ignition DODGE NEON 1999 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 236 of 1200

CHARGING SYSTEM

CONTENTS

page page

GENERAL INFORMATION

OVERVIEW............................. 1

DESCRIPTION AND OPERATION

BATTERY TEMPERATURE SENSOR.......... 2

CHARGING SYSTEM OPERATION........... 1

ELECTRONIC VOLTAGE REGULATOR......... 2

GENERATOR............................ 2

DIAGNOSIS AND TESTING

BATTERY TEMPERATURE SENSOR.......... 8

CHARGING SYSTEM RESISTANCE TESTS..... 5CHARGING SYSTEM...................... 2

CURRENT OUTPUT TEST.................. 8

ON-BOARD DIAGNOSTIC SYSTEM TEST..... 10

REMOVAL AND INSTALLATION

BATTERY TEMPERATURE SENSOR......... 11

GENERATOR........................... 10

SPECIFICATIONS

GENERATOR RATINGS................... 12

TORQUE.............................. 12

GENERAL INFORMATION

OVERVIEW

The battery, starting, and charging systems oper-

ate with one another, and must be tested as a com-

plete system. In order for the vehicle to start and

charge properly, all of the components involved in

these systems must perform within specifications.

Group 8A covers the battery, Group 8B covers the

starting system, and Group 8C covers the charging

system. Refer to Group 8W - Wiring Diagrams for

complete circuit descriptions and diagrams. We have

separated these systems to make it easier to locate

the information you are seeking within this Service

Manual. However, when attempting to diagnose any

of these systems, it is important that you keep their

interdependency in mind.

The diagnostic procedures used in these groups

include the most basic conventional diagnostic meth-

ods to the more sophisticated On-Board Diagnostics

(OBD) built into the Powertrain Control Module

(PCM). Use of an induction ammeter, volt/ohmmeter,

battery charger, carbon pile rheostat (load tester),

and 12-volt test lamp may be required.

All OBD-sensed systems are monitored by the

PCM. Each monitored circuit is assigned a Diagnos-

tic Trouble Code (DTC). The PCM will store a DTC in

electronic memory for any failure it detects. See the

On-Board Diagnostics Test in Group 8C - Charging

System for more information.

DESCRIPTION AND OPERATION

CHARGING SYSTEM OPERATION

The charging system consists of:

²Generator

²Electronic Voltage Regulator (EVR) circuitry

within the Powertrain Control Module (PCM)

²Ignition switch (refer to Group 8D, Ignition Sys-

tem for information)

²Battery (refer to Group 8A, Battery for informa-

tion)

²Battery temperature sensor

²Voltmeter (refer to Group 8E, Instrument Panel

and Gauges for information)

²Wiring harness and connections (refer to Group

8W, Wiring for information)

The charging system is turned on and off with the

ignition switch. When the ignition switch is turned to

the ON position, battery voltage is applied to the

generator rotor through one of the two field termi-

nals to produce a magnetic field. The generator is

driven by the engine through a serpentine belt and

pulley arrangement.

The amount of DC current produced by the gener-

ator is controlled by the EVR (field control) circuitry,

contained within the PCM. This circuitry is con-

nected in series with the second rotor field terminal

and ground.

PLCHARGING SYSTEM 8C - 1

Page 237 of 1200

A battery temperature sensor located on the front

bumper beam is used to sense battery temperature.

This temperature data, along with data from moni-

tored line voltage, is used by the PCM to vary the

battery charging rate. This is done by cycling the

ground path to control the strength of the rotor mag-

netic field. The PCM then compensates and regulates

generator current output accordingly and to maintain

the proper voltage depending on battery tempera-

ture.

All vehicles are equipped with On-Board Diagnos-

tics (OBD). All OBD-sensed systems, including the

EVR (field control) circuitry, are monitored by the

PCM. Each monitored circuit is assigned a Diagnos-

tic Trouble Code (DTC). The PCM will store a DTC in

electronic memory for any failure it detects. See On-

Board Diagnostic System Test in this group for more

information.

GENERATOR

The generator is belt-driven by the engine. It is

serviced only as a complete assembly. If the genera-

tor fails for any reason, the entire assembly must be

replaced.

As the energized rotor begins to rotate within the

generator, the spinning magnetic field induces a cur-

rent into the windings of the stator coil. Once the

generator begins producing sufficient current, it also

provides the current needed to energize the rotor.

The Y type stator winding connections deliver the

induced AC current to 3 positive and 3 negative

diodes for rectification. From the diodes, rectified DC

current is delivered to the vehicle electrical system

through the generator, battery, and ground terminals.

Noise emitting from the generator may be caused

by:

²Worn, loose or defective bearings

²Loose or defective drive pulley

²Incorrect, worn, damaged or misadjusted drive

belt

²Loose mounting bolts

²Misaligned drive pulley

²Defective stator or diode

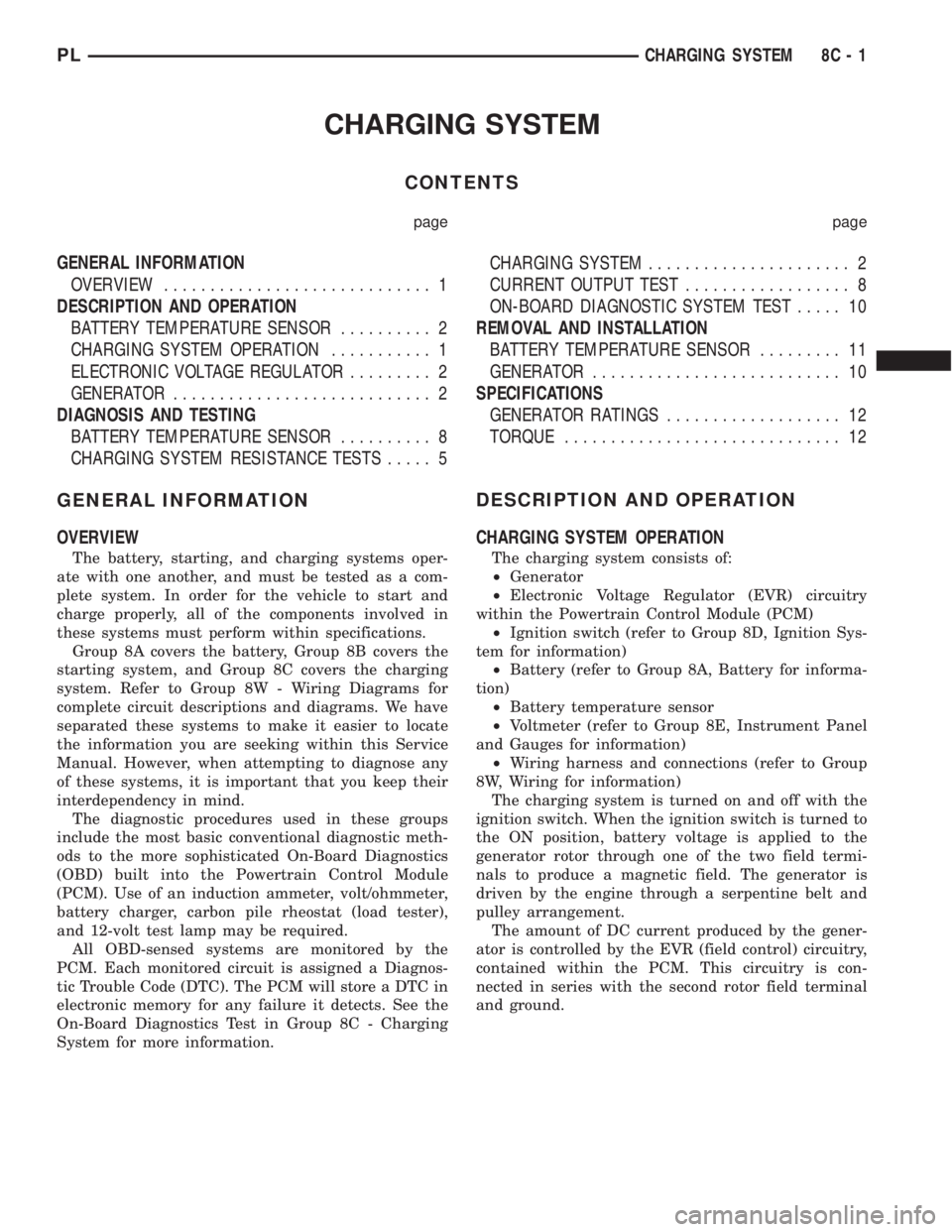

BATTERY TEMPERATURE SENSOR

The battery temperature sensor is used to deter-

mine the battery temperature. This temperature

data, along with data from monitored line voltage, is

used by the PCM to vary the battery charging rate.

System voltage will be higher at colder temperatures

and is gradually reduced at warmer temperatures.

The sensor is located on the bottom of the battery

tray (Fig. 1).

ELECTRONIC VOLTAGE REGULATOR

The Electronic Voltage Regulator (EVR) is not a

separate component. It is actually a voltage regulat-

ing circuit located within the Powertrain Control

Module (PCM). The EVR is not serviced separately. If

replacement is necessary, the PCM must be replaced.

Operation:The amount of DC current produced

by the generator is controlled by EVR circuitry con-

tained within the PCM. This circuitry is connected in

series with the generators second rotor field terminal

and its ground.

Voltage is regulated by cycling the ground path to

control the strength of the rotor magnetic field. The

EVR circuitry monitors system line voltage and bat-

tery temperature (refer to Battery Temperature Sen-

sor for more information). It then compensates and

regulates generator current output accordingly. Also

refer to Charging System Operation for additional

information.

DIAGNOSIS AND TESTING

CHARGING SYSTEM

When the ignition switch is turned to the ON posi-

tion, battery potential will register on the voltmeter.

During engine cranking a lower voltage will appear

on the meter. With the engine running, a voltage

reading higher than the first reading (ignition in ON)

should register.

The following are possible symptoms of a charging

system fault:

²The voltmeter does not operate properly

²An undercharged or overcharged battery condi-

tion occurs.

Fig. 1 Battery Temperature Sensor

8C - 2 CHARGING SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 238 of 1200

Remember that an undercharged battery is often

caused by:

²Accessories being left on with the engine not

running

²A faulty or improperly adjusted switch that

allows a lamp to stay on. See Ignition-Off Draw Test

in Group 8A, Battery for more information.

The following procedures may be used to correct a

problem diagnosed as a charging system fault.

INSPECTION

(1) Inspect condition of battery cable terminals,

battery posts, connections at engine block, starter

solenoid and relay. They should be clean and tight.

Repair as required.

(2) Inspect all fuses in the fuseblock module and

Power Distribution Center (PDC) for tightness in

receptacles. They should be properly installed and

tight. Repair or replace as required.(3) Inspect the electrolyte level in the battery.

Replace battery if electrolyte level is low.

(4) Inspect generator mounting bolts for tightness.

Replace or tighten bolts if required. Refer to the Gen-

erator Removal/Installation section of this group for

torque specifications.

(5) Inspect generator drive belt condition and ten-

sion. Tighten or replace belt as required. Refer to

Belt Tension Specifications in Group 7, Cooling Sys-

tem.

(6) Inspect automatic belt tensioner (if equipped).

Refer to Group 7, Cooling System for information.

(7) Inspect connections at generator field, battery

output, and ground terminals. Also check ground con-

nection at engine. They should all be clean and tight.

Repair as required.

PLCHARGING SYSTEM 8C - 3

DIAGNOSIS AND TESTING (Continued)

Page 246 of 1200

ifications chart in Group 8A, Battery/Starter/

Charging Systems Diagnostics.

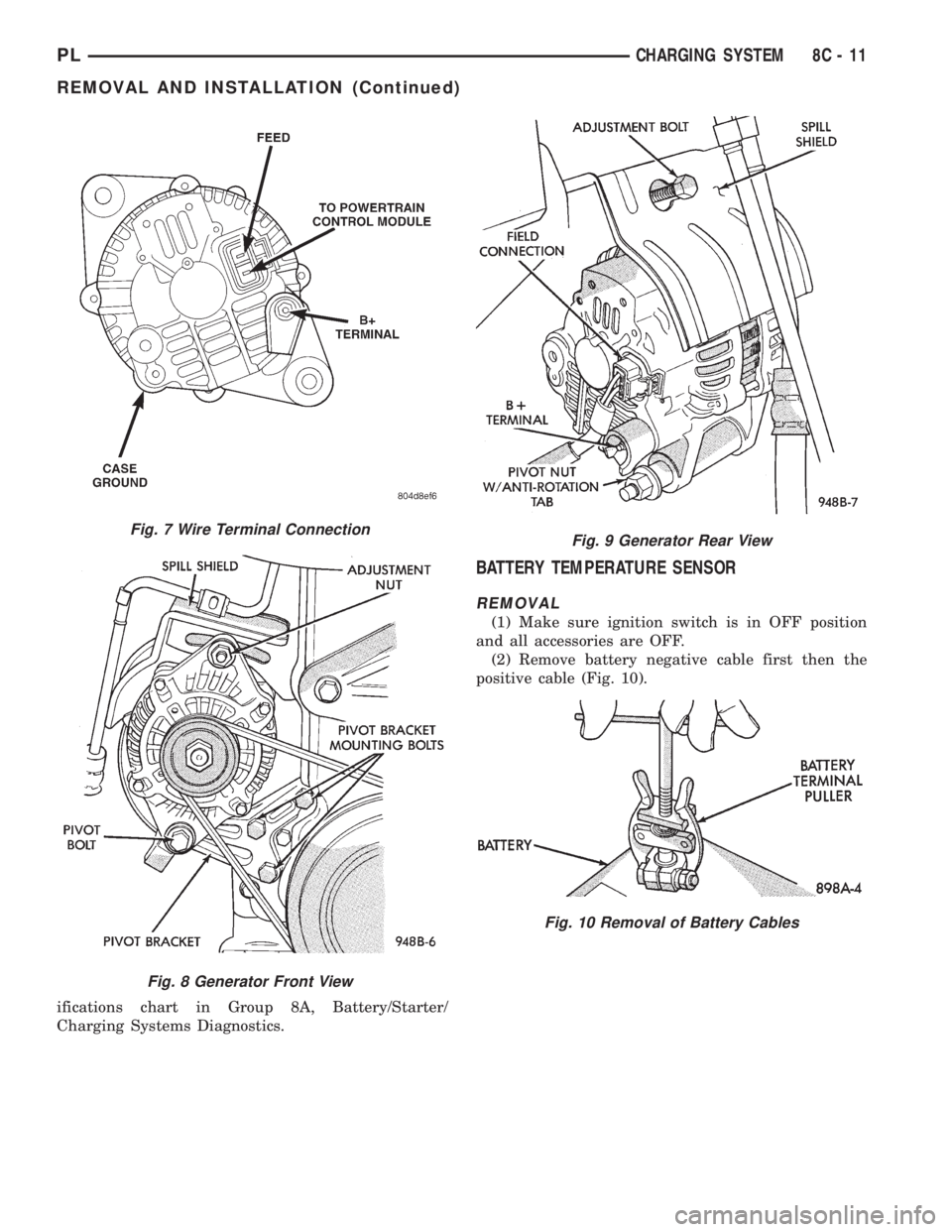

BATTERY TEMPERATURE SENSOR

REMOVAL

(1) Make sure ignition switch is in OFF position

and all accessories are OFF.

(2) Remove battery negative cable first then the

positive cable (Fig. 10).

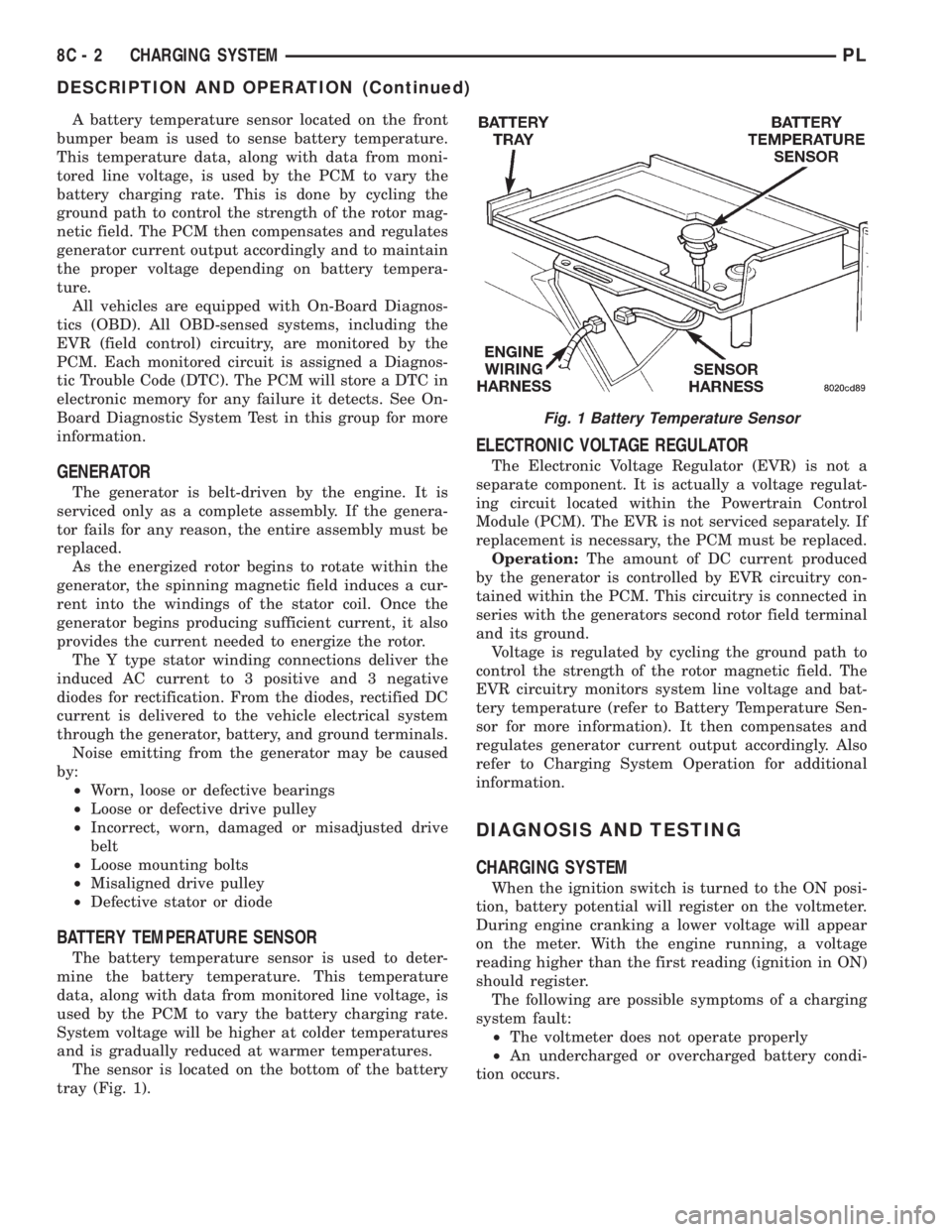

Fig. 7 Wire Terminal Connection

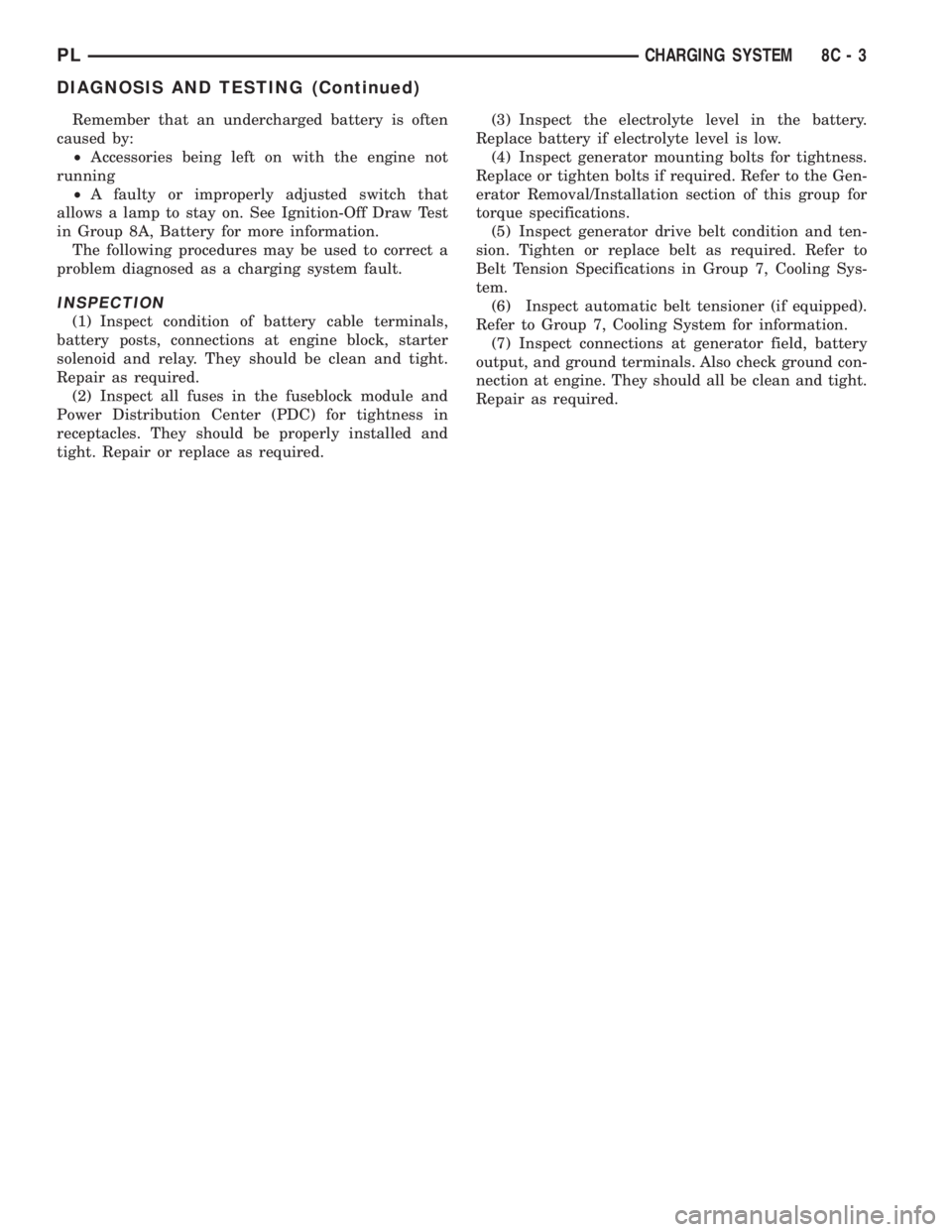

Fig. 8 Generator Front View

Fig. 9 Generator Rear View

Fig. 10 Removal of Battery Cables

PLCHARGING SYSTEM 8C - 11

REMOVAL AND INSTALLATION (Continued)

Page 250 of 1200

IGNITION SYSTEM

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DESCRIPTION AND OPERATION

AUTOMATIC SHUTDOWN RELAY............ 3

CAMSHAFT POSITION SENSOR............. 4

COMBINATION ENGINE COOLANT

TEMPERATURE SENSOR................. 5

CRANKSHAFT POSITION SENSOR........... 4

ELECTRONIC IGNITION COILS.............. 3

IGNITION INTERLOCK.................... 7

IGNITION SWITCH....................... 7

IGNITION SYSTEM....................... 1

INTAKE AIR TEMPERATURE SENSOR........ 6

KNOCK SENSOR......................... 6

LOCK KEY CYLINDER..................... 7

MANIFOLD ABSOLUTE PRESSURE SENSOR

(MAP)............................... 6

POWERTRAIN CONTROL MODULE.......... 2

SPARK PLUG CABLES.................... 2

SPARK PLUGS.......................... 2

THROTTLE POSITION SENSOR (TPS)........ 6

DIAGNOSIS AND TESTING

CAMSHAFT POSITION SENSOR AND

CRANKSHAFT POSITION SENSOR......... 9

CHECK COIL TEST....................... 8

ENGINE COOLANT TEMPERATURE SENSOR . . . 9

FAILURE TO START TESTÐ2.0/2.4L......... 8

IGNITION TIMING PROCEDURE............. 9

INTAKE AIR TEMPERATURE SENSOR........ 9

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSOR TEST......................... 9

SPARK PLUG CONDITION................ 10TESTING FOR SPARK AT COILÐ2.0/2.4L..... 7

THROTTLE POSITION SENSOR............. 9

REMOVAL AND INSTALLATION

AUTOMATIC SHUTDOWN RELAY........... 13

CAMSHAFT POSITION SENSORÐDOHC..... 14

CAMSHAFT POSITION SENSORÐSOHC..... 13

COMBINATION ENGINE COOLANT

TEMPERATURE SENSORÐDOHC........ 15

COMBINATION ENGINE COOLANT

TEMPERATURE SENSORÐSOHC......... 15

CRANKSHAFT POSITION SENSOR.......... 15

IGNITION COIL......................... 13

IGNITION INTERLOCK................... 18

IGNITION SWITCH...................... 16

LOCK CYLINDER HOUSING............... 18

LOCK KEY CYLINDER.................... 17

MAP/IAT SENSORÐDOHC................ 16

MAP/IAT SENSORÐSOHC................ 16

POWERTRAIN CONTROL MODULE (PCM) . . . 12

SPARK PLUG CABLE SERVICE............ 13

SPARK PLUG SERVICE.................. 12

SPARK PLUG TUBES.................... 13

THROTTLE POSITION SENSOR............ 16

SPECIFICATIONS

FIRING ORDERÐ2.0L................... 18

IGNITION COIL......................... 19

SPARK PLUG CABLE RESISTANCEÐDOHC . . 18

SPARK PLUG CABLE RESISTANCEÐSOHC . . . 18

SPARK PLUG.......................... 19

TORQUE SPECIFICATION................. 18

VECI LABEL........................... 18

GENERAL INFORMATION

INTRODUCTION

This section describes the electronic ignition sys-

tem for the 2.0L engines used in Neon vehicles.

The On-Board Diagnostics Section in Group 25

describes diagnostic trouble codes.

Group 0, Lubrication and Maintenance, contains

general maintenance information for ignition relateditems. The Owner's Manual also contains mainte-

nance information.DESCRIPTION AND OPERATION

IGNITION SYSTEM

Ignition system operation and diagnostics, are

identical for 2.0L Single Overhead Cam (SOHC) and

2.0L Duel Overhead Cam (DOHC) engines.

PLIGNITION SYSTEM 8D - 1

Page 251 of 1200

The major difference between the two engines is

component location which affects the ignition system

service procedures. There are various sensors that

are in different locations due to a different cylinder

head and intake manifold.

The 2.0L engines use a fixed ignition timing sys-

tem. The distributorless electronic ignition system is

referred to as the Direct Ignition System (DIS).

Basic ignition timing is not adjustable.The

Powertrain Control Module (PCM) determines spark

advance. The system's three main components are

the coil pack, crankshaft position sensor, and cam-

shaft position sensor.

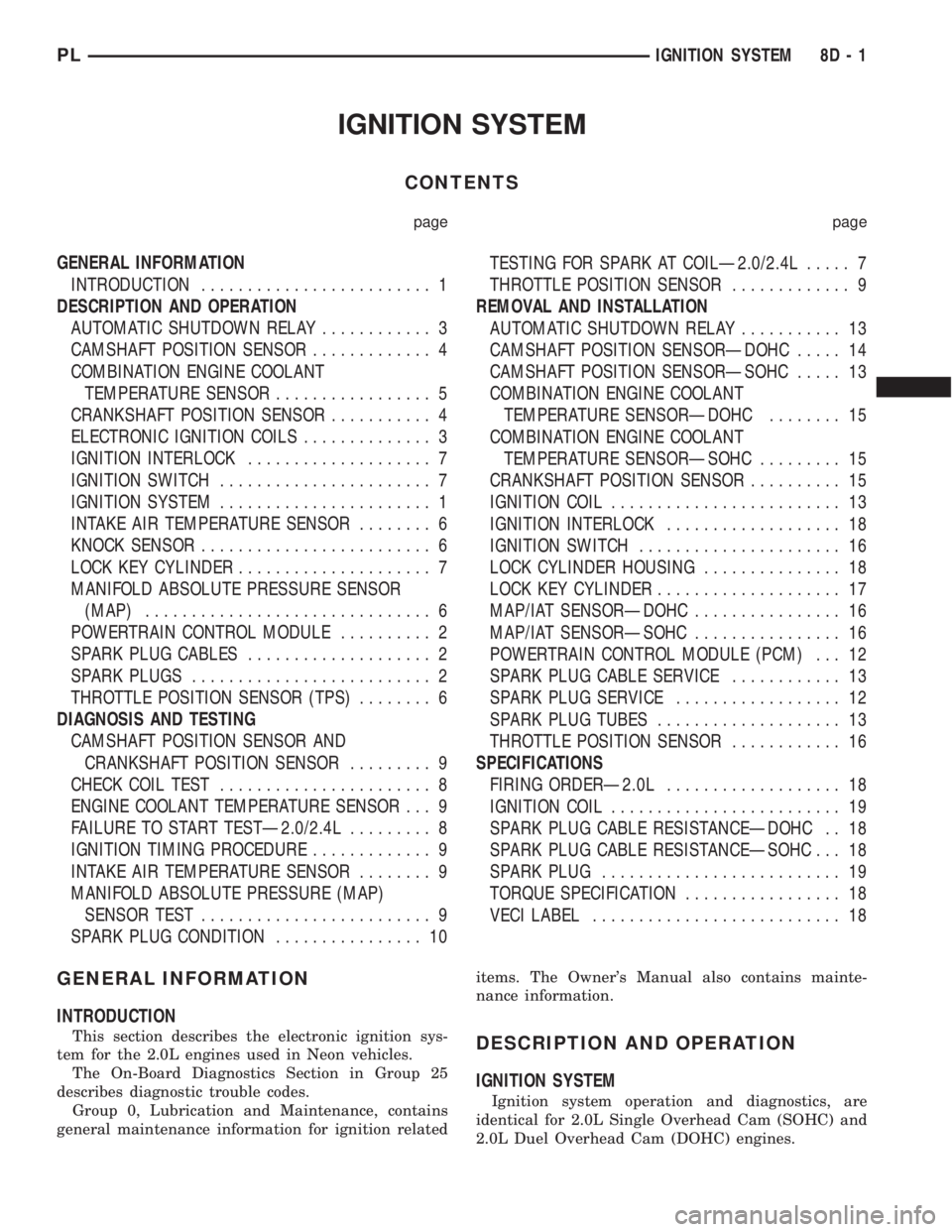

POWERTRAIN CONTROL MODULE

The Powertrain Control Module (PCM) controls the

ignition system (Fig. 1). The PCM supplies battery

voltage to the ignition coil through the Auto Shut-

down (ASD) Relay. The PCM also controls the ground

circuit for the ignition coil. By switching the ground

path for the coil on and off, the PCM adjusts ignition

timing to meet changing engine operating conditions.

During the crank-start period the PCM maintains

spark advance at 9É BTDC. During engine operation

the following inputs determine the amount of spark

advance provided by the PCM.

²Intake air temperature

²Coolant temperature

²Engine RPM

²Intake manifold vacuum

²Knock sensor

The PCM also regulates the fuel injection system.

Refer to the Fuel Injection sections of Group 14.

SPARK PLUGS

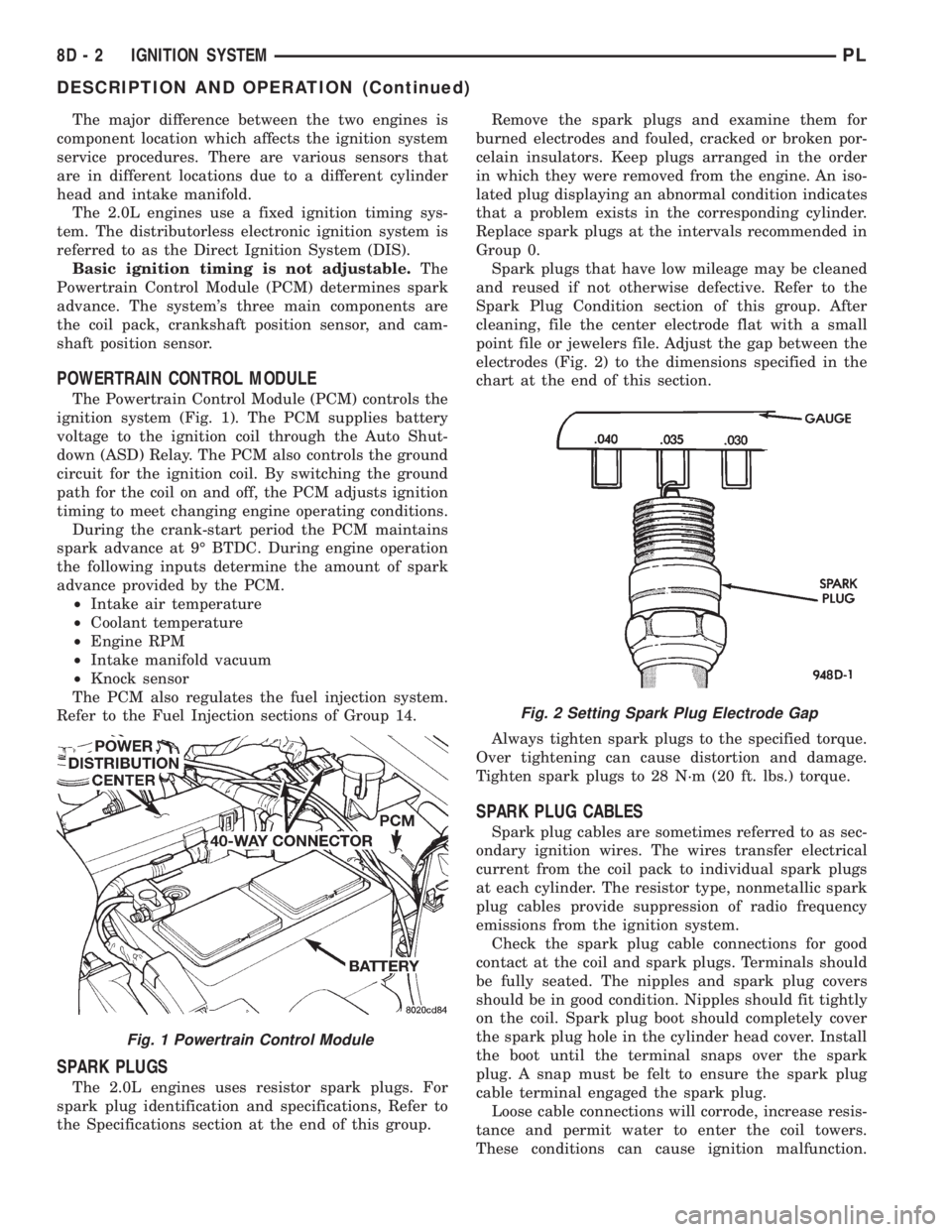

The 2.0L engines uses resistor spark plugs. For

spark plug identification and specifications, Refer to

the Specifications section at the end of this group.Remove the spark plugs and examine them for

burned electrodes and fouled, cracked or broken por-

celain insulators. Keep plugs arranged in the order

in which they were removed from the engine. An iso-

lated plug displaying an abnormal condition indicates

that a problem exists in the corresponding cylinder.

Replace spark plugs at the intervals recommended in

Group 0.

Spark plugs that have low mileage may be cleaned

and reused if not otherwise defective. Refer to the

Spark Plug Condition section of this group. After

cleaning, file the center electrode flat with a small

point file or jewelers file. Adjust the gap between the

electrodes (Fig. 2) to the dimensions specified in the

chart at the end of this section.

Always tighten spark plugs to the specified torque.

Over tightening can cause distortion and damage.

Tighten spark plugs to 28 N´m (20 ft. lbs.) torque.

SPARK PLUG CABLES

Spark plug cables are sometimes referred to as sec-

ondary ignition wires. The wires transfer electrical

current from the coil pack to individual spark plugs

at each cylinder. The resistor type, nonmetallic spark

plug cables provide suppression of radio frequency

emissions from the ignition system.

Check the spark plug cable connections for good

contact at the coil and spark plugs. Terminals should

be fully seated. The nipples and spark plug covers

should be in good condition. Nipples should fit tightly

on the coil. Spark plug boot should completely cover

the spark plug hole in the cylinder head cover. Install

the boot until the terminal snaps over the spark

plug. A snap must be felt to ensure the spark plug

cable terminal engaged the spark plug.

Loose cable connections will corrode, increase resis-

tance and permit water to enter the coil towers.

These conditions can cause ignition malfunction.

Fig. 1 Powertrain Control Module

Fig. 2 Setting Spark Plug Electrode Gap

8D - 2 IGNITION SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 252 of 1200

Plastic clips in various locations protect the cables

from damage. When the cables are replaced the clips

must be used to prevent damage to the cables. The

#1 cable must be routed under the PCV hose and

clipped to the #2 cable.

ELECTRONIC IGNITION COILS

WARNING: THE DIRECT IGNITION SYSTEM GEN-

ERATES APPROXIMATELY 40,000 VOLTS. PER-

SONAL INJURY COULD RESULT FROM CONTACT

WITH THIS SYSTEM.

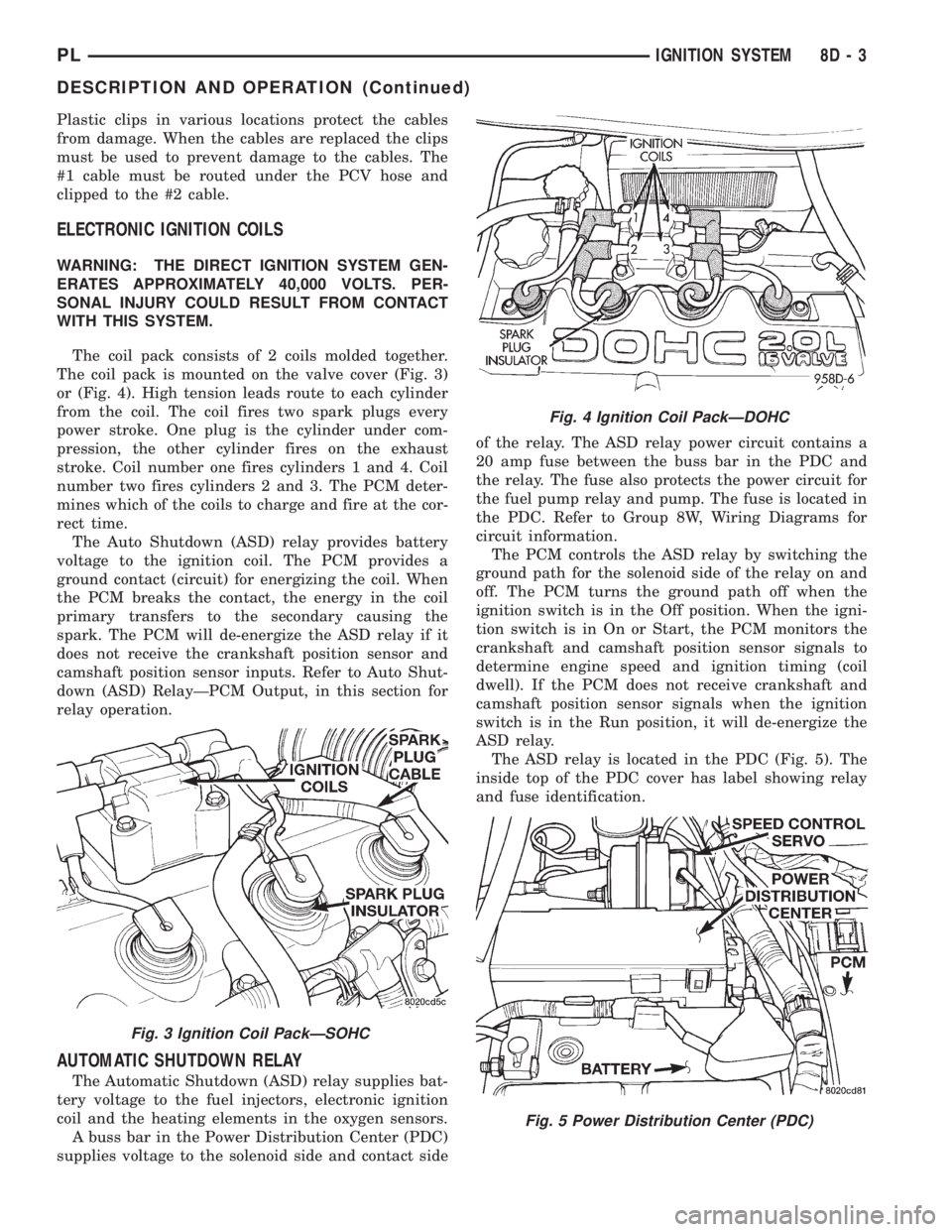

The coil pack consists of 2 coils molded together.

The coil pack is mounted on the valve cover (Fig. 3)

or (Fig. 4). High tension leads route to each cylinder

from the coil. The coil fires two spark plugs every

power stroke. One plug is the cylinder under com-

pression, the other cylinder fires on the exhaust

stroke. Coil number one fires cylinders 1 and 4. Coil

number two fires cylinders 2 and 3. The PCM deter-

mines which of the coils to charge and fire at the cor-

rect time.

The Auto Shutdown (ASD) relay provides battery

voltage to the ignition coil. The PCM provides a

ground contact (circuit) for energizing the coil. When

the PCM breaks the contact, the energy in the coil

primary transfers to the secondary causing the

spark. The PCM will de-energize the ASD relay if it

does not receive the crankshaft position sensor and

camshaft position sensor inputs. Refer to Auto Shut-

down (ASD) RelayÐPCM Output, in this section for

relay operation.

AUTOMATIC SHUTDOWN RELAY

The Automatic Shutdown (ASD) relay supplies bat-

tery voltage to the fuel injectors, electronic ignition

coil and the heating elements in the oxygen sensors.

A buss bar in the Power Distribution Center (PDC)

supplies voltage to the solenoid side and contact sideof the relay. The ASD relay power circuit contains a

20 amp fuse between the buss bar in the PDC and

the relay. The fuse also protects the power circuit for

the fuel pump relay and pump. The fuse is located in

the PDC. Refer to Group 8W, Wiring Diagrams for

circuit information.

The PCM controls the ASD relay by switching the

ground path for the solenoid side of the relay on and

off. The PCM turns the ground path off when the

ignition switch is in the Off position. When the igni-

tion switch is in On or Start, the PCM monitors the

crankshaft and camshaft position sensor signals to

determine engine speed and ignition timing (coil

dwell). If the PCM does not receive crankshaft and

camshaft position sensor signals when the ignition

switch is in the Run position, it will de-energize the

ASD relay.

The ASD relay is located in the PDC (Fig. 5). The

inside top of the PDC cover has label showing relay

and fuse identification.

Fig. 3 Ignition Coil PackÐSOHC

Fig. 4 Ignition Coil PackÐDOHC

Fig. 5 Power Distribution Center (PDC)

PLIGNITION SYSTEM 8D - 3

DESCRIPTION AND OPERATION (Continued)

Page 253 of 1200

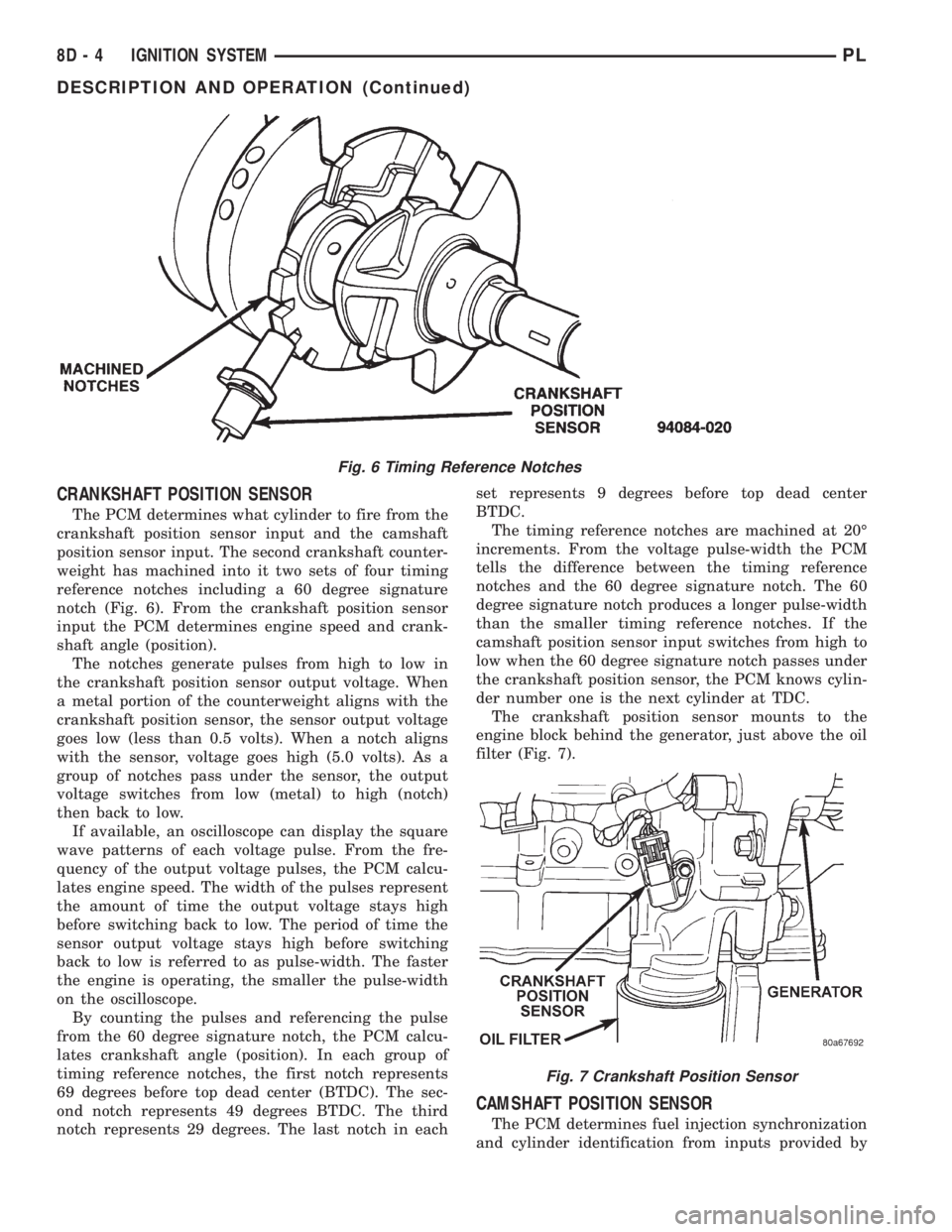

CRANKSHAFT POSITION SENSOR

The PCM determines what cylinder to fire from the

crankshaft position sensor input and the camshaft

position sensor input. The second crankshaft counter-

weight has machined into it two sets of four timing

reference notches including a 60 degree signature

notch (Fig. 6). From the crankshaft position sensor

input the PCM determines engine speed and crank-

shaft angle (position).

The notches generate pulses from high to low in

the crankshaft position sensor output voltage. When

a metal portion of the counterweight aligns with the

crankshaft position sensor, the sensor output voltage

goes low (less than 0.5 volts). When a notch aligns

with the sensor, voltage goes high (5.0 volts). As a

group of notches pass under the sensor, the output

voltage switches from low (metal) to high (notch)

then back to low.

If available, an oscilloscope can display the square

wave patterns of each voltage pulse. From the fre-

quency of the output voltage pulses, the PCM calcu-

lates engine speed. The width of the pulses represent

the amount of time the output voltage stays high

before switching back to low. The period of time the

sensor output voltage stays high before switching

back to low is referred to as pulse-width. The faster

the engine is operating, the smaller the pulse-width

on the oscilloscope.

By counting the pulses and referencing the pulse

from the 60 degree signature notch, the PCM calcu-

lates crankshaft angle (position). In each group of

timing reference notches, the first notch represents

69 degrees before top dead center (BTDC). The sec-

ond notch represents 49 degrees BTDC. The third

notch represents 29 degrees. The last notch in eachset represents 9 degrees before top dead center

BTDC.

The timing reference notches are machined at 20É

increments. From the voltage pulse-width the PCM

tells the difference between the timing reference

notches and the 60 degree signature notch. The 60

degree signature notch produces a longer pulse-width

than the smaller timing reference notches. If the

camshaft position sensor input switches from high to

low when the 60 degree signature notch passes under

the crankshaft position sensor, the PCM knows cylin-

der number one is the next cylinder at TDC.

The crankshaft position sensor mounts to the

engine block behind the generator, just above the oil

filter (Fig. 7).

CAMSHAFT POSITION SENSOR

The PCM determines fuel injection synchronization

and cylinder identification from inputs provided by

Fig. 6 Timing Reference Notches

Fig. 7 Crankshaft Position Sensor

8D - 4 IGNITION SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 254 of 1200

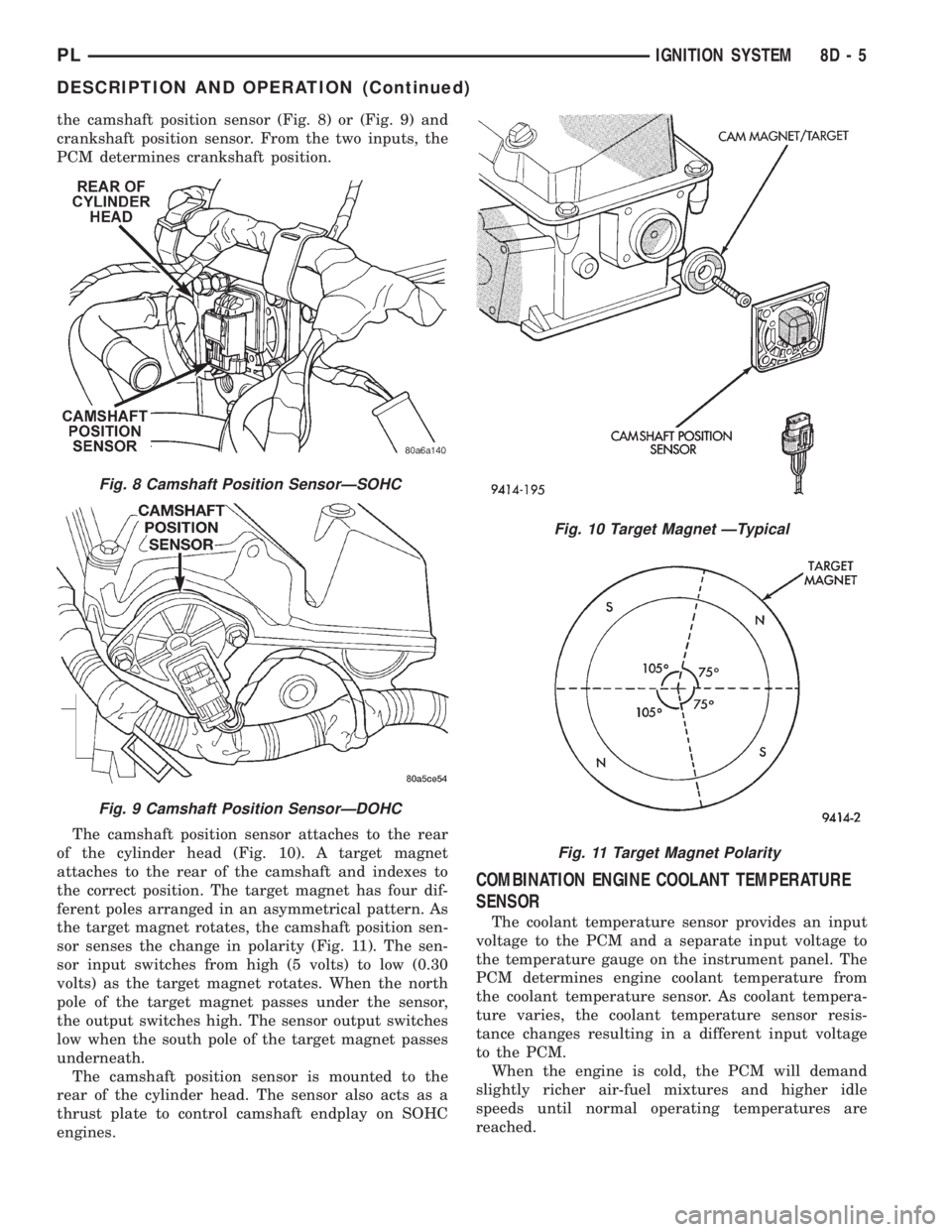

the camshaft position sensor (Fig. 8) or (Fig. 9) and

crankshaft position sensor. From the two inputs, the

PCM determines crankshaft position.

The camshaft position sensor attaches to the rear

of the cylinder head (Fig. 10). A target magnet

attaches to the rear of the camshaft and indexes to

the correct position. The target magnet has four dif-

ferent poles arranged in an asymmetrical pattern. As

the target magnet rotates, the camshaft position sen-

sor senses the change in polarity (Fig. 11). The sen-

sor input switches from high (5 volts) to low (0.30

volts) as the target magnet rotates. When the north

pole of the target magnet passes under the sensor,

the output switches high. The sensor output switches

low when the south pole of the target magnet passes

underneath.

The camshaft position sensor is mounted to the

rear of the cylinder head. The sensor also acts as a

thrust plate to control camshaft endplay on SOHC

engines.

COMBINATION ENGINE COOLANT TEMPERATURE

SENSOR

The coolant temperature sensor provides an input

voltage to the PCM and a separate input voltage to

the temperature gauge on the instrument panel. The

PCM determines engine coolant temperature from

the coolant temperature sensor. As coolant tempera-

ture varies, the coolant temperature sensor resis-

tance changes resulting in a different input voltage

to the PCM.

When the engine is cold, the PCM will demand

slightly richer air-fuel mixtures and higher idle

speeds until normal operating temperatures are

reached.

Fig. 8 Camshaft Position SensorÐSOHC

Fig. 9 Camshaft Position SensorÐDOHC

Fig. 10 Target Magnet ÐTypical

Fig. 11 Target Magnet Polarity

PLIGNITION SYSTEM 8D - 5

DESCRIPTION AND OPERATION (Continued)

Page 255 of 1200

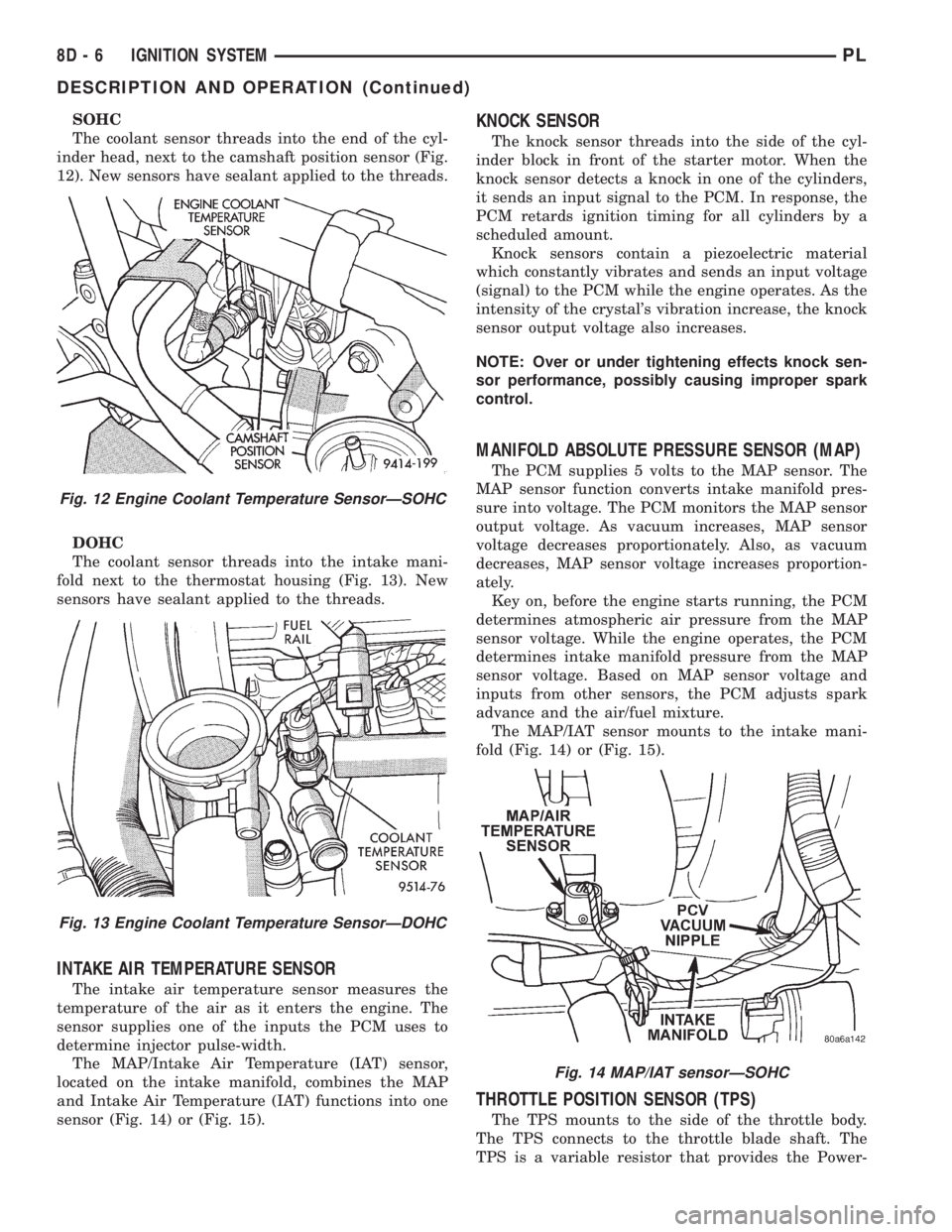

SOHC

The coolant sensor threads into the end of the cyl-

inder head, next to the camshaft position sensor (Fig.

12). New sensors have sealant applied to the threads.

DOHC

The coolant sensor threads into the intake mani-

fold next to the thermostat housing (Fig. 13). New

sensors have sealant applied to the threads.

INTAKE AIR TEMPERATURE SENSOR

The intake air temperature sensor measures the

temperature of the air as it enters the engine. The

sensor supplies one of the inputs the PCM uses to

determine injector pulse-width.

The MAP/Intake Air Temperature (IAT) sensor,

located on the intake manifold, combines the MAP

and Intake Air Temperature (IAT) functions into one

sensor (Fig. 14) or (Fig. 15).

KNOCK SENSOR

The knock sensor threads into the side of the cyl-

inder block in front of the starter motor. When the

knock sensor detects a knock in one of the cylinders,

it sends an input signal to the PCM. In response, the

PCM retards ignition timing for all cylinders by a

scheduled amount.

Knock sensors contain a piezoelectric material

which constantly vibrates and sends an input voltage

(signal) to the PCM while the engine operates. As the

intensity of the crystal's vibration increase, the knock

sensor output voltage also increases.

NOTE: Over or under tightening effects knock sen-

sor performance, possibly causing improper spark

control.

MANIFOLD ABSOLUTE PRESSURE SENSOR (MAP)

The PCM supplies 5 volts to the MAP sensor. The

MAP sensor function converts intake manifold pres-

sure into voltage. The PCM monitors the MAP sensor

output voltage. As vacuum increases, MAP sensor

voltage decreases proportionately. Also, as vacuum

decreases, MAP sensor voltage increases proportion-

ately.

Key on, before the engine starts running, the PCM

determines atmospheric air pressure from the MAP

sensor voltage. While the engine operates, the PCM

determines intake manifold pressure from the MAP

sensor voltage. Based on MAP sensor voltage and

inputs from other sensors, the PCM adjusts spark

advance and the air/fuel mixture.

The MAP/IAT sensor mounts to the intake mani-

fold (Fig. 14) or (Fig. 15).

THROTTLE POSITION SENSOR (TPS)

The TPS mounts to the side of the throttle body.

The TPS connects to the throttle blade shaft. The

TPS is a variable resistor that provides the Power-

Fig. 12 Engine Coolant Temperature SensorÐSOHC

Fig. 13 Engine Coolant Temperature SensorÐDOHC

Fig. 14 MAP/IAT sensorÐSOHC

8D - 6 IGNITION SYSTEMPL

DESCRIPTION AND OPERATION (Continued)