key DODGE NEON 1999 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 633 of 1200

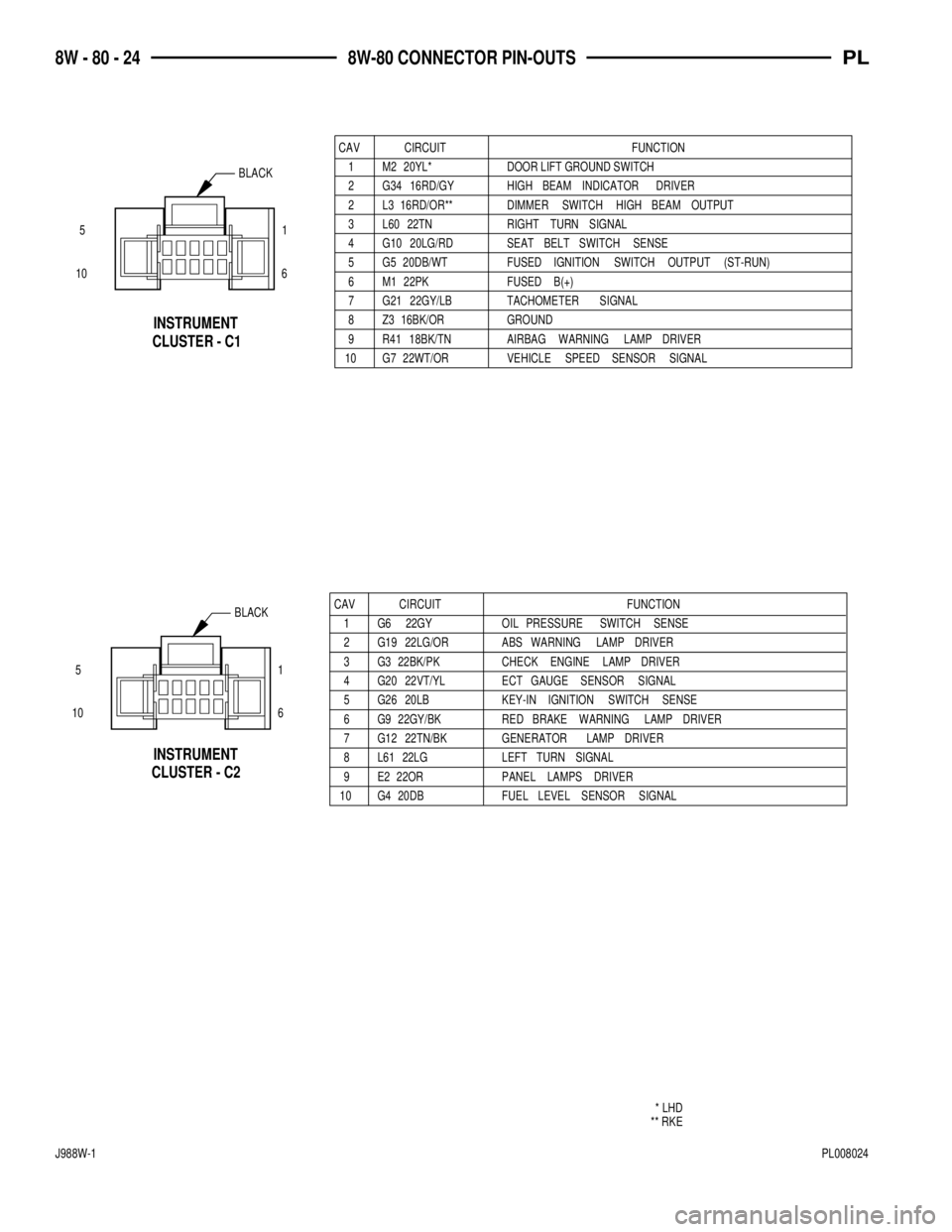

CAV CIRCUIT FUNCTION

1 M2 20YL* DOOR LIFT GROUND SWITCH

2 G34 16RD/GY HIGH BEAM INDICATOR DRIVER

2 L3 16RD/OR** DIMMER SWITCH HIGH BEAM OUTPUT

3 L60 22TN RIGHT TURN SIGNAL

4 G10 20LG/RD SEAT BELT SWITCH SENSE

5 G5 20DB/WT FUSED IGNITION SWITCH OUTPUT (ST-RUN)

6 M1 22PK FUSED B(+)

7 G21 22GY/LB TACHOMETER SIGNAL

8 Z3 16BK/OR GROUND

9 R41 18BK/TN AIRBAG WARNING LAMP DRIVER

10 G7 22WT/OR VEHICLE SPEED SENSOR SIGNAL

BLACK

51

10 6

** RKE

CAV CIRCUIT FUNCTION

1 G6 22GY OIL PRESSURE SWITCH SENSE

2 G19 22LG/OR ABS WARNING LAMP DRIVER

3 G3 22BK/PK CHECK ENGINE LAMP DRIVER

4 G20 22VT/YL ECT GAUGE SENSOR SIGNAL

5 G26 20LB KEY-IN IGNITION SWITCH SENSE

6 G9 22GY/BK RED BRAKE WARNING LAMP DRIVER

7 G12 22TN/BK GENERATOR LAMP DRIVER

8 L61 22LG LEFT TURN SIGNAL

9 E2 22OR PANEL LAMPS DRIVER

10 G4 20DB FUEL LEVEL SENSOR SIGNAL

BLACK

51

10 6

INSTRUMENT

CLUSTER - C1

CLUSTER - C2INSTRUMENT

* LHD

8W - 80 - 24 8W-80 CONNECTOR PIN-OUTSPL

J988W-1PL008024

Page 634 of 1200

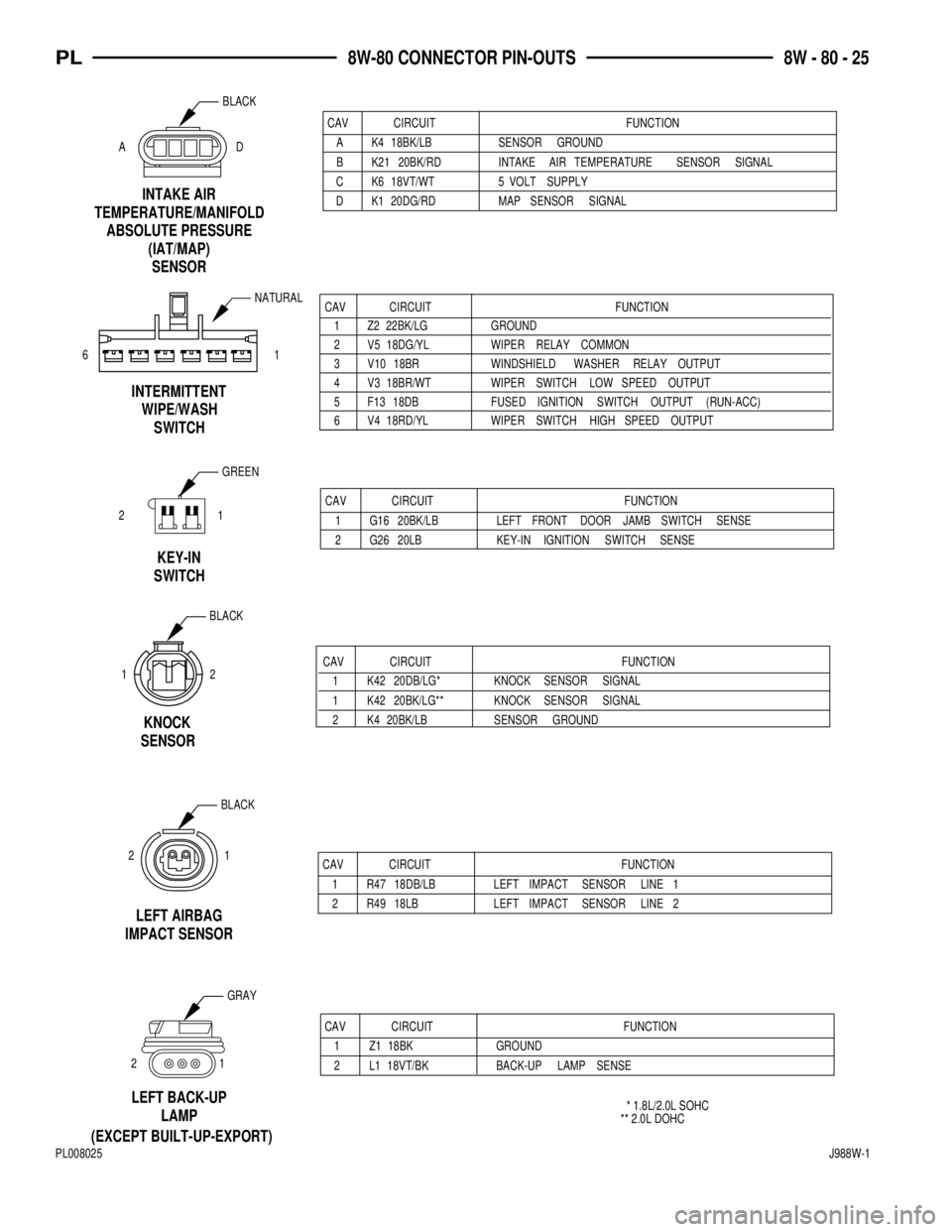

CAV CIRCUIT FUNCTION

A K4 18BK/LB SENSOR GROUND

B K21 20BK/RD INTAKE AIR TEMPERATURE SENSOR SIGNAL

C K6 18VT/WT 5 VOLT SUPPLY

D K1 20DG/RD MAP SENSOR SIGNAL BLACK

AD

CAV CIRCUIT FUNCTION

1 G16 20BK/LB LEFT FRONT DOOR JAMB SWITCH SENSE

2 G26 20LB KEY-IN IGNITION SWITCH SENSE

GREEN

21

CAV CIRCUIT FUNCTION

1 K42 20DB/LG* KNOCK SENSOR SIGNAL

1 K42 20BK/LG** KNOCK SENSOR SIGNAL

2 K4 20BK/LB SENSOR GROUND

** 2.0L DOHC* 1.8L/2.0L SOHC

CAV CIRCUIT FUNCTION

1 R47 18DB/LB LEFT IMPACT SENSOR LINE 1

2 R49 18LB LEFT IMPACT SENSOR LINE 2

BLACK

21

GRAY

21

CAV CIRCUIT FUNCTION

1 Z1 18BK GROUND

2 L1 18VT/BK BACK-UP LAMP SENSE

1

BLACK

2

CAV CIRCUIT FUNCTION

1 Z2 22BK/LG GROUND

2 V5 18DG/YL WIPER RELAY COMMON

3 V10 18BR WINDSHIELD WASHER RELAY OUTPUT

4 V3 18BR/WT WIPER SWITCH LOW SPEED OUTPUT

5 F13 18DB FUSED IGNITION SWITCH OUTPUT (RUN-ACC)

6 V4 18RD/YL WIPER SWITCH HIGH SPEED OUTPUT

NATURAL

61

INTAKE AIR

TEMPERATURE/MANIFOLD

ABSOLUTE PRESSURE

(IAT/MAP)

SENSOR

INTERMITTENT

WIPE/WASH

SWITCH

KEY-IN

SWITCH

KNOCK

SENSOR

LEFT AIRBAG

IMPACT SENSOR

LEFT BACK-UP

LAMP

(EXCEPT BUILT-UP-EXPORT)

PL8W-80 CONNECTOR PIN-OUTS 8W - 80 - 25

PL008025J988W-1

Page 645 of 1200

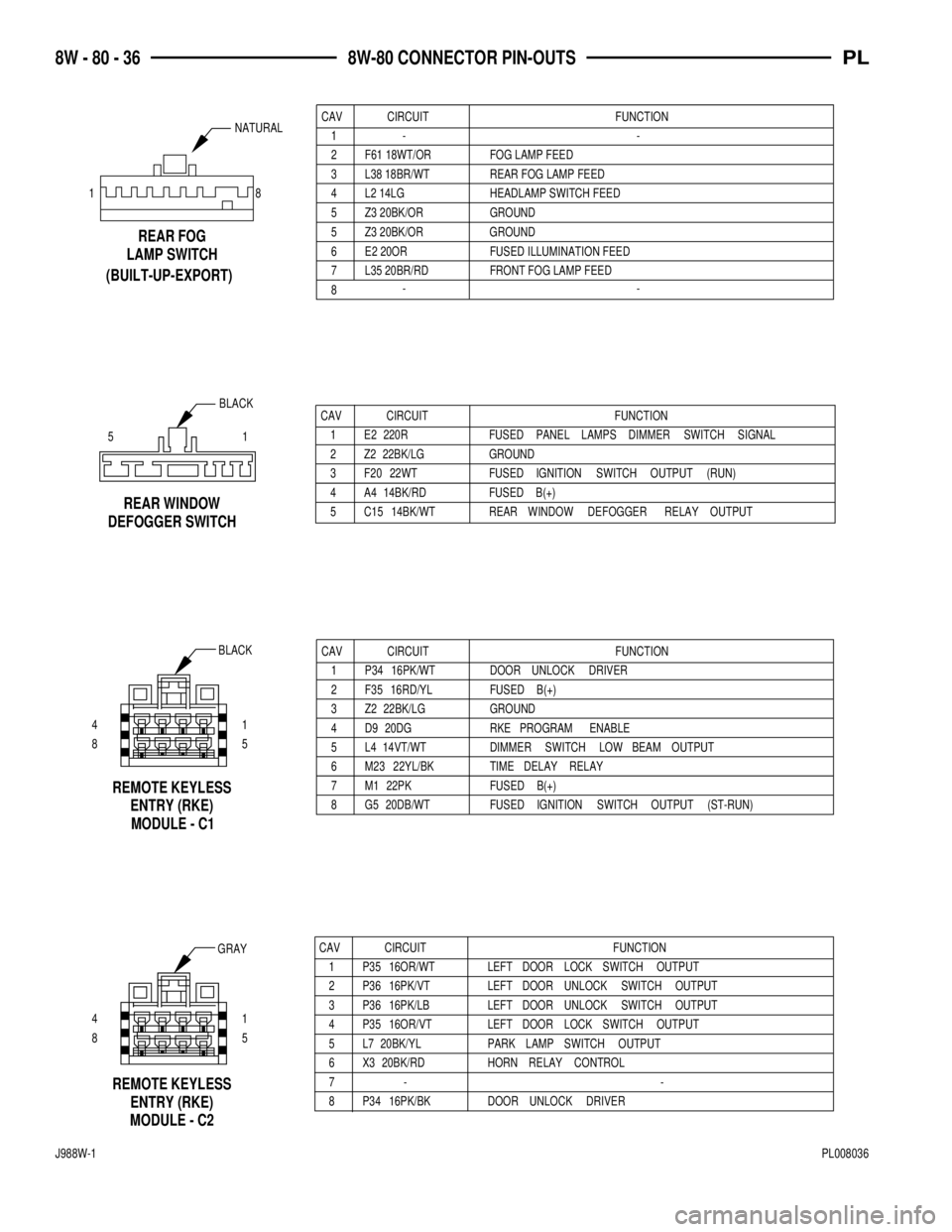

CAV CIRCUIT FUNCTION

1 E2 220R FUSED PANEL LAMPS DIMMER SWITCH SIGNAL

2 Z2 22BK/LG GROUND

3 F20 22WT FUSED IGNITION SWITCH OUTPUT (RUN)

4 A4 14BK/RD FUSED B(+)

5 C15 14BK/WT REAR WINDOW DEFOGGER RELAY OUTPUT

BLACK

51

41

85

CAV CIRCUIT FUNCTION

1 P34 16PK/WT DOOR UNLOCK DRIVER

2 F35 16RD/YL FUSED B(+)

3 Z2 22BK/LG GROUND

4 D9 20DG RKE PROGRAM ENABLE

5 L4 14VT/WT DIMMER SWITCH LOW BEAM OUTPUT

6 M23 22YL/BK TIME DELAY RELAY

7 M1 22PK FUSED B(+)

8 G5 20DB/WT FUSED IGNITION SWITCH OUTPUT (ST-RUN)

BLACK

41

85

CAV CIRCUIT FUNCTION

1 P35 16OR/WT LEFT DOOR LOCK SWITCH OUTPUT

2 P36 16PK/VT LEFT DOOR UNLOCK SWITCH OUTPUT

3 P36 16PK/LB LEFT DOOR UNLOCK SWITCH OUTPUT

4 P35 16OR/VT LEFT DOOR LOCK SWITCH OUTPUT

5 L7 20BK/YL PARK LAMP SWITCH OUTPUT

6 X3 20BK/RD HORN RELAY CONTROL

7- -

8 P34 16PK/BK DOOR UNLOCK DRIVER

GRAY

8FRONT FOG LAMP FEED L35 20BR/RD 7

FUSED ILLUMINATION FEED E2 20OR 6

GROUND Z3 20BK/OR 5

HEADLAMP SWITCH FEED L2 14LG 4

REAR FOG LAMP FEED L38 18BR/WT 3

FOG LAMP FEED F61 18WT/OR 2

- - 1

FUNCTION CIRCUIT CAV

- - Z3 20BK/OR GROUND

5

8 1

NATURAL

REAR FOG

LAMP SWITCH

REAR WINDOW

DEFOGGER SWITCH

REMOTE KEYLESS

ENTRY (RKE)

MODULE - C1

REMOTE KEYLESS

ENTRY (RKE)

MODULE - C2 (BUILT-UP-EXPORT)

8W - 80 - 36 8W-80 CONNECTOR PIN-OUTSPL

J988W-1PL008036

Page 655 of 1200

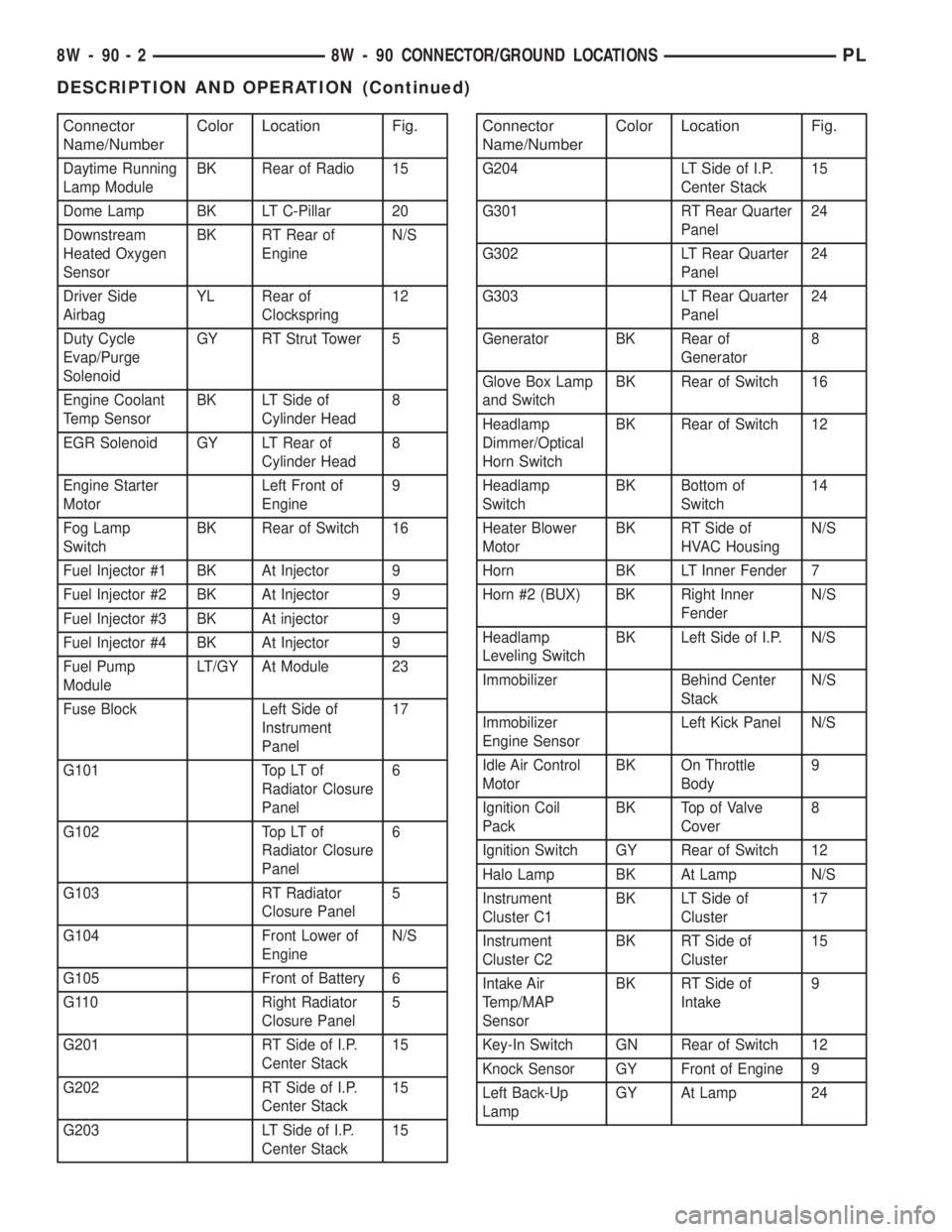

Connector

Name/NumberColor Location Fig.

Daytime Running

Lamp ModuleBK Rear of Radio 15

Dome Lamp BK LT C-Pillar 20

Downstream

Heated Oxygen

SensorBK RT Rear of

EngineN/S

Driver Side

AirbagYL Rear of

Clockspring12

Duty Cycle

Evap/Purge

SolenoidGY RT Strut Tower 5

Engine Coolant

Temp SensorBK LT Side of

Cylinder Head8

EGR Solenoid GY LT Rear of

Cylinder Head8

Engine Starter

MotorLeft Front of

Engine9

Fog Lamp

SwitchBK Rear of Switch 16

Fuel Injector #1 BK At Injector 9

Fuel Injector #2 BK At Injector 9

Fuel Injector #3 BK At injector 9

Fuel Injector #4 BK At Injector 9

Fuel Pump

ModuleLT/GY At Module 23

Fuse Block Left Side of

Instrument

Panel17

G101 Top LT of

Radiator Closure

Panel6

G102 Top LT of

Radiator Closure

Panel6

G103 RT Radiator

Closure Panel5

G104 Front Lower of

EngineN/S

G105 Front of Battery 6

G110 Right Radiator

Closure Panel5

G201 RT Side of I.P.

Center Stack15

G202 RT Side of I.P.

Center Stack15

G203 LT Side of I.P.

Center Stack15

Connector

Name/NumberColor Location Fig.

G204 LT Side of I.P.

Center Stack15

G301 RT Rear Quarter

Panel24

G302 LT Rear Quarter

Panel24

G303 LT Rear Quarter

Panel24

Generator BK Rear of

Generator8

Glove Box Lamp

and SwitchBK Rear of Switch 16

Headlamp

Dimmer/Optical

Horn SwitchBK Rear of Switch 12

Headlamp

SwitchBK Bottom of

Switch14

Heater Blower

MotorBK RT Side of

HVAC HousingN/S

Horn BK LT Inner Fender 7

Horn #2 (BUX) BK Right Inner

FenderN/S

Headlamp

Leveling SwitchBK Left Side of I.P. N/S

Immobilizer Behind Center

StackN/S

Immobilizer

Engine SensorLeft Kick Panel N/S

Idle Air Control

MotorBK On Throttle

Body9

Ignition Coil

PackBK Top of Valve

Cover8

Ignition Switch GY Rear of Switch 12

Halo Lamp BK At Lamp N/S

Instrument

Cluster C1BK LT Side of

Cluster17

Instrument

Cluster C2BK RT Side of

Cluster15

Intake Air

Temp/MAP

SensorBK RT Side of

Intake9

Key-In Switch GN Rear of Switch 12

Knock Sensor GY Front of Engine 9

Left Back-Up

LampGY At Lamp 24

8W - 90 - 2 8W - 90 CONNECTOR/GROUND LOCATIONSPL

DESCRIPTION AND OPERATION (Continued)

Page 656 of 1200

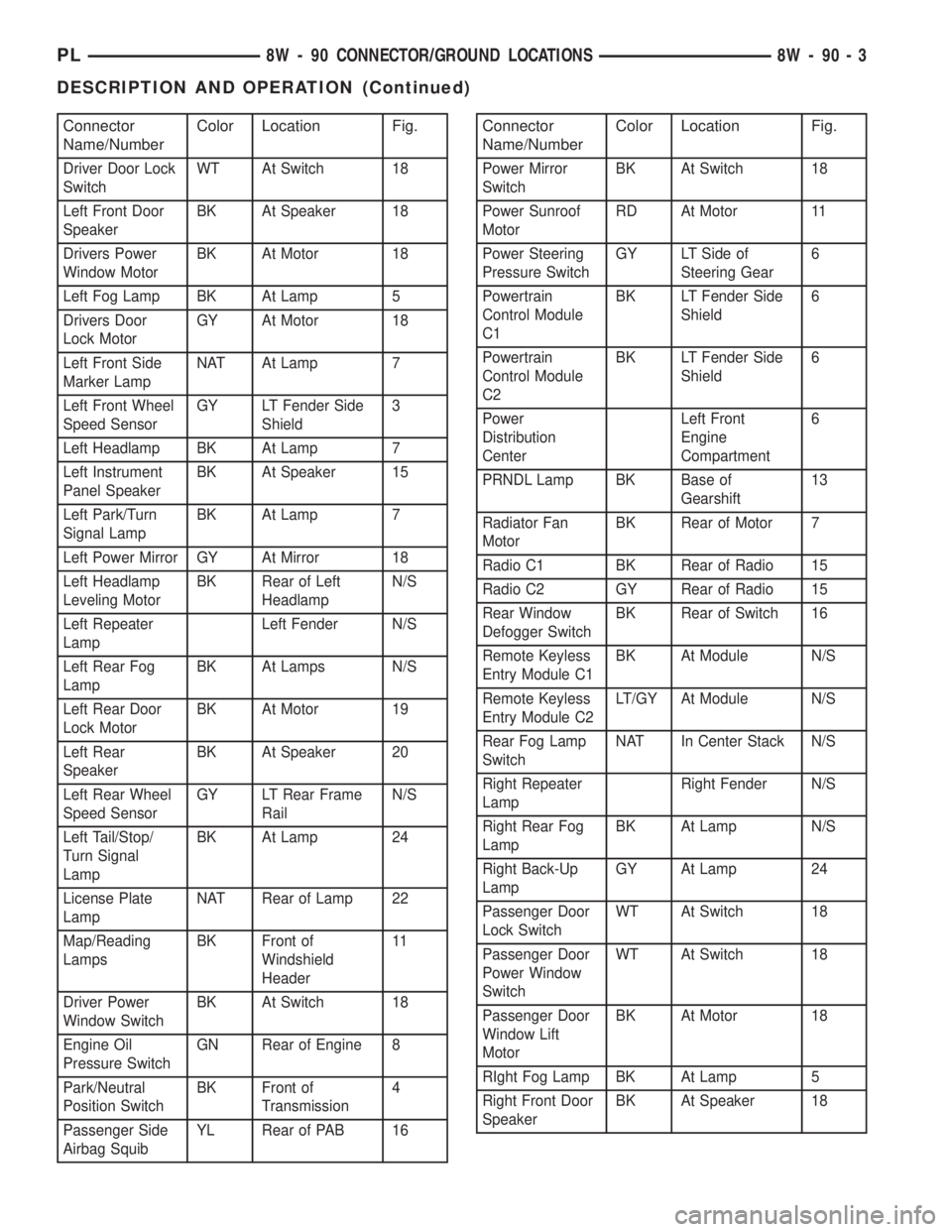

Connector

Name/NumberColor Location Fig.

Driver Door Lock

SwitchWT At Switch 18

Left Front Door

SpeakerBK At Speaker 18

Drivers Power

Window MotorBK At Motor 18

Left Fog Lamp BK At Lamp 5

Drivers Door

Lock MotorGY At Motor 18

Left Front Side

Marker LampNAT At Lamp 7

Left Front Wheel

Speed SensorGY LT Fender Side

Shield3

Left Headlamp BK At Lamp 7

Left Instrument

Panel SpeakerBK At Speaker 15

Left Park/Turn

Signal LampBK At Lamp 7

Left Power Mirror GY At Mirror 18

Left Headlamp

Leveling MotorBK Rear of Left

HeadlampN/S

Left Repeater

LampLeft Fender N/S

Left Rear Fog

LampBK At Lamps N/S

Left Rear Door

Lock MotorBK At Motor 19

Left Rear

SpeakerBK At Speaker 20

Left Rear Wheel

Speed SensorGY LT Rear Frame

RailN/S

Left Tail/Stop/

Turn Signal

LampBK At Lamp 24

License Plate

LampNAT Rear of Lamp 22

Map/Reading

LampsBK Front of

Windshield

Header11

Driver Power

Window SwitchBK At Switch 18

Engine Oil

Pressure SwitchGN Rear of Engine 8

Park/Neutral

Position SwitchBK Front of

Transmission4

Passenger Side

Airbag SquibYL Rear of PAB 16

Connector

Name/NumberColor Location Fig.

Power Mirror

SwitchBK At Switch 18

Power Sunroof

MotorRD At Motor 11

Power Steering

Pressure SwitchGY LT Side of

Steering Gear6

Powertrain

Control Module

C1BK LT Fender Side

Shield6

Powertrain

Control Module

C2BK LT Fender Side

Shield6

Power

Distribution

CenterLeft Front

Engine

Compartment6

PRNDL Lamp BK Base of

Gearshift13

Radiator Fan

MotorBK Rear of Motor 7

Radio C1 BK Rear of Radio 15

Radio C2 GY Rear of Radio 15

Rear Window

Defogger SwitchBK Rear of Switch 16

Remote Keyless

Entry Module C1BK At Module N/S

Remote Keyless

Entry Module C2LT/GY At Module N/S

Rear Fog Lamp

SwitchNAT In Center Stack N/S

Right Repeater

LampRight Fender N/S

Right Rear Fog

LampBK At Lamp N/S

Right Back-Up

LampGY At Lamp 24

Passenger Door

Lock SwitchWT At Switch 18

Passenger Door

Power Window

SwitchWT At Switch 18

Passenger Door

Window Lift

MotorBK At Motor 18

RIght Fog Lamp BK At Lamp 5

Right Front Door

SpeakerBK At Speaker 18

PL8W - 90 CONNECTOR/GROUND LOCATIONS 8W - 90 - 3

DESCRIPTION AND OPERATION (Continued)

Page 677 of 1200

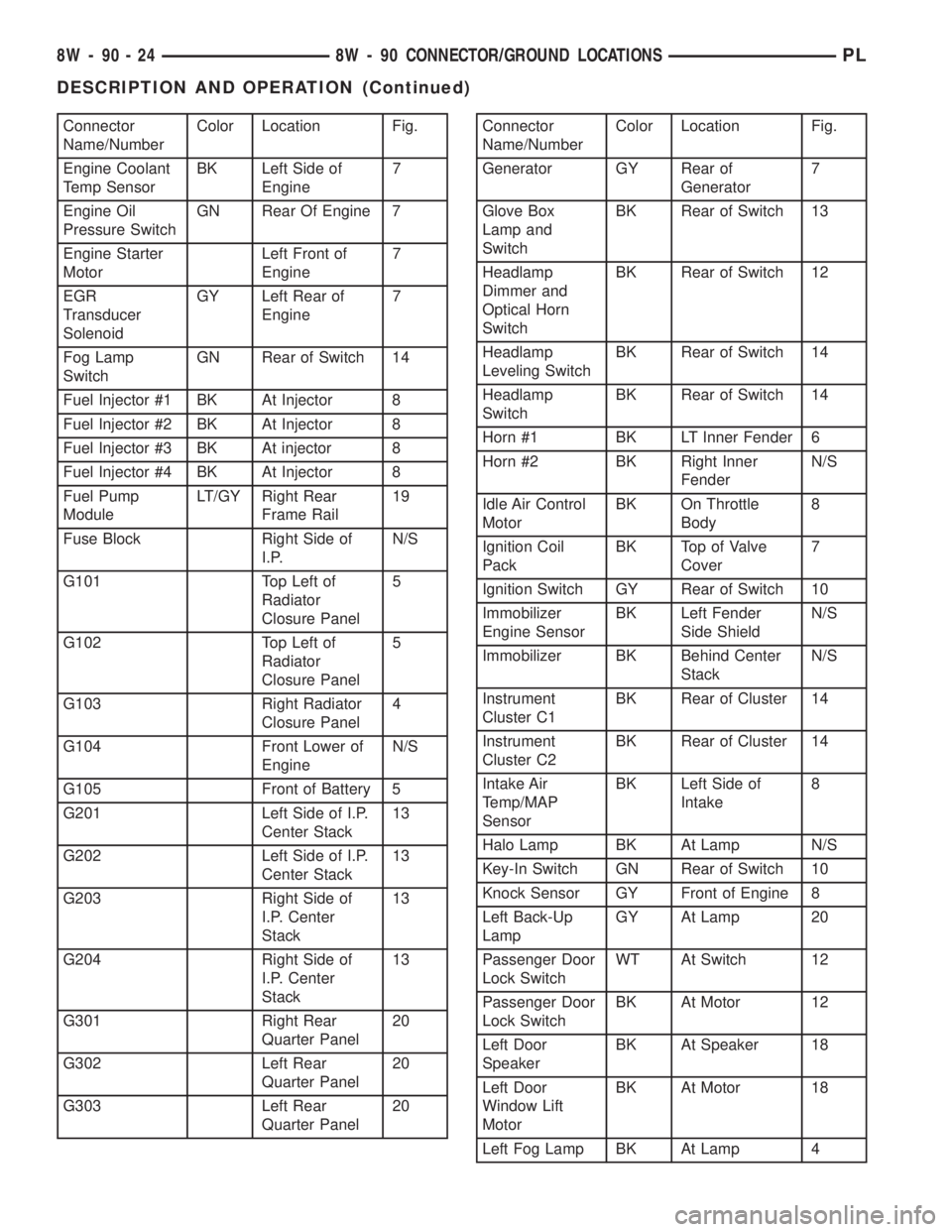

Connector

Name/NumberColor Location Fig.

Engine Coolant

Temp SensorBK Left Side of

Engine7

Engine Oil

Pressure SwitchGN Rear Of Engine 7

Engine Starter

MotorLeft Front of

Engine7

EGR

Transducer

SolenoidGY Left Rear of

Engine7

Fog Lamp

SwitchGN Rear of Switch 14

Fuel Injector #1 BK At Injector 8

Fuel Injector #2 BK At Injector 8

Fuel Injector #3 BK At injector 8

Fuel Injector #4 BK At Injector 8

Fuel Pump

ModuleLT/GY Right Rear

Frame Rail19

Fuse Block Right Side of

I.P.N/S

G101 Top Left of

Radiator

Closure Panel5

G102 Top Left of

Radiator

Closure Panel5

G103 Right Radiator

Closure Panel4

G104 Front Lower of

EngineN/S

G105 Front of Battery 5

G201 Left Side of I.P.

Center Stack13

G202 Left Side of I.P.

Center Stack13

G203 Right Side of

I.P. Center

Stack13

G204 Right Side of

I.P. Center

Stack13

G301 Right Rear

Quarter Panel20

G302 Left Rear

Quarter Panel20

G303 Left Rear

Quarter Panel20Connector

Name/NumberColor Location Fig.

Generator GY Rear of

Generator7

Glove Box

Lamp and

SwitchBK Rear of Switch 13

Headlamp

Dimmer and

Optical Horn

SwitchBK Rear of Switch 12

Headlamp

Leveling SwitchBK Rear of Switch 14

Headlamp

SwitchBK Rear of Switch 14

Horn #1 BK LT Inner Fender 6

Horn #2 BK Right Inner

FenderN/S

Idle Air Control

MotorBK On Throttle

Body8

Ignition Coil

PackBK Top of Valve

Cover7

Ignition Switch GY Rear of Switch 10

Immobilizer

Engine SensorBK Left Fender

Side ShieldN/S

Immobilizer BK Behind Center

StackN/S

Instrument

Cluster C1BK Rear of Cluster 14

Instrument

Cluster C2BK Rear of Cluster 14

Intake Air

Temp/MAP

SensorBK Left Side of

Intake8

Halo Lamp BK At Lamp N/S

Key-In Switch GN Rear of Switch 10

Knock Sensor GY Front of Engine 8

Left Back-Up

LampGY At Lamp 20

Passenger Door

Lock SwitchWT At Switch 12

Passenger Door

Lock SwitchBK At Motor 12

Left Door

SpeakerBK At Speaker 18

Left Door

Window Lift

MotorBK At Motor 18

Left Fog Lamp BK At Lamp 4

8W - 90 - 24 8W - 90 CONNECTOR/GROUND LOCATIONSPL

DESCRIPTION AND OPERATION (Continued)

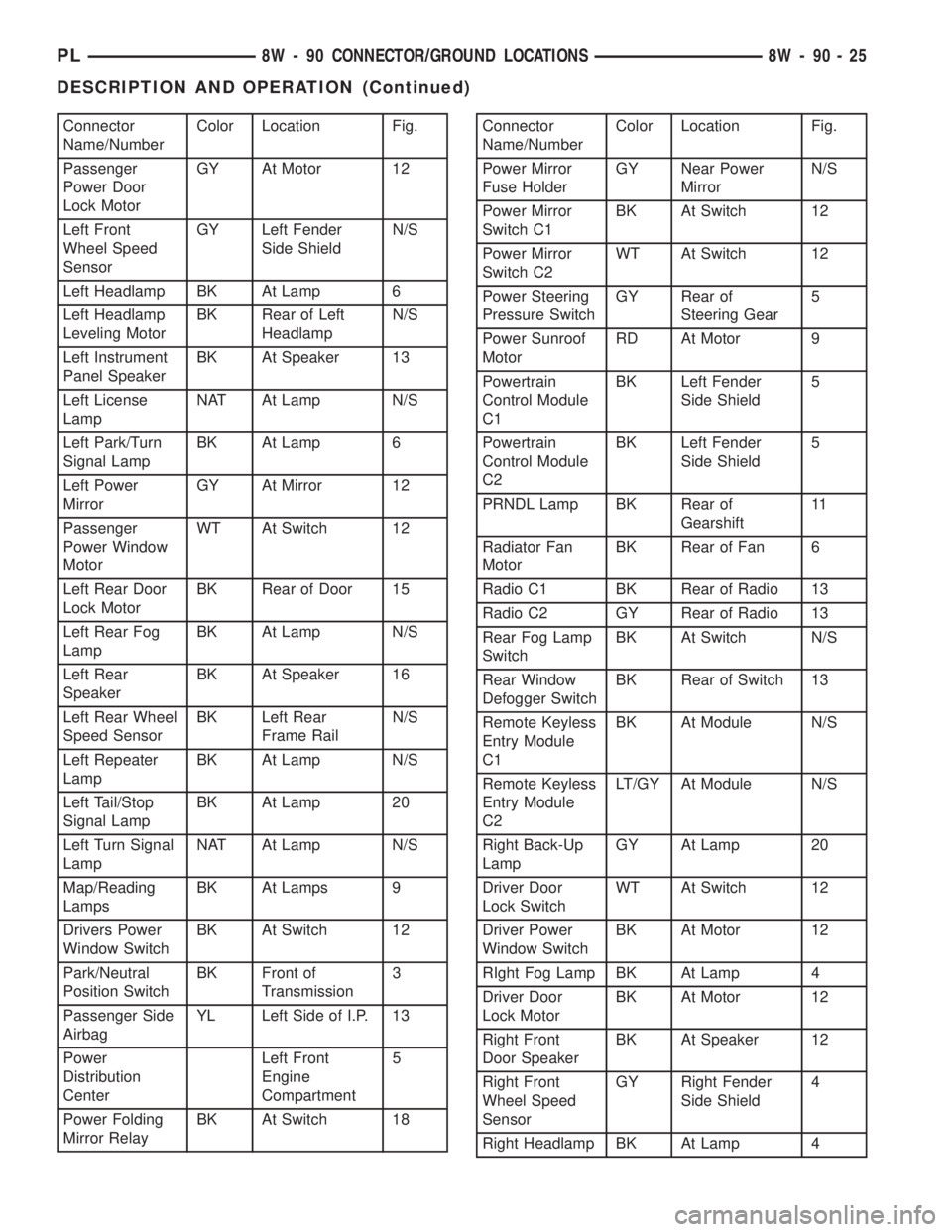

Page 678 of 1200

Connector

Name/NumberColor Location Fig.

Passenger

Power Door

Lock MotorGY At Motor 12

Left Front

Wheel Speed

SensorGY Left Fender

Side ShieldN/S

Left Headlamp BK At Lamp 6

Left Headlamp

Leveling MotorBK Rear of Left

HeadlampN/S

Left Instrument

Panel SpeakerBK At Speaker 13

Left License

LampNAT At Lamp N/S

Left Park/Turn

Signal LampBK At Lamp 6

Left Power

MirrorGY At Mirror 12

Passenger

Power Window

MotorWT At Switch 12

Left Rear Door

Lock MotorBK Rear of Door 15

Left Rear Fog

LampBK At Lamp N/S

Left Rear

SpeakerBK At Speaker 16

Left Rear Wheel

Speed SensorBK Left Rear

Frame RailN/S

Left Repeater

LampBK At Lamp N/S

Left Tail/Stop

Signal LampBK At Lamp 20

Left Turn Signal

LampNAT At Lamp N/S

Map/Reading

LampsBK At Lamps 9

Drivers Power

Window SwitchBK At Switch 12

Park/Neutral

Position SwitchBK Front of

Transmission3

Passenger Side

AirbagYL Left Side of I.P. 13

Power

Distribution

CenterLeft Front

Engine

Compartment5

Power Folding

Mirror RelayBK At Switch 18Connector

Name/NumberColor Location Fig.

Power Mirror

Fuse HolderGY Near Power

MirrorN/S

Power Mirror

Switch C1BK At Switch 12

Power Mirror

Switch C2WT At Switch 12

Power Steering

Pressure SwitchGY Rear of

Steering Gear5

Power Sunroof

MotorRD At Motor 9

Powertrain

Control Module

C1BK Left Fender

Side Shield5

Powertrain

Control Module

C2BK Left Fender

Side Shield5

PRNDL Lamp BK Rear of

Gearshift11

Radiator Fan

MotorBK Rear of Fan 6

Radio C1 BK Rear of Radio 13

Radio C2 GY Rear of Radio 13

Rear Fog Lamp

SwitchBK At Switch N/S

Rear Window

Defogger SwitchBK Rear of Switch 13

Remote Keyless

Entry Module

C1BK At Module N/S

Remote Keyless

Entry Module

C2LT/GY At Module N/S

Right Back-Up

LampGY At Lamp 20

Driver Door

Lock SwitchWT At Switch 12

Driver Power

Window SwitchBK At Motor 12

RIght Fog Lamp BK At Lamp 4

Driver Door

Lock MotorBK At Motor 12

Right Front

Door SpeakerBK At Speaker 12

Right Front

Wheel Speed

SensorGY Right Fender

Side Shield4

Right Headlamp BK At Lamp 4

PL8W - 90 CONNECTOR/GROUND LOCATIONS 8W - 90 - 25

DESCRIPTION AND OPERATION (Continued)

Page 847 of 1200

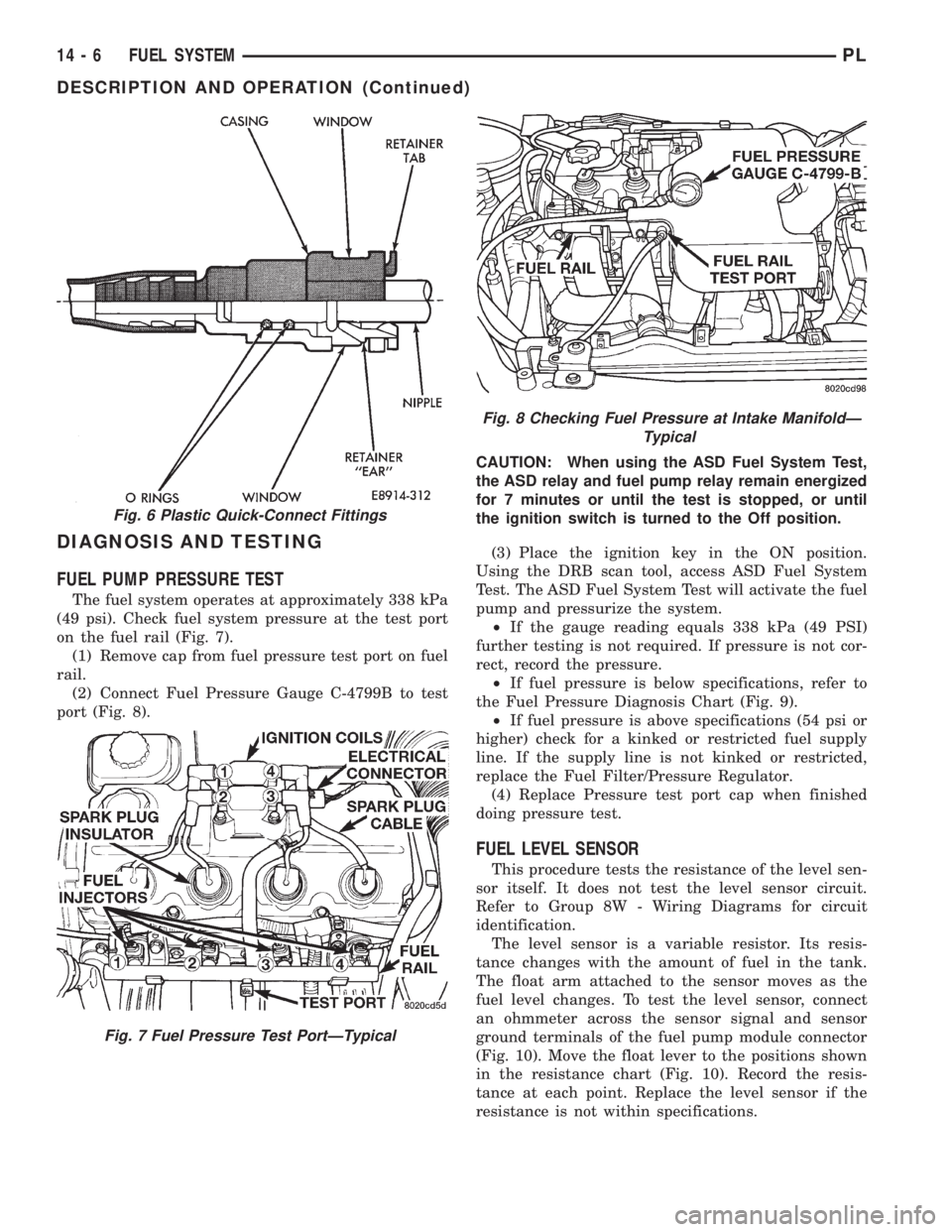

DIAGNOSIS AND TESTING

FUEL PUMP PRESSURE TEST

The fuel system operates at approximately 338 kPa

(49 psi). Check fuel system pressure at the test port

on the fuel rail (Fig. 7).

(1) Remove cap from fuel pressure test port on fuel

rail.

(2) Connect Fuel Pressure Gauge C-4799B to test

port (Fig. 8).CAUTION: When using the ASD Fuel System Test,

the ASD relay and fuel pump relay remain energized

for 7 minutes or until the test is stopped, or until

the ignition switch is turned to the Off position.

(3) Place the ignition key in the ON position.

Using the DRB scan tool, access ASD Fuel System

Test. The ASD Fuel System Test will activate the fuel

pump and pressurize the system.

²If the gauge reading equals 338 kPa (49 PSI)

further testing is not required. If pressure is not cor-

rect, record the pressure.

²If fuel pressure is below specifications, refer to

the Fuel Pressure Diagnosis Chart (Fig. 9).

²If fuel pressure is above specifications (54 psi or

higher) check for a kinked or restricted fuel supply

line. If the supply line is not kinked or restricted,

replace the Fuel Filter/Pressure Regulator.

(4) Replace Pressure test port cap when finished

doing pressure test.

FUEL LEVEL SENSOR

This procedure tests the resistance of the level sen-

sor itself. It does not test the level sensor circuit.

Refer to Group 8W - Wiring Diagrams for circuit

identification.

The level sensor is a variable resistor. Its resis-

tance changes with the amount of fuel in the tank.

The float arm attached to the sensor moves as the

fuel level changes. To test the level sensor, connect

an ohmmeter across the sensor signal and sensor

ground terminals of the fuel pump module connector

(Fig. 10). Move the float lever to the positions shown

in the resistance chart (Fig. 10). Record the resis-

tance at each point. Replace the level sensor if the

resistance is not within specifications.

Fig. 8 Checking Fuel Pressure at Intake ManifoldÐ

Typical

Fig. 6 Plastic Quick-Connect Fittings

Fig. 7 Fuel Pressure Test PortÐTypical

14 - 6 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 862 of 1200

GENERAL INFORMATION

INTRODUCTION

All engines used in this section have a sequential

Multi-Port Electronic Fuel Injection system. The MPI

system is computer regulated and provides precise

air/fuel ratios for all driving conditions. The Power-

train Control Module (PCM) operates the fuel injec-

tion system.

The PCM regulates:

²Ignition timing

²Air/fuel ratio

²Emission control devices

²Cooling fan

²Charging system

²Idle speed

²Vehicle speed control

Various sensors provide the inputs necessary for

the PCM to correctly operate these systems. In addi-

tion to the sensors, various switches also provide

inputs to the PCM.

All inputs to the PCM are converted into signals.

The PCM can adapt its programming to meet chang-

ing operating conditions.

Fuel is injected into the intake port above the

intake valve in precise metered amounts through

electrically operated injectors. The PCM fires the

injectors in a specific sequence. Under most operat-

ing conditions, the PCM maintains an air fuel ratio

of 14.7 parts air to 1 part fuel by constantly adjust-

ing injector pulse width. Injector pulse width is the

length of time the injector is open.

The PCM adjusts injector pulse width by opening

and closing the ground path to the injector. Engine

RPM (speed) and manifold absolute pressure (air

density) are the primary inputs that determine injec-

tor pulse width.

MODES OF OPERATION

As input signals to the PCM change, the PCM

adjusts its response to output devices. For example,

the PCM must calculate a different injector pulse

width and ignition timing for idle than it does for

Wide Open Throttle (WOT). There are several differ-

ent modes of operation that determine how the PCM

responds to the various input signals.

There are two different areas of operation, OPEN

LOOP and CLOSED LOOP.

During OPEN LOOP modes the PCM receives

input signals and responds according to preset PCM

programming. Inputs from the upstream and down-

stream heated oxygen sensors are not monitored dur-

ing OPEN LOOP modes, except for heated oxygen

sensor diagnostics (they are checked for shorted con-

ditions at all times).During CLOSED LOOP modes the PCM monitors

the inputs from the upstream and downstream

heated oxygen sensors. The upstream heated oxygen

sensor input tells the PCM if the calculated injector

pulse width resulted in the ideal air-fuel ratio of 14.7

to one. By monitoring the exhaust oxygen content

through the upstream heated oxygen sensor, the

PCM can fine tune injector pulse width. Fine tuning

injector pulse width allows the PCM to achieve opti-

mum fuel economy combined with low emissions.

For the PCM to enter CLOSED LOOP operation,

the following must occur:

(1) Engine coolant temperature must be over 35ÉF.

²If the coolant is over 35É the PCM will wait 44

seconds.

²If the coolant is over 50ÉF the PCM will wait 38

seconds.

²If the coolant is over 167ÉF the PCM will wait

11 seconds.

(2) For other temperatures the PCM will interpo-

late the correct waiting time.

(3) O2 sensor must read either greater than .745

volts or less than .1 volt.

(4) The multi-port fuel injection systems has the

following modes of operation:

²Ignition switch ON (Zero RPM)

²Engine start-up

²Engine warm-up

²Cruise

²Idle

²Acceleration

²Deceleration

²Wide Open Throttle

²Ignition switch OFF

(5) The engine start-up (crank), engine warm-up,

deceleration with fuel shutoff and wide open throttle

modes are OPEN LOOP modes. Under most operat-

ing conditions, the acceleration, deceleration (with

A/C on), idle and cruise modes,with the engine at

operating temperatureare CLOSED LOOP modes.

IGNITION SWITCH ON (ZERO RPM) MODE

When the ignition switch activates the fuel injec-

tion system, the following actions occur:

²The PCM monitors the engine coolant tempera-

ture sensor and throttle position sensor input. The

PCM determines basic fuel injector pulse width from

this input.

²The PCM determines atmospheric air pressure

from the MAP sensor input to modify injector pulse

width.

When the key is in the ON position and the engine

is not running (zero rpm), the Auto Shutdown (ASD)

and fuel pump relays de-energize after approximately

1 second. Therefore, battery voltage is not supplied to

the fuel pump, ignition coil, fuel injectors and heated

oxygen sensors.

PLFUEL SYSTEM 14 - 21

Page 870 of 1200

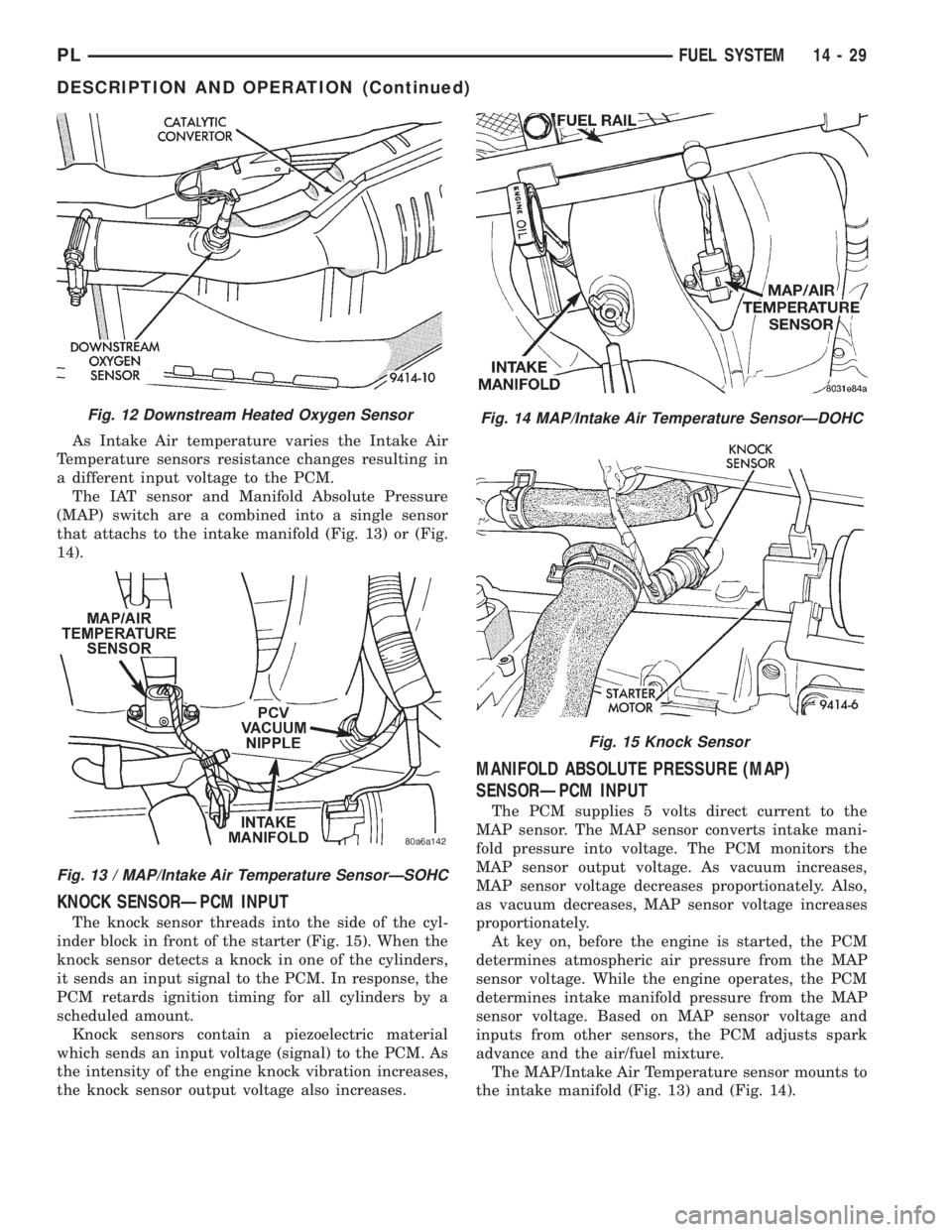

As Intake Air temperature varies the Intake Air

Temperature sensors resistance changes resulting in

a different input voltage to the PCM.

The IAT sensor and Manifold Absolute Pressure

(MAP) switch are a combined into a single sensor

that attachs to the intake manifold (Fig. 13) or (Fig.

14).

KNOCK SENSORÐPCM INPUT

The knock sensor threads into the side of the cyl-

inder block in front of the starter (Fig. 15). When the

knock sensor detects a knock in one of the cylinders,

it sends an input signal to the PCM. In response, the

PCM retards ignition timing for all cylinders by a

scheduled amount.

Knock sensors contain a piezoelectric material

which sends an input voltage (signal) to the PCM. As

the intensity of the engine knock vibration increases,

the knock sensor output voltage also increases.

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSORÐPCM INPUT

The PCM supplies 5 volts direct current to the

MAP sensor. The MAP sensor converts intake mani-

fold pressure into voltage. The PCM monitors the

MAP sensor output voltage. As vacuum increases,

MAP sensor voltage decreases proportionately. Also,

as vacuum decreases, MAP sensor voltage increases

proportionately.

At key on, before the engine is started, the PCM

determines atmospheric air pressure from the MAP

sensor voltage. While the engine operates, the PCM

determines intake manifold pressure from the MAP

sensor voltage. Based on MAP sensor voltage and

inputs from other sensors, the PCM adjusts spark

advance and the air/fuel mixture.

The MAP/Intake Air Temperature sensor mounts to

the intake manifold (Fig. 13) and (Fig. 14).

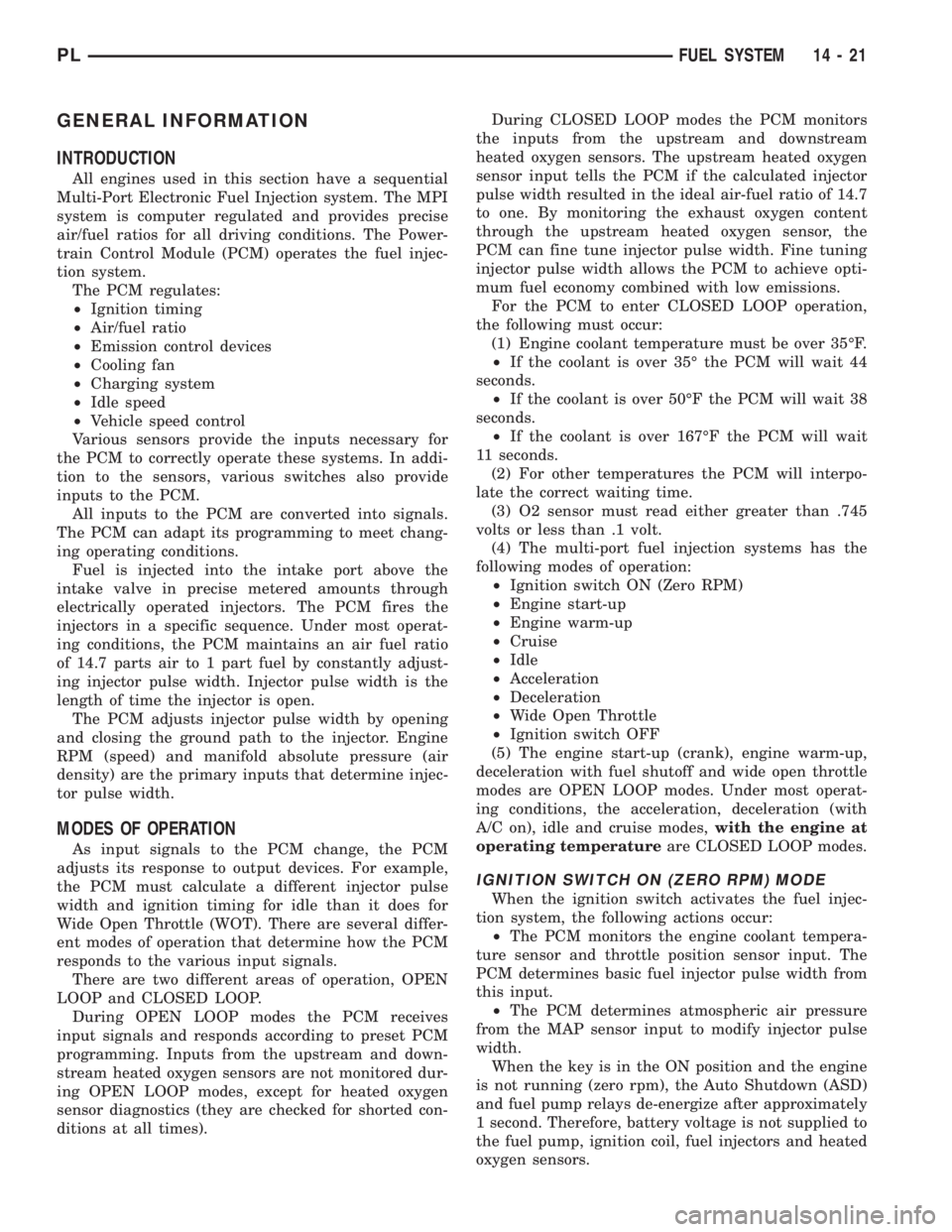

Fig. 12 Downstream Heated Oxygen Sensor

Fig. 13 / MAP/Intake Air Temperature SensorÐSOHC

Fig. 14 MAP/Intake Air Temperature SensorÐDOHC

Fig. 15 Knock Sensor

PLFUEL SYSTEM 14 - 29

DESCRIPTION AND OPERATION (Continued)