ECU DODGE NEON 1999 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 130 of 1200

(7) Remove both rear park brake cables from the

park brake cable equalizer (Fig. 131).

(8) Remove wiring harness electrical connector for

brake warning light ground from the park brake

lever (Fig. 132).

(9) Remove the 2 nuts (Fig. 133) attaching the

park brake lever to the console bracket. Remove park

brake lever mechanism from vehicle.

INSTALL

(1) Place park brake lever on console bracket.

Install and securely tighten the 2 attaching nuts

(Fig. 133).

(2) Install both rear park brake cables into equal-

izer on park brake lever output cable (Fig. 131).

(3) Ensure that park brake cable is correctly

installed and aligned with cable track on park brake

lever.

(4) Firmly grasp park brake lever locking pin (Fig.

134) and quickly remove it from the park brake levermechanism. This will allow the park brake lever

mechanism to correctly adjust the park brake cables.

(5) Connect electrical connector for brake warning

lamp onto terminal on park brake lever assembly

(Fig. 132).

(6) Cycle park brake lever once to position park

brake cables. Then return the park brake lever its

released position. Check the rear wheels of the vehi-

cle. They should rotate freely without dragging.

(7) Raise park brake lever to its fully engaged

position. This is necessary to allow installation of the

center console.

(8) Install center console assembly.

(9) Install the 4 center console assembly attaching

screws (Fig. 127), (Fig. 128) and (Fig. 129).

PARK BRAKE LEVER OUTPUT CABLE

On this vehicle, the park brake lever output cable

(Fig. 135), is not replaceable as a separate component

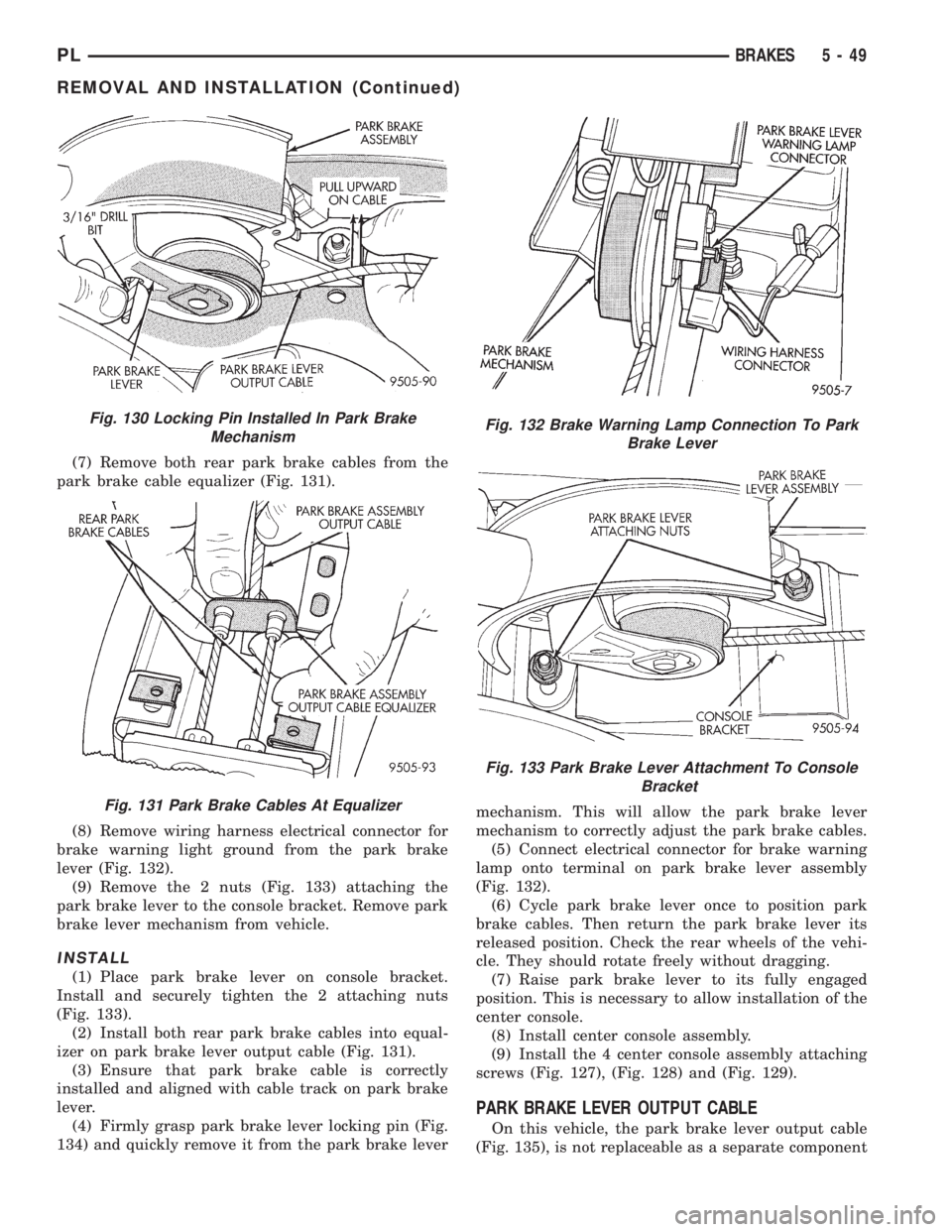

Fig. 130 Locking Pin Installed In Park Brake

Mechanism

Fig. 131 Park Brake Cables At Equalizer

Fig. 132 Brake Warning Lamp Connection To Park

Brake Lever

Fig. 133 Park Brake Lever Attachment To Console

Bracket

PLBRAKES 5 - 49

REMOVAL AND INSTALLATION (Continued)

Page 135 of 1200

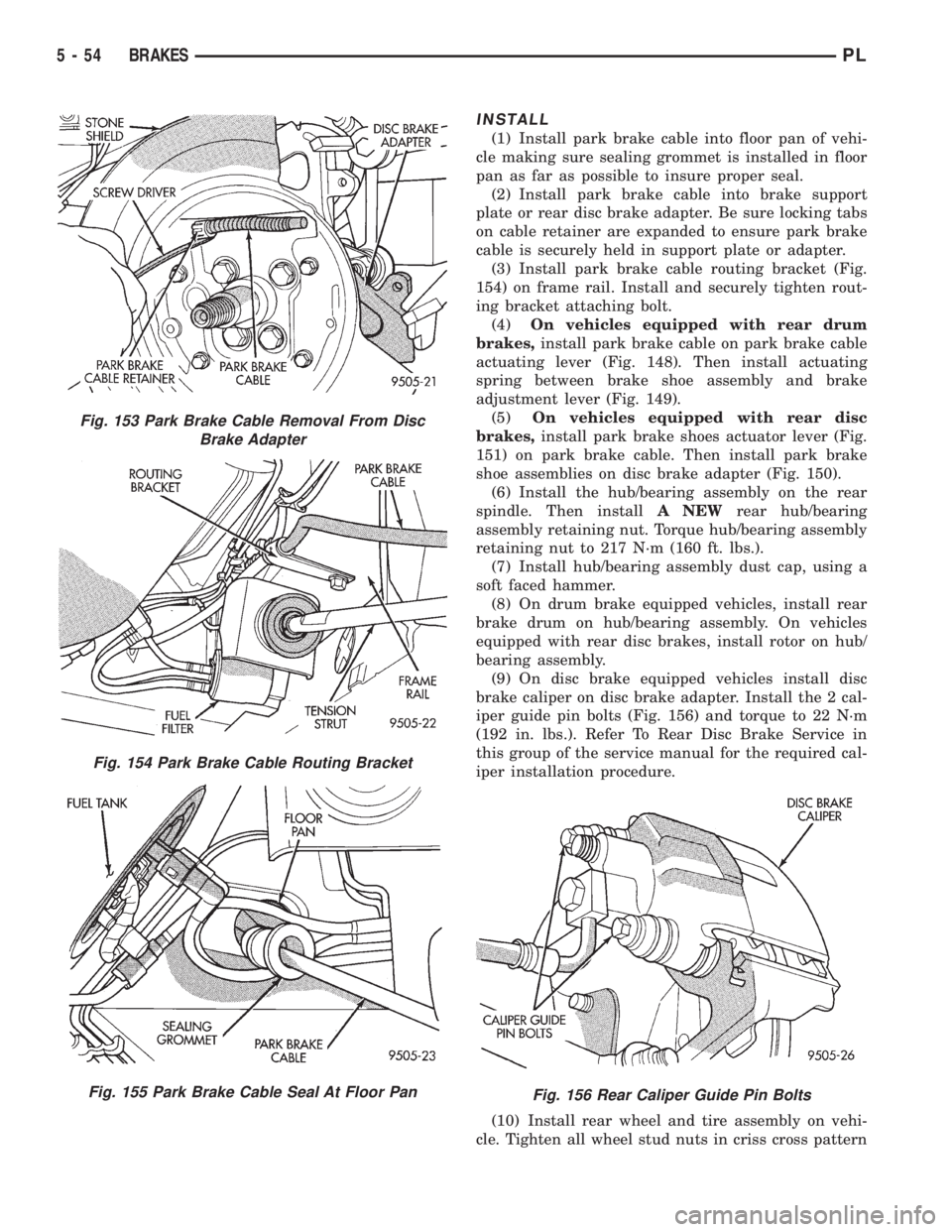

INSTALL

(1) Install park brake cable into floor pan of vehi-

cle making sure sealing grommet is installed in floor

pan as far as possible to insure proper seal.

(2) Install park brake cable into brake support

plate or rear disc brake adapter. Be sure locking tabs

on cable retainer are expanded to ensure park brake

cable is securely held in support plate or adapter.

(3) Install park brake cable routing bracket (Fig.

154) on frame rail. Install and securely tighten rout-

ing bracket attaching bolt.

(4)On vehicles equipped with rear drum

brakes,install park brake cable on park brake cable

actuating lever (Fig. 148). Then install actuating

spring between brake shoe assembly and brake

adjustment lever (Fig. 149).

(5)On vehicles equipped with rear disc

brakes,install park brake shoes actuator lever (Fig.

151) on park brake cable. Then install park brake

shoe assemblies on disc brake adapter (Fig. 150).

(6) Install the hub/bearing assembly on the rear

spindle. Then installA NEWrear hub/bearing

assembly retaining nut. Torque hub/bearing assembly

retaining nut to 217 N´m (160 ft. lbs.).

(7) Install hub/bearing assembly dust cap, using a

soft faced hammer.

(8) On drum brake equipped vehicles, install rear

brake drum on hub/bearing assembly. On vehicles

equipped with rear disc brakes, install rotor on hub/

bearing assembly.

(9) On disc brake equipped vehicles install disc

brake caliper on disc brake adapter. Install the 2 cal-

iper guide pin bolts (Fig. 156) and torque to 22 N´m

(192 in. lbs.). Refer To Rear Disc Brake Service in

this group of the service manual for the required cal-

iper installation procedure.

(10) Install rear wheel and tire assembly on vehi-

cle. Tighten all wheel stud nuts in criss cross pattern

Fig. 153 Park Brake Cable Removal From Disc

Brake Adapter

Fig. 154 Park Brake Cable Routing Bracket

Fig. 155 Park Brake Cable Seal At Floor PanFig. 156 Rear Caliper Guide Pin Bolts

5 - 54 BRAKESPL

Page 160 of 1200

A visual inspection for loose, disconnected, or mis-

routed wires should be done before attempting to

diagnose or service the ITT Teves Mark 20 antilock

brake system. A visual inspection will eliminate

unnecessary testing and diagnostics time. A thorough

visual inspection will include the following compo-

nents and areas of the vehicle.

(1) Inspect fuses in the power distribution center

(PDC) and the wiring junction block. Verify that all

fuses are fully inserted into the PDC and wring junc-

tion block. A label on the underside of the PDC cover

identifies the locations of the ABS fuses in the PDC.

(2) Inspect the 25-way electrical connector at the

CAB for damage, spread or backed-out wiring termi-

nals. Verify that the 25-way connector is fully

inserted in the socket on the CAB. Be sure that wires

are not stretched tight or pulled out of the connector.

(3) Verify that all the wheel speed sensor connec-

tions are secure.

(4) Poor mating of connector halves or terminals

not fully seated in the connector body.

(5) Improperly formed or damaged terminals. All

connector terminals in a suspect circuit should be

carefully reformed to increase contact tension.

(6) Poor terminal to wire connection. This requires

removing the terminal from the connector body to

inspect.

(7) Pin presence in the connector assembly

(8) Proper ground connections. Check all ground

connections for signs of corrosion, tight fasteners, or

other potential defects. Refer to wiring diagram man-

ual for ground locations.

(9) Problems with main power sources of the vehi-

cle. Inspect battery, generator, ignition circuits and

other related relays and fuses.

(10) If a visual check does not find the cause of the

problem, operate the car in an attempt to duplicate

the condition and record the trouble code.

(11) Most failures of the ABS system will disable

ABS function for the entire ignition cycle even if the

fault clears before key-off. There are some failure

conditions, however, which will allow ABS operation

to resume during the ignition cycle in which a failure

occurred if the failure conditions are no longer

present. The following conditions may result in inter-

mittent illumination of the ABS Warning Lamp. All

other failures will cause the lamp to remain on until

the ignition switch is turned off. Circuits involving

these inputs to the CAB should be investigated if a

complaint of intermittent warning system operation

is encountered.

(12) Low system voltage. If Low System Voltage is

detected by the CAB, the CAB will turn on the ABS

Warning Lamp until normal system voltage is

achieved. Once normal voltage is seen at the CAB,

normal operation resumes.(13) High system voltage. If high system voltage is

detected by the CAB, the CAB will turn on the

Amber ABS Warning Lamp until normal system volt-

age is achieved. Once normal voltage is again

detected by the CAB, normal ABS operation resumes.

(14) Additionally, any condition which results in

interruption of electrical current to the CAB or mod-

ulator assembly may cause the ABS Warning Lamp

to turn on intermittently.

(15) The body controller can turn on the (yellow)

ABS warning lamp if CCD communication between

the body controller and the CAB is interupted.

TONEWHEEL INSPECTION

CAUTION: The tone wheels used on this vehicle

equipped with the Teves Mark 20 Antilock Brake

System are different then those used on past mod-

els of this vehicle equipped with antilock brakes.

Reduced braking performance will result if this part

is used on earlier model vehicles and an accident

could result. Do not use on pre-1998 model year

vehicles.

Carefully inspect tonewheel at the suspected faulty

wheel speed sensor for missing, chipped or broken

teeth, this can cause erratic speed sensor signals.

Tonewheels should show no evidence of contact

with the wheel speed sensors. If contact was made,

determine cause and correct before replacing the

wheel speed sensor.

Excessive runout of the tonewheel can cause

erratic wheel speed sensor signals. Refer to Tone-

wheel Runout in the Specification Section in this sec-

tion of the service manual for the tonewheel runout

specification. Replace drive shaft assembly or rear

hub/bearing assembly if tonewheel runout exceeds

the specification.

Inspect tonewheels for looseness on their mounting

surfaces. Tonewheels are pressed onto their mounting

surfaces and should not rotate independently from

the mounting surface.

Check the wheel speed sensor head alignment to

the tone wheel. Also check the gap between the speed

sensor head and the tone wheel to ensure it is at

specification. Refer to Wheel Speed Sensor Clearance

in the Specification Section in this section of the ser-

vice manual.

PROPORTIONING VALVE

CAUTION: Proportioning valves should never be

disassembled.

If premature rear wheel skid occurs on a hard

brake application, it could be an indication that a

PLBRAKES 5 - 79

DIAGNOSIS AND TESTING (Continued)

Page 167 of 1200

(18) Install the wiring harness connector (Fig. 19)

on the speed control servo. Then install the routing

clip for the speed control servo wiring harness on the

speed control servo mounting bracket.

Install speed control servo mounting bracket on

body.

(19) Install and securely tighten the 2 bolts (Fig.

18) mounting the bracket for the speed control servo

to the body.

(20) Install the vacuum supply hose on the speed

control servo (Fig. 18).

(21) Install the power distribution center (PDC)

(Fig. 17) on the battery thermogaurd. PDC is install

by pushing straight down on it until the two retain-

ing clips holding it to the thermogaurd are latched to

the thermogaurd.

(22) Connect the negative (ground) cable on the

battery.

(23) Bleed the base brakes and the ABS brakes

hydraulic systems. Refer to Bleeding Base Brake

Hydraulic System in Service Procedures of the Base

Brake Section and Antilock Brakes Hydraulic System

Bleeding Procedure in Service Procedures of the

Antilock Brake Section for the required procedures.

(24) Fill the master cylinder to the proper fill

level.

(25) Road test vehicle to ensure proper operation

of the base and ABS brake systems.

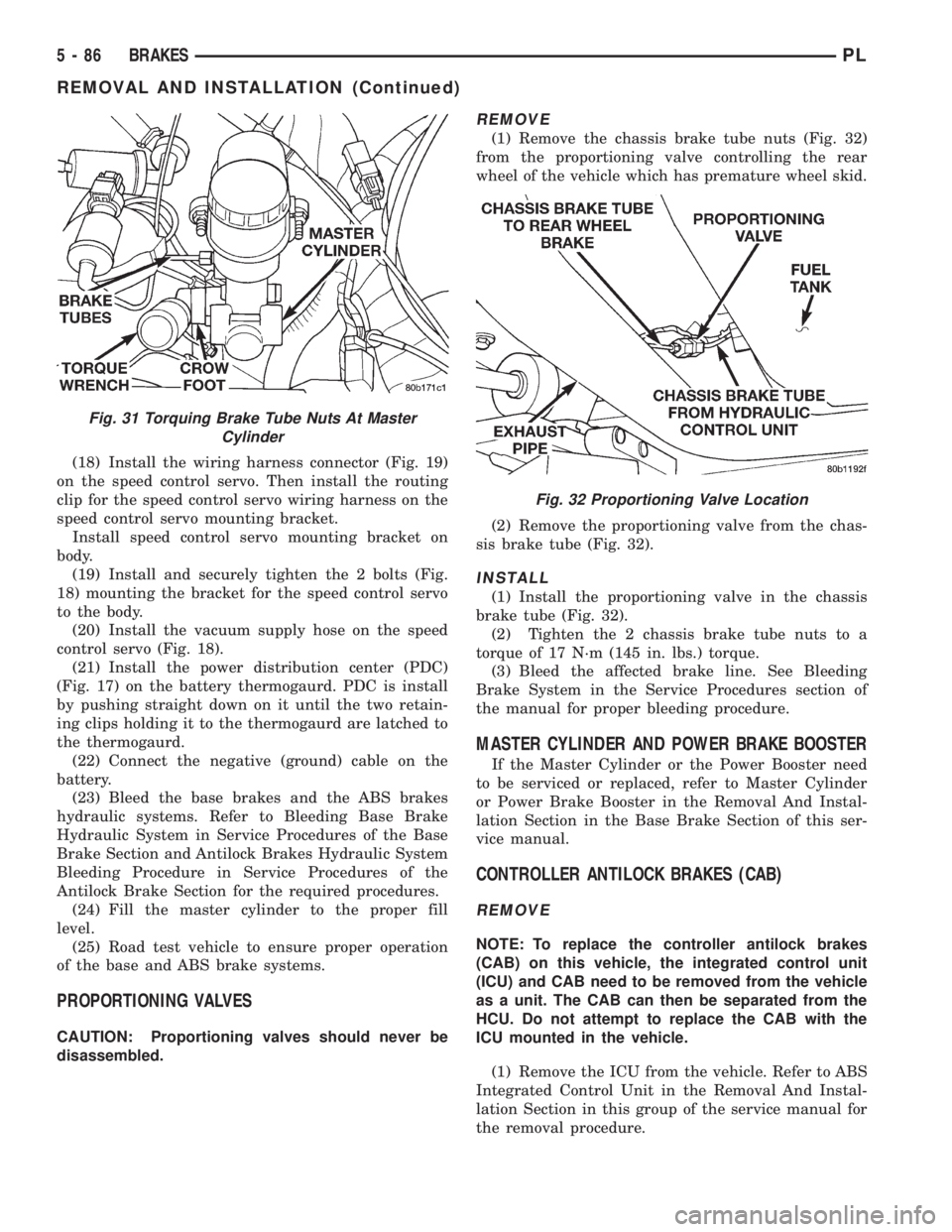

PROPORTIONING VALVES

CAUTION: Proportioning valves should never be

disassembled.

REMOVE

(1) Remove the chassis brake tube nuts (Fig. 32)

from the proportioning valve controlling the rear

wheel of the vehicle which has premature wheel skid.

(2) Remove the proportioning valve from the chas-

sis brake tube (Fig. 32).

INSTALL

(1) Install the proportioning valve in the chassis

brake tube (Fig. 32).

(2) Tighten the 2 chassis brake tube nuts to a

torque of 17 N´m (145 in. lbs.) torque.

(3) Bleed the affected brake line. See Bleeding

Brake System in the Service Procedures section of

the manual for proper bleeding procedure.

MASTER CYLINDER AND POWER BRAKE BOOSTER

If the Master Cylinder or the Power Booster need

to be serviced or replaced, refer to Master Cylinder

or Power Brake Booster in the Removal And Instal-

lation Section in the Base Brake Section of this ser-

vice manual.

CONTROLLER ANTILOCK BRAKES (CAB)

REMOVE

NOTE: To replace the controller antilock brakes

(CAB) on this vehicle, the integrated control unit

(ICU) and CAB need to be removed from the vehicle

as a unit. The CAB can then be separated from the

HCU. Do not attempt to replace the CAB with the

ICU mounted in the vehicle.

(1) Remove the ICU from the vehicle. Refer to ABS

Integrated Control Unit in the Removal And Instal-

lation Section in this group of the service manual for

the removal procedure.

Fig. 31 Torquing Brake Tube Nuts At Master

Cylinder

Fig. 32 Proportioning Valve Location

5 - 86 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 178 of 1200

(4) Guide cable through slot in transaxle and dis-

connect cable from release lever.

(5) Disconnect clutch cable up-stop/spacer with

cable strand from clutch pedal.

NOTE: Depressing the clutch pedal provides

access to the clutch cable strand. Disconnect the

cable up-stop/spacer from the pedal pivot pin by

removing the snap ring at the top of the clutch

pedal. Wedge a flat±blade pry tool between the pin

and the retaining tab. While holding the tab slightly

separated from the pin, pull the up-stop/spacer off

the pedal. Now remove the cable end from the up-

stop/spacer.

CAUTION: Do not pull on the clutch cable to

remove it from the dash panel. Damage to the cable

self-adjuster may occur.

(6) Remove the cable from the cable routing tube

and clutch bracket.

INSTALLATION

(1) Insert the self±adjuster mechanism end of the

clutch cable through the cable routing tube and into

the bracket.

(2) Be sure the self±adjuster is firmly seated

against the clutch bracket to ensure proper adjuster

mechanism function.

(3) Connect the clutch cable to the up-stop/spacer.

(4) Connect the up-stop/spacer to the clutch pedal.

(5) Install snap ring to hold up-stop spacer in

place.

(6) Perform the Adjuster Mechanism Function

Check before finishing installation.

ADJUSTER MECHANISM FUNCTION CHECK

(1) With slight pressure, pull the clutch release

lever end of the cable to draw the cable taut. Push

the clutch cable housing toward the dash panel (With

less than 25 lbs. of effort, the cable housing should

move 30-50mm.). This indicates proper adjuster

mechanism function. If the cable does not adjust,

determine if the mechanism is properly seated on the

bracket tube.

(2) If the adjust mechanism functions properly,

guide the cable through the slot in the transaxle

housing. Connect cable to release lever, seating the

cupped washer securely on lever tangs.

(3) Pull back on clutch cable housing and insert

into transaxle housing (Fig. 2).

(4) Reinstall cable inspection cover and PDC.

Check clutch pedal position switch operation.

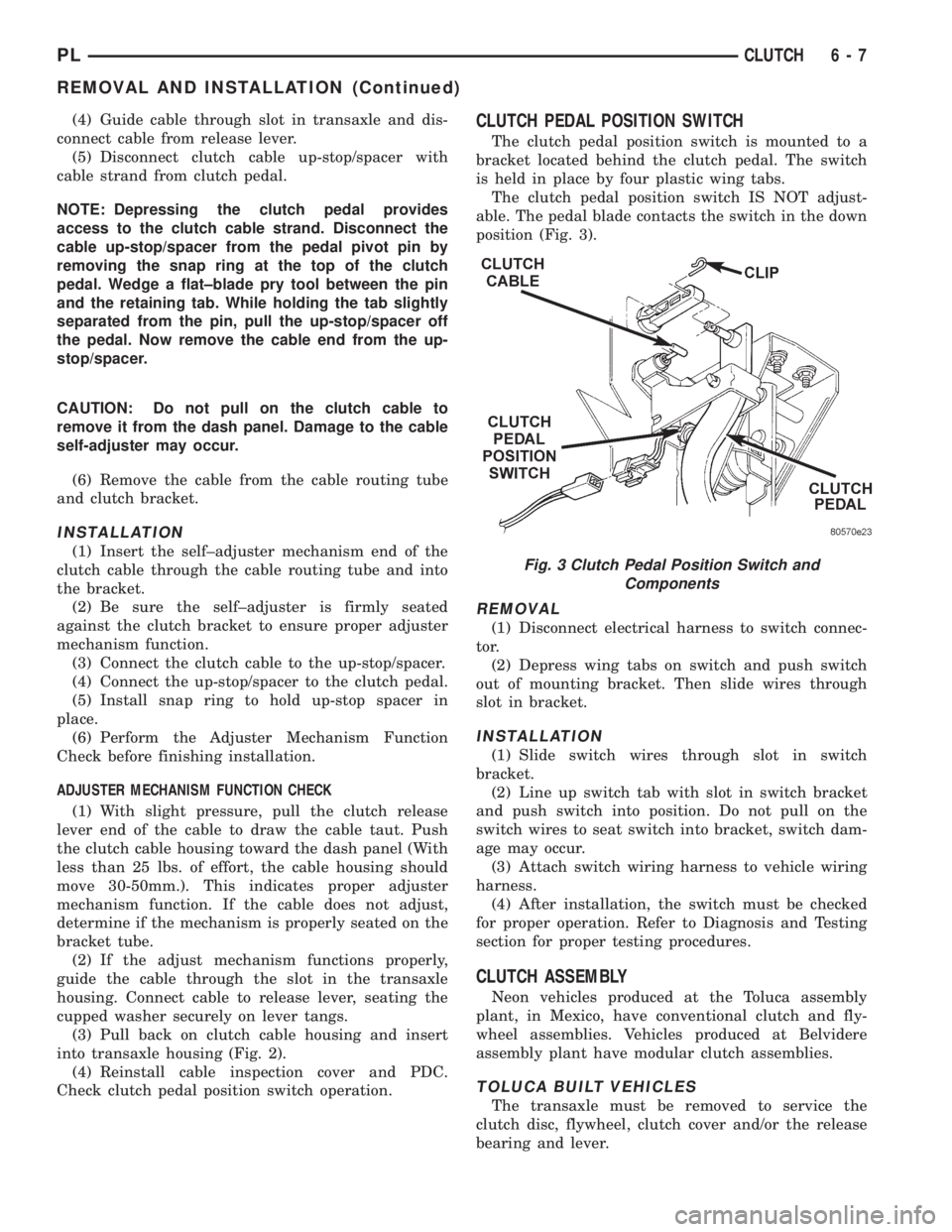

CLUTCH PEDAL POSITION SWITCH

The clutch pedal position switch is mounted to a

bracket located behind the clutch pedal. The switch

is held in place by four plastic wing tabs.

The clutch pedal position switch IS NOT adjust-

able. The pedal blade contacts the switch in the down

position (Fig. 3).

REMOVAL

(1) Disconnect electrical harness to switch connec-

tor.

(2) Depress wing tabs on switch and push switch

out of mounting bracket. Then slide wires through

slot in bracket.

INSTALLATION

(1) Slide switch wires through slot in switch

bracket.

(2) Line up switch tab with slot in switch bracket

and push switch into position. Do not pull on the

switch wires to seat switch into bracket, switch dam-

age may occur.

(3) Attach switch wiring harness to vehicle wiring

harness.

(4) After installation, the switch must be checked

for proper operation. Refer to Diagnosis and Testing

section for proper testing procedures.

CLUTCH ASSEMBLY

Neon vehicles produced at the Toluca assembly

plant, in Mexico, have conventional clutch and fly-

wheel assemblies. Vehicles produced at Belvidere

assembly plant have modular clutch assemblies.

TOLUCA BUILT VEHICLES

The transaxle must be removed to service the

clutch disc, flywheel, clutch cover and/or the release

bearing and lever.

Fig. 3 Clutch Pedal Position Switch and

Components

PLCLUTCH 6 - 7

REMOVAL AND INSTALLATION (Continued)

Page 181 of 1200

INSTALLATION

(1) The pivot ball pocket in the fork is Teflon

coated and should be installed WITHOUT any lubri-

cant such as grease. Using grease will break down

the Teflon coating. Be sure the ball stud and fork

pocket are clean of contamination and dirt.

(2) Assemble the fork to the bearing. The small

pegs on the bearing must go over the fork arms.

(3) Slide the bearing and fork assembly onto the

input shaft bearing retainer, as a unit.

(4) Snap the clutch fork onto the pivot ball.

(5) Reinstall transaxle assembly. Refer to Group

21, Transaxle for further information.

CLEANING AND INSPECTION

CLUTCH CONTAMINATION

Fluid contamination is a frequent cause of clutch

malfunctions. Oil, grease, water, or other fluids on

the clutch contact surfaces will cause faulty opera-

tion.

During inspection, note if any components are con-

taminated. Look for evidence of oil, grease, or water/

road splash on clutch components.

OIL CONTAMINATION

Oil contamination indicates a leak at the rear main

seal and/or transaxle input shaft. Oil leaks produce a

residue of oil on the transaxle housing interior, clutch

cover and flywheel. Heat buildup caused by slippage

can bake the oil residue onto the components. This

glaze-like residue ranges in color from amber to

black.

GREASE CONTAMINATION

Grease contamination is usually a product of over-

lubrication. During clutch service, apply only a small

amount of grease to the input shaft splines. Excess

grease may be thrown off during operation, contami-

nating the disc.

ROAD SPLASH/WATER CONTAMINATION

Road splash contamination is usually caused by

driving the vehicle through deep water puddles.

Water can be forced into the clutch housing, causing

clutch components to become contaminated. Facing of

disc will absorb moisture and bond to the flywheel

and/or, pressure plate, if vehicle is allowed to stand

for some time before use. If this condition occurs,

replacement of clutch assembly may be required.

Drive the vehicle until normal clutch operating tem-

perature has been obtained. This will dry off disc

assembly, pressure plate, and flywheel.

CLEANING PRECAUTIONS

Condensation from steam vapors tend to accumu-

late on the internal clutch mechanism when the vehi-

cle is steam cleaned. Facing of disc will absorb

moisture and will bond to flywheel and/or pressure

plate, if vehicle is allowed to stand for some time

before use. If this condition occurs, it may require

replacement of clutch assembly. After cleaning, drive

the vehicle to its normal clutch operating tempera-

ture. This will dry off disc assembly, pressure plate,

and flywheel.

ADJUSTMENTS

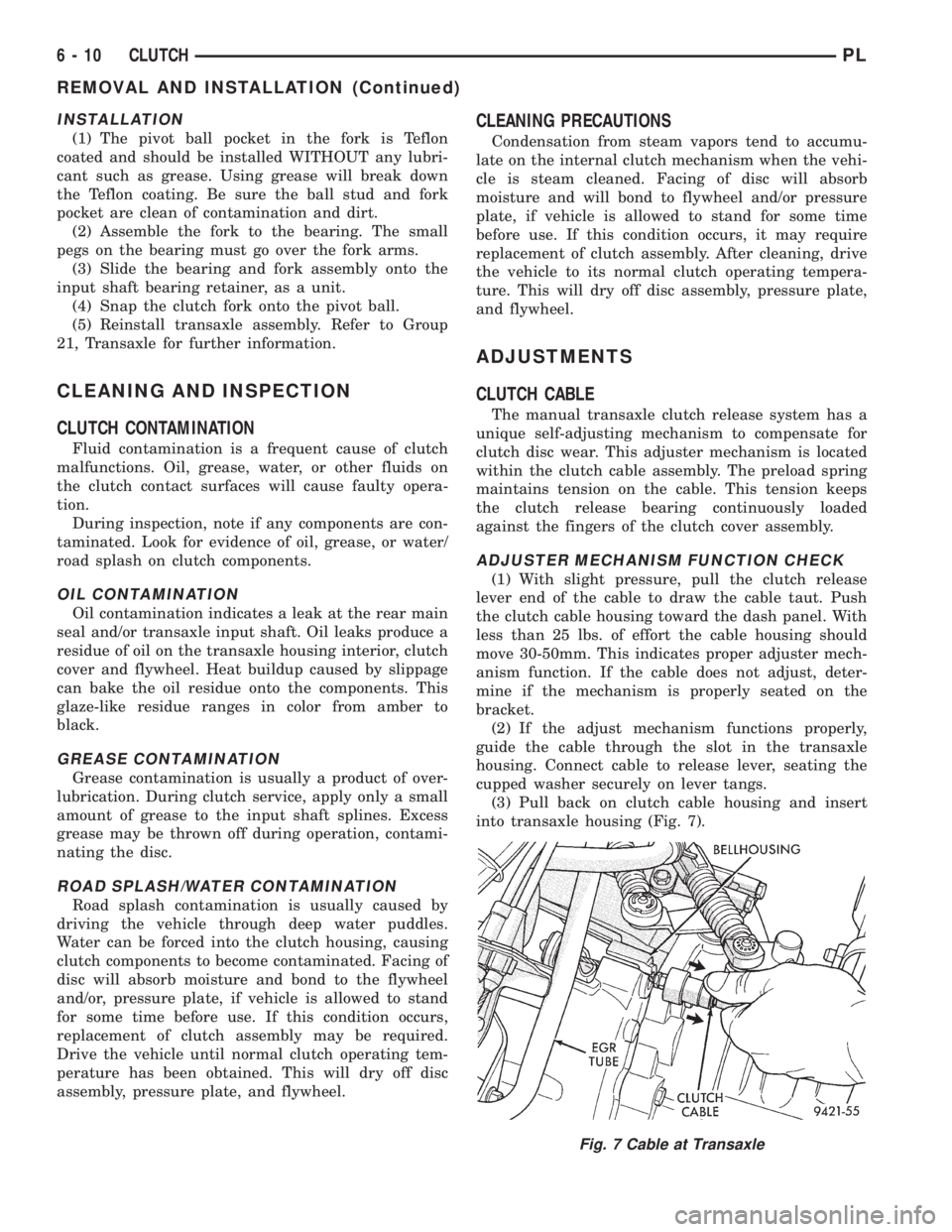

CLUTCH CABLE

The manual transaxle clutch release system has a

unique self-adjusting mechanism to compensate for

clutch disc wear. This adjuster mechanism is located

within the clutch cable assembly. The preload spring

maintains tension on the cable. This tension keeps

the clutch release bearing continuously loaded

against the fingers of the clutch cover assembly.

ADJUSTER MECHANISM FUNCTION CHECK

(1) With slight pressure, pull the clutch release

lever end of the cable to draw the cable taut. Push

the clutch cable housing toward the dash panel. With

less than 25 lbs. of effort the cable housing should

move 30-50mm. This indicates proper adjuster mech-

anism function. If the cable does not adjust, deter-

mine if the mechanism is properly seated on the

bracket.

(2) If the adjust mechanism functions properly,

guide the cable through the slot in the transaxle

housing. Connect cable to release lever, seating the

cupped washer securely on lever tangs.

(3) Pull back on clutch cable housing and insert

into transaxle housing (Fig. 7).

Fig. 7 Cable at Transaxle

6 - 10 CLUTCHPL

REMOVAL AND INSTALLATION (Continued)

Page 189 of 1200

SERVICE DIAGNOSIS±CLUTCH PEDAL NOISE

CONDITION POSSIBLE CAUSES CORRECTION

CLUTCH PEDAL SQUEAKS

WHEN DEPRESSED TO FLOORPedal bushings worn out or

inadequate lubricationReplace or lubricate bushings

CLASH±INTO±REVERSE COMPLAINTS

Some Right Hand Drive NV T350 (A-578) manual

transaxles are equipped with a reverse brake. It pre-

vents clash when shifting into reverse, but only if the

vehicle is not moving. See Group 21, Transaxle for

further diagnosis.

(1) Depress clutch pedal to floor and hold. After

three seconds, shift to reverse. If clash is present,

clutch has excessive spin time, and the reverse brake

may not be functioning.

NOTE: Verify that nothing is obstructing pedal

travel. Floormats or other articles located under-

neath the clutch pedal could prevent the clutch

from disengaging fully. Also make sure that the

hydraulic clutch release mechanism is functioning

properly.

(2) Remove transaxle. See Group 21, Manual Tran-

saxle for procedure.

(3) Check the input shaft spline, clutch disc

splines, and release bearing for dry rust. If present,

clean rust off and apply a light coat of bearing grease

to the input shaft splines. Apply grease on the input

shaft splines only where the clutch disc slides. Verify

that the clutch disc slides freely along the input shaft

spline.

(4) Check to see if the clutch disc hub splines are

damaged, and replace with new clutch assembly if

required.

(5) Check the input shaft for damaged splines.

Replace as necessary.

(6) Check for broken clutch cover diaphragm

spring fingers.

(7) Install clutch assembly and transaxle.

REMOVAL AND INSTALLATION

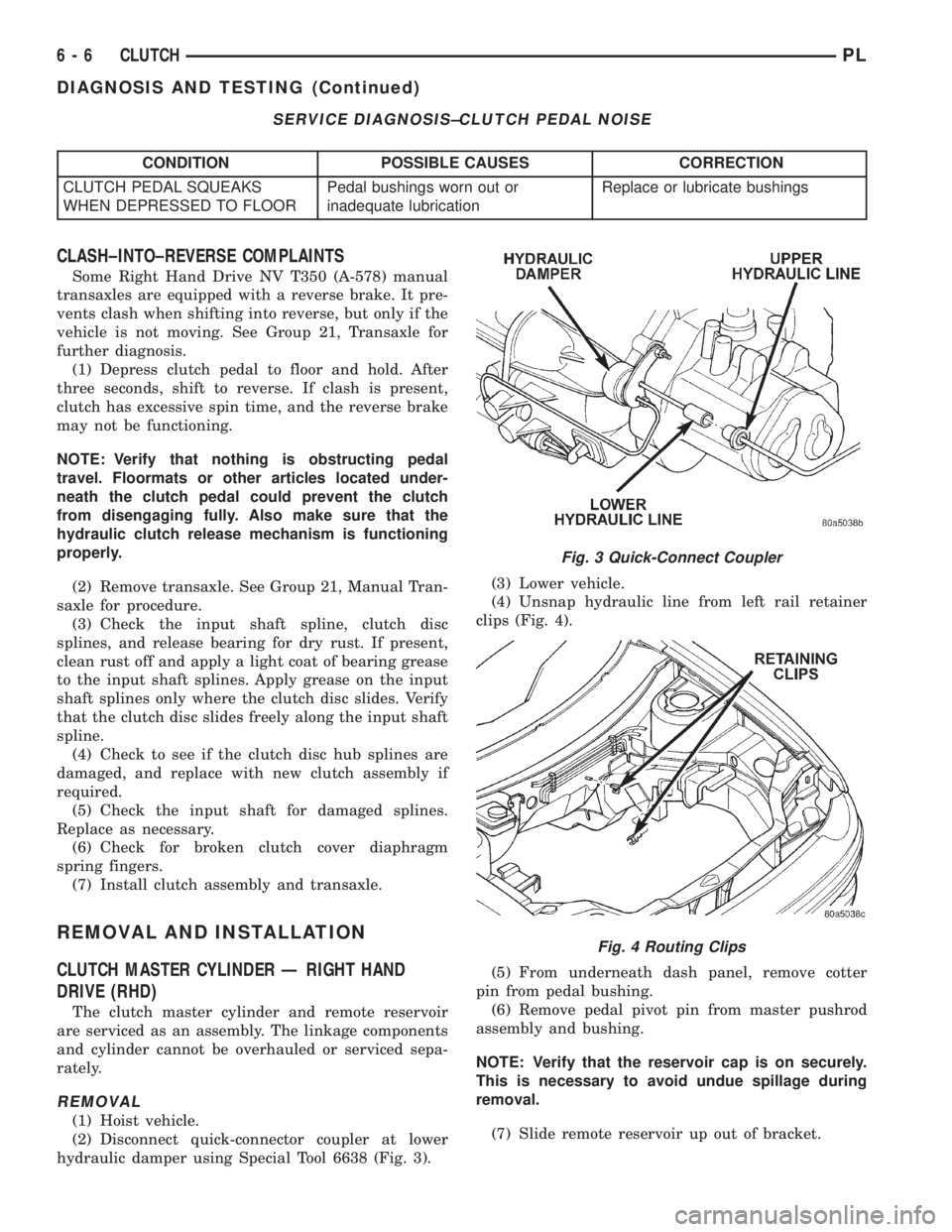

CLUTCH MASTER CYLINDER Ð RIGHT HAND

DRIVE (RHD)

The clutch master cylinder and remote reservoir

are serviced as an assembly. The linkage components

and cylinder cannot be overhauled or serviced sepa-

rately.

REMOVAL

(1) Hoist vehicle.

(2) Disconnect quick-connector coupler at lower

hydraulic damper using Special Tool 6638 (Fig. 3).(3) Lower vehicle.

(4) Unsnap hydraulic line from left rail retainer

clips (Fig. 4).

(5) From underneath dash panel, remove cotter

pin from pedal bushing.

(6) Remove pedal pivot pin from master pushrod

assembly and bushing.

NOTE: Verify that the reservoir cap is on securely.

This is necessary to avoid undue spillage during

removal.

(7) Slide remote reservoir up out of bracket.

Fig. 3 Quick-Connect Coupler

Fig. 4 Routing Clips

6 - 6 CLUTCHPL

DIAGNOSIS AND TESTING (Continued)

Page 190 of 1200

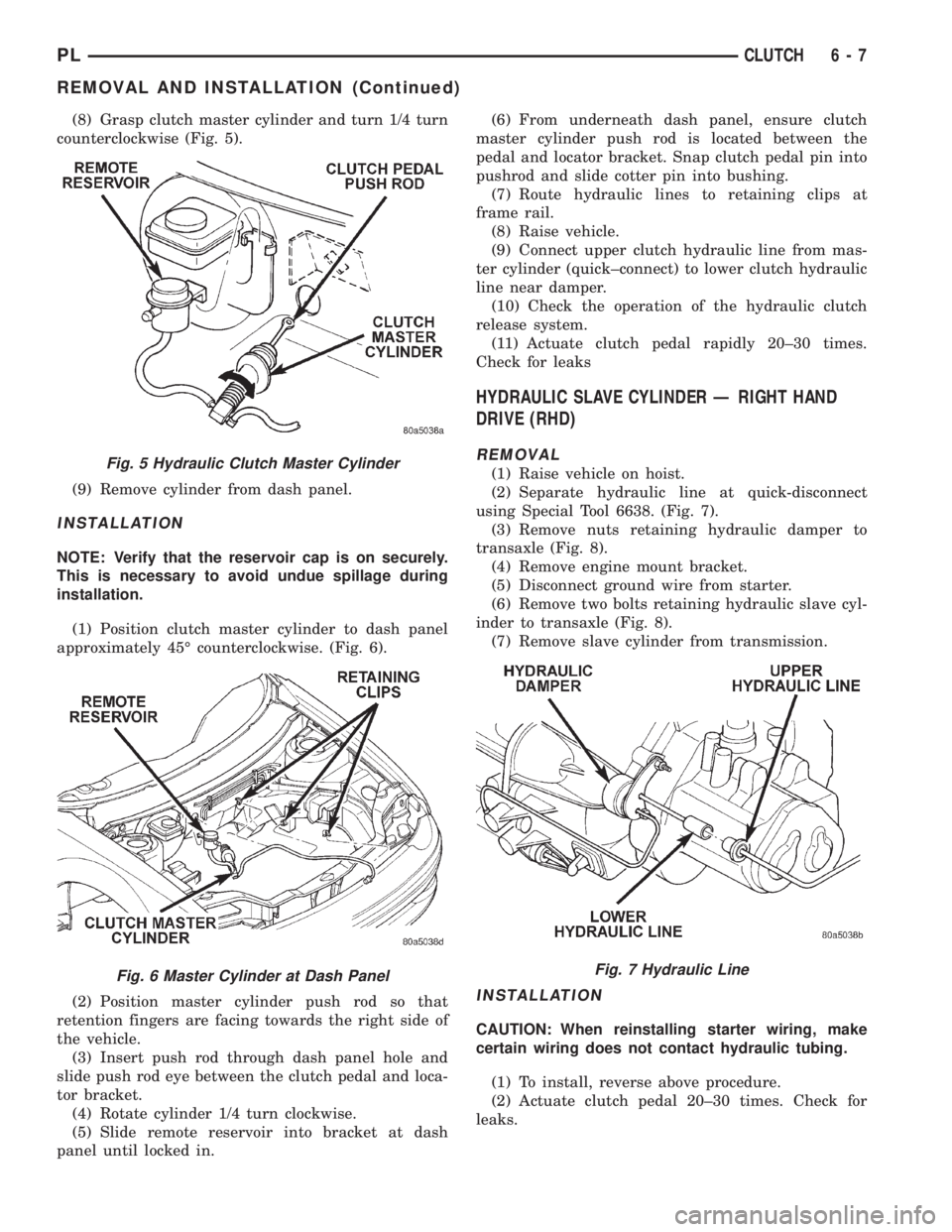

(8) Grasp clutch master cylinder and turn 1/4 turn

counterclockwise (Fig. 5).

(9) Remove cylinder from dash panel.

INSTALLATION

NOTE: Verify that the reservoir cap is on securely.

This is necessary to avoid undue spillage during

installation.

(1) Position clutch master cylinder to dash panel

approximately 45É counterclockwise. (Fig. 6).

(2) Position master cylinder push rod so that

retention fingers are facing towards the right side of

the vehicle.

(3) Insert push rod through dash panel hole and

slide push rod eye between the clutch pedal and loca-

tor bracket.

(4) Rotate cylinder 1/4 turn clockwise.

(5) Slide remote reservoir into bracket at dash

panel until locked in.(6) From underneath dash panel, ensure clutch

master cylinder push rod is located between the

pedal and locator bracket. Snap clutch pedal pin into

pushrod and slide cotter pin into bushing.

(7) Route hydraulic lines to retaining clips at

frame rail.

(8) Raise vehicle.

(9) Connect upper clutch hydraulic line from mas-

ter cylinder (quick±connect) to lower clutch hydraulic

line near damper.

(10) Check the operation of the hydraulic clutch

release system.

(11) Actuate clutch pedal rapidly 20±30 times.

Check for leaks

HYDRAULIC SLAVE CYLINDER Ð RIGHT HAND

DRIVE (RHD)

REMOVAL

(1) Raise vehicle on hoist.

(2) Separate hydraulic line at quick-disconnect

using Special Tool 6638. (Fig. 7).

(3) Remove nuts retaining hydraulic damper to

transaxle (Fig. 8).

(4) Remove engine mount bracket.

(5) Disconnect ground wire from starter.

(6) Remove two bolts retaining hydraulic slave cyl-

inder to transaxle (Fig. 8).

(7) Remove slave cylinder from transmission.

INSTALLATION

CAUTION: When reinstalling starter wiring, make

certain wiring does not contact hydraulic tubing.

(1) To install, reverse above procedure.

(2) Actuate clutch pedal 20±30 times. Check for

leaks.

Fig. 5 Hydraulic Clutch Master Cylinder

Fig. 6 Master Cylinder at Dash PanelFig. 7 Hydraulic Line

PLCLUTCH 6 - 7

REMOVAL AND INSTALLATION (Continued)

Page 198 of 1200

SELECTION AND ADDITIVES

The use of aluminum cylinder heads, intake mani-

folds DOHC, and water pumps requires special corro-

sion protection. MopartAntifreeze or the equivalent

is recommended for best engine cooling without cor-

rosion. When mixed only to a freeze point of -37ÉC

(-35ÉF) to -59ÉC (-50ÉF). If it looses color or becomes

contaminated, drain, flush, and replace with fresh

properly mixed solution.

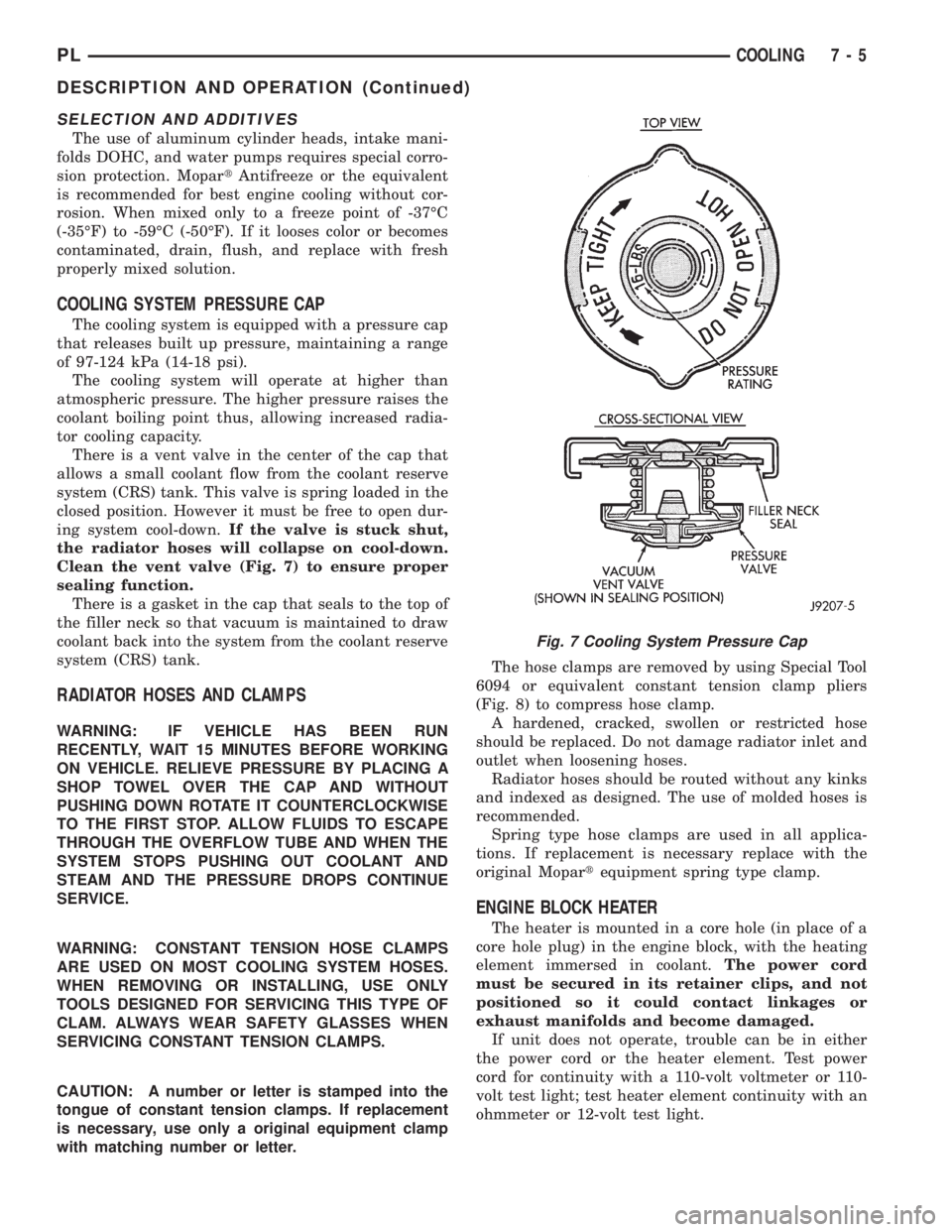

COOLING SYSTEM PRESSURE CAP

The cooling system is equipped with a pressure cap

that releases built up pressure, maintaining a range

of 97-124 kPa (14-18 psi).

The cooling system will operate at higher than

atmospheric pressure. The higher pressure raises the

coolant boiling point thus, allowing increased radia-

tor cooling capacity.

There is a vent valve in the center of the cap that

allows a small coolant flow from the coolant reserve

system (CRS) tank. This valve is spring loaded in the

closed position. However it must be free to open dur-

ing system cool-down.If the valve is stuck shut,

the radiator hoses will collapse on cool-down.

Clean the vent valve (Fig. 7) to ensure proper

sealing function.

There is a gasket in the cap that seals to the top of

the filler neck so that vacuum is maintained to draw

coolant back into the system from the coolant reserve

system (CRS) tank.

RADIATOR HOSES AND CLAMPS

WARNING: IF VEHICLE HAS BEEN RUN

RECENTLY, WAIT 15 MINUTES BEFORE WORKING

ON VEHICLE. RELIEVE PRESSURE BY PLACING A

SHOP TOWEL OVER THE CAP AND WITHOUT

PUSHING DOWN ROTATE IT COUNTERCLOCKWISE

TO THE FIRST STOP. ALLOW FLUIDS TO ESCAPE

THROUGH THE OVERFLOW TUBE AND WHEN THE

SYSTEM STOPS PUSHING OUT COOLANT AND

STEAM AND THE PRESSURE DROPS CONTINUE

SERVICE.

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAM. ALWAYS WEAR SAFETY GLASSES WHEN

SERVICING CONSTANT TENSION CLAMPS.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only a original equipment clamp

with matching number or letter.The hose clamps are removed by using Special Tool

6094 or equivalent constant tension clamp pliers

(Fig. 8) to compress hose clamp.

A hardened, cracked, swollen or restricted hose

should be replaced. Do not damage radiator inlet and

outlet when loosening hoses.

Radiator hoses should be routed without any kinks

and indexed as designed. The use of molded hoses is

recommended.

Spring type hose clamps are used in all applica-

tions. If replacement is necessary replace with the

original Mopartequipment spring type clamp.

ENGINE BLOCK HEATER

The heater is mounted in a core hole (in place of a

core hole plug) in the engine block, with the heating

element immersed in coolant.The power cord

must be secured in its retainer clips, and not

positioned so it could contact linkages or

exhaust manifolds and become damaged.

If unit does not operate, trouble can be in either

the power cord or the heater element. Test power

cord for continuity with a 110-volt voltmeter or 110-

volt test light; test heater element continuity with an

ohmmeter or 12-volt test light.

Fig. 7 Cooling System Pressure Cap

PLCOOLING 7 - 5

DESCRIPTION AND OPERATION (Continued)

Page 210 of 1200

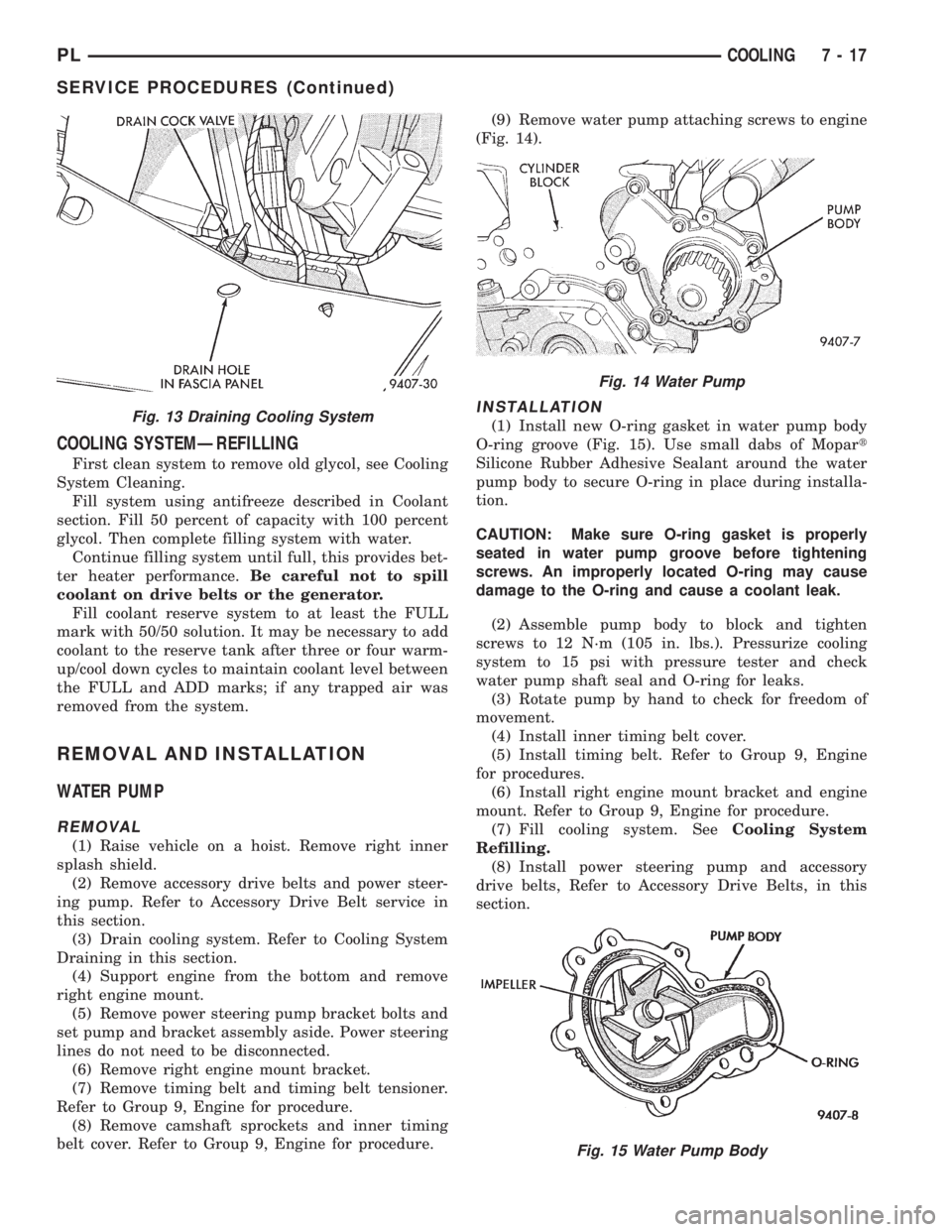

COOLING SYSTEMÐREFILLING

First clean system to remove old glycol, see Cooling

System Cleaning.

Fill system using antifreeze described in Coolant

section. Fill 50 percent of capacity with 100 percent

glycol. Then complete filling system with water.

Continue filling system until full, this provides bet-

ter heater performance.Be careful not to spill

coolant on drive belts or the generator.

Fill coolant reserve system to at least the FULL

mark with 50/50 solution. It may be necessary to add

coolant to the reserve tank after three or four warm-

up/cool down cycles to maintain coolant level between

the FULL and ADD marks; if any trapped air was

removed from the system.

REMOVAL AND INSTALLATION

WATER PUMP

REMOVAL

(1) Raise vehicle on a hoist. Remove right inner

splash shield.

(2) Remove accessory drive belts and power steer-

ing pump. Refer to Accessory Drive Belt service in

this section.

(3) Drain cooling system. Refer to Cooling System

Draining in this section.

(4) Support engine from the bottom and remove

right engine mount.

(5) Remove power steering pump bracket bolts and

set pump and bracket assembly aside. Power steering

lines do not need to be disconnected.

(6) Remove right engine mount bracket.

(7) Remove timing belt and timing belt tensioner.

Refer to Group 9, Engine for procedure.

(8) Remove camshaft sprockets and inner timing

belt cover. Refer to Group 9, Engine for procedure.(9) Remove water pump attaching screws to engine

(Fig. 14).

INSTALLATION

(1) Install new O-ring gasket in water pump body

O-ring groove (Fig. 15). Use small dabs of Mopart

Silicone Rubber Adhesive Sealant around the water

pump body to secure O-ring in place during installa-

tion.

CAUTION: Make sure O-ring gasket is properly

seated in water pump groove before tightening

screws. An improperly located O-ring may cause

damage to the O-ring and cause a coolant leak.

(2) Assemble pump body to block and tighten

screws to 12 N´m (105 in. lbs.). Pressurize cooling

system to 15 psi with pressure tester and check

water pump shaft seal and O-ring for leaks.

(3) Rotate pump by hand to check for freedom of

movement.

(4) Install inner timing belt cover.

(5) Install timing belt. Refer to Group 9, Engine

for procedures.

(6) Install right engine mount bracket and engine

mount. Refer to Group 9, Engine for procedure.

(7) Fill cooling system. SeeCooling System

Refilling.

(8) Install power steering pump and accessory

drive belts, Refer to Accessory Drive Belts, in this

section.Fig. 13 Draining Cooling System

Fig. 14 Water Pump

Fig. 15 Water Pump Body

PLCOOLING 7 - 17

SERVICE PROCEDURES (Continued)