remove

three

sun

visor

attaching

screws

and

detach

sun

visor

3

Remove

two

assist

rail

attaching

screws

and

detach

assist

rail

4

Remove

room

lamp

5

Open

doors

and

remove

body

side

welts

on

each

side

6

Remove

windshield

glass

and

weatherstrip

7

Remove

back

window

and

weath

erstrip

8

Remove

garnish

securing

the

end

of

headlining

to

rear

pillar

by

listing

wires

The

design

is

quite

similar

to

that

used

in

a

passenger

car

A

BF648A

Fig

BF

43

Headlining

CD

r

h

i

r

J

I

I

I

II

CID

BF661

1

Headlining

cloth

4

Door

glass

2

Clip

5

Back

window

glass

3

Garnish

Fig

BF

44

Removing

gami8h

9

Detach

all

cemented

edges

of

headlining

from

flanged

portion

of

roof

rail

10

Disengage

listing

wires

from

roof

rail

and

detach

headlining

INSTALLATION

I

Apply

adhesive

cement

to

the

outer

surface

of

flange

and

headlining

attaching

surface

evenly

8F

18

2

Install

listing

wires

in

place

on

roof

rail

3

First

attach

front

headlining

to

the

flanged

portion

of

roof

rail

Secondly

attach

the

rear

edges

of

headlining

in

place

while

pulling

the

headlining

material

to

avoid

wrinkles

4

Attach

the

right

and

left

edges

of

headlining

material

to

the

flanged

por

tions

using

care

to

avoid

wrinkles

5

Cut

excess

headlining

material

ex

cept

for

that

at

the

upper

areas

of

front

center

and

rear

pillars

not

covered

by

body

side

welt

The

edges

of

headlining

ma

terial

at

these

areas

should

be

so

cut

that

it

can

be

folded

properly

in

place

6

Install

garnish

on

the

extreme

end

of

headlining

at

rear

pillar

7

Drill

a

hole

in

headlining

where

room

lamp

is

located

Install

room

lamp

8

Install

body

side

welts

9

Install

windshield

glass

10

Install

back

window

glass

11

Install

assist

rail

sun

visor

and

inside

rearview

mirror

BACK

TRIM

AND

BACK

INSIDE

FINISHER

DELUXE

CAB

REMOVAL

AND

INSTALLATION

Back

trim

I

Move

floor

carpet

aside

2

Remove

four

bolts

attaching

back

trim

to

floor

3

Remove

five

trim

clips

and

detach

back

trim

4

Installation

is

the

reverse

order

of

removal

Back

Inside

finisher

I

Remove

seat

belt

retractor

2

Remove

five

trim

clips

and

detach

back

inside

fmisher

3

Installation

is

the

reverse

order

of

removal