light DODGE NEON 1999 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 290 of 1200

ANTENNA

The antenna has a short cable which connects into

the instrument panel harness. The connection is

made on the right side of the instrument panel.

Antenna performance may be tested by substitut-

ing a known good antenna. It is also possible to

check short or open circuits with an ohmmeter or

continuity light once the antenna cable is discon-

nected from the radio as follows:

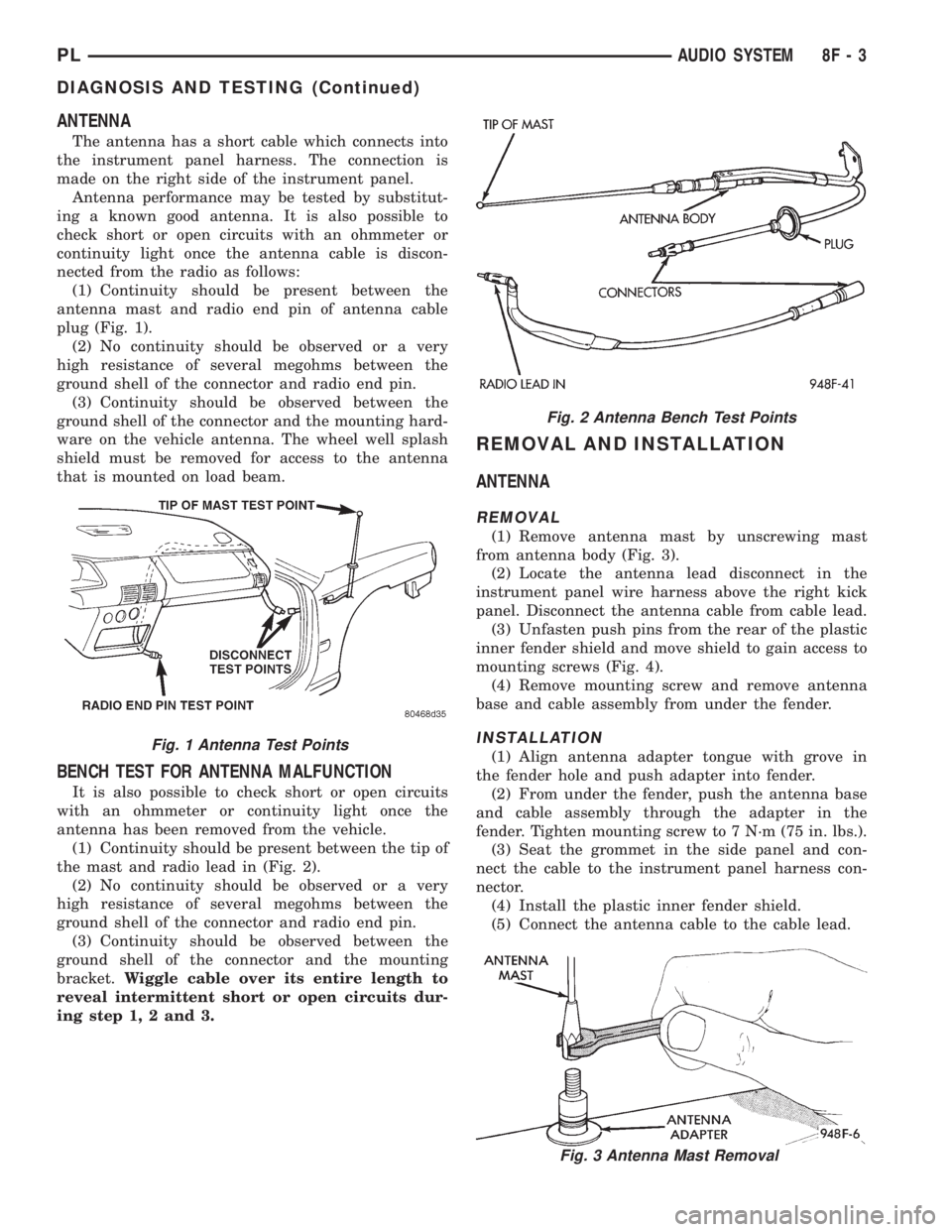

(1) Continuity should be present between the

antenna mast and radio end pin of antenna cable

plug (Fig. 1).

(2) No continuity should be observed or a very

high resistance of several megohms between the

ground shell of the connector and radio end pin.

(3) Continuity should be observed between the

ground shell of the connector and the mounting hard-

ware on the vehicle antenna. The wheel well splash

shield must be removed for access to the antenna

that is mounted on load beam.

BENCH TEST FOR ANTENNA MALFUNCTION

It is also possible to check short or open circuits

with an ohmmeter or continuity light once the

antenna has been removed from the vehicle.

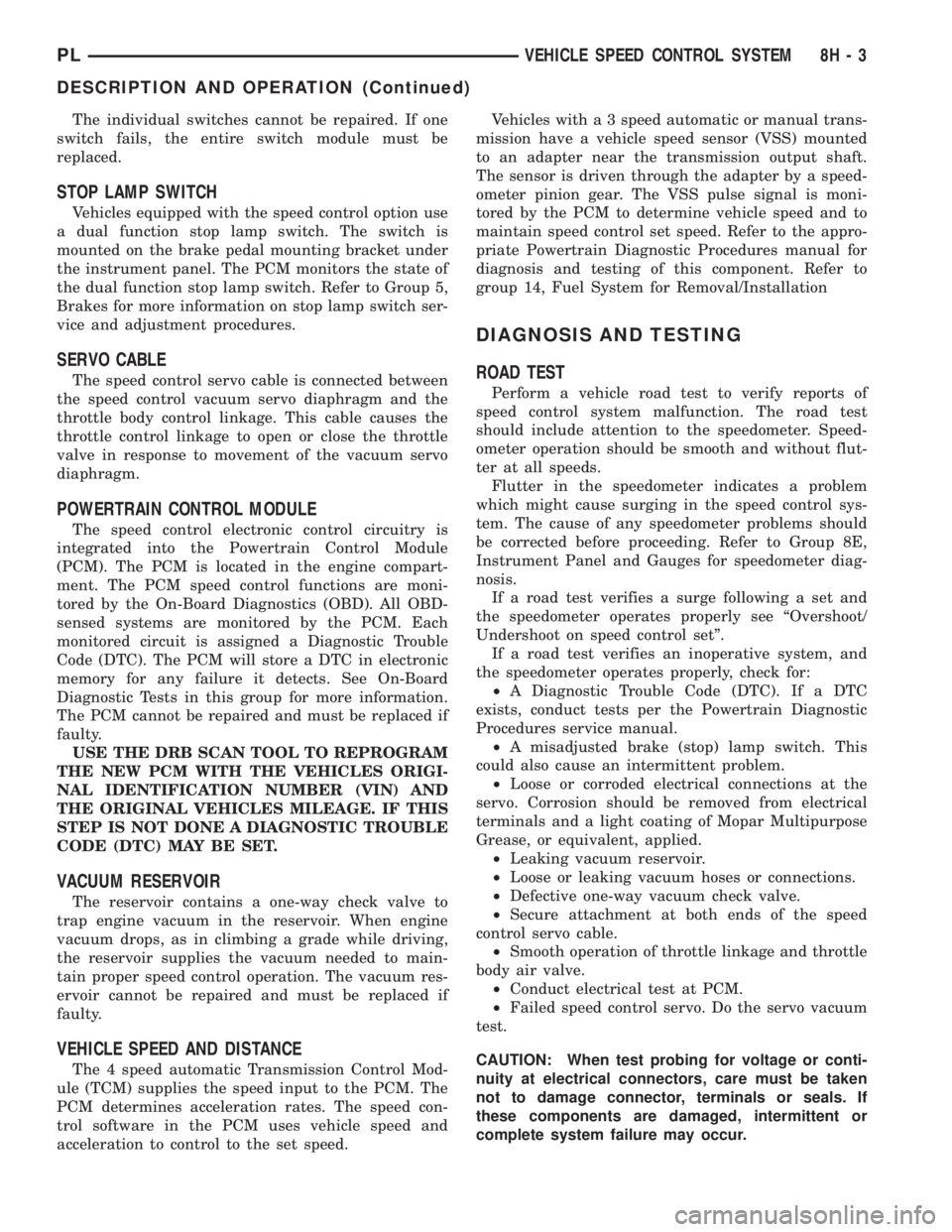

(1) Continuity should be present between the tip of

the mast and radio lead in (Fig. 2).

(2) No continuity should be observed or a very

high resistance of several megohms between the

ground shell of the connector and radio end pin.

(3) Continuity should be observed between the

ground shell of the connector and the mounting

bracket.Wiggle cable over its entire length to

reveal intermittent short or open circuits dur-

ing step 1, 2 and 3.

REMOVAL AND INSTALLATION

ANTENNA

REMOVAL

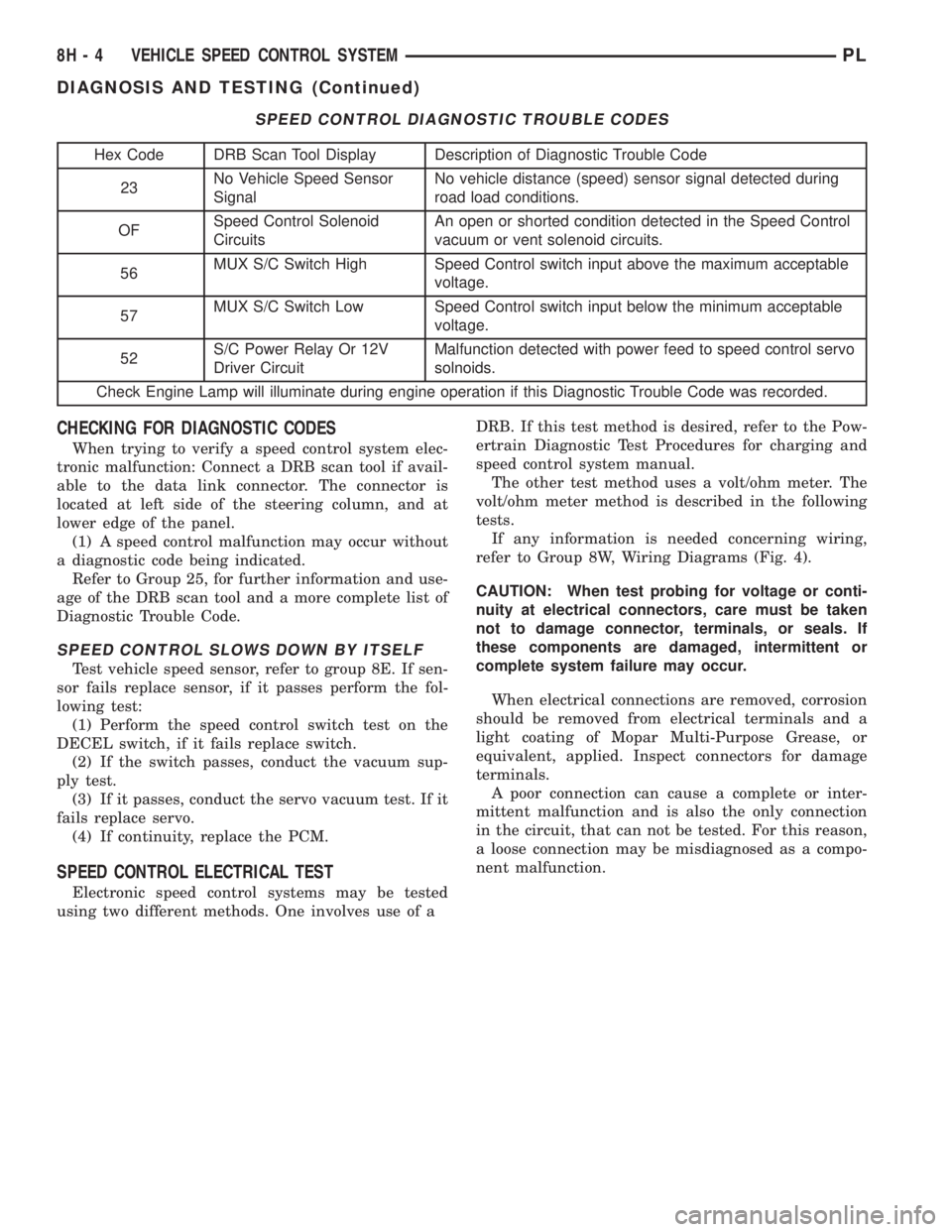

(1) Remove antenna mast by unscrewing mast

from antenna body (Fig. 3).

(2) Locate the antenna lead disconnect in the

instrument panel wire harness above the right kick

panel. Disconnect the antenna cable from cable lead.

(3) Unfasten push pins from the rear of the plastic

inner fender shield and move shield to gain access to

mounting screws (Fig. 4).

(4) Remove mounting screw and remove antenna

base and cable assembly from under the fender.

INSTALLATION

(1) Align antenna adapter tongue with grove in

the fender hole and push adapter into fender.

(2) From under the fender, push the antenna base

and cable assembly through the adapter in the

fender. Tighten mounting screw to 7 N´m (75 in. lbs.).

(3) Seat the grommet in the side panel and con-

nect the cable to the instrument panel harness con-

nector.

(4) Install the plastic inner fender shield.

(5) Connect the antenna cable to the cable lead.

Fig. 2 Antenna Bench Test Points

Fig. 3 Antenna Mast Removal

Fig. 1 Antenna Test Points

PLAUDIO SYSTEM 8F - 3

DIAGNOSIS AND TESTING (Continued)

Page 300 of 1200

The individual switches cannot be repaired. If one

switch fails, the entire switch module must be

replaced.

STOP LAMP SWITCH

Vehicles equipped with the speed control option use

a dual function stop lamp switch. The switch is

mounted on the brake pedal mounting bracket under

the instrument panel. The PCM monitors the state of

the dual function stop lamp switch. Refer to Group 5,

Brakes for more information on stop lamp switch ser-

vice and adjustment procedures.

SERVO CABLE

The speed control servo cable is connected between

the speed control vacuum servo diaphragm and the

throttle body control linkage. This cable causes the

throttle control linkage to open or close the throttle

valve in response to movement of the vacuum servo

diaphragm.

POWERTRAIN CONTROL MODULE

The speed control electronic control circuitry is

integrated into the Powertrain Control Module

(PCM). The PCM is located in the engine compart-

ment. The PCM speed control functions are moni-

tored by the On-Board Diagnostics (OBD). All OBD-

sensed systems are monitored by the PCM. Each

monitored circuit is assigned a Diagnostic Trouble

Code (DTC). The PCM will store a DTC in electronic

memory for any failure it detects. See On-Board

Diagnostic Tests in this group for more information.

The PCM cannot be repaired and must be replaced if

faulty.

USE THE DRB SCAN TOOL TO REPROGRAM

THE NEW PCM WITH THE VEHICLES ORIGI-

NAL IDENTIFICATION NUMBER (VIN) AND

THE ORIGINAL VEHICLES MILEAGE. IF THIS

STEP IS NOT DONE A DIAGNOSTIC TROUBLE

CODE (DTC) MAY BE SET.

VACUUM RESERVOIR

The reservoir contains a one-way check valve to

trap engine vacuum in the reservoir. When engine

vacuum drops, as in climbing a grade while driving,

the reservoir supplies the vacuum needed to main-

tain proper speed control operation. The vacuum res-

ervoir cannot be repaired and must be replaced if

faulty.

VEHICLE SPEED AND DISTANCE

The 4 speed automatic Transmission Control Mod-

ule (TCM) supplies the speed input to the PCM. The

PCM determines acceleration rates. The speed con-

trol software in the PCM uses vehicle speed and

acceleration to control to the set speed.Vehicles with a 3 speed automatic or manual trans-

mission have a vehicle speed sensor (VSS) mounted

to an adapter near the transmission output shaft.

The sensor is driven through the adapter by a speed-

ometer pinion gear. The VSS pulse signal is moni-

tored by the PCM to determine vehicle speed and to

maintain speed control set speed. Refer to the appro-

priate Powertrain Diagnostic Procedures manual for

diagnosis and testing of this component. Refer to

group 14, Fuel System for Removal/Installation

DIAGNOSIS AND TESTING

ROAD TEST

Perform a vehicle road test to verify reports of

speed control system malfunction. The road test

should include attention to the speedometer. Speed-

ometer operation should be smooth and without flut-

ter at all speeds.

Flutter in the speedometer indicates a problem

which might cause surging in the speed control sys-

tem. The cause of any speedometer problems should

be corrected before proceeding. Refer to Group 8E,

Instrument Panel and Gauges for speedometer diag-

nosis.

If a road test verifies a surge following a set and

the speedometer operates properly see ªOvershoot/

Undershoot on speed control setº.

If a road test verifies an inoperative system, and

the speedometer operates properly, check for:

²A Diagnostic Trouble Code (DTC). If a DTC

exists, conduct tests per the Powertrain Diagnostic

Procedures service manual.

²A misadjusted brake (stop) lamp switch. This

could also cause an intermittent problem.

²Loose or corroded electrical connections at the

servo. Corrosion should be removed from electrical

terminals and a light coating of Mopar Multipurpose

Grease, or equivalent, applied.

²Leaking vacuum reservoir.

²Loose or leaking vacuum hoses or connections.

²Defective one-way vacuum check valve.

²Secure attachment at both ends of the speed

control servo cable.

²Smooth operation of throttle linkage and throttle

body air valve.

²Conduct electrical test at PCM.

²Failed speed control servo. Do the servo vacuum

test.

CAUTION: When test probing for voltage or conti-

nuity at electrical connectors, care must be taken

not to damage connector, terminals or seals. If

these components are damaged, intermittent or

complete system failure may occur.

PLVEHICLE SPEED CONTROL SYSTEM 8H - 3

DESCRIPTION AND OPERATION (Continued)

Page 301 of 1200

CHECKING FOR DIAGNOSTIC CODES

When trying to verify a speed control system elec-

tronic malfunction: Connect a DRB scan tool if avail-

able to the data link connector. The connector is

located at left side of the steering column, and at

lower edge of the panel.

(1) A speed control malfunction may occur without

a diagnostic code being indicated.

Refer to Group 25, for further information and use-

age of the DRB scan tool and a more complete list of

Diagnostic Trouble Code.

SPEED CONTROL SLOWS DOWN BY ITSELF

Test vehicle speed sensor, refer to group 8E. If sen-

sor fails replace sensor, if it passes perform the fol-

lowing test:

(1) Perform the speed control switch test on the

DECEL switch, if it fails replace switch.

(2) If the switch passes, conduct the vacuum sup-

ply test.

(3) If it passes, conduct the servo vacuum test. If it

fails replace servo.

(4) If continuity, replace the PCM.

SPEED CONTROL ELECTRICAL TEST

Electronic speed control systems may be tested

using two different methods. One involves use of aDRB. If this test method is desired, refer to the Pow-

ertrain Diagnostic Test Procedures for charging and

speed control system manual.

The other test method uses a volt/ohm meter. The

volt/ohm meter method is described in the following

tests.

If any information is needed concerning wiring,

refer to Group 8W, Wiring Diagrams (Fig. 4).

CAUTION: When test probing for voltage or conti-

nuity at electrical connectors, care must be taken

not to damage connector, terminals, or seals. If

these components are damaged, intermittent or

complete system failure may occur.

When electrical connections are removed, corrosion

should be removed from electrical terminals and a

light coating of Mopar Multi-Purpose Grease, or

equivalent, applied. Inspect connectors for damage

terminals.

A poor connection can cause a complete or inter-

mittent malfunction and is also the only connection

in the circuit, that can not be tested. For this reason,

a loose connection may be misdiagnosed as a compo-

nent malfunction.

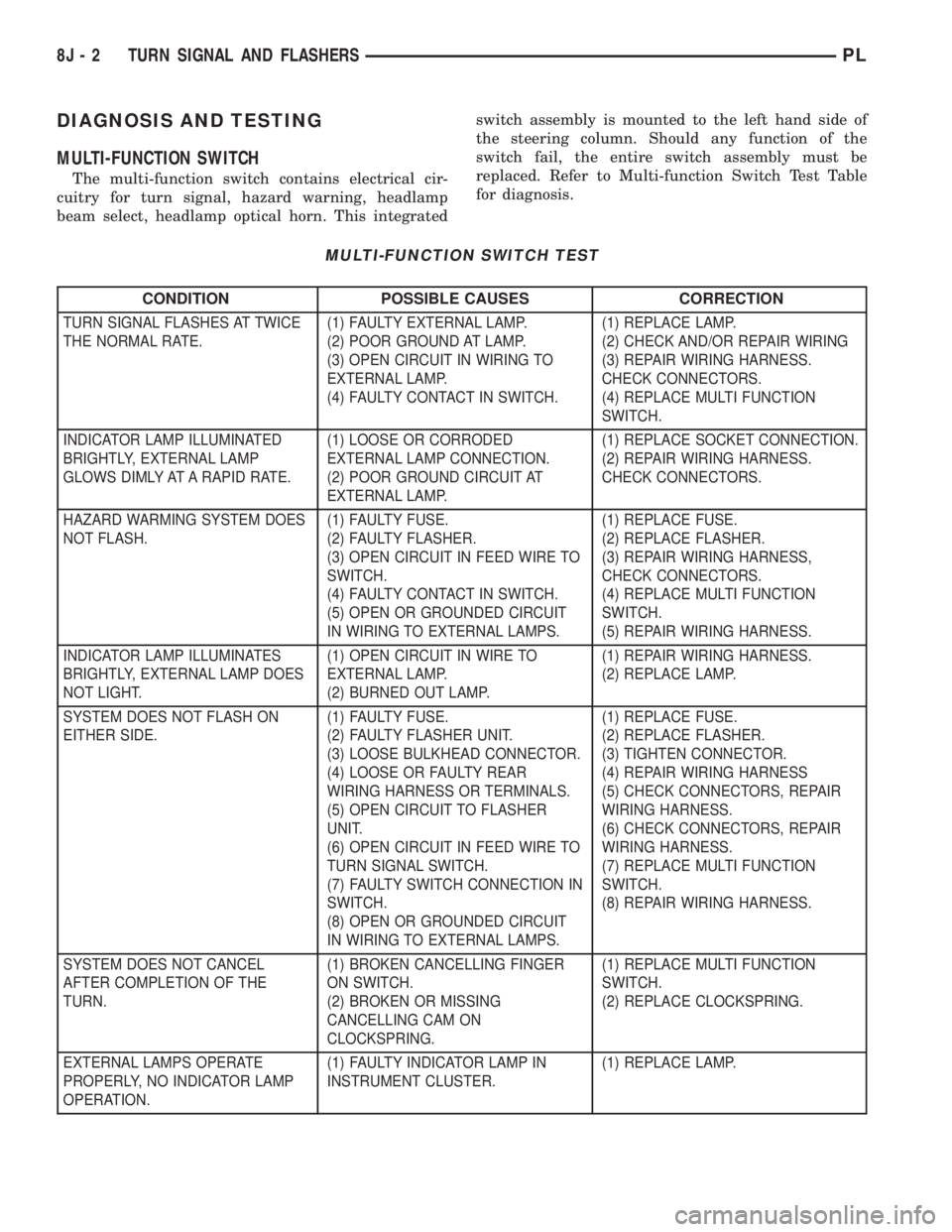

SPEED CONTROL DIAGNOSTIC TROUBLE CODES

Hex Code DRB Scan Tool Display Description of Diagnostic Trouble Code

23No Vehicle Speed Sensor

SignalNo vehicle distance (speed) sensor signal detected during

road load conditions.

OFSpeed Control Solenoid

CircuitsAn open or shorted condition detected in the Speed Control

vacuum or vent solenoid circuits.

56MUX S/C Switch High Speed Control switch input above the maximum acceptable

voltage.

57MUX S/C Switch Low Speed Control switch input below the minimum acceptable

voltage.

52S/C Power Relay Or 12V

Driver CircuitMalfunction detected with power feed to speed control servo

solnoids.

Check Engine Lamp will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

8H - 4 VEHICLE SPEED CONTROL SYSTEMPL

DIAGNOSIS AND TESTING (Continued)

Page 311 of 1200

DIAGNOSIS AND TESTING

MULTI-FUNCTION SWITCH

The multi-function switch contains electrical cir-

cuitry for turn signal, hazard warning, headlamp

beam select, headlamp optical horn. This integratedswitch assembly is mounted to the left hand side of

the steering column. Should any function of the

switch fail, the entire switch assembly must be

replaced. Refer to Multi-function Switch Test Table

for diagnosis.

MULTI-FUNCTION SWITCH TEST

CONDITION POSSIBLE CAUSES CORRECTION

TURN SIGNAL FLASHES AT TWICE

THE NORMAL RATE.(1) FAULTY EXTERNAL LAMP.

(2) POOR GROUND AT LAMP.

(3) OPEN CIRCUIT IN WIRING TO

EXTERNAL LAMP.

(4) FAULTY CONTACT IN SWITCH.(1) REPLACE LAMP.

(2) CHECK AND/OR REPAIR WIRING

(3) REPAIR WIRING HARNESS.

CHECK CONNECTORS.

(4) REPLACE MULTI FUNCTION

SWITCH.

INDICATOR LAMP ILLUMINATED

BRIGHTLY, EXTERNAL LAMP

GLOWS DIMLY AT A RAPID RATE.(1) LOOSE OR CORRODED

EXTERNAL LAMP CONNECTION.

(2) POOR GROUND CIRCUIT AT

EXTERNAL LAMP.(1) REPLACE SOCKET CONNECTION.

(2) REPAIR WIRING HARNESS.

CHECK CONNECTORS.

HAZARD WARMING SYSTEM DOES

NOT FLASH.(1) FAULTY FUSE.

(2) FAULTY FLASHER.

(3) OPEN CIRCUIT IN FEED WIRE TO

SWITCH.

(4) FAULTY CONTACT IN SWITCH.

(5) OPEN OR GROUNDED CIRCUIT

IN WIRING TO EXTERNAL LAMPS.(1) REPLACE FUSE.

(2) REPLACE FLASHER.

(3) REPAIR WIRING HARNESS,

CHECK CONNECTORS.

(4) REPLACE MULTI FUNCTION

SWITCH.

(5) REPAIR WIRING HARNESS.

INDICATOR LAMP ILLUMINATES

BRIGHTLY, EXTERNAL LAMP DOES

NOT LIGHT.(1) OPEN CIRCUIT IN WIRE TO

EXTERNAL LAMP.

(2) BURNED OUT LAMP.(1) REPAIR WIRING HARNESS.

(2) REPLACE LAMP.

SYSTEM DOES NOT FLASH ON

EITHER SIDE.(1) FAULTY FUSE.

(2) FAULTY FLASHER UNIT.

(3) LOOSE BULKHEAD CONNECTOR.

(4) LOOSE OR FAULTY REAR

WIRING HARNESS OR TERMINALS.

(5) OPEN CIRCUIT TO FLASHER

UNIT.

(6) OPEN CIRCUIT IN FEED WIRE TO

TURN SIGNAL SWITCH.

(7) FAULTY SWITCH CONNECTION IN

SWITCH.

(8) OPEN OR GROUNDED CIRCUIT

IN WIRING TO EXTERNAL LAMPS.(1) REPLACE FUSE.

(2) REPLACE FLASHER.

(3) TIGHTEN CONNECTOR.

(4) REPAIR WIRING HARNESS

(5) CHECK CONNECTORS, REPAIR

WIRING HARNESS.

(6) CHECK CONNECTORS, REPAIR

WIRING HARNESS.

(7) REPLACE MULTI FUNCTION

SWITCH.

(8) REPAIR WIRING HARNESS.

SYSTEM DOES NOT CANCEL

AFTER COMPLETION OF THE

TURN.(1) BROKEN CANCELLING FINGER

ON SWITCH.

(2) BROKEN OR MISSING

CANCELLING CAM ON

CLOCKSPRING.(1) REPLACE MULTI FUNCTION

SWITCH.

(2) REPLACE CLOCKSPRING.

EXTERNAL LAMPS OPERATE

PROPERLY, NO INDICATOR LAMP

OPERATION.(1) FAULTY INDICATOR LAMP IN

INSTRUMENT CLUSTER.(1) REPLACE LAMP.

8J - 2 TURN SIGNAL AND FLASHERSPL

Page 319 of 1200

WIPER LINKAGE

REMOVAL

(1) Remove wiper module refer above (Fig. 9).

(2) Disconnect wiper arm linkage, by insert screw-

driver between ball cap and linkage, then twist the

screwdriver and lift straight up on linkage.

INSTALLATION

For installation reverse the above procedures.

Using pliers or hand press the ball cap straight on to

the ball stud.

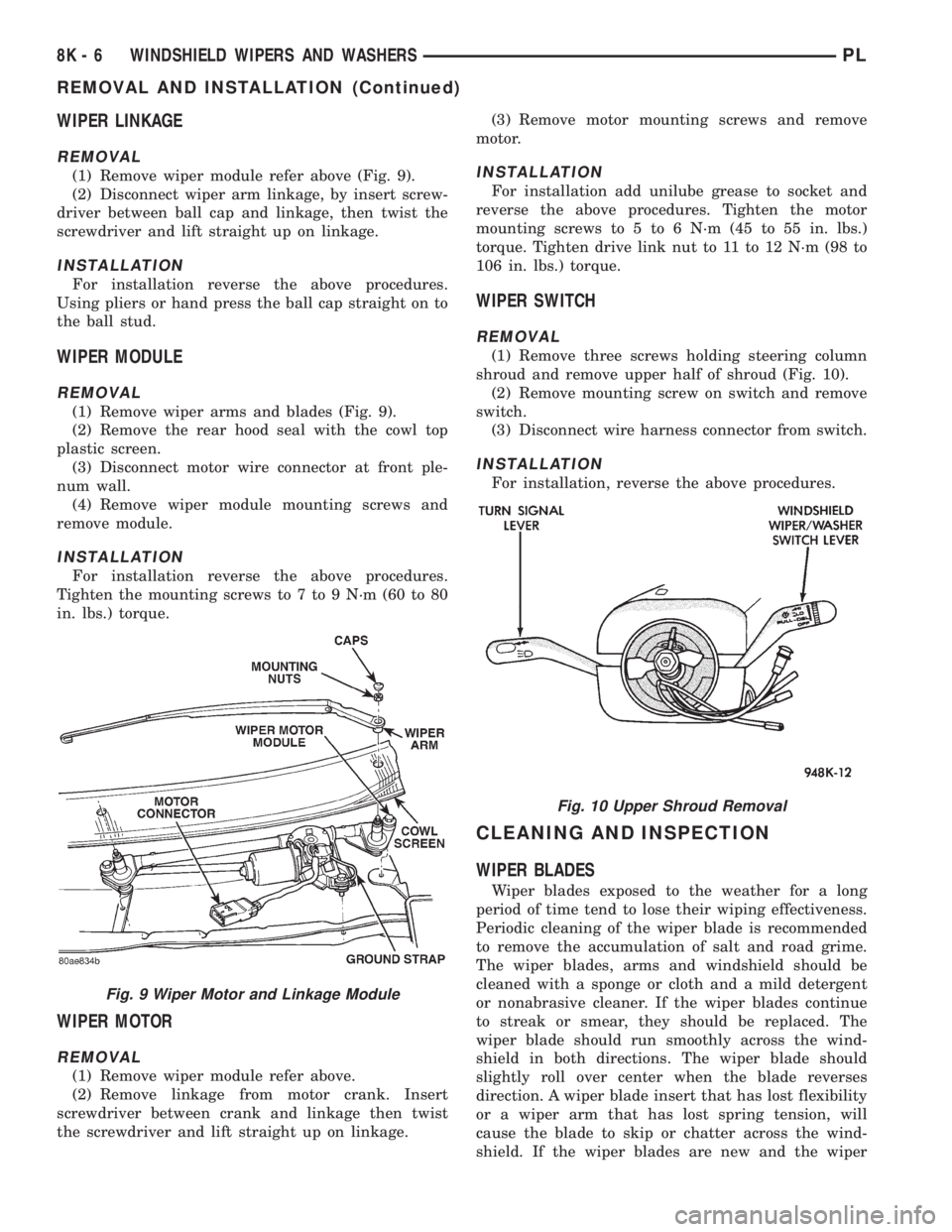

WIPER MODULE

REMOVAL

(1) Remove wiper arms and blades (Fig. 9).

(2) Remove the rear hood seal with the cowl top

plastic screen.

(3) Disconnect motor wire connector at front ple-

num wall.

(4) Remove wiper module mounting screws and

remove module.

INSTALLATION

For installation reverse the above procedures.

Tighten the mounting screws to 7 to 9 N´m (60 to 80

in. lbs.) torque.

WIPER MOTOR

REMOVAL

(1) Remove wiper module refer above.

(2) Remove linkage from motor crank. Insert

screwdriver between crank and linkage then twist

the screwdriver and lift straight up on linkage.(3) Remove motor mounting screws and remove

motor.

INSTALLATION

For installation add unilube grease to socket and

reverse the above procedures. Tighten the motor

mounting screws to 5 to 6 N´m (45 to 55 in. lbs.)

torque. Tighten drive link nut to 11 to 12 N´m (98 to

106 in. lbs.) torque.

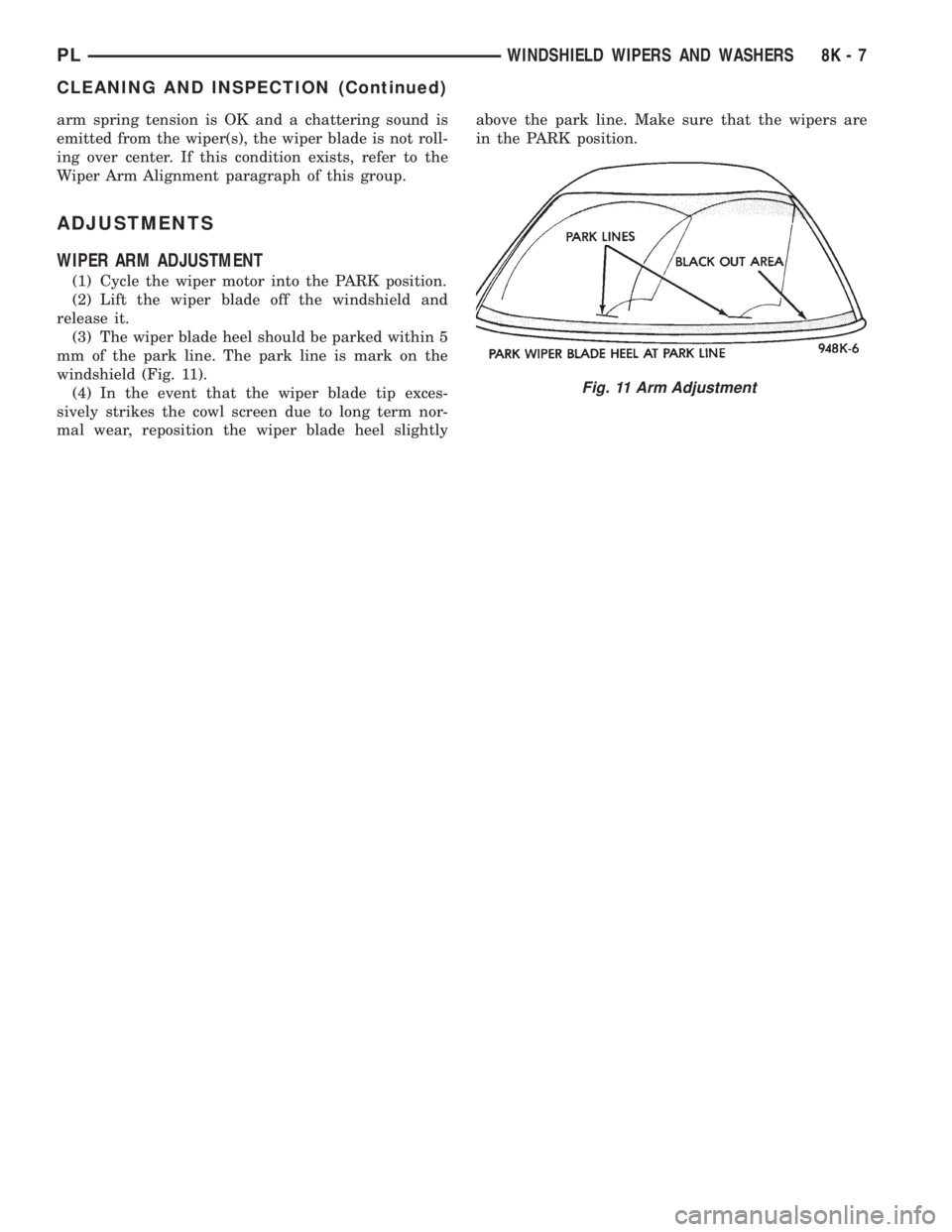

WIPER SWITCH

REMOVAL

(1) Remove three screws holding steering column

shroud and remove upper half of shroud (Fig. 10).

(2) Remove mounting screw on switch and remove

switch.

(3) Disconnect wire harness connector from switch.

INSTALLATION

For installation, reverse the above procedures.

CLEANING AND INSPECTION

WIPER BLADES

Wiper blades exposed to the weather for a long

period of time tend to lose their wiping effectiveness.

Periodic cleaning of the wiper blade is recommended

to remove the accumulation of salt and road grime.

The wiper blades, arms and windshield should be

cleaned with a sponge or cloth and a mild detergent

or nonabrasive cleaner. If the wiper blades continue

to streak or smear, they should be replaced. The

wiper blade should run smoothly across the wind-

shield in both directions. The wiper blade should

slightly roll over center when the blade reverses

direction. A wiper blade insert that has lost flexibility

or a wiper arm that has lost spring tension, will

cause the blade to skip or chatter across the wind-

shield. If the wiper blades are new and the wiper

Fig. 9 Wiper Motor and Linkage Module

Fig. 10 Upper Shroud Removal

8K - 6 WINDSHIELD WIPERS AND WASHERSPL

REMOVAL AND INSTALLATION (Continued)

Page 320 of 1200

arm spring tension is OK and a chattering sound is

emitted from the wiper(s), the wiper blade is not roll-

ing over center. If this condition exists, refer to the

Wiper Arm Alignment paragraph of this group.

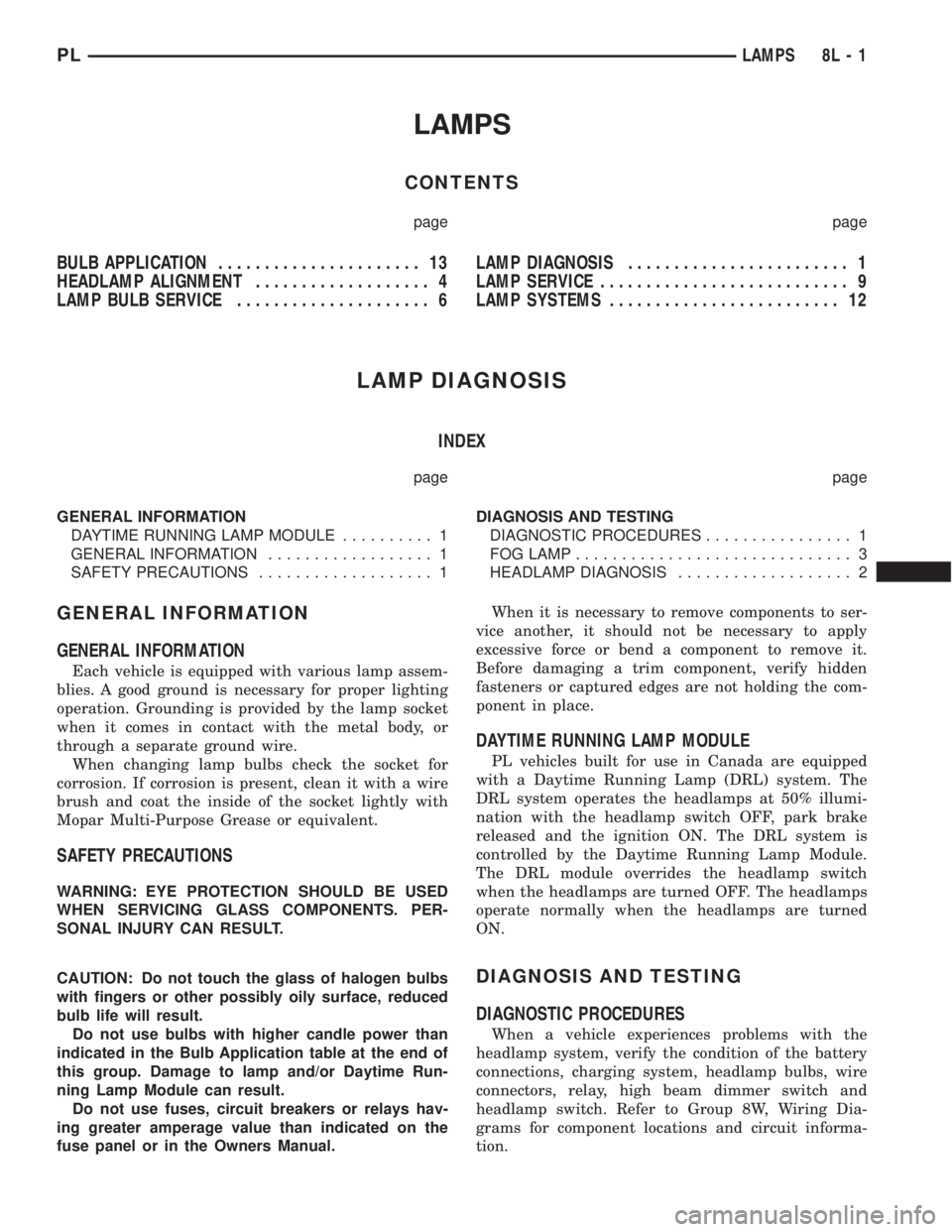

ADJUSTMENTS

WIPER ARM ADJUSTMENT

(1) Cycle the wiper motor into the PARK position.

(2) Lift the wiper blade off the windshield and

release it.

(3) The wiper blade heel should be parked within 5

mm of the park line. The park line is mark on the

windshield (Fig. 11).

(4) In the event that the wiper blade tip exces-

sively strikes the cowl screen due to long term nor-

mal wear, reposition the wiper blade heel slightlyabove the park line. Make sure that the wipers are

in the PARK position.

Fig. 11 Arm Adjustment

PLWINDSHIELD WIPERS AND WASHERS 8K - 7

CLEANING AND INSPECTION (Continued)

Page 330 of 1200

LAMPS

CONTENTS

page page

BULB APPLICATION...................... 13

HEADLAMP ALIGNMENT................... 4

LAMP BULB SERVICE..................... 6LAMP DIAGNOSIS........................ 1

LAMP SERVICE........................... 9

LAMP SYSTEMS......................... 12

LAMP DIAGNOSIS

INDEX

page page

GENERAL INFORMATION

DAYTIME RUNNING LAMP MODULE.......... 1

GENERAL INFORMATION.................. 1

SAFETY PRECAUTIONS................... 1DIAGNOSIS AND TESTING

DIAGNOSTIC PROCEDURES................ 1

FOG LAMP.............................. 3

HEADLAMP DIAGNOSIS................... 2

GENERAL INFORMATION

GENERAL INFORMATION

Each vehicle is equipped with various lamp assem-

blies. A good ground is necessary for proper lighting

operation. Grounding is provided by the lamp socket

when it comes in contact with the metal body, or

through a separate ground wire.

When changing lamp bulbs check the socket for

corrosion. If corrosion is present, clean it with a wire

brush and coat the inside of the socket lightly with

Mopar Multi-Purpose Grease or equivalent.

SAFETY PRECAUTIONS

WARNING: EYE PROTECTION SHOULD BE USED

WHEN SERVICING GLASS COMPONENTS. PER-

SONAL INJURY CAN RESULT.

CAUTION: Do not touch the glass of halogen bulbs

with fingers or other possibly oily surface, reduced

bulb life will result.

Do not use bulbs with higher candle power than

indicated in the Bulb Application table at the end of

this group. Damage to lamp and/or Daytime Run-

ning Lamp Module can result.

Do not use fuses, circuit breakers or relays hav-

ing greater amperage value than indicated on the

fuse panel or in the Owners Manual.When it is necessary to remove components to ser-

vice another, it should not be necessary to apply

excessive force or bend a component to remove it.

Before damaging a trim component, verify hidden

fasteners or captured edges are not holding the com-

ponent in place.

DAYTIME RUNNING LAMP MODULE

PL vehicles built for use in Canada are equipped

with a Daytime Running Lamp (DRL) system. The

DRL system operates the headlamps at 50% illumi-

nation with the headlamp switch OFF, park brake

released and the ignition ON. The DRL system is

controlled by the Daytime Running Lamp Module.

The DRL module overrides the headlamp switch

when the headlamps are turned OFF. The headlamps

operate normally when the headlamps are turned

ON.

DIAGNOSIS AND TESTING

DIAGNOSTIC PROCEDURES

When a vehicle experiences problems with the

headlamp system, verify the condition of the battery

connections, charging system, headlamp bulbs, wire

connectors, relay, high beam dimmer switch and

headlamp switch. Refer to Group 8W, Wiring Dia-

grams for component locations and circuit informa-

tion.

PLLAMPS 8L - 1

Page 331 of 1200

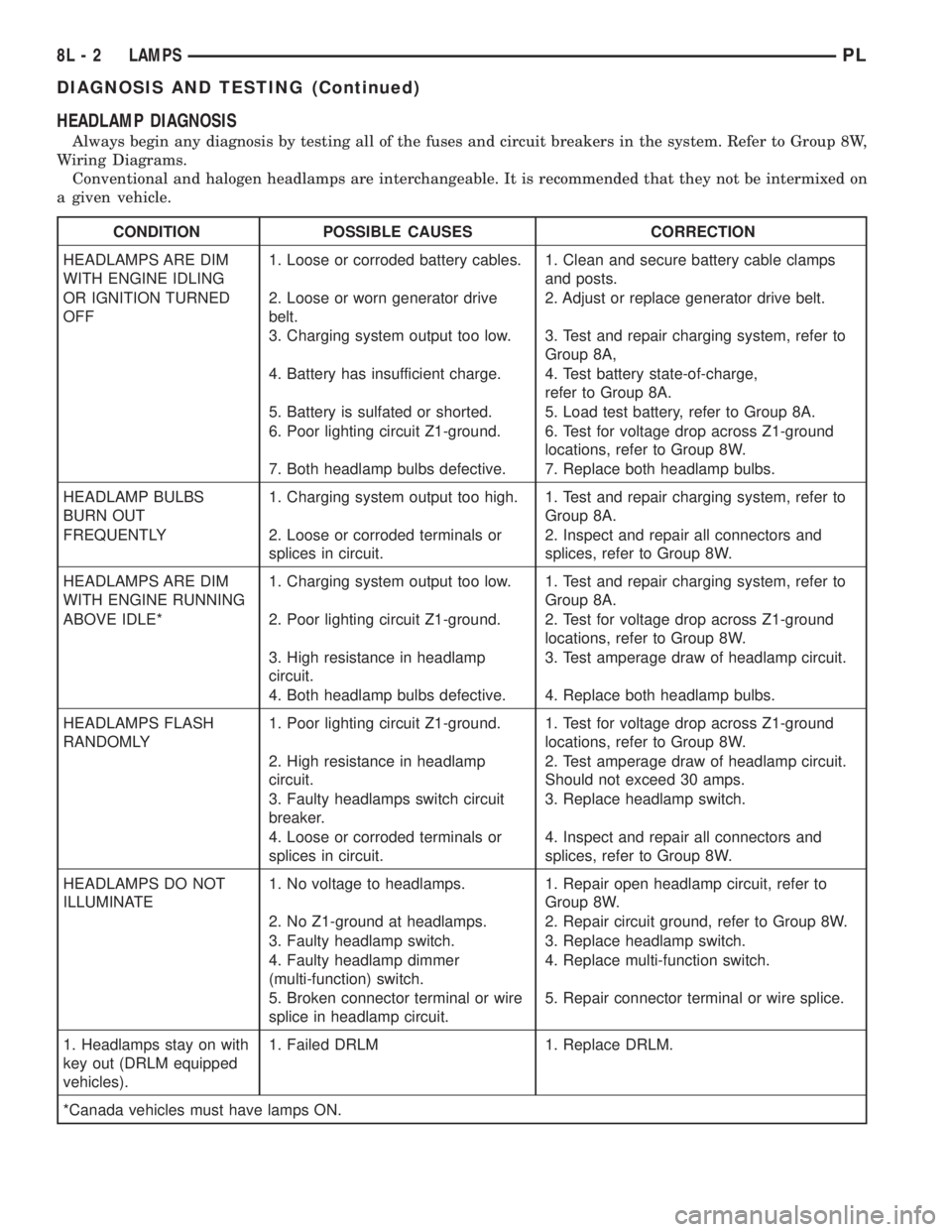

HEADLAMP DIAGNOSIS

Always begin any diagnosis by testing all of the fuses and circuit breakers in the system. Refer to Group 8W,

Wiring Diagrams.

Conventional and halogen headlamps are interchangeable. It is recommended that they not be intermixed on

a given vehicle.

CONDITION POSSIBLE CAUSES CORRECTION

HEADLAMPS ARE DIM

WITH ENGINE IDLING1. Loose or corroded battery cables. 1. Clean and secure battery cable clamps

and posts.

OR IGNITION TURNED

OFF2. Loose or worn generator drive

belt.2. Adjust or replace generator drive belt.

3. Charging system output too low. 3. Test and repair charging system, refer to

Group 8A,

4. Battery has insufficient charge. 4. Test battery state-of-charge,

refer to Group 8A.

5. Battery is sulfated or shorted. 5. Load test battery, refer to Group 8A.

6. Poor lighting circuit Z1-ground. 6. Test for voltage drop across Z1-ground

locations, refer to Group 8W.

7. Both headlamp bulbs defective. 7. Replace both headlamp bulbs.

HEADLAMP BULBS

BURN OUT1. Charging system output too high. 1. Test and repair charging system, refer to

Group 8A.

FREQUENTLY 2. Loose or corroded terminals or

splices in circuit.2. Inspect and repair all connectors and

splices, refer to Group 8W.

HEADLAMPS ARE DIM

WITH ENGINE RUNNING1. Charging system output too low. 1. Test and repair charging system, refer to

Group 8A.

ABOVE IDLE* 2. Poor lighting circuit Z1-ground. 2. Test for voltage drop across Z1-ground

locations, refer to Group 8W.

3. High resistance in headlamp

circuit.3. Test amperage draw of headlamp circuit.

4. Both headlamp bulbs defective. 4. Replace both headlamp bulbs.

HEADLAMPS FLASH

RANDOMLY1. Poor lighting circuit Z1-ground. 1. Test for voltage drop across Z1-ground

locations, refer to Group 8W.

2. High resistance in headlamp

circuit.2. Test amperage draw of headlamp circuit.

Should not exceed 30 amps.

3. Faulty headlamps switch circuit

breaker.3. Replace headlamp switch.

4. Loose or corroded terminals or

splices in circuit.4. Inspect and repair all connectors and

splices, refer to Group 8W.

HEADLAMPS DO NOT

ILLUMINATE1. No voltage to headlamps. 1. Repair open headlamp circuit, refer to

Group 8W.

2. No Z1-ground at headlamps. 2. Repair circuit ground, refer to Group 8W.

3. Faulty headlamp switch. 3. Replace headlamp switch.

4. Faulty headlamp dimmer

(multi-function) switch.4. Replace multi-function switch.

5. Broken connector terminal or wire

splice in headlamp circuit.5. Repair connector terminal or wire splice.

1. Headlamps stay on with

key out (DRLM equipped

vehicles).1. Failed DRLM 1. Replace DRLM.

*Canada vehicles must have lamps ON.

8L - 2 LAMPSPL

DIAGNOSIS AND TESTING (Continued)

Page 332 of 1200

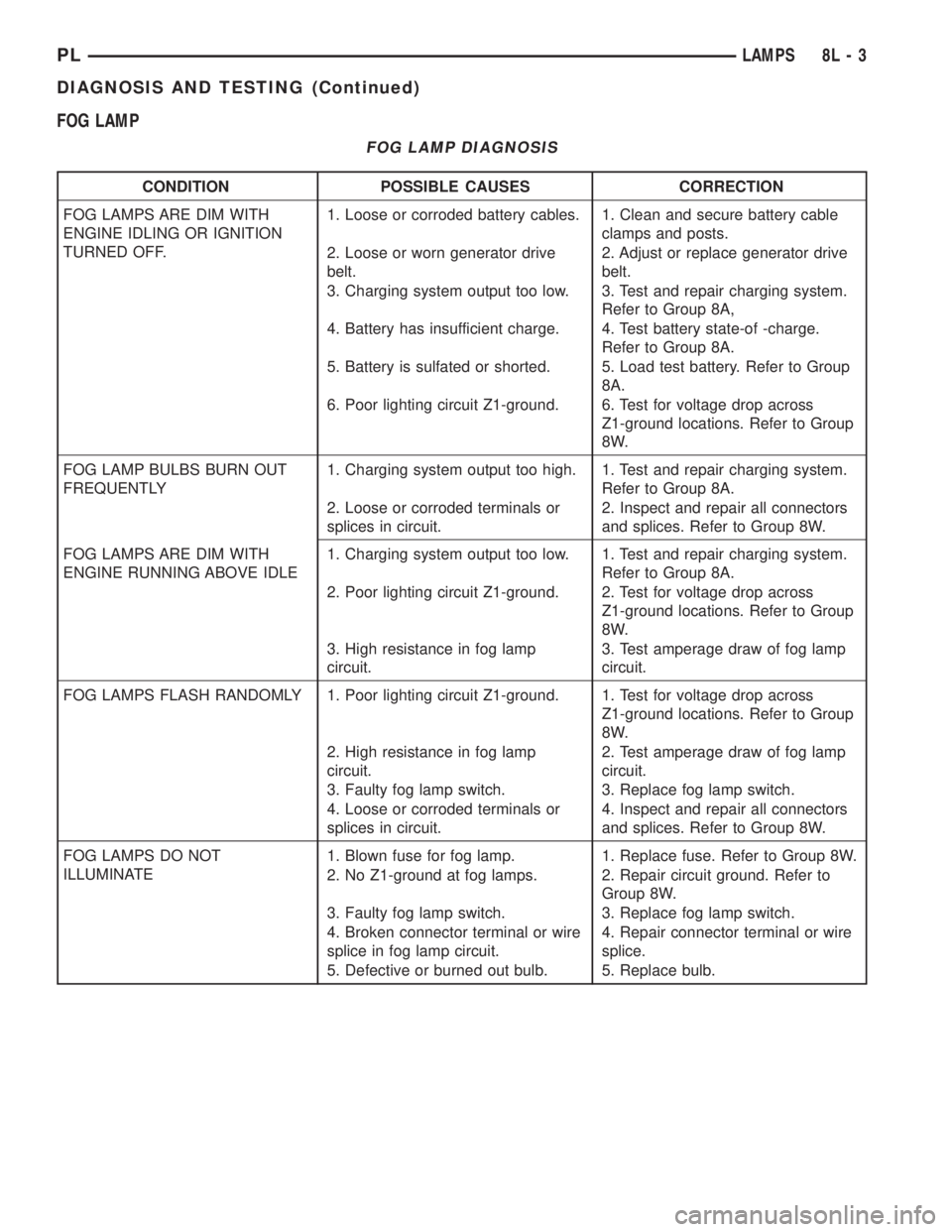

FOG LAMP

FOG LAMP DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

FOG LAMPS ARE DIM WITH

ENGINE IDLING OR IGNITION

TURNED OFF.1. Loose or corroded battery cables. 1. Clean and secure battery cable

clamps and posts.

2. Loose or worn generator drive

belt.2. Adjust or replace generator drive

belt.

3. Charging system output too low. 3. Test and repair charging system.

Refer to Group 8A,

4. Battery has insufficient charge. 4. Test battery state-of -charge.

Refer to Group 8A.

5. Battery is sulfated or shorted. 5. Load test battery. Refer to Group

8A.

6. Poor lighting circuit Z1-ground. 6. Test for voltage drop across

Z1-ground locations. Refer to Group

8W.

FOG LAMP BULBS BURN OUT

FREQUENTLY1. Charging system output too high. 1. Test and repair charging system.

Refer to Group 8A.

2. Loose or corroded terminals or

splices in circuit.2. Inspect and repair all connectors

and splices. Refer to Group 8W.

FOG LAMPS ARE DIM WITH

ENGINE RUNNING ABOVE IDLE1. Charging system output too low. 1. Test and repair charging system.

Refer to Group 8A.

2. Poor lighting circuit Z1-ground. 2. Test for voltage drop across

Z1-ground locations. Refer to Group

8W.

3. High resistance in fog lamp

circuit.3. Test amperage draw of fog lamp

circuit.

FOG LAMPS FLASH RANDOMLY 1. Poor lighting circuit Z1-ground. 1. Test for voltage drop across

Z1-ground locations. Refer to Group

8W.

2. High resistance in fog lamp

circuit.2. Test amperage draw of fog lamp

circuit.

3. Faulty fog lamp switch. 3. Replace fog lamp switch.

4. Loose or corroded terminals or

splices in circuit.4. Inspect and repair all connectors

and splices. Refer to Group 8W.

FOG LAMPS DO NOT

ILLUMINATE1. Blown fuse for fog lamp. 1. Replace fuse. Refer to Group 8W.

2. No Z1-ground at fog lamps. 2. Repair circuit ground. Refer to

Group 8W.

3. Faulty fog lamp switch. 3. Replace fog lamp switch.

4. Broken connector terminal or wire

splice in fog lamp circuit.4. Repair connector terminal or wire

splice.

5. Defective or burned out bulb. 5. Replace bulb.

PLLAMPS 8L - 3

DIAGNOSIS AND TESTING (Continued)

Page 342 of 1200

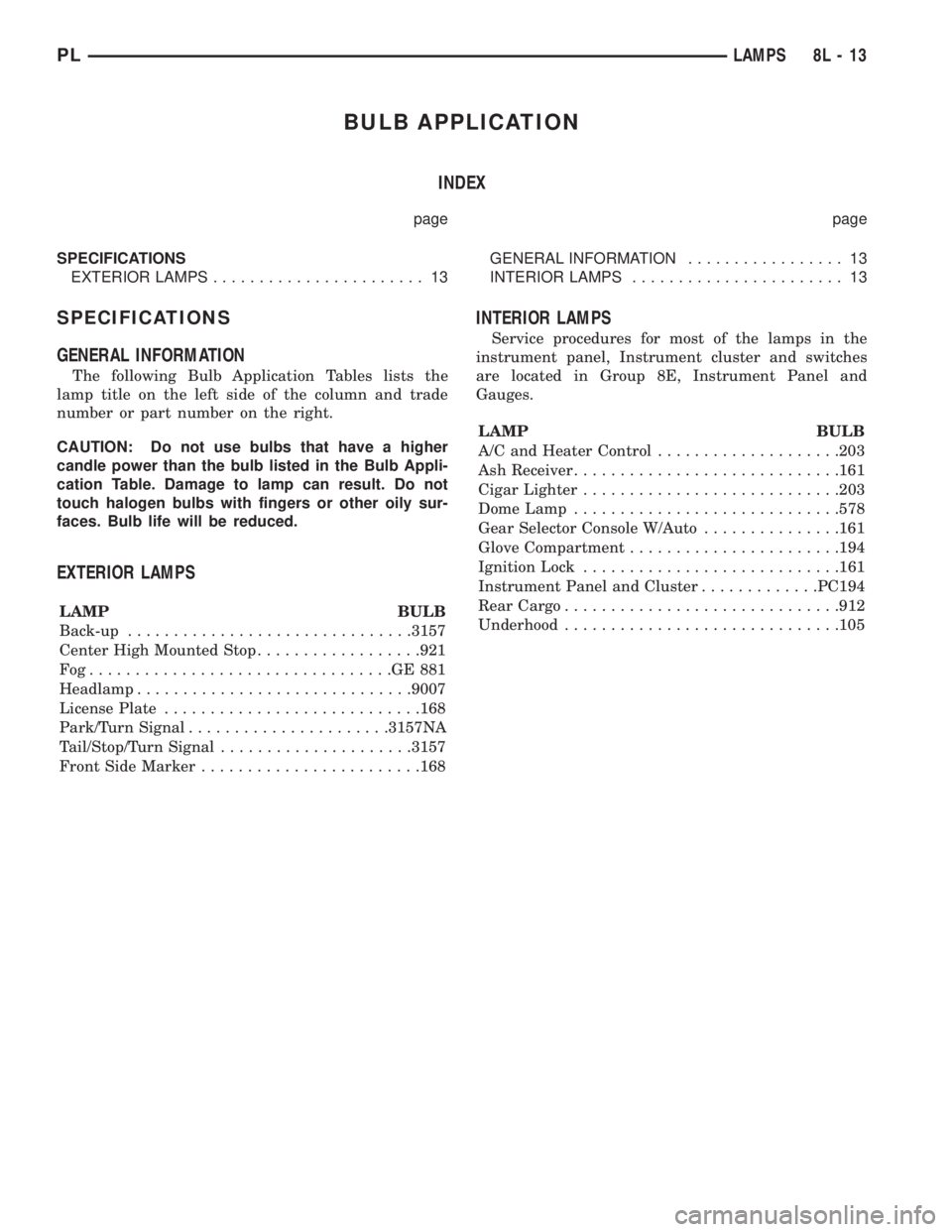

BULB APPLICATION

INDEX

page page

SPECIFICATIONS

EXTERIOR LAMPS....................... 13GENERAL INFORMATION................. 13

INTERIOR LAMPS....................... 13

SPECIFICATIONS

GENERAL INFORMATION

The following Bulb Application Tables lists the

lamp title on the left side of the column and trade

number or part number on the right.

CAUTION: Do not use bulbs that have a higher

candle power than the bulb listed in the Bulb Appli-

cation Table. Damage to lamp can result. Do not

touch halogen bulbs with fingers or other oily sur-

faces. Bulb life will be reduced.

EXTERIOR LAMPS

LAMP BULB

Back-up...............................3157

Center High Mounted Stop..................921

Fog.................................GE881

Headlamp..............................9007

License Plate............................168

Park/Turn Signal......................3157NA

Tail/Stop/Turn Signal.....................3157

Front Side Marker........................168

INTERIOR LAMPS

Service procedures for most of the lamps in the

instrument panel, Instrument cluster and switches

are located in Group 8E, Instrument Panel and

Gauges.

LAMP BULB

A/C and Heater Control....................203

Ash Receiver.............................161

Cigar Lighter............................203

Dome Lamp.............................578

Gear Selector Console W/Auto...............161

Glove Compartment.......................194

Ignition Lock............................161

Instrument Panel and Cluster.............PC194

Rear Cargo..............................912

Underhood..............................105

PLLAMPS 8L - 13