ECU DODGE NEON 1999 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 852 of 1200

The hose clamps have rolled edges to prevent the

clamp from cutting into the hose. Only use clamps

that are original equipment or equivalent. Other

types of clamps may cut into the hoses and cause

high pressure fuel leaks. Tighten hose clamps to 1

N´m (10 in. lbs.) torque.

QUICK-CONNECT FITTINGS

REMOVAL

When disconnecting a quick-connect fitting, the

retainer will remain on the fuel tube nipple.

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE DISCONNECTING A QUICK-CONNECT FIT-

TINGS. REFER TO THE FUEL PRESSURE RELEASE

PROCEDURE.

(1) Disconnect negative cable from battery.

(2) Perform Fuel Pressure Release Procedure.

Refer to the Fuel Pressure Release Procedure in this

section.

(3) Squeeze retainer tabs together and pull fuel

tube/quick-connect fitting assembly off of fuel tube

nipple. The retainer will remain on fuel tube.

INSTALLATION

CAUTION: Never install a quick-connect fitting

without the retainer being either on the fuel tube or

already in the quick-connect fitting. In either case,

ensure the retainer locks securely into the quick-

connect fitting by firmly pulling on fuel tube and fit-

ting to ensure it is secured.

(1) Using a clean lint free cloth, clean the fuel tube

nipple and retainer.

(2) Prior to connecting the fitting to the fuel tube,

coat the fuel tube nipple with clean 30 weight engine

oil.

(3) Push the quick-connect fitting over the fuel

tube until theretainer seats and a click is heard.

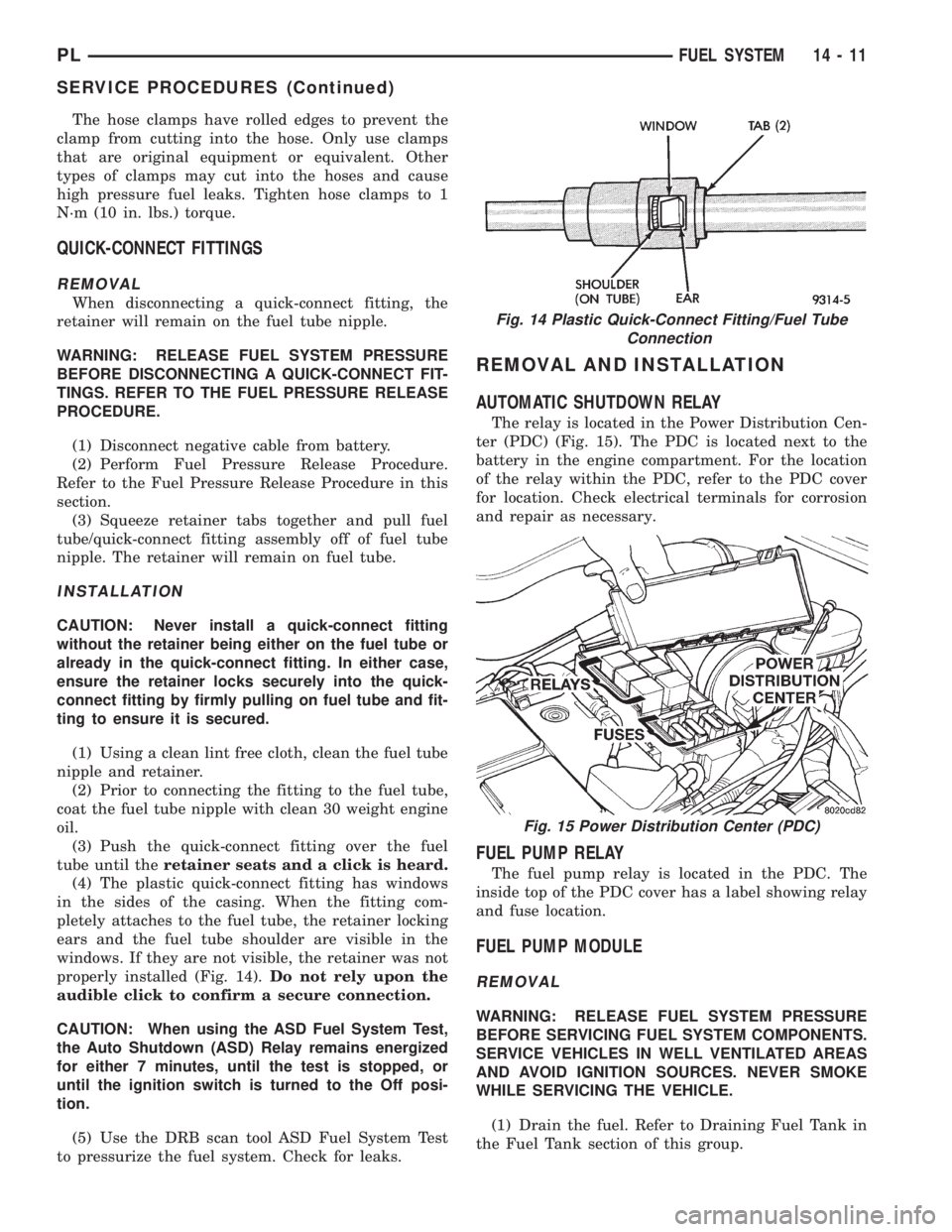

(4) The plastic quick-connect fitting has windows

in the sides of the casing. When the fitting com-

pletely attaches to the fuel tube, the retainer locking

ears and the fuel tube shoulder are visible in the

windows. If they are not visible, the retainer was not

properly installed (Fig. 14).Do not rely upon the

audible click to confirm a secure connection.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or

until the ignition switch is turned to the Off posi-

tion.

(5) Use the DRB scan tool ASD Fuel System Test

to pressurize the fuel system. Check for leaks.

REMOVAL AND INSTALLATION

AUTOMATIC SHUTDOWN RELAY

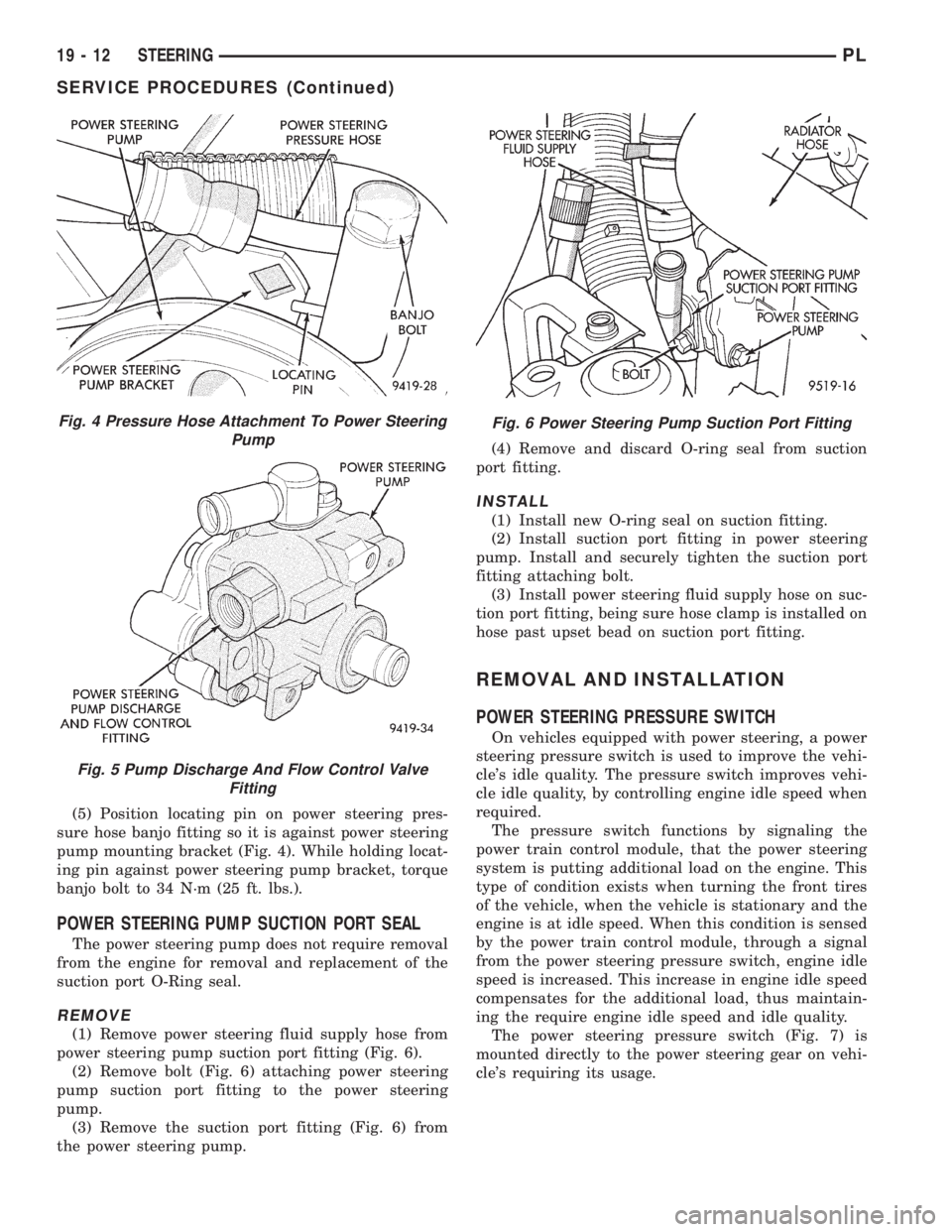

The relay is located in the Power Distribution Cen-

ter (PDC) (Fig. 15). The PDC is located next to the

battery in the engine compartment. For the location

of the relay within the PDC, refer to the PDC cover

for location. Check electrical terminals for corrosion

and repair as necessary.

FUEL PUMP RELAY

The fuel pump relay is located in the PDC. The

inside top of the PDC cover has a label showing relay

and fuse location.

FUEL PUMP MODULE

REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE.

(1) Drain the fuel. Refer to Draining Fuel Tank in

the Fuel Tank section of this group.

Fig. 14 Plastic Quick-Connect Fitting/Fuel Tube

Connection

Fig. 15 Power Distribution Center (PDC)

PLFUEL SYSTEM 14 - 11

SERVICE PROCEDURES (Continued)

Page 913 of 1200

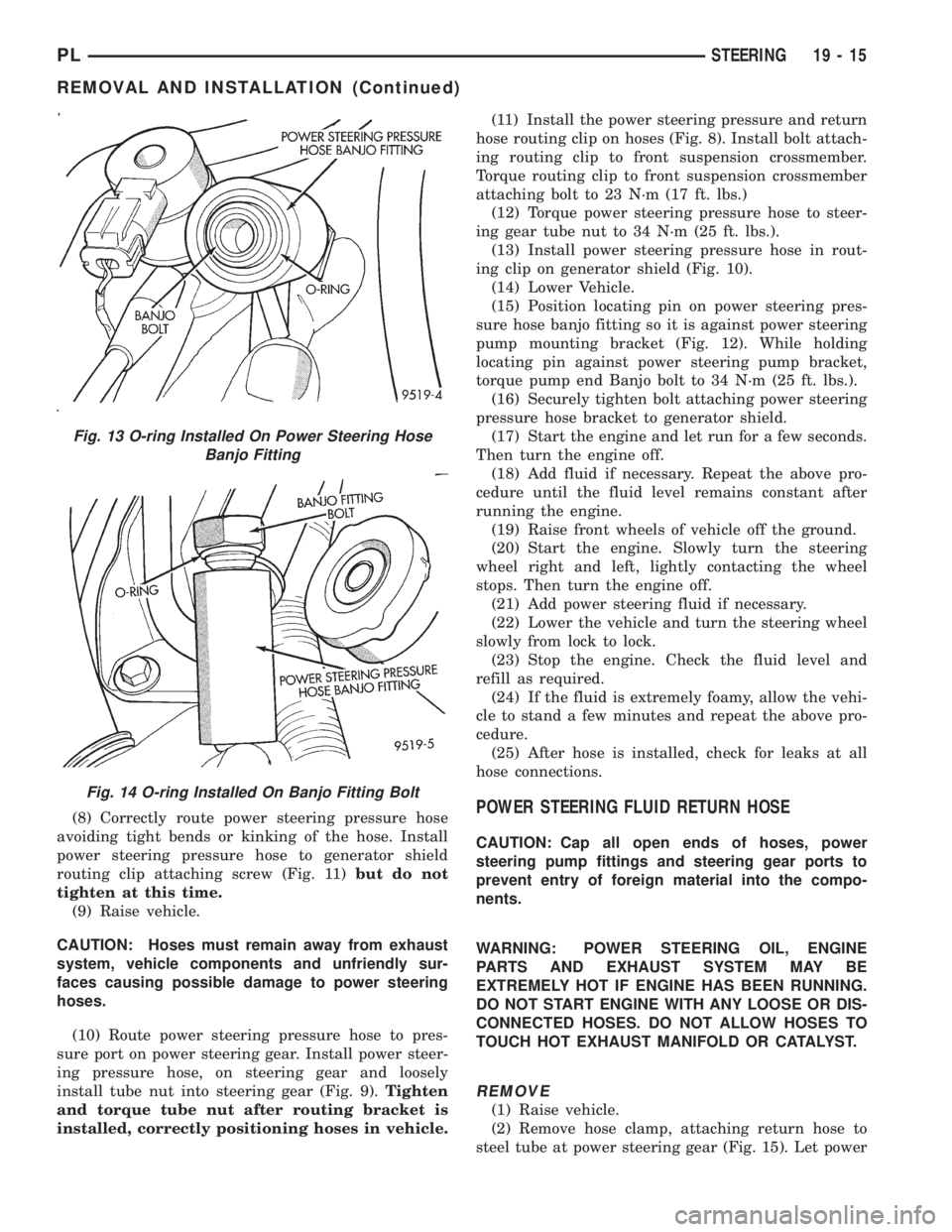

(5) Position locating pin on power steering pres-

sure hose banjo fitting so it is against power steering

pump mounting bracket (Fig. 4). While holding locat-

ing pin against power steering pump bracket, torque

banjo bolt to 34 N´m (25 ft. lbs.).

POWER STEERING PUMP SUCTION PORT SEAL

The power steering pump does not require removal

from the engine for removal and replacement of the

suction port O-Ring seal.

REMOVE

(1) Remove power steering fluid supply hose from

power steering pump suction port fitting (Fig. 6).

(2) Remove bolt (Fig. 6) attaching power steering

pump suction port fitting to the power steering

pump.

(3) Remove the suction port fitting (Fig. 6) from

the power steering pump.(4) Remove and discard O-ring seal from suction

port fitting.

INSTALL

(1) Install new O-ring seal on suction fitting.

(2) Install suction port fitting in power steering

pump. Install and securely tighten the suction port

fitting attaching bolt.

(3) Install power steering fluid supply hose on suc-

tion port fitting, being sure hose clamp is installed on

hose past upset bead on suction port fitting.

REMOVAL AND INSTALLATION

POWER STEERING PRESSURE SWITCH

On vehicles equipped with power steering, a power

steering pressure switch is used to improve the vehi-

cle's idle quality. The pressure switch improves vehi-

cle idle quality, by controlling engine idle speed when

required.

The pressure switch functions by signaling the

power train control module, that the power steering

system is putting additional load on the engine. This

type of condition exists when turning the front tires

of the vehicle, when the vehicle is stationary and the

engine is at idle speed. When this condition is sensed

by the power train control module, through a signal

from the power steering pressure switch, engine idle

speed is increased. This increase in engine idle speed

compensates for the additional load, thus maintain-

ing the require engine idle speed and idle quality.

The power steering pressure switch (Fig. 7) is

mounted directly to the power steering gear on vehi-

cle's requiring its usage.

Fig. 4 Pressure Hose Attachment To Power Steering

Pump

Fig. 5 Pump Discharge And Flow Control Valve

Fitting

Fig. 6 Power Steering Pump Suction Port Fitting

19 - 12 STEERINGPL

SERVICE PROCEDURES (Continued)

Page 916 of 1200

(8) Correctly route power steering pressure hose

avoiding tight bends or kinking of the hose. Install

power steering pressure hose to generator shield

routing clip attaching screw (Fig. 11)but do not

tighten at this time.

(9) Raise vehicle.

CAUTION: Hoses must remain away from exhaust

system, vehicle components and unfriendly sur-

faces causing possible damage to power steering

hoses.

(10) Route power steering pressure hose to pres-

sure port on power steering gear. Install power steer-

ing pressure hose, on steering gear and loosely

install tube nut into steering gear (Fig. 9).Tighten

and torque tube nut after routing bracket is

installed, correctly positioning hoses in vehicle.(11) Install the power steering pressure and return

hose routing clip on hoses (Fig. 8). Install bolt attach-

ing routing clip to front suspension crossmember.

Torque routing clip to front suspension crossmember

attaching bolt to 23 N´m (17 ft. lbs.)

(12) Torque power steering pressure hose to steer-

ing gear tube nut to 34 N´m (25 ft. lbs.).

(13) Install power steering pressure hose in rout-

ing clip on generator shield (Fig. 10).

(14) Lower Vehicle.

(15) Position locating pin on power steering pres-

sure hose banjo fitting so it is against power steering

pump mounting bracket (Fig. 12). While holding

locating pin against power steering pump bracket,

torque pump end Banjo bolt to 34 N´m (25 ft. lbs.).

(16) Securely tighten bolt attaching power steering

pressure hose bracket to generator shield.

(17) Start the engine and let run for a few seconds.

Then turn the engine off.

(18) Add fluid if necessary. Repeat the above pro-

cedure until the fluid level remains constant after

running the engine.

(19) Raise front wheels of vehicle off the ground.

(20) Start the engine. Slowly turn the steering

wheel right and left, lightly contacting the wheel

stops. Then turn the engine off.

(21) Add power steering fluid if necessary.

(22) Lower the vehicle and turn the steering wheel

slowly from lock to lock.

(23) Stop the engine. Check the fluid level and

refill as required.

(24) If the fluid is extremely foamy, allow the vehi-

cle to stand a few minutes and repeat the above pro-

cedure.

(25) After hose is installed, check for leaks at all

hose connections.POWER STEERING FLUID RETURN HOSE

CAUTION: Cap all open ends of hoses, power

steering pump fittings and steering gear ports to

prevent entry of foreign material into the compo-

nents.

WARNING: POWER STEERING OIL, ENGINE

PARTS AND EXHAUST SYSTEM MAY BE

EXTREMELY HOT IF ENGINE HAS BEEN RUNNING.

DO NOT START ENGINE WITH ANY LOOSE OR DIS-

CONNECTED HOSES. DO NOT ALLOW HOSES TO

TOUCH HOT EXHAUST MANIFOLD OR CATALYST.

REMOVE

(1) Raise vehicle.

(2) Remove hose clamp, attaching return hose to

steel tube at power steering gear (Fig. 15). Let power

Fig. 13 O-ring Installed On Power Steering Hose

Banjo Fitting

Fig. 14 O-ring Installed On Banjo Fitting Bolt

PLSTEERING 19 - 15

REMOVAL AND INSTALLATION (Continued)

Page 923 of 1200

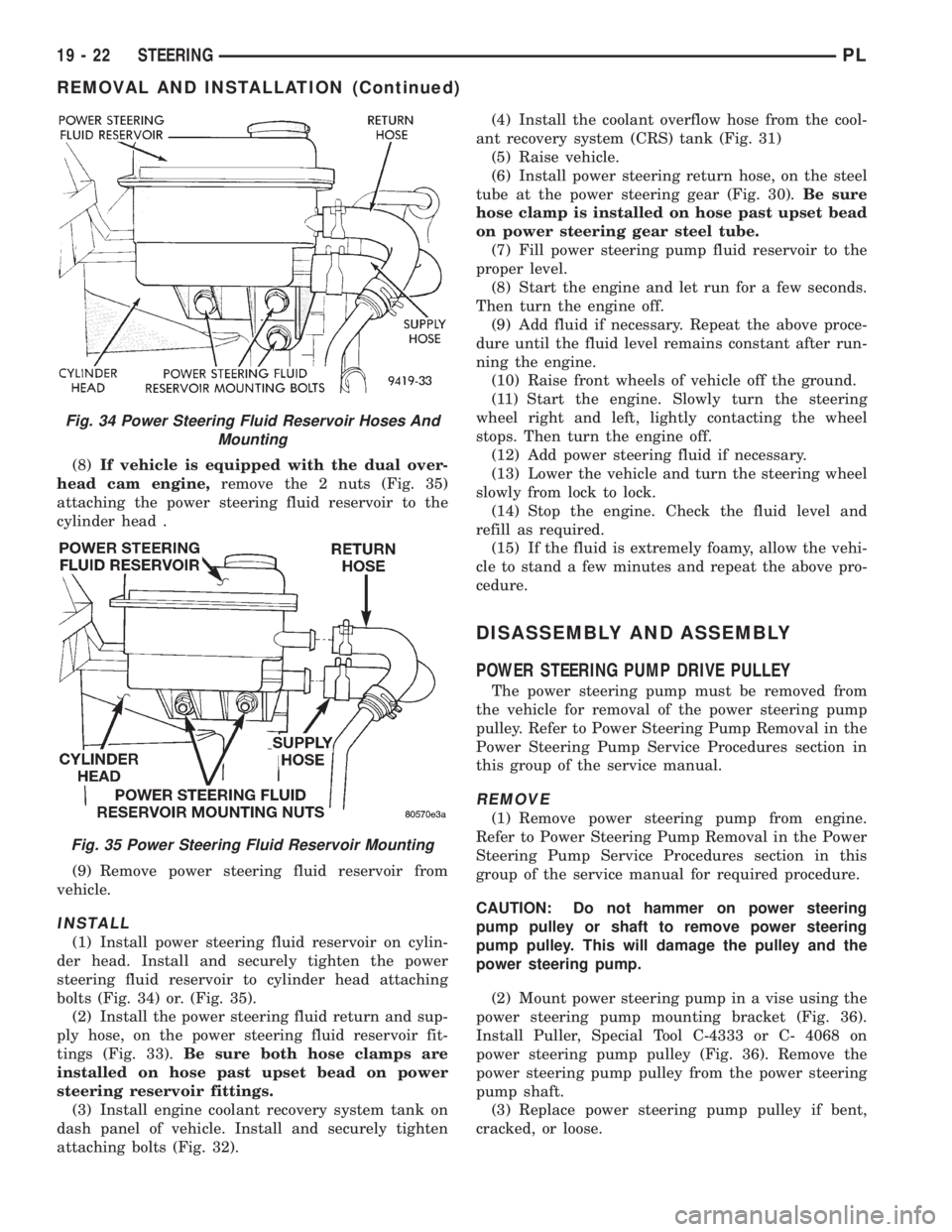

(8)If vehicle is equipped with the dual over-

head cam engine,remove the 2 nuts (Fig. 35)

attaching the power steering fluid reservoir to the

cylinder head .

(9) Remove power steering fluid reservoir from

vehicle.

INSTALL

(1) Install power steering fluid reservoir on cylin-

der head. Install and securely tighten the power

steering fluid reservoir to cylinder head attaching

bolts (Fig. 34) or. (Fig. 35).

(2) Install the power steering fluid return and sup-

ply hose, on the power steering fluid reservoir fit-

tings (Fig. 33).Be sure both hose clamps are

installed on hose past upset bead on power

steering reservoir fittings.

(3) Install engine coolant recovery system tank on

dash panel of vehicle. Install and securely tighten

attaching bolts (Fig. 32).(4) Install the coolant overflow hose from the cool-

ant recovery system (CRS) tank (Fig. 31)

(5) Raise vehicle.

(6) Install power steering return hose, on the steel

tube at the power steering gear (Fig. 30).Be sure

hose clamp is installed on hose past upset bead

on power steering gear steel tube.

(7) Fill power steering pump fluid reservoir to the

proper level.

(8) Start the engine and let run for a few seconds.

Then turn the engine off.

(9) Add fluid if necessary. Repeat the above proce-

dure until the fluid level remains constant after run-

ning the engine.

(10) Raise front wheels of vehicle off the ground.

(11) Start the engine. Slowly turn the steering

wheel right and left, lightly contacting the wheel

stops. Then turn the engine off.

(12) Add power steering fluid if necessary.

(13) Lower the vehicle and turn the steering wheel

slowly from lock to lock.

(14) Stop the engine. Check the fluid level and

refill as required.

(15) If the fluid is extremely foamy, allow the vehi-

cle to stand a few minutes and repeat the above pro-

cedure.

DISASSEMBLY AND ASSEMBLY

POWER STEERING PUMP DRIVE PULLEY

The power steering pump must be removed from

the vehicle for removal of the power steering pump

pulley. Refer to Power Steering Pump Removal in the

Power Steering Pump Service Procedures section in

this group of the service manual.

REMOVE

(1) Remove power steering pump from engine.

Refer to Power Steering Pump Removal in the Power

Steering Pump Service Procedures section in this

group of the service manual for required procedure.

CAUTION: Do not hammer on power steering

pump pulley or shaft to remove power steering

pump pulley. This will damage the pulley and the

power steering pump.

(2) Mount power steering pump in a vise using the

power steering pump mounting bracket (Fig. 36).

Install Puller, Special Tool C-4333 or C- 4068 on

power steering pump pulley (Fig. 36). Remove the

power steering pump pulley from the power steering

pump shaft.

(3) Replace power steering pump pulley if bent,

cracked, or loose.

Fig. 34 Power Steering Fluid Reservoir Hoses And

Mounting

Fig. 35 Power Steering Fluid Reservoir Mounting

19 - 22 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 932 of 1200

Torque the 4 steering gear mounting bolts to 68 N´m

(50 ft. lbs.).

(2) Using the transmission jack, raise front sus-

pension crossmember and steering gear against body

and frame rails of vehicle. Start the 2 rear bolts into

tapping plates, attaching front suspension crossmem-

ber to body of vehicle (Fig. 13). Then install the 2

front bolts, attaching front suspension crossmember

to frame rails of vehicle (Fig. 13). Tighten the 4

mounting bolts, until front suspension crossmember

is against body of vehicle at the 4 mounting points.

Then torque the 4 mounting bolts to 2 N´m (20 in.

lbs.) to hold front suspension crossmember in posi-

tion.

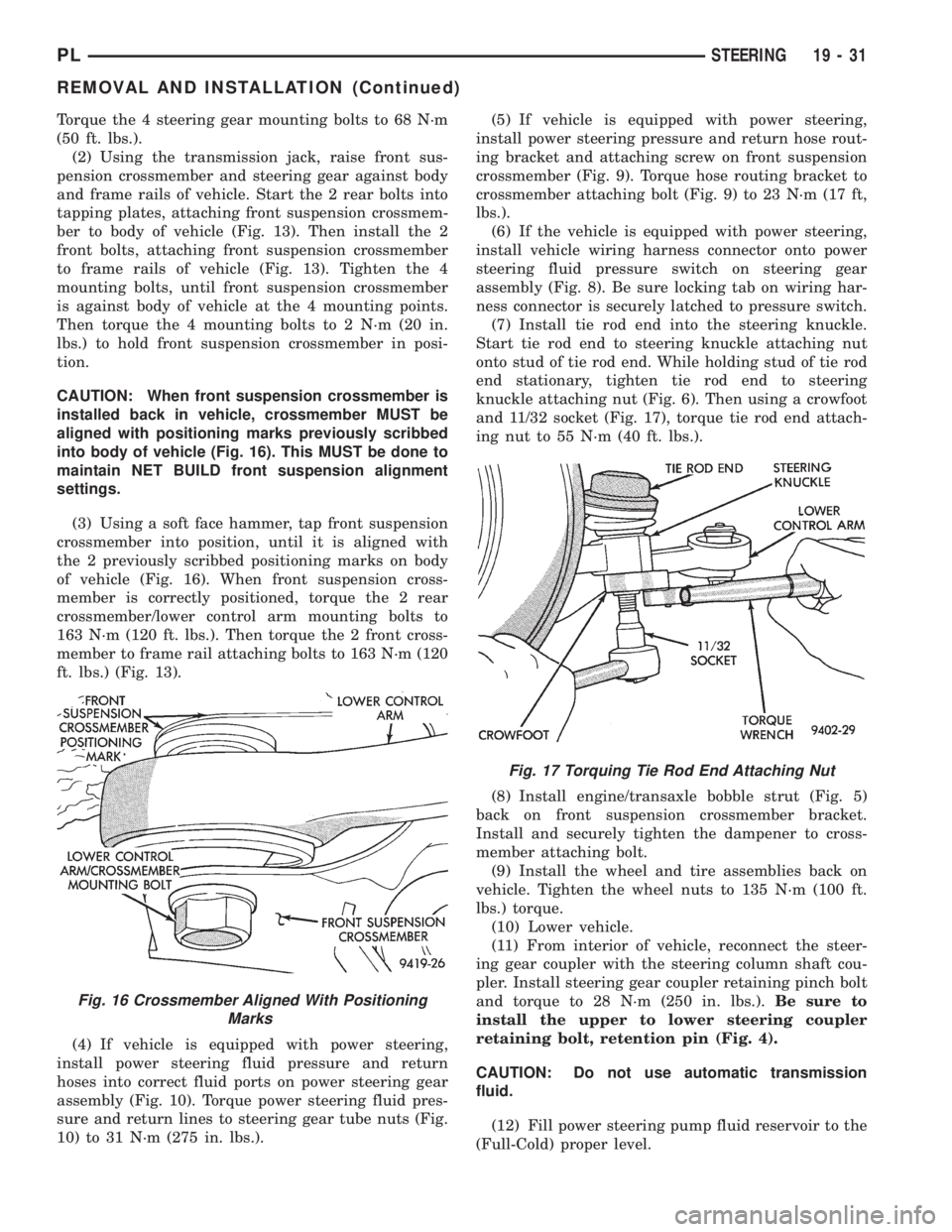

CAUTION: When front suspension crossmember is

installed back in vehicle, crossmember MUST be

aligned with positioning marks previously scribbed

into body of vehicle (Fig. 16). This MUST be done to

maintain NET BUILD front suspension alignment

settings.

(3) Using a soft face hammer, tap front suspension

crossmember into position, until it is aligned with

the 2 previously scribbed positioning marks on body

of vehicle (Fig. 16). When front suspension cross-

member is correctly positioned, torque the 2 rear

crossmember/lower control arm mounting bolts to

163 N´m (120 ft. lbs.). Then torque the 2 front cross-

member to frame rail attaching bolts to 163 N´m (120

ft. lbs.) (Fig. 13).

(4) If vehicle is equipped with power steering,

install power steering fluid pressure and return

hoses into correct fluid ports on power steering gear

assembly (Fig. 10). Torque power steering fluid pres-

sure and return lines to steering gear tube nuts (Fig.

10) to 31 N´m (275 in. lbs.).(5) If vehicle is equipped with power steering,

install power steering pressure and return hose rout-

ing bracket and attaching screw on front suspension

crossmember (Fig. 9). Torque hose routing bracket to

crossmember attaching bolt (Fig. 9) to 23 N´m (17 ft,

lbs.).

(6) If the vehicle is equipped with power steering,

install vehicle wiring harness connector onto power

steering fluid pressure switch on steering gear

assembly (Fig. 8). Be sure locking tab on wiring har-

ness connector is securely latched to pressure switch.

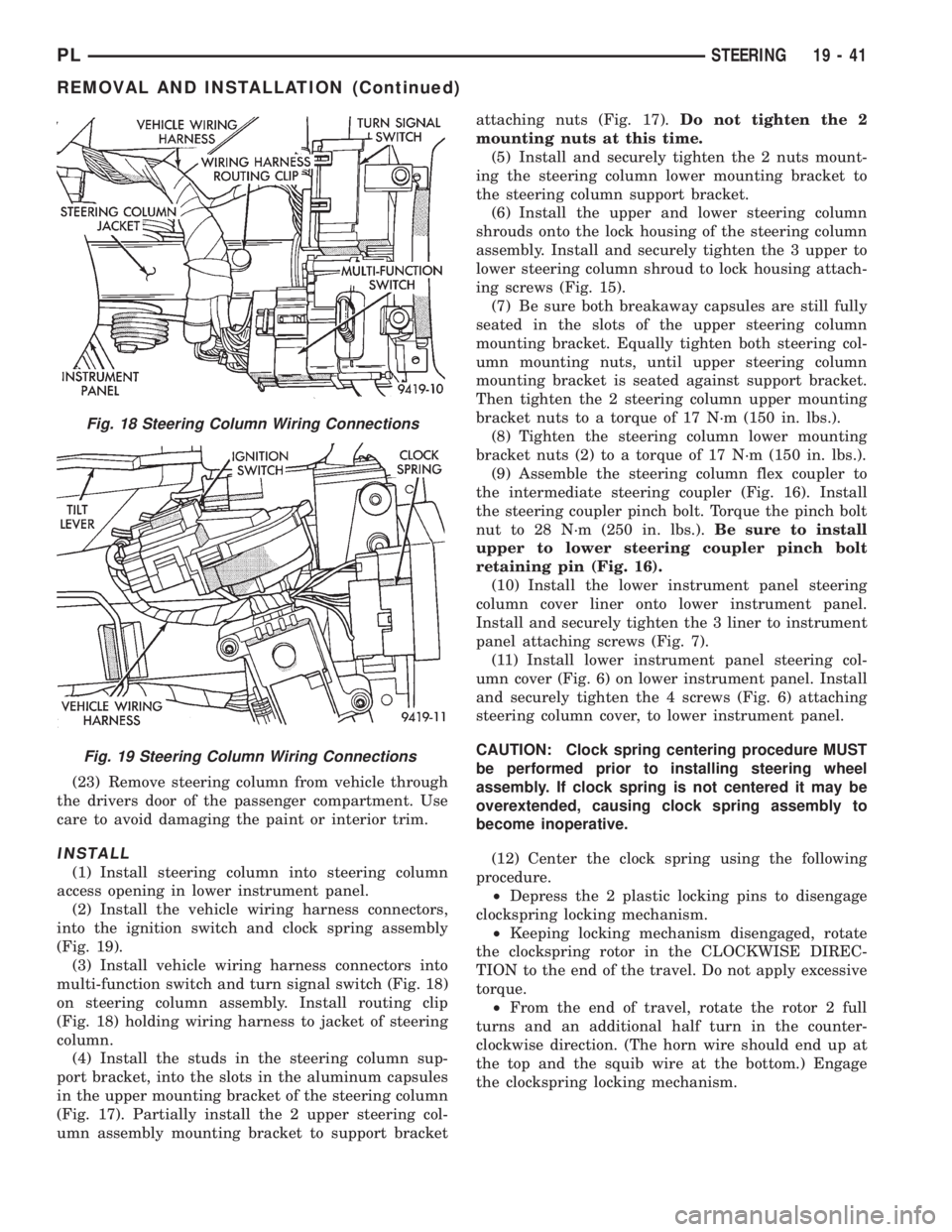

(7) Install tie rod end into the steering knuckle.

Start tie rod end to steering knuckle attaching nut

onto stud of tie rod end. While holding stud of tie rod

end stationary, tighten tie rod end to steering

knuckle attaching nut (Fig. 6). Then using a crowfoot

and 11/32 socket (Fig. 17), torque tie rod end attach-

ing nut to 55 N´m (40 ft. lbs.).

(8) Install engine/transaxle bobble strut (Fig. 5)

back on front suspension crossmember bracket.

Install and securely tighten the dampener to cross-

member attaching bolt.

(9) Install the wheel and tire assemblies back on

vehicle. Tighten the wheel nuts to 135 N´m (100 ft.

lbs.) torque.

(10) Lower vehicle.

(11) From interior of vehicle, reconnect the steer-

ing gear coupler with the steering column shaft cou-

pler. Install steering gear coupler retaining pinch bolt

and torque to 28 N´m (250 in. lbs.).Be sure to

install the upper to lower steering coupler

retaining bolt, retention pin (Fig. 4).

CAUTION: Do not use automatic transmission

fluid.

(12) Fill power steering pump fluid reservoir to the

(Full-Cold) proper level.

Fig. 16 Crossmember Aligned With Positioning

Marks

Fig. 17 Torquing Tie Rod End Attaching Nut

PLSTEERING 19 - 31

REMOVAL AND INSTALLATION (Continued)

Page 942 of 1200

(23) Remove steering column from vehicle through

the drivers door of the passenger compartment. Use

care to avoid damaging the paint or interior trim.

INSTALL

(1) Install steering column into steering column

access opening in lower instrument panel.

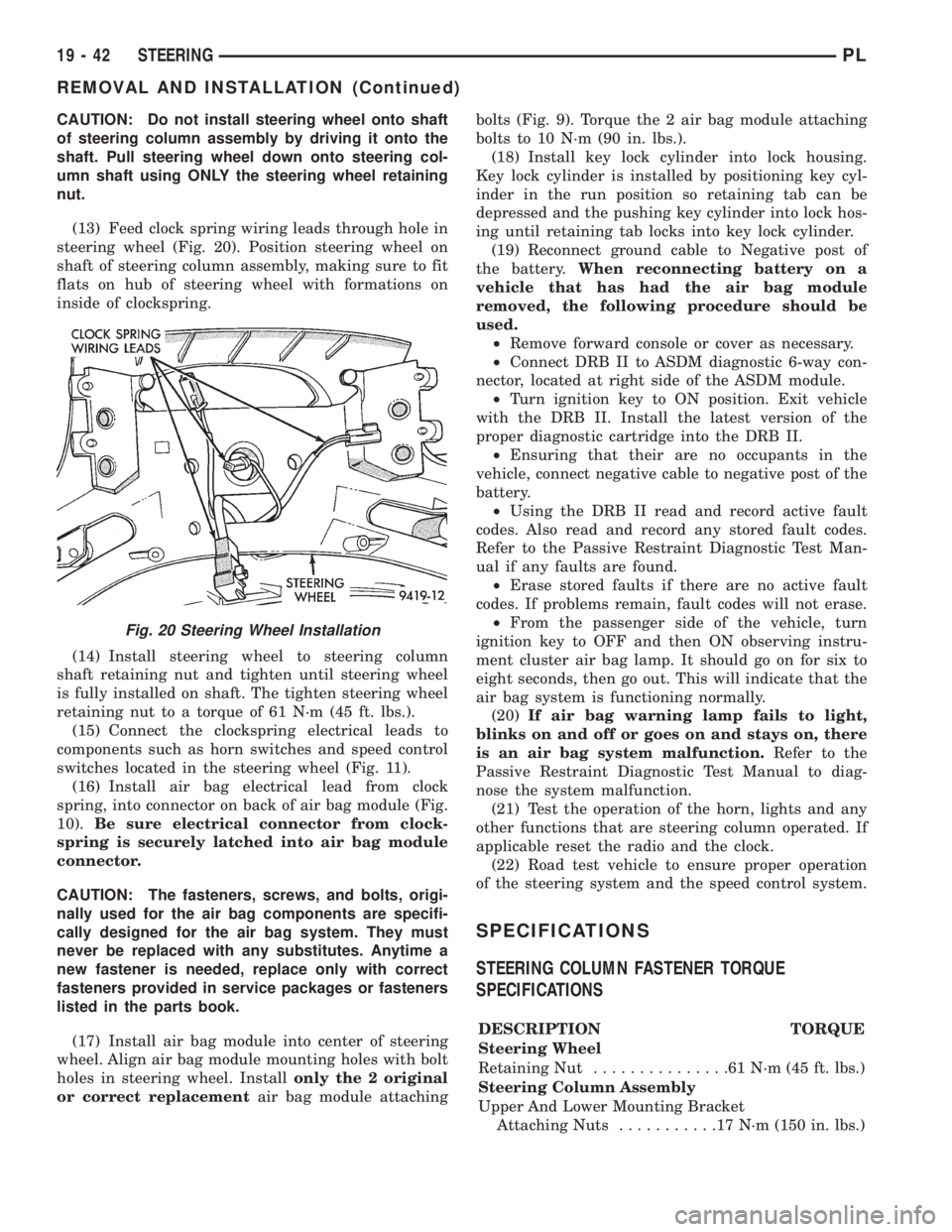

(2) Install the vehicle wiring harness connectors,

into the ignition switch and clock spring assembly

(Fig. 19).

(3) Install vehicle wiring harness connectors into

multi-function switch and turn signal switch (Fig. 18)

on steering column assembly. Install routing clip

(Fig. 18) holding wiring harness to jacket of steering

column.

(4) Install the studs in the steering column sup-

port bracket, into the slots in the aluminum capsules

in the upper mounting bracket of the steering column

(Fig. 17). Partially install the 2 upper steering col-

umn assembly mounting bracket to support bracketattaching nuts (Fig. 17).Do not tighten the 2

mounting nuts at this time.

(5) Install and securely tighten the 2 nuts mount-

ing the steering column lower mounting bracket to

the steering column support bracket.

(6) Install the upper and lower steering column

shrouds onto the lock housing of the steering column

assembly. Install and securely tighten the 3 upper to

lower steering column shroud to lock housing attach-

ing screws (Fig. 15).

(7) Be sure both breakaway capsules are still fully

seated in the slots of the upper steering column

mounting bracket. Equally tighten both steering col-

umn mounting nuts, until upper steering column

mounting bracket is seated against support bracket.

Then tighten the 2 steering column upper mounting

bracket nuts to a torque of 17 N´m (150 in. lbs.).

(8) Tighten the steering column lower mounting

bracket nuts (2) to a torque of 17 N´m (150 in. lbs.).

(9) Assemble the steering column flex coupler to

the intermediate steering coupler (Fig. 16). Install

the steering coupler pinch bolt. Torque the pinch bolt

nut to 28 N´m (250 in. lbs.).Be sure to install

upper to lower steering coupler pinch bolt

retaining pin (Fig. 16).

(10) Install the lower instrument panel steering

column cover liner onto lower instrument panel.

Install and securely tighten the 3 liner to instrument

panel attaching screws (Fig. 7).

(11) Install lower instrument panel steering col-

umn cover (Fig. 6) on lower instrument panel. Install

and securely tighten the 4 screws (Fig. 6) attaching

steering column cover, to lower instrument panel.

CAUTION: Clock spring centering procedure MUST

be performed prior to installing steering wheel

assembly. If clock spring is not centered it may be

overextended, causing clock spring assembly to

become inoperative.

(12) Center the clock spring using the following

procedure.

²Depress the 2 plastic locking pins to disengage

clockspring locking mechanism.

²Keeping locking mechanism disengaged, rotate

the clockspring rotor in the CLOCKWISE DIREC-

TION to the end of the travel. Do not apply excessive

torque.

²From the end of travel, rotate the rotor 2 full

turns and an additional half turn in the counter-

clockwise direction. (The horn wire should end up at

the top and the squib wire at the bottom.) Engage

the clockspring locking mechanism.

Fig. 18 Steering Column Wiring Connections

Fig. 19 Steering Column Wiring Connections

PLSTEERING 19 - 41

REMOVAL AND INSTALLATION (Continued)

Page 943 of 1200

CAUTION: Do not install steering wheel onto shaft

of steering column assembly by driving it onto the

shaft. Pull steering wheel down onto steering col-

umn shaft using ONLY the steering wheel retaining

nut.

(13) Feed clock spring wiring leads through hole in

steering wheel (Fig. 20). Position steering wheel on

shaft of steering column assembly, making sure to fit

flats on hub of steering wheel with formations on

inside of clockspring.

(14) Install steering wheel to steering column

shaft retaining nut and tighten until steering wheel

is fully installed on shaft. The tighten steering wheel

retaining nut to a torque of 61 N´m (45 ft. lbs.).

(15) Connect the clockspring electrical leads to

components such as horn switches and speed control

switches located in the steering wheel (Fig. 11).

(16) Install air bag electrical lead from clock

spring, into connector on back of air bag module (Fig.

10).Be sure electrical connector from clock-

spring is securely latched into air bag module

connector.

CAUTION: The fasteners, screws, and bolts, origi-

nally used for the air bag components are specifi-

cally designed for the air bag system. They must

never be replaced with any substitutes. Anytime a

new fastener is needed, replace only with correct

fasteners provided in service packages or fasteners

listed in the parts book.

(17) Install air bag module into center of steering

wheel. Align air bag module mounting holes with bolt

holes in steering wheel. Installonly the 2 original

or correct replacementair bag module attachingbolts (Fig. 9). Torque the 2 air bag module attaching

bolts to 10 N´m (90 in. lbs.).

(18) Install key lock cylinder into lock housing.

Key lock cylinder is installed by positioning key cyl-

inder in the run position so retaining tab can be

depressed and the pushing key cylinder into lock hos-

ing until retaining tab locks into key lock cylinder.

(19) Reconnect ground cable to Negative post of

the battery.When reconnecting battery on a

vehicle that has had the air bag module

removed, the following procedure should be

used.

²Remove forward console or cover as necessary.

²Connect DRB II to ASDM diagnostic 6-way con-

nector, located at right side of the ASDM module.

²Turn ignition key to ON position. Exit vehicle

with the DRB II. Install the latest version of the

proper diagnostic cartridge into the DRB II.

²Ensuring that their are no occupants in the

vehicle, connect negative cable to negative post of the

battery.

²Using the DRB II read and record active fault

codes. Also read and record any stored fault codes.

Refer to the Passive Restraint Diagnostic Test Man-

ual if any faults are found.

²Erase stored faults if there are no active fault

codes. If problems remain, fault codes will not erase.

²From the passenger side of the vehicle, turn

ignition key to OFF and then ON observing instru-

ment cluster air bag lamp. It should go on for six to

eight seconds, then go out. This will indicate that the

air bag system is functioning normally.

(20)If air bag warning lamp fails to light,

blinks on and off or goes on and stays on, there

is an air bag system malfunction.Refer to the

Passive Restraint Diagnostic Test Manual to diag-

nose the system malfunction.

(21) Test the operation of the horn, lights and any

other functions that are steering column operated. If

applicable reset the radio and the clock.

(22) Road test vehicle to ensure proper operation

of the steering system and the speed control system.

SPECIFICATIONS

STEERING COLUMN FASTENER TORQUE

SPECIFICATIONS

DESCRIPTION TORQUE

Steering Wheel

Retaining Nut...............61N´m(45ft.lbs.)

Steering Column Assembly

Upper And Lower Mounting Bracket

Attaching Nuts...........17N´m(150 in. lbs.)

Fig. 20 Steering Wheel Installation

19 - 42 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 948 of 1200

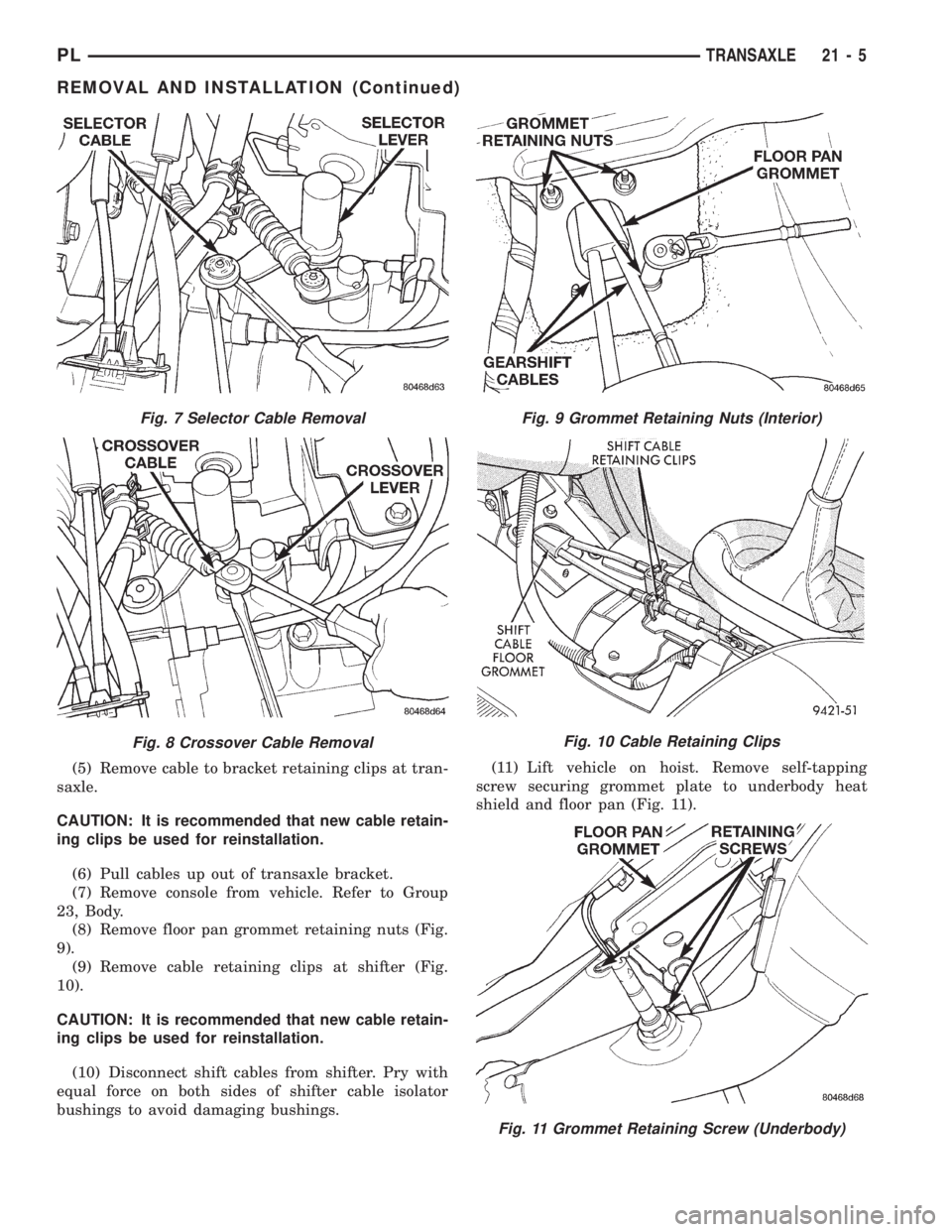

(5) Remove cable to bracket retaining clips at tran-

saxle.

CAUTION: It is recommended that new cable retain-

ing clips be used for reinstallation.

(6) Pull cables up out of transaxle bracket.

(7) Remove console from vehicle. Refer to Group

23, Body.

(8) Remove floor pan grommet retaining nuts (Fig.

9).

(9) Remove cable retaining clips at shifter (Fig.

10).

CAUTION: It is recommended that new cable retain-

ing clips be used for reinstallation.

(10) Disconnect shift cables from shifter. Pry with

equal force on both sides of shifter cable isolator

bushings to avoid damaging bushings.(11) Lift vehicle on hoist. Remove self-tapping

screw securing grommet plate to underbody heat

shield and floor pan (Fig. 11).

Fig. 7 Selector Cable Removal

Fig. 8 Crossover Cable Removal

Fig. 9 Grommet Retaining Nuts (Interior)

Fig. 10 Cable Retaining Clips

Fig. 11 Grommet Retaining Screw (Underbody)

PLTRANSAXLE 21 - 5

REMOVAL AND INSTALLATION (Continued)

Page 1007 of 1200

VEHICLE SPEED SENSOR PINION GEAR

When the sensor is removed for any reason, a

NEW O-ring must be installed on its outside diame-

ter.

REMOVAL

(1) Remove harness connector from sensor. Be sure

weather seal stays on harness connector.

(2) Remove bolt securing the sensor in the exten-

sion housing.

(3) Carefully pull sensor and pinion gear assembly

out of extension housing.

(4) Remove pinion gear from sensor.

INSTALLATION

(1) To install, reverse the above procedure. Be sure

extension housing and sensor flange are clean prior

to installation. Always use a NEW sensor O-ring.

(2) Tighten bolt to 7 N´m (60 in. lbs.). Tighten

speedometer cable to 4 N´m (35 in. lbs.).

PARK/NEUTRAL STARTING AND BACK-UP LAMP

SWITCH

TEST

The park/neutral starting switch is the center ter-

minal of the three terminal switch. It provides

ground for the starter solenoid circuit through the

selector lever in PARK and NEUTRAL positions only.

(1) To test switch, remove wiring connector from

switch and test for continuity between center pin of

switch and transaxle case. Continuity should exist

only when transaxle is in PARK or NEUTRAL.

(2) Check gearshift cable adjustment before replac-

ing a switch that tests bad.

REMOVAL

(1) Unscrew switch from transaxle case allowing

fluid to drain into a container. Move selector lever to

PARK, then to NEUTRAL position, and inspect to see

the switch operating lever fingers are centered in

switch opening.

INSTALLATION

(1) Screw the switch with a new seal into tran-

saxle case and tighten to 33 N´m (24 ft. lbs.). Retest

switch with the test lamp.

(2) Add fluid to transaxle to bring up to proper

level.

(3) The back-up lamp switch circuit is through the

two outside terminals of the three terminal switch.

(4) To test switch, remove wiring connector from

switch and test for continuity between the two out-

side pins.

(5) Continuity should exist only with transaxle in

REVERSE position.(6) No continuity should exist from either pin to

the case.

TRANSAXLE

REMOVAL

NOTE: The transaxle can be removed from the

vehicle without having to remove the engine.

The transaxle and torque converter must be

removed as an assembly; otherwise, the torque con-

verter drive plate, pump bushing, or oil seal may be

damaged. The drive plate will not support a load;

therefore, none of the weight of the transaxle should

be allowed to rest on the plate during removal.

All transaxle components are serviced with the

transaxle out of the vehicle. The components that are

serviceable in the vehicle are:

²Axle shaft seals

²Back±up lamp switch

²End plate

²Extension housing

²Neutral safety switch

²Shift lever

²Transaxle oil pan

²Valve Body

²Vehicle speed sensor

(1) Disconnect the battery.

(2) Pull Power Distribution Center up and out of

its holding bracket. Set Power Distribution Center

aside to gain clearance.

(3) Remove battery heat shield and remove battery

from engine compartment. Remove battery tray from

engine compartment. Disconnect cruise control (if

equipped).

(4) Remove vehicle speed sensor wiring.

(5) Disconnect neutral safety switch and torque

converter control wiring at transaxle.

CAUTION: Pry up with equal force on both sides of

shifter cable isolator bushing to avoid damaging

cable isolator bushing.

(6) Disconnect gear shift cable end from transaxle

shift lever (Fig. 22). Remove bracket bolt at transaxle

(Fig. 23).

(7) Remove throttle pressure control cable from

lever. Then remove bracket bolts at the transaxle

(Fig. 24).

(8) Remove dipstick tube.

(9) Remove transaxle cooler lines and plug lines

(Fig. 25).

(10) Remove throttle pressure control cable sup-

port bracket bolts. Remove upper bellhousing bolts

and upper starter bolt (Fig. 26).

21 - 64 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 1009 of 1200

CAUTION: When reinstalling driveshafts, new drive-

shaft retaining clips must be used. Do not reuse old

clips. Failure to use new clips may result in disen-

gagement of inner constant±velocity joint.

CAUTION: The exhaust flex joint must be discon-

nected from the exhaust manifold anytime the

engine is lowered. If the engine is lowered while the

flex pipe is attached, damage will occur.

(14) Remove bolts securing exhaust flex joint to

exhaust manifold. Disconnect exhaust pipe from

manifold.

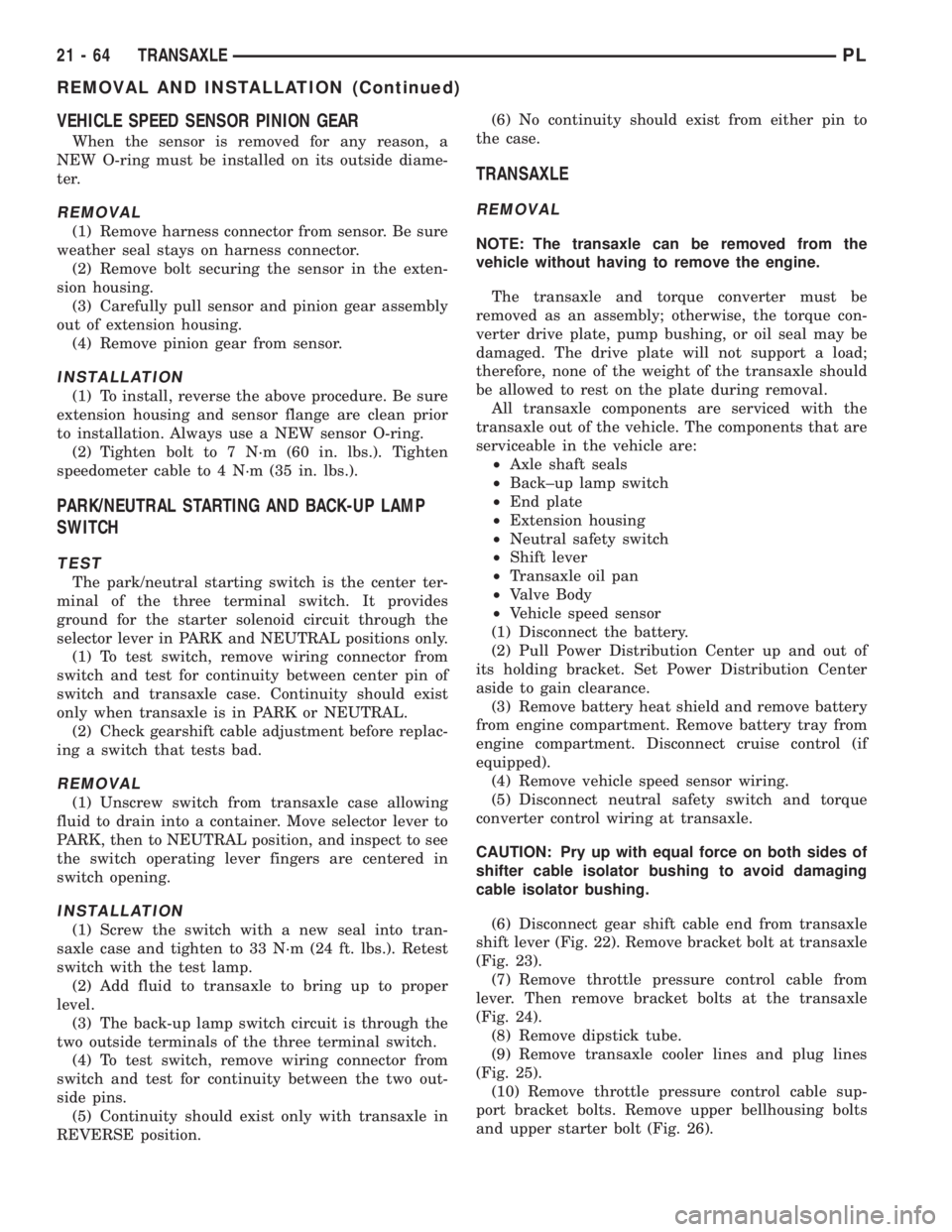

(15) Remove transaxle to rear lateral bending

strut from engine and transaxle (Fig. 28).

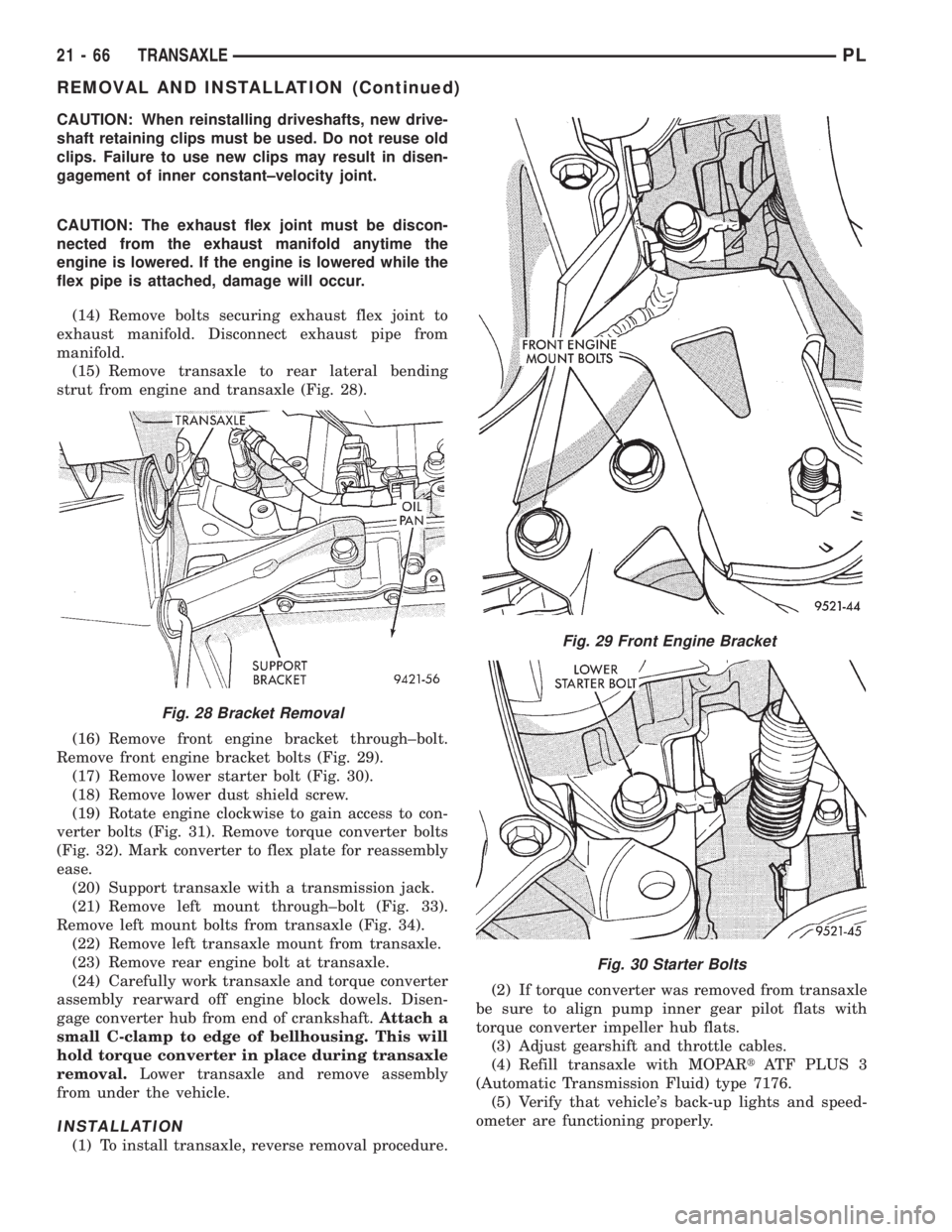

(16) Remove front engine bracket through±bolt.

Remove front engine bracket bolts (Fig. 29).

(17) Remove lower starter bolt (Fig. 30).

(18) Remove lower dust shield screw.

(19) Rotate engine clockwise to gain access to con-

verter bolts (Fig. 31). Remove torque converter bolts

(Fig. 32). Mark converter to flex plate for reassembly

ease.

(20) Support transaxle with a transmission jack.

(21) Remove left mount through±bolt (Fig. 33).

Remove left mount bolts from transaxle (Fig. 34).

(22) Remove left transaxle mount from transaxle.

(23) Remove rear engine bolt at transaxle.

(24) Carefully work transaxle and torque converter

assembly rearward off engine block dowels. Disen-

gage converter hub from end of crankshaft.Attach a

small C-clamp to edge of bellhousing. This will

hold torque converter in place during transaxle

removal.Lower transaxle and remove assembly

from under the vehicle.

INSTALLATION

(1) To install transaxle, reverse removal procedure.(2) If torque converter was removed from transaxle

be sure to align pump inner gear pilot flats with

torque converter impeller hub flats.

(3) Adjust gearshift and throttle cables.

(4) Refill transaxle with MOPARtATF PLUS 3

(Automatic Transmission Fluid) type 7176.

(5) Verify that vehicle's back-up lights and speed-

ometer are functioning properly.

Fig. 28 Bracket Removal

Fig. 29 Front Engine Bracket

Fig. 30 Starter Bolts

21 - 66 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)