ECU DATSUN PICK-UP 1977 Workshop Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 308 of 537

Fig

AT

96

Measuring

clearanc

Automatic

Transmission

6

u

ST255801JOO

AT264

Fig

AT

99

Measuring

runout

5

Tighten

pump

securing

bolts

to

specified

torque

0

6

to

0

8

kg

m

4

to

6

ft

Ib

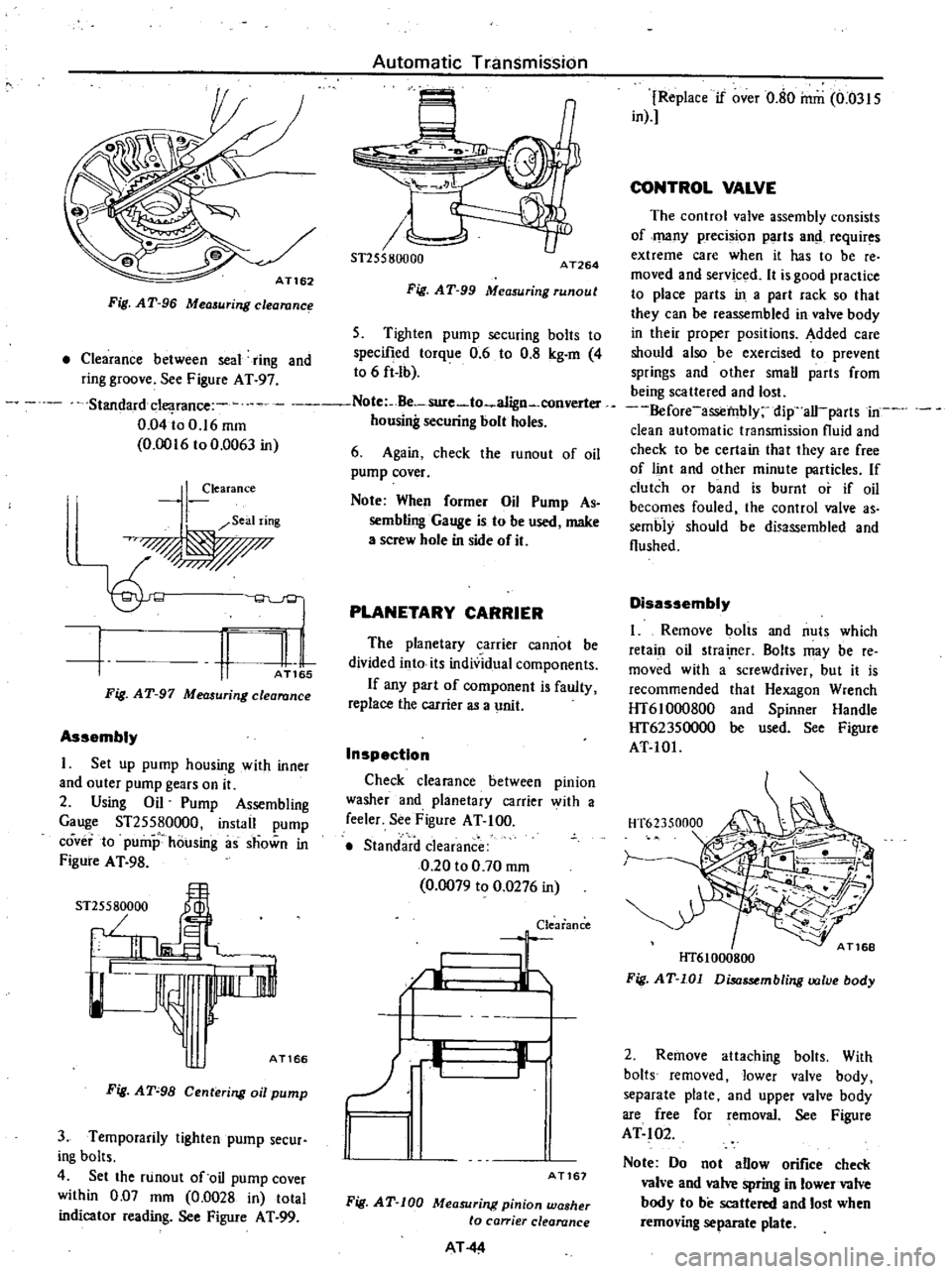

Clearance

between

seal

ring

and

ring

groove

See

Figure

AT

97

Standarddearance

Note

Be

sure

to

a1ign

converter

0

04

io

0

16

mm

housing

securing

bolt

holes

0

0016

to

0

0063

in

6

Again

check

the

runout

of

oil

pump

cover

I

learance

Seal

ring

q

I

n

l

1

AT

5

Fig

AT

97

Measuring

clearance

Assembly

I

Set

up

pump

housing

with

inner

and

outer

pump

gears

on

it

2

Using

Oil

Pump

Assembling

Gauge

ST25580000

instail

pump

coverta

pump

housing

as

shown

in

Figure

A

T

98

ST

5

000

J

I

I

JL

AT166

Fig

AT

98

Centering

oil

pump

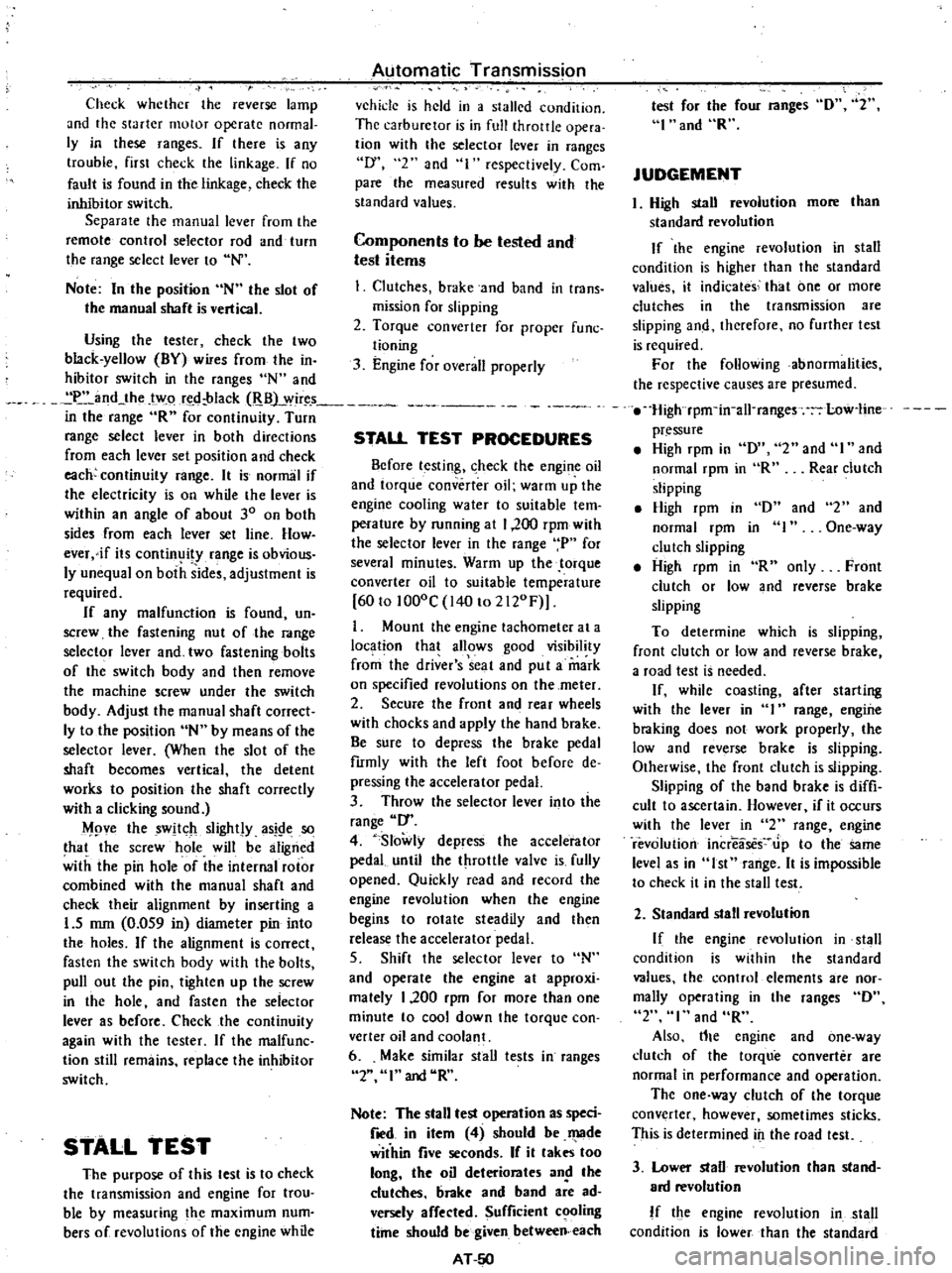

3

Temporarily

lighten

pump

secur

ing

bolts

4

Set

the

runout

of

oil

pump

cover

within

0

D7

mm

0

0028

in

total

indicator

reading

See

Figure

AT

99

Note

When

former

Oil

Pump

As

sembling

Gauge

is

to

be

used

make

a

screw

hole

in

side

of

it

PLANETARY

CARRIER

The

planetary

carrier

cannot

be

divided

into

its

individual

components

If

any

part

of

component

is

faulty

replace

the

carrier

as

a

unit

Inspection

Check

clearance

between

pinion

washer

and

planetary

carrier

with

a

feeler

See

Figure

AT

100

Standard

clearance

0

20

to

0

70

mm

0

0079

to

0

0276

in

Clearance

I

Jr

I

1

11

r

AT167

Fig

AT

100

Measuring

pinion

washer

to

ca

ier

clearance

AT

44

Replace

if

over

0

80

mm

0

0315

in

CONTROL

VALVE

The

control

valve

assembly

consists

of

many

preci

ion

parts

and

requir

s

extreme

care

when

it

has

to

be

reo

moved

and

serviced

It

is

good

practice

to

place

parts

in

a

part

rack

so

that

they

can

be

reassembled

in

valve

body

in

their

proper

positions

Added

care

should

also

be

exercised

to

prevent

springs

and

other

small

parts

from

being

scattered

and

lo

t

Before

assembly

dip

all

parts

in

clean

automatic

transmission

fluid

and

check

to

be

certain

that

they

are

free

of

lint

and

other

minute

particles

If

clutch

or

band

is

burnt

or

if

oil

becomes

fouled

the

control

valve

as

sembly

should

be

di

ssembled

and

flushed

Disassembly

I

Remove

bolts

and

nuts

which

retain

oil

trainer

Bolts

may

be

re

moved

with

a

screwdriver

but

it

is

recommended

that

Hexagon

Wrench

HT610oo800

and

Spinner

Handle

HT62350000

be

used

See

Figure

AT

101

HT61000800

Fig

AT

101

Disassembling

valve

body

2

Remove

attaching

bolts

With

bolts

removed

lower

valve

body

separate

plate

and

upper

valve

body

are

free

for

removal

See

Figure

AT

102

Note

Do

not

allow

orifice

check

vah

e

and

valve

spring

in

lower

valve

body

to

be

scattered

and

lost

when

removing

separate

plate

Page 314 of 537

Using

the

tester

check

the

two

black

yellow

BY

wires

from

the

in

hibitor

switch

in

the

ranges

N

and

I

and

the

tw

re

d

black

RBj

wir

s

in

the

range

R

for

continuity

Turn

range

select

lever

in

both

directions

from

each

lever

set

position

and

check

each

continuity

range

It

is

normal

if

the

electricity

is

on

while

the

lever

is

within

an

angle

of

about

30

on

both

sides

from

each

lever

set

line

How

ever

if

its

continl

ity

range

is

obvious

ly

unequal

on

both

sides

adjustment

is

required

If

any

malfunction

is

found

un

screw

the

fastening

nut

of

the

range

selector

lever

and

two

fastening

bolts

of

the

switch

body

and

then

remove

the

machine

screw

under

the

switch

body

Adjust

the

manual

shaft

correct

ly

to

the

position

N

by

means

of

the

selector

lever

When

the

slot

of

the

shaft

becomes

vertical

the

detent

works

to

position

the

shaft

correctly

with

a

clicking

sound

MSlVe

the

switch

slightly

asj

Je

so

that

the

screw

hole

will

be

aligned

with

the

pin

hole

of

the

internal

rotor

combined

with

the

manual

shaft

and

check

their

alignment

by

inserting

a

1

5

mm

0

059

in

diameter

pin

into

the

holes

If

the

alignment

is

correct

fasten

the

switch

body

with

the

bolts

pull

out

the

pin

tighten

up

the

screw

in

the

hole

and

fasten

the

selector

lever

as

before

Check

the

continuity

again

with

the

tester

If

the

malfunc

tion

still

remains

replace

the

inhibitor

switch

Chcck

whether

the

reverse

lamp

and

the

starter

motor

operate

normal

ly

in

these

ranges

If

Ihere

is

any

lrouble

first

check

the

linkage

If

no

fault

is

found

in

the

linkage

check

the

inhibitor

switch

Separate

the

manual

lever

from

Ihe

remote

control

selector

rod

and

turn

the

range

selcct

lever

to

N

Note

In

the

position

N

the

slot

of

the

manual

shaft

is

vertical

STALL

TEST

The

purpose

of

this

test

is

to

check

the

transmission

and

engine

for

trou

ble

by

measuring

the

maximum

num

bers

of

revolutions

of

the

engine

while

Automatic

Transmission

vehicle

is

held

in

a

stalled

condition

The

carburctor

is

in

full

throttle

opera

tion

with

the

selector

lever

in

ranges

f

2

and

I

respectively

Com

pare

the

measured

results

with

the

slandard

values

Components

to

be

tested

and

test

items

I

Clutches

brake

and

band

in

trans

mission

for

slipping

2

Torque

converter

for

proper

fune

tioning

3

Engine

for

overall

properly

STALL

TEST

PROCEDURES

Before

Icsting

c

heck

the

engine

oil

and

torque

converter

oil

warm

up

the

engine

cooling

water

to

suitable

tem

perature

by

running

at

1

200

rpm

with

the

selector

lever

in

the

range

P

for

several

minutes

Warm

up

the

torque

converter

oil

to

suitable

temperature

6010

1000C

140

to

2l20F

I

Mount

the

engine

tachometer

at

a

location

that

allows

good

visibility

fro

the

dri

er

s

seat

and

put

a

mark

on

specified

revolutions

on

the

meter

2

Secure

the

front

and

rear

wheels

with

chocks

and

apply

the

hand

brake

Be

sure

to

depress

the

brake

pedal

fumly

with

the

left

foot

before

de

pressing

the

accelerator

pedal

3

Throw

the

selector

lever

into

the

range

1

4

Slowly

depress

the

accelerator

pedal

until

the

throttle

valvc

is

fully

opened

Quickly

read

and

record

the

engine

revolution

when

the

engine

begins

to

rotate

steadily

and

then

release

the

accelerator

pedal

5

Shift

the

selector

lever

to

N

and

operate

the

engine

at

approxi

mately

1

200

rpm

for

more

than

one

minute

to

cool

down

the

torque

con

ver

ter

oil

and

coolant

6

Make

similar

stall

tests

in

ranges

2

I

and

RIO

Note

The

stall

test

operation

as

speci

f

d

in

item

4

should

be

I

l3de

wiihin

five

seconds

If

it

takes

too

long

the

oil

deteriorates

an

the

clutches

brake

and

band

are

ad

versely

affected

Sufficient

cooling

time

should

be

given

between

each

AT

5O

test

for

the

four

ranges

0

2

I

and

R

JUDGEMENT

High

stall

revolution

more

than

standard

revolution

If

the

engine

revolution

in

stall

condition

is

higher

than

the

standard

values

it

indicates

that

one

or

more

clutches

in

the

transmission

are

slipping

and

therefore

no

further

test

is

required

For

the

following

abnormalities

the

respective

causes

are

presumed

High

rpm

in

all

ranges

low

Iine

pressure

High

rpm

in

D

2

and

I

and

normal

rpm

in

R

Rear

clutch

slipping

High

rpm

in

0

and

normal

rpm

in

I

clutch

slipping

High

rpm

in

R

only

Front

clutch

or

low

and

reverse

brake

slipping

To

determine

which

is

slipping

front

clutch

or

low

and

reverse

brake

a

road

test

is

nceded

If

whilc

coasting

after

starting

with

the

lever

in

1

range

engine

braking

does

not

work

properly

the

low

and

reverse

brake

is

slipping

Otherwise

the

front

clutch

is

slipping

Slipping

of

the

band

brake

is

diffi

cult

to

ascertain

However

if

it

occurs

with

the

lever

in

2

range

engine

revolution

increases

Jp

to

thesarne

level

as

in

I

strange

It

is

impossible

to

check

it

in

the

stall

test

2

and

One

way

2

Standard

stall

revolution

If

the

engine

revolution

in

stall

condition

is

within

the

standard

values

the

control

elements

are

nor

mally

operating

in

the

ranges

0

2

I

and

R

Also

tIle

engine

and

one

way

clutch

of

the

torque

converter

are

normal

in

performance

and

operation

The

one

way

clutch

of

the

torque

converter

however

sometimes

sticks

This

is

determined

in

the

road

test

3

Lower

stall

revolution

than

stand

ard

revolution

If

the

engine

revolution

in

stall

condition

is

lower

than

the

standard

Page 335 of 537

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

REMOVAL

I

Jack

up

rear

of

vehicle

and

sup

port

it

by

placing

a

safety

stand

under

rear

axle

case

Drain

gear

oil

2

Remove

propeller

shaft

and

rear

axle

shafts

These

works

can

be

done

by

referring

to

Rear

Axle

and

Rear

Suspension

3

Loosen

off

bolts

securing

differ

ential

carrier

to

rear

axle

cas

and

take

out

differential

carrier

assembly

PRE

DISASSEMBLY

INSPECTION

Differential

carrier

should

be

in

spected

before

any

parts

are

removed

from

it

These

inspections

are

helpful

to

fmd

the

cause

of

a

problem

and

to

determine

the

corrections

needed

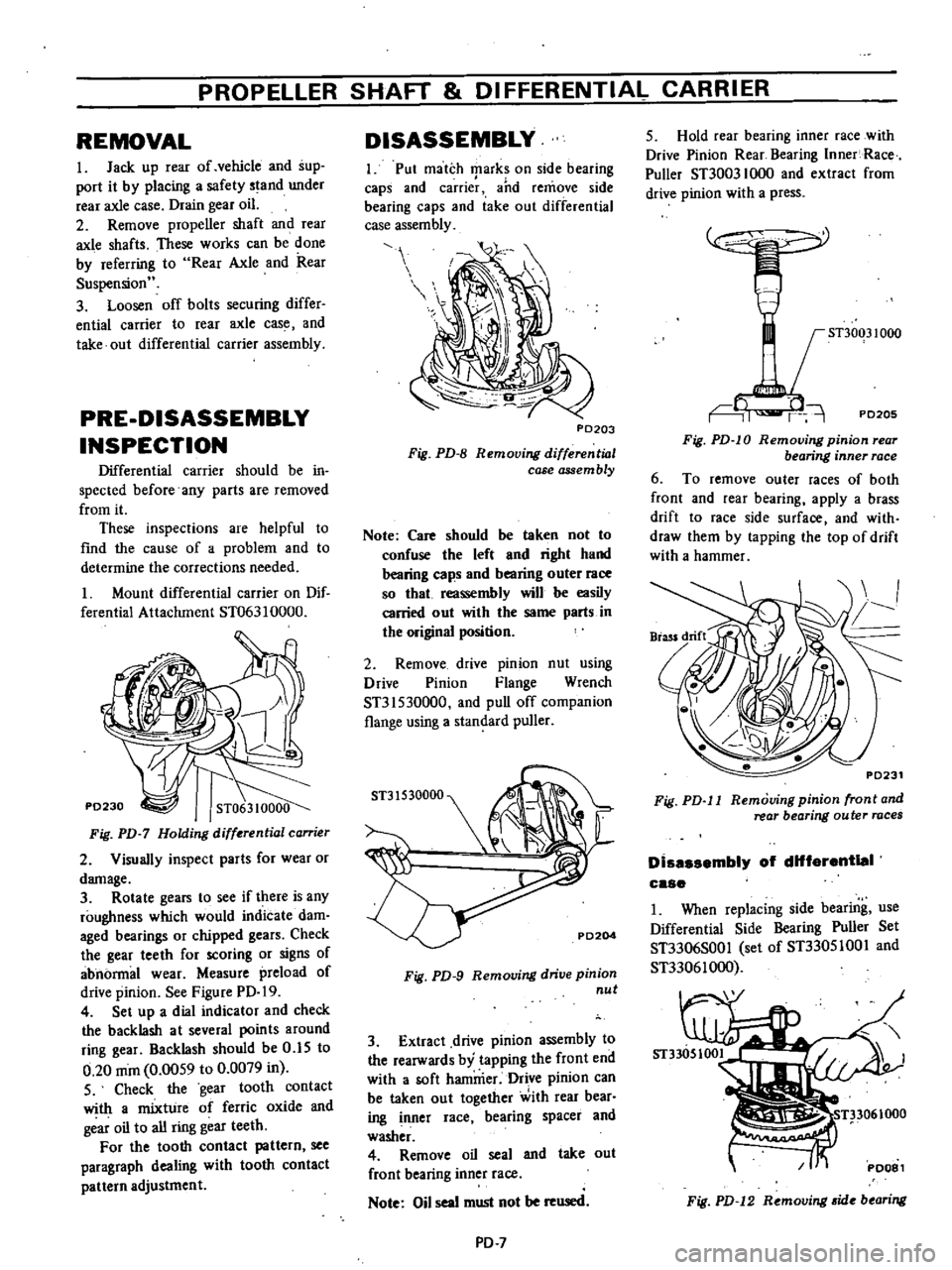

I

Mount

differential

carrier

on

Dif

ferential

Attachment

ST063

I

0000

ST063

10000

Fig

PD

7

Holding

differential

can

ier

2

Visually

inspect

parts

for

wear

or

damage

3

Rotate

gears

to

see

if

there

is

any

roughness

which

would

indicate

dam

aged

bearings

or

chipped

gears

Check

the

gear

teeth

for

scoring

or

signs

of

abnormal

wear

Measure

preload

of

drive

pinion

See

Figure

PD

19

4

Set

up

a

dial

indicator

and

check

the

backlash

at

several

points

around

ring

gear

Backlash

should

be

0

15

to

0

20

mOl

0

00S9

to

0

0079

in

S

Check

the

gear

tooth

contact

with

a

mixture

of

ferric

oxide

and

g

ar

oil

to

all

ring

gear

teeth

For

the

tooth

contact

pattern

see

paragraph

dealing

with

tooth

contact

pattern

adjustment

DISASSEMBLY

I

Put

match

tpark

on

side

bearing

caps

and

carrier

and

remove

side

bearing

caps

and

take

out

differential

case

assembly

P0203

Fig

PD

B

Removing

differenlwl

case

assem

bly

Note

Care

should

be

taken

not

to

confuse

the

left

and

right

hand

bearing

caps

and

bearing

outer

race

so

that

reassembly

will

be

easily

carried

out

with

the

same

parts

in

the

original

position

2

Remove

drive

pinion

nut

using

Drive

Pinion

Flange

Wrench

ST31530000

and

pull

off

companion

flange

using

a

standard

puller

Fig

PD

9

Removing

drive

pinion

nul

3

Extract

drive

pinion

assembly

to

the

rearwards

by

tapping

the

front

end

with

a

soft

hammer

Drive

pinion

can

be

taken

out

together

with

rear

bear

ing

nner

race

bearing

spacer

and

washer

4

Remove

oil

seal

and

take

out

front

bearing

inner

race

Note

Oil

seal

must

not

be

used

PD

7

5

Hold

rear

bearing

inner

race

with

Drive

Pinion

Rear

Bearing

Inner

Race

Puller

ST30031000

and

extract

from

drive

pinion

with

a

press

STJ0031000

PD205

Fig

PD

10

Removing

pinion

rear

bearing

inner

race

6

To

remove

outer

races

of

both

front

and

rear

bearing

apply

a

brass

drift

to

race

side

surface

and

with

draw

them

by

tapping

the

top

of

drift

with

a

hammer

Fig

PD

l1

Removing

pinion

front

and

rear

bearing

outer

races

Dissssembly

of

dHferentIeI

case

1

When

replacing

side

bearing

use

Differential

Side

Bearing

Puller

Set

ST3306S00

I

set

of

ST330S100

I

and

ST33061000

Fig

PD

12

Removing

ide

bearing

Page 336 of 537

PROPElli

ER

SHAfT

DIFFERENTIAL

G

ARRIERf

Notes

a

PUller

should

be

handled

with

care

in

catchins

the

edge

of

bearing

inner

race

b

Be

careful

not

to

confuse

left

and

right

hand

parts

2

Remove

ring

gear

by

spreading

out

lock

strap

and

loosening

ring

gear

bolts

in

diagonally

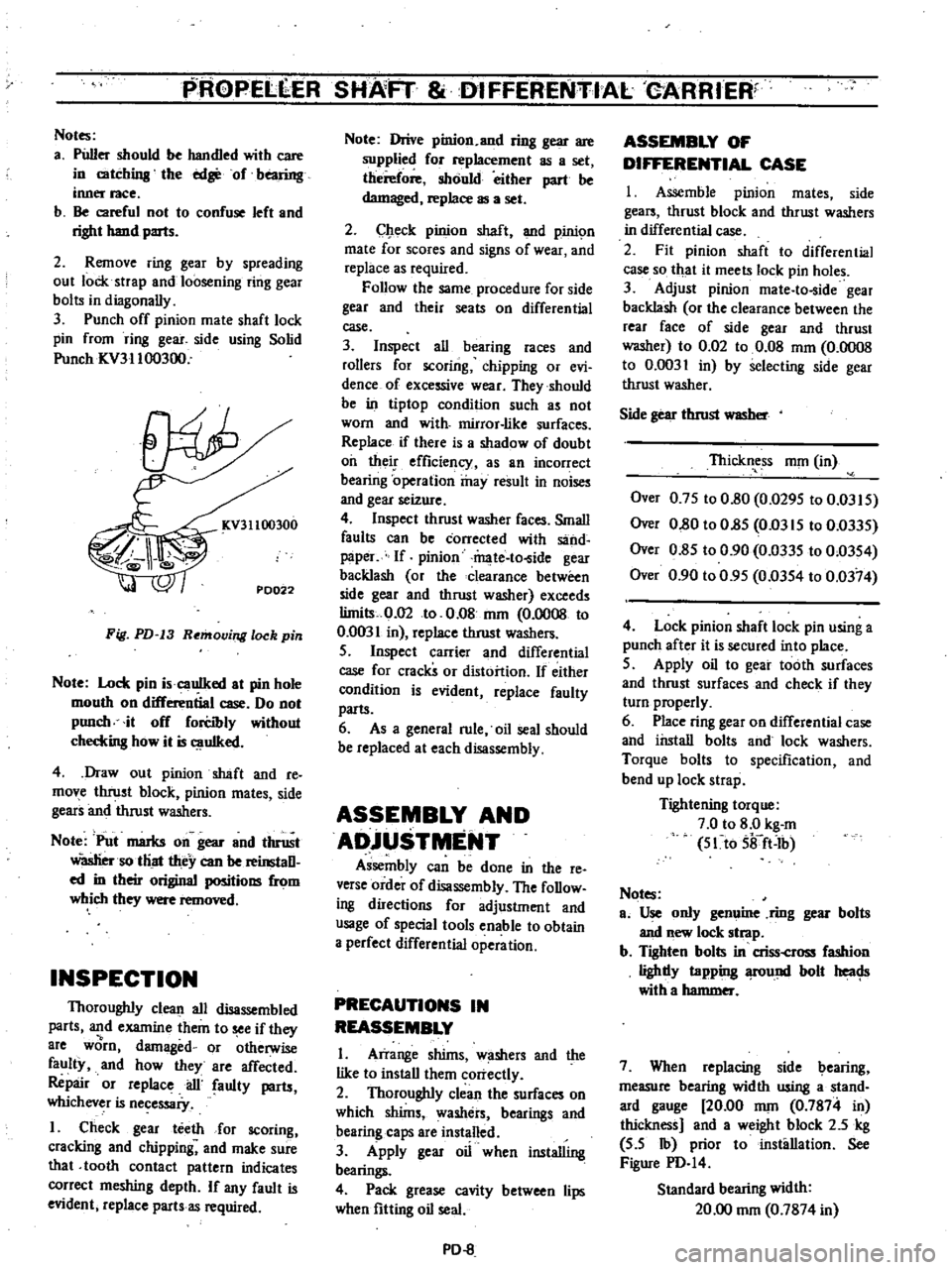

3

Punch

off

pinion

mate

shaft

lock

pin

from

ring

gear

side

using

Solid

Punch

ICV31100300

KV31100300

PD022

Fig

PD

13

Removing

lock

pin

Note

Lock

pin

i

cauIked

at

pin

hole

mouth

on

differential

case

Do

not

punch

it

off

forCibly

without

checkins

how

it

is

uIked

4

Draw

out

pinion

shaft

and

re

move

thrust

block

pinion

mates

side

gears

and

thrust

washers

Note

Put

marks

on

gear

and

thrust

Wasliersotliat

they

can

be

reinstaD

ed

in

their

original

positions

from

which

they

were

removed

INSPECTION

Thoroughly

clean

all

disassembled

parts

and

examine

them

to

see

if

they

8re

worn

damaged

or

otherwise

faulty

and

how

they

are

affected

Repair

or

replace

ail

faulty

parts

whichever

is

necessaiy

I

Check

gear

teeth

for

scoring

cracking

and

chipping

and

make

sure

that

tooth

contact

pattern

indicates

correct

meshing

depth

If

any

fault

is

evident

replace

parts

as

required

Note

Drive

pinion

and

ring

gear

are

supplied

for

replacement

as

a

set

therefore

should

either

part

be

damaged

replace

as

a

set

2

Check

pinion

shaft

and

pinic

m

mate

for

scores

and

signs

of

wear

and

replace

as

required

Follow

the

same

procedure

for

side

gear

and

their

seats

on

differential

case

3

Inspect

all

bearing

races

and

rollers

for

scoring

chipping

or

evi

dence

of

excessive

wear

They

should

be

in

tiptop

condition

such

as

not

worn

and

with

mirror

like

surfaces

Replace

if

there

is

a

shadow

of

doubt

oil

their

efficiency

as

an

incorrect

bearing

operation

may

result

in

noises

and

gear

seizure

4

Inspect

thrust

washer

faces

Small

faults

can

be

corrected

with

sand

paper

If

pinion

mate

to

ide

gear

backlash

or

the

clearance

between

side

gear

and

thrust

washer

exceeds

limits

0

02

to

0

08

nun

0

0008

to

0

0031

in

replace

thrust

washers

S

Inspect

carrier

and

differential

case

for

cracks

or

distortion

If

either

condition

is

evident

replace

faulty

parts

6

As

a

general

rule

oil

seal

should

be

replaced

at

each

disassembly

ASSEMBLY

AND

ADjUSTMENT

Assembly

can

be

done

in

the

reo

verse

order

of

disassembly

The

foDow

ing

directions

for

adjustment

and

usage

of

special

tools

enable

to

obtain

a

perfect

differential

operation

PRECAUTIONS

IN

REASSEMBLY

I

Arrange

shims

w

shers

and

the

like

to

install

them

correctly

2

Thoroughly

clean

the

surfaces

on

which

shims

washers

bearings

and

bearing

caps

are

installed

3

Apply

gear

oil

when

installing

bearings

4

Pack

grease

cavity

between

lips

when

fitting

oil

seal

PD

8

ASSEMBLY

OF

DIFFERENTIAL

CASE

I

Assemble

pinion

mates

side

gears

thrust

block

and

thrust

washers

in

differential

case

2

Fit

pinion

shaft

to

differential

case

so

that

it

meets

lock

pin

holes

3

Adjust

pinion

mate

to

ide

gear

backlash

or

the

clearance

between

the

rear

face

of

side

gear

and

thrust

washer

to

0

02

to

0

08

mOl

0

0008

to

0

0031

in

by

selecting

side

gear

thrust

washer

Side

gear

thrust

WlISber

Thickness

nun

in

Over

0

7S

to

0

80

0

029S

to

0

03IS

Over

0

80

to

O

8S

Om

IS

to

0

033S

Over

0

8S

to

0

90

0

033S

to

0

03S4

Over

0

90

to

0

9S

0

03S4

to

0

0374

4

Lock

pinion

shaft

lock

pin

using

a

punch

after

it

is

secured

into

place

S

Apply

oil

to

gear

tooth

surfaces

and

thrust

surfaces

and

check

if

they

turn

properly

6

Place

ring

gear

on

differential

case

and

install

bolts

and

lock

washers

Torque

bolts

to

specification

and

bend

up

lock

strap

Tightening

torque

7

0

to

8

0

kg

m

S1to

Sifft

Ib

Notes

ao

Use

only

genuine

ring

gear

bolts

and

new

lock

strap

b

Tighten

bolts

in

criss

cross

fashion

lighdy

tapping

fOund

bolt

heac

Js

with

a

hammer

7

When

replacing

side

bearing

measure

bearing

width

using

a

stand

ard

gauge

20

00

nun

0

7874

in

thickness

and

a

weight

block

2

5

kg

S

S

Ib

prior

to

installation

See

Figure

PD

I4

Standard

bearing

width

20

00

nun

0

7874

in

Page 341 of 537

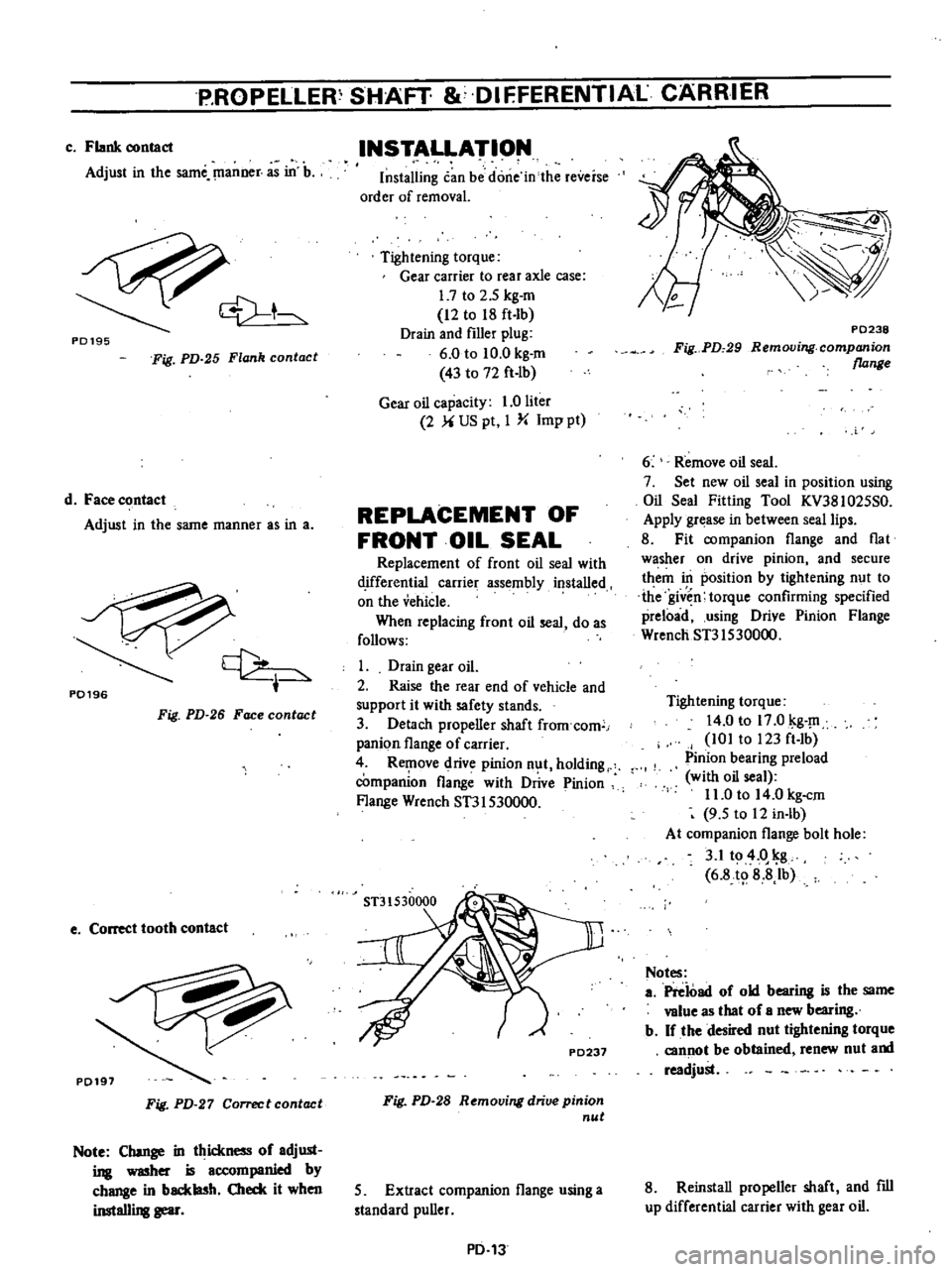

P

ROPELLER

SHAFT

DIFFERENTIAL

CARRIER

c

Flank

oontact

Adjust

in

the

same

manner

as

in

b

cV

t

PD195

Fig

PD

25

Flank

contact

d

Face

contact

Adjust

in

the

same

manner

as

in

a

P0196

t

Fig

PD

26

Face

contact

e

Correct

tooth

contact

Fig

PD

27

Correct

contact

Note

Change

in

thickness

of

adjWll

ing

washer

is

accompanied

by

change

in

backlash

Oled

it

when

instaIIi

gear

INSTALLATION

Installing

can

be

done

in

the

reverse

order

of

removal

Tightening

torque

Gear

carrier

to

rear

axle

case

1

7

to

2

5

kg

m

12

to

18

ft

lb

Drain

and

filler

plug

6

0

to

10

0

kg

m

43

to

72

ft

lb

Gear

oil

capacity

1

0

liter

2

US

pt

I

Y

Imp

pt

REPLACEMENT

OF

FRONT

OIL

SEAL

Replacement

of

front

oil

seal

with

d

ifferential

carrier

assembly

installed

on

the

vehicle

When

replacing

front

oil

seal

do

as

follows

1

Drain

gear

oil

2

Raise

the

rear

end

of

vehicle

and

support

it

with

safety

stands

3

Detach

propeller

shaft

from

com

panion

flange

of

carrier

4

R

1

ove

drive

pinion

n

t

holding

companion

flange

with

Drive

Pinion

Flange

Wrench

ST31S30000

P0238

Fig

PD

29

Removing

companion

flange

6

Remove

oil

seal

7

Set

new

oil

seal

in

position

using

Oil

Seal

Fitting

Tool

KV38102SS0

Apply

grease

in

between

seal

lips

8

Fit

companion

flange

and

flat

w

sher

on

drive

pinion

and

secure

them

in

position

by

tightening

nut

to

the

given

torque

confirming

specified

preload

using

Drive

Pinion

Flange

WrencliST31530000

Tightening

torque

14

0

to

17

0

kg

101

to

123

ft

Ib

Pinion

bearing

preload

with

oil

seal

11

0

to

14

0

kg

cm

9

5

to

12

in

lb

At

companion

flange

bolt

hole

3

1

to

4

o

g

6

8

8

8Ib

Notes

a

Preioad

of

old

bearing

is

the

same

value

as

that

of

a

new

bearing

b

If

the

desired

nut

tightening

torque

P0237

can

ot

be

obtained

renew

nut

and

readjust

Fig

PD

28

R

moving

drive

pinion

nut

S

Extract

companion

flange

using

a

standard

puller

PD

13

8

Reinstall

propeller

shaft

and

fill

up

differential

carrier

with

gear

oil

Page 352 of 537

The

design

of

the

front

suspension

adopts

the

independent

double

wishbone

type

suspension

used

the

torsion

bar

spring

Both

the

upper

and

lower

links

are

installed

on

the

bracket

which

is

welded

on

the

frame

A

1d

the

above

links

swing

to

allow

the

knuckle

spindle

to

move

freely

in

a

vertical

dimension

The

top

and

bottom

of

the

knuckle

spindle

support

are

connected

to

the

upper

link

through

rubber

bushing

and

to

the

lower

lick

through

screw

bushing

The

tension

rod

held

by

the

brack

ets

on

the

chassis

frame

and

lower

lick

wiih

rubber

bushings

bears

the

force

of

fore

and

aft

direction

The

front

end

of

the

torsion

bar

spring

is

installed

to

the

torque

arm

which

attaches

to

the

lower

link

The

opposite

end

is

installed

to

the

spring

anchor

that

secures

to

chassis

frame

firmly

The

both

ends

of

the

torsion

bar

spring

are

serrated

The

shock

absorber

is

double

action

telescopic

hydraulic

type

The

upper

stem

is

attached

to

the

bracket

of

the

chassis

frame

The

lower

insulated

bracket

is

bolted

to

the

lower

lick

The

bumper

rubber

secured

to

the

bracket

Of

the

frame

limits

the

verti

cal

motion

of

the

suspension

lick

The

knuckle

spindle

is

connecied

to

the

k

ufkle

spindle

arm

by

the

king

pin

The

king

pin

bushings

are

fitted

to

the

upper

and

lower

arm

portIOns

of

the

knuckle

spindle

and

seals

are

provided

at

the

portions

mentioned

to

keep

water

and

dirt

from

enteri

g

The

knuckle

arm

is

connected

to

the

lower

end

of

the

knuckle

spindle

to

transmit

ttLe

movement

of

the

steering

wheel

to

the

knuckle

spindle

The

wheel

hub

is

supported

by

two

taper

roller

bearings

on

the

knuckle

spindle

Tlie

brake

drum

and

wheel

are

secured

to

ihe

hub

by

the

hub

bolts

Front

Axle

Front

Suspension

FRONT

AXLE

REMOVAL

AND

INSTALLATION

Removal

I

Jack

up

and

support

vehicle

on

the

stands

at

the

frame

in

a

safe

manner

2

Remove

front

wheel

3

Re

ove

brake

hose

together

with

connector

from

wheel

cylinder

4

Remove

brake

drum

S

Remove

hub

cap

and

then

remove

cotter

pin

adjusting

cap

and

spindle

nut

from

knuckle

spindle

6

Remove

wheel

hub

outer

and

inner

wheel

bearings

bearing

washer

and

grease

seal

from

knuckle

spindle

7

Remove

brake

disc

assembly

from

the

flange

of

knuckle

spindle

8

Remove

knuckle

arm

from

knuckle

spindle

9

Remove

king

pin

lock

bolt

FA225

Fig

FA

R

mol1ing

king

pin

loch

nut

10

After

removing

air

breather

re

move

plug

from

the

top

of

king

pin

with

the

following

method

Drill

a

10

5

mm

0

413

in

diameter

hole

on

the

plug

thread

hole

with

a

tap

M

12

1

2S

screw

a

bolt

into

threaded

hole

and

pull

out

the

plug

II

Apply

drift

to

the

top

of

king

pin

and

drive

out

king

pin

along

with

lower

plug

12

Tap

spindle

with

a

soft

haJnmer

and

detach

it

from

knuckle

spindle

support

Take

care

not

io

drop

thrust

bearing

FA

3

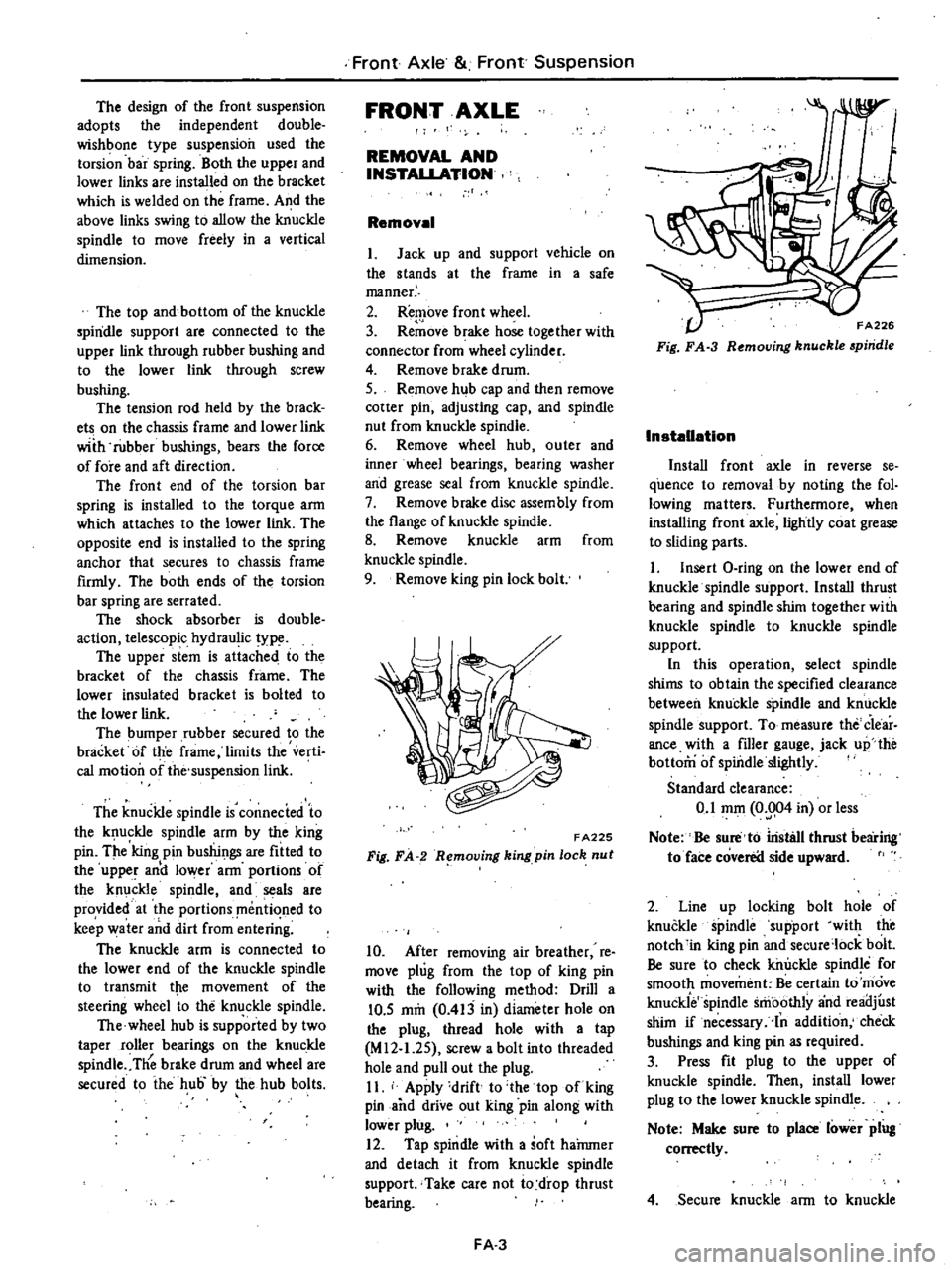

FA226

Fig

FA

3

R

moving

knuckle

piridle

Installation

Install

front

axle

in

reverse

se

quence

to

removal

by

noting

the

fol

lowing

matters

Furthermore

when

installing

front

axle

lightly

coat

grease

to

sliding

parts

I

Insert

O

ring

on

the

lower

end

of

knuckle

spindle

support

Install

thrust

bearing

and

spindle

shim

together

with

knuckle

spindle

to

knuckle

spindle

support

In

this

operation

select

spindle

shims

to

obtain

the

specified

clearance

between

knuckle

spindle

and

knuckle

spindle

support

To

measure

the

Clear

ance

with

a

filler

gauge

jack

up

the

bottom

of

spindle

slightly

Standard

clearance

0

1

mOl

0

004

in

or

less

Note

Be

sure

to

iristsll

thrust

bearing

to

face

coverea

side

upward

2

Line

up

locking

bolt

hole

of

knuckle

spindle

support

with

the

notch

in

king

pin

and

secure

lock

bolt

Be

sure

to

check

killJckle

spindle

for

smooth

movement

Be

certain

to

move

knuckie

spindle

smoothly

and

reailjust

shim

if

necessary

In

addition

check

bushings

and

king

pin

as

required

3

Press

fit

plug

to

the

upper

of

knuckle

spindle

Then

install

lower

plug

to

the

lower

knuckle

spindle

Note

Make

sure

to

place

lower

plug

conectly

4

Secure

knuckle

arm

to

knuckle

Page 353 of 537

spindle

and

torque

bolt

to

10

3

to

12

1

kg

m

75

to

88

ft

lb

Bend

lock

plate

to

engaged

flats

on

boll

head

Note

When

disassembled

discard

used

lock

plate

5

Pack

grea

to

the

upP

r

and

lower

bushings

on

knuckle

spindle

until

grease

c

omes

out

from

gr

ease

seal

6

Fill

wheel

hub

and

cap

with

grease

up

to

the

described

level

See

Figure

F

A

4

FA141

Fig

FA

4

Gre

ing

wheel

hub

7

Pack

roller

and

cone

assembly

and

the

cavity

of

grease

seal

lip

with

grease

8

Coat

grease

to

the

thread

of

knuckle

spindle

bearing

washer

and

bearing

lock

nul

9

Secure

wheel

hub

bearings

bear

ing

washer

and

spindle

nut

on

knuckle

spindle

and

adju

t

bearing

preload

referring

to

the

paragraph

Wheel

bearing

adjustment

Note

Be

sure

to

obtain

correct

pre

load

on

wheel

bearings

for

the

pu

rpose

of

ving

their

long

life

taking

care

to

keep

wheel

be8rlngs

grease

seal

bearing

washer

and

spin

dle

nut

clean

when

installing

them

WHEEL

BEARING

D

TM

NT

Wrong

adjustment

of

wheel

bear

ing

causes

abnonnal

wear

and

score

on

the

bearings

and

knuckle

spindle

Front

Axle

Front

Suspension

To

attain

proper

preload

on

wheel

bearings

proceed

the

following

opera

tions

I

Torque

spindle

nut

to

3

0

to

3

S

kg

m

22

to

25

ft

lb

using

torque

wrench

FA227

Fig

FA

5

Tightening

apindle

nut

2

Rotate

wheel

hub

a

few

turns

clockwise

and

counterclockwise

to

seat

bearings

Then

retighten

spindle

nut

to

the

same

tightening

torque

Be

certain

to

rotate

hub

smoothly

3

Back

off

spindle

nut

in

range

from

40

to

70

degrees

Locate

adjust

ing

cap

on

spindle

nut

so

as

to

align

the

castellation

on

the

cap

with

the

cotter

pin

hole

in

the

spindle

4

Check

the

hub

rotation

If

hub

rotates

properly

measure

bearing

rota

tion

starting

torque

If

measured

torque

is

deviated

from

the

specified

value

r

place

beari

gs

r

re

dju

st

The

starting

torque

can

be

mea

sured

by

a

spring

balance

as

shown

in

Figure

F

A

6

Spring

balance

indication

at

hub

bolt

New

bearing

2

1

kg

4

Ib

o

ess

Used

bearing

1

0

kg

2

2

lb

or

less

Notes

a

When

measuring

the

starting

force

pull

the

spring

balance

toward

tan

gential

direction

against

normal

line

connected

between

hub

boll

and

spindle

center

b

Axial

play

is

permissible

to

exist

in

0

1

mm

0

004

in

or

less

FA

4

fA22S

Fig

FA

6

Mea

uring

bearing

rotation

atarting

torque

S

Install

a

new

cotter

pin

Bend

the

ends

of

coller

pin

around

the

castel

lated

flange

of

adjusting

cap

Then

install

hub

cap

DISASSEMBLY

AND

ASSEMBLY

Knuckle

spindle

I

Drive

spindle

bushing

and

grease

seal

out

of

knuckle

spindle

with

KiTlg

Pin

Bush

Drift

ST3S380000

Discard

bushing

and

grease

seal

when

disas

sembled

2

After

cleaning

king

pin

bores

thoroughly

install

bushing

carefully

by

using

the

above

special

tpol

Posi

tion

bushing

in

accordance

With

the

instructions

fIlled

in

Figure

F

A

7

and

FA

8

34

mm

1

34

in

Upper

side

in

lower

boss

I

I

1

II

I

Pla

ce

this

position

in

line

with

grease

nipple

hole

Upper

side

in

upper

boss

FA229

Fig

FA

7

King

pin

bu

hing

Page 357 of 537

SHOCK

ABSORBER

REMOVAL

AND

INSTAUATION

1

Raise

vehicle

on

a

hoist

or

stands

2

Remove

wheel

3

Hold

the

upper

stem

of

shock

absorber

and

remove

outs

washer

and

rubber

bushing

4

Remove

bolt

from

the

lower

end

of

shock

absorber

FA232

Fig

FA

13

Shock

absorber

S

Retain

lower

rubber

bushing

in

position

install

the

lower

end

of

shock

absorber

to

the

bracket

of

lower

link

and

torque

the

bolt

to

3

1

to

4

1

kg

m

23

to

30

ft

lb

Note

Insert

the

bolt

from

the

front

side

of

vehicle

6

Install

the

upper

end

of

shock

absorber

to

body

bracket

and

tighten

lock

n

Jt

to

the

specifjcations

Tightening

torque

1

6

to

2

2

kg

m

121016

ft

lb

INSPECTION

I

Check

shock

absorber

for

visible

defects

and

oil

leaks

Place

shock

absorber

vertically

in

a

vise

and

hand

stroke

shock

absorber

as

outlined

be

low

Extend

and

compress

shock

ab

sorber

as

faI

as

possible

travelling

as

long

as

possible

If

smooth

hydraulic

resistance

is

not

present

in

bqth

Iirection

replace

absorber

2

Replace

rubber

bushing

if

crack

or

deterioration

is

detected

Front

Axle

Front

Suspension

Specifications

for

shock

absorber

Model

Item

Piston

stroke

mm

in

Damping

force

kg

lb

0

3

m

sec

0

98

ft

sec

j

Rebound

Compression

STABILIZER

REMOVAL

AND

INSTAUATION

I

Raise

vehicle

on

a

hoist

or

stands

2

Remove

wheel

3

Loosen

secUring

nut

at

the

lower

link

side

of

stabilizer

4

Remove

bolt

securing

stabilizer

mounting

bracket

to

chassis

frame

Install

stabilizer

in

the

reverse

se

quence

to

removal

noting

the

follow

ing

instructions

S

Attach

stabilizer

mounting

brack

et

to

chassis

frame

tightening

bolt

to

1

6

to

2

2

kg

m

12

to

16

ft

lb

torque

6

Install

stabilizer

lower

link

side

to

connecting

rod

and

tighten

nut

to

the

specifications

as

shown

in

Figure

FA

14

Then

torque

lock

nut

toJ

6

to

2

2

kg

m

12

to

16

ft

lb

F

A233

Fig

FA

14

Stabilizer

detail

INSPECTION

Check

stabilizer

for

deformation

FA

S

All

models

110

4

3

76

168

38

84

and

rubber

bushings

for

crack

wear

and

deterioration

Replace

if

ne

cessary

TENSION

POD

REMOVAL

AND

INSTALLATION

I

Raise

vehicle

on

a

hoist

or

stands

2

Remove

wheel

3

Remove

nuts

CD

from

both

ends

of

tension

rod

4

Remove

bracket

bolt

@

from

the

front

end

of

tension

rod

and

remove

tension

rod

with

bracket

CD

@

f

A234

Fig

FA

15

Ten

ion

rod

Install

tension

rod

in

reverse

00

qunce

to

removal

noting

the

following

instructions

Page 359 of 537

UPPER

AND

LOWER

LINKS

REMOVAL

AND

INSTALLATION

Removal

I

Raise

vehicle

on

a

hoist

or

stands

2

Remove

wheel

and

brake

drum

as

an

assembly

3

Remove

wheel

hub

Refer

to

see

tion

Front

Axle

4

Loosen

bolts

retaining

brake

disc

to

knuckle

spindle

and

remove

brake

disc

5

Remove

knuckle

arm

torsion

bar

spimgJ

stabilizer

shock

absorber

and

tension

rod

in

t

ili

order

referring

the

related

sections

6

Remove

upper

fulcrum

bolt

se

curing

knuckle

spindle

support

to

upper

link

assembly

and

disassemble

them

7

Remove

upper

link

bushings

from

knuckle

spindle

support

8

Remove

screw

bushings

from

both

ends

of

lower

link

fulcrum

pin

9

Loosen

nut

at

lower

portion

of

knuckle

spindle

support

from

inside

and

pull

out

cotter

pin

retaining

ful

crum

pin

10

Pull

out

fulcrum

pin

with

drift

and

remove

knuckle

spindle

support

with

knuckle

spindle

from

lower

link

Then

detach

dust

cover

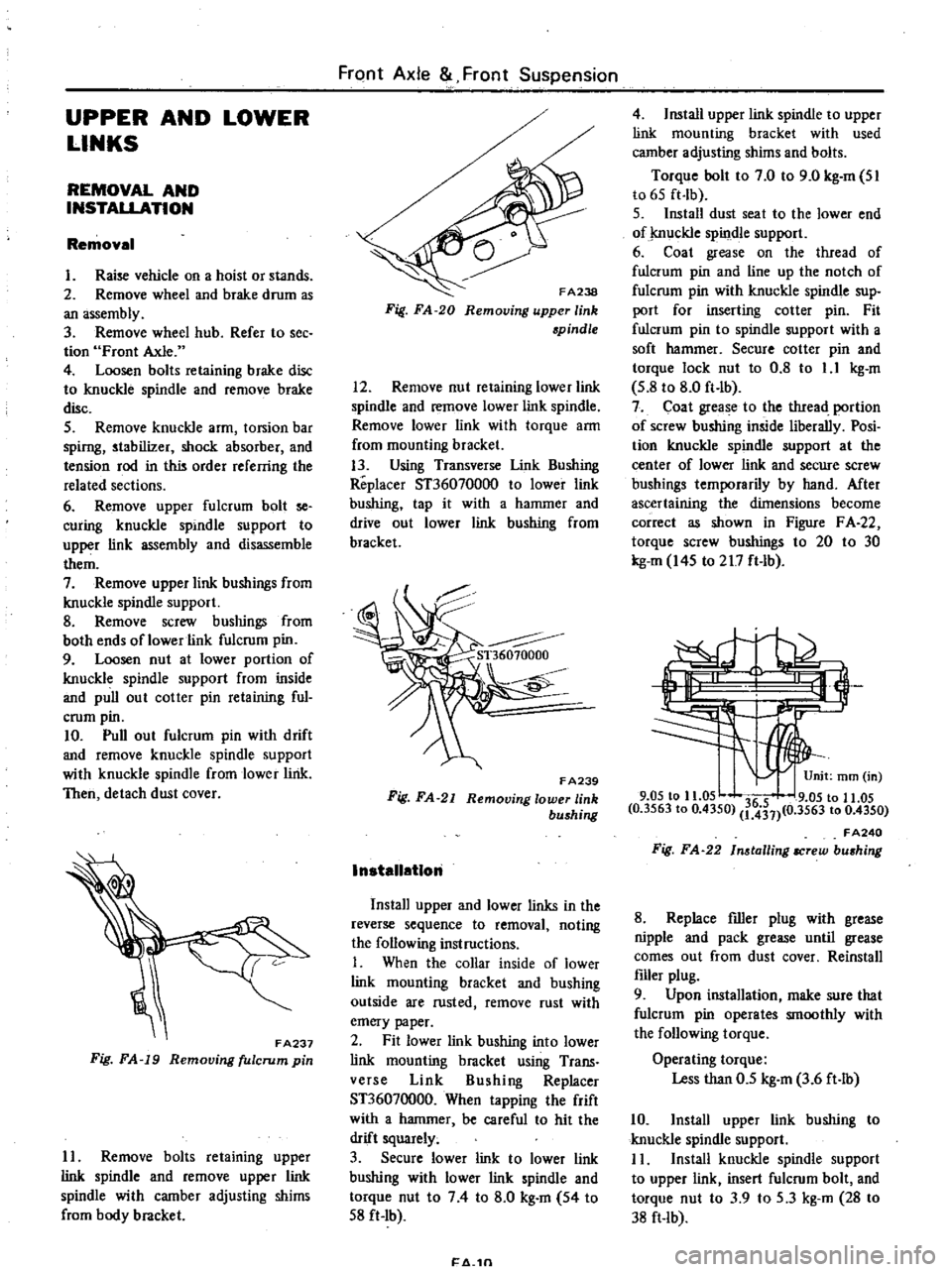

FA237

Fig

FA

19

Removing

fulcrum

pin

II

Remove

bolts

retaining

upper

link

spindle

and

remove

upper

link

spindle

with

camber

adjusting

shims

from

body

bracket

FrClnt

Axle

Front

Suspension

FA238

Fig

FA

20

Removing

upper

link

spindle

12

Remove

nut

retaining

lower

link

spindle

and

remove

lower

link

spindle

Remove

lower

link

with

torque

arm

from

mounting

bracket

13

Using

Transverse

Unk

Bushing

Replacer

ST36070000

to

lower

link

bushing

tap

it

with

a

hammer

and

drive

out

lower

link

bushing

from

bracket

F

A239

Fig

FA

21

Removing

lower

link

bushing

InstallatIon

Install

upper

and

lower

links

in

the

reverse

sequence

to

removal

noting

the

following

instructions

I

When

the

collar

inside

of

lower

link

mounting

bracket

and

bushing

outside

are

rusted

remove

rust

with

emery

paper

2

Fit

lower

link

bushing

into

lower

link

mounting

bracket

using

Trans

verse

Link

Bushing

Replacer

ST36070000

When

tapping

the

frift

with

a

hammer

be

careful

to

hit

the

drift

squarely

3

Secure

lower

link

to

lower

link

bushing

with

lower

link

spindle

and

torque

nut

to

74

to

8

0

kg

m

54

to

S8

ft

Ib

1

4

1n

4

Install

upper

link

spindle

to

upper

link

mounting

bracket

with

used

camber

adjusting

shims

and

bolts

Torque

bolt

to

7

0

to

9

0

kg

m

SI

to

6S

ft

lb

S

Install

dust

seat

to

the

lower

end

of

j

nuckle

spindle

support

6

Coat

grease

on

the

thread

of

fulcrum

pin

and

line

up

the

notch

of

fulcrum

pin

with

knuckle

spindle

sup

port

for

inserting

cotter

pin

Fit

fulcrum

pin

to

spindle

support

with

a

soft

hammer

Secure

cotter

pin

and

torque

lock

nut

to

0

8

to

1

1

kg

m

S

8

to

8

0

ft

lb

7

Coat

grease

to

the

tIuead

portion

of

screw

bushing

inside

liberally

Posi

tion

knuckle

spindle

support

at

the

center

of

lower

link

and

secure

screw

bushings

temporarily

by

hand

Mter

ascertaining

the

dimensions

become

correct

as

shown

in

Figure

F

A

22

torque

screw

bushings

to

20

to

30

kg

m

I4S

to

217

ft

lb

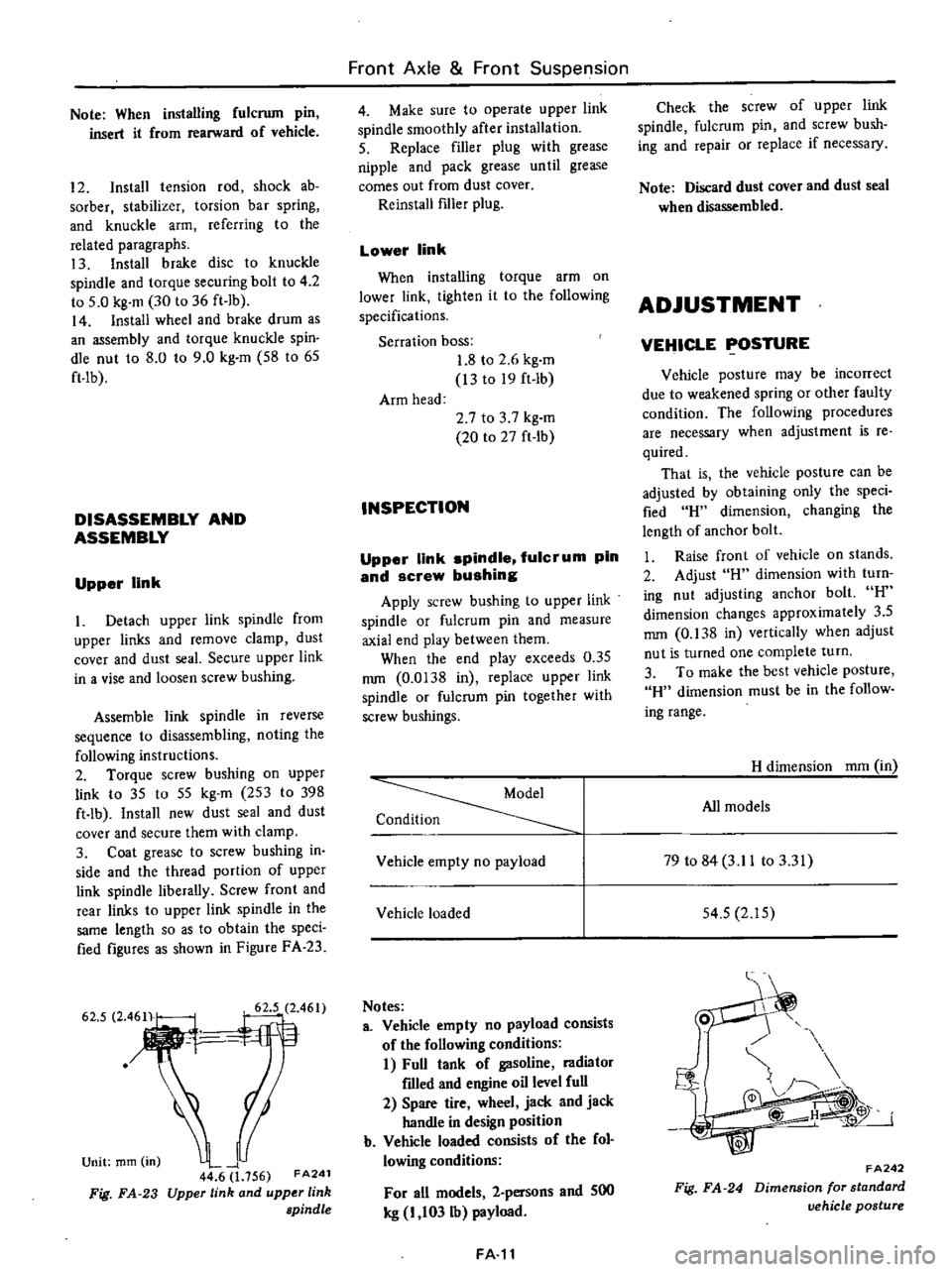

3

9

05

to

11

05

36

5

9

05

to

11

05

0

3563

to

0

4350

1

431

0

3563

to

0

4350

FA240

Fig

FA

22

In

tailing

IICrew

bu

hing

8

Replace

filler

plug

with

grease

nipple

and

pack

grease

until

grease

comes

out

from

dust

cover

Reinstall

filler

plug

9

Upon

installation

make

sure

that

fulcrum

pin

operates

smoothly

with

the

following

torque

Operating

torque

Less

than

0

5

kg

m

3

6

ft

lb

10

Install

upper

link

bushing

to

knuckle

spindle

support

I

I

Install

knuckle

spindle

support

to

upper

link

insert

fulcrum

bolt

and

torque

nut

to

3

9

to

S

3

kg

m

28

to

38

ft

lb

Page 360 of 537

Note

When

installing

fulcrum

pin

insert

it

from

rearward

of

vehicle

12

Install

tension

rod

shock

ab

sorber

I

stabilizer

torsion

bar

spring

and

knuckle

arm

referring

to

the

related

paragraphs

13

Install

brake

disc

to

knuckle

spindle

and

torque

securing

bolt

to

4

2

to

5

0

kg

m

30

to

36

ft

Ib

14

Install

wheel

and

brake

drum

as

an

assembly

and

torque

knuckle

spin

dle

nut

to

8

0

to

9

0

kg

m

58

to

65

ft

Ib

DISASSEMBLY

AND

ASSEMBLY

Upper

link

I

Detach

upper

link

spindle

from

upper

links

and

remove

clamp

dust

cover

and

dust

seal

Secure

upper

link

in

a

vise

and

loosen

screw

bushing

Assemble

link

spindle

in

reverse

sequence

to

disassembling

noting

the

following

instructions

2

Torque

screw

bushing

on

upper

link

to

3S

to

55

kg

m

253

to

398

ft

Ib

Install

new

dust

seal

and

dust

cover

and

secure

them

with

clamp

3

Coat

grease

to

screw

bushing

in

side

and

the

thread

portion

of

upper

link

spindle

liberally

Screw

front

and

rear

links

to

upper

link

spindle

in

the

same

length

so

as

to

obtain

the

speci

fied

figures

as

shown

in

Figure

FA

23

Unit

mm

in

I

44

6

1

156

FA2

Upper

link

and

upper

link

spindle

Fig

FA

23

Front

Axle

Front

Suspension

4

Make

sure

to

operate

upper

link

spindle

smoothly

after

installation

5

Replace

filler

plug

with

grease

nipple

and

pack

grease

until

grease

comes

out

from

dust

cover

Reinstall

f1ller

plug

Lower

link

When

installing

torque

arm

on

lower

link

tighten

it

to

the

following

specifications

Serration

boss

1

8

to

2

6

kg

m

13

to

19

ft

Ib

Arm

head

2

7

to

3

7

kg

m

20

to

27

ft

tb

INSPECTION

Upper

link

spindle

fulcrum

pin

and

screw

bushing

Apply

screw

bushing

to

upper

link

spindle

or

fulcrum

pin

and

measure

axial

end

play

between

them

When

the

end

play

exceeds

0

35

mm

0

0138

in

replace

upper

link

spindle

or

fulcrum

pin

together

with

screw

bushings

Condition

Vehicle

empty

no

payload

Vehicle

loaded

Notes

a

Vehicle

empty

no

payload

consists

of

the

following

conditions

I

Full

tank

of

gasoline

radiator

f1lled

and

engine

oil

level

full

2

Spare

tire

wheel

jack

and

jack

handle

in

design

position

b

Vehicle

loaded

consists

of

the

fol

lowing

conditions

For

all

models

2

persons

and

SIlO

leg

I

103lb

payload

FA

Check

the

screw

of

upper

link

spindle

fulcrum

pin

and

screw

bush

ing

and

repair

or

replace

if

necessary

Note

Discard

dust

cover

and

dust

seal

when

disassembled

ADJUSTMENT

VEHICLE

POSTURE

Vehicle

posture

may

be

incorrect

due

to

weakened

spring

or

other

faulty

condition

The

following

procedures

are

necessary

when

adjustment

is

Ie

quired

That

is

the

vehicle

posture

can

be

adjusted

by

obtaining

only

the

speci

fied

H

dimension

changing

the

length

of

anchor

bolt

I

Raise

front

of

vehicle

on

stands

2

Adjust

H

dimension

with

turn

ing

nut

adjusting

anchor

bolt

H

dimension

changes

approximately

3

5

mm

0

J38

in

vertically

when

adjust

nut

is

turned

one

complete

turn

3

To

make

the

best

vehicle

posture

H

dimension

must

be

in

the

follow

ing

range

H

dimension

mOl

in

All

models

79

to

84

3

11

to

3

31

54

5

2

15

o

i

Fig

FA

24

FA242

Dimension

for

standard

vehicle

postl4re