check engine DODGE NEON 1999 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 206 of 1200

ENGINE THERMOSTAT TESTING

The thermostat is operated by a wax filled con-

tainer (pellet) which is sealed. When heated coolant

reaches a predetermined temperature the wax pellet

expands enough to overcome the closing spring and

water pump pressure, which forces the valve to open.

Coolant leakage into the pellet will cause a thermo-

stat to fail open. Do not attempt to free up a thermo-

stat with a screwdriver.The thermostat that opens too soon type failure

mode is included in the on-board diagnosis. The

check engine light will not be lit by an open too soon

condition. If it has failed open, a diagnostic trouble

code (DTC) will be set. Do not change a thermostat

for lack of heater performance or temperature gauge

position, unless a DTC is present. See Diagnosis for

other probable causes. Thermostat failing shut is the

normal long term mode of failure, and normally, only

on high mileage vehicles. The temperature gauge will

indicate this. Refer to Diagnosis in this section.

ACCESSORY DRIVE BELT DIAGNOSIS

CONDITION POSSIBLE CAUSE CORRECTION

INSUFFICIENT ACCESSORY

OUTPUT DUE TO BELT SLIPPAGE1. Belt too loose. 1. Adjust belt tension.

2. Belt excessively glazed or worn. 2. Replace and tighten as specified.

BELT SQUEAL WHEN

ACCELERATING ENGINE1. Belts too loose. 1. Adjust belt tension.

2. Belts glazed. 2. Replace belts.

BELT CHIRP AT IDLE 1. Belts too loose. 1. Adjust belt tension.

2. Foreign material imbedded in

belt.2. Replace belt.

3. Non-uniform belt. 3. Replace belt.

4. Misaligned pulley(s). 4. Align accessories.

5. Non-uniform groove or eccentric

pulley.5. Replace pulley(s).

BELT ROLLED OVER IN GROOVE

OR BELT JUMPS OFF1. Broken cord in belt. 1. Replace belt.

2. Belt too loose, or too tight. 2. Adjust belt tension.

3. Misaligned pulleys. 3. Align accessories.

4. Non-uniform grooves or eccentric

pulley.4. Replace pulley(s).

PLCOOLING 7 - 13

DIAGNOSIS AND TESTING (Continued)

Page 207 of 1200

WATER PUMP DIAGNOSIS

A quick flow test to tell whether or not the pump is

working is to see if the heater warms properly. A

defective pump will not be able to circulate heated

coolant through the long heater hose.

Another flow test to help determine pump opera-

tion.

WARNING: DO NOT remove radiator cap if the cool-

ing system is hot or under pressure.

(1) Remove radiator cap.

(2) Remove a small amount of coolant from the

system, start the engine and warm up until thermo-

stat opens. With the thermostat open and coolant

level low you will see if the water pump is pumping

coolant through the system.

COOLING SYSTEM FLOW CHECK

To determine whether coolant is flowing through

the cooling system, use the following procedures:

(1) If engine is cold, idle engine until normal oper-

ating temperature is reached. Then feel the upper

radiator hose. If it is hot, coolant is circulating.

WARNING: DO NOT REMOVE THE COOLING SYS-

TEM PRESSURE CAP WITH THE SYSTEM HOT AND

UNDER PRESSURE BECAUSE SERIOUS BURNS

FROM COOLANT CAN OCCUR.

(2) Remove pressure cap when engine is cold,

remove small amount of coolant Idle engine until

thermostat opens, you should observe coolant flow

while looking down the filler neck. Once flow is

detected install the pressure cap.

RADIATOR FAN CONTROL

Fan control is accomplished two ways. The fan

always runs when the air conditioning compressor

clutch is engaged. In addition to this control, the fan

is turned on by the temperature of the coolant which

is sensed by the coolant temperature sensor which

sends the message to the Powertrain Control Module

(PCM). The (PCM) turns on the fan through the

Solid State Fan Relay. The Solid State Fan Relay is

located on the left front inner frame just behind the

radiator. See Wiring Diagrams Manual for circuity

and diagnostics provided.

Switching through the (PCM) provides fan control

for the following conditions.

²The fan will not run during cranking until the

engine starts no matter what the coolant tempera-

ture is.

²Fan will run when the air conditioning clutch is

engaged and low pressure cutout switch is closed.

²Fan will run at vehicle speeds above about 40

mph only if coolant temperature reaches 110ÉC(230ÉF). It will turn off when the temperature drops

to 104ÉC (220ÉF). At speeds below 40 mph the fan

switches on at 102ÉC (215ÉF) and off at 93ÉC (200ÉF).

Refer to Radiator Fan Control Module Group 14,

Fuel Injection for more information.

ELECTRIC FAN MOTOR TEST

Refer to Powertrain Diagnostic Manual for procedure.

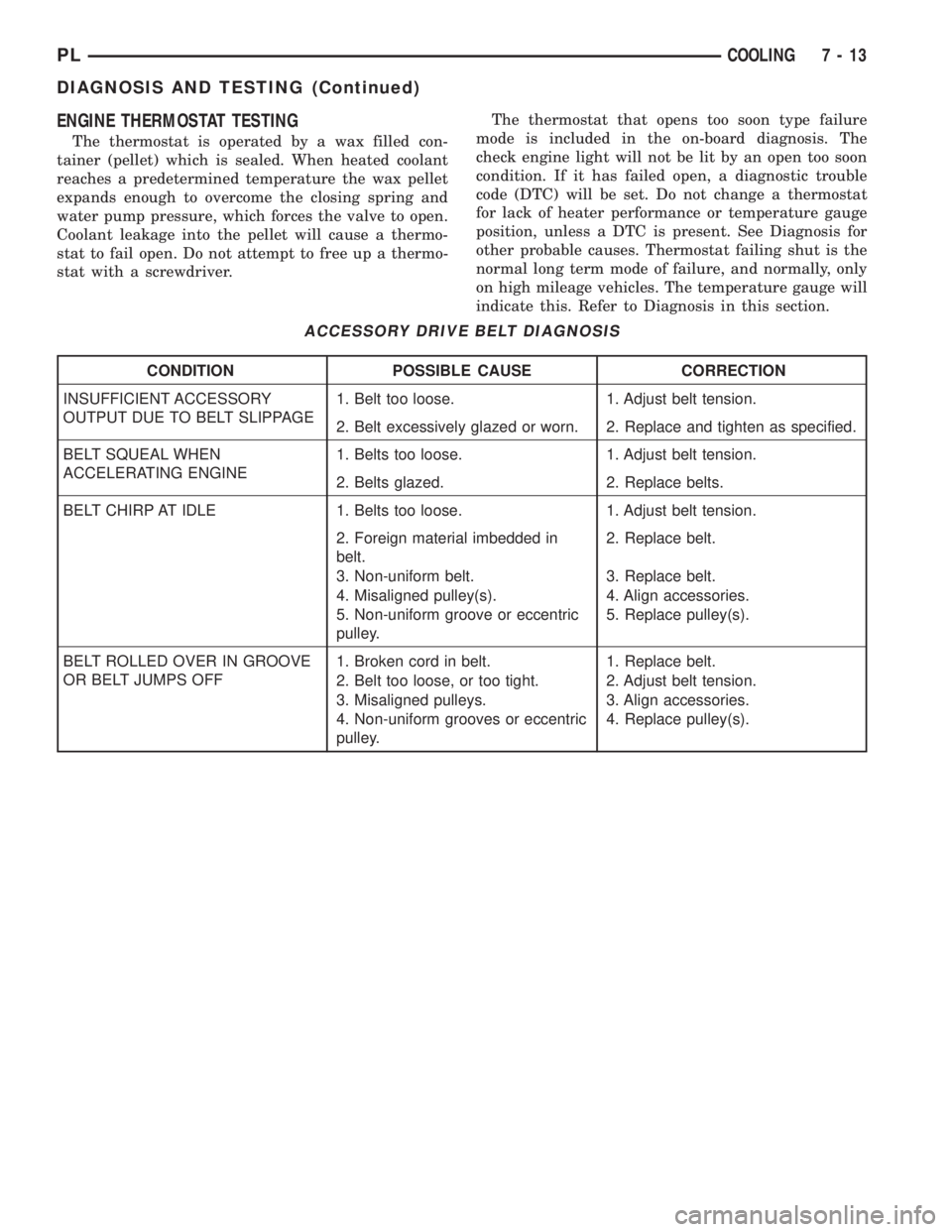

TESTING COOLING SYSTEM FOR LEAKS

The system should be full. With the engine not

running, wipe the filler neck sealing seat clean.

Attach a radiator pressure tester to the filler neck,

as shown in (Fig. 9) and apply 104 kPa (15 psi) pres-

sure. If the pressure drops more than 2 psi in 2 min-

utes, inspect the system for external leaks.

Move all hoses at the radiator and heater while

system is pressurize at 15 psi, since some leaks occur

due to engine rock while driving.

If there are no external leaks after the gauge dial

shows a drop in pressure, detach the tester. Start the

engine, and run the engine to normal operating tem-

perature in order to open the thermostat and allow

the coolant to expand. Reattach the tester. If the nee-

dle on the dial fluctuates it indicates a combustion

leak, usually a head gasket leak.

WARNING: WITH THE PRESSURE TESTER IN

PLACE PRESSURE BUILDS UP QUICKLY. ANY

EXCESSIVE PRESSURE BUILD-UP DUE TO CON-

TINUOUS ENGINE OPERATION MUST BE

RELEASED TO A SAFE PRESSURE POINT. NEVER

PERMIT PRESSURE TO EXCEED 138 kPa (20 psi).

If the needle on the dial does not fluctuate, race

the engine a few times. If an abnormal amount of

coolant or steam is emitted from the tail pipe, it may

indicate a faulty head gasket, cracked engine block,

or cracked cylinder head.

Fig. 9 Pressure Testing Cooling SystemÐTypical

7 - 14 COOLINGPL

DIAGNOSIS AND TESTING (Continued)

Page 208 of 1200

There may be internal leaks, which can be deter-

mined by removing the oil dipstick. If water globules

appear intermixed with the oil, it indicates an inter-

nal leak in the engine. If there is an internal leak,

the engine must be disassembled for repair.

PRESSURE CAP TO FILLER NECK SEAL

PRESSURE RELIEF CHECK

The pressure cap upper gasket (seal) pressure

relief can be checked by removing the overflow hose

at the radiator filler neck nipple (Fig. 10). Attach the

radiator pressure tester to thefiller neck nipple,

and pump air into the system. The pressure cap

upper gasket should relieve pressure at 69-124 kPa

(10-18 psi), and hold pressure at 55 kPa (8 psi) min-

imum.

WARNING: THE WARNING WORDS DO NOT OPEN

HOT ON THE PRESSURE CAP IS A SAFETY PRE-

CAUTION. WHEN HOT, THE COOLING SYSTEM

BUILDS UP PRESSURE. TO PREVENT SCALDING

OR OTHER INJURY, THE PRESSURE CAP SHOULD

NOT BE REMOVED WHILE THE SYSTEM IS HOT

AND/OR UNDER PRESSURE.

There is no need to remove the pressure cap at any

timeexceptfor the following purposes:

²Check and adjust coolant freeze point²Refill system with new coolant

²Conducting service procedures

²Checking for leaks

WARNING: IF VEHICLE HAS BEEN RUN

RECENTLY, WAIT 15 MINUTES BEFORE REMOVING

CAP. PLACE A SHOP TOWEL OVER THE CAP, AND

WITHOUT PUSHING DOWN, ROTATE IT COUNTER-

CLOCKWISE TO THE FIRST STOP. ALLOW FLUIDS

TO ESCAPE THROUGH THE OVERFLOW TUBE.

WHEN THE SYSTEM STOPS PUSHING COOLANT

AND STEAM INTO THE CRS TANK AND PRESSURE

DROPS, PUSH DOWN ON THE CAP AND REMOVE

IT COMPLETELY. SQUEEZING THE RADIATOR

INLET HOSE WITH A SHOP TOWEL (TO CHECK

PRESSURE) BEFORE AND AFTER TURNING TO

THE FIRST STOP IS RECOMMENDED.

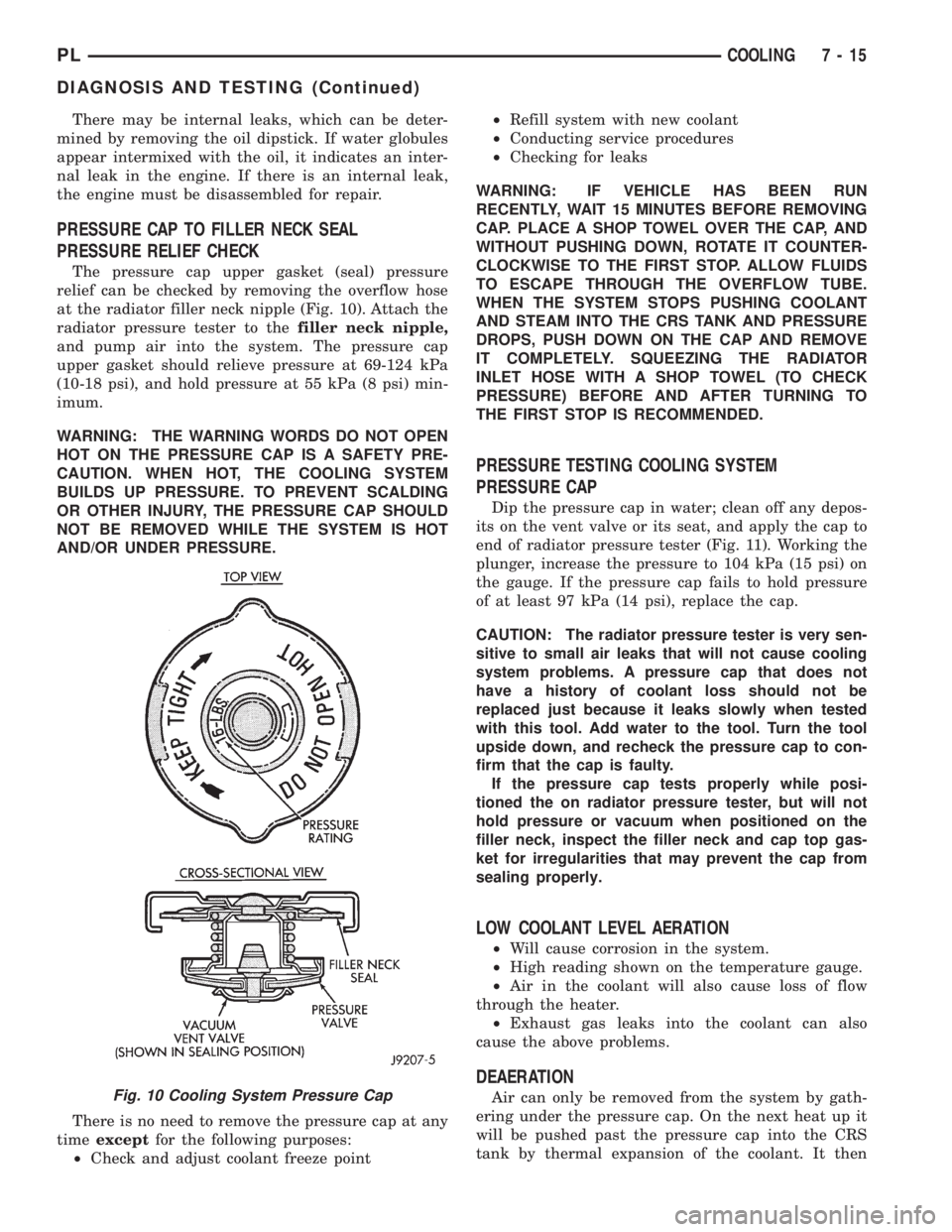

PRESSURE TESTING COOLING SYSTEM

PRESSURE CAP

Dip the pressure cap in water; clean off any depos-

its on the vent valve or its seat, and apply the cap to

end of radiator pressure tester (Fig. 11). Working the

plunger, increase the pressure to 104 kPa (15 psi) on

the gauge. If the pressure cap fails to hold pressure

of at least 97 kPa (14 psi), replace the cap.

CAUTION: The radiator pressure tester is very sen-

sitive to small air leaks that will not cause cooling

system problems. A pressure cap that does not

have a history of coolant loss should not be

replaced just because it leaks slowly when tested

with this tool. Add water to the tool. Turn the tool

upside down, and recheck the pressure cap to con-

firm that the cap is faulty.

If the pressure cap tests properly while posi-

tioned the on radiator pressure tester, but will not

hold pressure or vacuum when positioned on the

filler neck, inspect the filler neck and cap top gas-

ket for irregularities that may prevent the cap from

sealing properly.

LOW COOLANT LEVEL AERATION

²Will cause corrosion in the system.

²High reading shown on the temperature gauge.

²Air in the coolant will also cause loss of flow

through the heater.

²Exhaust gas leaks into the coolant can also

cause the above problems.

DEAERATION

Air can only be removed from the system by gath-

ering under the pressure cap. On the next heat up it

will be pushed past the pressure cap into the CRS

tank by thermal expansion of the coolant. It thenFig. 10 Cooling System Pressure Cap

PLCOOLING 7 - 15

DIAGNOSIS AND TESTING (Continued)

Page 209 of 1200

escapes to the atmosphere in the CRS tank and is

replaced with solid coolant on cool down.

TEMPERATURE GAUGE INDICATION

At idle the temperature gauge could rise slowly to

about 1/2 gauge travel. The fan will come on and the

gauge could drop to about 1/3 gauge travel, this is

normal.

SERVICE PROCEDURES

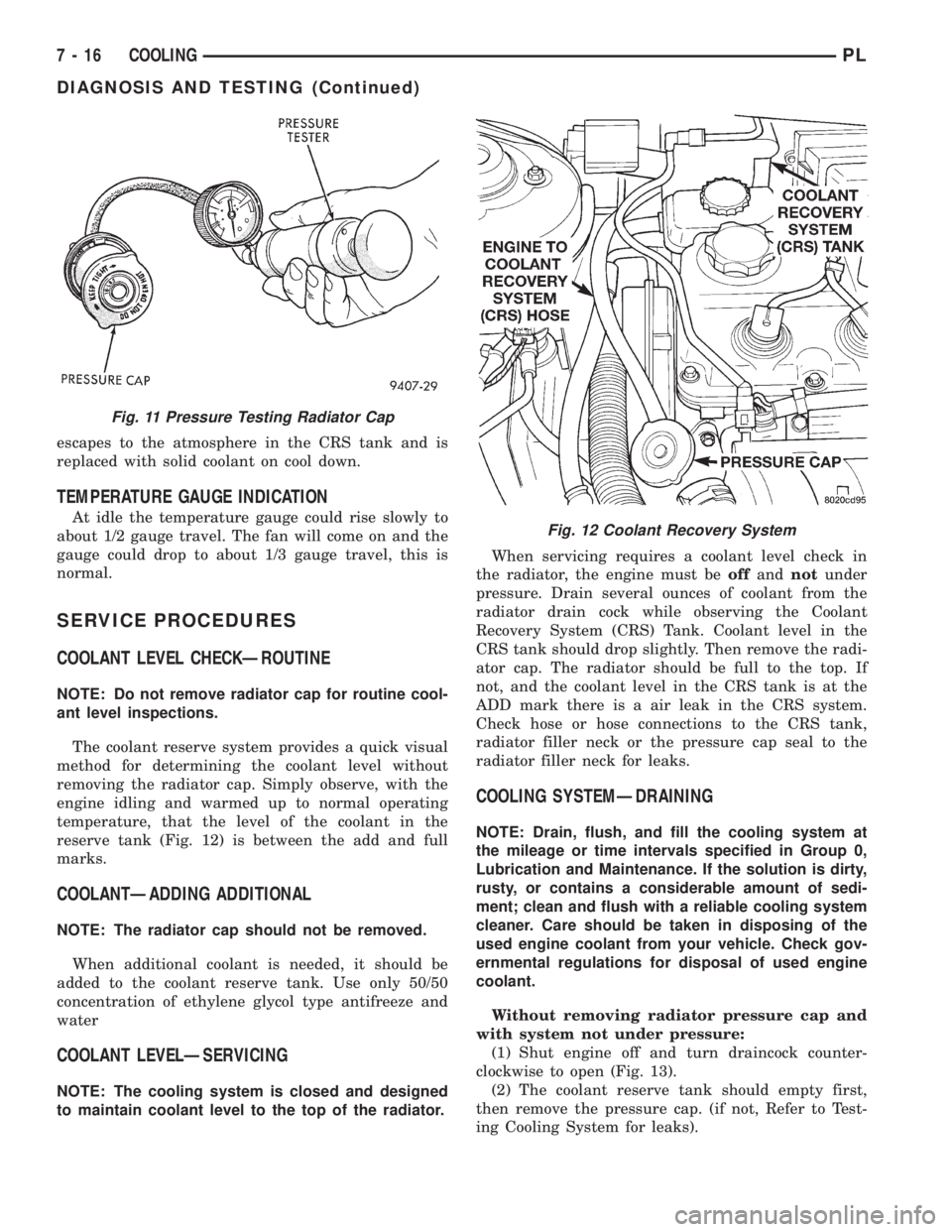

COOLANT LEVEL CHECKÐROUTINE

NOTE: Do not remove radiator cap for routine cool-

ant level inspections.

The coolant reserve system provides a quick visual

method for determining the coolant level without

removing the radiator cap. Simply observe, with the

engine idling and warmed up to normal operating

temperature, that the level of the coolant in the

reserve tank (Fig. 12) is between the add and full

marks.

COOLANTÐADDING ADDITIONAL

NOTE: The radiator cap should not be removed.

When additional coolant is needed, it should be

added to the coolant reserve tank. Use only 50/50

concentration of ethylene glycol type antifreeze and

water

COOLANT LEVELÐSERVICING

NOTE: The cooling system is closed and designed

to maintain coolant level to the top of the radiator.When servicing requires a coolant level check in

the radiator, the engine must beoffandnotunder

pressure. Drain several ounces of coolant from the

radiator drain cock while observing the Coolant

Recovery System (CRS) Tank. Coolant level in the

CRS tank should drop slightly. Then remove the radi-

ator cap. The radiator should be full to the top. If

not, and the coolant level in the CRS tank is at the

ADD mark there is a air leak in the CRS system.

Check hose or hose connections to the CRS tank,

radiator filler neck or the pressure cap seal to the

radiator filler neck for leaks.

COOLING SYSTEMÐDRAINING

NOTE: Drain, flush, and fill the cooling system at

the mileage or time intervals specified in Group 0,

Lubrication and Maintenance. If the solution is dirty,

rusty, or contains a considerable amount of sedi-

ment; clean and flush with a reliable cooling system

cleaner. Care should be taken in disposing of the

used engine coolant from your vehicle. Check gov-

ernmental regulations for disposal of used engine

coolant.

Without removing radiator pressure cap and

with system not under pressure:

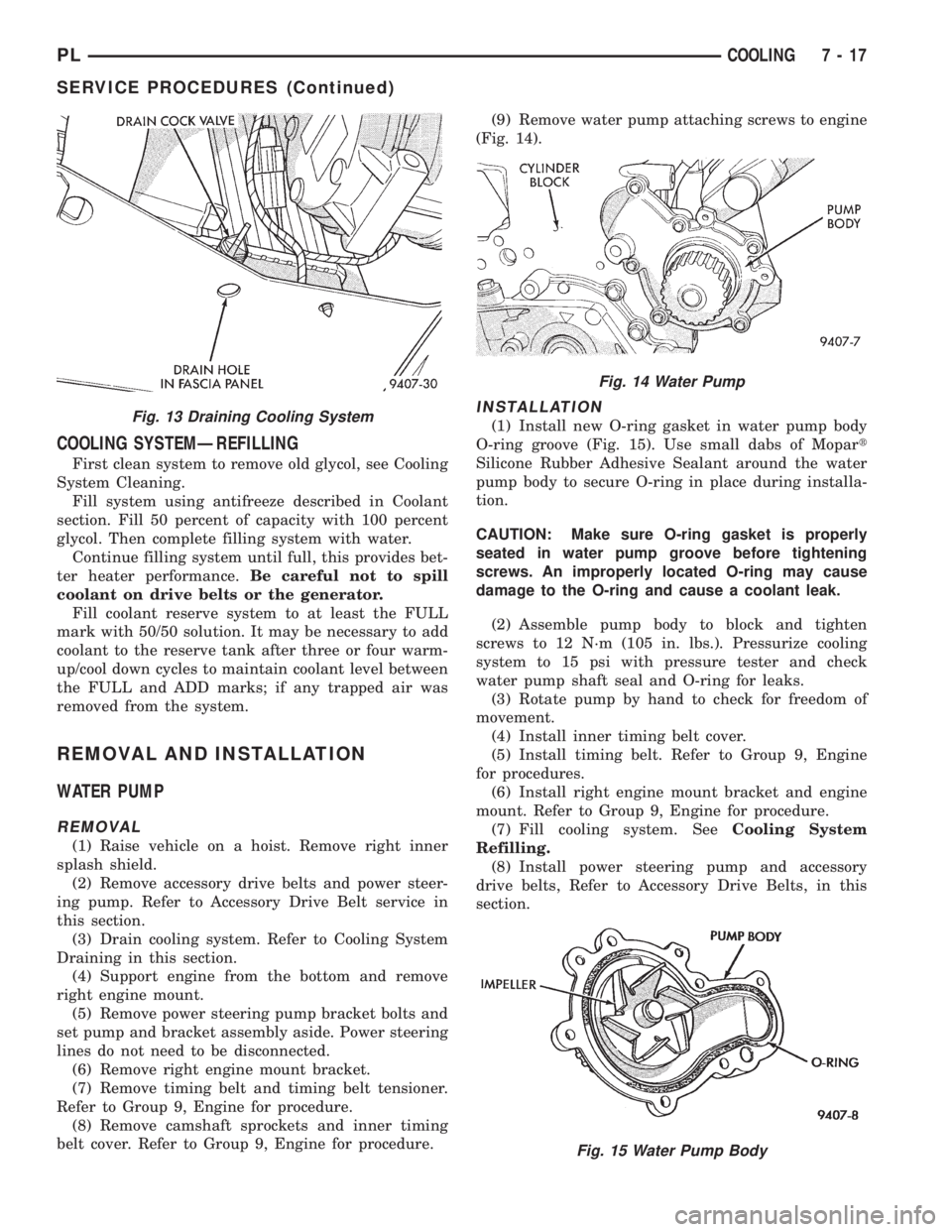

(1) Shut engine off and turn draincock counter-

clockwise to open (Fig. 13).

(2) The coolant reserve tank should empty first,

then remove the pressure cap. (if not, Refer to Test-

ing Cooling System for leaks).

Fig. 11 Pressure Testing Radiator Cap

Fig. 12 Coolant Recovery System

7 - 16 COOLINGPL

DIAGNOSIS AND TESTING (Continued)

Page 210 of 1200

COOLING SYSTEMÐREFILLING

First clean system to remove old glycol, see Cooling

System Cleaning.

Fill system using antifreeze described in Coolant

section. Fill 50 percent of capacity with 100 percent

glycol. Then complete filling system with water.

Continue filling system until full, this provides bet-

ter heater performance.Be careful not to spill

coolant on drive belts or the generator.

Fill coolant reserve system to at least the FULL

mark with 50/50 solution. It may be necessary to add

coolant to the reserve tank after three or four warm-

up/cool down cycles to maintain coolant level between

the FULL and ADD marks; if any trapped air was

removed from the system.

REMOVAL AND INSTALLATION

WATER PUMP

REMOVAL

(1) Raise vehicle on a hoist. Remove right inner

splash shield.

(2) Remove accessory drive belts and power steer-

ing pump. Refer to Accessory Drive Belt service in

this section.

(3) Drain cooling system. Refer to Cooling System

Draining in this section.

(4) Support engine from the bottom and remove

right engine mount.

(5) Remove power steering pump bracket bolts and

set pump and bracket assembly aside. Power steering

lines do not need to be disconnected.

(6) Remove right engine mount bracket.

(7) Remove timing belt and timing belt tensioner.

Refer to Group 9, Engine for procedure.

(8) Remove camshaft sprockets and inner timing

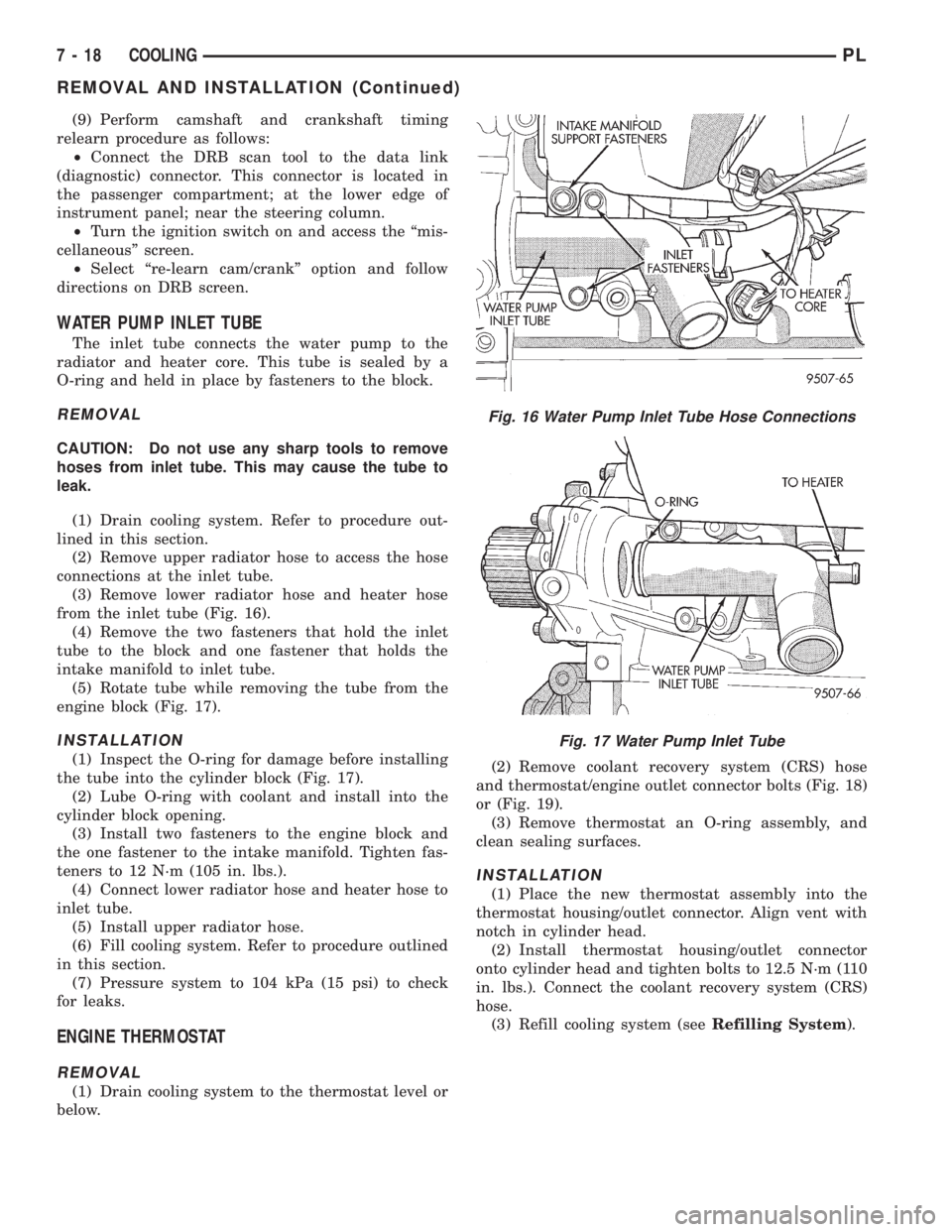

belt cover. Refer to Group 9, Engine for procedure.(9) Remove water pump attaching screws to engine

(Fig. 14).

INSTALLATION

(1) Install new O-ring gasket in water pump body

O-ring groove (Fig. 15). Use small dabs of Mopart

Silicone Rubber Adhesive Sealant around the water

pump body to secure O-ring in place during installa-

tion.

CAUTION: Make sure O-ring gasket is properly

seated in water pump groove before tightening

screws. An improperly located O-ring may cause

damage to the O-ring and cause a coolant leak.

(2) Assemble pump body to block and tighten

screws to 12 N´m (105 in. lbs.). Pressurize cooling

system to 15 psi with pressure tester and check

water pump shaft seal and O-ring for leaks.

(3) Rotate pump by hand to check for freedom of

movement.

(4) Install inner timing belt cover.

(5) Install timing belt. Refer to Group 9, Engine

for procedures.

(6) Install right engine mount bracket and engine

mount. Refer to Group 9, Engine for procedure.

(7) Fill cooling system. SeeCooling System

Refilling.

(8) Install power steering pump and accessory

drive belts, Refer to Accessory Drive Belts, in this

section.Fig. 13 Draining Cooling System

Fig. 14 Water Pump

Fig. 15 Water Pump Body

PLCOOLING 7 - 17

SERVICE PROCEDURES (Continued)

Page 211 of 1200

(9) Perform camshaft and crankshaft timing

relearn procedure as follows:

²Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

WATER PUMP INLET TUBE

The inlet tube connects the water pump to the

radiator and heater core. This tube is sealed by a

O-ring and held in place by fasteners to the block.

REMOVAL

CAUTION: Do not use any sharp tools to remove

hoses from inlet tube. This may cause the tube to

leak.

(1) Drain cooling system. Refer to procedure out-

lined in this section.

(2) Remove upper radiator hose to access the hose

connections at the inlet tube.

(3) Remove lower radiator hose and heater hose

from the inlet tube (Fig. 16).

(4) Remove the two fasteners that hold the inlet

tube to the block and one fastener that holds the

intake manifold to inlet tube.

(5) Rotate tube while removing the tube from the

engine block (Fig. 17).

INSTALLATION

(1) Inspect the O-ring for damage before installing

the tube into the cylinder block (Fig. 17).

(2) Lube O-ring with coolant and install into the

cylinder block opening.

(3) Install two fasteners to the engine block and

the one fastener to the intake manifold. Tighten fas-

teners to 12 N´m (105 in. lbs.).

(4) Connect lower radiator hose and heater hose to

inlet tube.

(5) Install upper radiator hose.

(6) Fill cooling system. Refer to procedure outlined

in this section.

(7) Pressure system to 104 kPa (15 psi) to check

for leaks.

ENGINE THERMOSTAT

REMOVAL

(1) Drain cooling system to the thermostat level or

below.(2) Remove coolant recovery system (CRS) hose

and thermostat/engine outlet connector bolts (Fig. 18)

or (Fig. 19).

(3) Remove thermostat an O-ring assembly, and

clean sealing surfaces.

INSTALLATION

(1) Place the new thermostat assembly into the

thermostat housing/outlet connector. Align vent with

notch in cylinder head.

(2) Install thermostat housing/outlet connector

onto cylinder head and tighten bolts to 12.5 N´m (110

in. lbs.). Connect the coolant recovery system (CRS)

hose.

(3) Refill cooling system (seeRefilling System).

Fig. 16 Water Pump Inlet Tube Hose Connections

Fig. 17 Water Pump Inlet Tube

7 - 18 COOLINGPL

REMOVAL AND INSTALLATION (Continued)

Page 213 of 1200

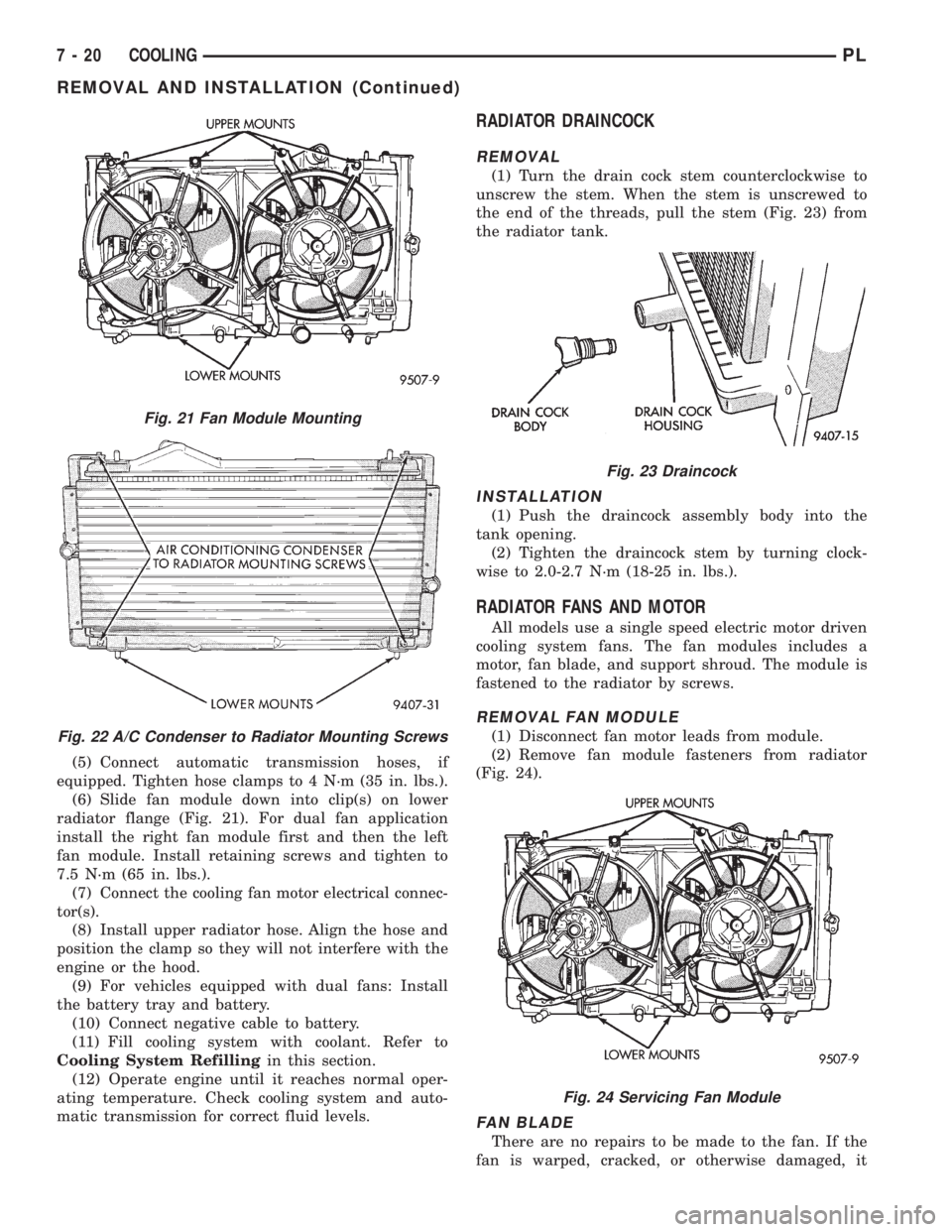

(5) Connect automatic transmission hoses, if

equipped. Tighten hose clamps to 4 N´m (35 in. lbs.).

(6) Slide fan module down into clip(s) on lower

radiator flange (Fig. 21). For dual fan application

install the right fan module first and then the left

fan module. Install retaining screws and tighten to

7.5 N´m (65 in. lbs.).

(7) Connect the cooling fan motor electrical connec-

tor(s).

(8) Install upper radiator hose. Align the hose and

position the clamp so they will not interfere with the

engine or the hood.

(9) For vehicles equipped with dual fans: Install

the battery tray and battery.

(10) Connect negative cable to battery.

(11) Fill cooling system with coolant. Refer to

Cooling System Refillingin this section.

(12) Operate engine until it reaches normal oper-

ating temperature. Check cooling system and auto-

matic transmission for correct fluid levels.

RADIATOR DRAINCOCK

REMOVAL

(1) Turn the drain cock stem counterclockwise to

unscrew the stem. When the stem is unscrewed to

the end of the threads, pull the stem (Fig. 23) from

the radiator tank.

INSTALLATION

(1) Push the draincock assembly body into the

tank opening.

(2) Tighten the draincock stem by turning clock-

wise to 2.0-2.7 N´m (18-25 in. lbs.).

RADIATOR FANS AND MOTOR

All models use a single speed electric motor driven

cooling system fans. The fan modules includes a

motor, fan blade, and support shroud. The module is

fastened to the radiator by screws.

REMOVAL FAN MODULE

(1) Disconnect fan motor leads from module.

(2) Remove fan module fasteners from radiator

(Fig. 24).

FAN BLADE

There are no repairs to be made to the fan. If the

fan is warped, cracked, or otherwise damaged, it

Fig. 21 Fan Module Mounting

Fig. 22 A/C Condenser to Radiator Mounting Screws

Fig. 23 Draincock

Fig. 24 Servicing Fan Module

7 - 20 COOLINGPL

REMOVAL AND INSTALLATION (Continued)

Page 220 of 1200

NOTE: BLACK OR DARK=0to75%state-of-charge

The battery is INADEQUATELY charged and must

be charged until green dot is visible, (12.4 volts or

greater) before the battery is tested or returned to

use. Refer to Causes of Battery Discharging in this

Group for more information.

NOTE: CLEAR COLOR = Replace Battery

WARNING: DO NOT CHARGE, ASSIST BOOST,

LOAD TEST, OR ADD WATER TO THE BATTERY

WHEN CLEAR COLOR DOT IS VISIBLE. PERSONAL

INJURY MAY OCCUR.

A clear color dot shows electrolyte level in battery

is below the test indicator (Fig. 1). Water cannot be

added to a maintenance free battery. The battery

must be replaced. A low electrolyte level may be

caused by an over charging condition. Refer to Gen-

erator Test Procedures on Vehicle.

CAUSES OF BATTERY DISCHARGING

It is normal to have a small 5 to 25 milliamperes

continuous electrical draw from the battery. This

draw will take place with the ignition in the OFF

position, and the courtesy, dome, storage compart-

ments, and engine compartment lights OFF. The con-

tinuous draw is due to various electronic features or

accessories that require electrical current with the

ignition OFF to function properly. When a vehicle is

not used over an extended period of approximately 20

days the IOD fuse should be pulled. The fuse is

located in the power distribution center. removal of

this fuse will reduce the level of battery discharge.

Refer to the Battery Diagnosis and Testing Table for

proper diagnosis.

ABNORMAL BATTERY DISCHARGING

²Corroded battery posts, cables or terminals.

²Loose or worn generator drive belt.

²Electrical loads that exceed the output of the

charging system due to equipment or accessories

installed after delivery.

²Slow driving speeds in heavy traffic conditions

or prolonged idling with high-amperage electrical

systems in use.

²Defective electrical circuit or component causing

excess Ignition Off Draw (IOD). Refer to Battery

Ignition Off Draw (IOD).

²Defective charging system.

²Defective battery.

BATTERY IGNITION OFF DRAW (IOD)

High current draw on the battery with the ignition

OFF will discharge a battery. After a dead battery is

recharged, the vehicle ignition off draw (IOD) shouldbe checked. To determine if a high current draw con-

dition exists first check the vehicle with a test lamp.

(1) Verify that all electrical accessories are OFF.

²Remove key from ignition switch

²Turn off all lights

²Trunk lid is closed

²Engine compartment hood lamp is disconnected

or lamp removed

²Glove box door is closed

²Sun visor vanity lights are OFF

²All doors are closed

²Allow the ignition key lamp system to time out

in approximately 30 seconds, if equipped.

(2) Disconnect battery negative cable (Fig. 4).

(3) Connect a 12 Volt test lamp, with a cold resis-

tance of 5-7 ohms, between the battery negative cable

clamp and the negative post (Fig. 5). If test lamp

goes out system is OK. If test lamp lights and stays

ON, go to Test Lamp Stays ON procedure.

TEST LAMP STAYS ON

There is either a short circuit or a fault in an elec-

tronic module. Two fuses in the Power Distribution

Center (PDC) feed the modules with ignition off

draw.

²Interior lamps fuse (10 Amp) (IOD) PDC.

²Fuel pump fuse (20 Amp) in PDC

(1) Remove interior lamp and fuel pump fuses. By

removing these fuses all ignition off draw from the

vehicle electronics will be disconnected. The test

lamp should go out. If test lamp goes out go to Step

2. If test lamp does not go out there is a current

draw or short circuit. Refer to Group 8W, Wiring Dia-

grams.

(2) Install the fuel pump fuse. If test lamp lights,

there is a current draw or short circuit in the A14

wiring circuit feed.

(a) Disconnect Powertrain Control Module.

(b) If test lamp goes out, replace Powertrain

Control Module.

(c) If test lamp does not go out, there is a cur-

rent draw or short circuit in the A14 circuit feed.

Refer to Group 8W, Wiring Diagrams.

(3) Install the interior lamp fuse. If test lamp

lights, there is a current draw or short circuit in the

M01 circuit. Refer to Group 8W, Wiring Diagrams. If

test lamp stays out, go to Step 4

(4) Use a multi-meter that has at least a range of

200 milliamperes. Install meter between the battery

negative cable and battery negative post (Fig. 6).

Carefully remove the test lamp without disconnecting

the meter. After all modules time-out the total vehi-

cle IOD should be less than 10 milliamperes. If igni-

tion off draw is more than 10 milliamperes go to Step

5.

(5) Remove both fuses from the Power Distribution

Center:

PLBATTERY 8A - 3

DIAGNOSIS AND TESTING (Continued)

Page 230 of 1200

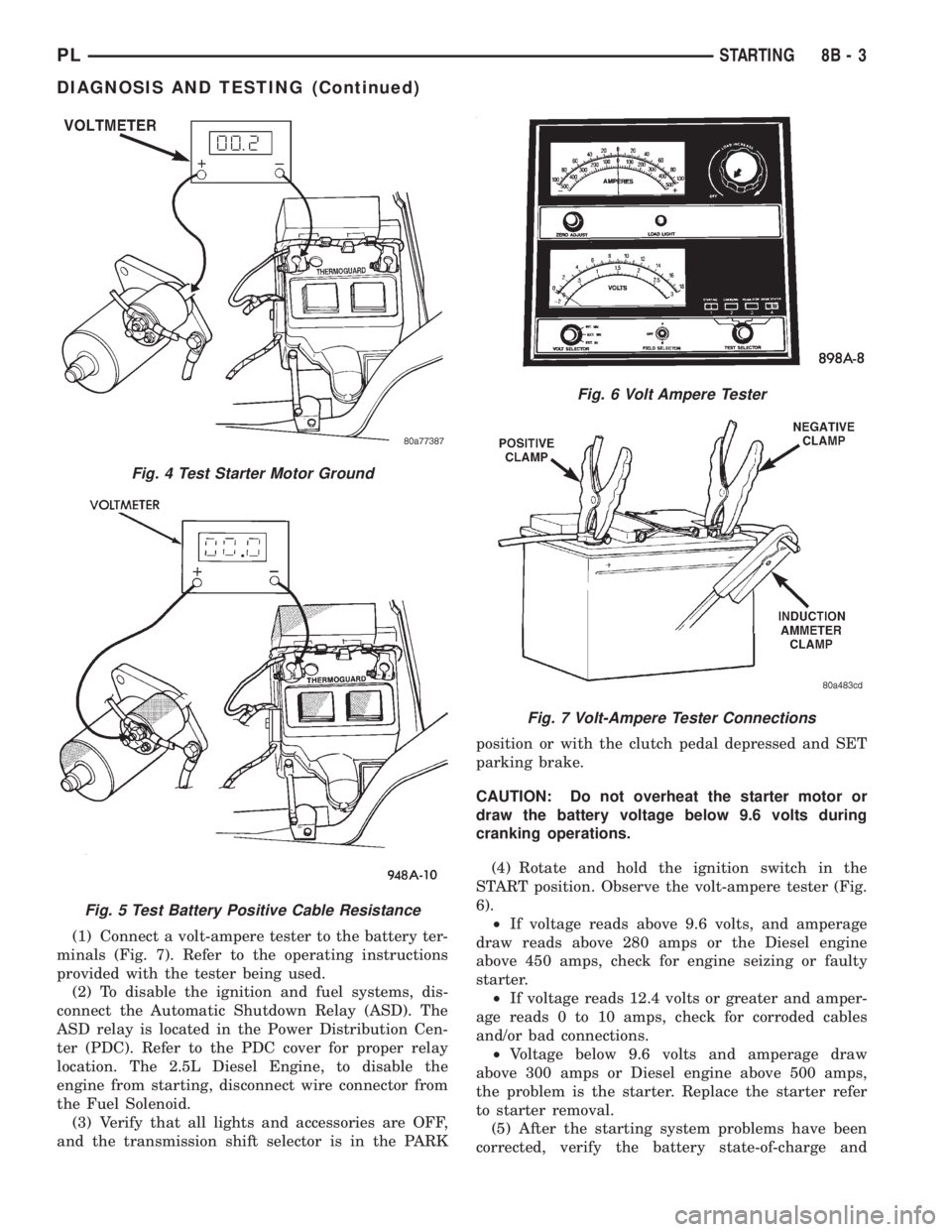

(1) Connect a volt-ampere tester to the battery ter-

minals (Fig. 7). Refer to the operating instructions

provided with the tester being used.

(2) To disable the ignition and fuel systems, dis-

connect the Automatic Shutdown Relay (ASD). The

ASD relay is located in the Power Distribution Cen-

ter (PDC). Refer to the PDC cover for proper relay

location. The 2.5L Diesel Engine, to disable the

engine from starting, disconnect wire connector from

the Fuel Solenoid.

(3) Verify that all lights and accessories are OFF,

and the transmission shift selector is in the PARKposition or with the clutch pedal depressed and SET

parking brake.

CAUTION: Do not overheat the starter motor or

draw the battery voltage below 9.6 volts during

cranking operations.

(4) Rotate and hold the ignition switch in the

START position. Observe the volt-ampere tester (Fig.

6).

²If voltage reads above 9.6 volts, and amperage

draw reads above 280 amps or the Diesel engine

above 450 amps, check for engine seizing or faulty

starter.

²If voltage reads 12.4 volts or greater and amper-

age reads 0 to 10 amps, check for corroded cables

and/or bad connections.

²Voltage below 9.6 volts and amperage draw

above 300 amps or Diesel engine above 500 amps,

the problem is the starter. Replace the starter refer

to starter removal.

(5) After the starting system problems have been

corrected, verify the battery state-of-charge and

Fig. 6 Volt Ampere Tester

Fig. 7 Volt-Ampere Tester Connections

Fig. 4 Test Starter Motor Ground

Fig. 5 Test Battery Positive Cable Resistance

PLSTARTING 8B - 3

DIAGNOSIS AND TESTING (Continued)

Page 232 of 1200

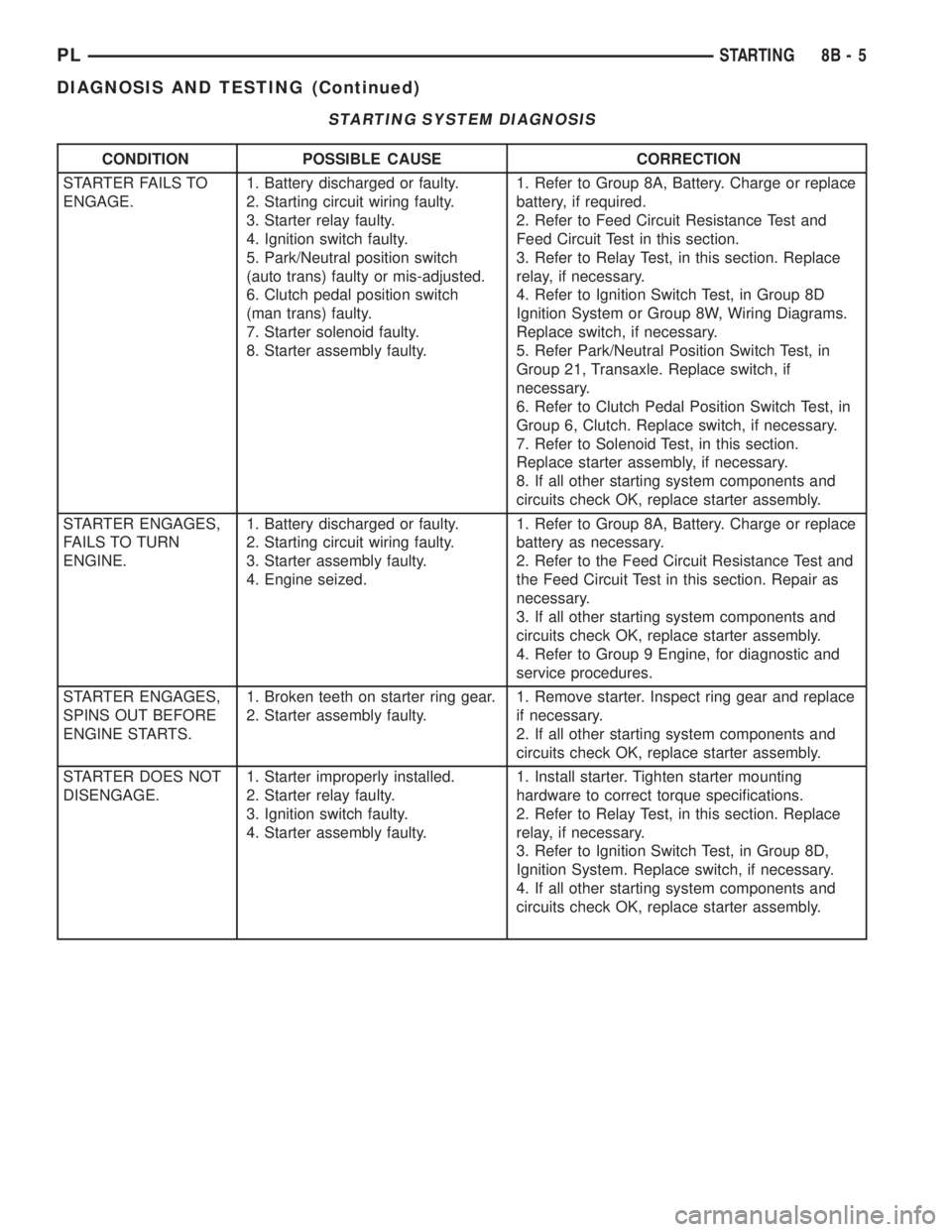

STARTING SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSE CORRECTION

STARTER FAILS TO

ENGAGE.1. Battery discharged or faulty.

2. Starting circuit wiring faulty.

3. Starter relay faulty.

4. Ignition switch faulty.

5. Park/Neutral position switch

(auto trans) faulty or mis-adjusted.

6. Clutch pedal position switch

(man trans) faulty.

7. Starter solenoid faulty.

8. Starter assembly faulty.1. Refer to Group 8A, Battery. Charge or replace

battery, if required.

2. Refer to Feed Circuit Resistance Test and

Feed Circuit Test in this section.

3. Refer to Relay Test, in this section. Replace

relay, if necessary.

4. Refer to Ignition Switch Test, in Group 8D

Ignition System or Group 8W, Wiring Diagrams.

Replace switch, if necessary.

5. Refer Park/Neutral Position Switch Test, in

Group 21, Transaxle. Replace switch, if

necessary.

6. Refer to Clutch Pedal Position Switch Test, in

Group 6, Clutch. Replace switch, if necessary.

7. Refer to Solenoid Test, in this section.

Replace starter assembly, if necessary.

8. If all other starting system components and

circuits check OK, replace starter assembly.

STARTER ENGAGES,

FAILS TO TURN

ENGINE.1. Battery discharged or faulty.

2. Starting circuit wiring faulty.

3. Starter assembly faulty.

4. Engine seized.1. Refer to Group 8A, Battery. Charge or replace

battery as necessary.

2. Refer to the Feed Circuit Resistance Test and

the Feed Circuit Test in this section. Repair as

necessary.

3. If all other starting system components and

circuits check OK, replace starter assembly.

4. Refer to Group 9 Engine, for diagnostic and

service procedures.

STARTER ENGAGES,

SPINS OUT BEFORE

ENGINE STARTS.1. Broken teeth on starter ring gear.

2. Starter assembly faulty.1. Remove starter. Inspect ring gear and replace

if necessary.

2. If all other starting system components and

circuits check OK, replace starter assembly.

STARTER DOES NOT

DISENGAGE.1. Starter improperly installed.

2. Starter relay faulty.

3. Ignition switch faulty.

4. Starter assembly faulty.1. Install starter. Tighten starter mounting

hardware to correct torque specifications.

2. Refer to Relay Test, in this section. Replace

relay, if necessary.

3. Refer to Ignition Switch Test, in Group 8D,

Ignition System. Replace switch, if necessary.

4. If all other starting system components and

circuits check OK, replace starter assembly.

PLSTARTING 8B - 5

DIAGNOSIS AND TESTING (Continued)