air condition DATSUN PICK-UP 1977 Owner's Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 109 of 537

Engine

Fuel

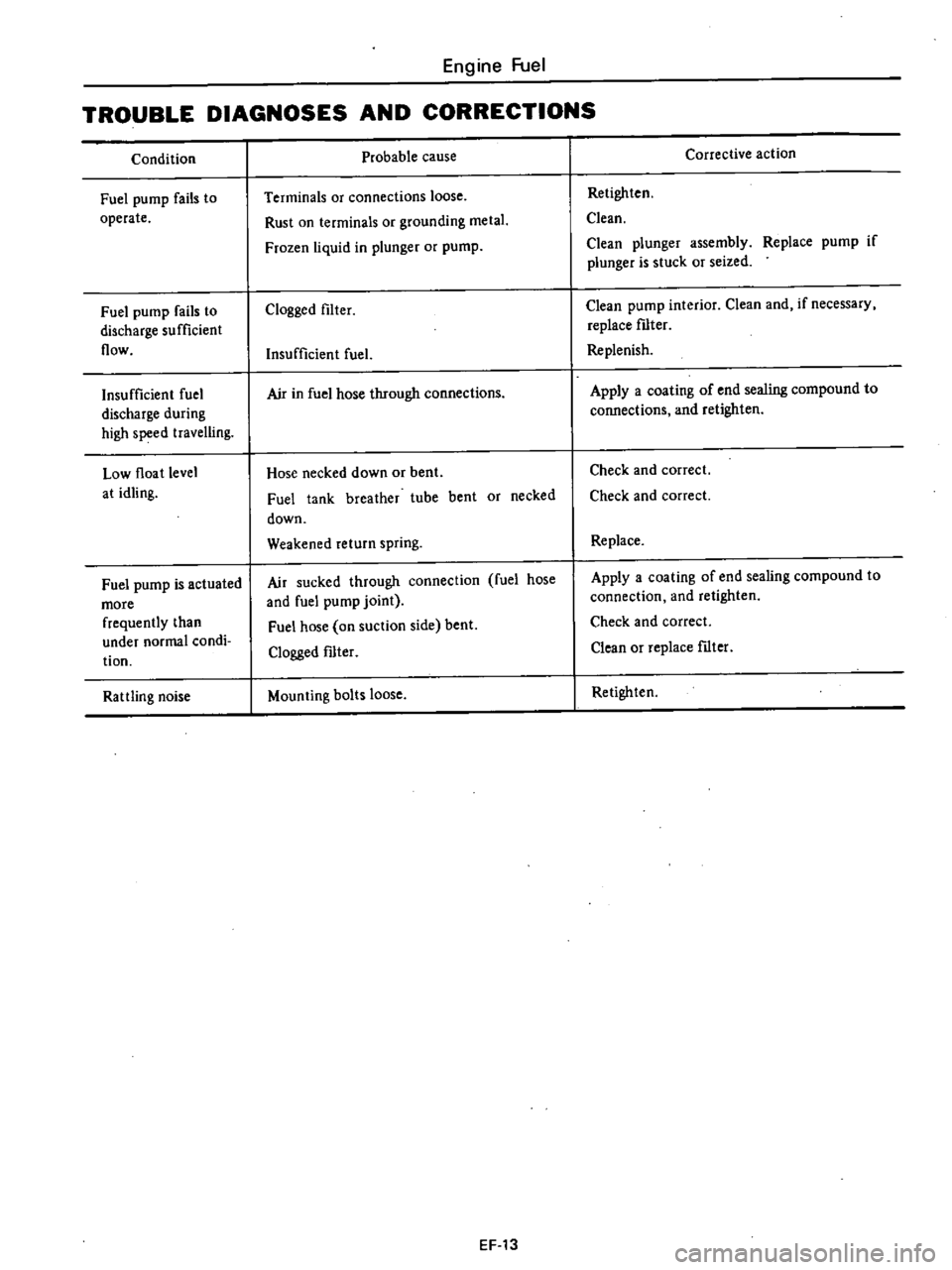

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Fuel

pump

fails

to

operate

Fuel

pump

fails

to

discharge

sufficient

flow

Insufficient

fuel

discharge

during

high

speed

travelling

Low

float

level

at

idling

Fuel

pump

is

actuated

more

frequently

than

under

normal

condi

tion

Rattling

noise

Probable

cause

Terminals

or

connections

loose

Rust

on

terminals

or

grounding

metal

Frozen

liquid

in

plunger

or

pump

Clogged

filter

Insufficient

fuel

Air

in

fuel

hose

through

connections

Hose

necked

down

or

bent

Fuel

tank

breather

tube

bent

or

necked

down

Weakened

return

spring

Air

sucked

through

connection

fuel

hose

and

fuel

pump

joint

Fuel

hose

on

suction

side

bent

Clogged

fIlter

Mounting

bolts

loose

EF

13

Corrective

action

Retighten

Clean

Clean

plunger

assembly

Replace

pump

if

plunger

is

stuck

or

seized

Clean

pump

interior

Clean

and

if

necessary

replace

fIlter

Replenish

Apply

a

coating

of

end

sealing

compound

to

connections

and

retighten

Check

and

correct

Check

and

correct

Replace

Apply

a

coating

of

end

sealing

compound

to

connection

and

retighten

Check

and

correct

Clean

or

replace

fIlter

Retighten

Page 110 of 537

Engine

Fuel

CARBURETOR

CONTENTS

DESCRIPTION

EF

14

CHOKE

UNLOADER

EF

23

STRUCTURE

AND

OPERATION

EF

14

ELECTRIC

AUTOMATIC

CHOKE

EF

24

PRIMARY

SYSTEM

EF

15

INTERLOCK

OPENING

OF

PRIMARY

AND

SECONDARY

SYSTEM

EF

16

SECONDARY

THROTTLE

VALVE

EF

24

ANTI

DIESELING

SYSTEM

EF

17

DASH

POT

EF

25

FLOAT

SYSTEM

EF

18

ACCELERATING

PUMP

EF

25

BOOST

CONTROLLED

DECELERATION

ANTI

DIESELING

SOLENOID

VALVE

EF

25

DEVICE

B

C

D

D

EF

1B

B

C

D

D

CIRCUIT

WITH

FUNCTION

ELECTRIC

AUTOMATIC

CHOKE

EF

20

TEST

CONNECTOR

EF

25

DASH

POT

SYSTEM

EF

20

ALTITUDE

COMPENSATOR

ALTITUDE

COMPENSATOR

California

modelsl

EF

29

California

models

EF

20

MAJOR

SERVICE

OPERATION

EF

29

ADJUSTMENT

AND

INSPECTION

EF

21

REMOVAL

EF

29

CARBURETOR

IDLE

RPM

AND

DISASSEMBLY

AND

ASSEMBLY

EF

30

MIXTURE

RATIO

EF

21

CLEANING

AND

INSPECTION

EF

34

FUEL

LEVEL

EF

22

SERVICE

DATA

AND

SPECIFICATIONS

EF

35

FAST

IDLE

EF

22

TROU8LE

DIAGNOSES

AND

VACUUM

BREAK

EF

23

CORRECTIONS

EF

36

DESCRIPTION

The

carburetors

are

of

down

draft

two

barrel

types

which

produce

the

optimum

air

fuel

mixture

under

all

operating

conditions

They

present

several

distinct

features

of

importance

to

the

vehicle

owners

A

summary

of

the

features

is

as

follows

1

A

slow

economizer

to

make

a

smooth

connection

with

acceleration

or

deceleration

during

light

load

run

ning

It

also

assures

stable

low

speed

performance

2

An

idle

limiter

to

reduce

harmful

exhaust

emissions

to

a

minimum

3

A

B

C

D

D

device

for

reducing

hydrocarbon

H

C

emissions

4

An

electric

automatic

choke

to

facilitate

cold

starting

and

to

reduce

exhaust

emissions

5

An

anti

dieseling

solenoid

to

eliminate

dieseling

run

on

6

A

power

valve

or

vacuum

actu

ated

booster

to

ensure

smooth

high

speed

operation

7

The

carburetor

comes

equipped

with

dash

pot

which

ensures

smooth

deceleration

without

engine

stall

under

all

operating

conditions

8

The

hand

operated

altitude

com

pensator

is

installed

in

the

California

models

EF

14

STRUCTURE

AND

OPERATION

These

carburetors

consist

of

a

primary

system

for

normal

running

and

a

secondary

system

for

full

load

running

A

float

system

common

to

both

primary

and

secondary

systems

a

se

condary

switch

over

mechanism

an

accelerating

mechanism

etc

are

also

attached

An

anti

dieseling

solenoid

valve

and

a

power

valve

mechanism

are

also

installed

The

hand

operated

altitude

com

pensator

corrects

air

fuel

mixture

to

an

optimum

ratio

Page 116 of 537

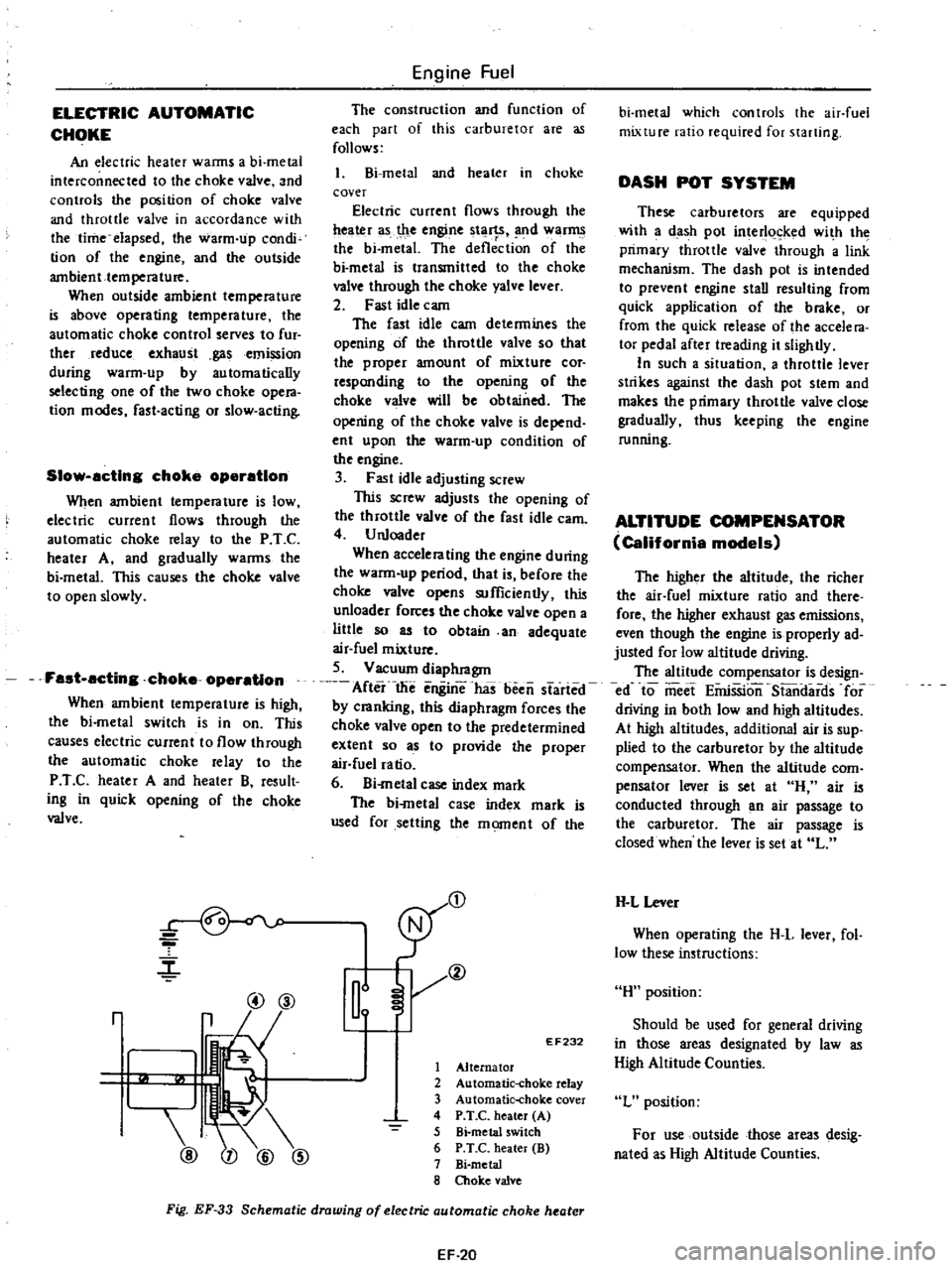

ELECTRIC

AUTOMATIC

CHOKE

An

electric

heater

wanns

a

bi

metal

interconnected

to

the

choke

valve

and

controls

the

position

of

choke

valve

and

throttle

valve

in

accordance

with

the

time

elapsed

the

warm

up

condi

tion

of

the

engine

and

the

outside

ambient

temperature

When

outside

ambient

temperature

is

above

operating

temperature

the

automatic

choke

control

serves

to

fur

ther

reduce

exhaust

gasemission

during

warm

up

by

automatically

selecting

one

of

the

two

choke

opera

tion

modes

fast

acting

or

slow

acting

Slow

acting

choke

operation

When

ambient

temperature

is

low

electric

current

flows

through

the

automatic

choke

relay

to

the

P

T

C

heater

A

and

gradually

warms

the

bi

metal

This

causes

the

choke

valve

to

open

slowly

Fast

acting

choke

operation

When

ambient

temperature

is

high

the

bi

metal

switch

is

in

on

This

causes

electric

current

to

flow

through

the

automatic

choke

relay

to

the

P

T

C

heater

A

and

heater

B

result

ing

in

quick

opening

of

the

choke

valve

r

@@

r

@

Engine

Fuel

The

construction

and

function

of

each

part

of

this

carburetor

are

as

follows

l

Bi

metal

and

heater

in

choke

cover

Electric

current

flows

through

the

ttea

r

as

t

le

engine

tl

1

SI

nd

war

the

bi

metal

The

deflection

of

the

bi

metal

is

transmitted

to

the

choke

valve

through

the

choke

yalve

lever

2

Fast

idle

cam

The

fast

idle

cam

determines

the

opening

of

the

throttle

valve

so

that

the

proper

amount

of

mixture

cor

responding

to

the

opening

of

the

choke

valve

will

be

obtained

The

opening

of

the

choke

valve

is

depend

ent

upon

the

warm

up

condition

of

the

engine

3

Fast

idle

adjusting

screw

This

screw

adjusts

the

opening

of

the

throttle

valve

of

the

fast

idle

earn

4

U

nloader

When

accelerating

the

engine

during

the

warm

up

period

that

is

before

the

choke

valve

opens

sufficiently

this

unloader

forces

the

choke

valve

open

a

liUle

so

as

to

obtain

an

adequate

air

fuel

mixture

5

Vacuum

diaphragm

After

the

enginThas

been

started

by

cranking

this

diaphragm

forces

the

choke

valve

open

to

the

predetermined

extent

so

as

to

provide

the

proper

air

fuel

ratio

6

Bi

metal

case

index

mark

The

bi

metal

case

index

mark

is

used

for

setting

the

moment

of

the

D

Il

EF232

1

Alternator

2

Automatic

choke

relay

3

Automatic

choke

cover

4

P

T

C

heater

A

5

Bi

metal

switch

6

P

T

C

heater

B

7

Bi

metal

8

Choke

valve

Fig

EF

33

Schematic

drawing

of

electric

automatic

choke

heater

EF

20

bi

metal

which

controls

the

air

fuel

mixture

ratio

required

for

starting

DASH

POT

SYSTEM

These

carburetors

are

equipped

with

a

dash

pot

interl

ked

wi

h

the

primary

throttle

valve

through

a

link

mechanism

The

dash

pot

is

intended

to

prevent

engine

stall

resulting

from

quick

application

of

the

brake

or

from

the

quick

release

of

the

accele

ra

tor

pedal

after

treading

it

slightly

In

such

a

situation

a

throttle

lever

strikes

against

the

dash

pot

stem

and

makes

the

primary

throttle

valve

close

gradually

thus

keeping

the

engine

running

ALTITUDE

COMPENSATOR

California

models

The

higher

the

altitude

the

richer

the

air

fuel

mixture

ratio

and

there

fore

the

higher

exhaust

gas

emissions

even

though

the

engine

is

properly

ad

justed

for

low

altitude

driving

The

altitude

compensator

is

design

ed

to

meet

EiiriSSion

S13ndards

for

driving

in

both

low

and

high

altitudes

At

high

altitudes

additional

air

is

sup

plied

to

the

carburetor

by

the

altitude

compensator

When

the

altitude

com

pensator

lever

is

set

at

H

air

is

conducted

through

an

air

passage

to

the

carburetor

The

air

passage

is

closed

when

the

lever

is

set

at

L

H

L

Lever

When

operating

the

H

L

lever

fol

low

these

instructions

H

position

Should

be

used

for

general

driving

in

those

areas

designated

by

law

as

High

Altitude

Counties

L

position

For

use

outside

those

areas

desig

nated

as

High

Altitude

Counties

Page 117 of 537

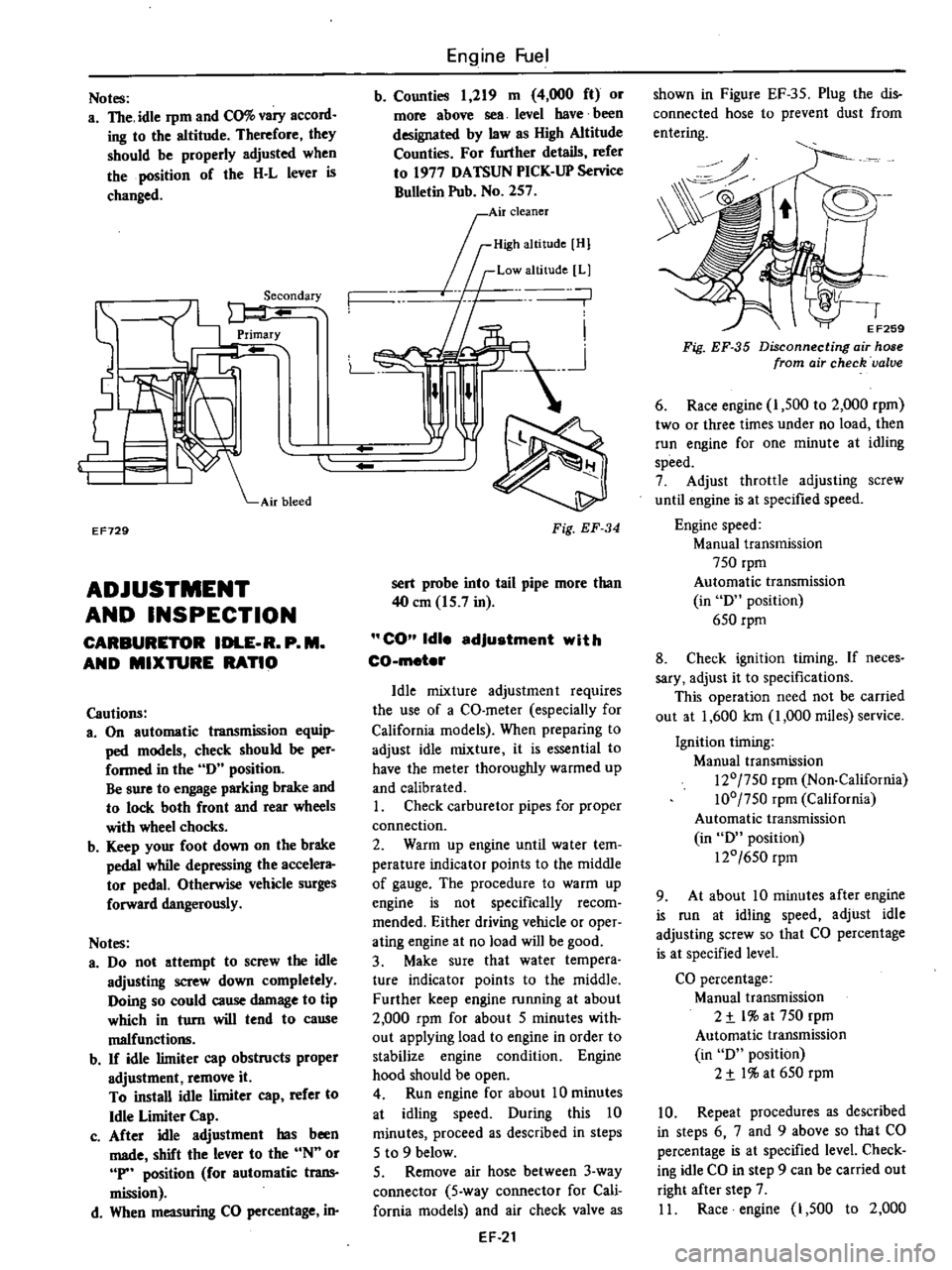

Notes

a

The

idle

rpm

and

CO

vary

accord

ing

to

the

altitude

Therefore

they

should

be

properly

adjusted

when

the

position

of

the

H

L

lever

is

changed

EF729

ADJUSTMENT

AND

INSPECTION

CARBURETOR

IDLE

R

P

M

AND

MIXTURE

RATIO

Cautions

3

On

automatic

transmission

equi

ped

models

check

should

be

per

formed

in

the

0

position

Be

sure

to

engage

parking

brake

and

to

lock

both

front

and

rear

wheels

with

wheel

chocks

b

Keep

your

foot

down

on

the

brake

pedal

while

depressing

the

accelera

tor

pedal

Otherwise

vehicle

surges

forward

dangerously

Notes

a

00

not

attempt

to

screw

the

idle

adjusting

screw

down

completely

Ooing

so

could

cause

damage

to

tip

which

in

turn

will

tend

to

cause

malfunctio11ll

b

If

idle

limiter

cap

obstructs

proper

adjustment

remove

it

To

install

idle

limiter

cap

refer

to

Idle

Limiter

Cap

c

After

idle

adjustment

has

been

made

shift

the

lever

to

the

N

or

P

position

for

automatic

trans

mission

d

When

measuring

CO

percentage

in

Engine

Fuel

b

Counties

1

219

m

4

000

ft

or

more

above

sea

level

have

been

designated

by

law

as

High

Altitude

Counties

For

further

details

refer

to

1977

OATSUN

PICK

UP

Service

Bulletin

Pub

No

257

0

I

Air

cleaner

rID

mOl

If

Low

altitude

Ll

n

n

L

n

Fig

EF

34

sert

probe

into

tail

pipe

more

than

40

em

15

7

in

CO

Idle

adjustment

with

CO

meter

Idle

mixture

adjustment

requires

the

use

of

a

CO

meter

especially

for

California

models

When

preparing

to

adjust

idle

mixture

it

is

essential

to

have

the

meter

thoroughly

warmed

up

and

calibrated

I

Check

carburetor

pipes

for

proper

connection

2

Warm

up

engine

until

water

tem

perature

indicator

points

to

the

middle

of

gauge

The

procedure

to

warm

up

engine

is

not

specifically

recom

mended

Either

driving

vehicle

or

oper

ating

engine

at

no

load

will

be

good

3

Make

sure

that

water

tempera

ture

indicator

points

to

the

middle

Further

keep

engine

running

at

about

2

000

rpm

for

about

5

minutes

with

out

applying

load

to

engine

in

order

to

stabilize

engine

condition

Engine

hood

should

be

open

4

Run

engine

for

about

10

minutes

at

idling

speed

Ouring

this

10

minutes

proceed

as

described

in

steps

5

to

9

below

5

Remove

air

hose

between

3

way

connector

5

way

connector

for

Cali

fornia

models

and

air

check

valve

as

EF

21

shown

in

Figure

EF

35

Plug

the

dis

connected

hose

to

prevent

dust

from

entering

0

o

EF259

Fig

EF

35

Disconnecting

air

hose

from

air

check

valve

6

Race

engine

I

500

to

2

000

rpm

two

or

three

times

under

no

load

then

run

engine

for

one

minute

at

idling

speed

7

Adjust

throttle

adjusting

screw

until

engine

is

at

specified

speed

Engine

speed

Manual

transmission

750

rpm

Automatic

transmission

in

0

position

650

rpm

8

Check

ignition

timing

If

neces

sary

adjust

it

to

specifications

This

operation

need

not

be

carried

out

at

1

600

Ian

1

000

miles

service

Ignition

timing

Manual

transmission

120

750

rpm

Non

California

100

750

rpm

California

Automatic

transmission

in

0

position

120

650

rpm

9

At

about

10

minutes

after

engine

is

run

at

idling

speed

adjust

idle

adjusting

screw

so

that

CO

percentage

is

at

specified

level

CO

percentage

Manual

transmission

2

t

l

at

750

rpm

Automatic

transmission

in

0

position

2

t

I

at

650

rpm

10

Repeat

procedures

as

described

in

steps

6

7

and

9

above

so

that

CO

percentage

is

at

specified

level

Check

ing

idle

CO

in

step

9

can

be

carried

out

right

after

step

7

II

Race

engine

1

500

to

2

000

Page 118 of 537

rpm

two

or

three

iimes

under

no

load

and

make

sure

that

specified

CO

per

centage

is

obtained

12

Connect

air

hose

to

air

check

valve

If

engine

speed

increases

readjust

it

to

the

specified

speed

with

throttle

adjustingsqew

CO

idle

edJustment

without

CO

meter

If

CO

meter

is

not

available

the

following

procedures

may

be

used

L

Check

carburetor

pipes

for

proper

connection

2

Warm

up

engine

until

water

tem

perature

indicator

points

to

the

middle

of

gauge

The

procedure

to

warm

up

engine

is

not

specifically

recom

mended

Either

driving

vehicle

or

oper

ating

engine

at

no

load

will

be

good

3

Make

sure

that

water

temperature

indicator

points

to

the

middle

Further

keep

engine

running

at

about

2

000

rpm

for

about

5

minutes

without

applying

load

to

engine

in

order

to

stabilize

engine

condition

Engine

hood

should

be

open

4

Run

engine

for

about

10

minutes

at

idling

speed

During

this

10

minutes

proceed

as

described

in

steps

5

to

9

below

5

Remove

air

hose

between

3

way

connector

5

way

connector

for

Cali

fornia

models

and

air

check

valve

shown

in

Figure

EF

35

Plug

the

dis

connected

hose

19

prevent

dust

from

entering

6

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

then

run

engine

for

one

minute

at

idling

speed

7

Adjust

throttle

adjusting

screw

so

that

engine

speeds

are

as

indicated

below

Engine

speed

Manual

transmission

815

rpm

Automatic

transmission

in

D

position

670

rpm

8

Check

ignition

timing

if

neces

sary

adjust

it

to

the

value

required

by

specifications

This

operation

need

not

be

carried

out

at

1

600

km

1

000

miles

service

9

At

about

10

minutes

after

engine

Engine

Fuel

is

run

at

idling

speed

adjust

idle

adjusting

screw

until

maximum

rpm

is

obtained

10

Repeat

procedures

as

described

in

steps

6

7

and

9

above

until

engine

speed

at

best

idle

mixture

is

815

rpm

for

manual

transmission

models

and

670

rpm

for

automatic

transmission

models

in

D

position

Adjustment

in

step

9

can

be

carried

out

right

after

step

7

11

Turn

the

idle

adjusting

screw

clockwise

until

engine

speed

drops

off

below

specified

rpm

Engine

speed

drops

off

Manual

transmission

60

to

70

rpm

Automatic

transmission

in

D

position

15

to

25

rpm

12

Connect

air

hose

to

air

check

valve

If

engine

speed

increases

readjust

it

to

the

specified

speed

with

throttle

adjusting

screw

Idle

limiter

cep

Do

not

remove

this

idle

limiter

cap

unless

necessary

If

this

unit

is

re

moved

it

must

be

readjusted

at

lime

of

installation

To

adjust

proceed

as

follows

I

After

adjusting

throttle

or

idle

speed

adjusting

screw

check

to

be

sure

that

the

amount

of

CO

contained

in

exhaust

gases

meets

the

established

standard

2

Install

idle

limiter

cap

in

position

making

sure

that

the

adjusting

screw

can

rotate

another

1

8

turn

in

the

CO

RICH

direction

Carbo

to

per

CO

rich

450

lIS

rotation

t

CO

lean

J

SQ

dl

lim

ET031

1

e

Iter

cap

Fig

EF

36

Setting

idle

limiter

cap

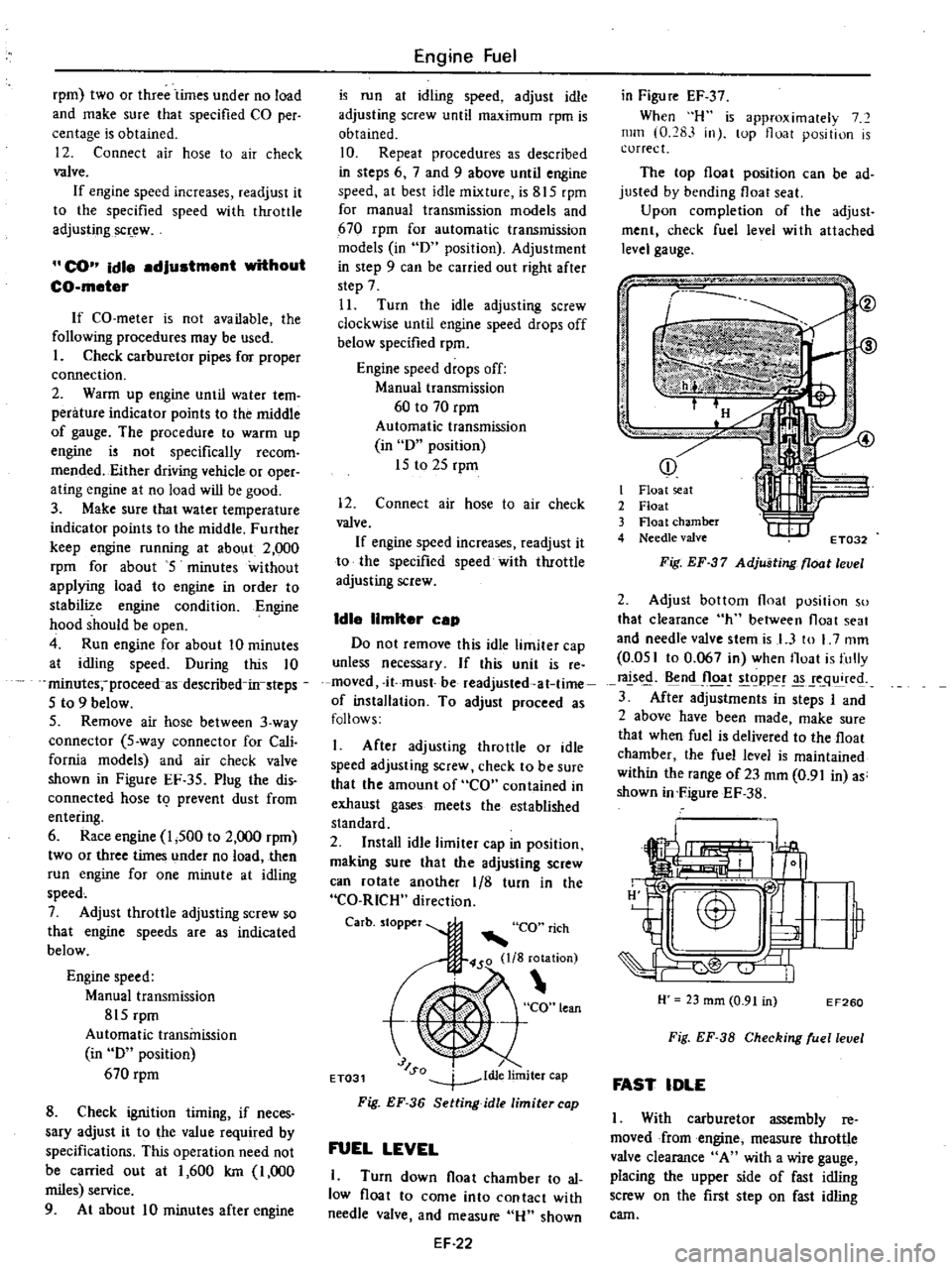

FUEL

LEVEL

1

Turn

down

float

chamber

to

al

low

float

to

come

into

contact

with

needle

valve

and

measure

Hu

shown

EF

22

in

Figu

re

EF

37

When

H

is

approximalely

7

mill

0

283

in

lOp

float

position

is

correct

The

top

float

position

can

be

ad

justed

by

bending

float

seat

Upon

completion

of

the

adjust

ment

check

fuel

level

wi

th

attached

level

gauge

p

j

i

I

it

I

Float

seat

2

Float

3

Float

chamber

4

Needle

valve

t

I

IIf

ET032

Fig

EF

37

Adjusting

float

level

2

Adjust

bottom

float

position

so

that

clearance

h

between

float

seat

and

needle

valve

stemis

I

3

to

L

7

mm

0

051

to

0

067

in

when

Iloat

is

fully

rals

n

Jloa

t

goppe

q

re

3

After

adjustments

in

steps

I

and

2

above

have

been

made

make

sure

that

when

fuel

is

delivered

to

the

float

chamber

the

fuel

level

is

maintained

within

the

range

of23

mm

0

91

in

as

shown

in

FigureEF

38

H

23

mm

0

91

in

EF260

Fig

EF

38

Checking

ruellevel

FAST

IDLE

I

With

carburetor

assembly

reo

moved

from

engine

measure

throttle

valve

clearance

A

with

a

wire

gauge

placing

the

upper

side

of

fast

idling

screw

on

the

first

step

on

fast

idling

cam

Page 125 of 537

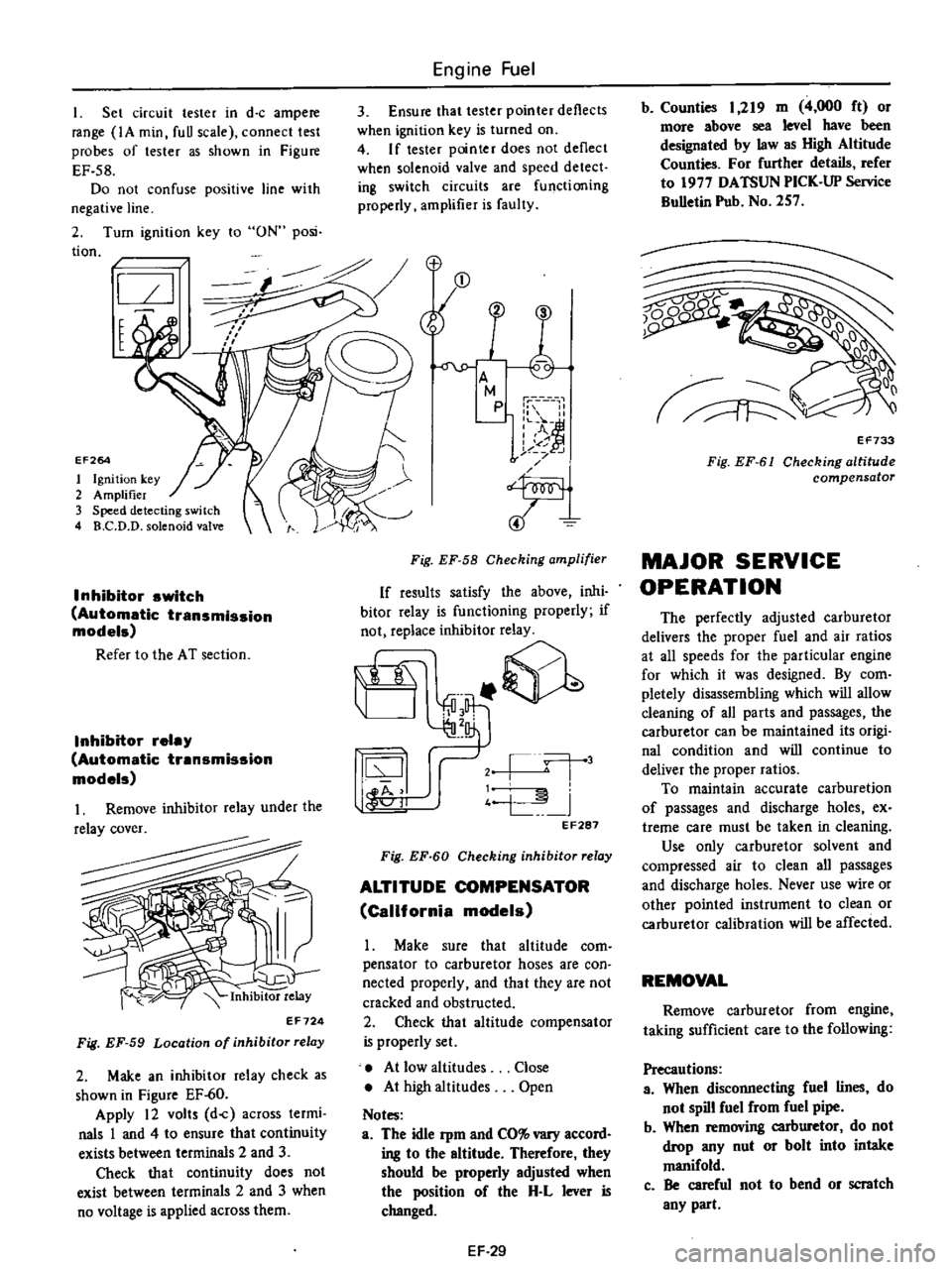

I

Set

circuit

tester

in

d

c

ampere

range

IA

min

fuU

scale

connect

test

probes

of

tester

as

shown

in

Figure

EF

58

Do

not

confuse

positive

line

with

negative

line

2

Turn

ignition

key

to

ON

posi

tion

I

t

EF264

1

Ignition

key

2

Amplifier

3

Speed

detecting

switch

4

B

C

D

D

solenoid

valve

Inhibitor

switch

Automatic

transmission

models

Refer

to

the

AT

section

Inhibitor

relay

Automatic

transmission

models

Inhibitor

relay

EF724

Fig

EF

59

Location

of

inhibitor

relay

2

Make

an

inhibitor

relay

check

as

shown

in

Figure

EF

60

Apply

12

volts

d

c

across

termi

nals

1

and

4

to

ensure

that

continuity

exists

between

terminals

2

and

3

Check

that

continuity

does

not

exist

between

terminals

2

and

3

when

no

voltage

is

applied

across

them

Engine

Fuel

3

Ensure

that

tester

pointer

deflects

when

ignition

key

is

turned

on

4

If

tester

pointer

does

not

deflect

when

solenoid

valve

and

speed

detect

ing

switch

circuits

are

functioning

properly

amplifier

is

faulty

Fig

EF

58

Checking

amplifier

If

results

satisfy

the

above

inhi

bitor

relay

is

functioning

properly

if

not

replace

inhibitor

relay

it

@

j

l

j

4

L

I

44

11

oJ

EF287

Fig

EF

60

Checking

inhibitor

relay

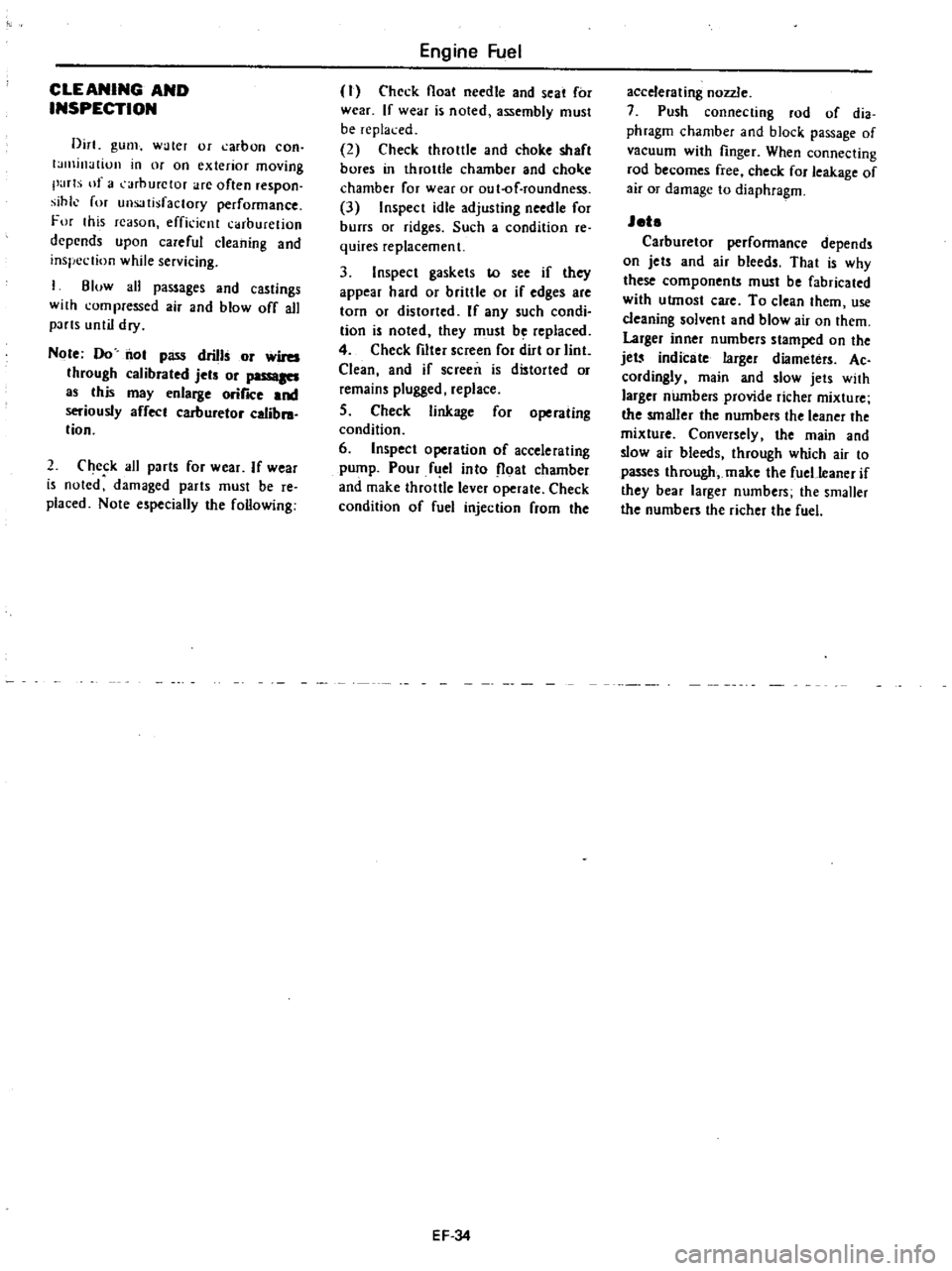

ALTITUDE

COMPENSATOR

California

models

Make

sure

that

altitude

com

pensator

to

carburetor

hoses

are

con

nected

properly

and

that

they

are

not

cracked

and

obstructed

2

Check

that

altitude

compensator

is

properly

set

At

low

altitudes

At

high

altitudes

Notes

a

The

idle

Pm

and

CO

vary

accord

ing

to

the

altitude

Therefore

they

should

be

properly

adjusted

when

the

position

of

the

H

L

lever

is

changed

Close

Open

EF

29

b

Counties

1

219

m

4

000

ft

or

more

above

sea

level

have

been

designated

by

law

as

High

Altitude

Counties

For

further

details

refer

to

1977

DATSUN

PICK

UP

Service

BuUetin

Pub

No

257

Q0

1

v

EF733

Fig

EF

61

Checking

altitude

compensator

MAJOR

SERVICE

OPERATION

The

perfectly

adjusted

carburetor

delivers

the

proper

fuel

and

air

ratios

at

all

speeds

for

the

particular

engine

for

which

it

was

designed

By

com

pletely

disassembling

which

will

allow

deaning

of

all

parts

and

passages

the

carburetor

can

be

maintained

its

origi

nal

condition

and

will

continue

to

deliver

the

proper

ratios

To

maintain

accurate

carburetion

of

passages

and

discharge

holes

ex

treme

care

must

be

taken

in

cleaning

Use

only

carburetor

solvent

and

compressed

air

to

clean

all

passages

and

discharge

holes

Never

use

wire

or

other

pointed

instrument

to

clean

or

carburetor

calibration

will

be

affected

REMOVAL

Remove

carburetor

from

engine

taking

sufficient

care

to

the

following

Precautions

a

When

disconnecting

fuel

lines

do

not

spill

fuel

from

fuel

pipe

b

When

removing

carburetor

do

not

drop

any

nut

or

bolt

into

intake

manifold

c

Be

careful

not

to

bend

or

scratch

any

part

Page 130 of 537

CLEANING

AND

INSPECTION

Dirt

gum

wuler

or

l

arbon

con

taminatiun

in

or

on

exterior

moving

parts

of

a

arburctor

arc

often

respon

sihk

for

unsatisfactory

performance

For

this

reason

efficient

carbutetioll

dcpends

upon

careful

cleaning

and

inspection

while

servicing

I

Blow

all

passages

and

castings

with

compressed

air

and

blow

off

all

parts

until

dry

Note

Do

not

pass

drills

or

wires

through

calibrated

jet

or

passaaa

as

this

may

enlarge

orirlce

and

seriously

affect

carburetor

calibrs

lion

2

Check

all

parts

for

wear

If

wear

is

noted

damaged

parts

must

be

re

placed

Note

especially

the

following

Engine

Fuel

I

Check

float

needle

and

seat

for

wear

If

wear

is

noted

assembly

must

be

replaced

2

Check

throule

and

choke

shaft

bores

in

throtlle

chamber

and

choice

chamber

for

wear

or

out

of

roundness

3

Inspect

idle

adjusting

needle

for

burrs

or

ridges

Such

a

condition

re

quires

replacemen

1

3

Inspect

gaskets

0

see

if

they

appear

hard

or

briUle

or

if

edges

are

torn

or

distorted

If

any

such

condi

tion

i

noted

they

must

be

replaced

4

Check

filter

screen

for

dirt

or

lint

Clean

and

if

screen

is

distorted

or

remain

plugged

replace

5

Check

linkage

for

operating

condition

6

Inspect

operation

of

accelerating

pump

Pour

f

el

into

jloat

chamber

and

make

throtlle

lever

operate

Check

condition

of

fuel

injection

from

the

EF

34

accelerating

nowe

7

Push

connecting

rod

of

dia

phragm

chamber

and

block

passage

of

vacuum

with

finger

When

connecting

rod

becomes

free

check

for

leakage

of

air

or

damage

to

diaphragm

Jets

Carburetor

performance

depends

on

jet

and

air

bleed

That

is

why

these

components

must

be

fabricated

with

utmost

care

To

clean

them

use

cleaning

solvent

and

blow

air

on

them

Larger

inner

numbers

tamped

on

the

jet

indicate

larger

diameters

Ac

cordingly

main

and

slow

jets

with

lalger

nUmbers

provide

richer

mixture

the

smaller

the

numbers

the

leaner

the

mixture

Conversely

the

main

and

slow

air

bleeds

through

which

air

to

passes

through

make

the

fueLleaner

if

they

bear

larger

numbers

the

smaller

the

numbers

the

richer

the

fuel

Page 132 of 537

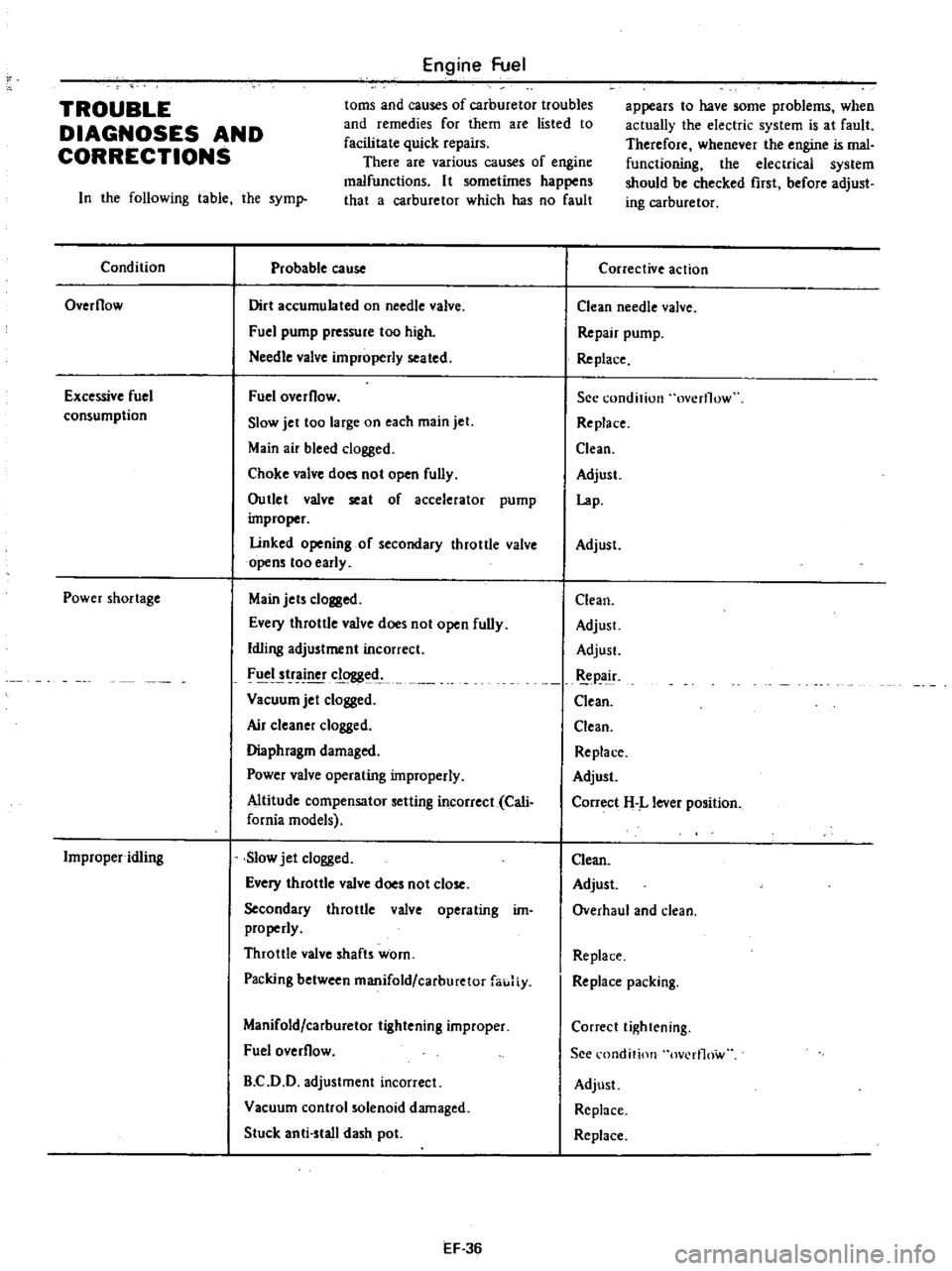

Engine

Fuel

toms

and

causes

of

carburetor

troubles

and

remedies

for

them

are

listed

to

facilitate

quick

repairs

There

are

various

causes

of

engine

malfunctions

It

sometimes

happens

that

a

carburetor

which

has

no

fault

TROUBLE

DIAGNOSES

AND

CORRECTIONS

In

the

following

table

the

syml

Condition

Probable

cause

Overflow

Dirt

accumulated

on

needle

valve

Fuel

pump

pressure

too

high

Needle

valve

improperly

seated

Excessive

fuel

consumption

Fuel

overflow

Slow

jet

too

large

on

each

main

jet

Main

air

bleed

clogged

Choke

valve

does

not

open

fully

Outlet

valve

seat

of

accelerator

pump

improper

Linked

opening

of

secondary

throttle

valve

opens

too

early

Power

shortage

Main

jets

clogged

Every

throttle

valve

does

not

open

fully

Idling

adjustment

incorrect

FIICI

tr

clogged

Vacuum

jet

clogged

Air

c1eane

clogged

Diaphragm

damaged

Power

valve

operating

improperly

Altitude

compensator

setting

incorrect

Cali

fornia

models

Improper

idling

Slow

jet

clogged

Every

throttle

valve

does

not

close

Secondary

throttle

valve

operating

im

properly

Throttle

valve

shafts

worn

Packing

between

manifold

carburetor

fauJiy

Manifold

carburetor

tightening

improper

Fuel

overflow

B

C

D

D

adjustment

incorrect

Vacuum

control

solenoid

damaged

Stuck

anti

stall

dash

pot

EF

36

appears

to

have

some

problems

when

actually

the

electric

system

is

at

fault

Therefore

whenever

the

engine

is

mal

functioning

the

electrical

system

should

be

checked

rust

before

adjust

ing

carburetor

Corrective

action

Clean

needle

valve

Repair

pump

Re

place

See

condition

overflow

Replace

Clean

Adjust

Lap

Adjust

Clean

Adjust

AdjusL

pa

ir

Clean

Clean

Replace

Adjust

Correct

H

L

lever

position

Clean

Adjust

Overhaul

and

clean

Replace

Replace

packing

Correct

tightening

See

l

ondition

ov

rl1ow

Adjust

Replace

Replace

Page 135 of 537

There

are

three

types

of

control

system

These

are

J

Closed

type

CIllnkcase

emission

control

system

Emission

Control

System

of

GENERAL

DESCRIPTION

2

Exhaust

emission

control

system

3

Evaporative

ell

lhsion

control

sys

tem

Pericxiic

inspection

and

required

seCV1Clng

of

these

systems

should

be

carried

out

to

reduce

harmful

emis

sions

to

a

minimum

CRANKCASE

EMISSION

CONTROL

SYSTEM

c

01

Lkf

If

1

TIL

II

tll

1

j

GUuuu

DESCRIPTION

This

system

returns

blow

by

gas

to

both

the

intake

manifold

and

carbure

tor

air

cleaner

The

positive

crankcase

ventilation

p

C

V

valve

is

provided

to

conduct

crankcase

blow

by

gas

to

the

intake

manifold

During

partial

throttle

operation

of

the

engine

the

intake

manifold

sucks

the

blow

by

gas

through

the

P

C

V

valve

Normally

the

capacity

of

the

valve

is

sufficient

to

handle

any

blow

by

and

a

small

amount

of

ventilating

air

4

c

Fresh

air

Blow

by

gas

The

ventilating

air

is

then

drawn

from

the

dust

side

of

the

cadlUretor

air

cleaner

tluough

the

tube

con

necting

carburetor

air

cleaner

to

rock

er

cover

into

the

crankcase

Under

full

tluottle

condition

the

manifold

vacuwn

is

insufficient

to

draw

the

blow

by

flow

tluough

the

valve

and

its

flow

goes

through

the

tube

connection

in

the

reverse

diree

tion

On

vehicles

with

an

excessively

high

blow

by

some

of

the

flow

will

go

through

the

tube

connection

to

carbu

retor

air

cleaner

under

all

conditions

1

Sealtypc

oil

level

gauge

2

Bame

plate

3

Flame

arrester

4

Filler

5

P

C

Y

valve

6

Steel

net

7

Bame

plate

EC716

Fig

EC

l

Crankcase

miaion

control

ay

tem

EC

2

INSPECTION

P

c

V

VALVE

AND

FILTER

Checking

P

C

V

valve

in

accord

ance

with

the

following

method

With

engine

running

at

idle

remove

the

ventilator

hose

from

P

C

V

valve

if

the

valve

is

working

a

hissing

noise

will

be

heard

as

air

passes

through

the

valve

and

a

strong

vacuwn

should

be

felt

immediately

when

a

fmger

is

placed

over

valve

inlet

Replace

P

C

V

valve

and

filter

in

accordance

with

the

maintenance

schedule

VENTILATION

HOSE

1

Check

hoses

and

hose

connec

tions

for

leaks

2

Disconnect

all

hoses

and

clean

with

compressed

air

If

any

hose

cannot

be

free

of

obstructions

replace

Ensure

that

flame

arrester

is

surely

inserted

in

hose

between

air

cleaner

and

rocker

cover

Page 139 of 537

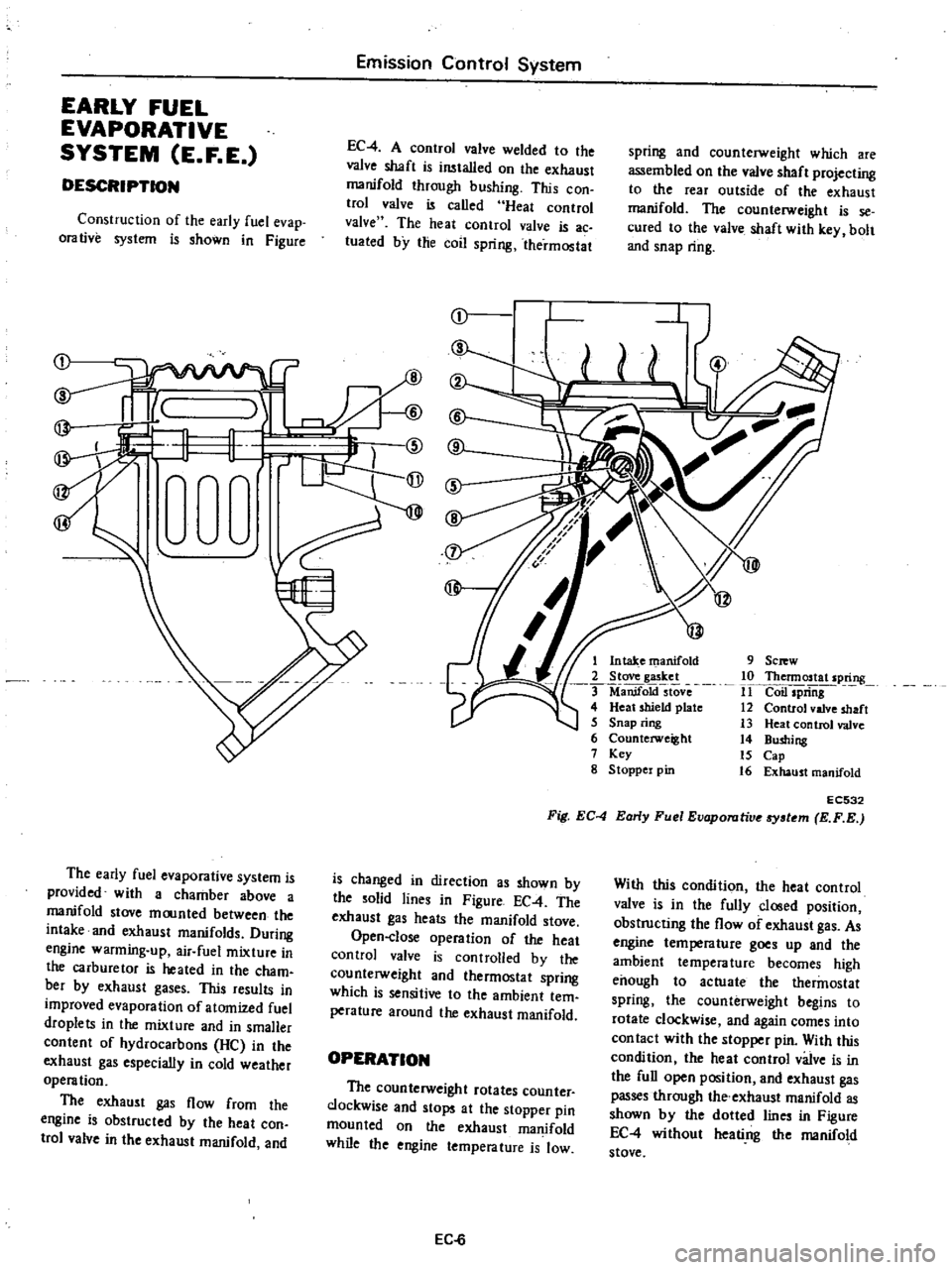

Emission

Control

System

EARLY

FUEL

EVAPORATIVE

SYSTEM

E

F

E

DESCRIPTION

spring

and

counterweight

which

are

assembled

on

the

valve

shaft

projecting

to

the

rear

outside

of

the

exhaust

manifold

The

counterweight

is

se

cured

to

the

valve

shaft

with

key

bolt

and

snap

ring

EC

4

A

control

valve

welded

to

the

valve

shaft

is

wtalled

on

the

exhaust

manifold

through

bushing

This

con

trol

valve

is

called

Heat

control

valve

The

heat

control

valve

is

ac

luated

by

the

coil

spring

thermostat

Construction

of

the

early

fuel

evap

orative

system

is

shown

in

Figure

r

I

1

@

rW

9

Sc

w

10

Thennostat

spring

11

Coil

spriiig

12

Control

valve

shaft

13

Heat

control

valve

14

Bushing

15

Cap

16

Exhaust

manifold

1

Intake

manifold

2

Stove

gasket

ManifoktstOve

4

Heat

shield

plate

5

Snap

ring

6

Counterweight

7

Key

g

Stoppel

pin

EC532

Fig

EC

4

Early

Fuel

Evaporutive

tem

E

F

E

The

early

fuel

evaporative

system

is

provided

with

a

chamber

above

a

manifold

stove

moonted

between

the

intake

and

exhaust

manifolds

During

engine

warming

up

air

fuel

mixture

in

the

carburetor

is

heated

in

the

cham

bet

by

exhaust

gases

This

results

in

improved

evaporation

of

atomized

fuel

droplets

in

the

mixture

and

in

smaller

content

of

hydrocarbons

He

in

the

exhaust

gas

especially

in

cold

weather

operation

The

exhaust

gas

flow

from

the

engine

is

obstructed

by

the

heat

con

trol

valve

in

the

exhaust

manifold

and

is

changed

in

direction

as

shown

by

the

solid

lines

in

Figure

EC

4

The

exhaust

gas

heats

the

manifold

stove

Open

close

operation

of

the

heat

control

valve

is

controlled

by

the

counterweight

and

thermostat

spring

which

is

sensitive

to

the

ambient

tem

perature

around

the

exhaust

manifold

With

this

condition

the

heat

control

valve

is

in

the

fully

closed

position

obstructing

the

flow

of

exhaust

gas

As

engine

tempera

lure

goes

up

and

the

ambient

temperature

becomes

high

enough

to

actuate

the

thermostat

spring

the

counterweight

begins

to

rotate

clockwise

and

again

comes

into

con

tact

with

the

stopper

pin

With

this

condition

the

heat

control

valve

is

in

the

full

open

position

and

exhaust

gas

passes

through

the

exhaust

manifold

as

shown

by

the

dotted

lines

in

Figure

EC

4

without

heati

ng

the

manifold

stove

OPERATION

The

counterweight

rotates

counter

clockwise

and

stops

at

the

stopper

pin

mounted

on

the

exhaust

manifold

while

the

engine

temperature

is

low

EC

6