ABS DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 892 of 1200

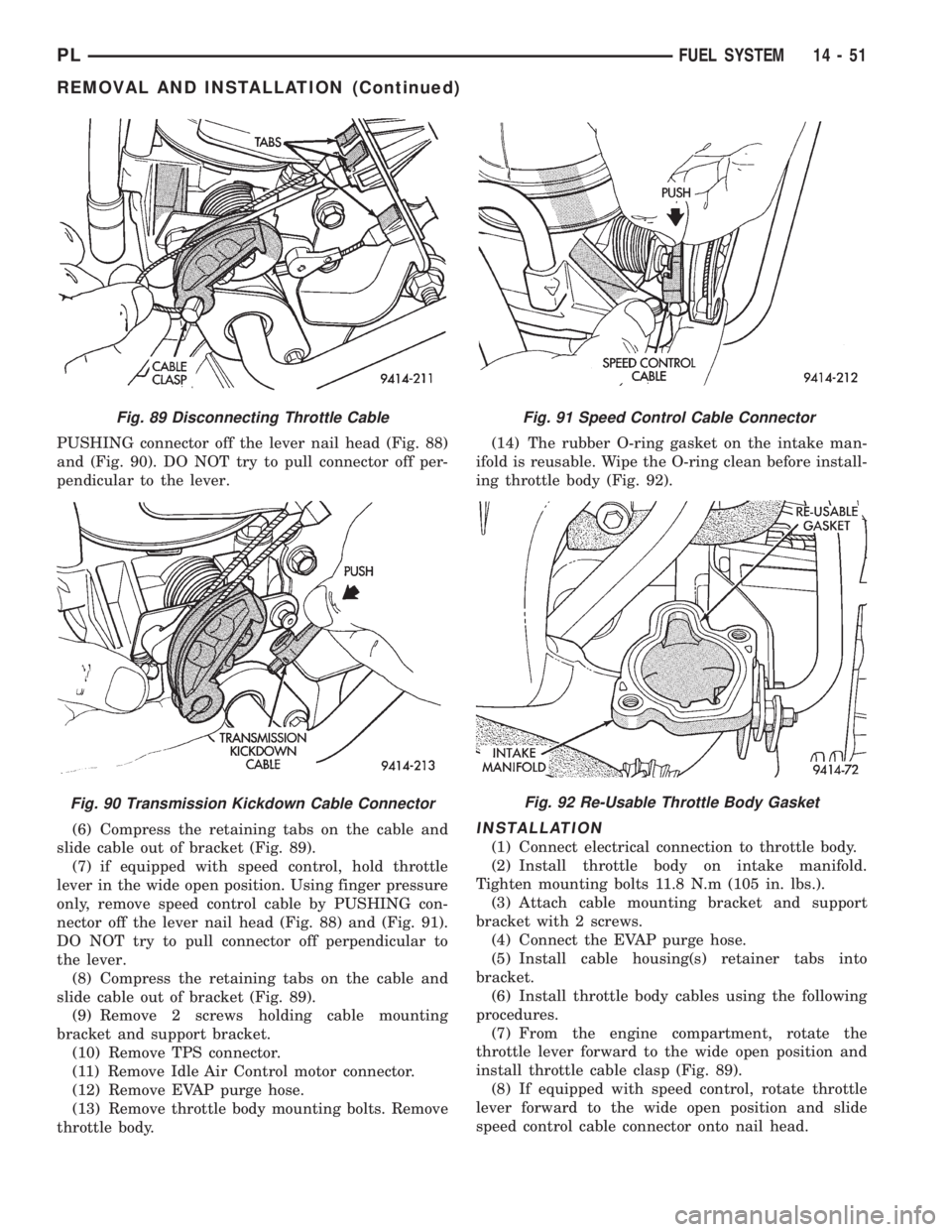

PUSHING connector off the lever nail head (Fig. 88)

and (Fig. 90). DO NOT try to pull connector off per-

pendicular to the lever.

(6) Compress the retaining tabs on the cable and

slide cable out of bracket (Fig. 89).

(7) if equipped with speed control, hold throttle

lever in the wide open position. Using finger pressure

only, remove speed control cable by PUSHING con-

nector off the lever nail head (Fig. 88) and (Fig. 91).

DO NOT try to pull connector off perpendicular to

the lever.

(8) Compress the retaining tabs on the cable and

slide cable out of bracket (Fig. 89).

(9) Remove 2 screws holding cable mounting

bracket and support bracket.

(10) Remove TPS connector.

(11) Remove Idle Air Control motor connector.

(12) Remove EVAP purge hose.

(13) Remove throttle body mounting bolts. Remove

throttle body.(14) The rubber O-ring gasket on the intake man-

ifold is reusable. Wipe the O-ring clean before install-

ing throttle body (Fig. 92).

INSTALLATION

(1) Connect electrical connection to throttle body.

(2) Install throttle body on intake manifold.

Tighten mounting bolts 11.8 N.m (105 in. lbs.).

(3) Attach cable mounting bracket and support

bracket with 2 screws.

(4) Connect the EVAP purge hose.

(5) Install cable housing(s) retainer tabs into

bracket.

(6) Install throttle body cables using the following

procedures.

(7) From the engine compartment, rotate the

throttle lever forward to the wide open position and

install throttle cable clasp (Fig. 89).

(8) If equipped with speed control, rotate throttle

lever forward to the wide open position and slide

speed control cable connector onto nail head.

Fig. 89 Disconnecting Throttle Cable

Fig. 90 Transmission Kickdown Cable Connector

Fig. 91 Speed Control Cable Connector

Fig. 92 Re-Usable Throttle Body Gasket

PLFUEL SYSTEM 14 - 51

REMOVAL AND INSTALLATION (Continued)

Page 893 of 1200

(9) Rotate throttle lever forward to the wide open

position and slide kickdown cable connector onto nail

head.

(10) Install throttle cable cover. Tighten bolt to 5.6

N´m (50 ins. lbs.).

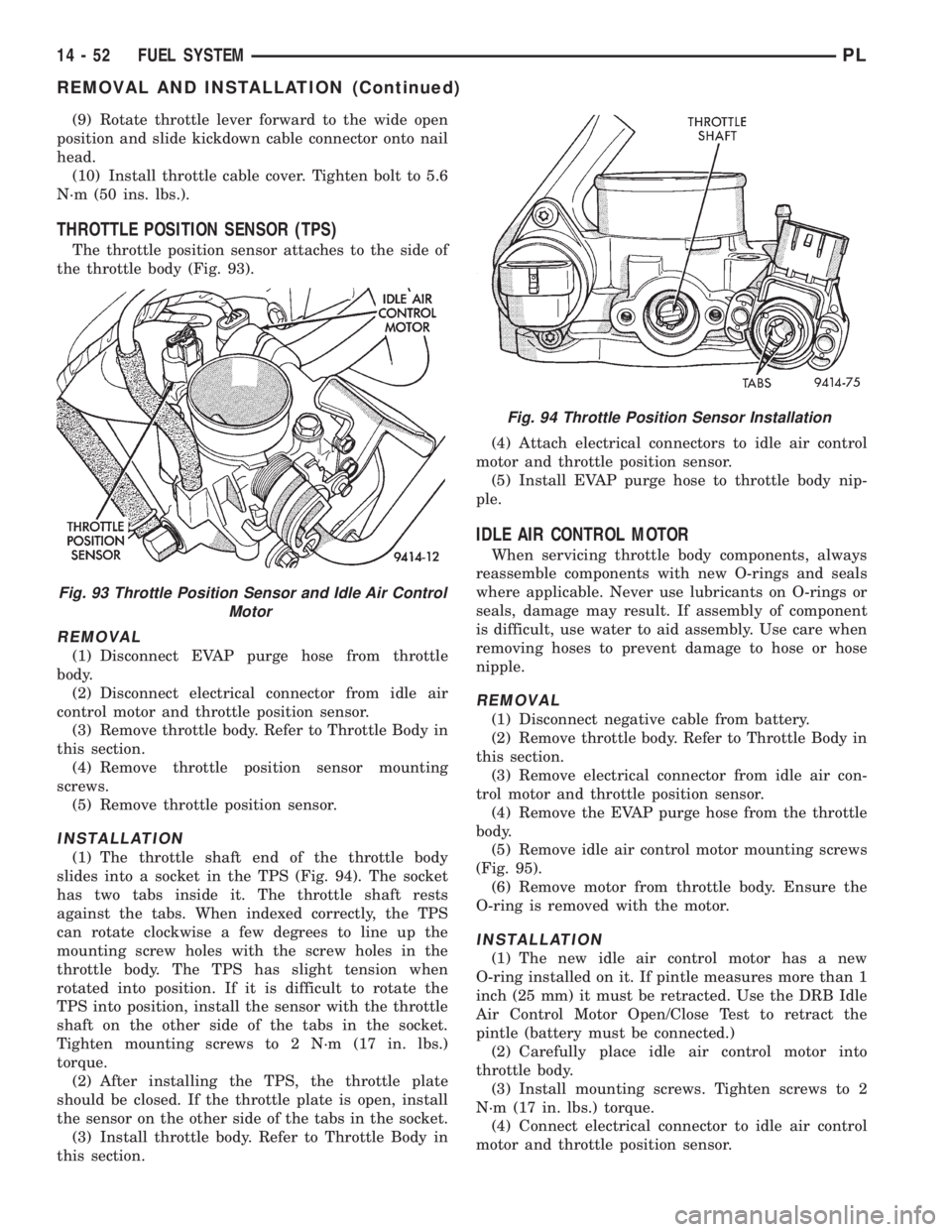

THROTTLE POSITION SENSOR (TPS)

The throttle position sensor attaches to the side of

the throttle body (Fig. 93).

REMOVAL

(1) Disconnect EVAP purge hose from throttle

body.

(2) Disconnect electrical connector from idle air

control motor and throttle position sensor.

(3) Remove throttle body. Refer to Throttle Body in

this section.

(4) Remove throttle position sensor mounting

screws.

(5) Remove throttle position sensor.

INSTALLATION

(1) The throttle shaft end of the throttle body

slides into a socket in the TPS (Fig. 94). The socket

has two tabs inside it. The throttle shaft rests

against the tabs. When indexed correctly, the TPS

can rotate clockwise a few degrees to line up the

mounting screw holes with the screw holes in the

throttle body. The TPS has slight tension when

rotated into position. If it is difficult to rotate the

TPS into position, install the sensor with the throttle

shaft on the other side of the tabs in the socket.

Tighten mounting screws to 2 N´m (17 in. lbs.)

torque.

(2) After installing the TPS, the throttle plate

should be closed. If the throttle plate is open, install

the sensor on the other side of the tabs in the socket.

(3) Install throttle body. Refer to Throttle Body in

this section.(4) Attach electrical connectors to idle air control

motor and throttle position sensor.

(5) Install EVAP purge hose to throttle body nip-

ple.

IDLE AIR CONTROL MOTOR

When servicing throttle body components, always

reassemble components with new O-rings and seals

where applicable. Never use lubricants on O-rings or

seals, damage may result. If assembly of component

is difficult, use water to aid assembly. Use care when

removing hoses to prevent damage to hose or hose

nipple.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove throttle body. Refer to Throttle Body in

this section.

(3) Remove electrical connector from idle air con-

trol motor and throttle position sensor.

(4) Remove the EVAP purge hose from the throttle

body.

(5) Remove idle air control motor mounting screws

(Fig. 95).

(6) Remove motor from throttle body. Ensure the

O-ring is removed with the motor.

INSTALLATION

(1) The new idle air control motor has a new

O-ring installed on it. If pintle measures more than 1

inch (25 mm) it must be retracted. Use the DRB Idle

Air Control Motor Open/Close Test to retract the

pintle (battery must be connected.)

(2) Carefully place idle air control motor into

throttle body.

(3) Install mounting screws. Tighten screws to 2

N´m (17 in. lbs.) torque.

(4) Connect electrical connector to idle air control

motor and throttle position sensor.

Fig. 93 Throttle Position Sensor and Idle Air Control

Motor

Fig. 94 Throttle Position Sensor Installation

14 - 52 FUEL SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 895 of 1200

(3) Remove solenoid from bracket.

INSTALLATION

The top of the solenoid has TOP printed on it. The

solenoid will not operate unless it is installed cor-

rectly.

(1) Install solenoid on bracket.

(2) Connect vacuum tube to solenoid.

(3) Connect electrical connector to solenoid.

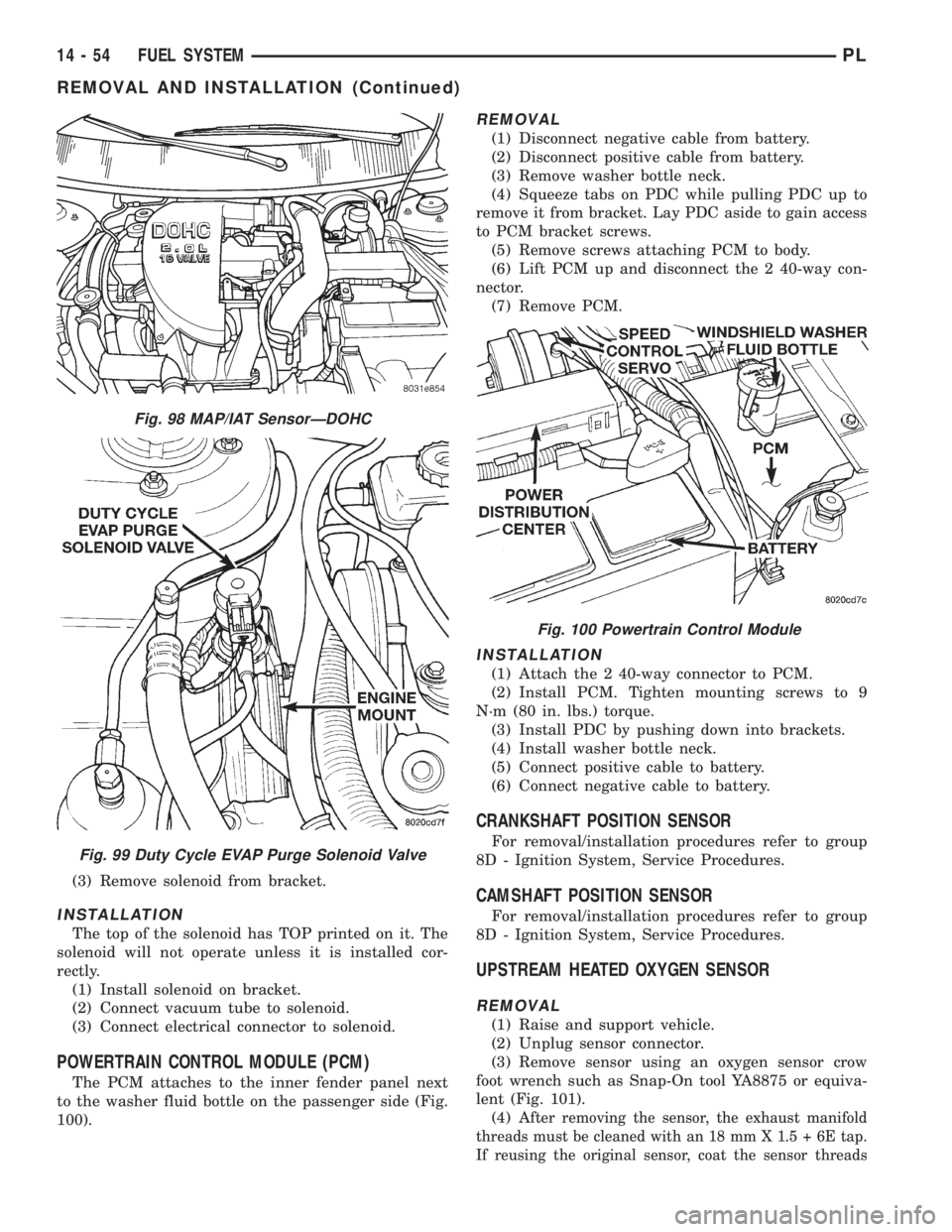

POWERTRAIN CONTROL MODULE (PCM)

The PCM attaches to the inner fender panel next

to the washer fluid bottle on the passenger side (Fig.

100).

REMOVAL

(1) Disconnect negative cable from battery.

(2) Disconnect positive cable from battery.

(3) Remove washer bottle neck.

(4) Squeeze tabs on PDC while pulling PDC up to

remove it from bracket. Lay PDC aside to gain access

to PCM bracket screws.

(5) Remove screws attaching PCM to body.

(6) Lift PCM up and disconnect the 2 40-way con-

nector.

(7) Remove PCM.

INSTALLATION

(1) Attach the 2 40-way connector to PCM.

(2) Install PCM. Tighten mounting screws to 9

N´m (80 in. lbs.) torque.

(3) Install PDC by pushing down into brackets.

(4) Install washer bottle neck.

(5) Connect positive cable to battery.

(6) Connect negative cable to battery.

CRANKSHAFT POSITION SENSOR

For removal/installation procedures refer to group

8D - Ignition System, Service Procedures.

CAMSHAFT POSITION SENSOR

For removal/installation procedures refer to group

8D - Ignition System, Service Procedures.

UPSTREAM HEATED OXYGEN SENSOR

REMOVAL

(1) Raise and support vehicle.

(2) Unplug sensor connector.

(3) Remove sensor using an oxygen sensor crow

foot wrench such as Snap-On tool YA8875 or equiva-

lent (Fig. 101).

(4) A

fter removing the sensor, the exhaust manifold

threads must be cleaned with an 18 mm X 1.5 + 6E tap.

If reusing the original sensor, coat the sensor threads

Fig. 98 MAP/IAT SensorÐDOHC

Fig. 99 Duty Cycle EVAP Purge Solenoid Valve

Fig. 100 Powertrain Control Module

14 - 54 FUEL SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 897 of 1200

(3) Remove air cleaner element from front housing

(Fig. 106).

INSTALLATION

(1) Install air cleaner element into front housing.

(2) Rotate front of housing forward then lower into

place and locate tabs in slots. Fasten clasps on top of

air cleaner housing.

(3) Install air intake duct at air cleaner and intake

manifold.

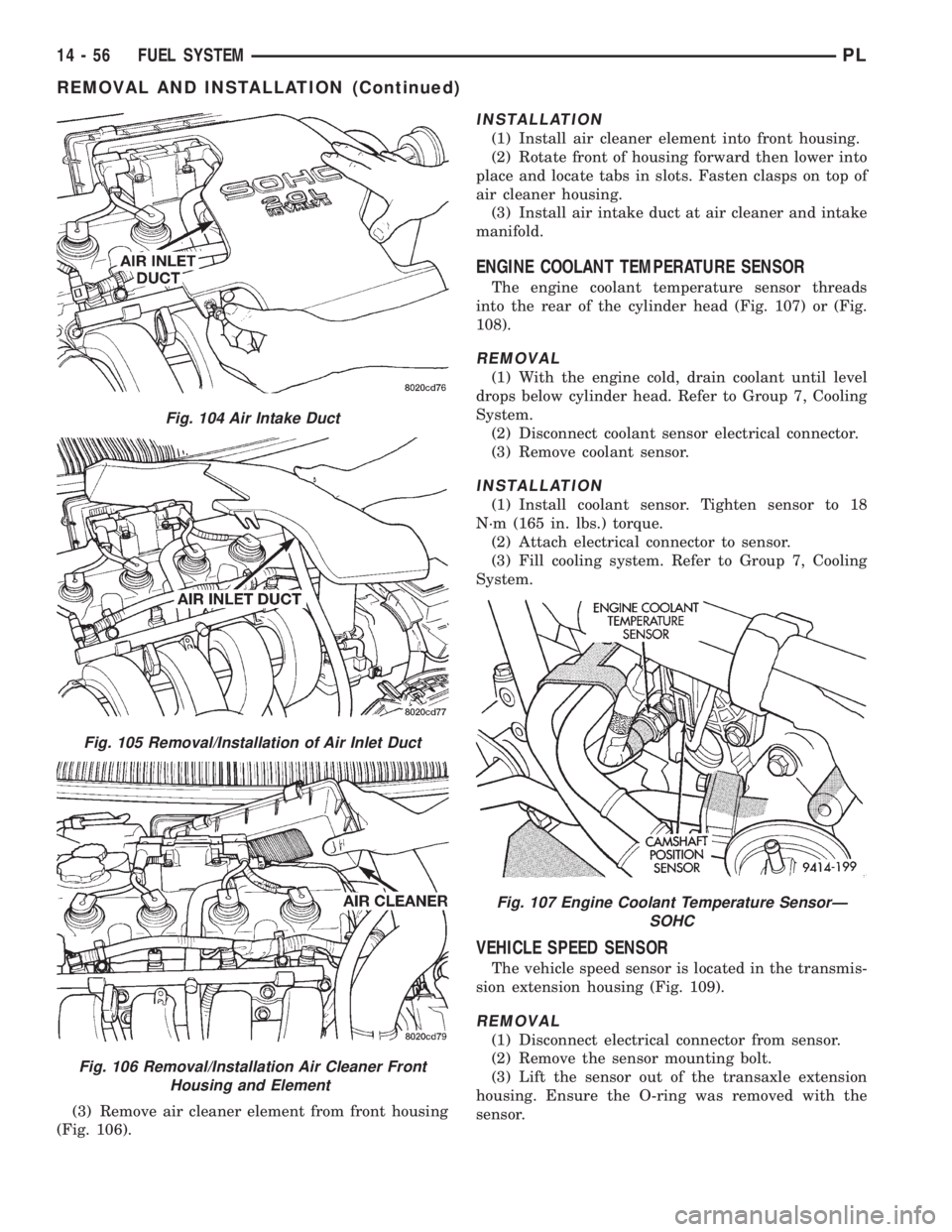

ENGINE COOLANT TEMPERATURE SENSOR

The engine coolant temperature sensor threads

into the rear of the cylinder head (Fig. 107) or (Fig.

108).

REMOVAL

(1) With the engine cold, drain coolant until level

drops below cylinder head. Refer to Group 7, Cooling

System.

(2) Disconnect coolant sensor electrical connector.

(3) Remove coolant sensor.

INSTALLATION

(1) Install coolant sensor. Tighten sensor to 18

N´m (165 in. lbs.) torque.

(2) Attach electrical connector to sensor.

(3) Fill cooling system. Refer to Group 7, Cooling

System.

VEHICLE SPEED SENSOR

The vehicle speed sensor is located in the transmis-

sion extension housing (Fig. 109).

REMOVAL

(1) Disconnect electrical connector from sensor.

(2) Remove the sensor mounting bolt.

(3) Lift the sensor out of the transaxle extension

housing. Ensure the O-ring was removed with the

sensor.

Fig. 104 Air Intake Duct

Fig. 105 Removal/Installation of Air Inlet Duct

Fig. 106 Removal/Installation Air Cleaner Front

Housing and Element

Fig. 107 Engine Coolant Temperature SensorÐ

SOHC

14 - 56 FUEL SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 1002 of 1200

(6) If fluid flow is still found to be inadequate,

check the line pressure using the Transaxle Hydrau-

lic Pressure Test procedure.

REMOVAL AND INSTALLATION

GEARSHIFT CABLE

REMOVAL

(1) Disconnect both battery cables.

(2) Pull up and remove the power distribution cen-

ter.

(3) Remove the battery thermoguard.

(4) Remove the battery and battery holddown from

the battery tray.

(5) Remove the battery tray and cruise control

servo (if equipped).

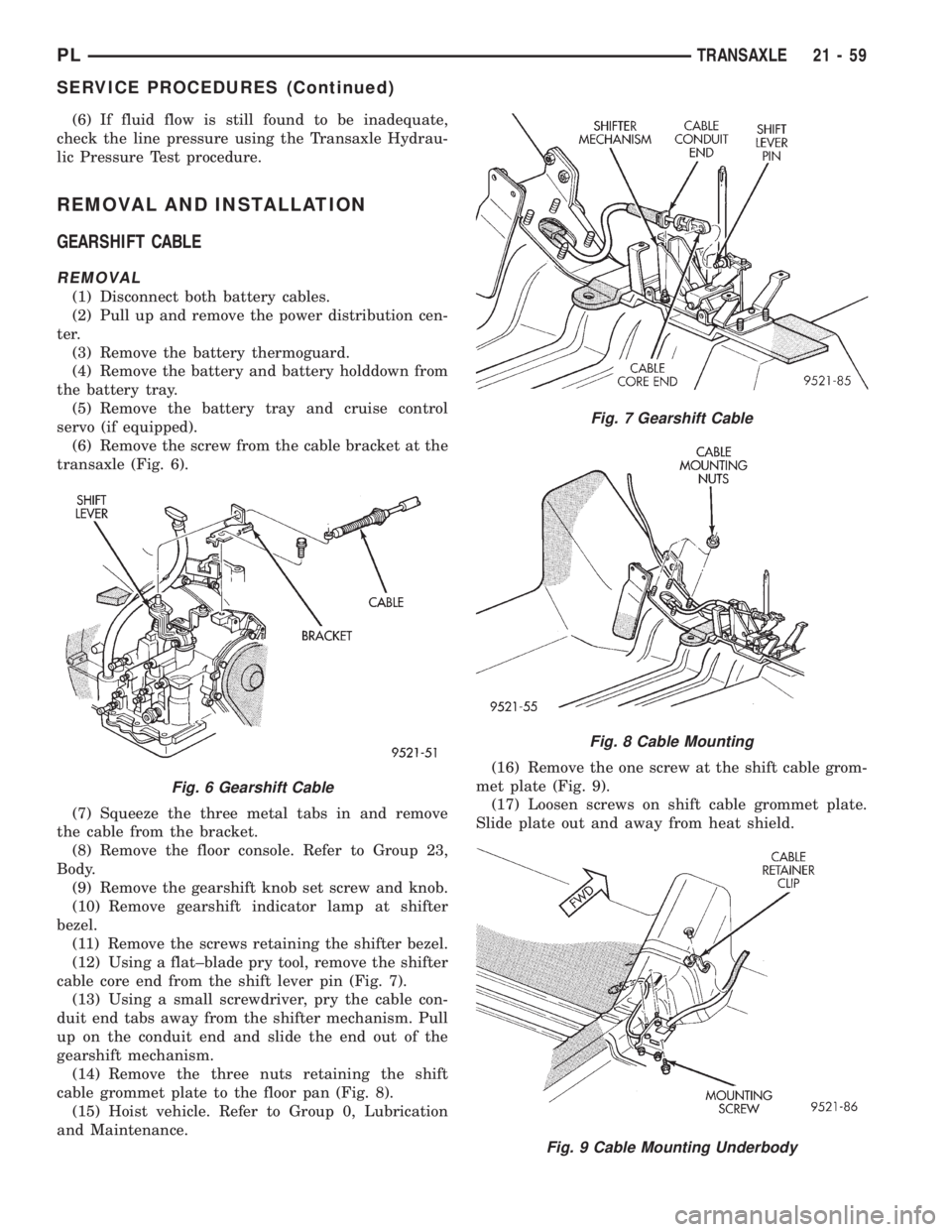

(6) Remove the screw from the cable bracket at the

transaxle (Fig. 6).

(7) Squeeze the three metal tabs in and remove

the cable from the bracket.

(8) Remove the floor console. Refer to Group 23,

Body.

(9) Remove the gearshift knob set screw and knob.

(10) Remove gearshift indicator lamp at shifter

bezel.

(11) Remove the screws retaining the shifter bezel.

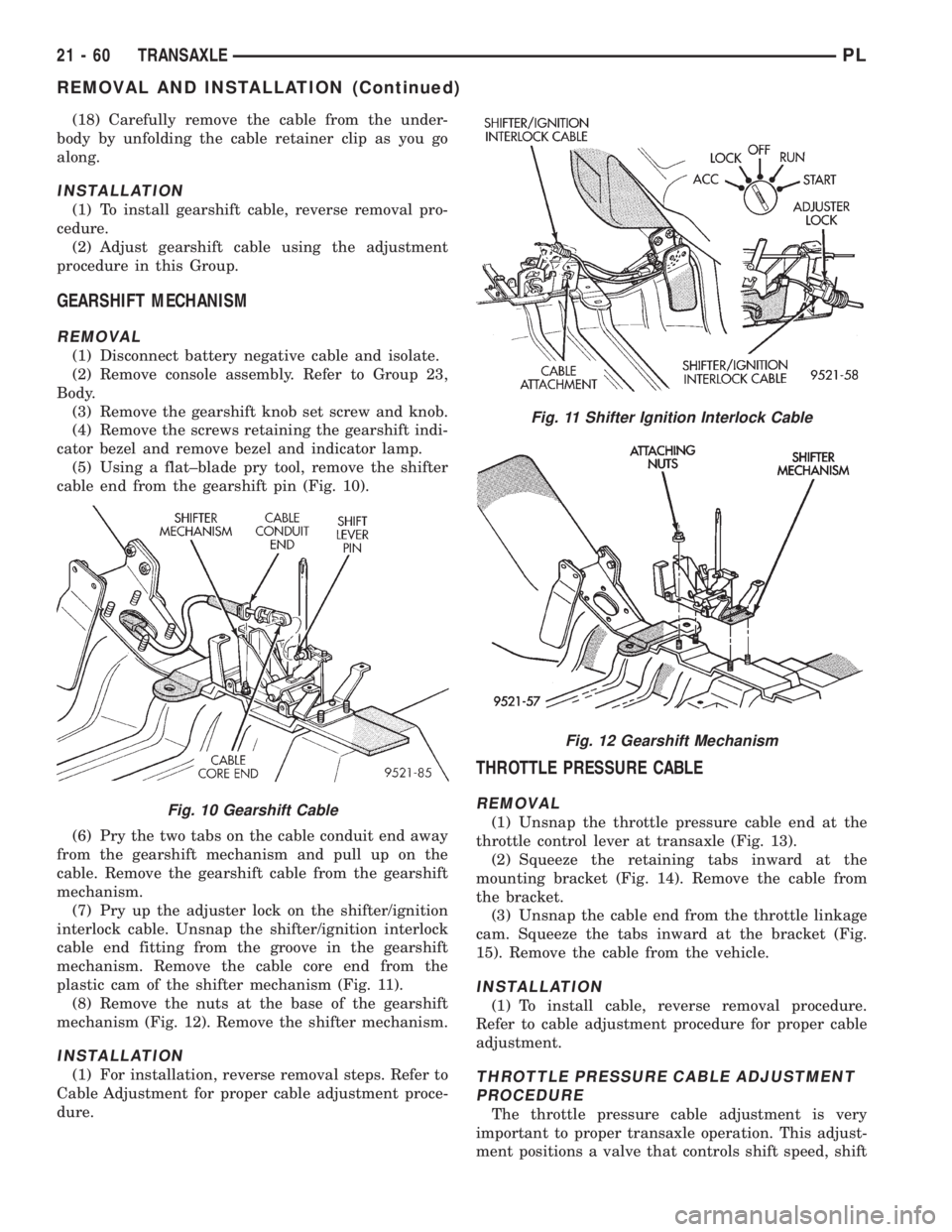

(12) Using a flat±blade pry tool, remove the shifter

cable core end from the shift lever pin (Fig. 7).

(13) Using a small screwdriver, pry the cable con-

duit end tabs away from the shifter mechanism. Pull

up on the conduit end and slide the end out of the

gearshift mechanism.

(14) Remove the three nuts retaining the shift

cable grommet plate to the floor pan (Fig. 8).

(15) Hoist vehicle. Refer to Group 0, Lubrication

and Maintenance.(16) Remove the one screw at the shift cable grom-

met plate (Fig. 9).

(17) Loosen screws on shift cable grommet plate.

Slide plate out and away from heat shield.

Fig. 6 Gearshift Cable

Fig. 7 Gearshift Cable

Fig. 8 Cable Mounting

Fig. 9 Cable Mounting Underbody

PLTRANSAXLE 21 - 59

SERVICE PROCEDURES (Continued)

Page 1003 of 1200

(18) Carefully remove the cable from the under-

body by unfolding the cable retainer clip as you go

along.

INSTALLATION

(1) To install gearshift cable, reverse removal pro-

cedure.

(2) Adjust gearshift cable using the adjustment

procedure in this Group.

GEARSHIFT MECHANISM

REMOVAL

(1) Disconnect battery negative cable and isolate.

(2) Remove console assembly. Refer to Group 23,

Body.

(3) Remove the gearshift knob set screw and knob.

(4) Remove the screws retaining the gearshift indi-

cator bezel and remove bezel and indicator lamp.

(5) Using a flat±blade pry tool, remove the shifter

cable end from the gearshift pin (Fig. 10).

(6) Pry the two tabs on the cable conduit end away

from the gearshift mechanism and pull up on the

cable. Remove the gearshift cable from the gearshift

mechanism.

(7) Pry up the adjuster lock on the shifter/ignition

interlock cable. Unsnap the shifter/ignition interlock

cable end fitting from the groove in the gearshift

mechanism. Remove the cable core end from the

plastic cam of the shifter mechanism (Fig. 11).

(8) Remove the nuts at the base of the gearshift

mechanism (Fig. 12). Remove the shifter mechanism.

INSTALLATION

(1) For installation, reverse removal steps. Refer to

Cable Adjustment for proper cable adjustment proce-

dure.

THROTTLE PRESSURE CABLE

REMOVAL

(1) Unsnap the throttle pressure cable end at the

throttle control lever at transaxle (Fig. 13).

(2) Squeeze the retaining tabs inward at the

mounting bracket (Fig. 14). Remove the cable from

the bracket.

(3) Unsnap the cable end from the throttle linkage

cam. Squeeze the tabs inward at the bracket (Fig.

15). Remove the cable from the vehicle.

INSTALLATION

(1) To install cable, reverse removal procedure.

Refer to cable adjustment procedure for proper cable

adjustment.

THROTTLE PRESSURE CABLE ADJUSTMENT

PROCEDURE

The throttle pressure cable adjustment is very

important to proper transaxle operation. This adjust-

ment positions a valve that controls shift speed, shift

Fig. 10 Gearshift Cable

Fig. 11 Shifter Ignition Interlock Cable

Fig. 12 Gearshift Mechanism

21 - 60 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 1027 of 1200

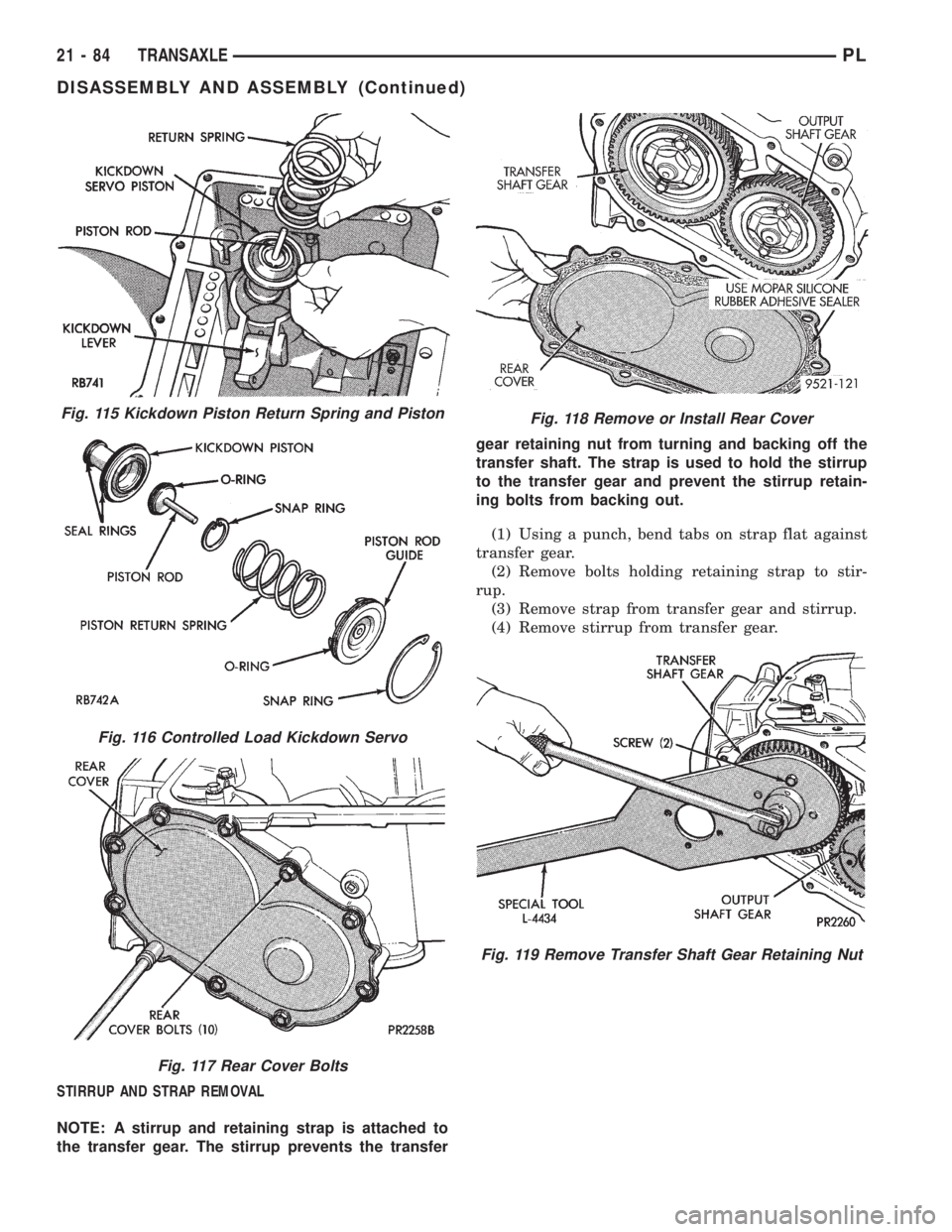

STIRRUP AND STRAP REMOVAL

NOTE: A stirrup and retaining strap is attached to

the transfer gear. The stirrup prevents the transfergear retaining nut from turning and backing off the

transfer shaft. The strap is used to hold the stirrup

to the transfer gear and prevent the stirrup retain-

ing bolts from backing out.

(1) Using a punch, bend tabs on strap flat against

transfer gear.

(2) Remove bolts holding retaining strap to stir-

rup.

(3) Remove strap from transfer gear and stirrup.

(4) Remove stirrup from transfer gear.

Fig. 115 Kickdown Piston Return Spring and Piston

Fig. 116 Controlled Load Kickdown Servo

Fig. 117 Rear Cover Bolts

Fig. 118 Remove or Install Rear Cover

Fig. 119 Remove Transfer Shaft Gear Retaining Nut

21 - 84 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1031 of 1200

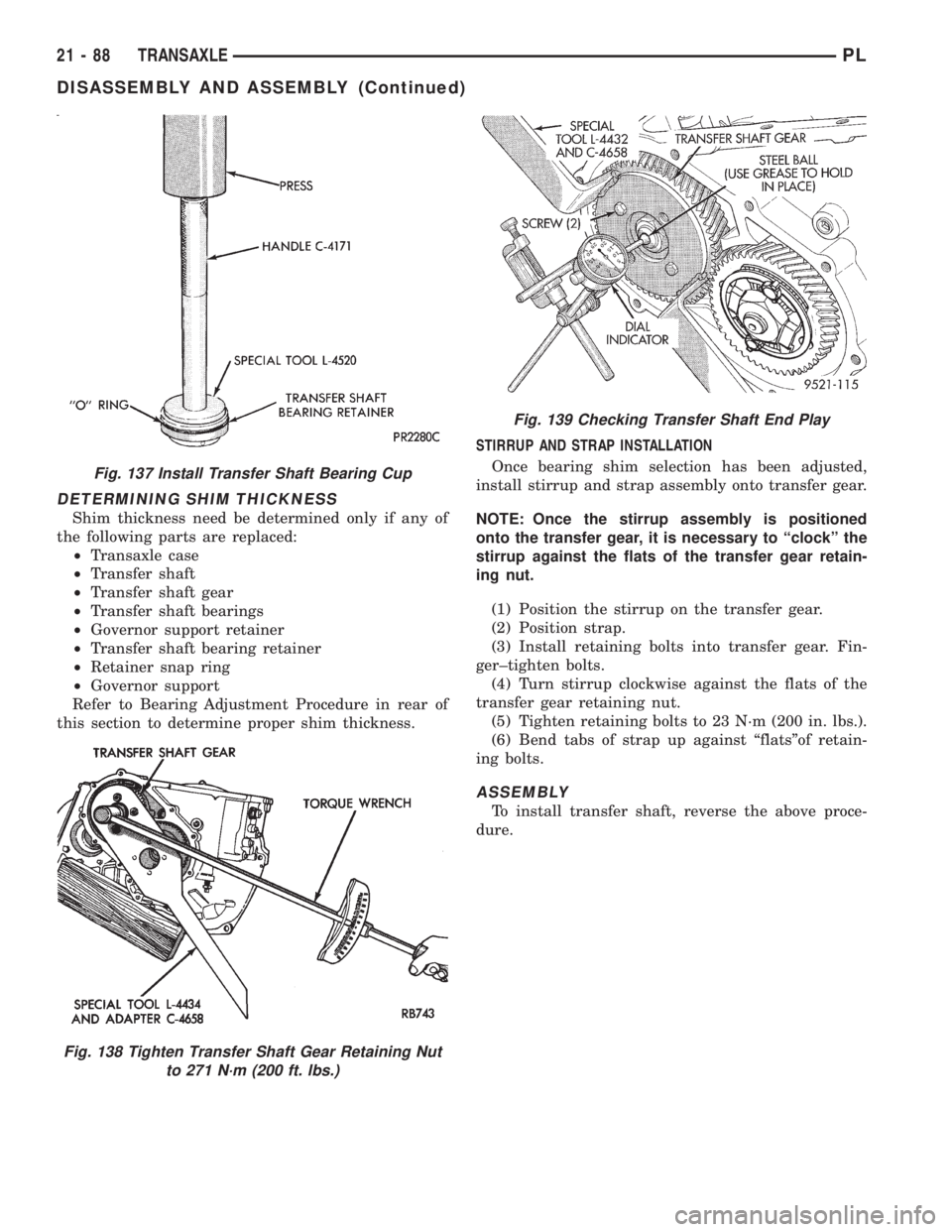

DETERMINING SHIM THICKNESS

Shim thickness need be determined only if any of

the following parts are replaced:

²Transaxle case

²Transfer shaft

²Transfer shaft gear

²Transfer shaft bearings

²Governor support retainer

²Transfer shaft bearing retainer

²Retainer snap ring

²Governor support

Refer to Bearing Adjustment Procedure in rear of

this section to determine proper shim thickness.STIRRUP AND STRAP INSTALLATION

Once bearing shim selection has been adjusted,

install stirrup and strap assembly onto transfer gear.

NOTE: Once the stirrup assembly is positioned

onto the transfer gear, it is necessary to ªclockº the

stirrup against the flats of the transfer gear retain-

ing nut.

(1) Position the stirrup on the transfer gear.

(2) Position strap.

(3) Install retaining bolts into transfer gear. Fin-

ger±tighten bolts.

(4) Turn stirrup clockwise against the flats of the

transfer gear retaining nut.

(5) Tighten retaining bolts to 23 N´m (200 in. lbs.).

(6) Bend tabs of strap up against ªflatsºof retain-

ing bolts.

ASSEMBLY

To install transfer shaft, reverse the above proce-

dure.

Fig. 137 Install Transfer Shaft Bearing Cup

Fig. 138 Tighten Transfer Shaft Gear Retaining Nut

to 271 N´m (200 ft. lbs.)

Fig. 139 Checking Transfer Shaft End Play

21 - 88 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1032 of 1200

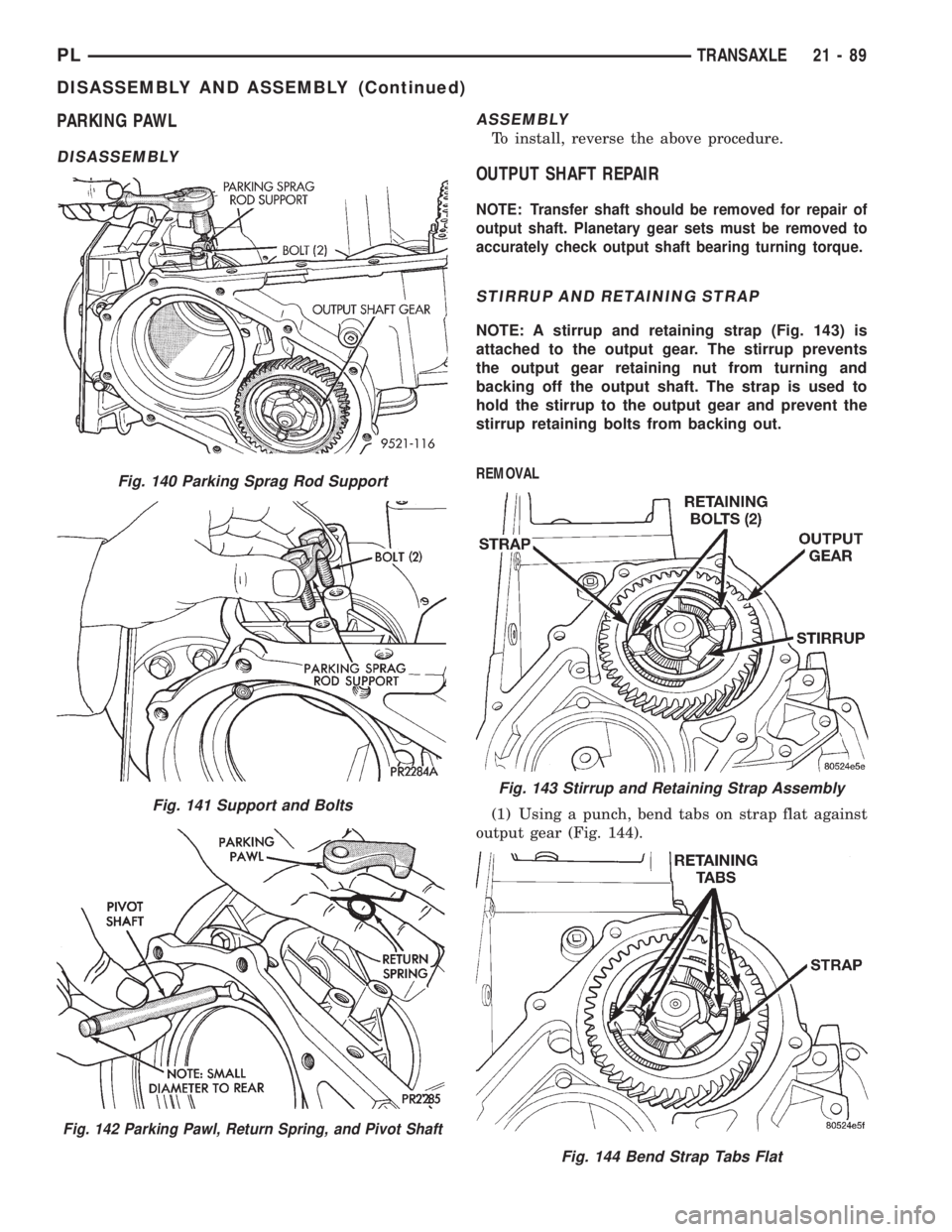

PARKING PAWL

DISASSEMBLYASSEMBLY

To install, reverse the above procedure.

OUTPUT SHAFT REPAIR

NOTE: Transfer shaft should be removed for repair of

output shaft. Planetary gear sets must be removed to

accurately check output shaft bearing turning torque.

STIRRUP AND RETAINING STRAP

NOTE: A stirrup and retaining strap (Fig. 143) is

attached to the output gear. The stirrup prevents

the output gear retaining nut from turning and

backing off the output shaft. The strap is used to

hold the stirrup to the output gear and prevent the

stirrup retaining bolts from backing out.

REMOVAL

(1) Using a punch, bend tabs on strap flat against

output gear (Fig. 144).

Fig. 140 Parking Sprag Rod Support

Fig. 141 Support and Bolts

Fig. 142 Parking Pawl, Return Spring, and Pivot Shaft

Fig. 143 Stirrup and Retaining Strap Assembly

Fig. 144 Bend Strap Tabs Flat

PLTRANSAXLE 21 - 89

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1037 of 1200

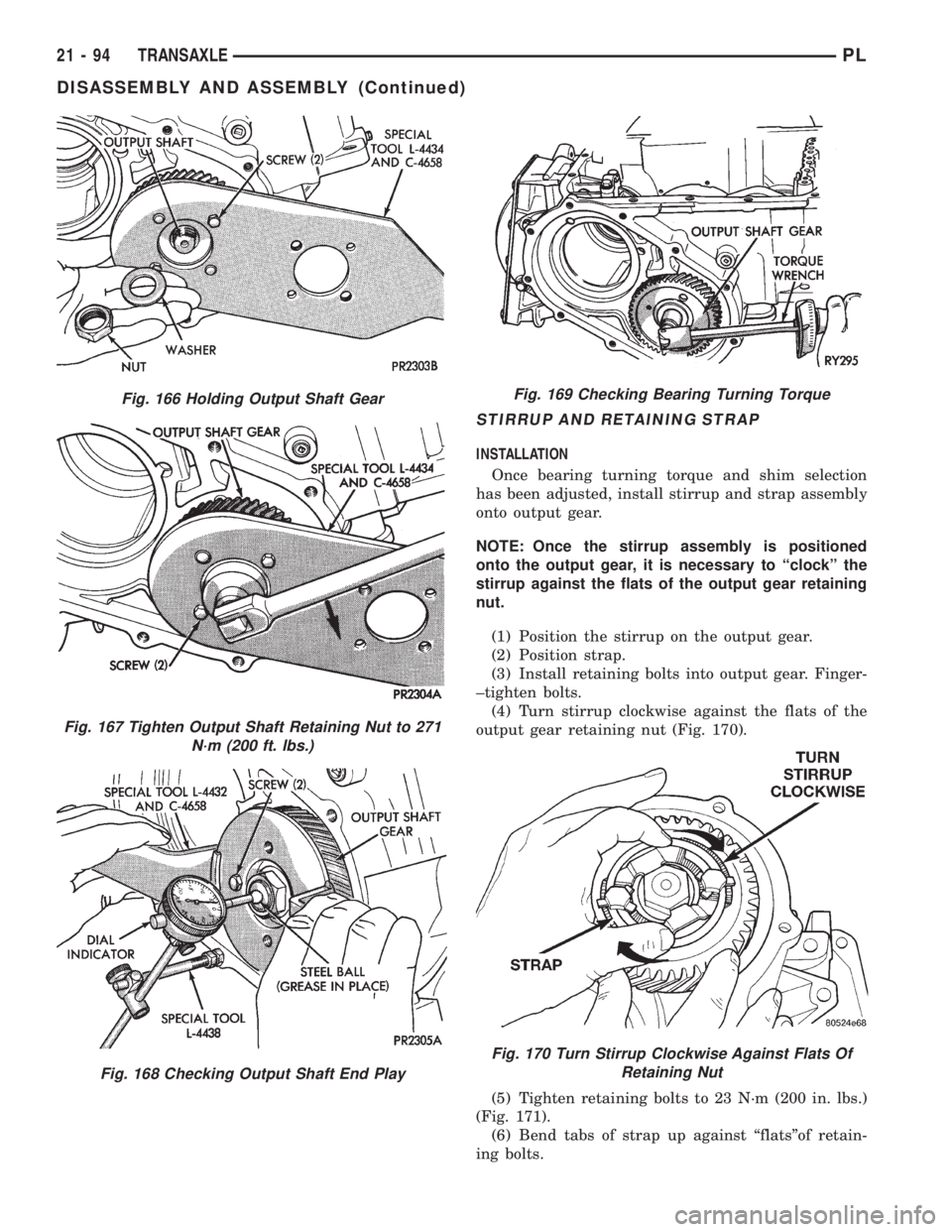

STIRRUP AND RETAINING STRAP

INSTALLATION

Once bearing turning torque and shim selection

has been adjusted, install stirrup and strap assembly

onto output gear.

NOTE: Once the stirrup assembly is positioned

onto the output gear, it is necessary to ªclockº the

stirrup against the flats of the output gear retaining

nut.

(1) Position the stirrup on the output gear.

(2) Position strap.

(3) Install retaining bolts into output gear. Finger-

±tighten bolts.

(4) Turn stirrup clockwise against the flats of the

output gear retaining nut (Fig. 170).

(5) Tighten retaining bolts to 23 N´m (200 in. lbs.)

(Fig. 171).

(6) Bend tabs of strap up against ªflatsºof retain-

ing bolts.

Fig. 166 Holding Output Shaft Gear

Fig. 167 Tighten Output Shaft Retaining Nut to 271

N´m (200 ft. lbs.)

Fig. 168 Checking Output Shaft End Play

Fig. 169 Checking Bearing Turning Torque

Fig. 170 Turn Stirrup Clockwise Against Flats Of

Retaining Nut

21 - 94 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)