ignition DODGE NEON 1999 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 266 of 1200

(3) Install electrical connectors to ignition switch.

(4) Install upper and lower shrouds.

(5) Install key cylinder (cylinder retaining tab will

depress only in the RUN position).

(6) Connect negative cable to battery.

(7) Check for proper operation of ignition switch

and key-in warning switch.

LOCK KEY CYLINDER

The lock cylinder is inserted in the end of the

housing opposite the ignition switch. The ignition key

rotates the cylinder to 5 different detentes (Fig. 45):

²Accessory

²Off (lock)

²Unlock

²On/Run

²Start

REMOVAL

(1) Disconnect negative cable from battery.

(2) Place key cylinder in RUN position. Through

the hole in the lower shroud, depress lock cylinder

retaining tab and remove key cylinder.

INSTALLATION

(1) Install key in lock cylinder. Turn key to run

position (retaining tab on lock cylinder can be

depressed).

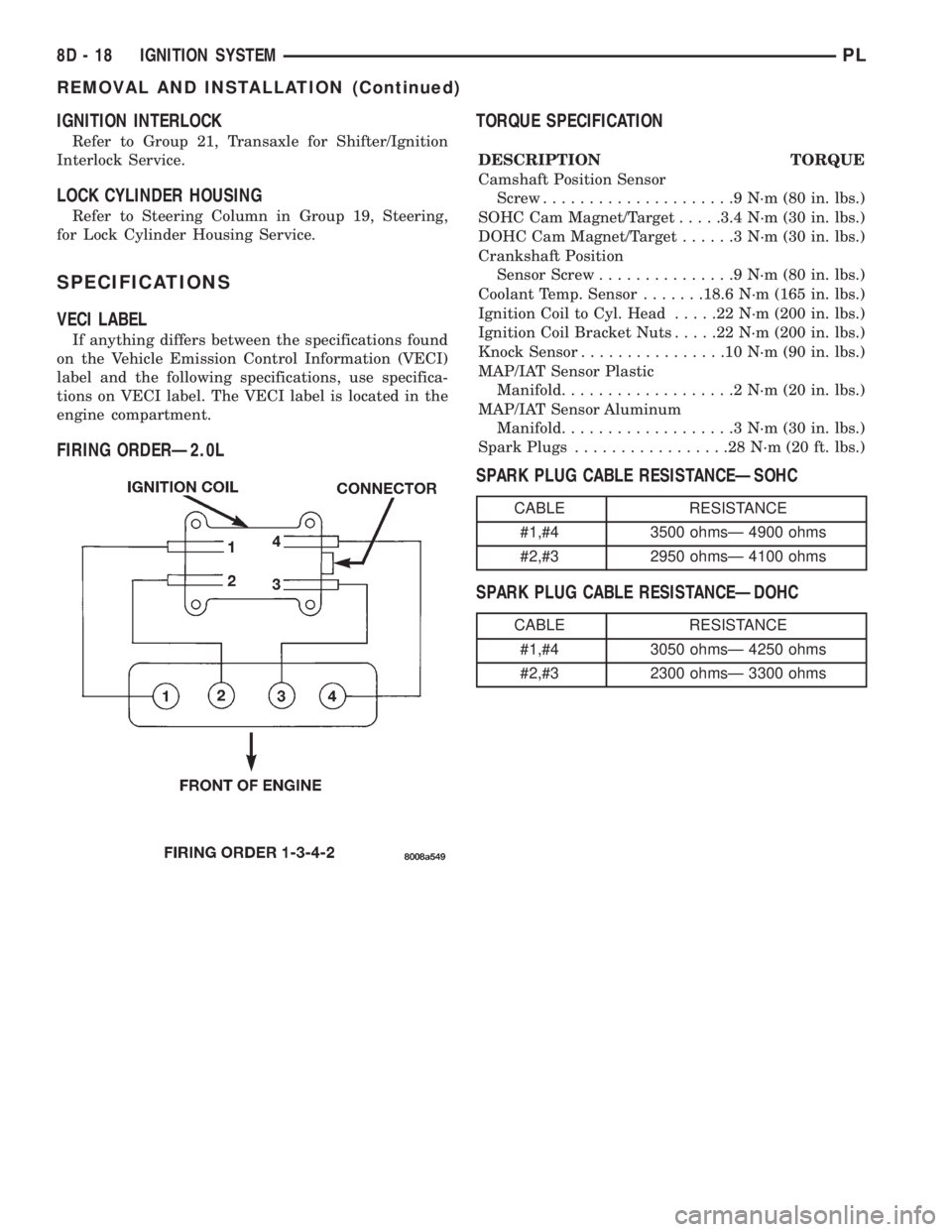

(2) The shaft at the end of the lock cylinder aligns

with the socket in the end of the housing. To align

the socket with the lock cylinder, ensure the socket is

in the Run position (Fig. 46).

(3) Align the lock cylinder with the grooves in the

housing. Slide the lock cylinder into the housing

until the tab sticks through the opening in the hous-

ing.

(4) Turn the key to the Off position. Remove the

key.

(5) Connect negative cable to battery.

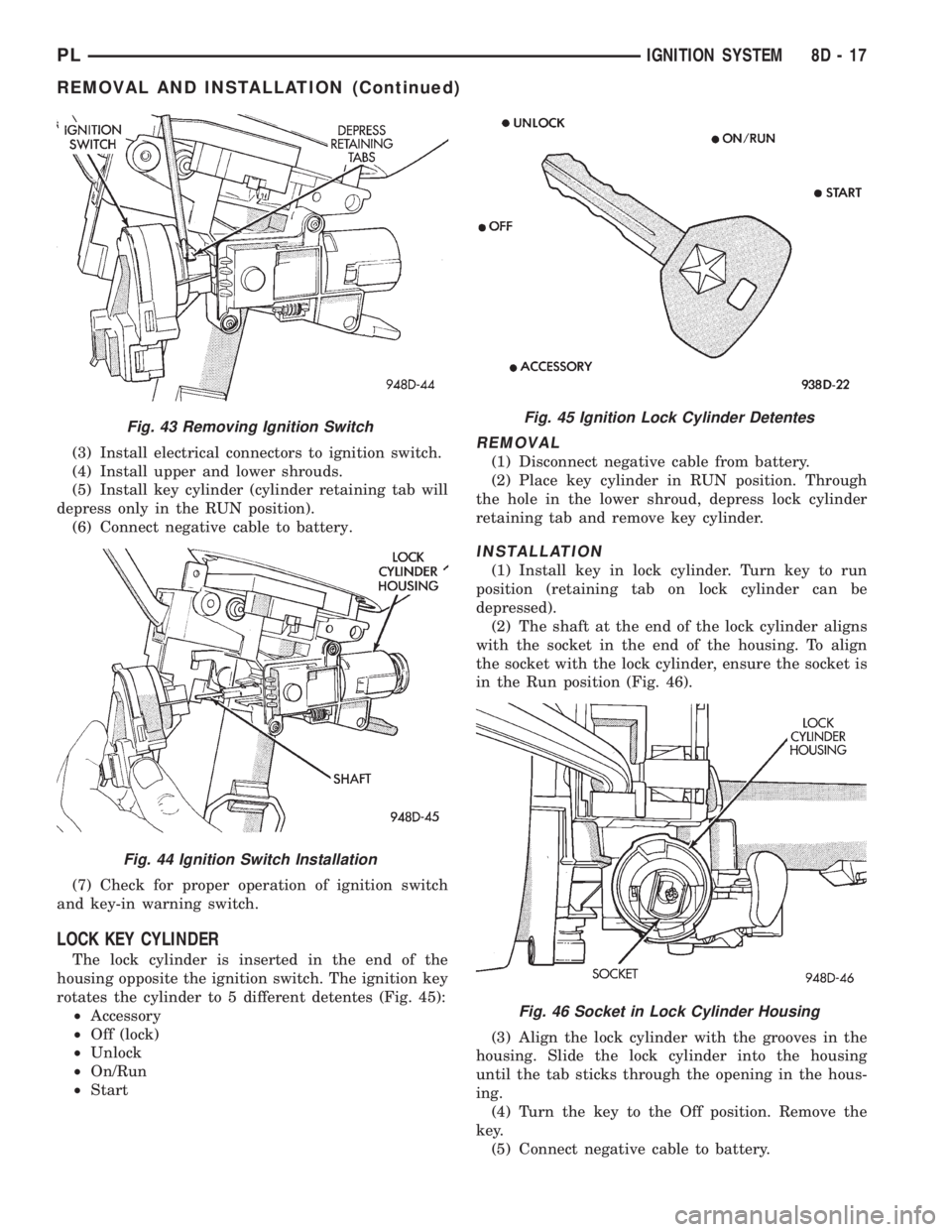

Fig. 43 Removing Ignition Switch

Fig. 44 Ignition Switch Installation

Fig. 45 Ignition Lock Cylinder Detentes

Fig. 46 Socket in Lock Cylinder Housing

PLIGNITION SYSTEM 8D - 17

REMOVAL AND INSTALLATION (Continued)

Page 267 of 1200

IGNITION INTERLOCK

Refer to Group 21, Transaxle for Shifter/Ignition

Interlock Service.

LOCK CYLINDER HOUSING

Refer to Steering Column in Group 19, Steering,

for Lock Cylinder Housing Service.

SPECIFICATIONS

VECI LABEL

If anything differs between the specifications found

on the Vehicle Emission Control Information (VECI)

label and the following specifications, use specifica-

tions on VECI label. The VECI label is located in the

engine compartment.

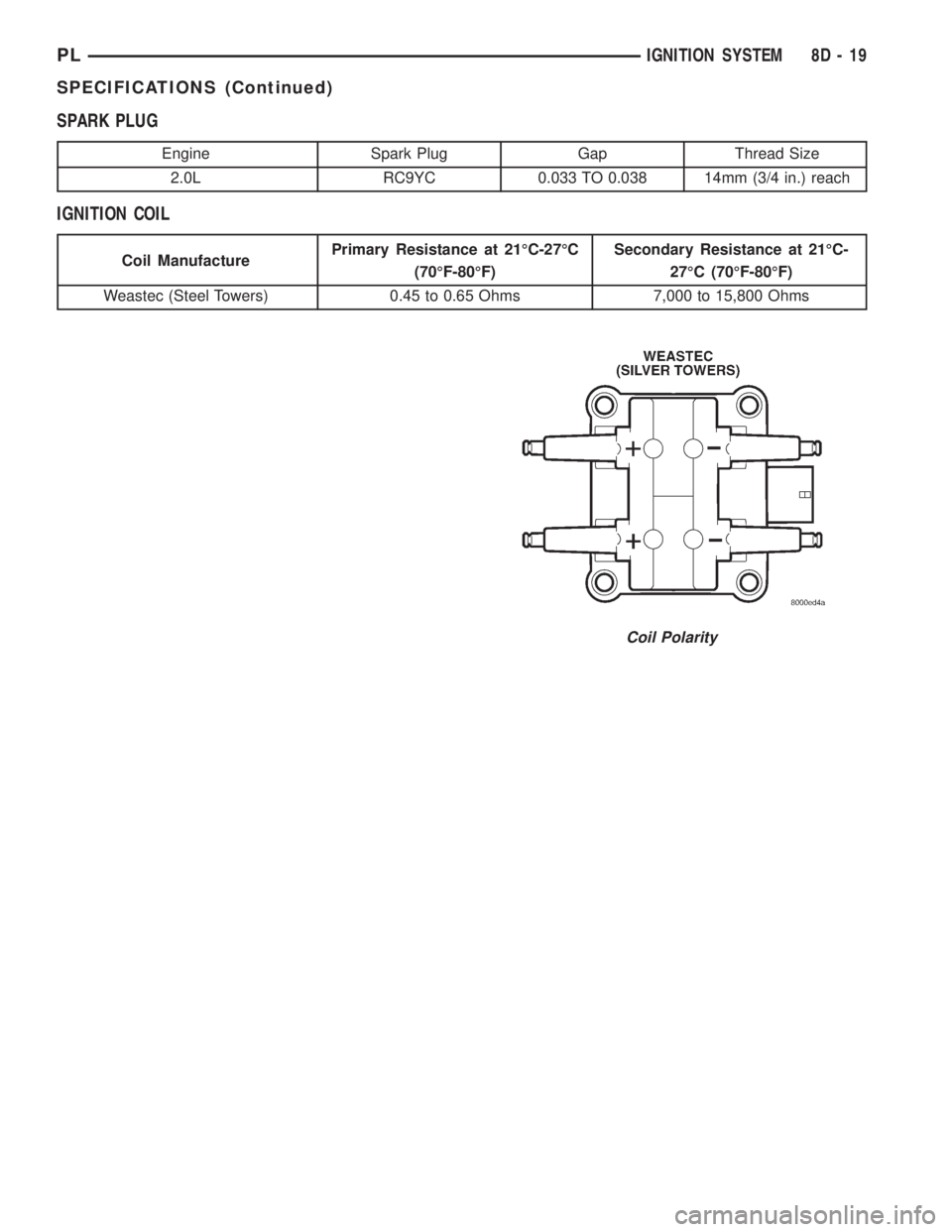

FIRING ORDERÐ2.0LTORQUE SPECIFICATION

DESCRIPTION TORQUE

Camshaft Position Sensor

Screw.....................9N´m(80in.lbs.)

SOHC Cam Magnet/Target.....3.4 N´m (30 in. lbs.)

DOHC Cam Magnet/Target......3N´m(30in.lbs.)

Crankshaft Position

Sensor Screw...............9N´m(80in.lbs.)

Coolant Temp. Sensor.......18.6 N´m (165 in. lbs.)

Ignition Coil to Cyl. Head.....22N´m(200 in. lbs.)

Ignition Coil Bracket Nuts.....22N´m(200 in. lbs.)

Knock Sensor................10N´m(90in.lbs.)

MAP/IAT Sensor Plastic

Manifold...................2N´m(20in.lbs.)

MAP/IAT Sensor Aluminum

Manifold...................3N´m(30in.lbs.)

Spark Plugs.................28N´m(20ft.lbs.)

SPARK PLUG CABLE RESISTANCEÐSOHC

SPARK PLUG CABLE RESISTANCEÐDOHC

CABLE RESISTANCE

#1,#4 3500 ohmsÐ 4900 ohms

#2,#3 2950 ohmsÐ 4100 ohms

CABLE RESISTANCE

#1,#4 3050 ohmsÐ 4250 ohms

#2,#3 2300 ohmsÐ 3300 ohms

8D - 18 IGNITION SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 268 of 1200

SPARK PLUG

IGNITION COIL

Coil Polarity

Engine Spark Plug Gap Thread Size

2.0L RC9YC 0.033 TO 0.038 14mm (3/4 in.) reach

Coil ManufacturePrimary Resistance at 21ÉC-27ÉC

(70ÉF-80ÉF)Secondary Resistance at 21ÉC-

27ÉC (70ÉF-80ÉF)

Weastec (Steel Towers) 0.45 to 0.65 Ohms 7,000 to 15,800 Ohms

PLIGNITION SYSTEM 8D - 19

SPECIFICATIONS (Continued)

Page 270 of 1200

INSTRUMENT PANEL AND SYSTEMS

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DESCRIPTION AND OPERATION

DOME LAMP............................ 1

ELECTRONIC DIGITAL CLOCK.............. 1

INSTRUMENT CLUSTER................... 2

WARNING AND INDICATOR LAMPS......... 2

DIAGNOSIS AND TESTING

AIRBAG WARNING SYSTEM............... 2

BRAKE SYSTEM WARNING LAMP TEST...... 2

FOG LAMP SWITCH TEST................. 2

FUEL TANK SENDING UNIT TEST........... 3

HEADLAMP SWITCH TEST................. 3

HEATER A/C BLOWER SWITCH TEST........ 3

HEATER BLOWER SWITCH TEST............ 3

INDIVIDUAL GAUGE INOPERATIVE.......... 4

INSTRUMENT PANEL AND COMPONENTS.... 4

LOW OIL PRESSURE WARNING LAMP TEST . . 4

MULTIPLE GAUGE INOPERATIVE TEST....... 4

SEAT BELT REMINDER SYSTEM TEST....... 6

SENDING UNIT......................... 6

SERVICE ENGINE SOON INDICATOR......... 6

VEHICLE SPEED SENSOR TEST............. 6

REMOVAL AND INSTALLATION

ASH RECEIVER RETAINER AND LAMP....... 6

CENTER BEZEL.......................... 6

CIGAR LIGHTER RECEPTACLE.............. 6

CLUSTER LAMP......................... 7

CLUSTER PRINTED CIRCUIT BOARD........ 7CLUSTER.............................. 7

DOME LENS/LAMP....................... 8

FLOOR CONSOLE........................ 8

GAUGE................................ 8

GLOVE BOX DOOR/BIN................... 8

GLOVE BOX SWITCH/LAMP................ 9

HEADLAMP SWITCH..................... 9

HEATER A/C CONTROL BLOWER SWITCH . . . 10

HEATER A/C CONTROL LAMP............ 10

HEATER A/C CONTROL................... 9

HEATER CONTROL BLOWER SWITCH....... 10

IGNITION KEY LAMP.................... 10

INSTRUMENT PANEL.................... 10

LEFT TRIM PANEL...................... 10

ODOMETER............................ 10

RADIO................................ 12

REAR WINDOW DEFOGGER AND/OR FOG

LAMP SWITCH....................... 12

RIGHT TRIM PANEL..................... 12

SHIFTER KNOB......................... 13

STEERING COLUMN COVER LINER......... 13

STEERING COLUMN COVER.............. 13

STEERING COLUMN SHROUDS............ 13

TOP COVER AND CLUSTER BEZEL

REMOVAL........................... 14

TRANSMISSION RANGE INDICATOR LAMP . . 14

TRUNK LAMP/LENS..................... 14

VEHICLE SPEED SENSOR................ 14

GENERAL INFORMATION

INTRODUCTION

The purpose of the dash gauges and indicator

lamps is to keep the driver informed about the oper-

ating condition of the vehicle. If an abnormal condi-

tion occurs, the driver is informed by indicator lamp.

The driver can seek service before damage occurs.

Indicator lamps use ON/OFF switch functions for

operation, while gauges use a sending unit or sensor.

DESCRIPTION AND OPERATION

DOME LAMP

The Dome Lamp operates when a door is open or

when the headlamp switch is placed in courtesy posi-

tion.

ELECTRONIC DIGITAL CLOCK

The electronic digital clock is in the radio. The

clock and radio each use the display panel built into

the radio. A digital readout indicates the time in

hours and minutes whenever the ignition switch is in

the ON or ACC position.

PLINSTRUMENT PANEL AND SYSTEMS 8E - 1

Page 271 of 1200

When the ignition switch is in the OFF position, or

when the radio frequency is being displayed, time

keeping is accurately maintained.

The procedure for setting the clock varies slightly

with each radio. The correct procedure is described in

the individual radio operating instructions. Refer to

the Owner's Manual supplied with the vehicle.

INSTRUMENT CLUSTER

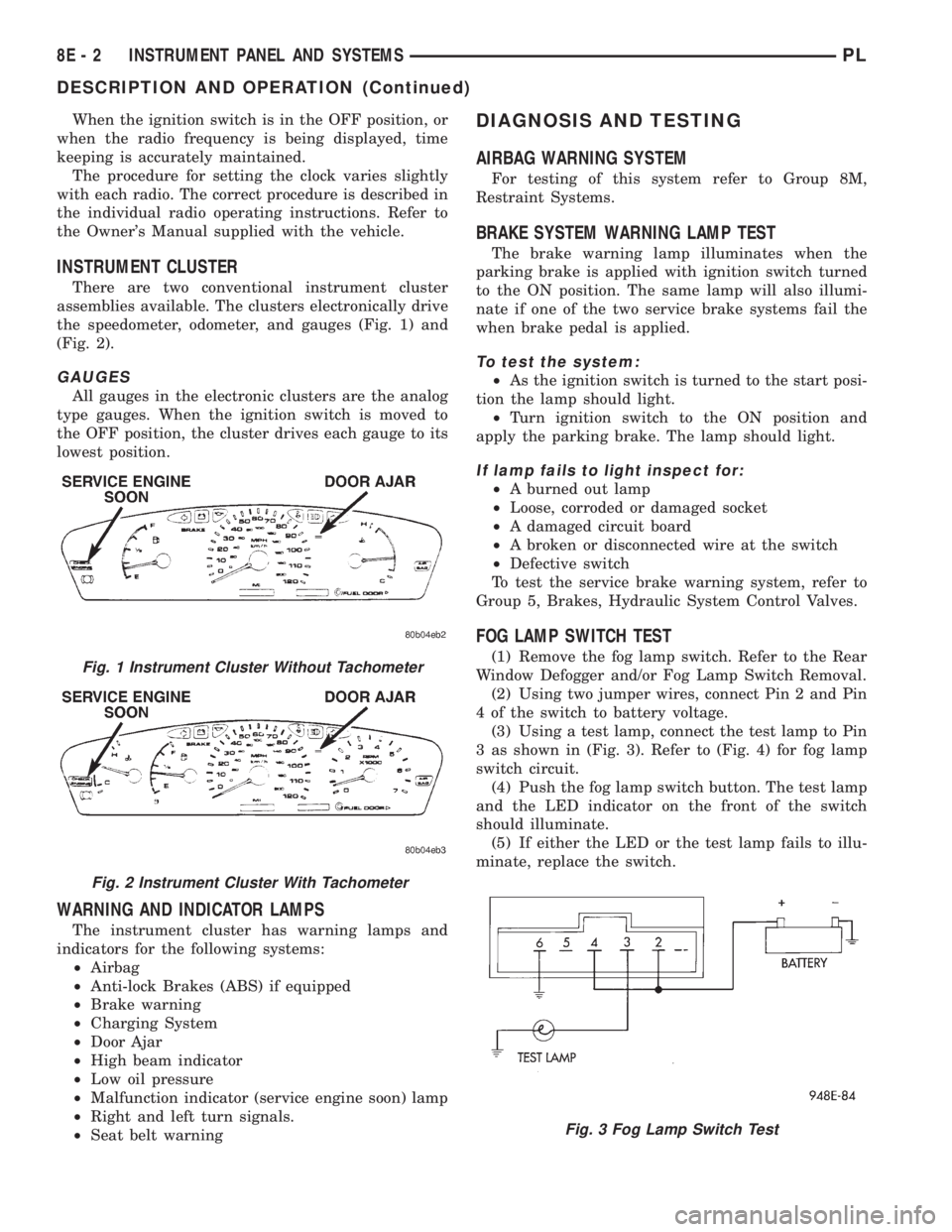

There are two conventional instrument cluster

assemblies available. The clusters electronically drive

the speedometer, odometer, and gauges (Fig. 1) and

(Fig. 2).

GAUGES

All gauges in the electronic clusters are the analog

type gauges. When the ignition switch is moved to

the OFF position, the cluster drives each gauge to its

lowest position.

WARNING AND INDICATOR LAMPS

The instrument cluster has warning lamps and

indicators for the following systems:

²Airbag

²Anti-lock Brakes (ABS) if equipped

²Brake warning

²Charging System

²Door Ajar

²High beam indicator

²Low oil pressure

²Malfunction indicator (service engine soon) lamp

²Right and left turn signals.

²Seat belt warning

DIAGNOSIS AND TESTING

AIRBAG WARNING SYSTEM

For testing of this system refer to Group 8M,

Restraint Systems.

BRAKE SYSTEM WARNING LAMP TEST

The brake warning lamp illuminates when the

parking brake is applied with ignition switch turned

to the ON position. The same lamp will also illumi-

nate if one of the two service brake systems fail the

when brake pedal is applied.

To test the system:

²As the ignition switch is turned to the start posi-

tion the lamp should light.

²Turn ignition switch to the ON position and

apply the parking brake. The lamp should light.

If lamp fails to light inspect for:

²A burned out lamp

²Loose, corroded or damaged socket

²A damaged circuit board

²A broken or disconnected wire at the switch

²Defective switch

To test the service brake warning system, refer to

Group 5, Brakes, Hydraulic System Control Valves.

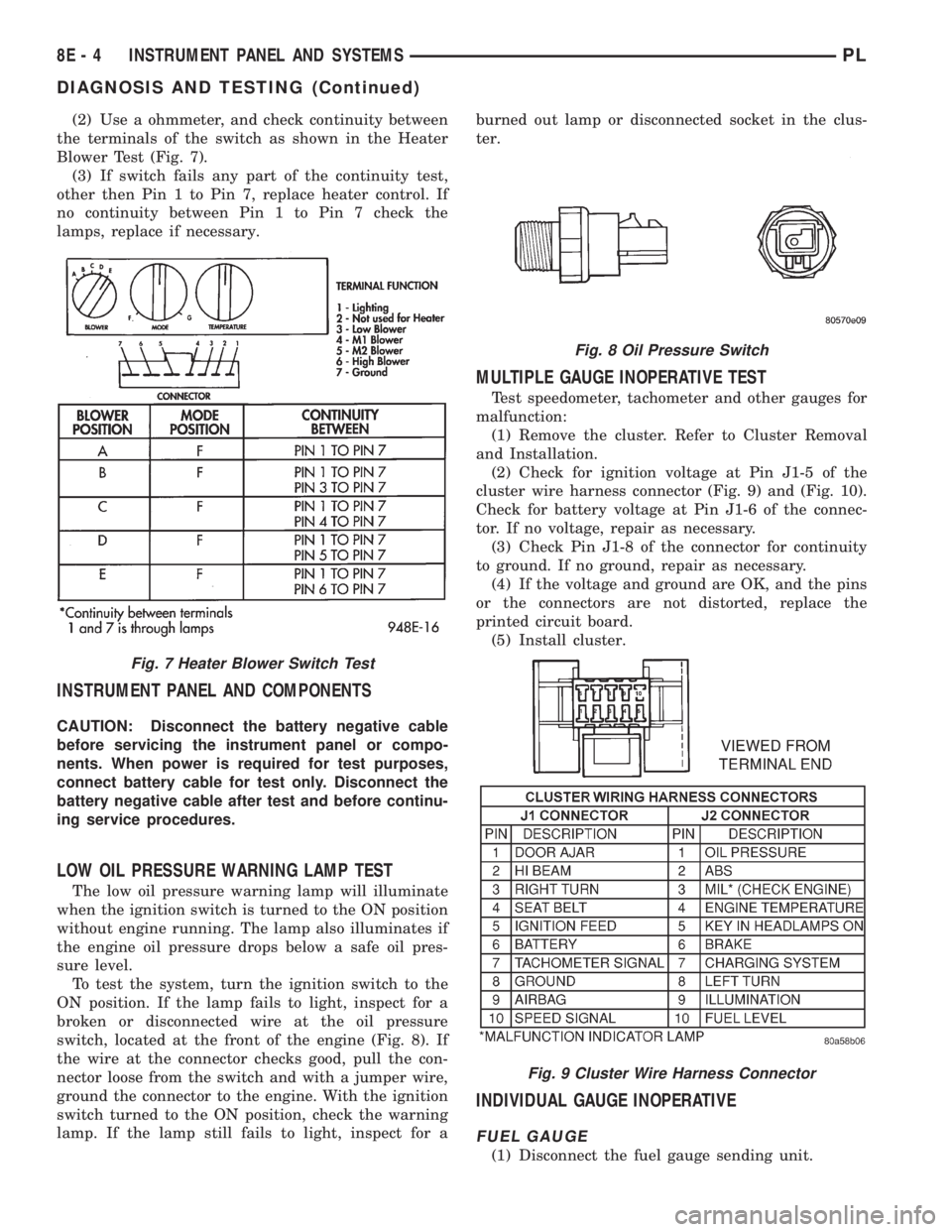

FOG LAMP SWITCH TEST

(1) Remove the fog lamp switch. Refer to the Rear

Window Defogger and/or Fog Lamp Switch Removal.

(2) Using two jumper wires, connect Pin 2 and Pin

4 of the switch to battery voltage.

(3) Using a test lamp, connect the test lamp to Pin

3 as shown in (Fig. 3). Refer to (Fig. 4) for fog lamp

switch circuit.

(4) Push the fog lamp switch button. The test lamp

and the LED indicator on the front of the switch

should illuminate.

(5) If either the LED or the test lamp fails to illu-

minate, replace the switch.Fig. 1 Instrument Cluster Without Tachometer

Fig. 2 Instrument Cluster With Tachometer

Fig. 3 Fog Lamp Switch Test

8E - 2 INSTRUMENT PANEL AND SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 273 of 1200

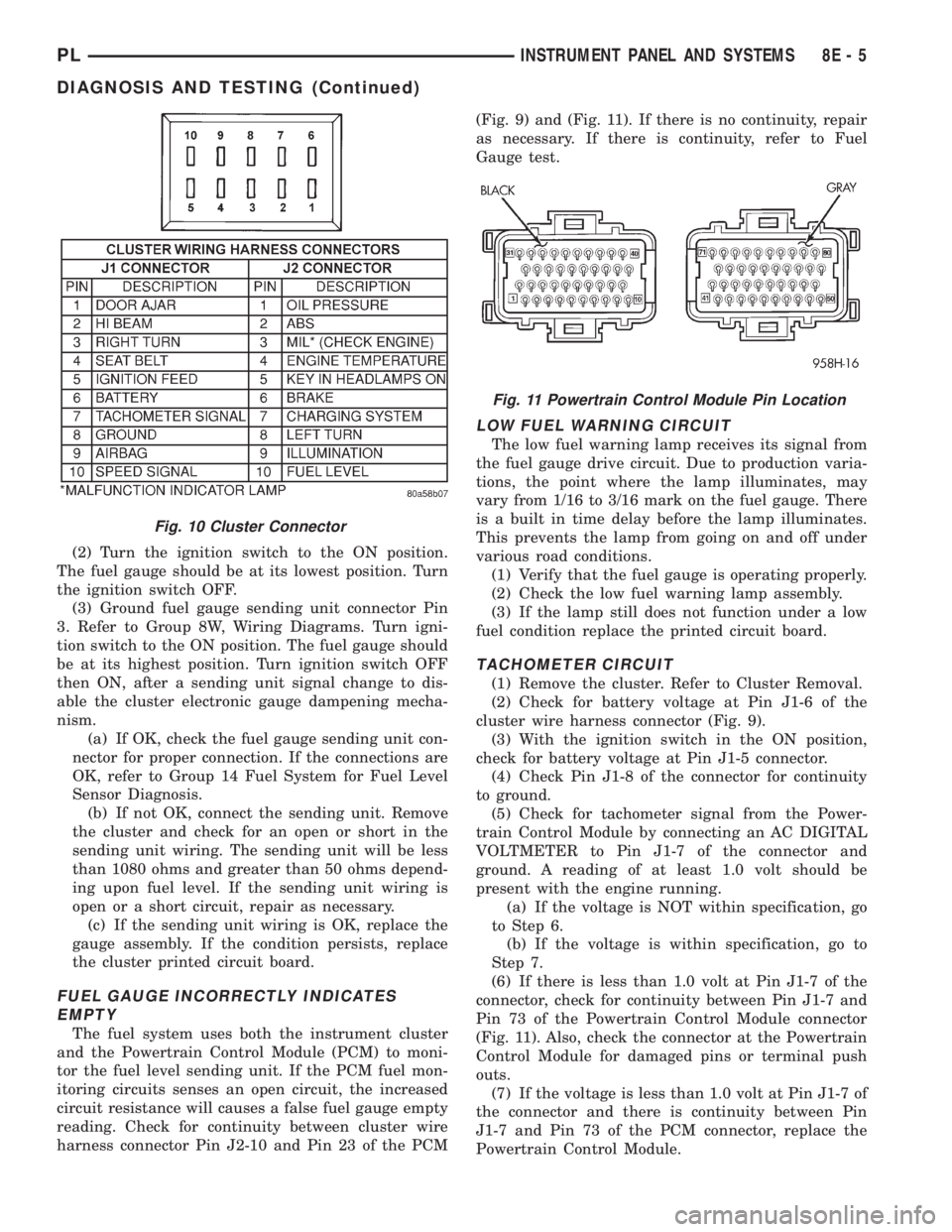

(2) Use a ohmmeter, and check continuity between

the terminals of the switch as shown in the Heater

Blower Test (Fig. 7).

(3) If switch fails any part of the continuity test,

other then Pin 1 to Pin 7, replace heater control. If

no continuity between Pin 1 to Pin 7 check the

lamps, replace if necessary.

INSTRUMENT PANEL AND COMPONENTS

CAUTION: Disconnect the battery negative cable

before servicing the instrument panel or compo-

nents. When power is required for test purposes,

connect battery cable for test only. Disconnect the

battery negative cable after test and before continu-

ing service procedures.

LOW OIL PRESSURE WARNING LAMP TEST

The low oil pressure warning lamp will illuminate

when the ignition switch is turned to the ON position

without engine running. The lamp also illuminates if

the engine oil pressure drops below a safe oil pres-

sure level.

To test the system, turn the ignition switch to the

ON position. If the lamp fails to light, inspect for a

broken or disconnected wire at the oil pressure

switch, located at the front of the engine (Fig. 8). If

the wire at the connector checks good, pull the con-

nector loose from the switch and with a jumper wire,

ground the connector to the engine. With the ignition

switch turned to the ON position, check the warning

lamp. If the lamp still fails to light, inspect for aburned out lamp or disconnected socket in the clus-

ter.

MULTIPLE GAUGE INOPERATIVE TEST

Test speedometer, tachometer and other gauges for

malfunction:

(1) Remove the cluster. Refer to Cluster Removal

and Installation.

(2) Check for ignition voltage at Pin J1-5 of the

cluster wire harness connector (Fig. 9) and (Fig. 10).

Check for battery voltage at Pin J1-6 of the connec-

tor. If no voltage, repair as necessary.

(3) Check Pin J1-8 of the connector for continuity

to ground. If no ground, repair as necessary.

(4) If the voltage and ground are OK, and the pins

or the connectors are not distorted, replace the

printed circuit board.

(5) Install cluster.

INDIVIDUAL GAUGE INOPERATIVE

FUEL GAUGE

(1) Disconnect the fuel gauge sending unit.

Fig. 7 Heater Blower Switch Test

Fig. 8 Oil Pressure Switch

Fig. 9 Cluster Wire Harness Connector

8E - 4 INSTRUMENT PANEL AND SYSTEMSPL

DIAGNOSIS AND TESTING (Continued)

Page 274 of 1200

(2) Turn the ignition switch to the ON position.

The fuel gauge should be at its lowest position. Turn

the ignition switch OFF.

(3) Ground fuel gauge sending unit connector Pin

3. Refer to Group 8W, Wiring Diagrams. Turn igni-

tion switch to the ON position. The fuel gauge should

be at its highest position. Turn ignition switch OFF

then ON, after a sending unit signal change to dis-

able the cluster electronic gauge dampening mecha-

nism.

(a) If OK, check the fuel gauge sending unit con-

nector for proper connection. If the connections are

OK, refer to Group 14 Fuel System for Fuel Level

Sensor Diagnosis.

(b) If not OK, connect the sending unit. Remove

the cluster and check for an open or short in the

sending unit wiring. The sending unit will be less

than 1080 ohms and greater than 50 ohms depend-

ing upon fuel level. If the sending unit wiring is

open or a short circuit, repair as necessary.

(c) If the sending unit wiring is OK, replace the

gauge assembly. If the condition persists, replace

the cluster printed circuit board.

FUEL GAUGE INCORRECTLY INDICATES

EMPTY

The fuel system uses both the instrument cluster

and the Powertrain Control Module (PCM) to moni-

tor the fuel level sending unit. If the PCM fuel mon-

itoring circuits senses an open circuit, the increased

circuit resistance will causes a false fuel gauge empty

reading. Check for continuity between cluster wire

harness connector Pin J2-10 and Pin 23 of the PCM(Fig. 9) and (Fig. 11). If there is no continuity, repair

as necessary. If there is continuity, refer to Fuel

Gauge test.

LOW FUEL WARNING CIRCUIT

The low fuel warning lamp receives its signal from

the fuel gauge drive circuit. Due to production varia-

tions, the point where the lamp illuminates, may

vary from 1/16 to 3/16 mark on the fuel gauge. There

is a built in time delay before the lamp illuminates.

This prevents the lamp from going on and off under

various road conditions.

(1) Verify that the fuel gauge is operating properly.

(2) Check the low fuel warning lamp assembly.

(3) If the lamp still does not function under a low

fuel condition replace the printed circuit board.

TACHOMETER CIRCUIT

(1) Remove the cluster. Refer to Cluster Removal.

(2) Check for battery voltage at Pin J1-6 of the

cluster wire harness connector (Fig. 9).

(3) With the ignition switch in the ON position,

check for battery voltage at Pin J1-5 connector.

(4) Check Pin J1-8 of the connector for continuity

to ground.

(5) Check for tachometer signal from the Power-

train Control Module by connecting an AC DIGITAL

VOLTMETER to Pin J1-7 of the connector and

ground. A reading of at least 1.0 volt should be

present with the engine running.

(a) If the voltage is NOT within specification, go

to Step 6.

(b) If the voltage is within specification, go to

Step 7.

(6) If there is less than 1.0 volt at Pin J1-7 of the

connector, check for continuity between Pin J1-7 and

Pin 73 of the Powertrain Control Module connector

(Fig. 11). Also, check the connector at the Powertrain

Control Module for damaged pins or terminal push

outs.

(7) If the voltage is less than 1.0 volt at Pin J1-7 of

the connector and there is continuity between Pin

J1-7 and Pin 73 of the PCM connector, replace the

Powertrain Control Module.

Fig. 10 Cluster Connector

Fig. 11 Powertrain Control Module Pin Location

PLINSTRUMENT PANEL AND SYSTEMS 8E - 5

DIAGNOSIS AND TESTING (Continued)

Page 275 of 1200

(8) If all tests performed test good, replace the dial

and gauge assembly.

(9) If the tachometer continues to be inoperative,

replace the print circuit board.

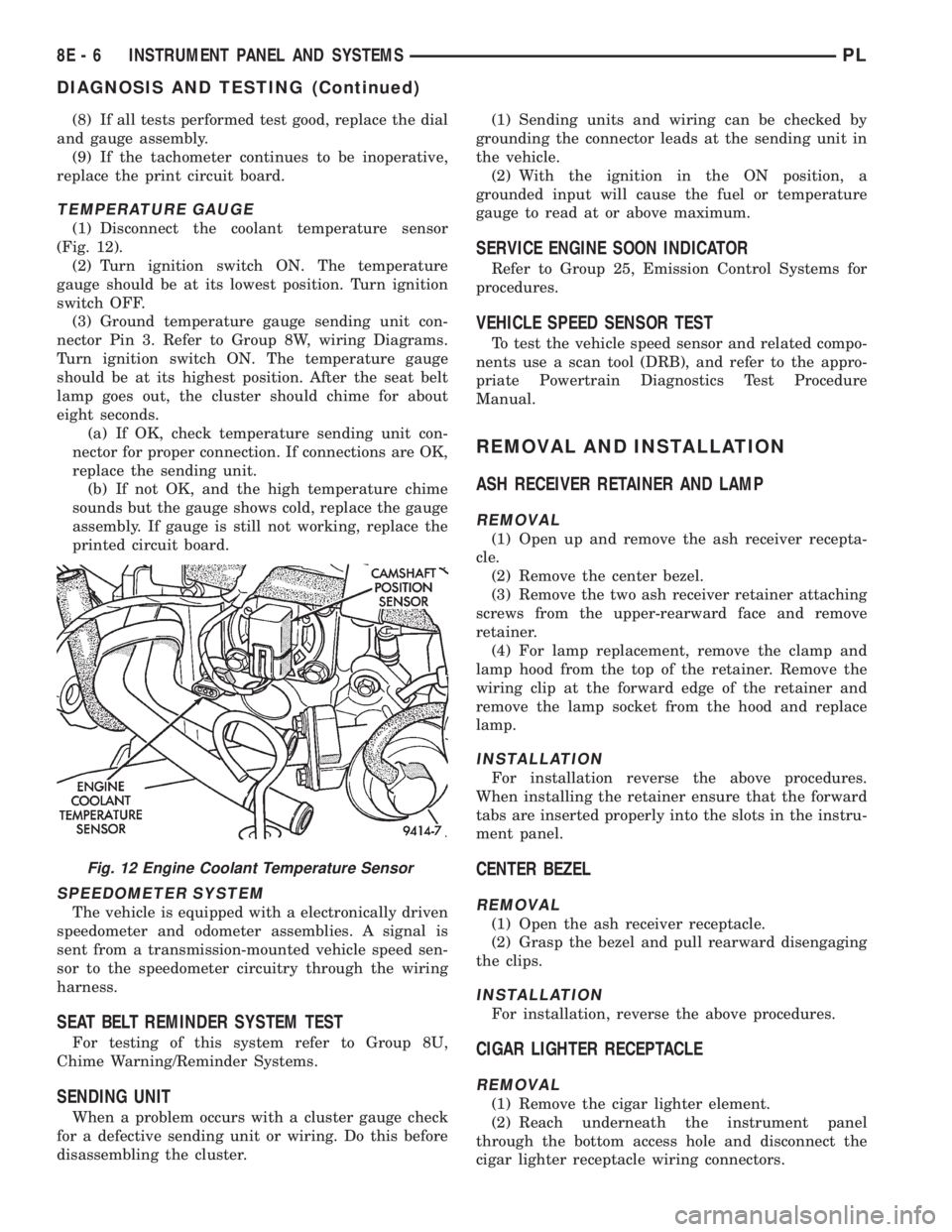

TEMPERATURE GAUGE

(1) Disconnect the coolant temperature sensor

(Fig. 12).

(2) Turn ignition switch ON. The temperature

gauge should be at its lowest position. Turn ignition

switch OFF.

(3) Ground temperature gauge sending unit con-

nector Pin 3. Refer to Group 8W, wiring Diagrams.

Turn ignition switch ON. The temperature gauge

should be at its highest position. After the seat belt

lamp goes out, the cluster should chime for about

eight seconds.

(a) If OK, check temperature sending unit con-

nector for proper connection. If connections are OK,

replace the sending unit.

(b) If not OK, and the high temperature chime

sounds but the gauge shows cold, replace the gauge

assembly. If gauge is still not working, replace the

printed circuit board.

SPEEDOMETER SYSTEM

The vehicle is equipped with a electronically driven

speedometer and odometer assemblies. A signal is

sent from a transmission-mounted vehicle speed sen-

sor to the speedometer circuitry through the wiring

harness.

SEAT BELT REMINDER SYSTEM TEST

For testing of this system refer to Group 8U,

Chime Warning/Reminder Systems.

SENDING UNIT

When a problem occurs with a cluster gauge check

for a defective sending unit or wiring. Do this before

disassembling the cluster.(1) Sending units and wiring can be checked by

grounding the connector leads at the sending unit in

the vehicle.

(2) With the ignition in the ON position, a

grounded input will cause the fuel or temperature

gauge to read at or above maximum.

SERVICE ENGINE SOON INDICATOR

Refer to Group 25, Emission Control Systems for

procedures.

VEHICLE SPEED SENSOR TEST

To test the vehicle speed sensor and related compo-

nents use a scan tool (DRB), and refer to the appro-

priate Powertrain Diagnostics Test Procedure

Manual.

REMOVAL AND INSTALLATION

ASH RECEIVER RETAINER AND LAMP

REMOVAL

(1) Open up and remove the ash receiver recepta-

cle.

(2) Remove the center bezel.

(3) Remove the two ash receiver retainer attaching

screws from the upper-rearward face and remove

retainer.

(4) For lamp replacement, remove the clamp and

lamp hood from the top of the retainer. Remove the

wiring clip at the forward edge of the retainer and

remove the lamp socket from the hood and replace

lamp.

INSTALLATION

For installation reverse the above procedures.

When installing the retainer ensure that the forward

tabs are inserted properly into the slots in the instru-

ment panel.

CENTER BEZEL

REMOVAL

(1) Open the ash receiver receptacle.

(2) Grasp the bezel and pull rearward disengaging

the clips.

INSTALLATION

For installation, reverse the above procedures.

CIGAR LIGHTER RECEPTACLE

REMOVAL

(1) Remove the cigar lighter element.

(2) Reach underneath the instrument panel

through the bottom access hole and disconnect the

cigar lighter receptacle wiring connectors.

Fig. 12 Engine Coolant Temperature Sensor

8E - 6 INSTRUMENT PANEL AND SYSTEMSPL

DIAGNOSIS AND TESTING (Continued)

Page 279 of 1200

HEATER A/C CONTROL BLOWER SWITCH

The switch is not serviced, replace heater A/C con-

trol. Refer to the Heater A/C Control Removal and

Installation.

HEATER A/C CONTROL LAMP

REMOVAL

(1) Remove the Heater A/C Control. Refer to the

Heater A/C Control Removal.

(2) Remove the two center knobs by pulling the

knob rearward.

(3) Replace the lamp.

INSTALLATION

For installation, reverse the above procedures.

HEATER CONTROL BLOWER SWITCH

The switch is not serviced, replace the heater con-

trol. Refer to the A/C Heater Control Removal and

Installation.

IGNITION KEY LAMP

REMOVAL

(1) Remove the steering column cover. Refer to

Steering Column Cover Removal.

(2) Disconnect the lamp hood from the base panel.

(3) Remove the lamp socket from hood and replace

the lamp.

INSTALLATION

For installation, reverse the above procedures.

INSTRUMENT PANEL

REMOVAL

CAUTION: Disconnect battery negative cable, in

engine compartment, before servicing instrument

panel.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the floor console. Refer to Floor Con-

sole Removal.

(3) Remove the right and left cowl side trim pan-

els (Fig. 19).

(4) Remove the steering column cover and liner.

(5) Remove the top cover and cluster bezel assem-

bly.

(6) Remove the right and left trim panel.

(7) Remove the defroster upper duct by lifting it

up.

(8) Remove the center outlet duct by pulling rear-

ward.(9) Disconnect the Heater A/C Control, by remov-

ing the control cables clips with a screwdriver and

remove the wire connector.

CAUTION: Lock the steering wheel in the straight

ahead position. This will prevent clockspring dam-

age when the steering wheel rotates freely.

(10) Disconnect the steering column at the bottom

slap together joint.

(11) Disconnect the ATX shifter interlock cable at

the shifter, if equipped.

(12) Disconnect the instrument panel wiring as

required.

(13) Remove the four attaching screws at the cen-

ter floor pan bracket (Fig. 20).

(14) Remove the four attaching screws at steering

column.

(15) Remove the four cowl top nuts.

(16) Remove the attaching screws from the left

and right lower cowl side bracket (Fig. 21).

(17) Remove the two attaching screws from the left

upper cowl side and one from the right upper cowl

side.

(18) Pull the instrument panel rearward away

from the dash/plenum.

(19) Remove the instrument panel from vehicle.

INSTALLATION

For installation, reverse the above procedures.

LEFT TRIM PANEL

REMOVAL

(1) Remove the top cover and cluster bezel (Fig.

19).

(2) Remove the steering column cover.

(3) Remove the two attaching screws along the

bottom and the one at the top of the trim panel and

pull rearward to remove.

INSTALLATION

For installation, reverse the above procedures.

ODOMETER

REMOVAL

(1) Remove the instrument panel top cover and

cluster bezel.

(2) Remove the four screws attaching cluster to

instrument panel (Fig. 22).

(3) Remove the cluster.

(4) Remove the screws attaching PC board cover to

cluster.

(5) Disconnect the odometer connector from the

printed circuit board.

8E - 10 INSTRUMENT PANEL AND SYSTEMSPL

REMOVAL AND INSTALLATION (Continued)

Page 283 of 1200

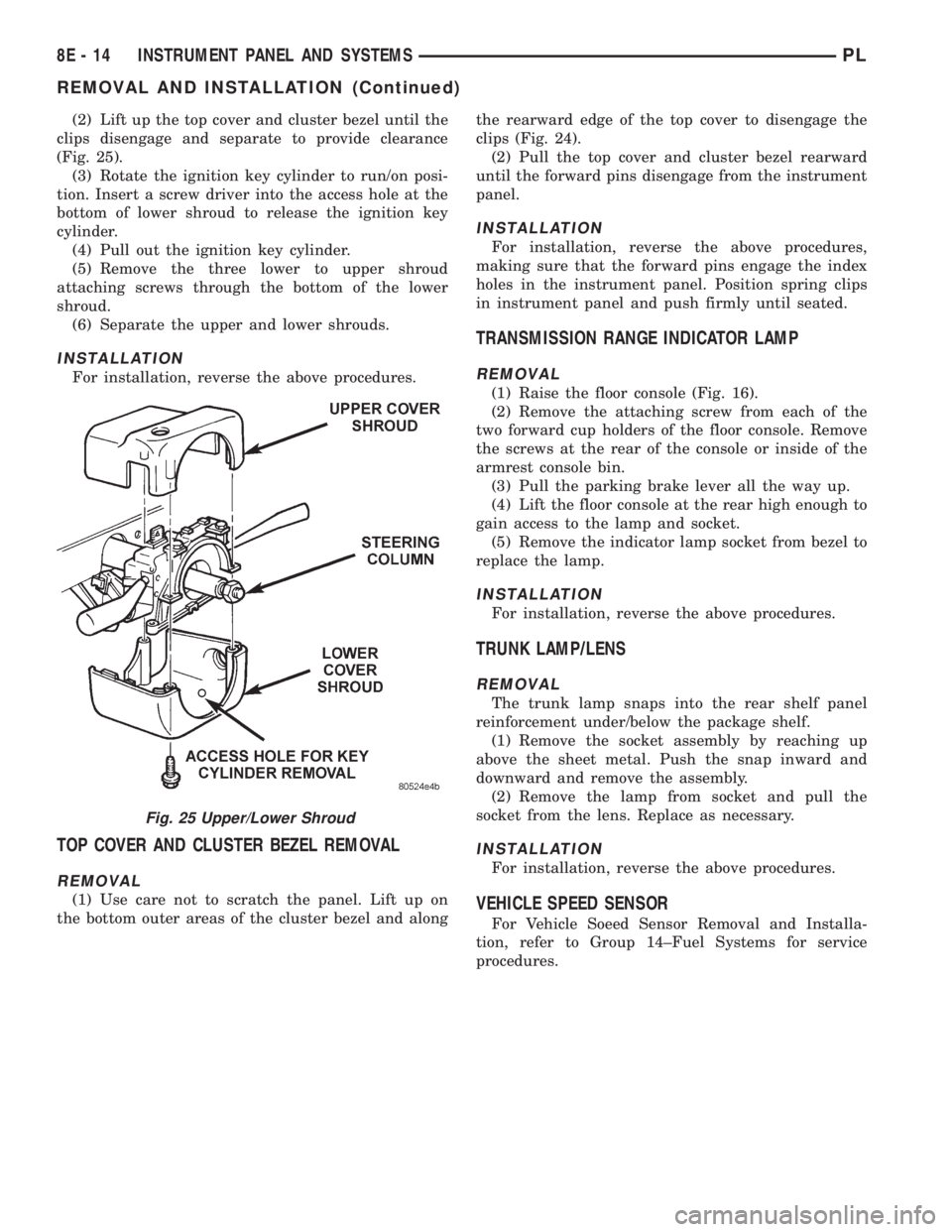

(2) Lift up the top cover and cluster bezel until the

clips disengage and separate to provide clearance

(Fig. 25).

(3) Rotate the ignition key cylinder to run/on posi-

tion. Insert a screw driver into the access hole at the

bottom of lower shroud to release the ignition key

cylinder.

(4) Pull out the ignition key cylinder.

(5) Remove the three lower to upper shroud

attaching screws through the bottom of the lower

shroud.

(6) Separate the upper and lower shrouds.

INSTALLATION

For installation, reverse the above procedures.

TOP COVER AND CLUSTER BEZEL REMOVAL

REMOVAL

(1) Use care not to scratch the panel. Lift up on

the bottom outer areas of the cluster bezel and alongthe rearward edge of the top cover to disengage the

clips (Fig. 24).

(2) Pull the top cover and cluster bezel rearward

until the forward pins disengage from the instrument

panel.

INSTALLATION

For installation, reverse the above procedures,

making sure that the forward pins engage the index

holes in the instrument panel. Position spring clips

in instrument panel and push firmly until seated.

TRANSMISSION RANGE INDICATOR LAMP

REMOVAL

(1) Raise the floor console (Fig. 16).

(2) Remove the attaching screw from each of the

two forward cup holders of the floor console. Remove

the screws at the rear of the console or inside of the

armrest console bin.

(3) Pull the parking brake lever all the way up.

(4) Lift the floor console at the rear high enough to

gain access to the lamp and socket.

(5) Remove the indicator lamp socket from bezel to

replace the lamp.

INSTALLATION

For installation, reverse the above procedures.

TRUNK LAMP/LENS

REMOVAL

The trunk lamp snaps into the rear shelf panel

reinforcement under/below the package shelf.

(1) Remove the socket assembly by reaching up

above the sheet metal. Push the snap inward and

downward and remove the assembly.

(2) Remove the lamp from socket and pull the

socket from the lens. Replace as necessary.

INSTALLATION

For installation, reverse the above procedures.

VEHICLE SPEED SENSOR

For Vehicle Soeed Sensor Removal and Installa-

tion, refer to Group 14±Fuel Systems for service

procedures.

Fig. 25 Upper/Lower Shroud

8E - 14 INSTRUMENT PANEL AND SYSTEMSPL

REMOVAL AND INSTALLATION (Continued)