bulb DODGE NEON 1999 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 339 of 1200

INSTALLATION

Reverse the preceding operation.

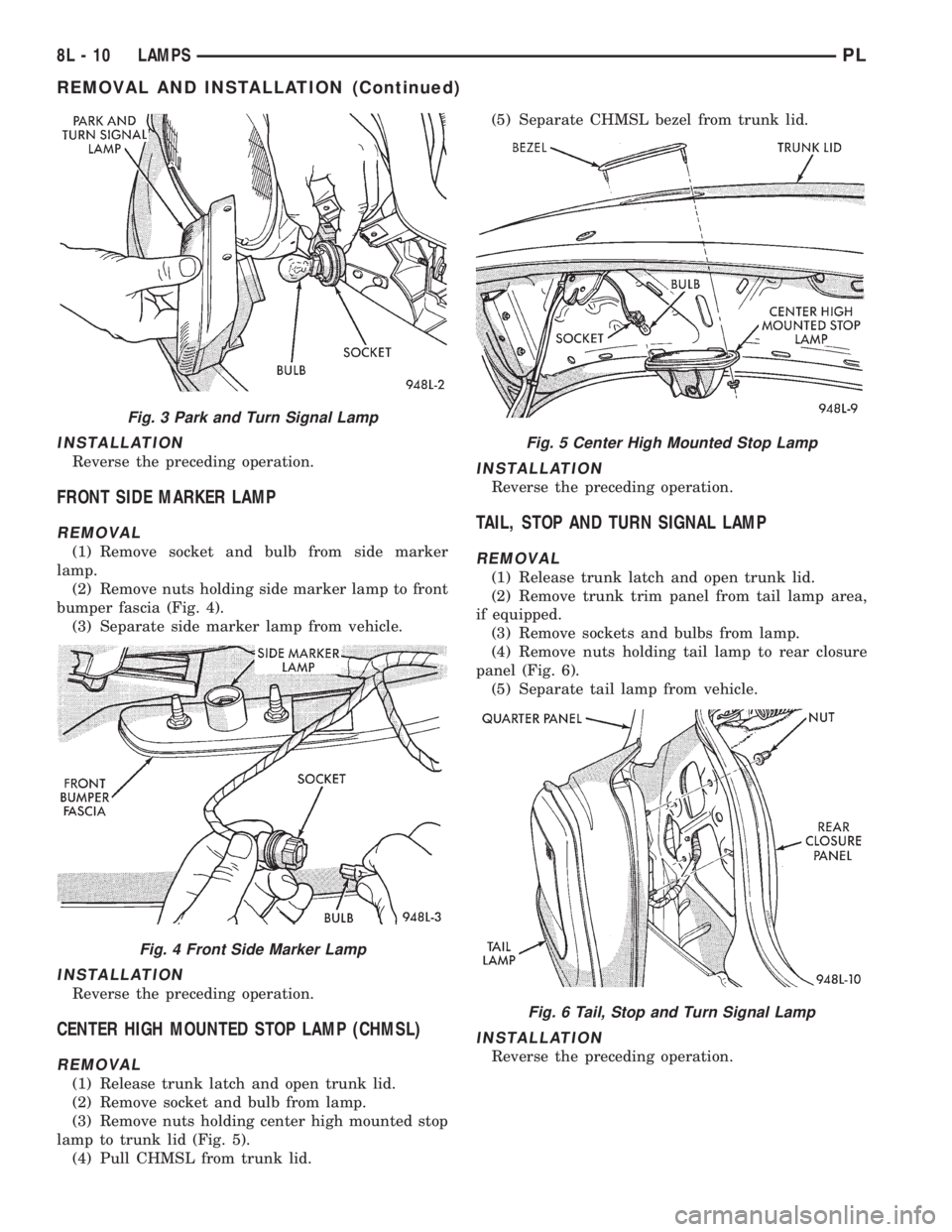

FRONT SIDE MARKER LAMP

REMOVAL

(1) Remove socket and bulb from side marker

lamp.

(2) Remove nuts holding side marker lamp to front

bumper fascia (Fig. 4).

(3) Separate side marker lamp from vehicle.

INSTALLATION

Reverse the preceding operation.

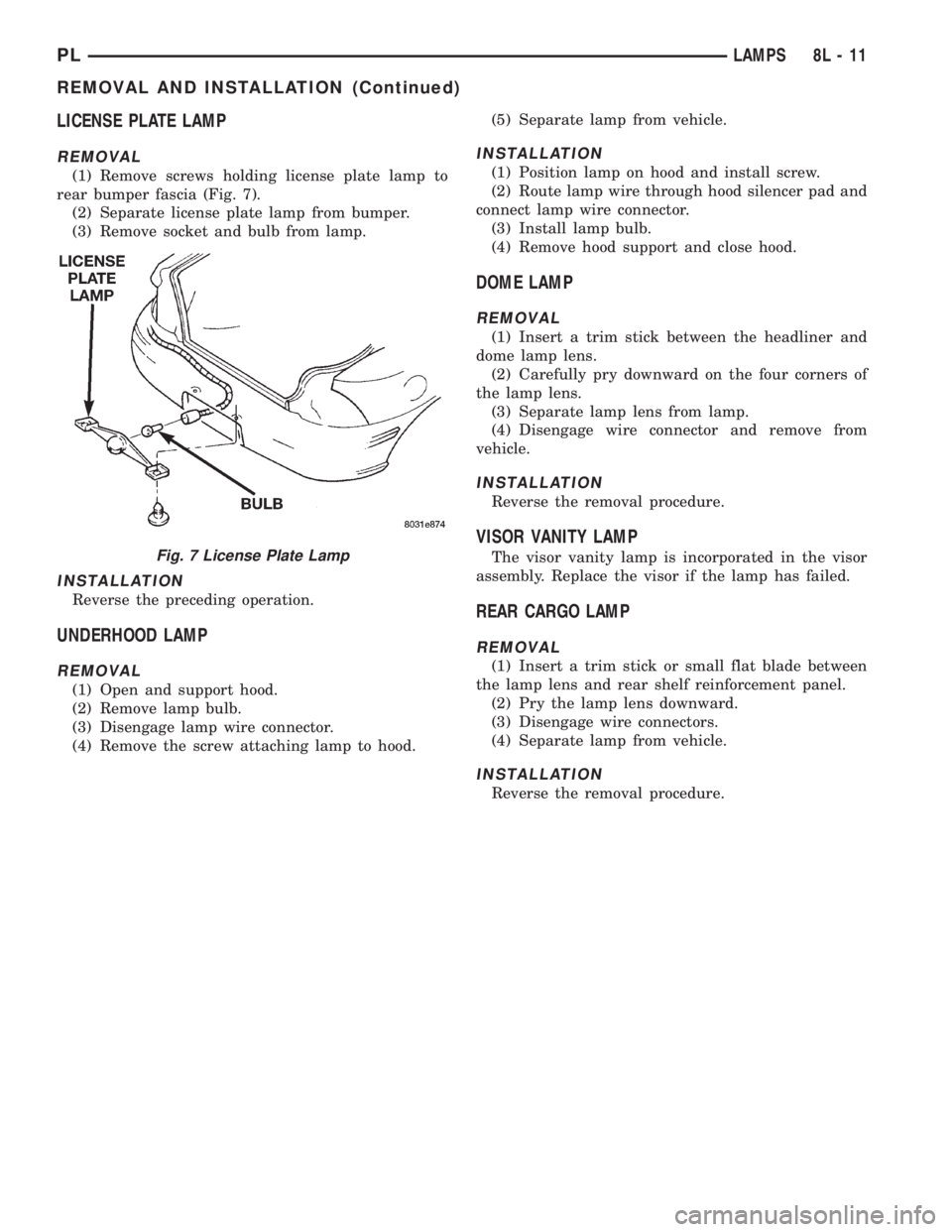

CENTER HIGH MOUNTED STOP LAMP (CHMSL)

REMOVAL

(1) Release trunk latch and open trunk lid.

(2) Remove socket and bulb from lamp.

(3) Remove nuts holding center high mounted stop

lamp to trunk lid (Fig. 5).

(4) Pull CHMSL from trunk lid.(5) Separate CHMSL bezel from trunk lid.

INSTALLATION

Reverse the preceding operation.

TAIL, STOP AND TURN SIGNAL LAMP

REMOVAL

(1) Release trunk latch and open trunk lid.

(2) Remove trunk trim panel from tail lamp area,

if equipped.

(3) Remove sockets and bulbs from lamp.

(4) Remove nuts holding tail lamp to rear closure

panel (Fig. 6).

(5) Separate tail lamp from vehicle.

INSTALLATION

Reverse the preceding operation.

Fig. 3 Park and Turn Signal Lamp

Fig. 4 Front Side Marker Lamp

Fig. 5 Center High Mounted Stop Lamp

Fig. 6 Tail, Stop and Turn Signal Lamp

8L - 10 LAMPSPL

REMOVAL AND INSTALLATION (Continued)

Page 340 of 1200

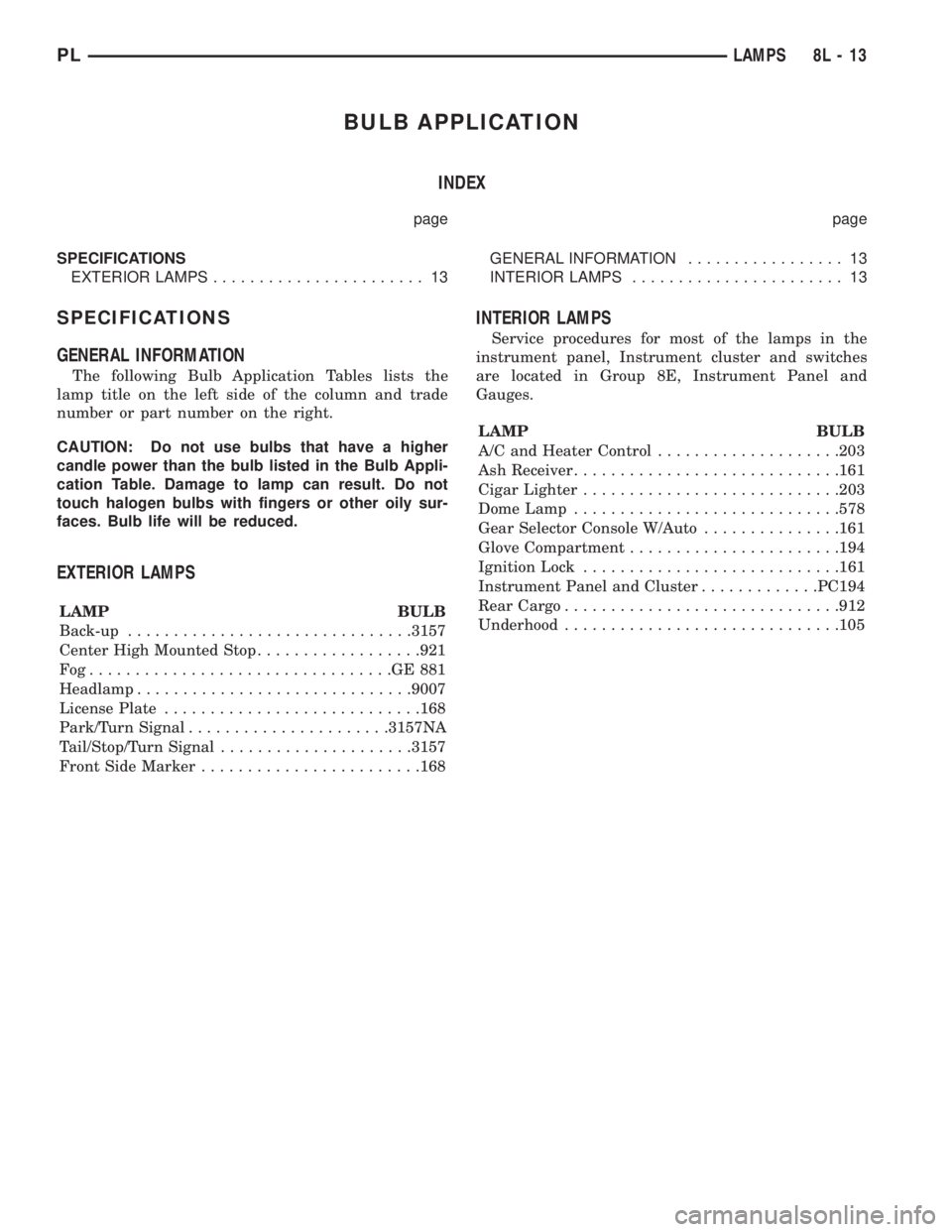

LICENSE PLATE LAMP

REMOVAL

(1) Remove screws holding license plate lamp to

rear bumper fascia (Fig. 7).

(2) Separate license plate lamp from bumper.

(3) Remove socket and bulb from lamp.

INSTALLATION

Reverse the preceding operation.

UNDERHOOD LAMP

REMOVAL

(1) Open and support hood.

(2) Remove lamp bulb.

(3) Disengage lamp wire connector.

(4) Remove the screw attaching lamp to hood.(5) Separate lamp from vehicle.

INSTALLATION

(1) Position lamp on hood and install screw.

(2) Route lamp wire through hood silencer pad and

connect lamp wire connector.

(3) Install lamp bulb.

(4) Remove hood support and close hood.

DOME LAMP

REMOVAL

(1) Insert a trim stick between the headliner and

dome lamp lens.

(2) Carefully pry downward on the four corners of

the lamp lens.

(3) Separate lamp lens from lamp.

(4) Disengage wire connector and remove from

vehicle.

INSTALLATION

Reverse the removal procedure.

VISOR VANITY LAMP

The visor vanity lamp is incorporated in the visor

assembly. Replace the visor if the lamp has failed.

REAR CARGO LAMP

REMOVAL

(1) Insert a trim stick or small flat blade between

the lamp lens and rear shelf reinforcement panel.

(2) Pry the lamp lens downward.

(3) Disengage wire connectors.

(4) Separate lamp from vehicle.

INSTALLATION

Reverse the removal procedure.

Fig. 7 License Plate Lamp

PLLAMPS 8L - 11

REMOVAL AND INSTALLATION (Continued)

Page 342 of 1200

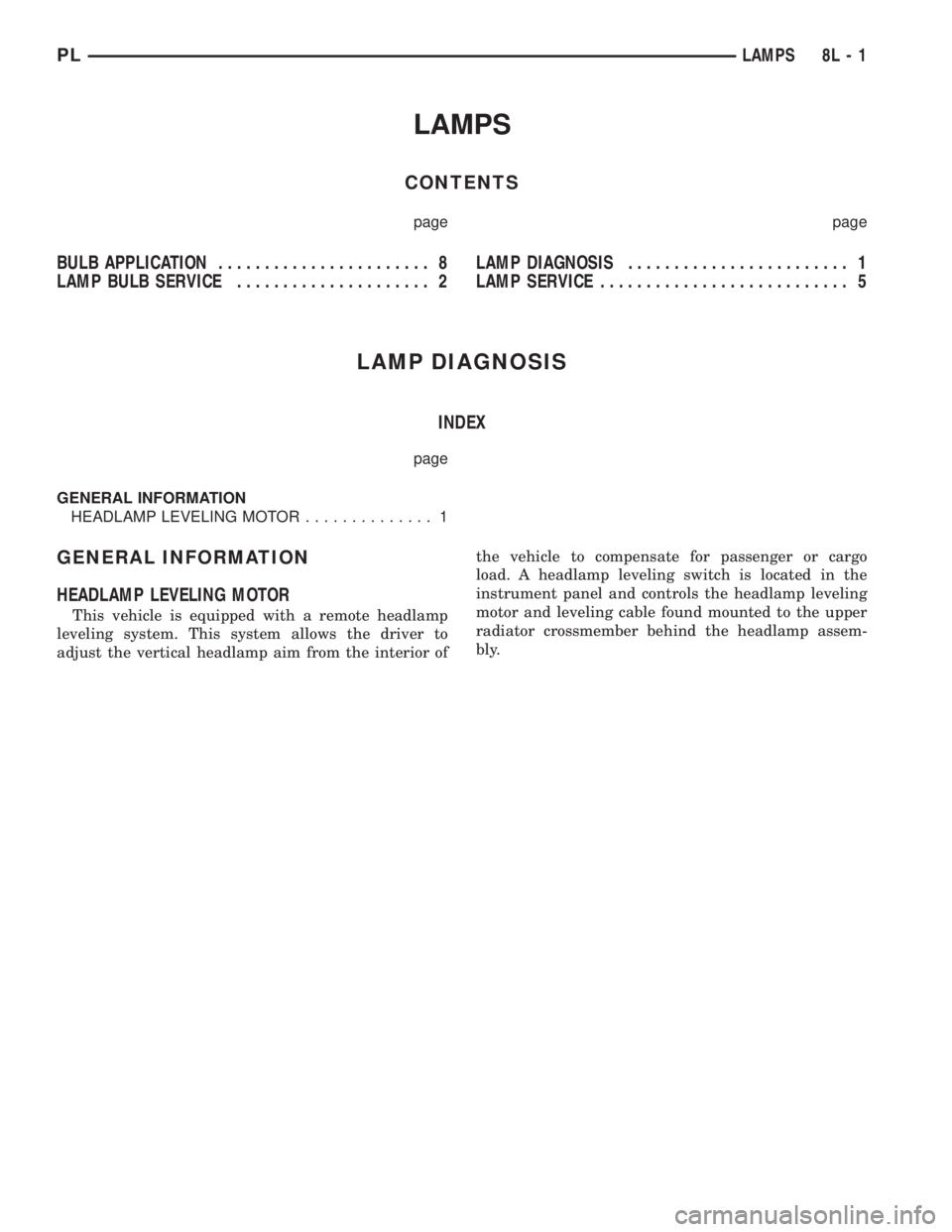

BULB APPLICATION

INDEX

page page

SPECIFICATIONS

EXTERIOR LAMPS....................... 13GENERAL INFORMATION................. 13

INTERIOR LAMPS....................... 13

SPECIFICATIONS

GENERAL INFORMATION

The following Bulb Application Tables lists the

lamp title on the left side of the column and trade

number or part number on the right.

CAUTION: Do not use bulbs that have a higher

candle power than the bulb listed in the Bulb Appli-

cation Table. Damage to lamp can result. Do not

touch halogen bulbs with fingers or other oily sur-

faces. Bulb life will be reduced.

EXTERIOR LAMPS

LAMP BULB

Back-up...............................3157

Center High Mounted Stop..................921

Fog.................................GE881

Headlamp..............................9007

License Plate............................168

Park/Turn Signal......................3157NA

Tail/Stop/Turn Signal.....................3157

Front Side Marker........................168

INTERIOR LAMPS

Service procedures for most of the lamps in the

instrument panel, Instrument cluster and switches

are located in Group 8E, Instrument Panel and

Gauges.

LAMP BULB

A/C and Heater Control....................203

Ash Receiver.............................161

Cigar Lighter............................203

Dome Lamp.............................578

Gear Selector Console W/Auto...............161

Glove Compartment.......................194

Ignition Lock............................161

Instrument Panel and Cluster.............PC194

Rear Cargo..............................912

Underhood..............................105

PLLAMPS 8L - 13

Page 344 of 1200

LAMPS

CONTENTS

page page

BULB APPLICATION....................... 8

LAMP BULB SERVICE..................... 2LAMP DIAGNOSIS........................ 1

LAMP SERVICE........................... 5

LAMP DIAGNOSIS

INDEX

page

GENERAL INFORMATION

HEADLAMP LEVELING MOTOR.............. 1

GENERAL INFORMATION

HEADLAMP LEVELING MOTOR

This vehicle is equipped with a remote headlamp

leveling system. This system allows the driver to

adjust the vertical headlamp aim from the interior ofthe vehicle to compensate for passenger or cargo

load. A headlamp leveling switch is located in the

instrument panel and controls the headlamp leveling

motor and leveling cable found mounted to the upper

radiator crossmember behind the headlamp assem-

bly.

PLLAMPS 8L - 1

Page 345 of 1200

LAMP BULB SERVICE

INDEX

page page

REMOVAL AND INSTALLATION

CITYLIGHT LAMP BULB.................... 3

FOG LAMP BULB......................... 3FRONT TURN SIGNAL LAMP BULB........... 2

HEADLAMP BULB........................ 2

SIDE REPEATER LAMP BULB............... 4

REMOVAL AND INSTALLATION

HEADLAMP BULB

REMOVAL

(1) Release hood latch and open hood.

(2) Disengage wire connector to headlamp bulb.

(3) Remove headlamp assembly from vehicle.

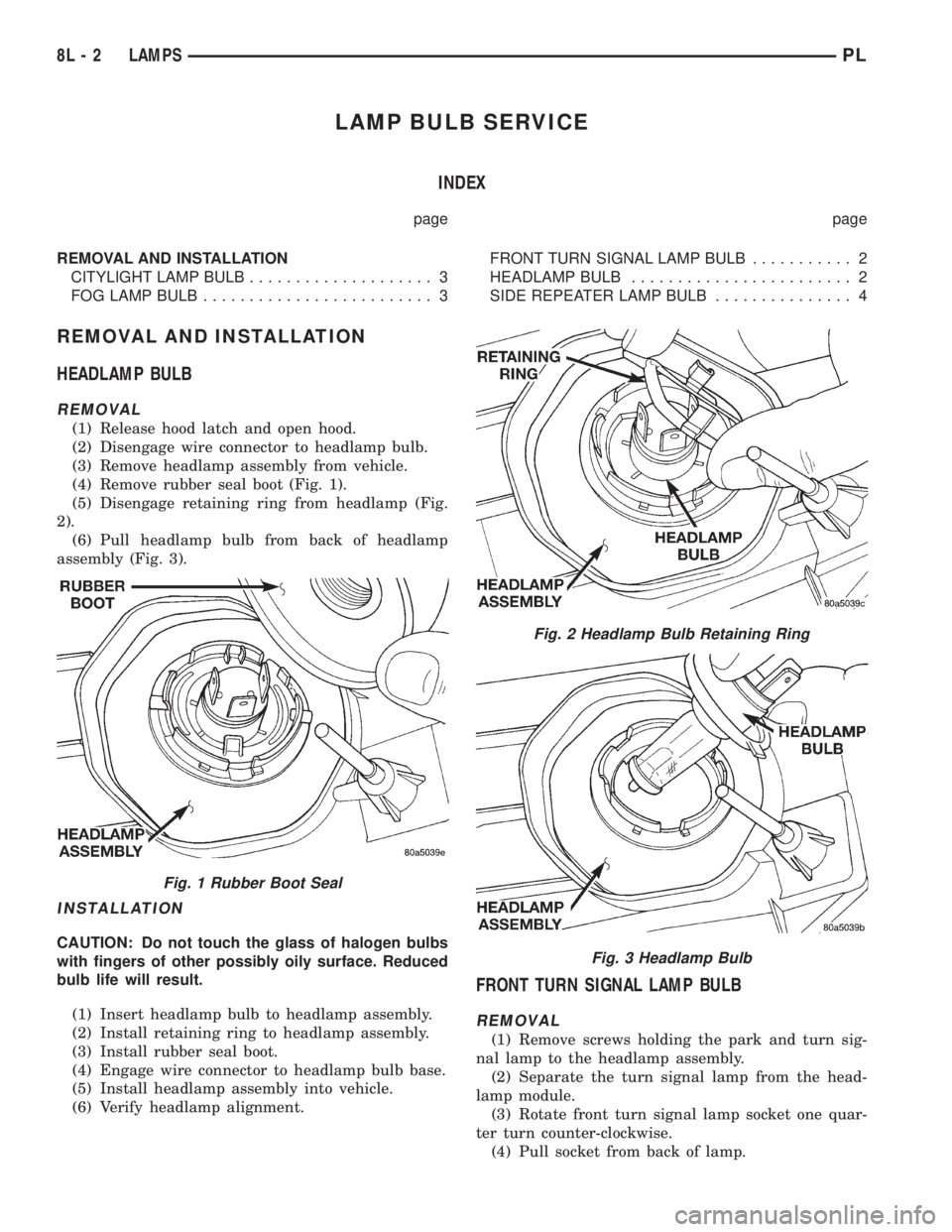

(4) Remove rubber seal boot (Fig. 1).

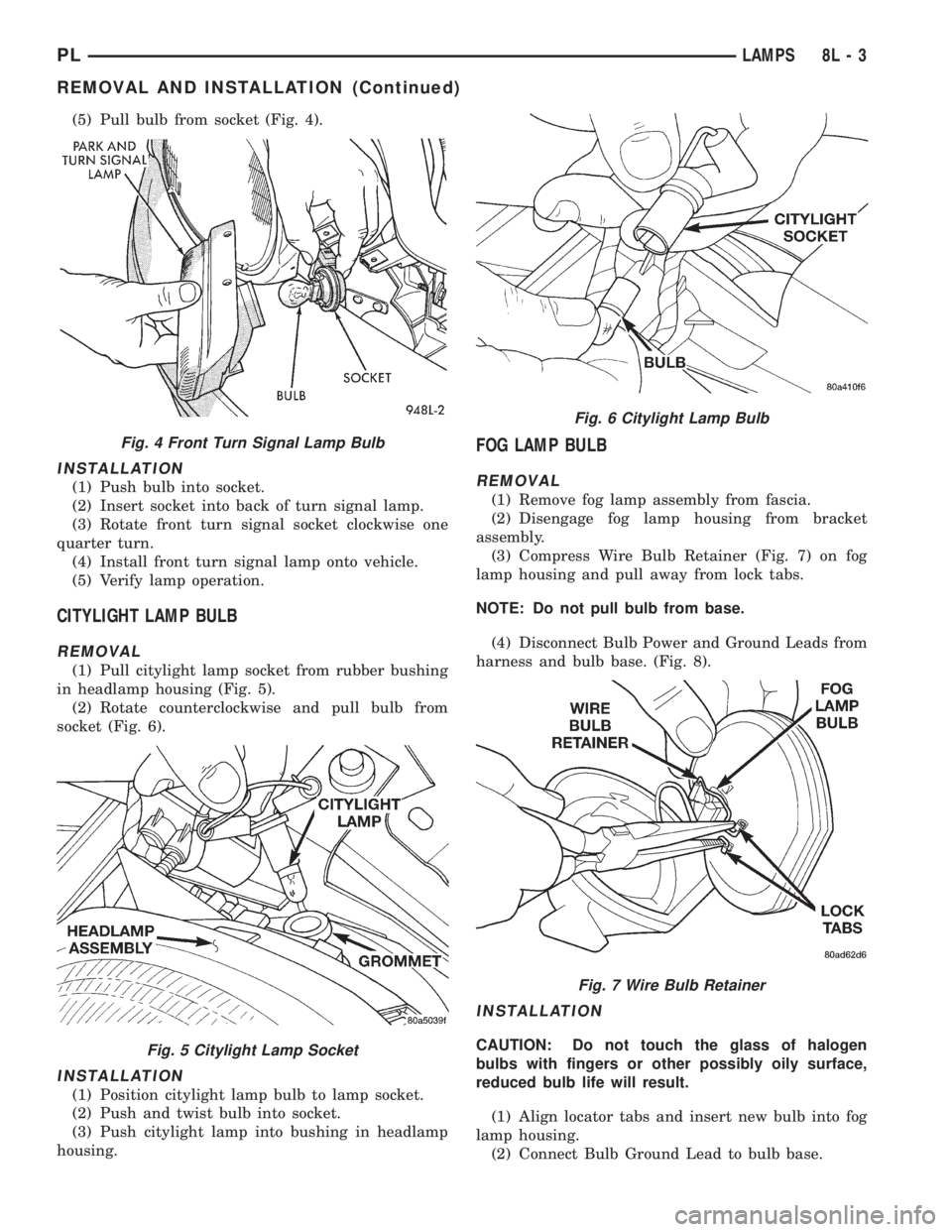

(5) Disengage retaining ring from headlamp (Fig.

2).

(6) Pull headlamp bulb from back of headlamp

assembly (Fig. 3).

INSTALLATION

CAUTION: Do not touch the glass of halogen bulbs

with fingers of other possibly oily surface. Reduced

bulb life will result.

(1) Insert headlamp bulb to headlamp assembly.

(2) Install retaining ring to headlamp assembly.

(3) Install rubber seal boot.

(4) Engage wire connector to headlamp bulb base.

(5) Install headlamp assembly into vehicle.

(6) Verify headlamp alignment.

FRONT TURN SIGNAL LAMP BULB

REMOVAL

(1) Remove screws holding the park and turn sig-

nal lamp to the headlamp assembly.

(2) Separate the turn signal lamp from the head-

lamp module.

(3) Rotate front turn signal lamp socket one quar-

ter turn counter-clockwise.

(4) Pull socket from back of lamp.

Fig. 1 Rubber Boot Seal

Fig. 2 Headlamp Bulb Retaining Ring

Fig. 3 Headlamp Bulb

8L - 2 LAMPSPL

Page 346 of 1200

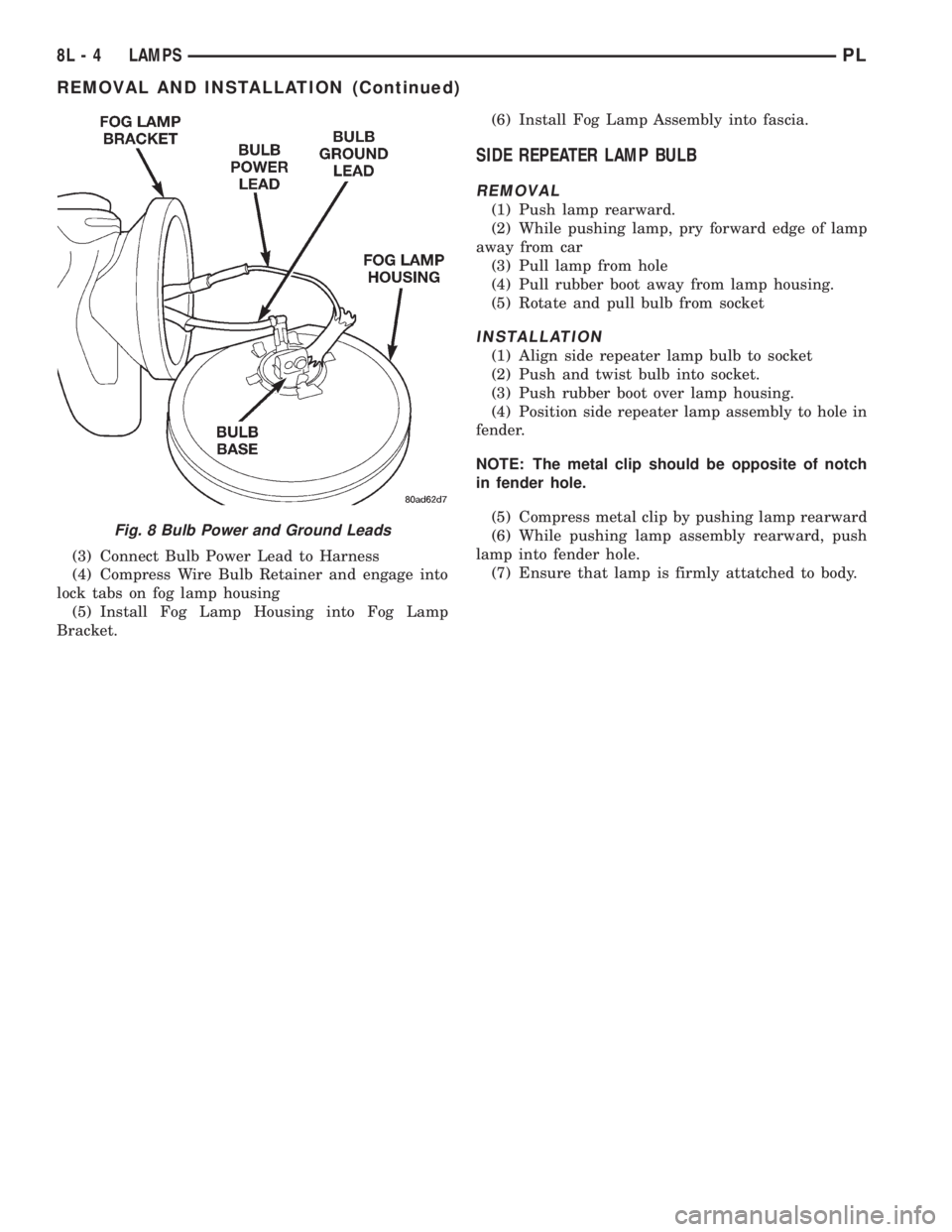

(5) Pull bulb from socket (Fig. 4).

INSTALLATION

(1) Push bulb into socket.

(2) Insert socket into back of turn signal lamp.

(3) Rotate front turn signal socket clockwise one

quarter turn.

(4) Install front turn signal lamp onto vehicle.

(5) Verify lamp operation.

CITYLIGHT LAMP BULB

REMOVAL

(1) Pull citylight lamp socket from rubber bushing

in headlamp housing (Fig. 5).

(2) Rotate counterclockwise and pull bulb from

socket (Fig. 6).

INSTALLATION

(1) Position citylight lamp bulb to lamp socket.

(2) Push and twist bulb into socket.

(3) Push citylight lamp into bushing in headlamp

housing.

FOG LAMP BULB

REMOVAL

(1) Remove fog lamp assembly from fascia.

(2) Disengage fog lamp housing from bracket

assembly.

(3) Compress Wire Bulb Retainer (Fig. 7) on fog

lamp housing and pull away from lock tabs.

NOTE: Do not pull bulb from base.

(4) Disconnect Bulb Power and Ground Leads from

harness and bulb base. (Fig. 8).

INSTALLATION

CAUTION: Do not touch the glass of halogen

bulbs with fingers or other possibly oily surface,

reduced bulb life will result.

(1) Align locator tabs and insert new bulb into fog

lamp housing.

(2) Connect Bulb Ground Lead to bulb base.

Fig. 4 Front Turn Signal Lamp Bulb

Fig. 5 Citylight Lamp Socket

Fig. 6 Citylight Lamp Bulb

Fig. 7 Wire Bulb Retainer

PLLAMPS 8L - 3

REMOVAL AND INSTALLATION (Continued)

Page 347 of 1200

(3) Connect Bulb Power Lead to Harness

(4) Compress Wire Bulb Retainer and engage into

lock tabs on fog lamp housing

(5) Install Fog Lamp Housing into Fog Lamp

Bracket.(6) Install Fog Lamp Assembly into fascia.

SIDE REPEATER LAMP BULB

REMOVAL

(1) Push lamp rearward.

(2) While pushing lamp, pry forward edge of lamp

away from car

(3) Pull lamp from hole

(4) Pull rubber boot away from lamp housing.

(5) Rotate and pull bulb from socket

INSTALLATION

(1) Align side repeater lamp bulb to socket

(2) Push and twist bulb into socket.

(3) Push rubber boot over lamp housing.

(4) Position side repeater lamp assembly to hole in

fender.

NOTE: The metal clip should be opposite of notch

in fender hole.

(5) Compress metal clip by pushing lamp rearward

(6) While pushing lamp assembly rearward, push

lamp into fender hole.

(7) Ensure that lamp is firmly attatched to body.

Fig. 8 Bulb Power and Ground Leads

8L - 4 LAMPSPL

REMOVAL AND INSTALLATION (Continued)

Page 351 of 1200

BULB APPLICATION

INDEX

page page

GENERAL INFORMATION

INTRODUCTION......................... 8

SPECIFICATIONS

EXTERIOR LAMPS........................ 8INTERIOR LAMPS........................ 8

GENERAL INFORMATION

INTRODUCTION

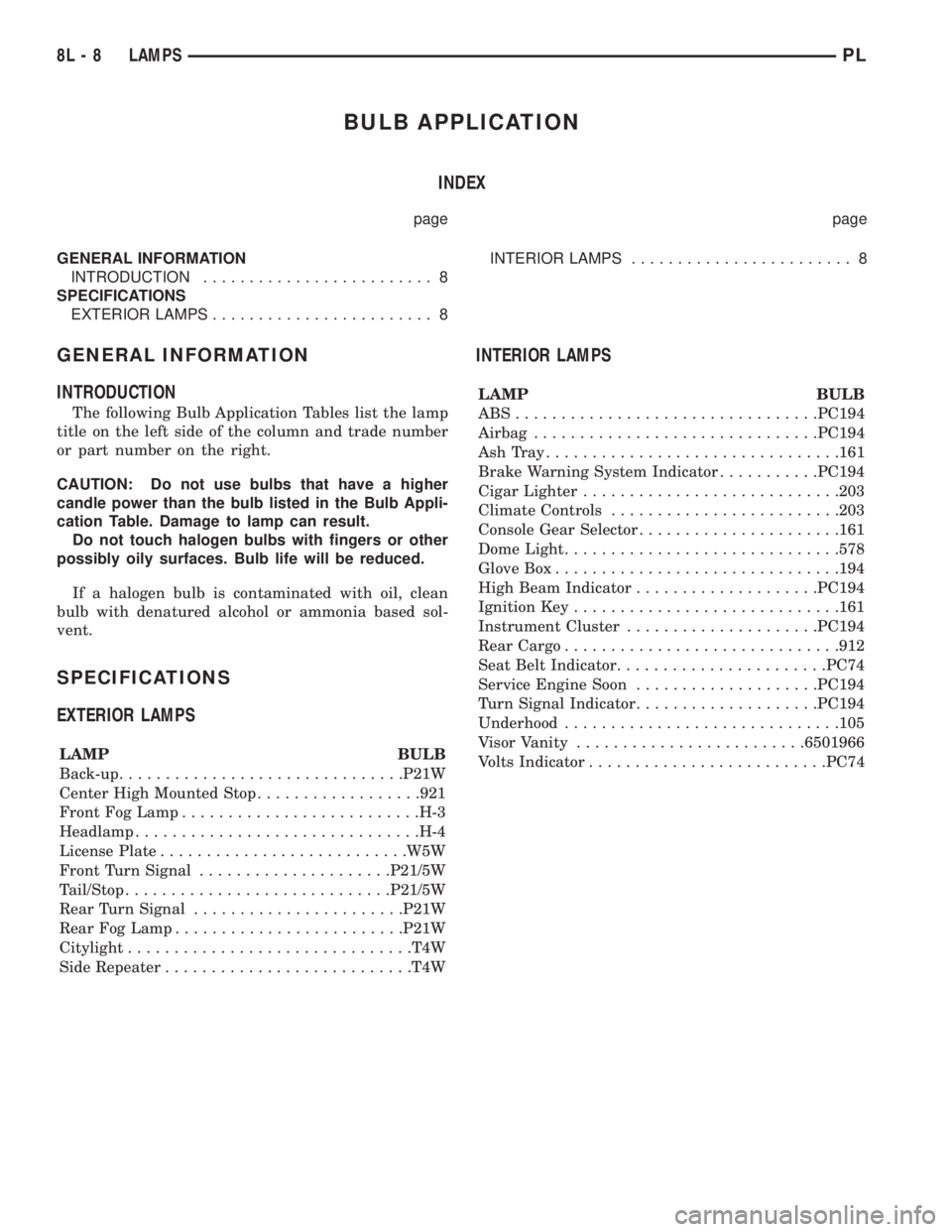

The following Bulb Application Tables list the lamp

title on the left side of the column and trade number

or part number on the right.

CAUTION: Do not use bulbs that have a higher

candle power than the bulb listed in the Bulb Appli-

cation Table. Damage to lamp can result.

Do not touch halogen bulbs with fingers or other

possibly oily surfaces. Bulb life will be reduced.

If a halogen bulb is contaminated with oil, clean

bulb with denatured alcohol or ammonia based sol-

vent.

SPECIFICATIONS

EXTERIOR LAMPS

LAMP BULB

Back-up...............................P21W

Center High Mounted Stop..................921

Front Fog Lamp..........................H-3

Headlamp...............................H-4

License Plate...........................W5W

Front Turn Signal.....................P21/5W

Tail/Stop.............................P21/5W

Rear Turn Signal.......................P21W

Rear Fog Lamp.........................P21W

Citylight...............................T4W

Side Repeater...........................T4W

INTERIOR LAMPS

LAMP BULB

ABS.................................PC194

Airbag...............................PC194

AshTray................................161

Brake Warning System Indicator...........PC194

Cigar Lighter............................203

Climate Controls.........................203

Console Gear Selector......................161

Dome Light..............................578

Glove Box...............................194

High Beam Indicator....................PC194

Ignition Key.............................161

Instrument Cluster.....................PC194

Rear Cargo..............................912

Seat Belt Indicator.......................PC74

Service Engine Soon....................PC194

Turn Signal Indicator....................PC194

Underhood..............................105

Visor Vanity.........................6501966

Volts Indicator..........................PC74

8L - 8 LAMPSPL

Page 384 of 1200

POWER MIRRORS

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DIAGNOSIS AND TESTING

MIRROR MOTOR........................ 2

MIRROR SWITCH TEST................... 1REMOVAL AND INSTALLATION

INSIDE MIRROR/READING LAMPS

ASSEMBLY............................ 2

INSIDE MIRROR/READING LAMPS

BULB/LENS........................... 2

MIRROR ASSEMBLY..................... 2

MIRROR SWITCH........................ 2

GENERAL INFORMATION

INTRODUCTION

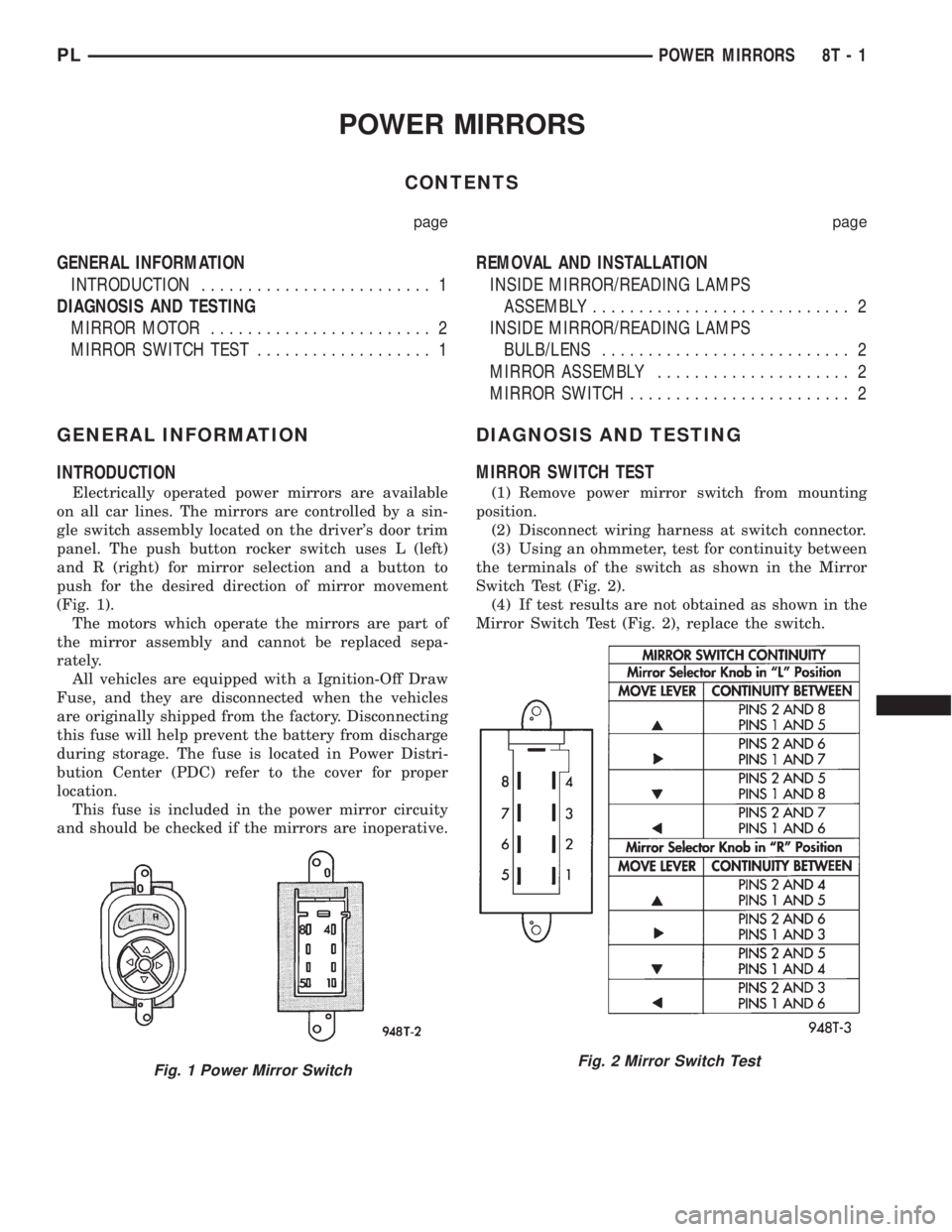

Electrically operated power mirrors are available

on all car lines. The mirrors are controlled by a sin-

gle switch assembly located on the driver's door trim

panel. The push button rocker switch uses L (left)

and R (right) for mirror selection and a button to

push for the desired direction of mirror movement

(Fig. 1).

The motors which operate the mirrors are part of

the mirror assembly and cannot be replaced sepa-

rately.

All vehicles are equipped with a Ignition-Off Draw

Fuse, and they are disconnected when the vehicles

are originally shipped from the factory. Disconnecting

this fuse will help prevent the battery from discharge

during storage. The fuse is located in Power Distri-

bution Center (PDC) refer to the cover for proper

location.

This fuse is included in the power mirror circuity

and should be checked if the mirrors are inoperative.

DIAGNOSIS AND TESTING

MIRROR SWITCH TEST

(1) Remove power mirror switch from mounting

position.

(2) Disconnect wiring harness at switch connector.

(3) Using an ohmmeter, test for continuity between

the terminals of the switch as shown in the Mirror

Switch Test (Fig. 2).

(4) If test results are not obtained as shown in the

Mirror Switch Test (Fig. 2), replace the switch.

Fig. 1 Power Mirror SwitchFig. 2 Mirror Switch Test

PLPOWER MIRRORS 8T - 1

Page 385 of 1200

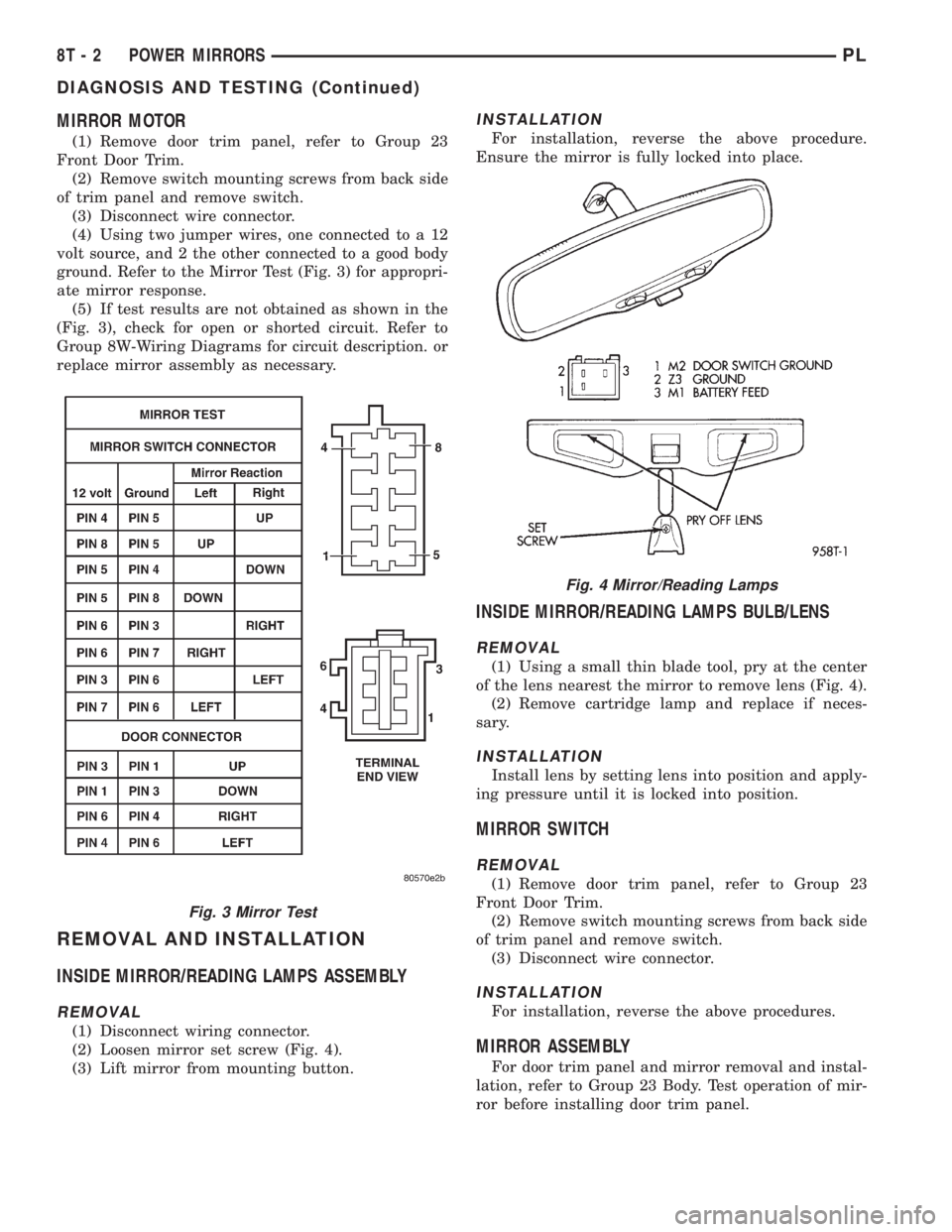

MIRROR MOTOR

(1) Remove door trim panel, refer to Group 23

Front Door Trim.

(2) Remove switch mounting screws from back side

of trim panel and remove switch.

(3) Disconnect wire connector.

(4) Using two jumper wires, one connected to a 12

volt source, and 2 the other connected to a good body

ground. Refer to the Mirror Test (Fig. 3) for appropri-

ate mirror response.

(5) If test results are not obtained as shown in the

(Fig. 3), check for open or shorted circuit. Refer to

Group 8W-Wiring Diagrams for circuit description. or

replace mirror assembly as necessary.

REMOVAL AND INSTALLATION

INSIDE MIRROR/READING LAMPS ASSEMBLY

REMOVAL

(1) Disconnect wiring connector.

(2) Loosen mirror set screw (Fig. 4).

(3) Lift mirror from mounting button.

INSTALLATION

For installation, reverse the above procedure.

Ensure the mirror is fully locked into place.

INSIDE MIRROR/READING LAMPS BULB/LENS

REMOVAL

(1) Using a small thin blade tool, pry at the center

of the lens nearest the mirror to remove lens (Fig. 4).

(2) Remove cartridge lamp and replace if neces-

sary.

INSTALLATION

Install lens by setting lens into position and apply-

ing pressure until it is locked into position.

MIRROR SWITCH

REMOVAL

(1) Remove door trim panel, refer to Group 23

Front Door Trim.

(2) Remove switch mounting screws from back side

of trim panel and remove switch.

(3) Disconnect wire connector.

INSTALLATION

For installation, reverse the above procedures.

MIRROR ASSEMBLY

For door trim panel and mirror removal and instal-

lation, refer to Group 23 Body. Test operation of mir-

ror before installing door trim panel.

Fig. 3 Mirror Test

Fig. 4 Mirror/Reading Lamps

8T - 2 POWER MIRRORSPL

DIAGNOSIS AND TESTING (Continued)